Patents

Literature

211 results about "Compressive strength test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressive Strength Testing. Compression testing is a very common testing method that is used to establish the compressive force or crush resistance of a material and the ability of the material to recover after a specified compressive force is applied and even held over a defined period of time.

Blasting damaged rock sample preparation and micro-macro combined damage degree determination method

InactiveCN104949868AEasy to operateThe test data is reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationDetonatorOsmotic coefficient

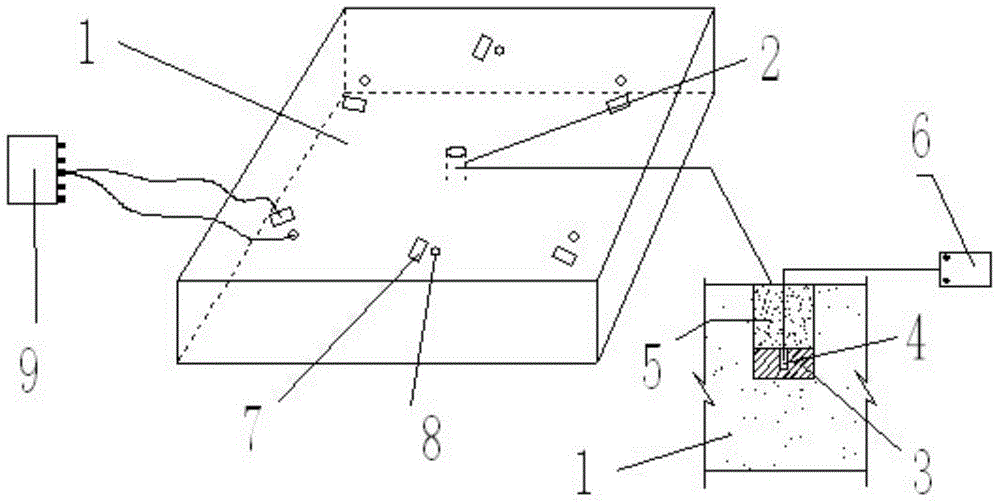

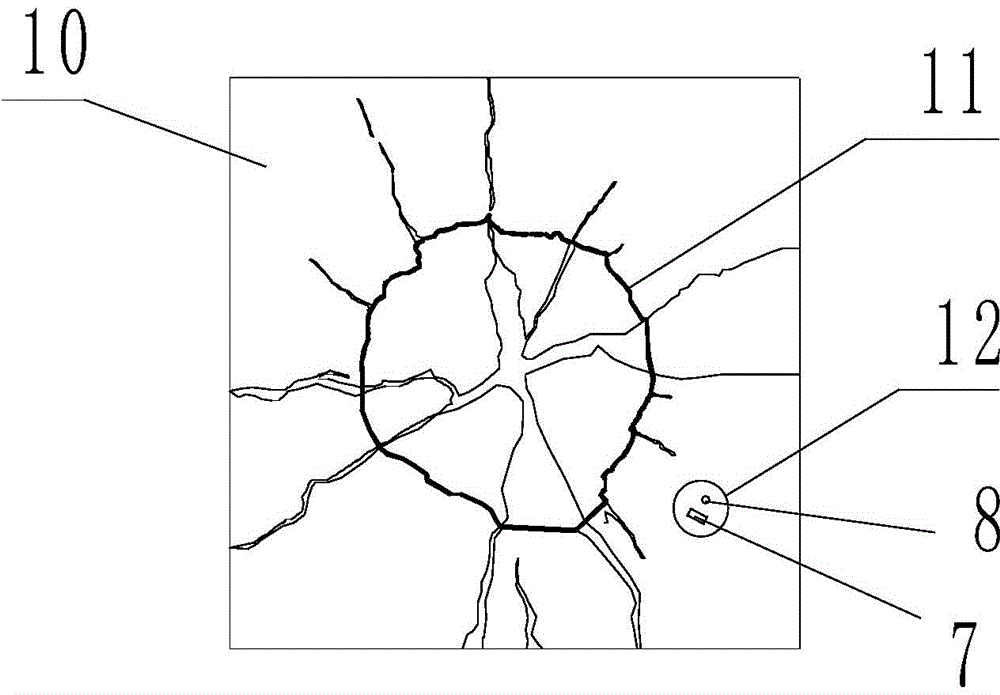

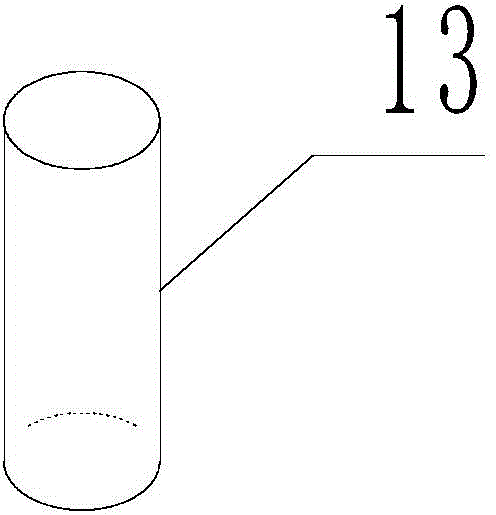

The invention discloses blasting damaged rock sample preparation and a micro-macro combined damage degree determination method, and belongs to a determination method for a damage degree of a damaged rock sample. The micro-macro combined damage degree determination method comprises the following steps: a, manufacturing a square rock with thickness of 105mm, putting an explosive and a detonator at the geometric center of the rock, adhering resistance strain gauges and acceleration sensors at key points of the rock, and connecting the resistance strain gauges and the acceleration sensors to a super dynamic data acquisition instrument; b, drilling the rock with large blasting fragment size with the key points as circle centers along the thickness direction, polishing standard rock samples, and collecting small irregular rocks; c, performing a mercury injection test on the irregular rocks, and performing CT, nuclear magnetic resonance, longitudinal wave velocity, osmotic coefficient, elasticity modulus and uniaxial compressive strength tests on the blasting damaged standard rock samples; e, performing identical micro-macro tests on homogeneous complete rock samples; and f, based on dynamic strains and acceleration waveforms, quantitatively determining the degree of damage, caused by blasting impact, to a rock material by synthesizing micro-macro test data. The determination method has the advantages of simplicity in operation and comprehensive and reliable test data.

Owner:CHINA UNIV OF MINING & TECH

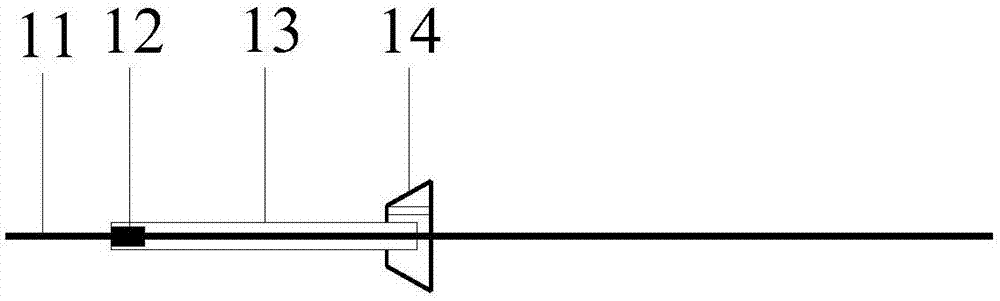

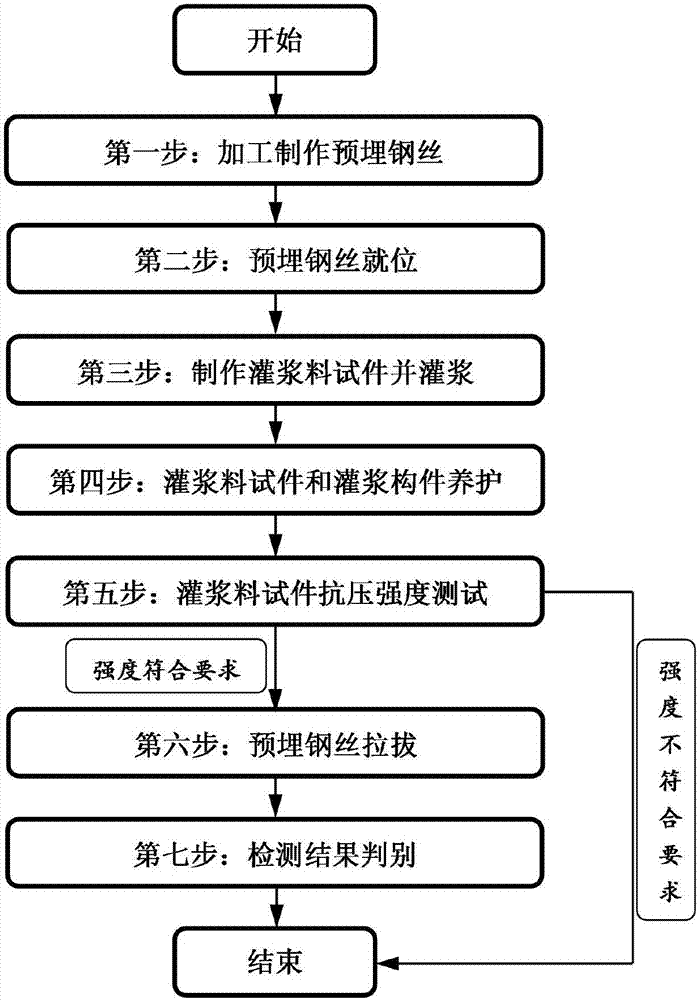

Detection device and detection method for sleeve grouting quality

ActiveCN107478512ADetection intensityPreparing sample for investigationMaterial strength using tensile/compressive forcesUltimate tensile strengthMaterials science

The invention discloses a detection device and a detection method for sleeve grouting quality. The detection device comprises drawing equipment and an adjustable support, and can draw an embedded steel wire. The detection method comprises the following steps: machining and producing the embedded steel wire; arranging the embedded steel wire in position; manufacturing a grouting material test piece and performing grouting; maintaining the grouting material test piece and a grouted component; testing compressive strength of the grouting material test piece; drawing the embedded steel wire; judging a detection result. According to the detection device and the detection method, whether the grouting material strength and the sleeve grouting fullness meet requirements can be detected effectively, and the detection device and the detection method can be used for field detection and construction quality control of sleeve grouting fullness of an assembled monolithic concrete structure.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

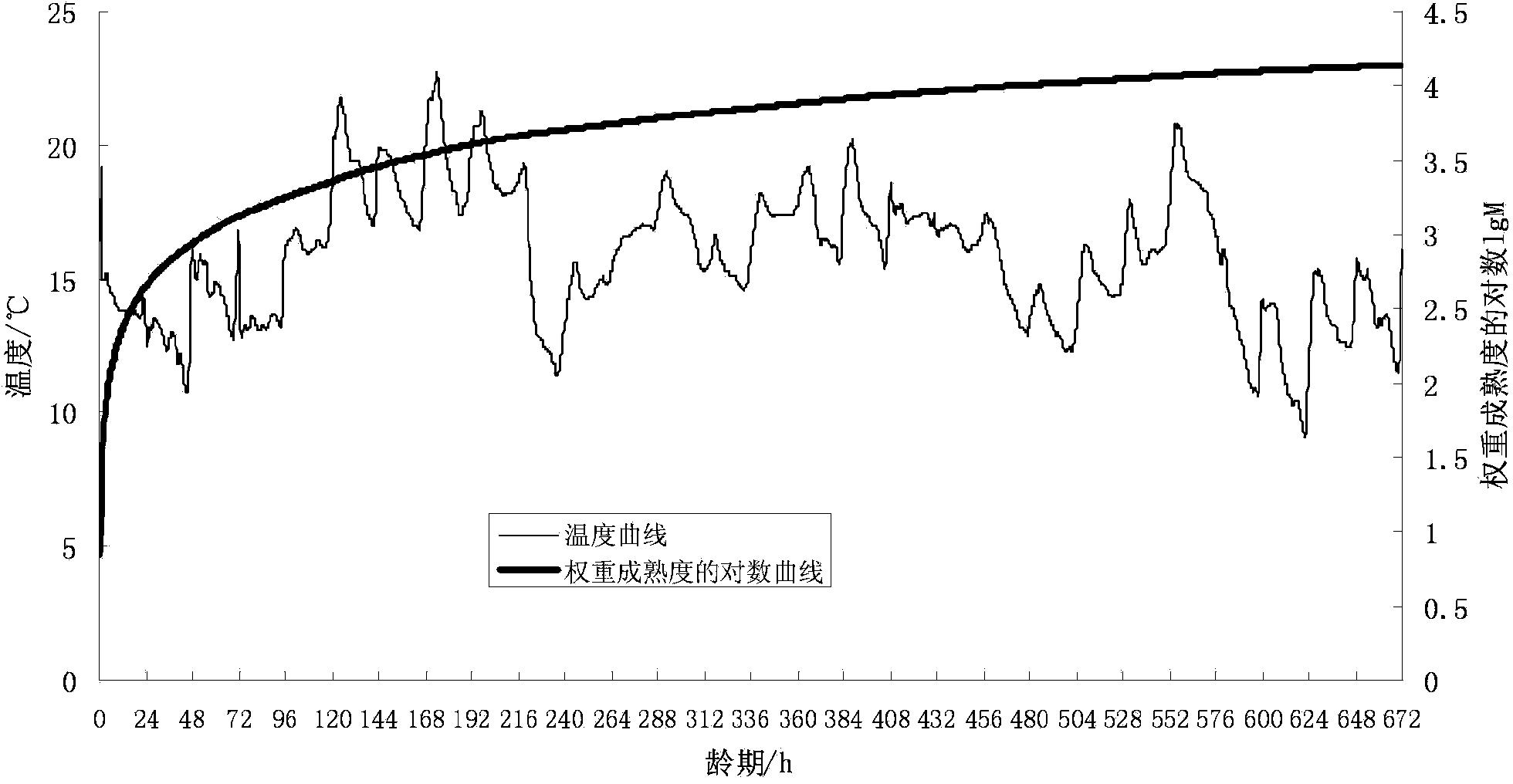

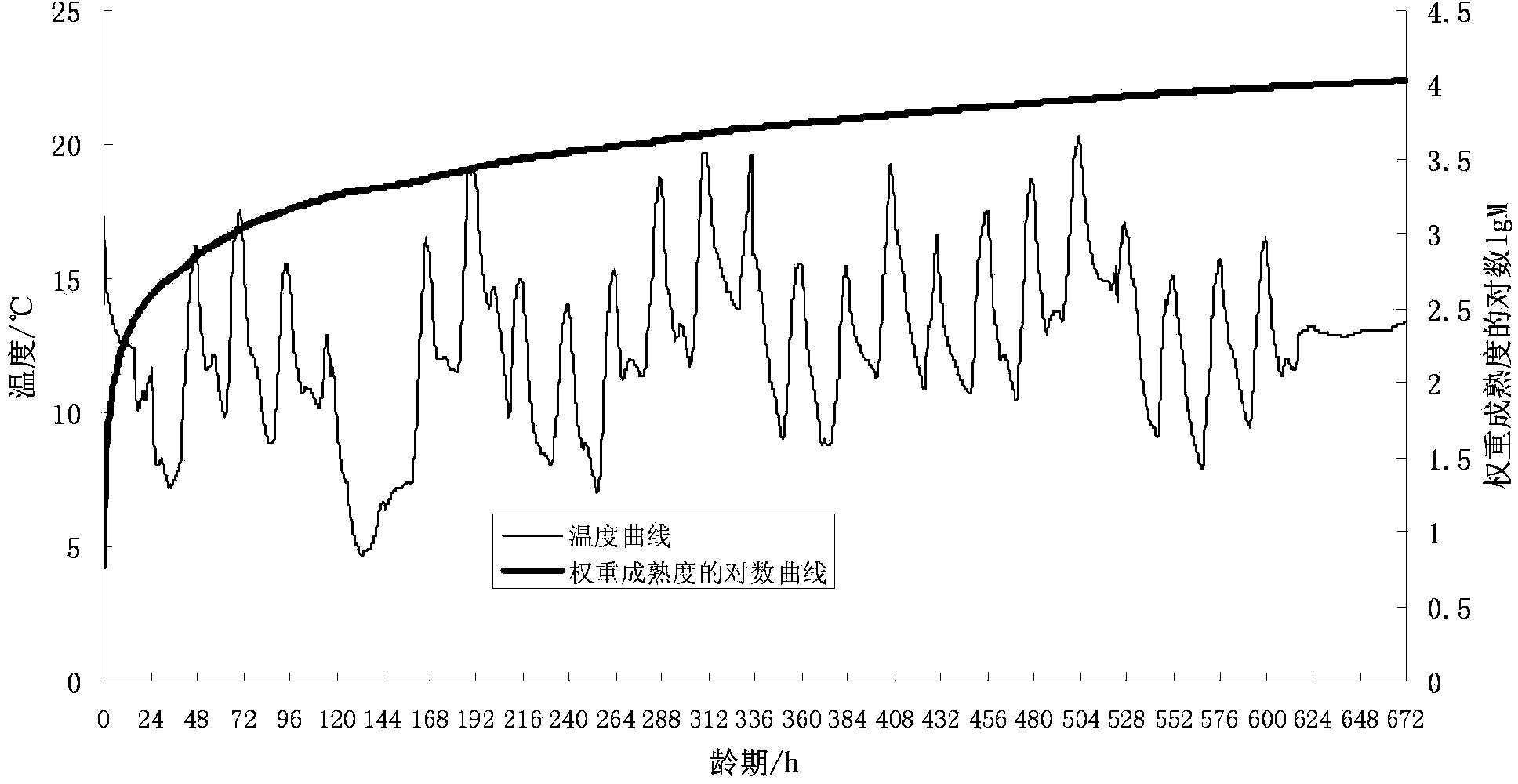

Method for estimating compressive strength of concrete in early stage

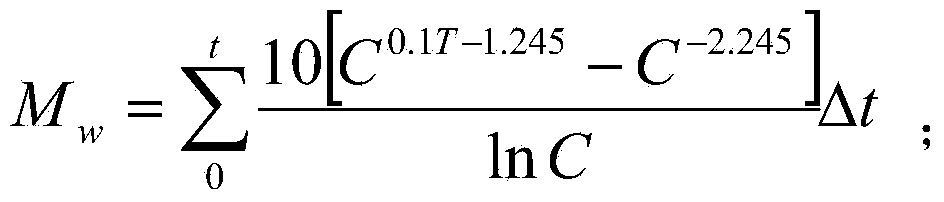

The invention provides a method for estimating the compressive strength of concrete in early stage. The method comprises the following steps of: recording the water filling time, the forming time and the temperature of concrete, carrying out wet and hot curing after a test block is formed, and respectively taking one test block to carry out compressive strength test at the ages of 24 hours and 48 hours; determining the mass percent of Portland cement P.I in cement according to the cement used in the concrete, calculating the mass percent of the Portland cement P.I in the total cementing material according to the proportion of the cement in the total cementing material, and then taking a C value according to the mass percents in C-value reference data; calculating the weight maturity according to different ages and temperatures; establishing a strength prediction relation according to the weight maturity and compressive strength under the wet and hot curing at the temperature of 55 DEG C for 24 hours and 48 hours; and calculating the weight maturity under standard curing at 20 DEG C at the age of 28 days according to the C value, substituting the weight maturity into the strength predication relation to obtain the compressive strength of concrete after standard curing for 28 days. The method provided by the invention has the advantages that the workload is small and the strength predication is more accurate.

Owner:王卫仑

Large-volume concrete beneficial for controlling temperature and shrinkage crack and construction process thereof

ActiveCN103073240AAvoid crackingSolve the problem of shrinkage cracksBuilding material handlingCrack resistanceThin layer

The invention relates to a large-volume concrete beneficial for controlling temperature and shrinkage crack and the construction process thereof. The large-volume concrete is as follows: the weight ratio of cement, coarse aggregate, fine aggregate and water is 1.3-3.5 to 2-2.3 to 0.45-0.55; and the construction method comprises the following steps: (1) trial preparing; (2) testing cube compressive strength of concrete; (3) mixing concrete raw materials according to selected materials for trail preparation and components in the mixing ratio; (4) for the concrete, using a casting method for casting at fixed point in a sectional way, casting with one slope, casting in a thin layer, gradually advancing and casting the top at one time, and using a secondary vibrating method, wherein three vibrating gas concretes are placed in front of, in the middle of and behind each concrete layer; (5) covering a plastic film and / or covering a 1 cm thick gunny bag on the concrete after the concrete is finally set and / or a watering and curing the concrete for not less than 14 days; and (6) respectively placing temperature measuring points in the concrete casting vertical height, the edge of the concrete casting surface and the middle part of the concrete casting surface; and measuring the temperatures by using a thermocouple thermometer. The large-volume concrete beneficial for controlling the temperature and the shrinkage crack has the advantages of controllable time and high crack resistance.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

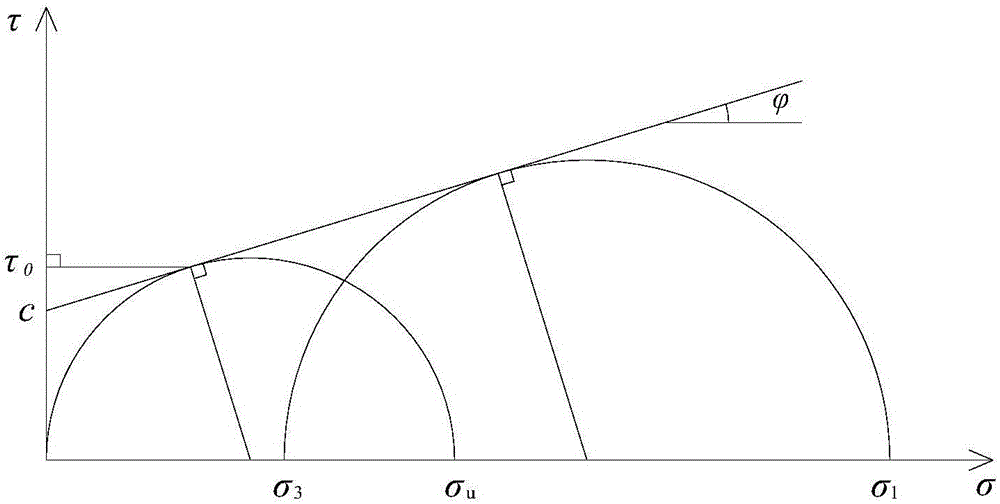

Method for determining number of times of flowing deformation of high-temperature creep instability points of asphalt mixture

ActiveCN105891013AComply with the stress stateSimple test conditionsMaterial strength using steady shearing forcesStress levelClassical mechanics

The invention provides a method for determining the number of times of flowing deformation of high-temperature creep instability points of an asphalt mixture. The method comprises steps as follows: firstly, a shear strength parameter of the asphalt mixture and a shear stress value on a failure surface under the most unfavorable load effect are obtained through an unconfined compressive strength test and a uniaxial penetration test; the high-temperature deformation instability characteristic of the asphalt mixture is analyzed through a uniaxial dynamic creep curve of the asphalt mixture under the cyclic load effect at a certain stress level, and a third-stage instability point of the asphalt mixture and the corresponding number of times of flowing deformation are determined; finally, through five uniaxial dynamic creep tests under cyclic load effects at different stress levels, a quantitative relation, that is, a shear fatigue equation, between numbers of times of instability flowing deformation and shear stress levels on instability failure surfaces is established. With the adoption of the method, a pressure shear fatigue equation of any asphalt mixture can be obtained, so that the number FN of times of flowing deformation of high-temperature creep instability points of the corresponding asphalt mixture under the cyclic load effect at any stress level can be predicted.

Owner:SOUTHEAST UNIV

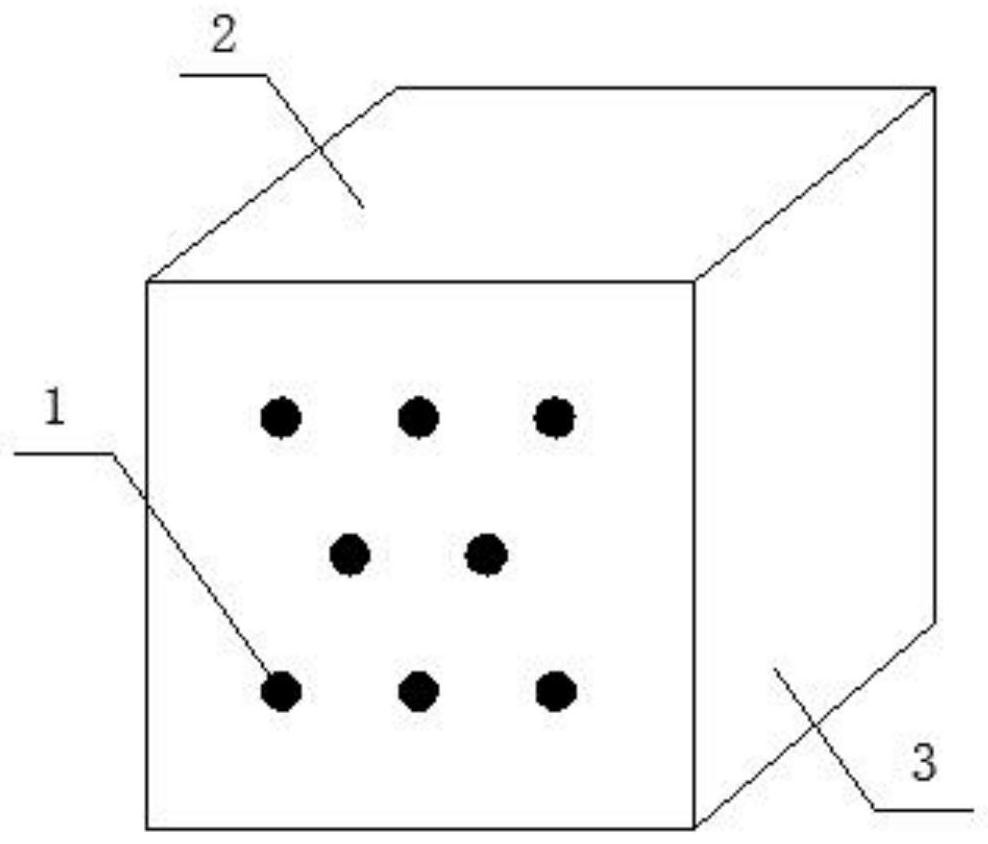

Geomechanics model simulating material for simulating weak rock mass and preparation method of geomechanics model simulating material

The invention discloses a geomechanics model simulating material for simulating a weak rock mass. The geomechanics model simulating material is composed of the following components in parts by mass: 100 parts of barite powder, 0.5-7 parts of semi-refined paraffin wax and 3-7 parts of No.32 hydraulic engine oil; the geomechanics model simulating material is prepared into a sample test with the volume weight of 26 KN / m<3> and the size of 10cm*10cm*10cm, the transformation modulus tested by the test sample is 13.2-28.3 MPa and the compressive strength tested by the test sample is 0.08-0.19 MPa; the geomechanics model simulating material is prepared into a test sample with the volume weight of 23 KN / m<3> and the size of 10cm*10cm*5cm, the transformation modulus tested by the test sample is 11.2-24.7 MPa and the compressive strength tested by the test sample is 0.07-0.17 MPa. The invention also discloses a preparation method of the geomechanics model simulating material. The compressive strength and the transformation modulus of the rock mass simulating material are lower so that the geomechanics model simulating material can be used as the more ideal geomechanics model simulating material for simulating the weak rock mass; and the geomechanics model simulating material provided by the invention has the advantages of wide source of the raw materials, no toxic side effects, simple preparation process, low energy consumption, high preparation efficiency and low cost.

Owner:SICHUAN UNIV

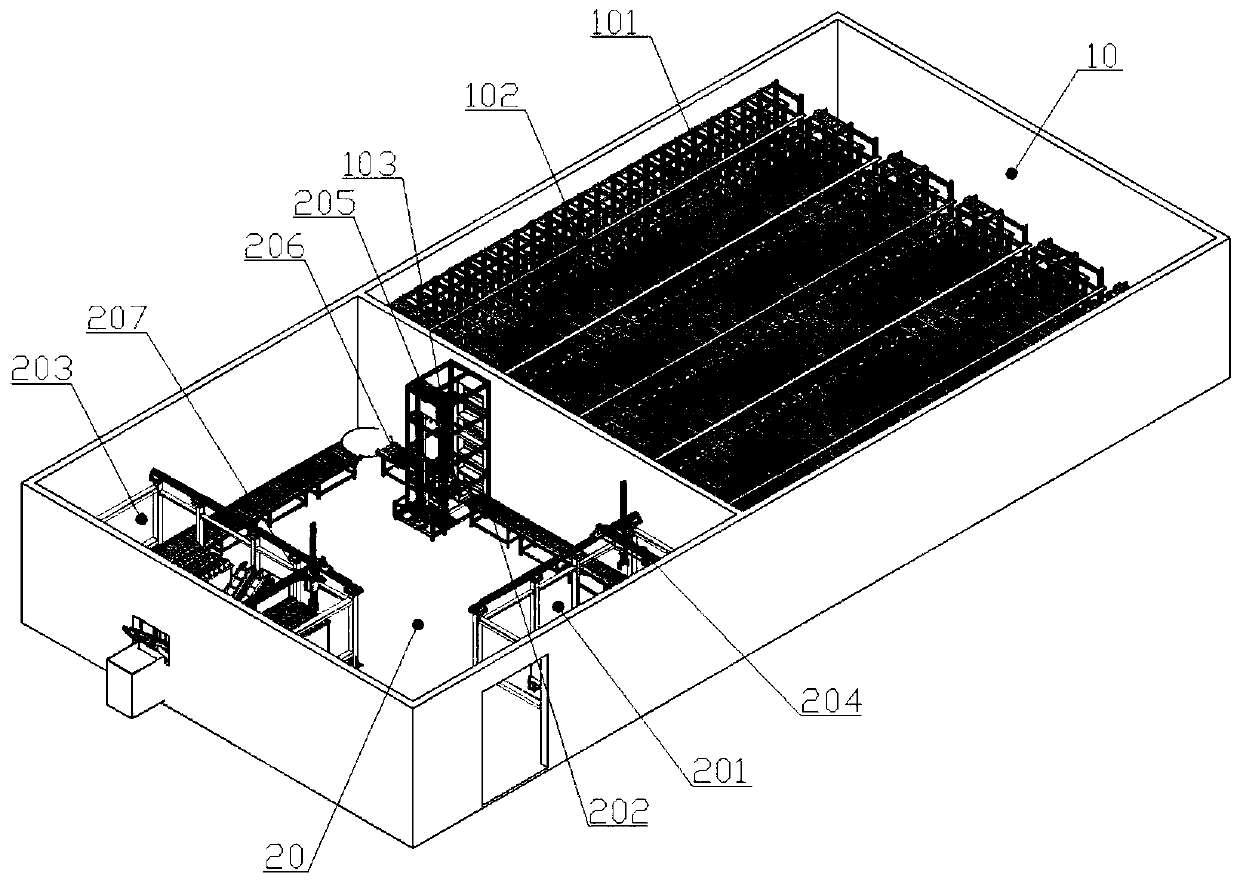

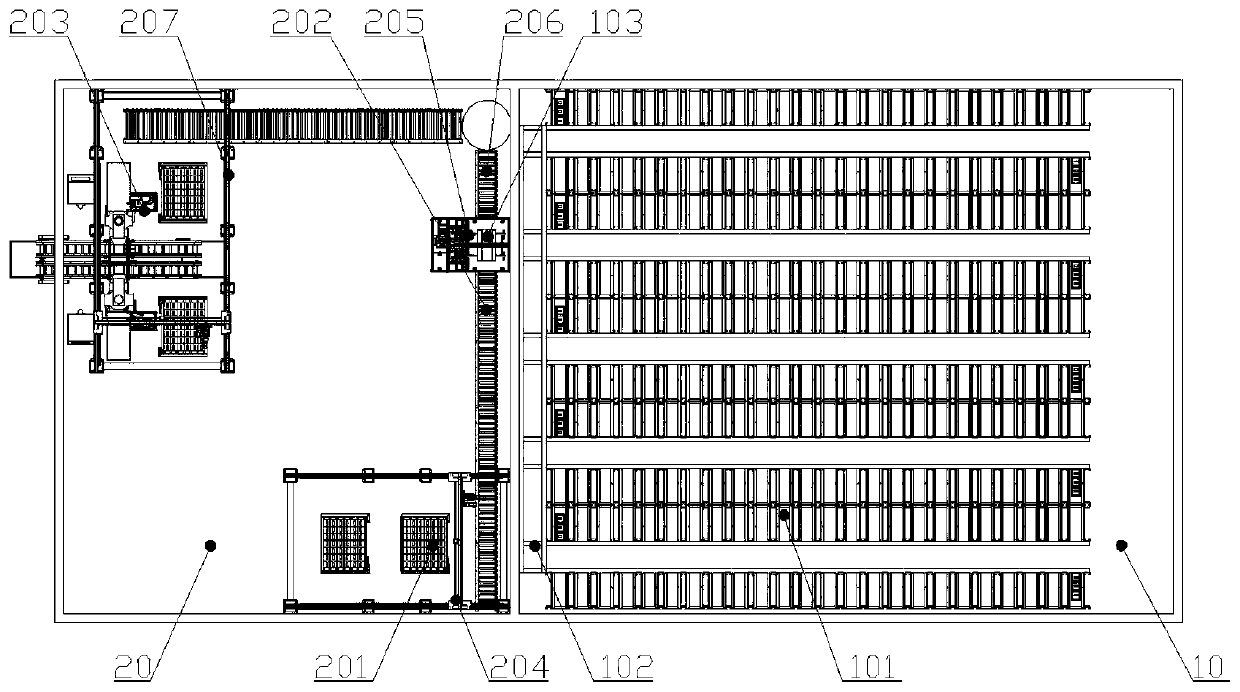

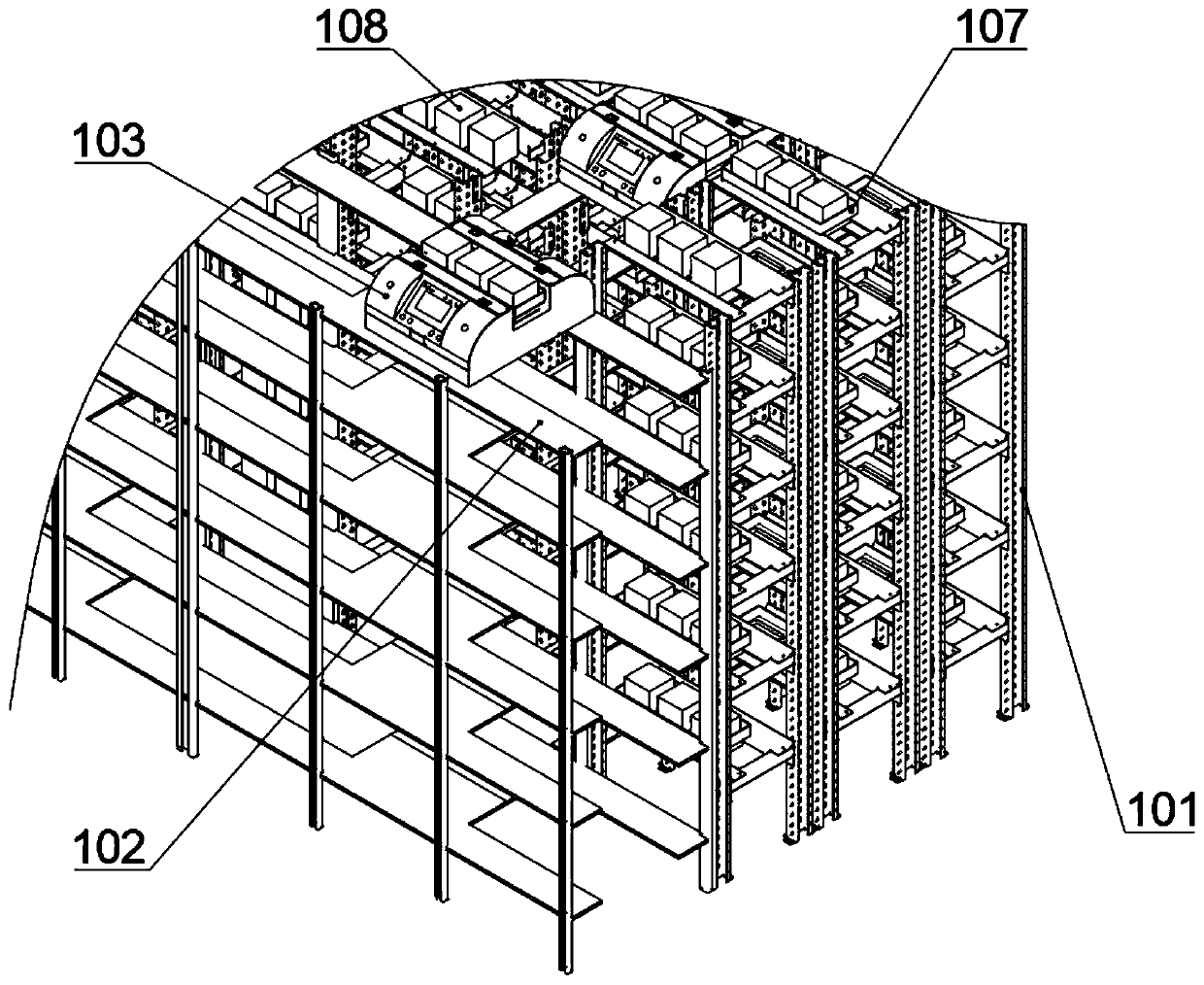

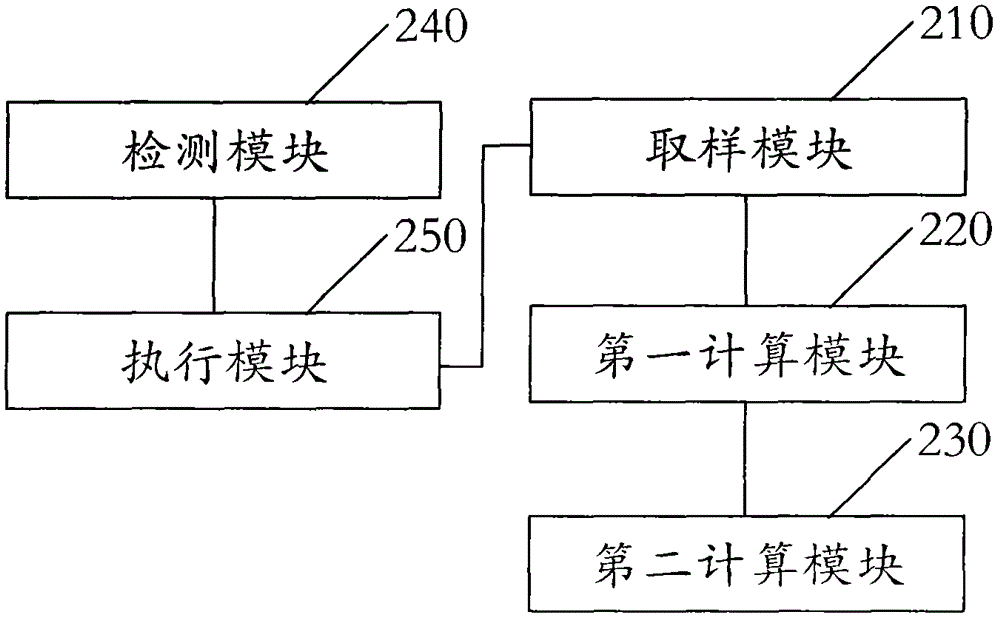

Full-automatic intelligent concrete curing detection system and method

PendingCN111175524ARealize automatic identificationReduce labor costsPreparing sample for investigationMaterial strength using tensile/compressive forcesControl systemStructural engineering

The invention relates to a full-automatic intelligent concrete curing detection system. The system comprises a warehouse-in feeding area, a standard curing chamber, a compressive strength detection area, a warehouse-in and warehouse-out conveying device and a control system. The wareshell feeding area is used for wareshell the concrete test part; the standard curing chamber is used for providing aconstant-temperature and constant-humidity curing environment; the compressive strength detection area is used for detecting a compressive strength value of the concrete test part and carrying out judgment and classification according to a test condition; the warehouse-in and warehouse-out conveying device is used for conveying concrete test parts among the warehouse-in feeding area, the standardcuring chamber and the compressive strength testing area; the control system is used for establishing data interaction connection with the warehouse-in feeding area, the standard curing chamber, thecompressive strength detection area and the warehouse-out and warehouse-in conveying device to implement control. The concrete curing system can realize automatic recognition, wareshell, curing, delivery and compressive strength detection of the test part, realizes 24-hour unmanned work in the whole process, reduces the labor cost, and improves the operation efficiency and stability.

Owner:南京研华智能科技有限公司

Application of a kind of sand-fixing agent in sandy sand barrier

InactiveCN102260503AImprove permeabilityImprove stress resistanceOther chemical processesOrganic fertilisersPolyvinyl alcoholWater resistant

The invention relates to the application of a sand-fixing agent in sand-fixing and control of sand damage. The sand-fixing agent is composed of 88-94% polyvinyl alcohol, 1-2% boric acid and 4-10% sawdust. When using, add water to dilute, stir evenly, and then spray evenly. The sand-fixing agent is a colorless, transparent, slightly turbid liquid with no peculiar smell, viscosity of 12Pa.s-15Pa.s, no sinking at 10-70°C, and experimental compressive strength of 1.0Mpa-12.1Mpa at low temperature of 10-20°C The weight loss rate is 0-1.8%, the intensity loss rate is 0-42% after 300 hours of ultraviolet light irradiation, and the wind erosion amount is 0.05g.h-1.100cm2 under the experimental wind speed of 5.0-25.0m / s. 0.5 cm thick consolidation layer. In the control of wind and sand hazards in the wild, the effective period is 5-10 years. In addition, it is water-resistant, environmentally friendly, has good mechanical properties, and does not produce secondary pollution.

Owner:LANZHOU RAILWAY SURVEY & DESIGN INST +1

Method and device for detecting compressive strength of concrete by bending method

InactiveCN102435499AAvoid damageFew influencing factorsMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a method and a device for detecting the compressive strength of concrete by a bending method. The method comprises the following steps of: recording rupture load during damage of the concrete and an area of a damaged section to calculate bending strength; and establishing a correlativity between the bending strength and the corresponding strength of a cubic test piece with the side length of 150mm to deduce the compressive strength of the concrete. By applying fracture resistance force to a test piece, influencing factors in the testing process are reduced and the testing accuracy is improved; moreover, the testing process is simple and feasible. The invention can be widely applied to detection of strength of concrete structure entities in the building industry, railway industry, traffic industry, water transportation industry, harborwork industry and the like.

Owner:王文明

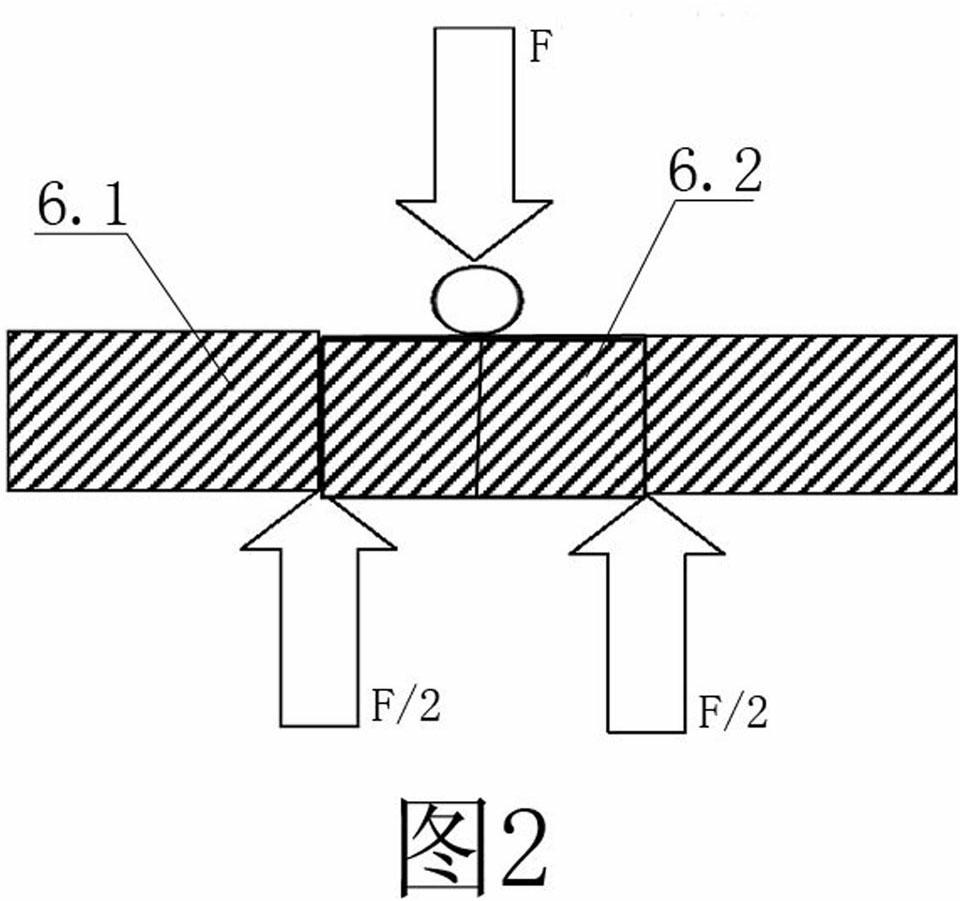

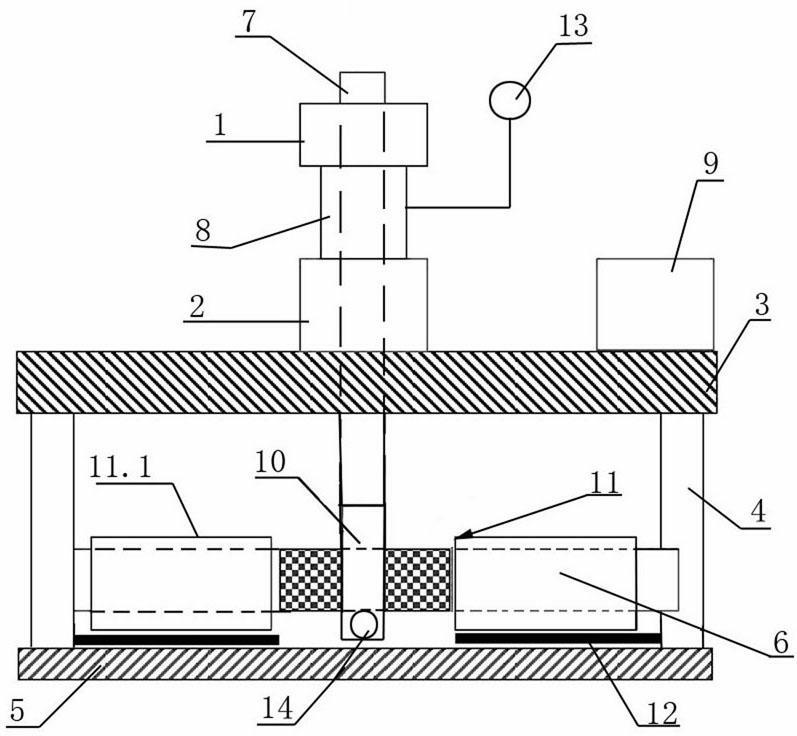

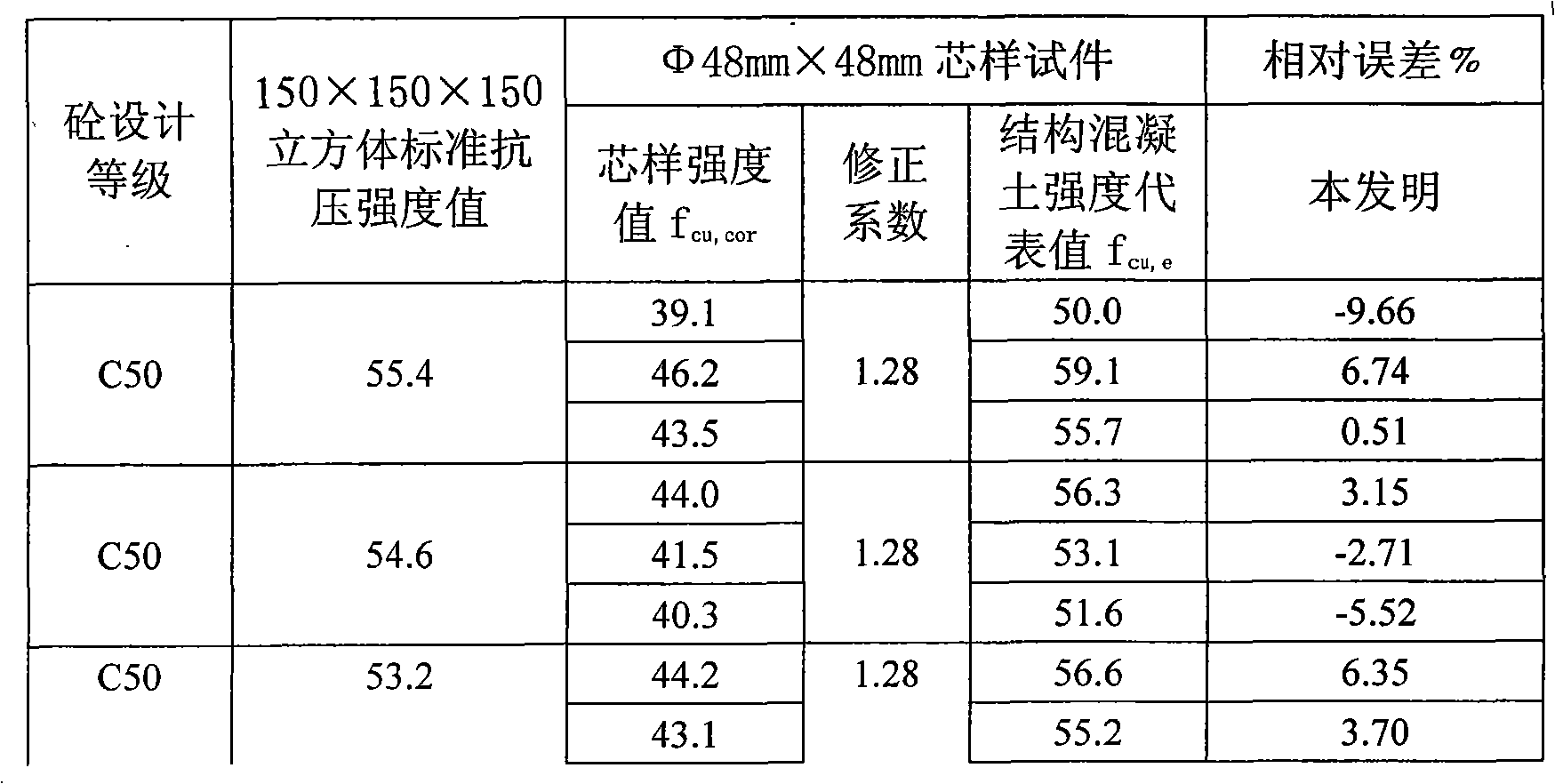

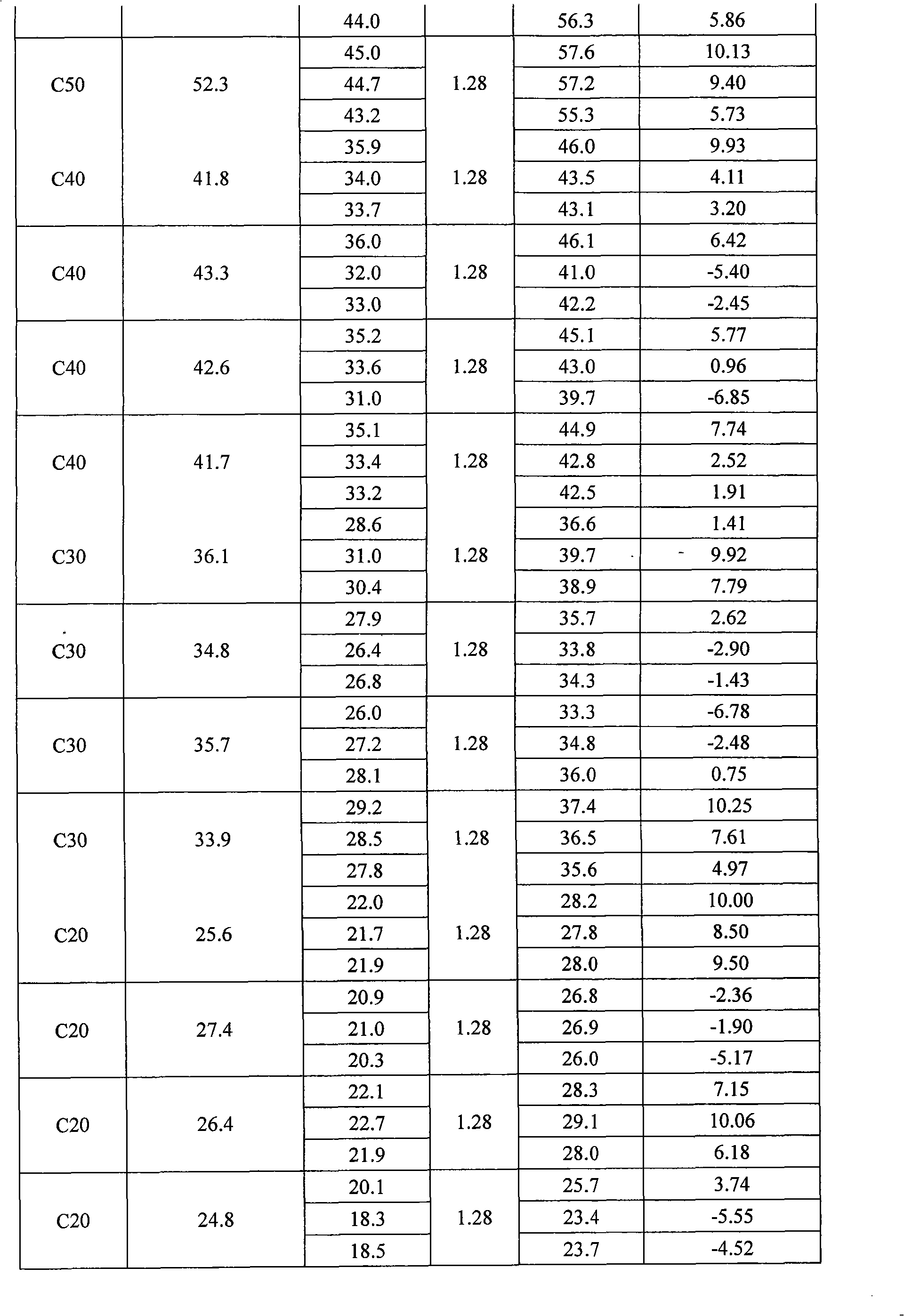

Method for estimating concrete strength of thin-walled structure by using small core sample strength

InactiveCN101551380ASmall intensity errorHigh precisionWithdrawing sample devicesMaterial strength using tensile/compressive forcesMaterials testingUltimate tensile strength

The invention discloses a method for estimating the concrete strength of the thin-walled structure by using the small core sample strength, which belongs to the concrete strength detection of construction projects. The main technical proposal is as follows: a core sample with the diameter of 48mm is drilled from the concrete entity of the thin-walled structure through the cutting and polishing, the compressive strength test is conducted by using an universal material testing machine to obtain a concrete compressive strength value of the small core sample, and the concrete strength of the thin-walled structure is deduced by a correction factor formula. The invention has the advantages of small error and high accuracy, can be applied to the quality control in the construction projects under construction, and the assessment and identification of justice in the existing building and the construction after the disaster.

Owner:XUZHOU INST OF ARCHITECTURAL TECH

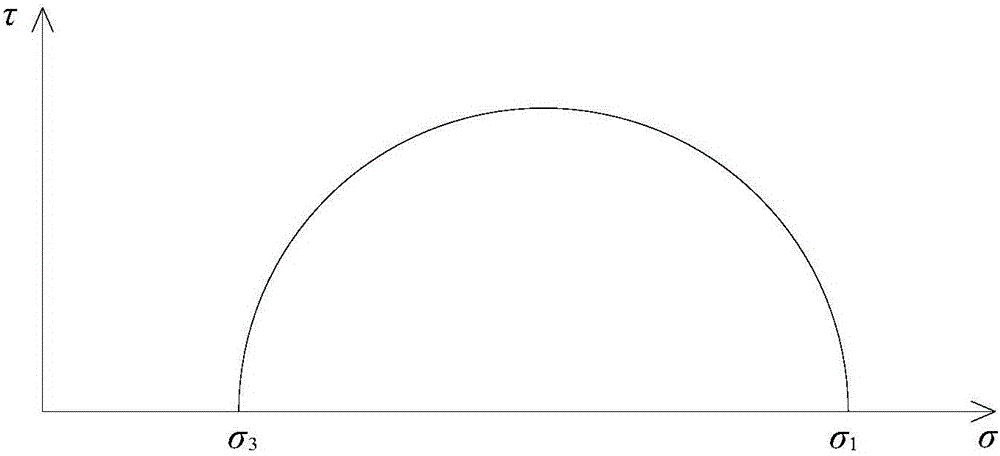

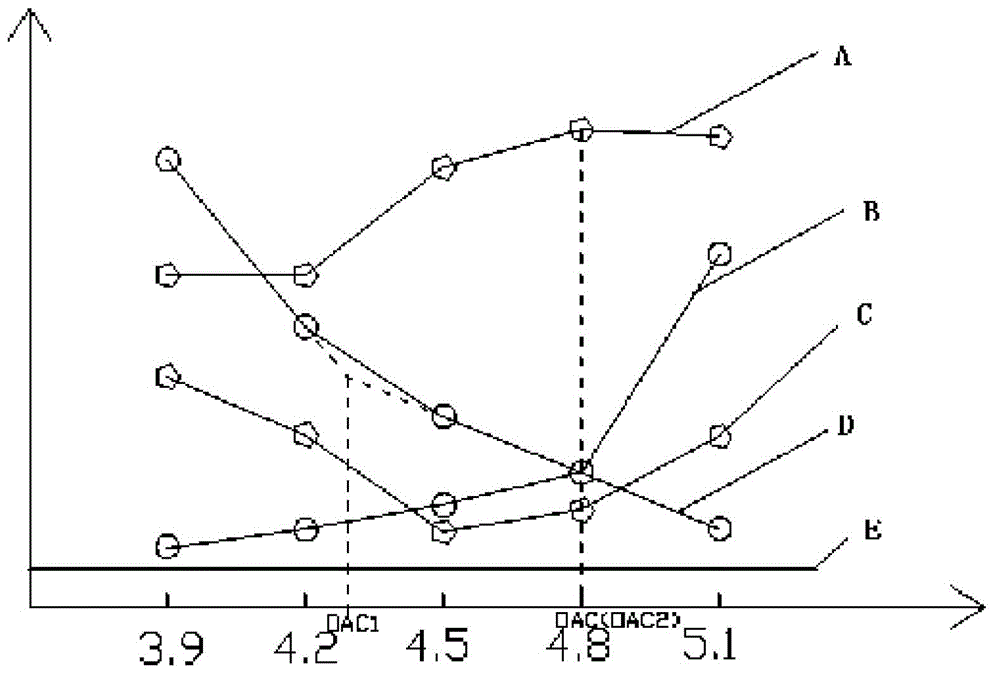

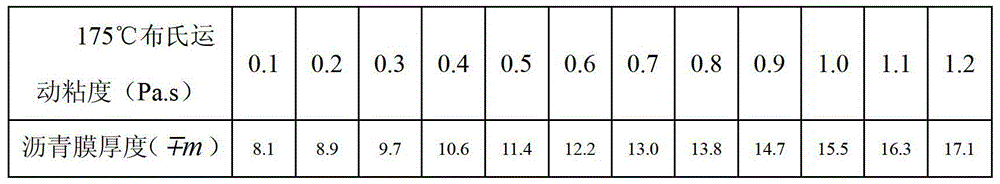

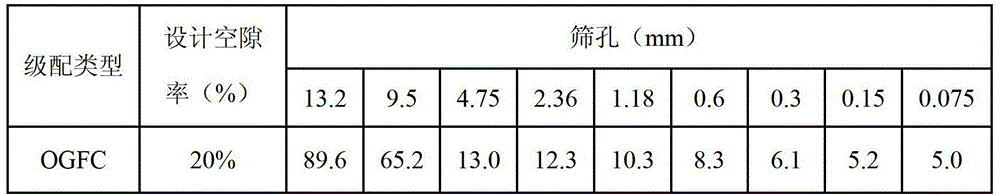

Determining method of optimal asphalt dosage of porous asphalt mixture

ActiveCN103332887ADetermine objective and accurateMake sure it is simple and effectiveVoid ratioPeak value

The invention relates to a determining method of an optimal asphalt dosage of a porous asphalt mixture. The determining method comprises the following steps: (1) determining a predicted asphalt film thickness according to the relationship between 175 DEG C power viscosity of an asphalt binder and an asphalt film thickness; (2) determining a predicted asphalt dosage according to a specific surface area computational formula of mineral aggregate and the predicted asphalt film thickness; (3) with the predicted asphalt dosage as a median and 0.3% or 0.5% as an interval change, forming five groups of asphalt dosages, performing a schellenberg asphalt leakage test and a cantabro dispersion test, and determining the optimal asphalt dosage range with the inflection points of the two curves as boundary; (4) forming five groups of test specimens through a vibration forming method to measure the connected voidage, and then, performing a uniaxial penetration test and an unconfined compressive strength test under a test temperature condition of 60 DEG C, and calculating a cohesive force C, wherein the asphalt dosage corresponding to the peak value of the cohesive force C is used as the optimal asphalt dosage; and (5) verifying the pavement performance. The invention provides a quick, convenient and reliable determining method of optimal asphalt dosage for designing the mixing proportion of porous asphalt mixture.

Owner:天津市市政工程研究院

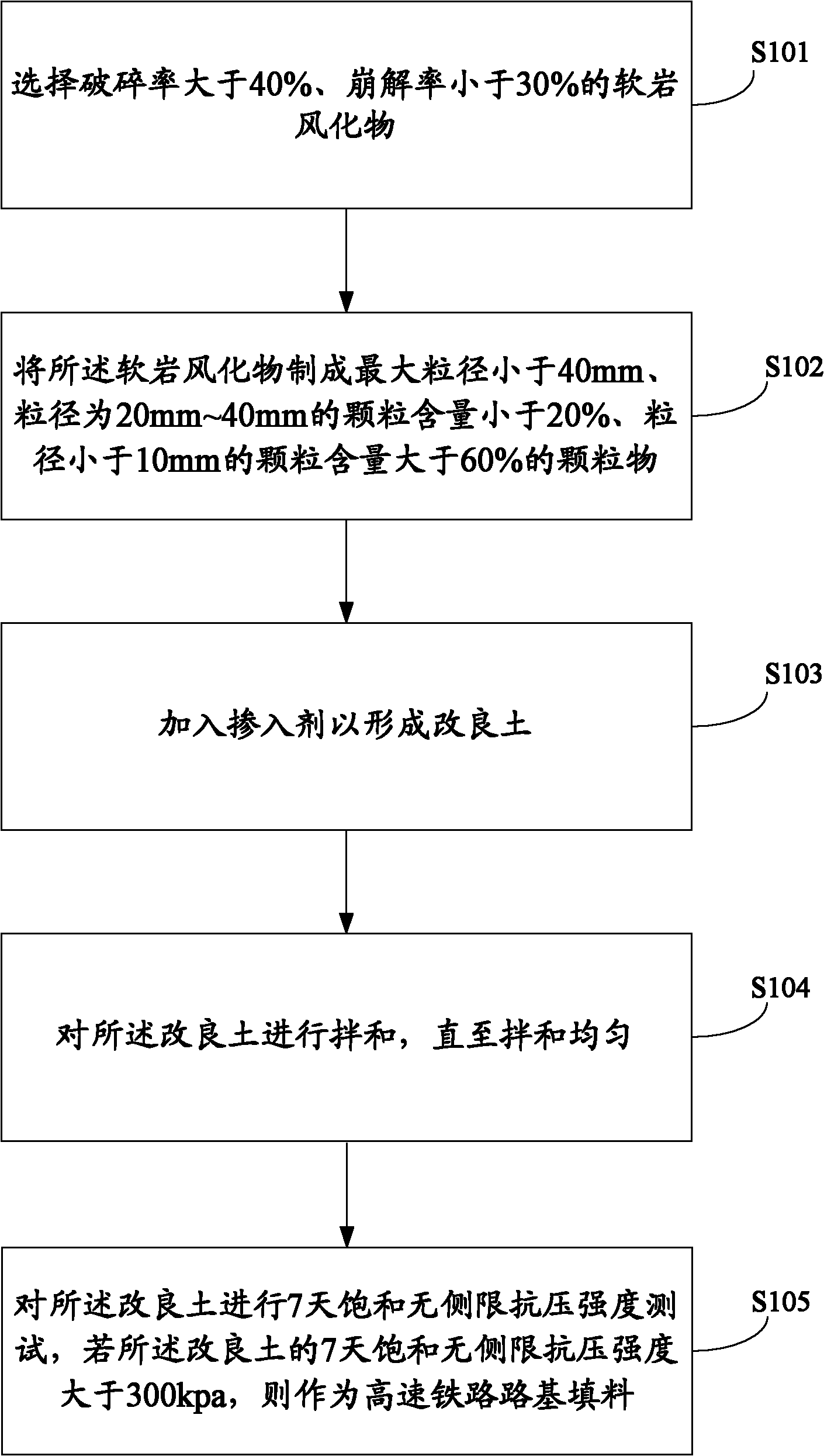

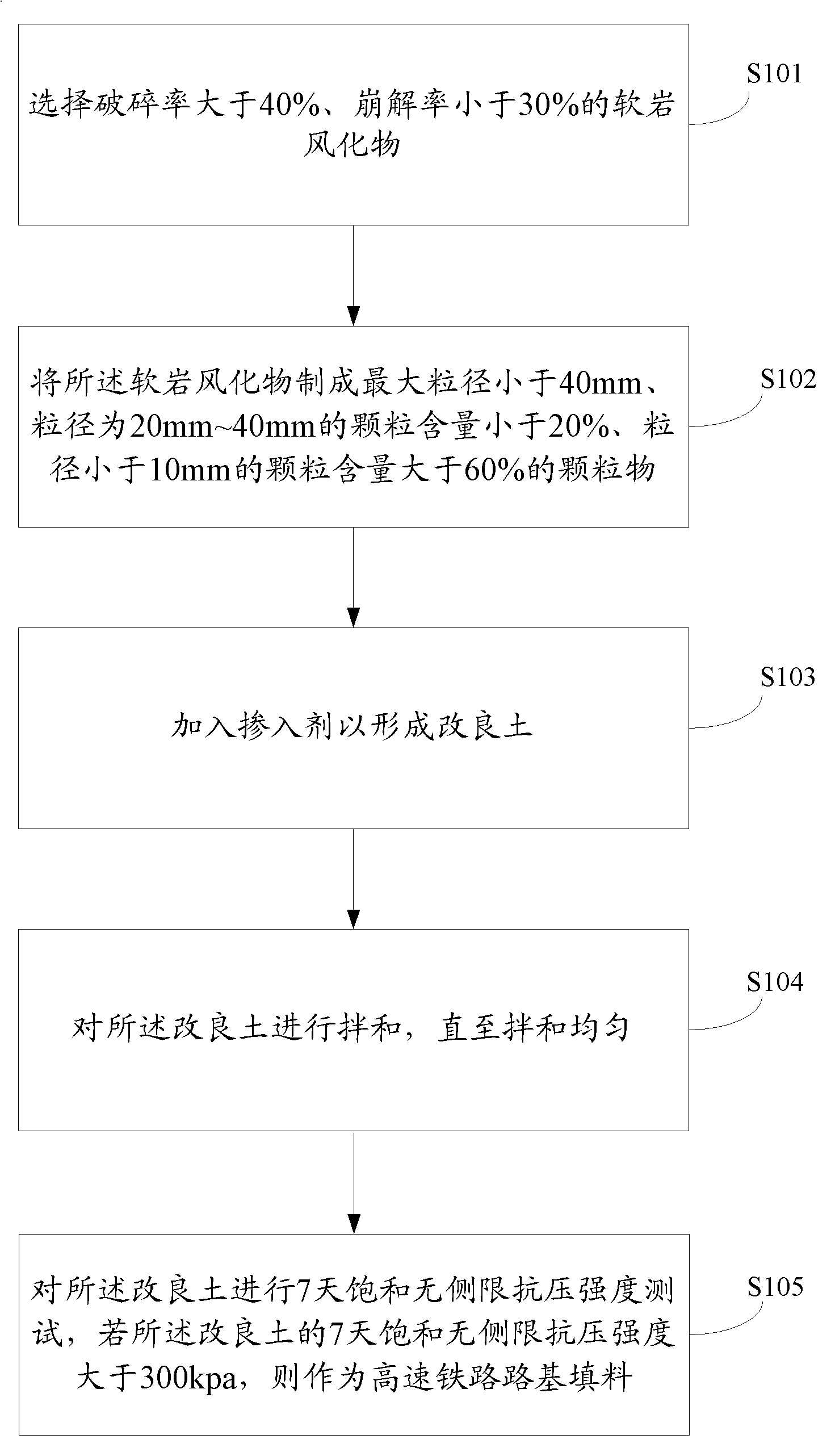

Chemical improving method using soft rock weathered material as high-speed railway subgrade filler

InactiveCN102153303AReduce engineering costsReduce wasteSolid waste managementSocial benefitsWaste material

The invention discloses a chemical improving method using a soft rock weathered material as a high-speed railway subgrade filler, comprising the following steps of: (1) selecting a soft rock weathered material with crushing rate of more than 40% and disintegration rate of less than 30%; (2) making a filler with maximum particle size of less than 40 mm by the soft rock weathered material, wherein the content of particles with particle sizes of 20-40 mm in the filler is less than 20% while the content of the particles with particle sizes of less than 10 mm is more than 60%; (3) adding a doping agent to form improved soil; (4) blending the improved soil until the improved soil is uniformly blended; and (5) carrying out saturated unconfined compressive strength testing on the improved soil for seven days, and if the seven-day saturated unconfined compressive strength of the improved soil is more than 300 kpa, using the improved soil as the high-speed railway subgrade filler. The soft rock weathered material can reach the standard of the high-speed railway subgrade filler after improved by the chemical improving method, and then the engineering cost can be largely reduced, waste materials are reduced, the environment is protected, and finally, good economic, technological, environmental and social benefits are obtained.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Concrete and construction process thereof

The invention relates to a concrete and its construction technology. The weight proportion of each component of the mass concrete is cement: coarse aggregate: fine aggregate: water: 1:3~3.5:2~2.3:0.45~0.55; construction method ①Trial mix; ②Concrete cubic compressive strength test; ③After passing the test, mix the concrete raw materials according to the materials selected in the trial mix and the components in the mix ratio; , step by step, one time to the top" pouring method, and adopt the second vibration method; arrange three vibrating air concrete in the front, middle and back of each layer of concrete for vibration; ⑤ After the final setting of the concrete, cover the plastic film and / or cover One layer of 1cm thick sacks and / or watering and curing, the curing time must not be less than 14 days; 6. arrange temperature measuring points respectively at the vertical height of concrete pouring, the edge and the middle of the surface and adopt thermocouple thermometers to measure the temperature, the present invention has time The advantages of controllability and high crack resistance.

Owner:安徽金兄弟环保科技股份有限公司

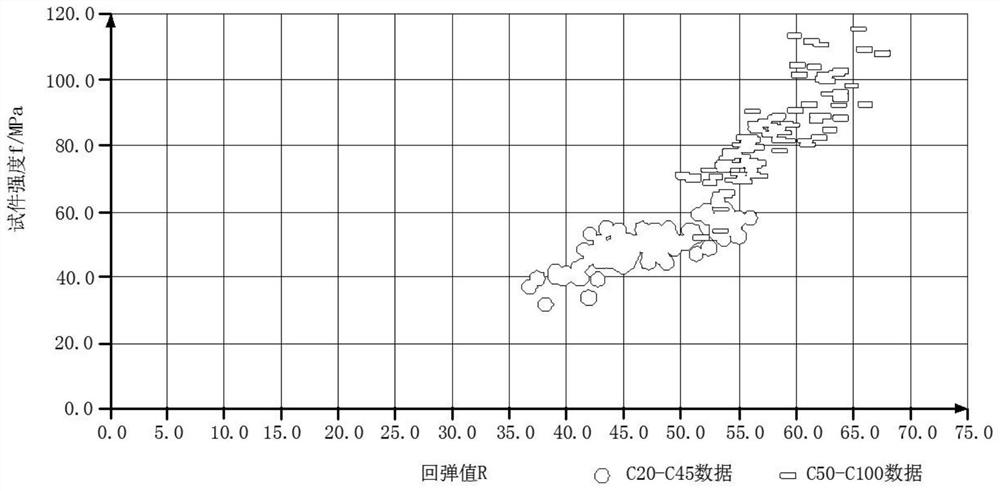

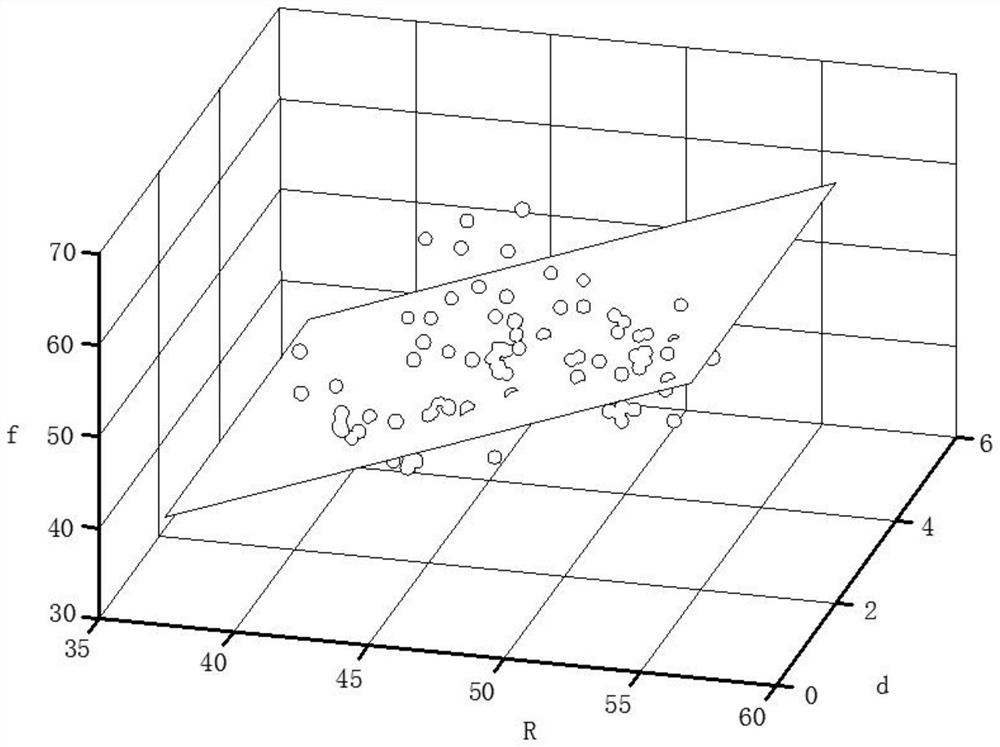

Establishment method for detecting concrete compressive strength curve by rebound method

PendingCN112213217AEasy to estimate strengthQuick Strength EstimationMaterial strength using tensile/compressive forcesInvestigating material hardnessArchitectural engineeringStructural engineering

The invention provides an establishment method for detecting a concrete compressive strength curve by a rebound method, and belongs to the technical field of concrete compressive strength measurement.The establishment method for detecting the concrete compressive strength curve by the rebound method comprises the following steps: S1, test piece selection: selecting a cubic test piece with a standard size; s2, numbering the test pieces: numbering the test pieces to be tested in groups of three by three; s3, marking measuring points: selecting a test surface of the test piece, and marking rebound measuring points; s4, rebound test: testing the rebound value of the test piece by using a rebound device, and determining a rebound representative value R of the test piece; s5, a compressive strength test: testing a compressive strength measured value fcu of the test piece by utilizing a press machine; s6, curve analysis: establishing a scatter diagram according to the rebound value R and thecompressive strength measured value fcu. According to the method, the strength curves are respectively established for the concrete with the strength grades of C20-C45 and C50-C100 so that the application range of the rebound device is expanded, the intersection between specifications and the limitation of instrument use are reduced, and the concrete strength is more convenient and faster to estimate.

Owner:LANGFANG CITY SUNSHINE CONSTR QUALITY INSPECTION CO LTD

Sealing integrity evaluation device for high-temperature and high-pressure casing-cement ring-formation and method thereof

ActiveUS20210231520A1Stable and reliable methodImprove performanceDetection of fluid at leakage pointMeasurement of fluid loss/gain rateControl systemClassical mechanics

A sealing integrity evaluation device for high-temperature and high-pressure casing-cement ring-formation and a method thereof are provided. the device includes: a high-temperature autoclave, a temperature and pressure control system, and a casing-cement-formation combination; wherein the autoclave realizes alternating temperature and pressure during the experiment; the control system monitors, controls and records the temperature and pressure data; the combination simulates a full size or a compact size casing-cement-formation of a well. Casing-cement-formation combination samples are designed and prepared by simulating working conditions such as alternating temperature, pressure, and casing internal pressure, by testing the channeling and leakage pressure of the first interface and the second interface of combination, analyzing the shape and size of the internal defects, testing the compressive strength, provided a more stable and reliable experimental method and data support for the detection of cementing sheath sealing ability and the evaluation of sealing integrity.

Owner:SOUTHWEST PETROLEUM UNIV +1

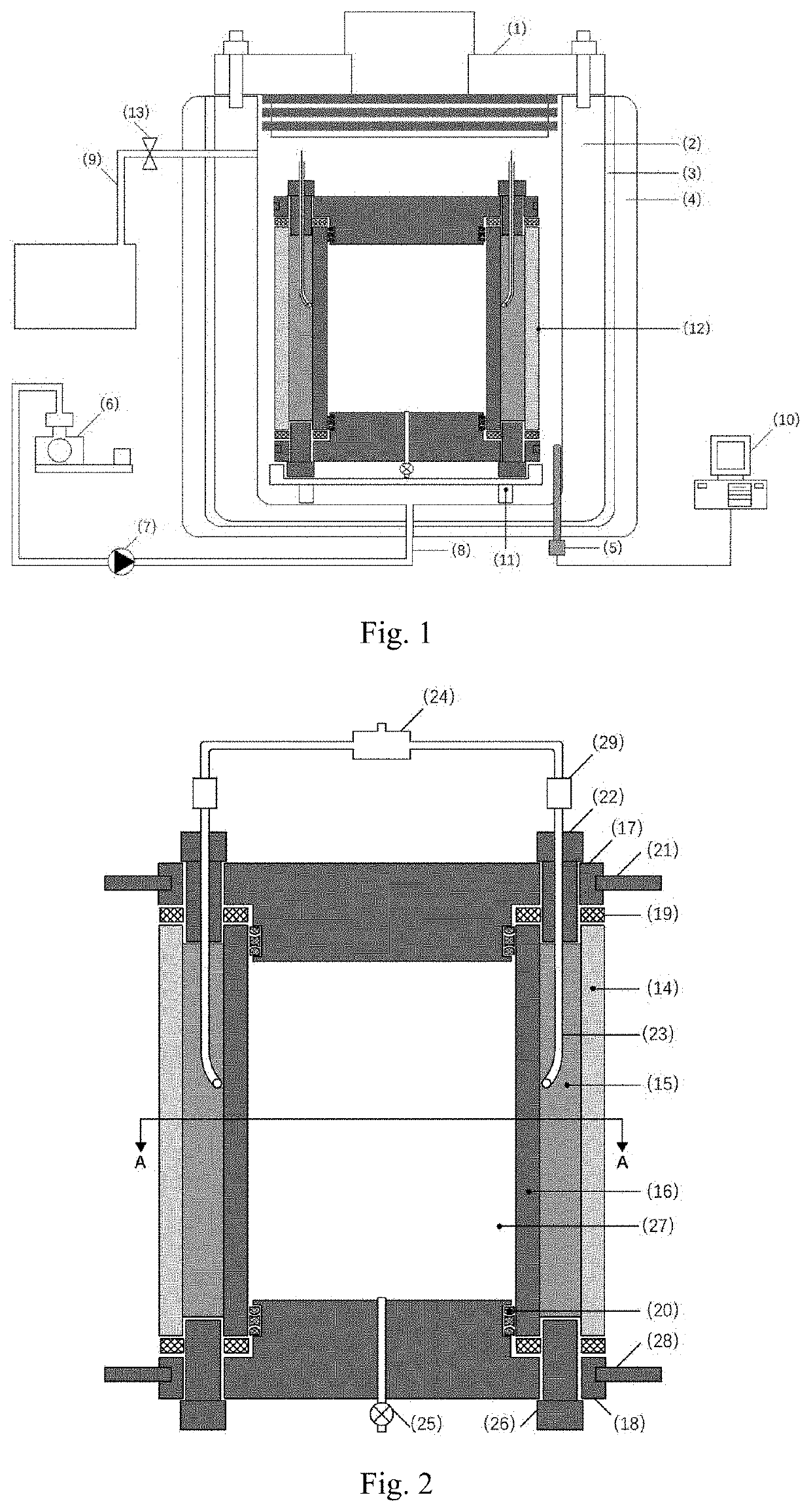

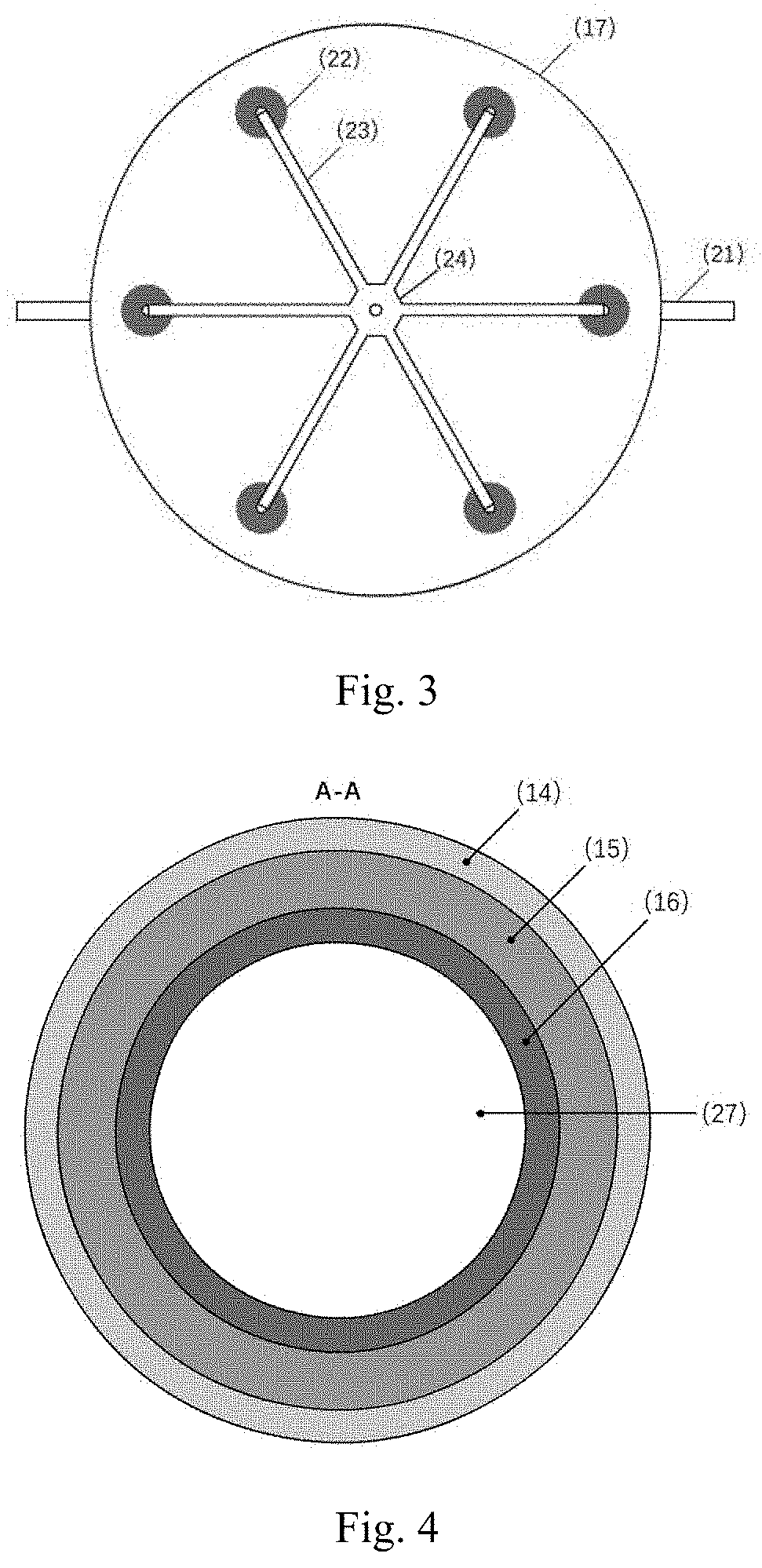

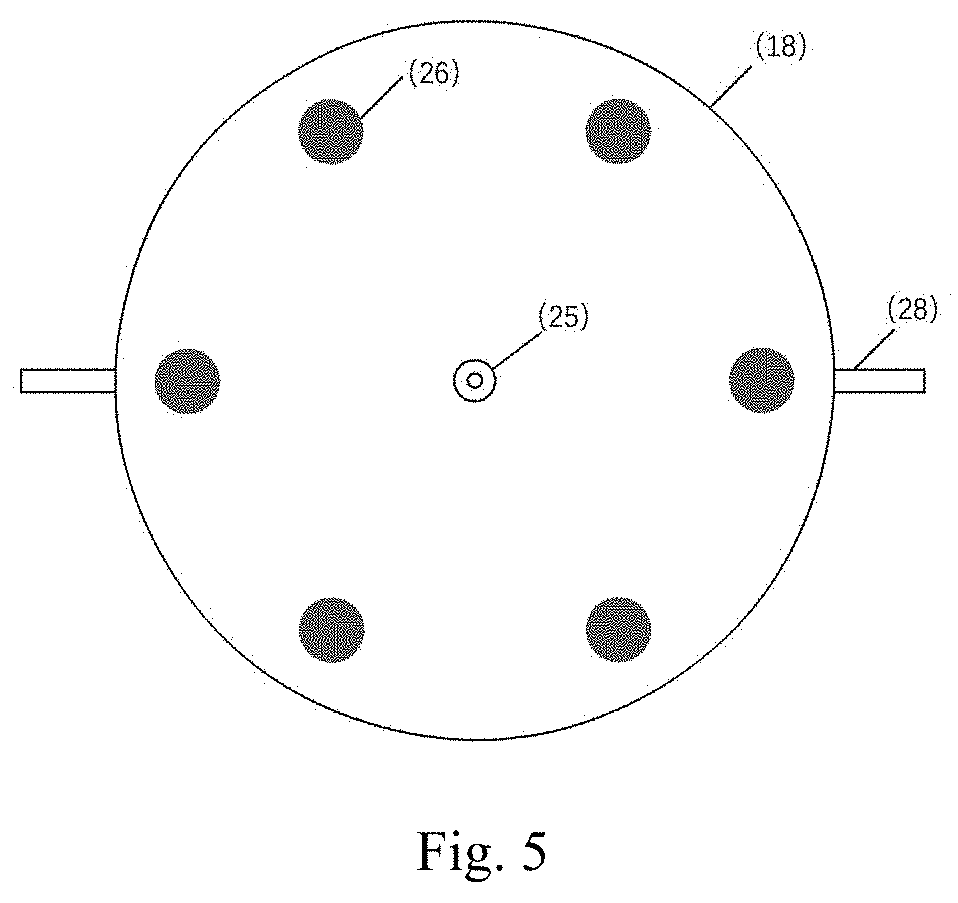

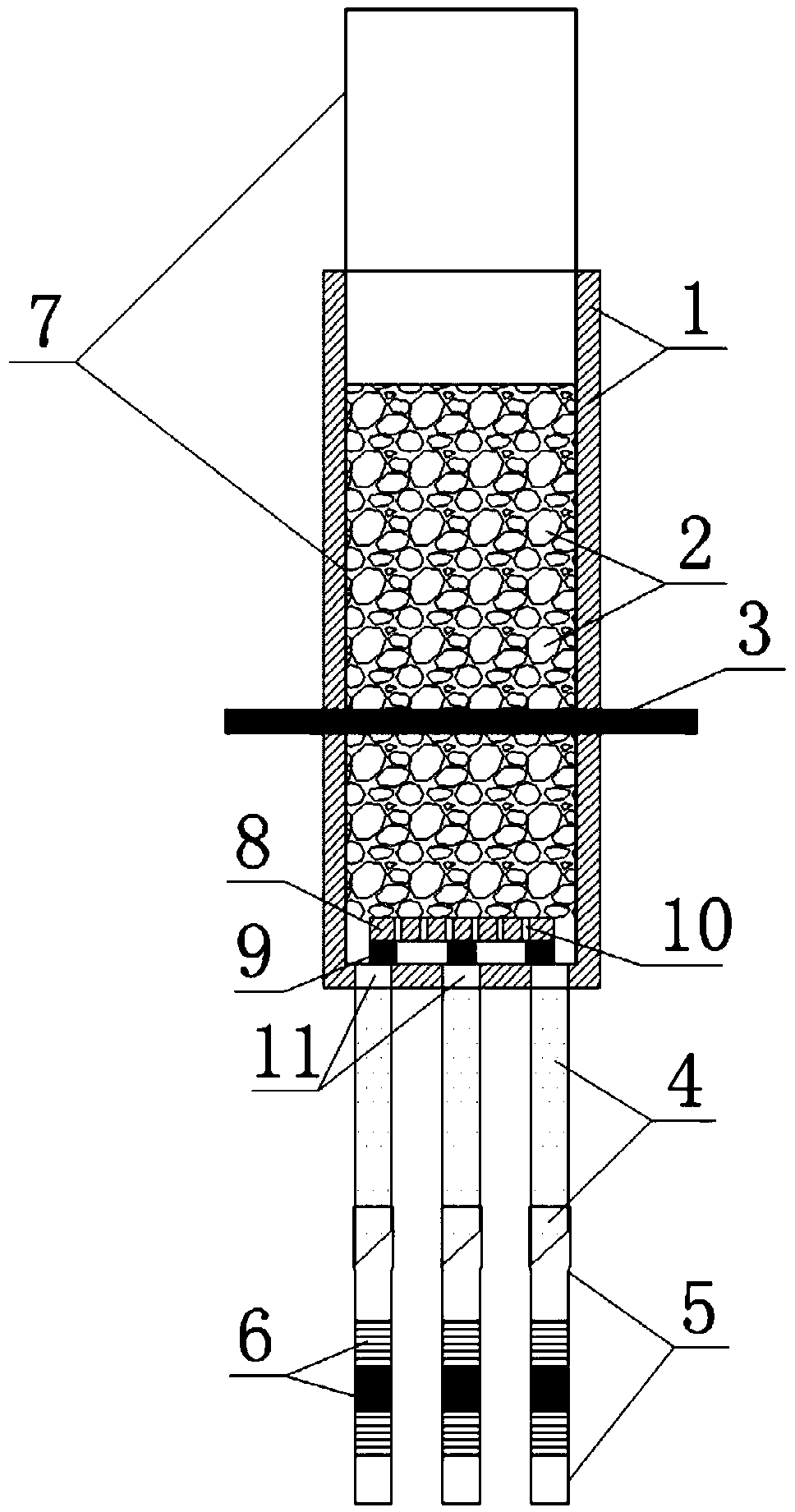

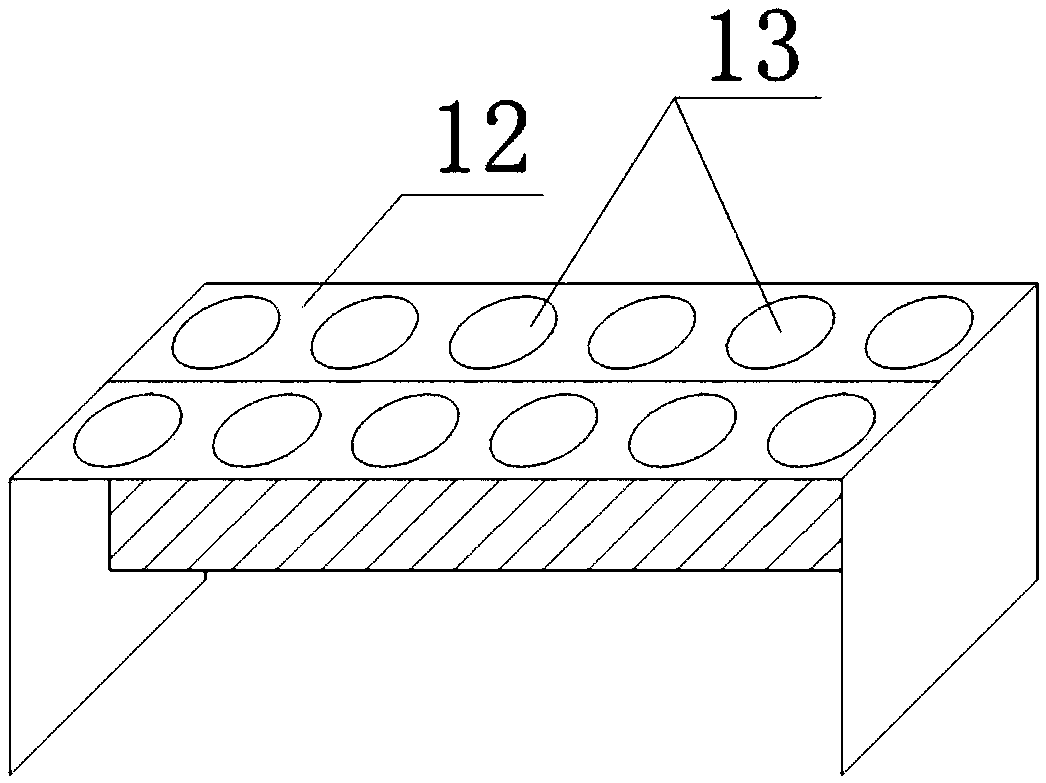

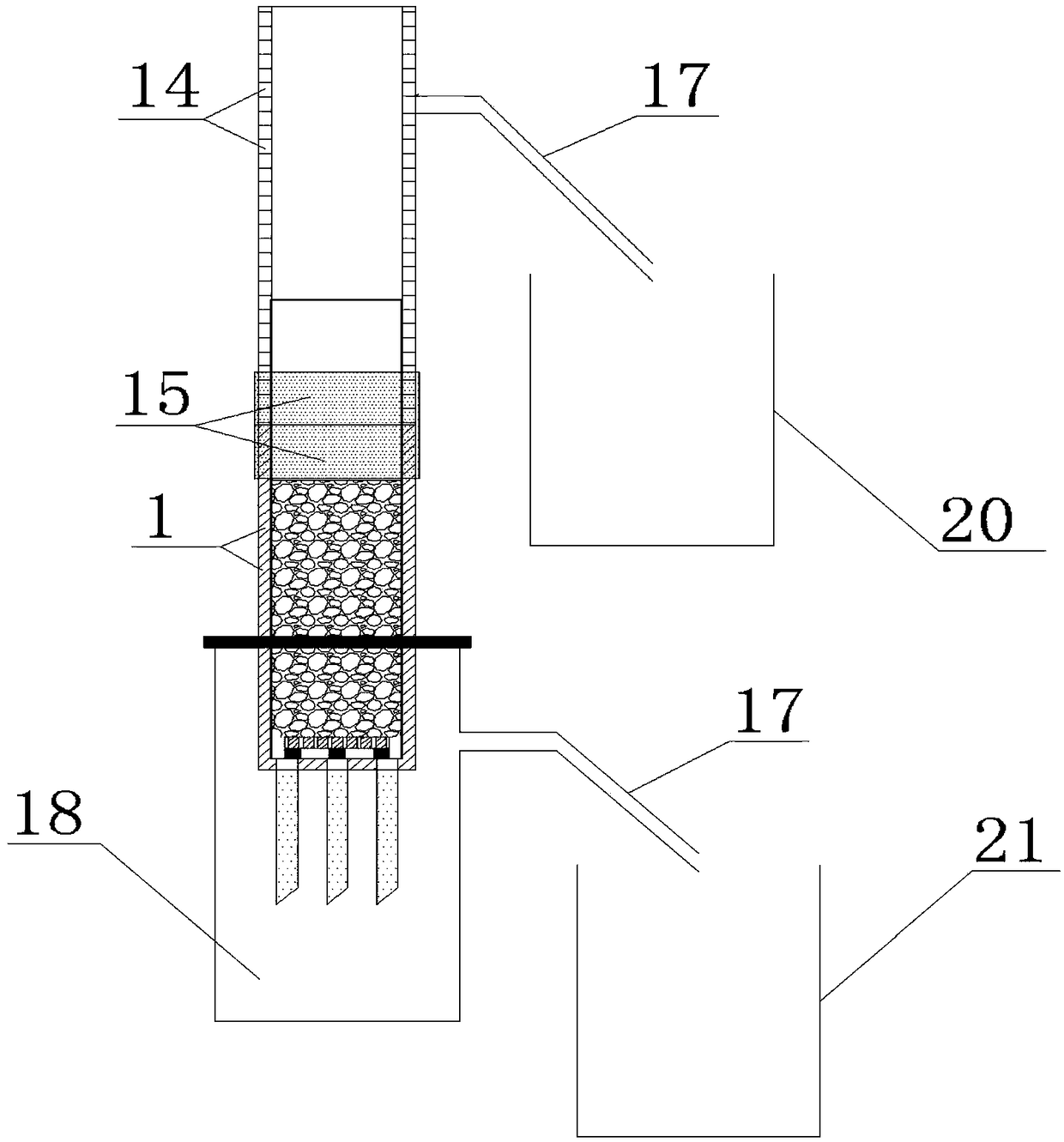

Device for simulating well cementation strength gradient layers of deepwater weakly cemented strata

ActiveCN106198933ASolve cementing quality problemsReal-time adjustment of grouting pressureEarth material testingInterior spaceLine tubing

The invention provides a device for simulating well cementation strength gradient layers of deepwater weakly cemented strata. The device has the advantages that solidifying slurry in an internal space of a medium filling device is subjected to pressurization compaction by the aid of nitrogen in a nitrogen tank, the compaction pressures can be adjusted and can be optimally 7 MPa, and accordingly pressure environments of the deepwater weakly cemented strata can be realistically simulated; a gas cylinder valve and a gas cylinder pressure gauge are arranged on a pressure pipeline between the nitrogen tank and the medium filling device, the gas cylinder valve can be adjusted, and accordingly the slurry ejection pressures on the solidifying slurry can be adjusted in real time; a separable top sealing plate and a separable bottom sealing plate are arranged at two ends of an annular side wall of the medium filling device, accordingly, cylindrical stone formed by the ejected solidifying slurry can be assuredly integrally taken out of the medium filling device, the stone can be used for carrying out compressive strength tests after the surfaces of the stone are subjected to simple treatment, and the pressure-resistant capacity of the solidification strength gradient layers of the deepwater weakly cemented strata can be conveniently reflected.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation for converting mud into building material and method thereof

The presoent invention relates to a building material made of mercury-containing sludge through the conversion treatment and its preparation method. It is characterized by that the mercury-containingsludge, sand, water and catalytic coagulating agent formed from magnesium oxide, magnesium chloride aqueous solutio, talcum powder, ferrous sulfate, trisodium phosphate, sodium polyphosphate, phosphoric acid, aluminium trichloride and 191 resin are fully stirred, press-moulded and cured so as to obtain the required building material.

Owner:吴伟文 +1

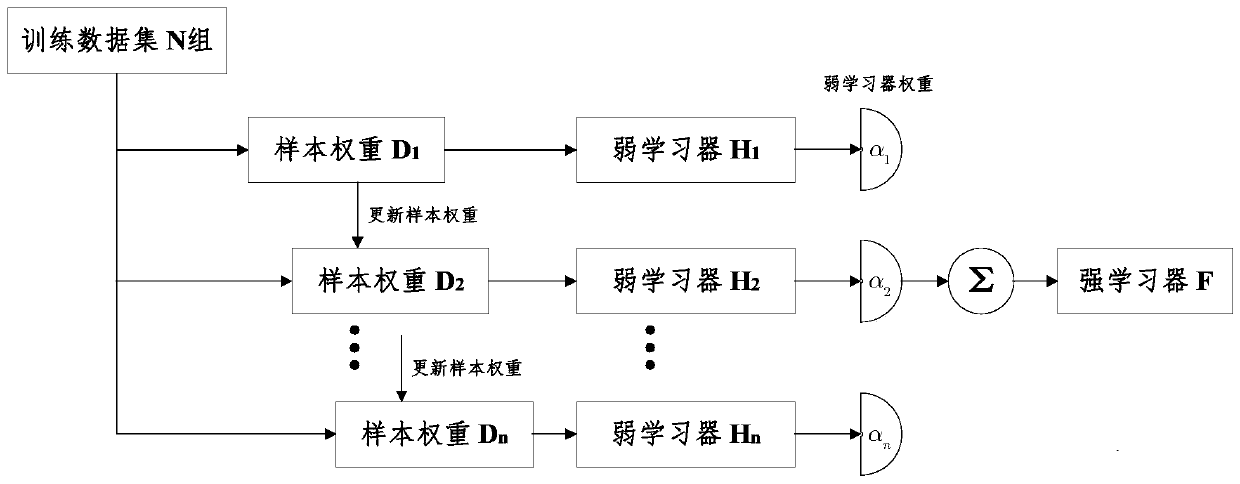

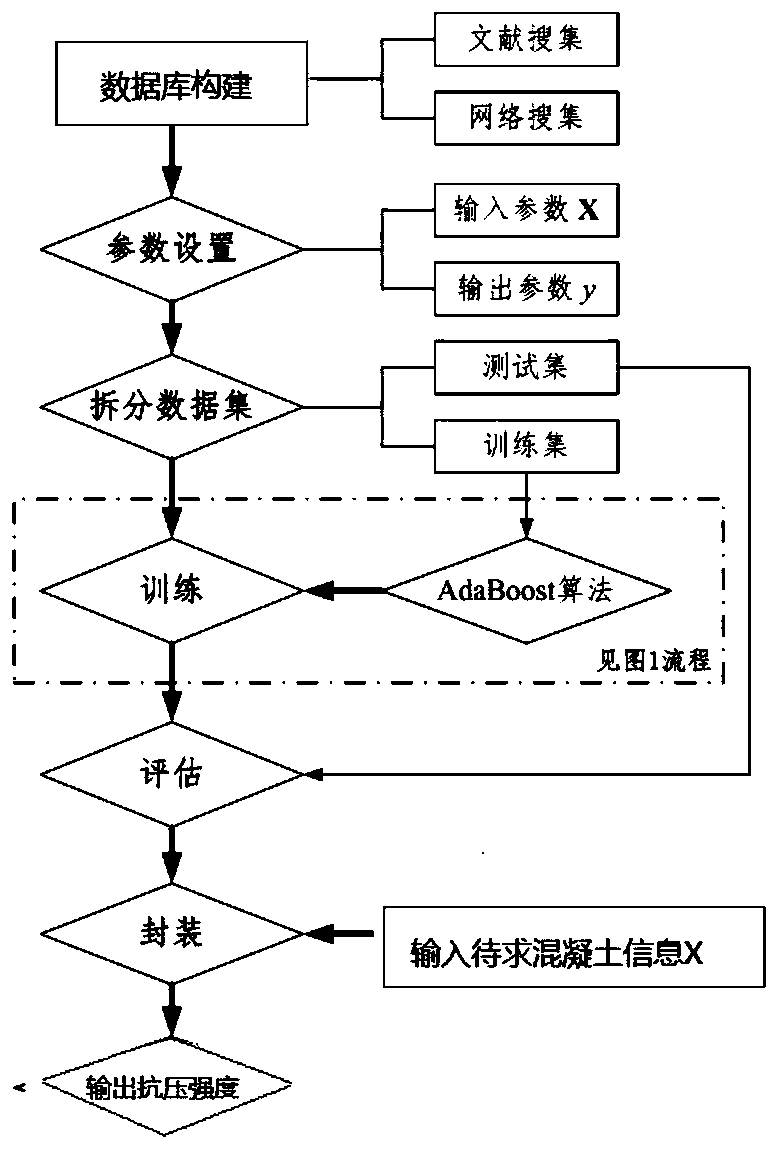

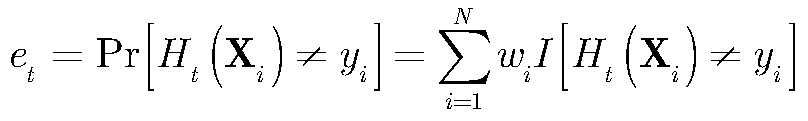

Concrete material compressive strength prediction method based on AdaBoost algorithm

PendingCN110163430AHigh precisionAvoid systematic errorsForecastingMachine learningAdaboost algorithmStudy methods

The invention discloses a concrete material compressive strength prediction method based on the AdaBoost algorithm. Firstly, a large amount of existing concrete compressive strength test data is collected as a training set; the proportion of each component of the concrete material is regarded as an input variable, and the compressive strength of the concrete material is used as an output variable;the test data is trained through a weak classifier in the AdaBoost algorithm; weights of different weak classifiers are determined according to accuracy of training results, weights of the weak classifiers low in prediction error rate are increased, weights of the weak classifiers high in prediction error rate are reduced, and therefore all the weak classifiers are combined into the strong classifier high in prediction precision, and the compressive strength of concrete can be given directly according to input relevant parameters. According to the method, the compressive strength of the concrete material can be quickly and accurately predicted only through simple data collection and machine learning method application, and popularization and application of professionals such as structuraldesign, identification and reinforcement are facilitated.

Owner:SOUTHEAST UNIV

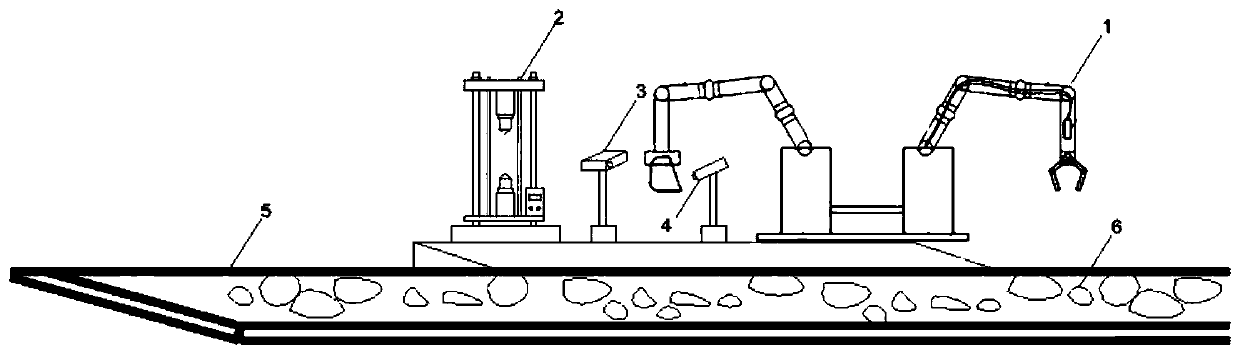

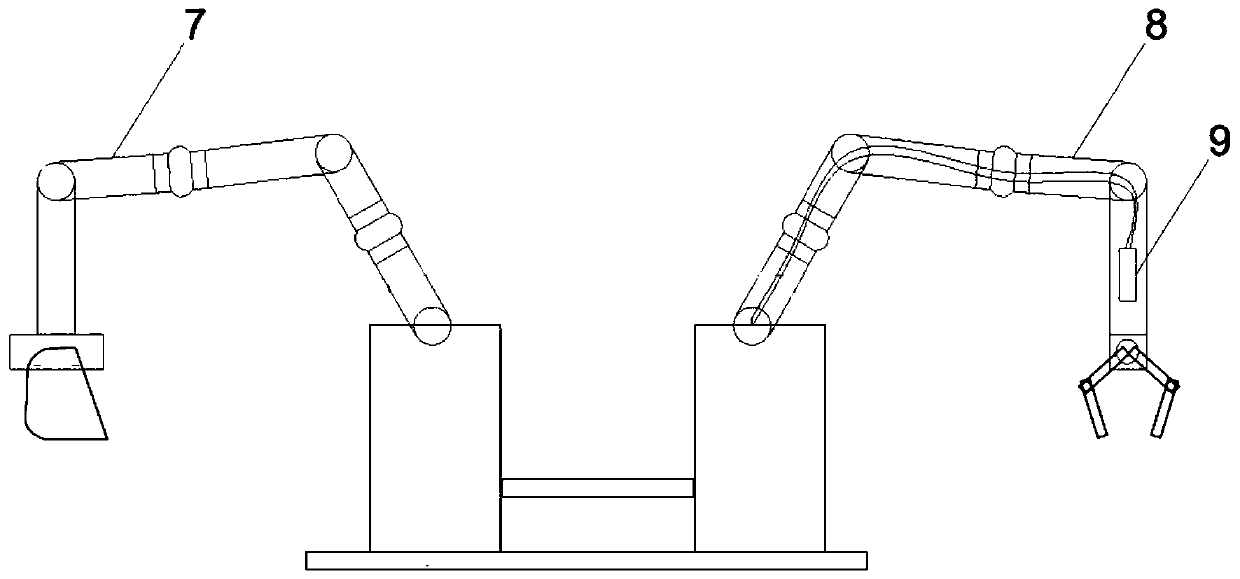

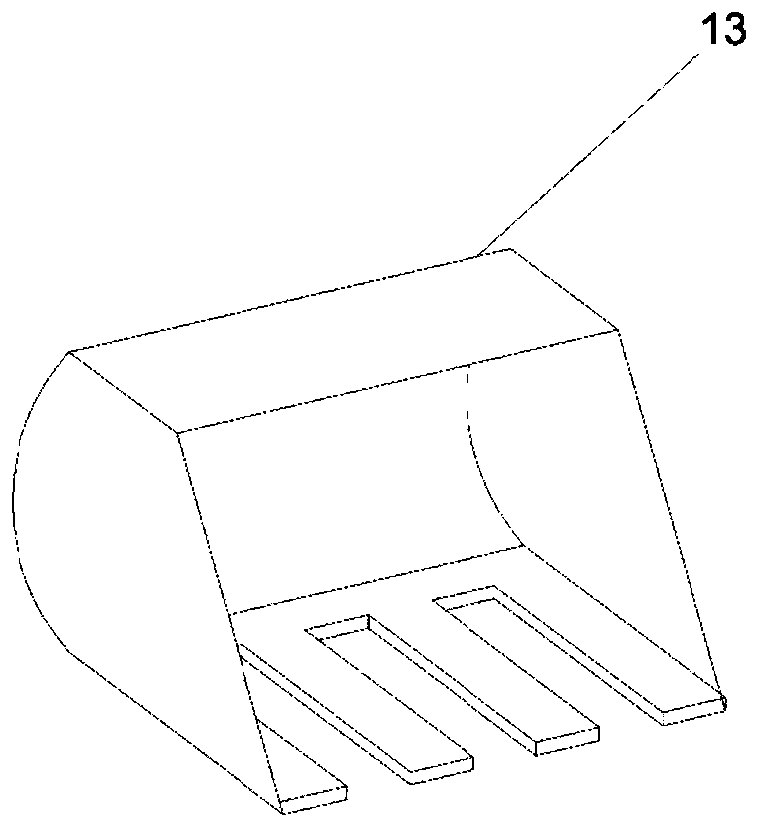

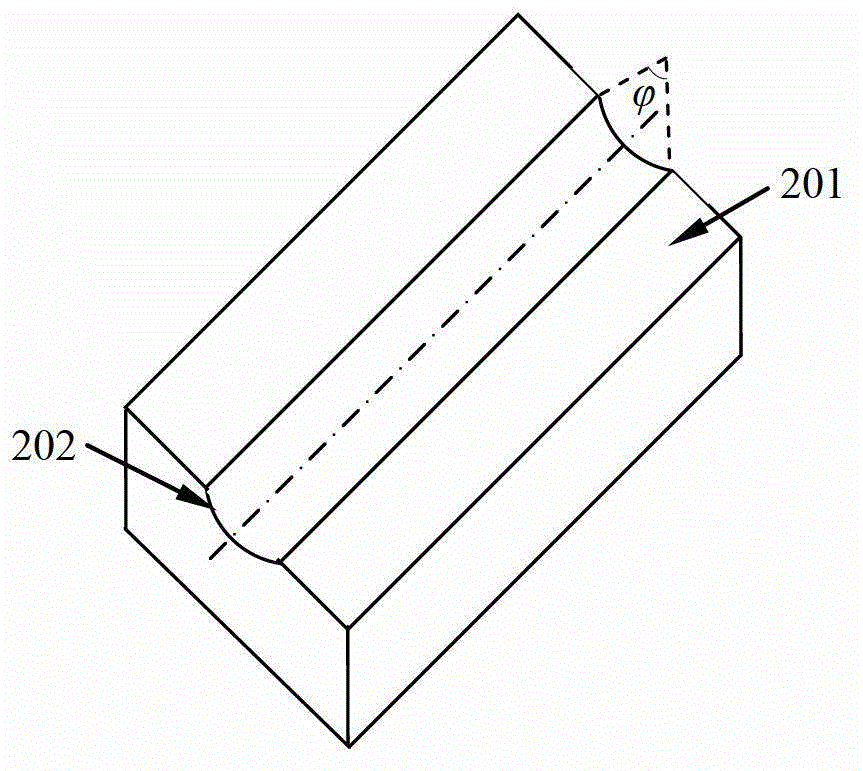

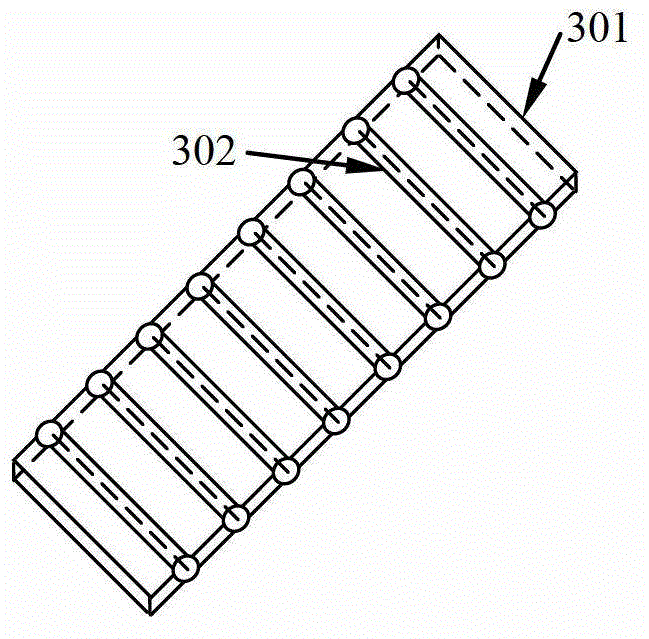

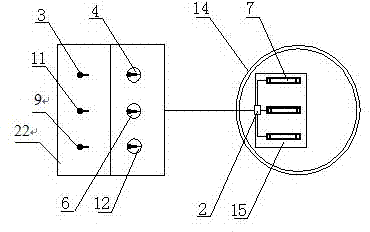

TBM-carried rock slag online compressive strength testing system and method

ActiveCN110823704AMeet the requirements of real-time online analysis and testingSatisfy faster requirementsMaterial strength using tensile/compressive forcesUsing optical meansVision processingGrating

The invention discloses a TBM-carried rock slag online compressive strength testing system and a TBM-carried rock slag online compressive strength testing method. The TBM-carried rock slag online compressive strength testing system comprises a robot, a grating projection device, a visual processing device and a compressive strength testing device, wherein the robot is used for acquiring rock slagin the TBM tunneling process; the grating projection device can project structured light to the tested rock slag to form a two-dimensional light bar image in the surface shape of the rock slag; the visual processing device can calculate to obtain a rock slag three-dimensional shape model according to the two-dimensional light bar image shot and projected onto the rock slag surface to form distortion; a loading point position is calculated by means of a rock slag three-dimensional shape model, and whether the tested rock slag meets the requirements or not through the distance between the loading points is judged; and the compressive strength testing device is used for automatically testing the compressive strength of the tested rock slag meeting the requirements. The TBM-carried rock slag online compressive strength testing system and the TBM-carried rock slag online compressive strength testing method have the beneficial effects of being high in timeliness, high in automation degree, safe, economical and the like, effectively solves the problem that surrounding rock strength information of current TBM construction is difficult to obtain in real time, and real-time surrounding rockcondition information and a control parameter decision basis are provided for TBM tunneling.

Owner:山东百廿慧通工程科技有限公司

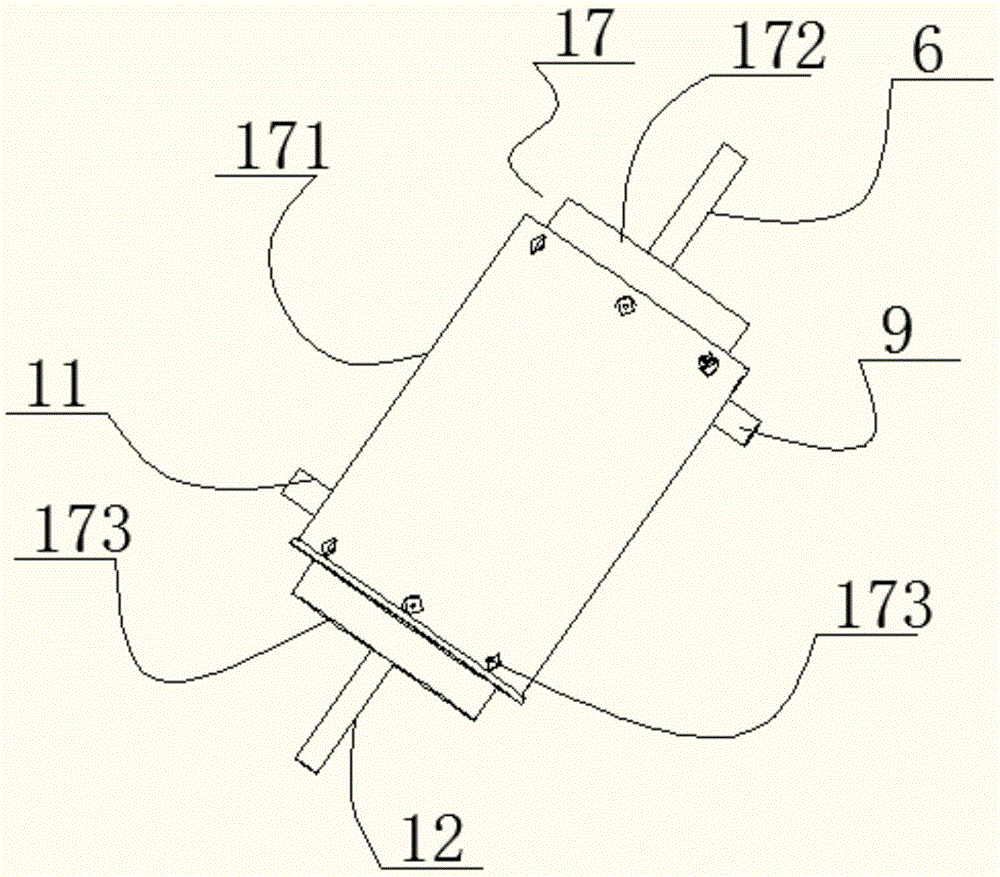

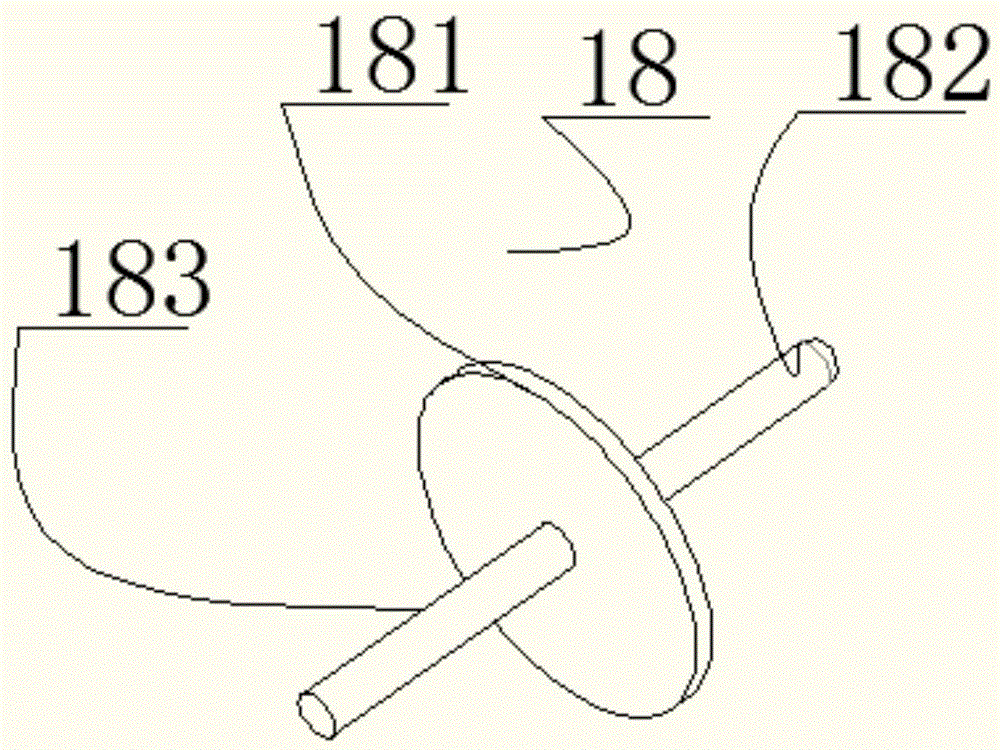

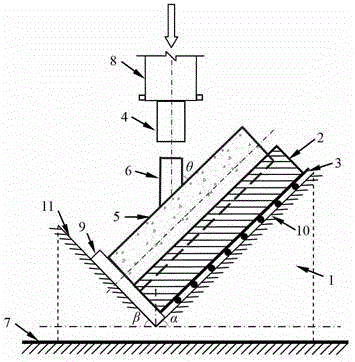

Radial inclination compressive strength test device for round-section concrete-filled steel tube

ActiveCN103063514AAchieve supportImplement testMaterial strength using tensile/compressive forcesEngineeringTower

The invention discloses a radial inclination compressive strength test device for a round-section concrete-filled steel tube and belongs to the field of structural engineering. The device is characterized in that by combination of a main foundation, an auxiliary foundation, a roller frame and the like, the radial inclination load of the concrete-filled steel tube is positioned in a vertical direction. When simple vertical load is applied to concrete-filled steel tube test blocks by a loading end head and a loading rod, the test stimulation of the inclination load transmitted by radial inclination limb rod pieces and applied to the test blocks is realized; and by the design of the circular arc surface of the auxiliary foundation, the round-section test blocks are effectively supported. The internal force of the rod pieces is tested in real time by using a load sensor; and strain data, deformation data and other data of the test blocks in the test process are obtained by using a strain gauge, a displacement meter and other measurement instruments. Different test blocks can be replaced conveniently, so that the device can be used repeatedly. The device is suitable for the strength test and the research of the round-section concrete-filled steel tube rod pieces in truss, tower, and lattice structures in the radial inclination load.

Owner:TSINGHUA UNIV

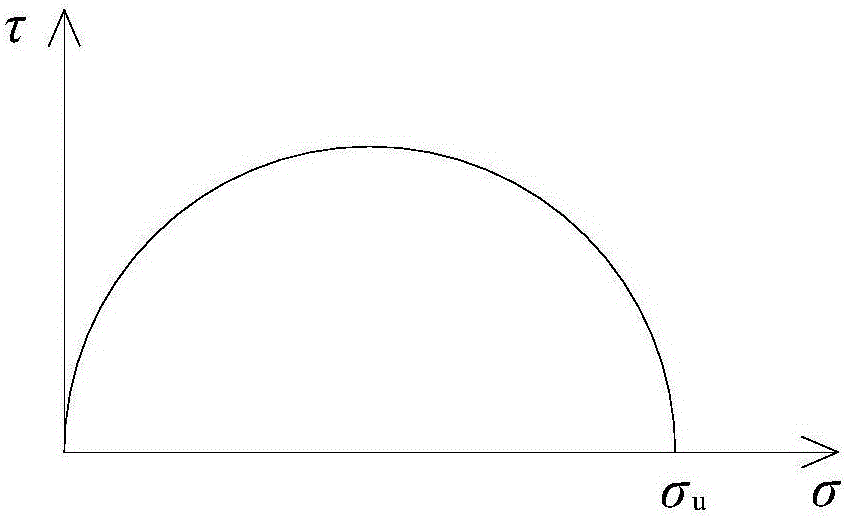

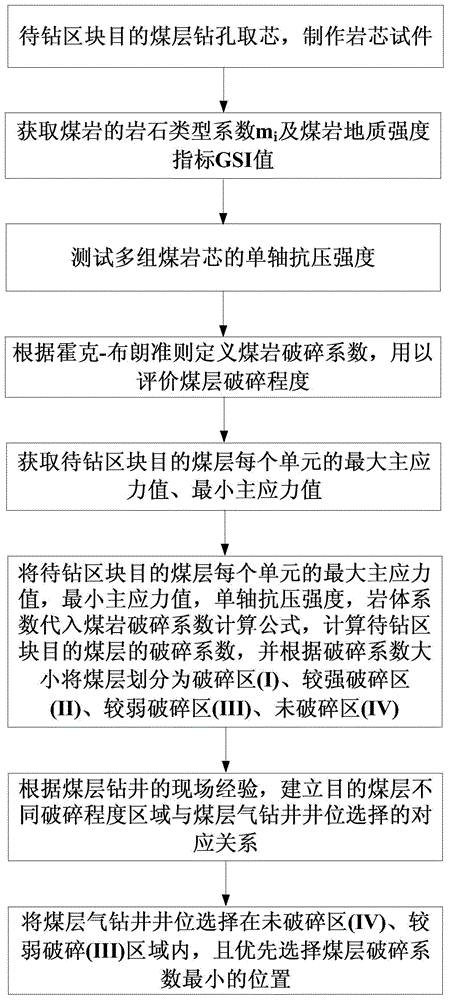

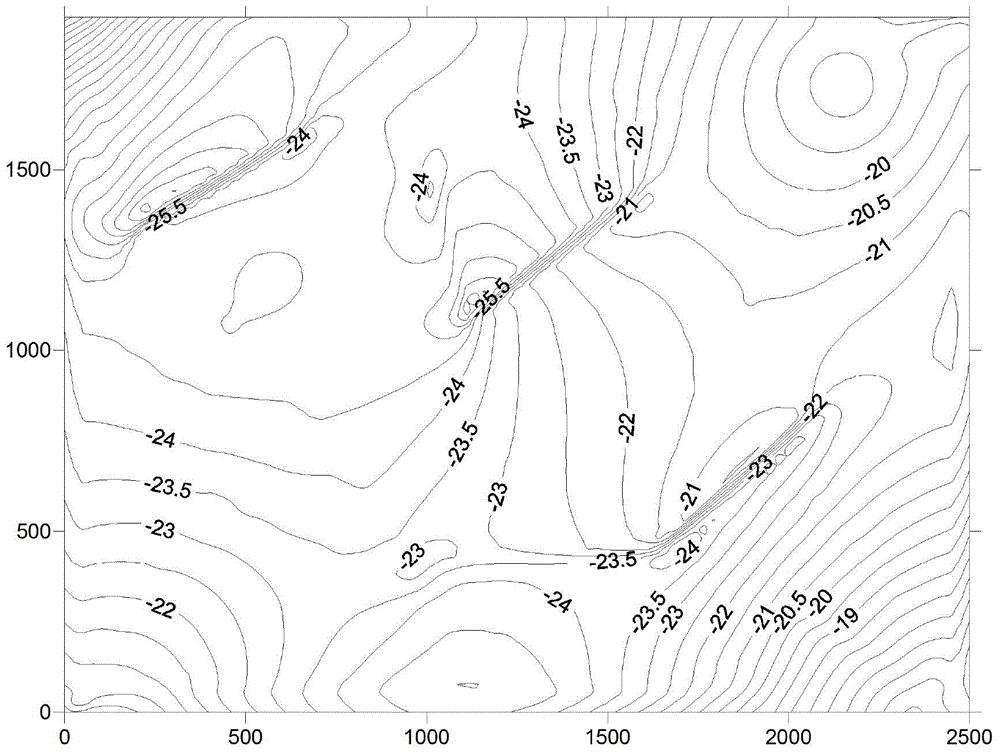

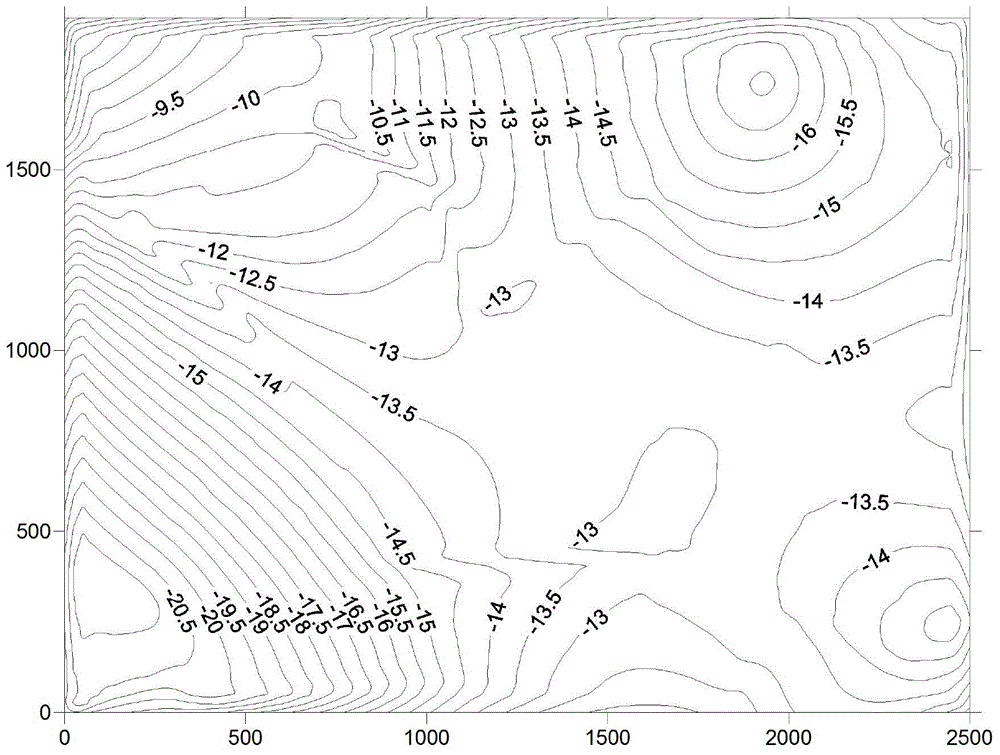

Well drilling position selection method in consideration of coal seam crushing degree

The invention discloses a well drilling position selection method in consideration of a coal seam crushing degree, and belongs to the field of coalbed methane drilling engineering. A bulk rock core is obtained from a coal seam drilling hole of a block to be drilled to determine rock type coefficients and geology strength indexes of coal rocks; the experimental sample processing is performed for the obtained bulk rock core to obtain multiple sets of standard cylinder coal rock core samples; the uniaxial compressive strength test is performed for the obtained multiple sets of coal rock cores by an uniaxial compressive strength tester, and the average value of multiple sets of test values serves as the uniaxial compressive strength of the coal rocks in the block to be drilled; a coal rock crushing coefficient formula is determined according to the Hoek-Brown criterion for evaluating the coal seam crushing degree; and a ground stress field of the coal seam in the bock to be drilled is determined according to a multiple linear regression method, and the maximal main stress value, the minimal main stress value, the uniaxial compressive strength and the rock body coefficient of each unit of the coal seam of the block to be drilled are substituted into the coal rock crushing coefficient formula to calculate the crushing coefficient of the coal seam of the block to be drilled.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Test device and method based on MICP reinforced calcareous coarse-grained soil

ActiveCN109459364AEasy to operateReasonable arrangementWeighing by removing componentPreparing sample for investigationSpecific testSoil science

The invention discloses a test device based on MICP reinforced calcareous coarse-grained soil. The test device based on the MICP reinforced calcareous coarse-grained soil comprises a specimen preparation device, a permeability coefficient measuring device and an unconfined compressive strength test device. Meanwhile, the invention also discloses a specific test method. The test method comprises the following steps: successively measuring specimens, measuring the permeability coefficients of the specimens and measuring the content of calcium carbonate. For the characteristics of large grain size, large pores and calcareous property of the calcareous coarse-grained soil, the test device and method are provided, are easy to operate and reasonable in arrangement, can be used for researching physical and mechanical properties of MICP cemented calcareous coarse-grained soil, and lay a foundation for promoting an MICP technology to the field of calcareous coarse-grained soil.

Owner:HOHAI UNIV

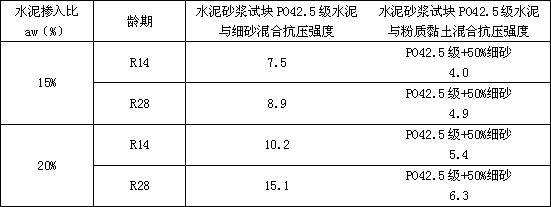

Method for improving strength of cement mixing piles for sand-rich geological high-rise building

InactiveCN111648355AIncrease the strength of the mixing pileEasy to operateFoundation testingBulkheads/pilesStructural engineeringLaboratory test

The invention relates to a method for improving the strength of cement mixing piles for a sand-rich geological high-rise building. The method for improving the strength of the cement mixing piles forthe sand-rich geological high-rise building is characterized by comprising the following steps of a, sampling, inspecting, and manufacturing test blocks; b, testing the test blocks; c, directly conducting unconfined compressive strength tests of pile bodies at different ages for test block samples; and d, conducting a laboratory test for cement mortar test blocks so as to obtain compressive strength indexes, specifically, according to different cement-mixed ratios, conducting the laboratory test on the cement mortar test blocks at different ages so as to obtain the compressive strength indexes. The method for improving the strength of the cement mixing piles for the sand-rich geological high-rise building provided by the invention has the characteristics of scientific and standard experimental procedure setting, high operability, capability on ensuring high pile body strength of cement mortar piles, a high bearing capacity characteristic value of a single pile and a high bearing capacity characteristic value of a composite foundation, capability on enabling the strength of the cement mixing piles to reach to 390 KPa, and high safety degree and economic effect.

Owner:CHINA MCC5 GROUP CORP

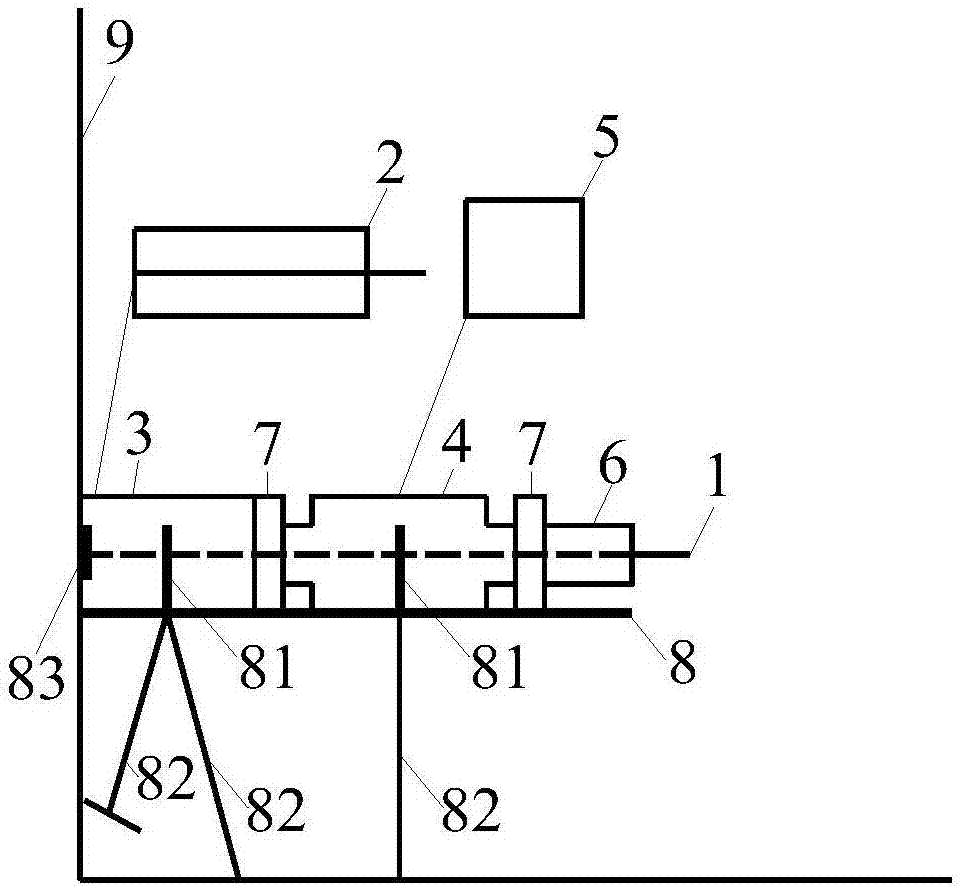

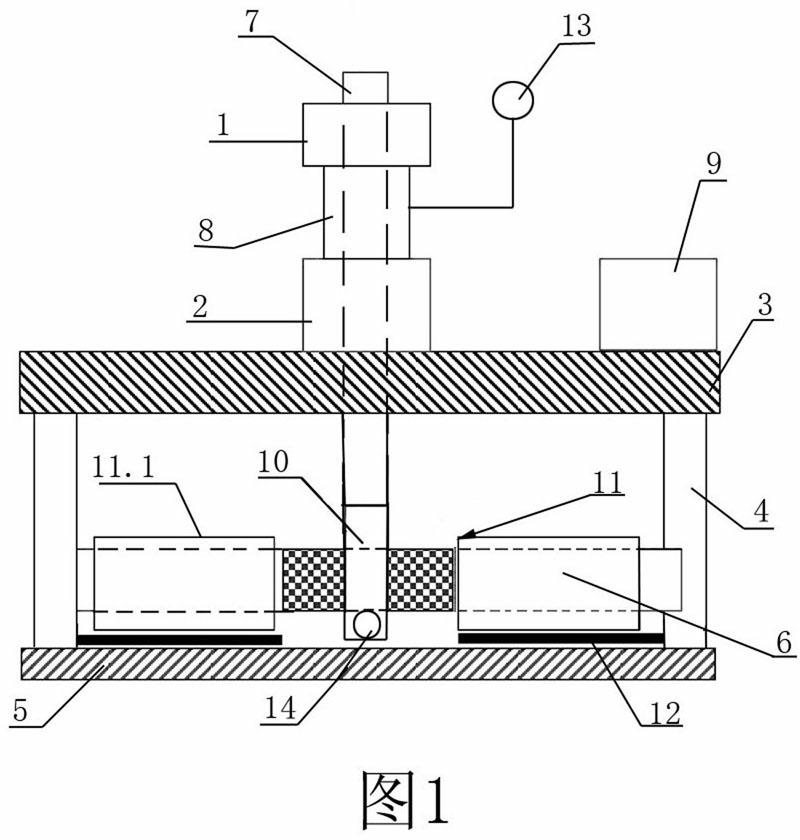

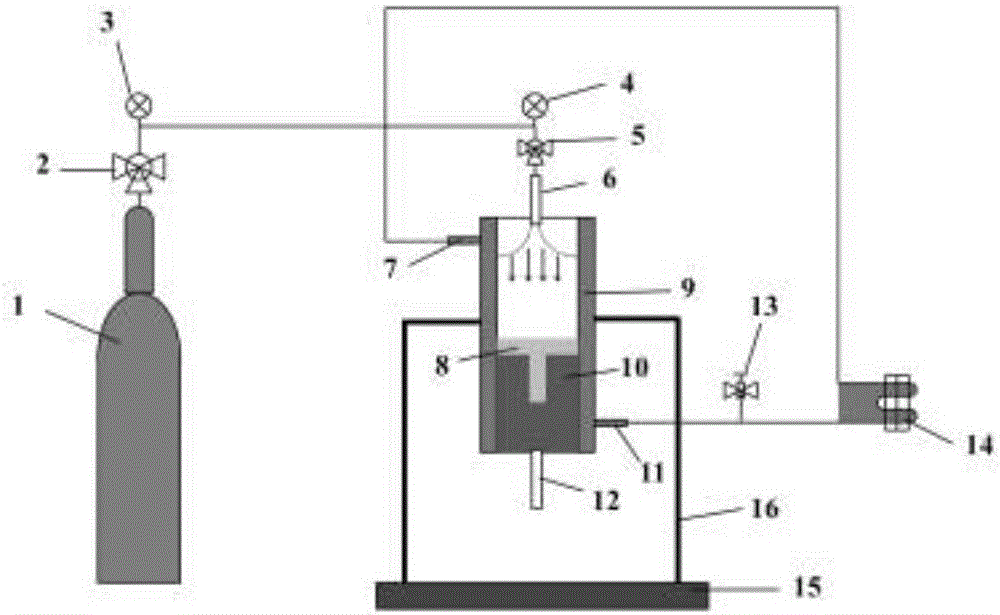

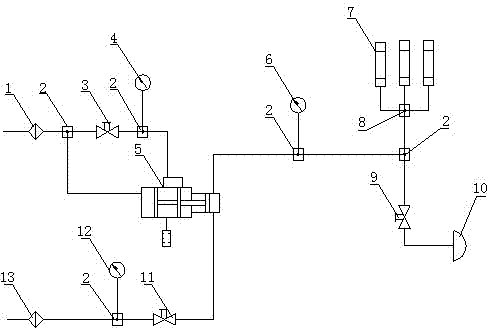

Tester for compressive strength of hollow glass beads

InactiveCN103245567ACalculate the bearing strengthAccurately measure breakageMaterial strength using tensile/compressive forcesData displayEngineering

The invention discloses a tester for the compressive strength of hollow glass beads. The tester is formed by combining a pressurized part and a high pressure testing part, wherein the pressurized part consists of an air compressor (1), a compressed air control valve (3), a compressed air pressure gauge (4), a booster pump (5), a nitrogen cylinder (13), a nitrogen pressure gauge (12) and a nitrogen control valve (11); the high pressure testing part comprises high pressure chambers (7); the high pressure chambers (7) are arranged in an explosion-proof barrel; the high pressure chambers (7) consist of high-pressure hexagonal tanks, high-pressure hollow bolts, high-pressure bolts and sample chambers; the sample chambers consist of transparent glass tubes and micropore plugs; the high-pressure chambers (7) are connected with a pressure relief and air leakage device consisting of a pressure relief valve (9) and an air leakage safety cap (10); and the compressed air pressure gauge (4), a high-pressure nitrogen pressure gauge (6), the nitrogen pressure gauge (12), the compressed air control valve (3), the nitrogen control valve (11) and the pressure relief valve (9) are mounted on an operating instrument panel. The tester is simple in structure, accurate and convenient to operate, and visual and detailed in data display.

Owner:SINOSTEEL MIMR NEW MATERIAL TECH CO LTD +1

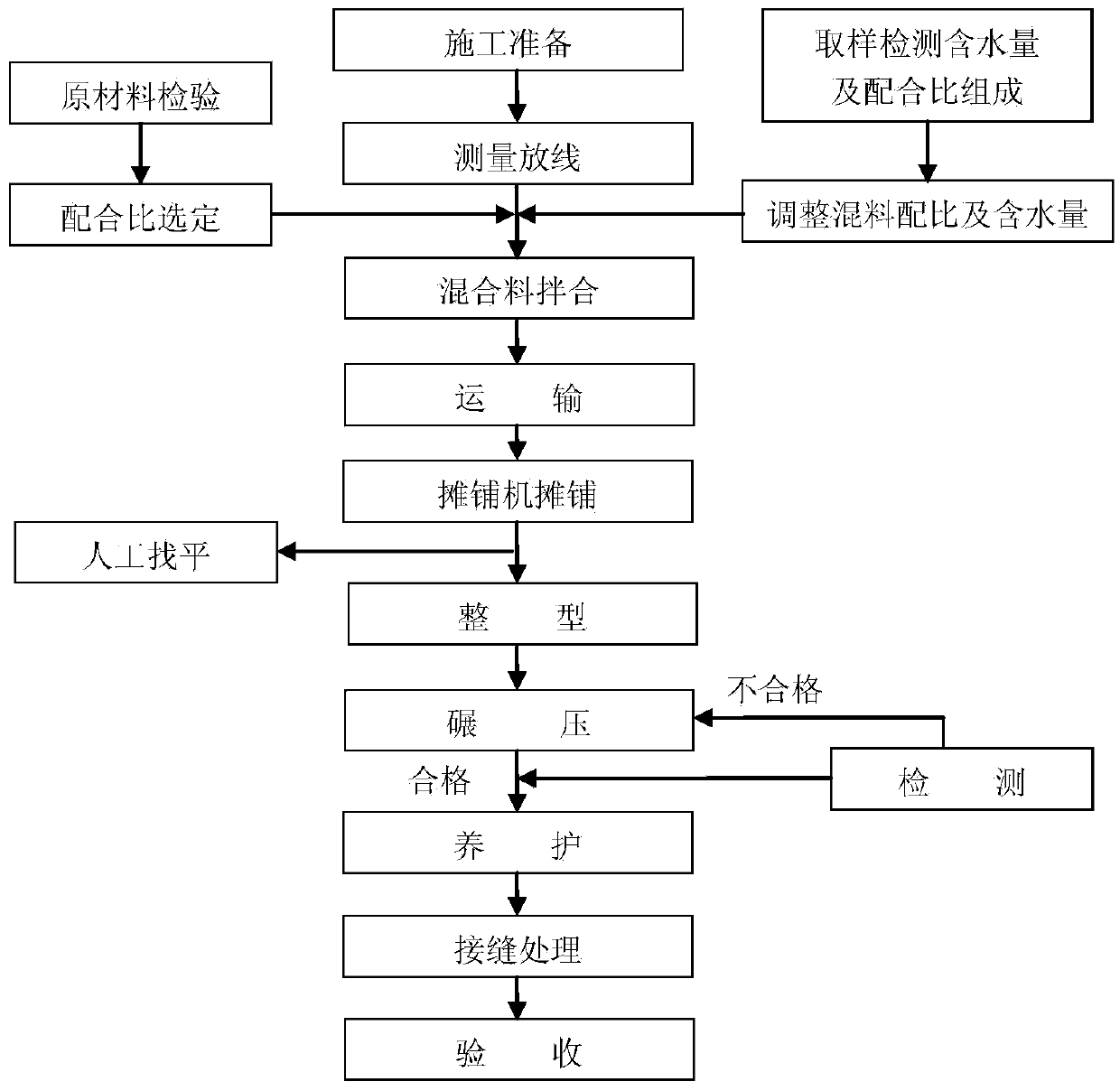

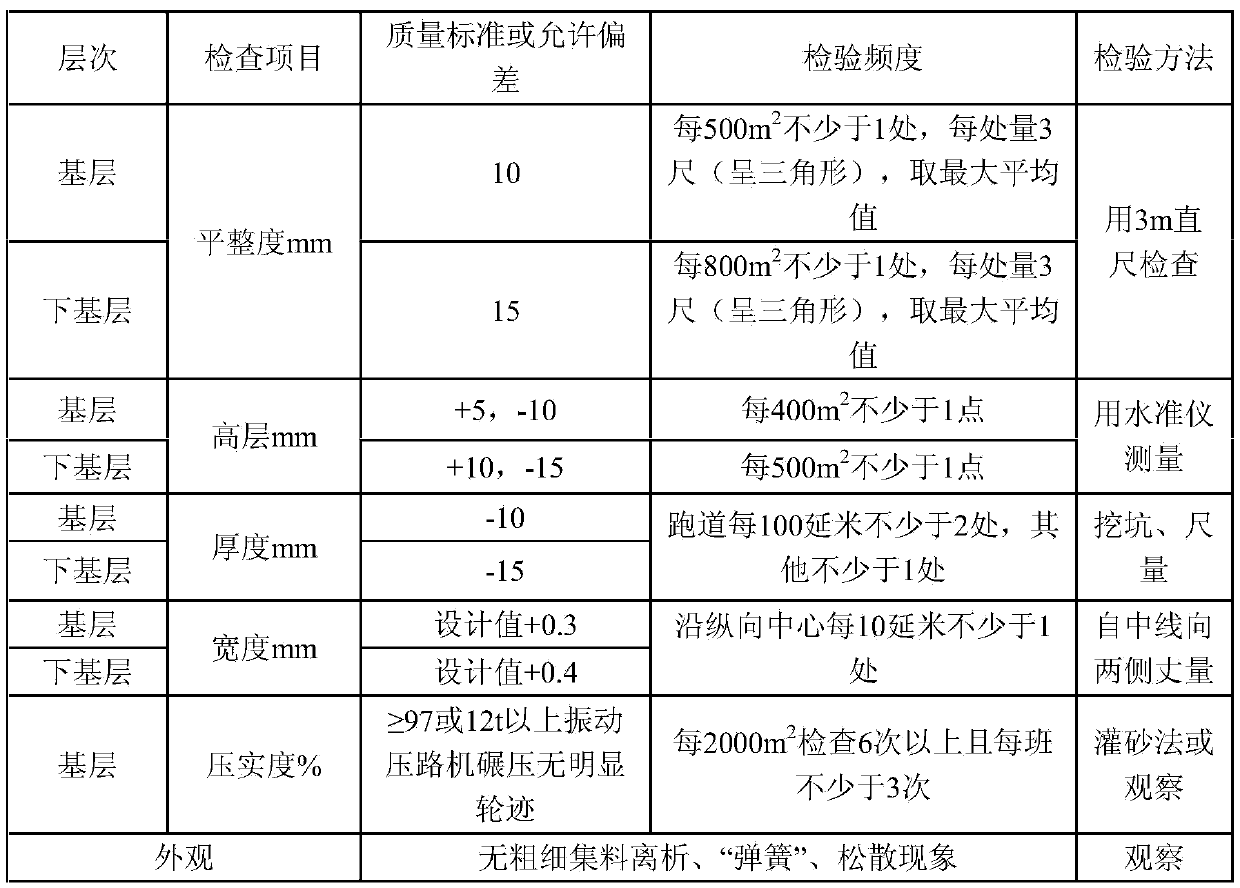

Cement-stabilized coral reef sand construction process

InactiveCN105369721ASolve overseas transportation problemsMeet the designRoads maintainencePortland cementCrushed stone

The invention discloses a cement-stabilized coral reef sand construction process. The process comprises, through an on-site test method, determining largest dry density and optimum water content of a mixture, carrying out an unconfined compressive strength test on the mixture according to compactness requirements so that a design strength requirement is satisfied, selecting PO42.5 ordinary portland cement, island coral reef sand with particle sizes of 6cm or less and seawater on the island as raw materials, replacing the common cement-stabilized macadam by cement-stabilized coral reef sand as a base layer, wherein the cement-stabilized base layer has thickness of 35cm, carrying out centralized mixing on the mixture in a factory by a stabilized soil mixer, carrying out transportation by a dumper, spreading the mixture by a spreading machine, carrying out rolling compaction by a vibratory roller, and carrying out seawater maintenance on the roll-molded base layer by a non-woven fabric or a regenerated cloth for 7 days or more. The cement-stabilized coral reef sand construction process can satisfy design and runway usage requirements, solves the problem that sand and stones in a special geographical position in an island are difficultly transported to open seas, realizes local material use and saves an engineering cost.

Owner:NO 4 ENG CO LTD OF CCCC FIRST HARBOR ENG CO LTD

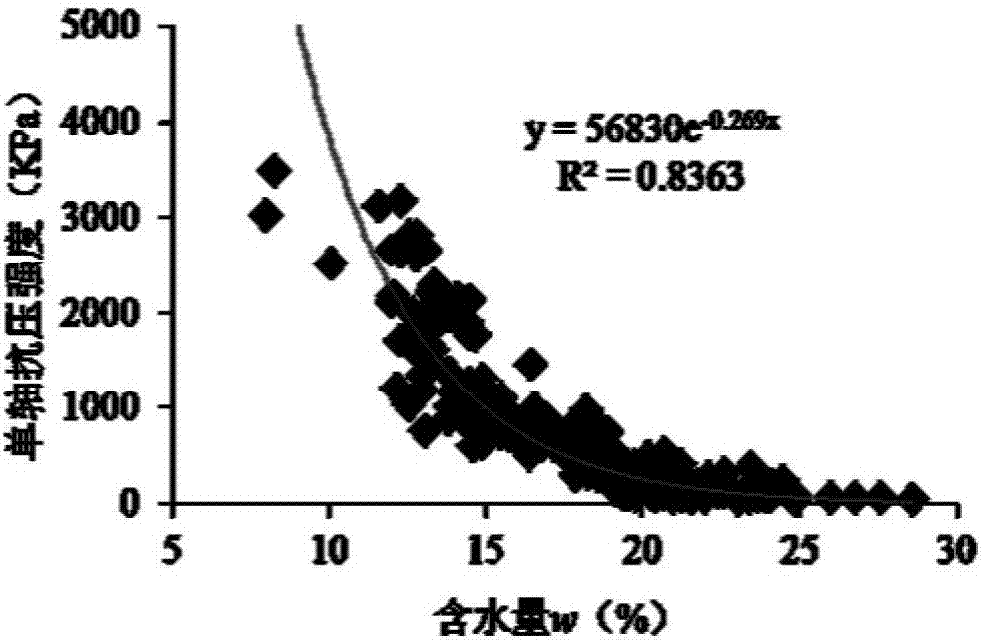

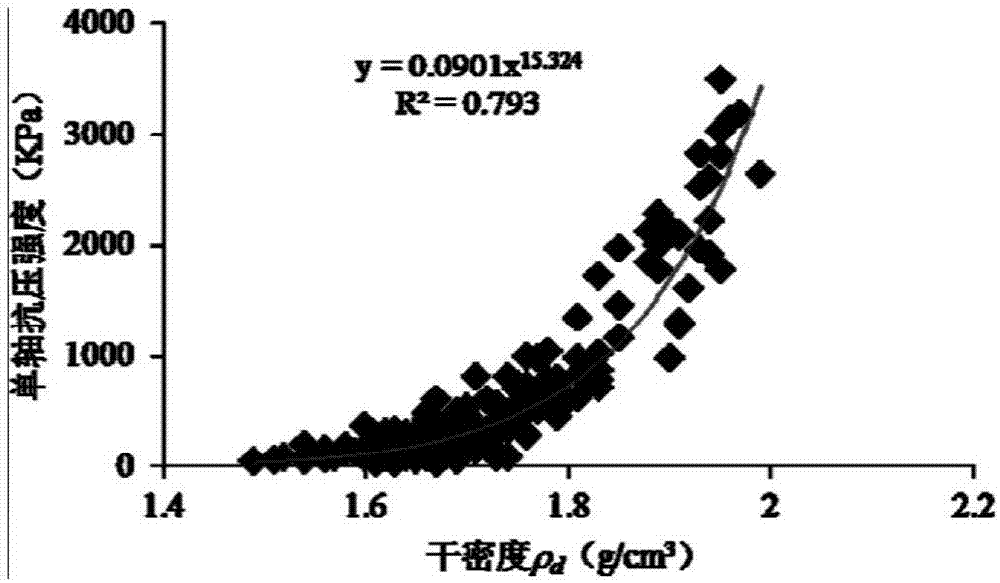

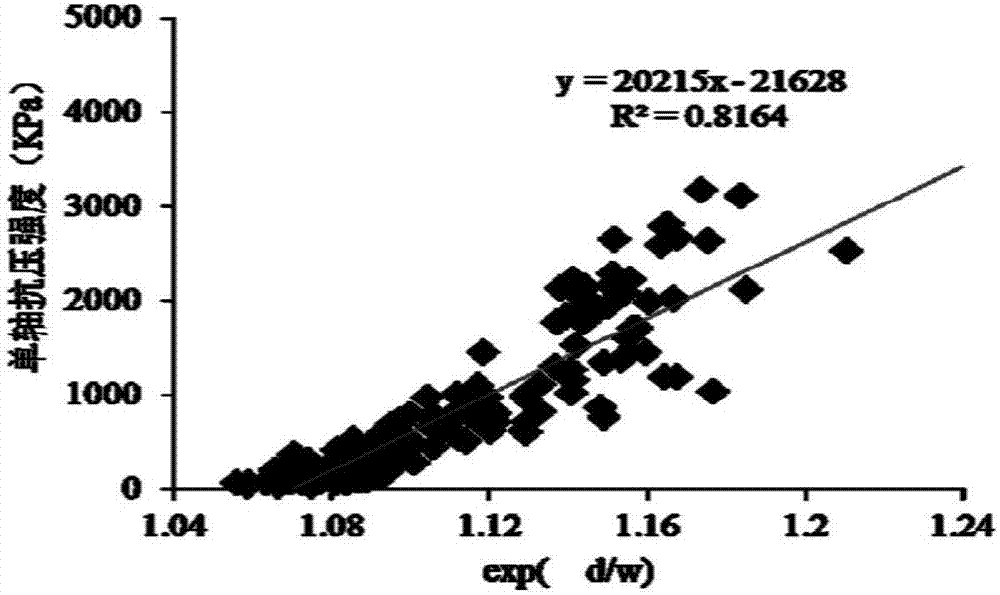

Method for establishing sandy mudstone uniaxial compressive strength curve

ActiveCN107121336AMaterial strength using tensile/compressive forcesTest sampleUltimate tensile strength

The invention discloses a method for establishing a sandy mudstone uniaxial compressive strength curve. The method comprises the following steps: I, selecting sandy mudstone in an area to be tested, and manufacturing a cylindrical sandy mudstone test sample; II, testing a damage limit loading value as uniaxial compressive strength of the sandy mudstone, of the sandy mudstone test sample in the step I; III, fitting the value of the uniaxial compressive strength tested in the step II by using a least square method, so as to obtain the relationship between water contents and the uniaxial compressive strength; fitting the value of the tested uniaxial compressive strength by using the least square method, so as to obtain the relationship between dry densities and the uniaxial compressive strength; IV, fitting the relationship between ratios (exp (rhod / w )) of different dry densities to water contents and the uniaxial compressive strength of the sandy mudstone by using the least square method, and according to a curve diagram of the relationship between the ratios (exp (rhod / w )) of the different dry densities to the water contents and the uniaxial compressive strength of the sandy mudstone, establishing mathematic expressions of the uniaxial compressive strength of the sandy mudstone based on the water contents and the dry densities.

Owner:SHAANXI SCI TECH UNIV

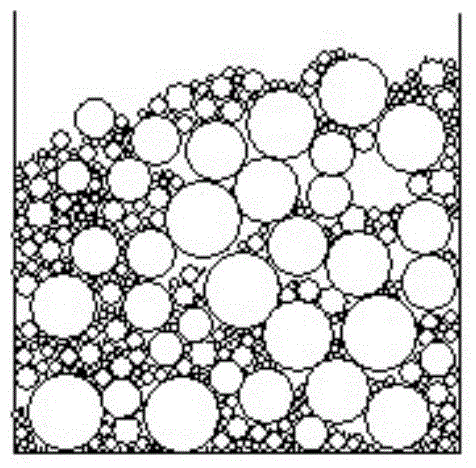

Graded broken stone compressive strength value test method

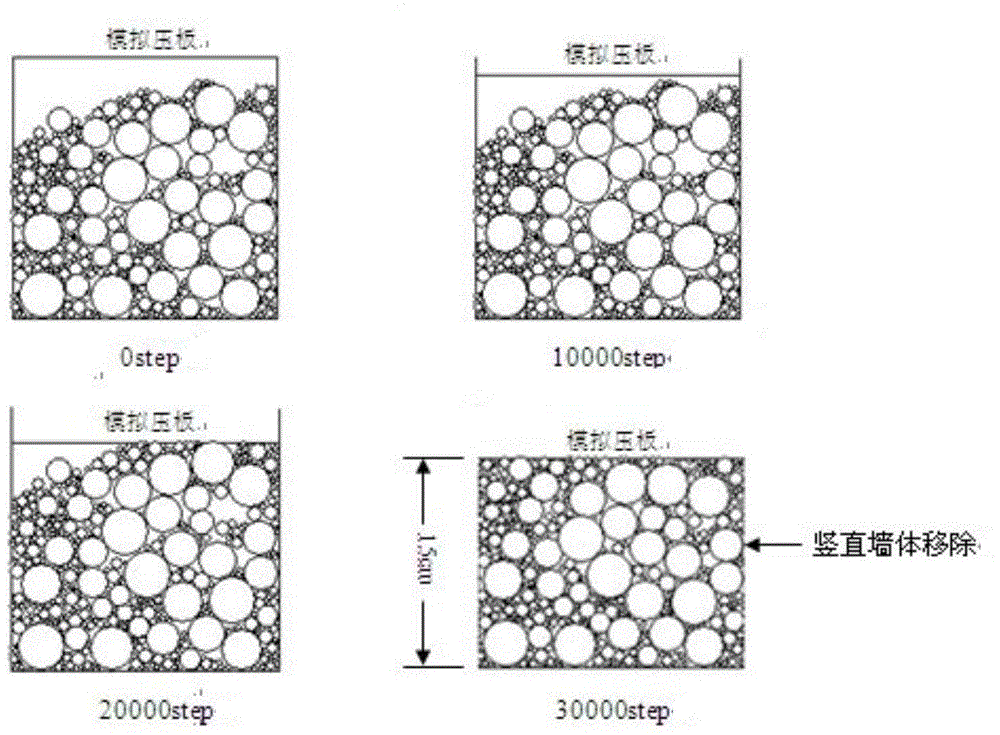

InactiveCN103955597AEasy to predictSimple compositionSpecial data processing applicationsCrushed stonePhysical model

The invention discloses a graded broken stone compressive strength value test method. According to the method, the simulation of the graded broken stone compressive strength value test is carried out through building a physical model. The method comprises the steps that basic parameters are tested, simulation generation of compressive strength test molds, virtual test specimens, compressive strength loading plates and the like is carried out, physical models are endowed with micro mechanical parameters, the compressive strength test loading process is simulated, the simulation results are sorted, a relationship curve of simulated press plate contact force and compression displacement is obtained, and the graded broken stone compressive strength is obtained through obtaining the peak value of the curve and carrying out the calculation. The method can be used for fast and accurately predicting the graded broken stone compressive strength value and reproducing the mechanical variation rule of graded broken stones during the compression load bearing.

Owner:上海频谱顿交通科技有限公司

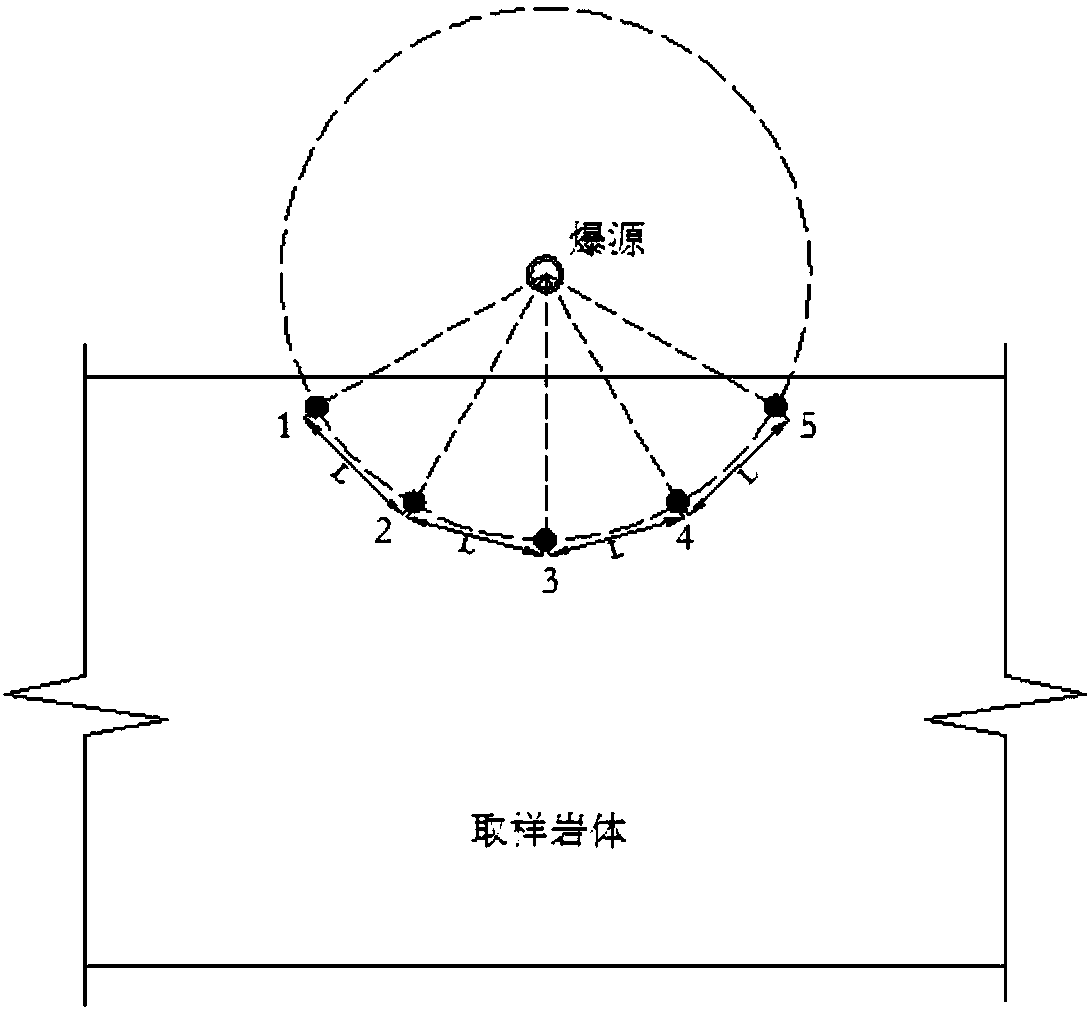

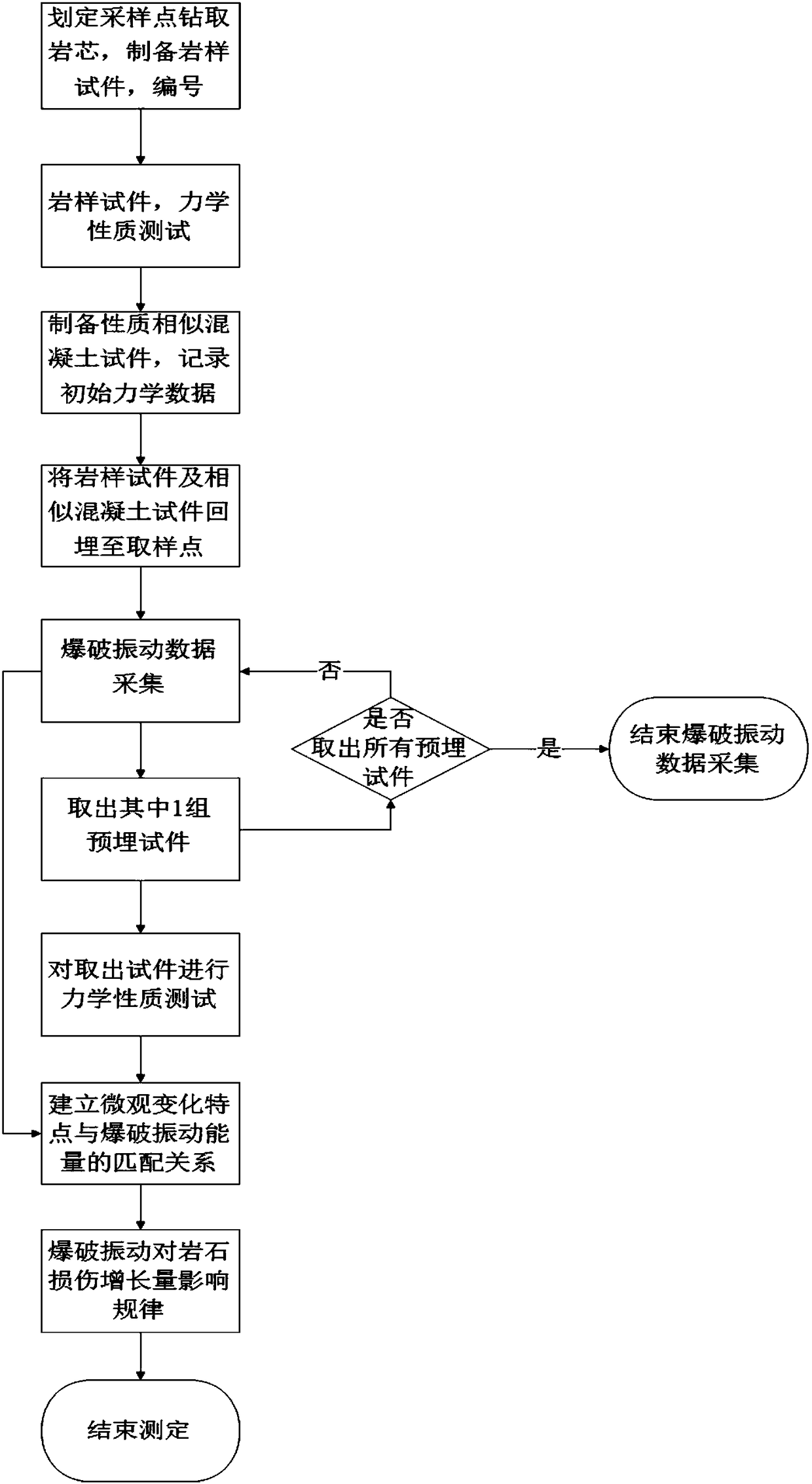

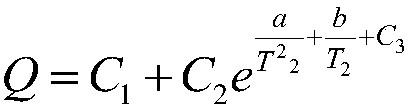

Method used for calculating rock damaged degree under explosion effects based on nuclear magnetic resonance

ActiveCN108344806AEasy to chooseEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesNMR - Nuclear magnetic resonanceLongitudinal wave

The invention provides a method used for calculating rock damaged degree under explosion effects based on nuclear magnetic resonance. The method is used for measuring internal damage degree of rock inexplosion vibration influenced regions. The method comprises following steps: sampling points at equal intervals are selected taking an explosion source as a circle center; rock samples are collectedat the sampling points, and are prepared into rock test pieces to test the uniaxial compressive strength, the longitudinal wave velocity, and the nuclear magnetic resonance times; cement test pieceswith a mechanical property tolerance range ranging from 5 to 8% are prepared based on the mechanical properties of the rock test pieces, the cement test pieces and the rock test pieces are subjected to pre-embedding at sampling points, and explosion vibration data acquisition is carried out; the rock test pieces and the cement test pieces are subjected to uniaxial compressive strength test and acoustic wave velocity test; influence laws of explosion vibration on rock damage increment are obtained based on nuclear magnetic resonance images and the transverse relaxation time so that rock damagedegree under different explosion vibration effects is determined, explosion design is guided, low energy consumption and high efficiency explosion operation are realized, and influences of explosion vibration on non-action object engineering are reduced.

Owner:UNIV OF SCI & TECH LIAONING

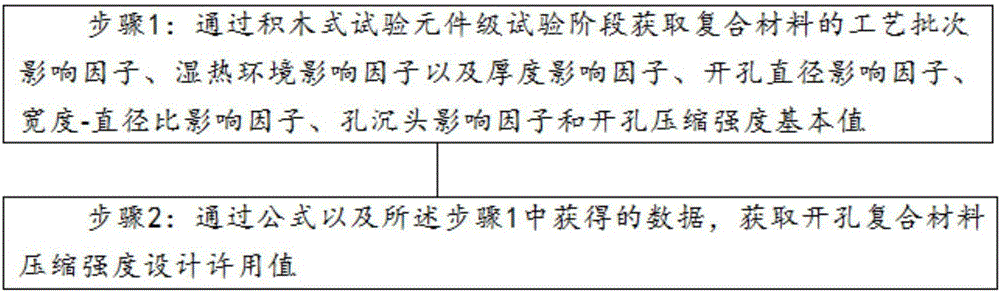

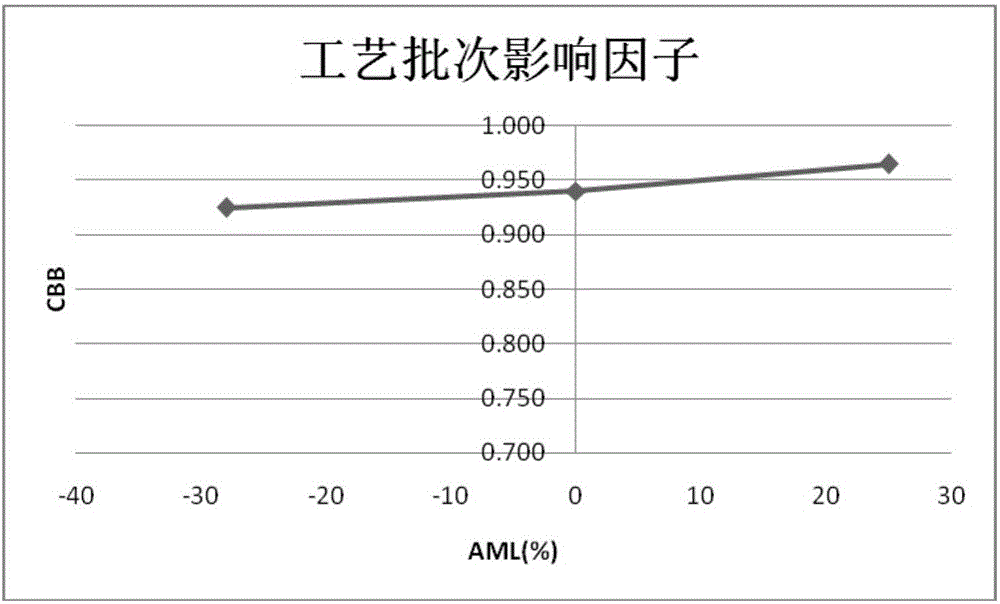

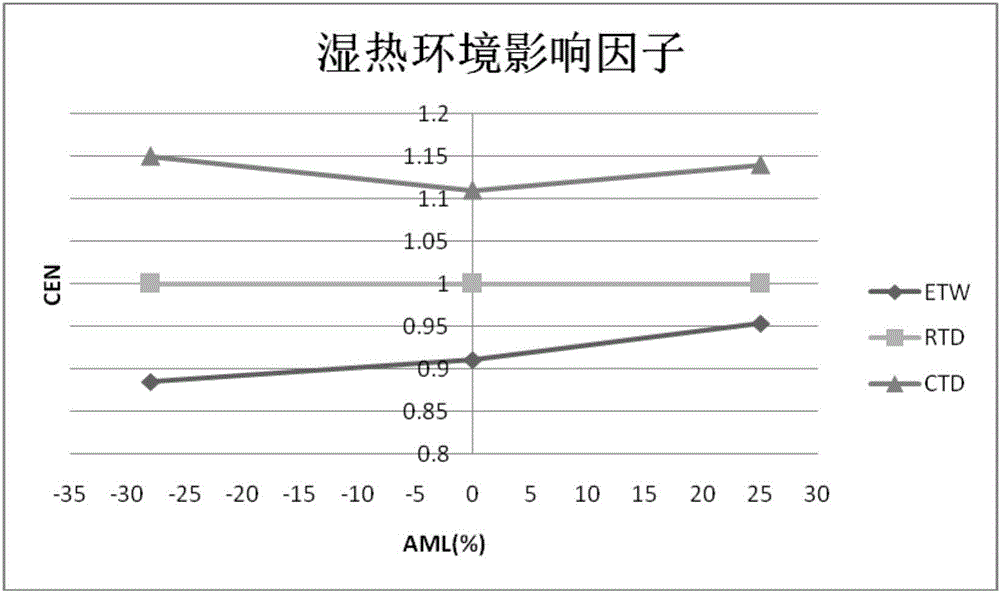

Testing method for design allowable value of composite material opening pore compressive strength

InactiveCN106442180AA large number of test piecesLong test cycleMaterial strength using repeated/pulsating forcesSystem testingStrength design

The invention discloses a testing method for a design allowable value of a composite material opening pore comprehensive strength. The testing method for the design allowable value of the composite material opening pore comprehensive strength comprises the steps of 1, obtaining basic values of impact factors of technology batch, hygrothermal environment, thickness, diameter of opening pore, ratio of breadth to diameter, pore countersunk head and the opening pore compressive strength of the composite material through a cordwood system testing component and testing stage; 2, obtaining the design allowable value of the composite material opening pore comprehensive strength through a formula and the obtained data in the step 1. The adoption of the testing method for the design allowable value of the composite material opening pore comprehensive strength can solve problems in engineering practices that the obtained design allowable value of the composite material opening pore comprehensive strength through a traditional testing method has a large deviation, the quantity of testing articles is large, the cycle of testing is long, and the testing result is influenced greatly by constraint conditions such as size effect, boundary conditions and load distribution.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

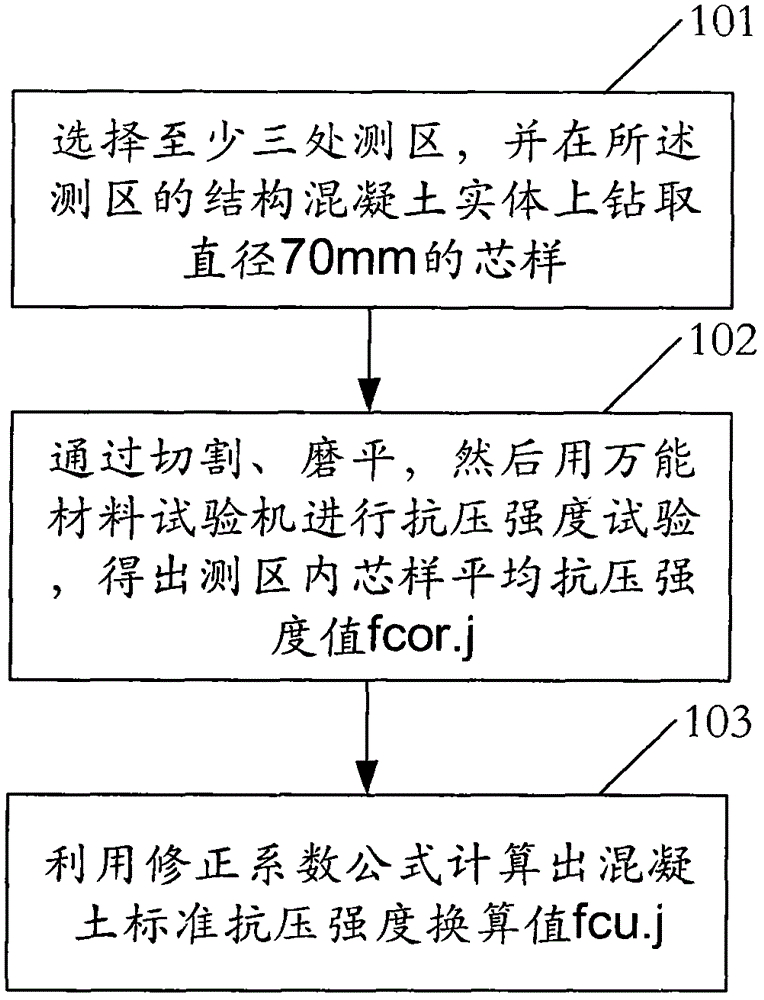

Pit sand concrete compressive strength detection method and apparatus thereof

InactiveCN104964874AStrong detection adaptabilityImprove detection accuracyMaterial strength using tensile/compressive forcesMaterials testingUltimate tensile strength

The invention relates to the field of civil and architectural engineering, and discloses a pit sand concrete compressive strength detection method and an apparatus thereof. The method comprises the following steps: selecting at least three detection zones, and drilling a core sample with the diameter of 70mm on the structural concrete of each of the detection zones; cutting, rubbing, and carrying out compressive strength test by using a universal material testing machine to obtain the average compressive strength fcor.j of the core samples in the detection zones; and calculating the concrete standard compressive strength equivalent value fcu.j by using a correction coefficient formula. The method and the apparatus enhance the detection adaptability of the compressive strength and improve the detection precision.

Owner:宿州学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com