Method and device for detecting compressive strength of concrete by bending method

A technology of concrete strength and compressive strength, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as complex stress conditions, damage to tested components, inaccurate test results, etc., and achieve low cost and wide range , The effect of the test process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

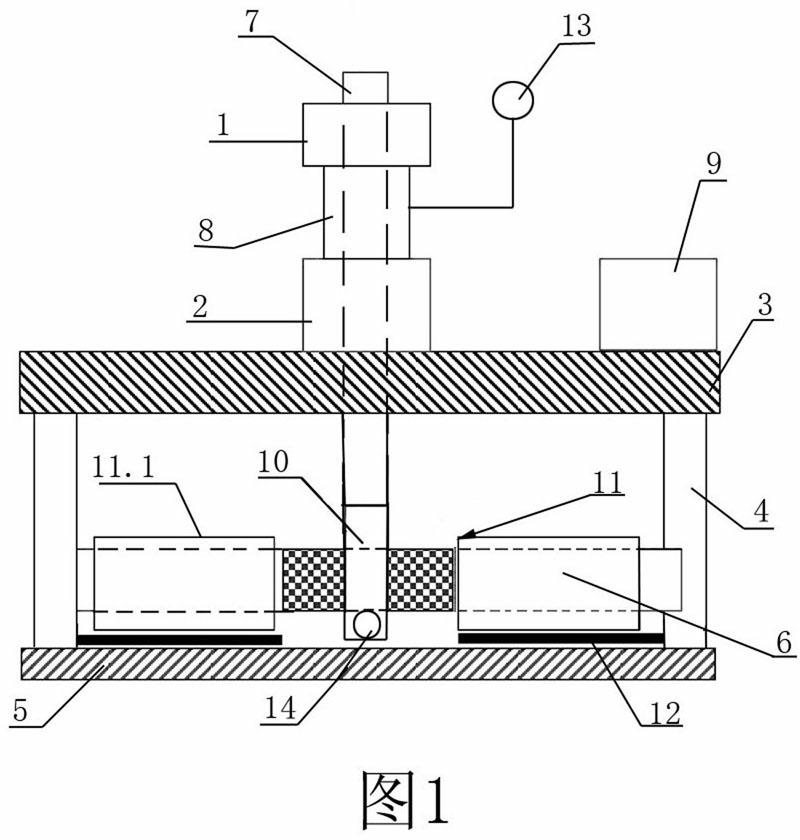

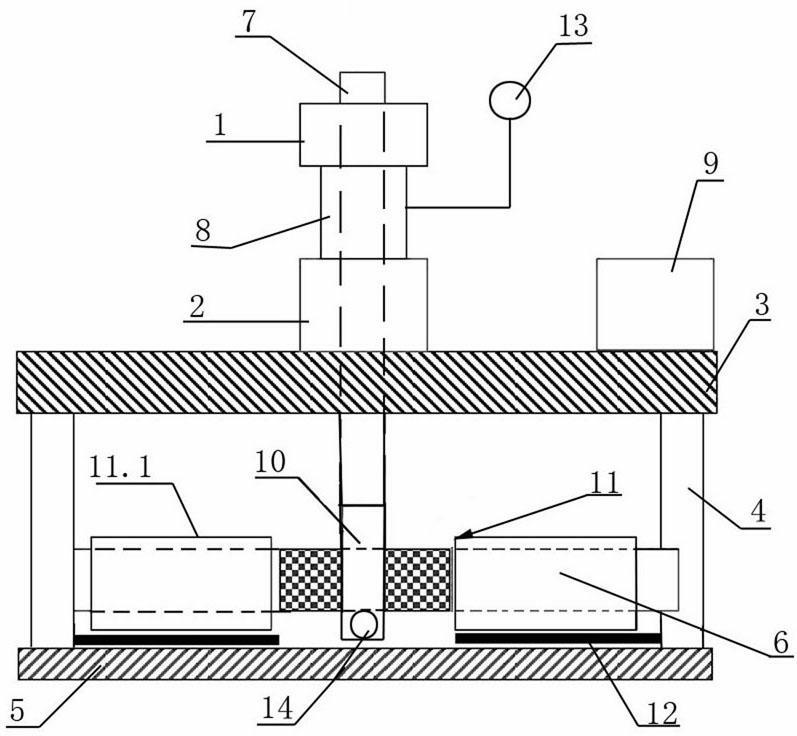

[0030] A method for detecting the compressive strength of concrete by anti-bending method, the steps are as follows:

[0031] Step 1: Randomly drill three flexural test pieces 6 on the concrete structure or member to be tested; when drilling the flexural test pieces, hollow water drills are used, and the inner diameter of the hollow water drills is not less than 44mm;

[0032] Step 2, put the first anti-bending test piece into the test piece conduit 11 of the anti-bending device, connect the central area of the anti-bending test piece 6 with the tension rod 7 through the connecting plate 10 with a socket, and place it in the socket Insert the anti-bending piece 14, start the hand-operated oil pump 9 to apply upward pulling force to the central area of the anti-bending test piece through the tension rod 7;

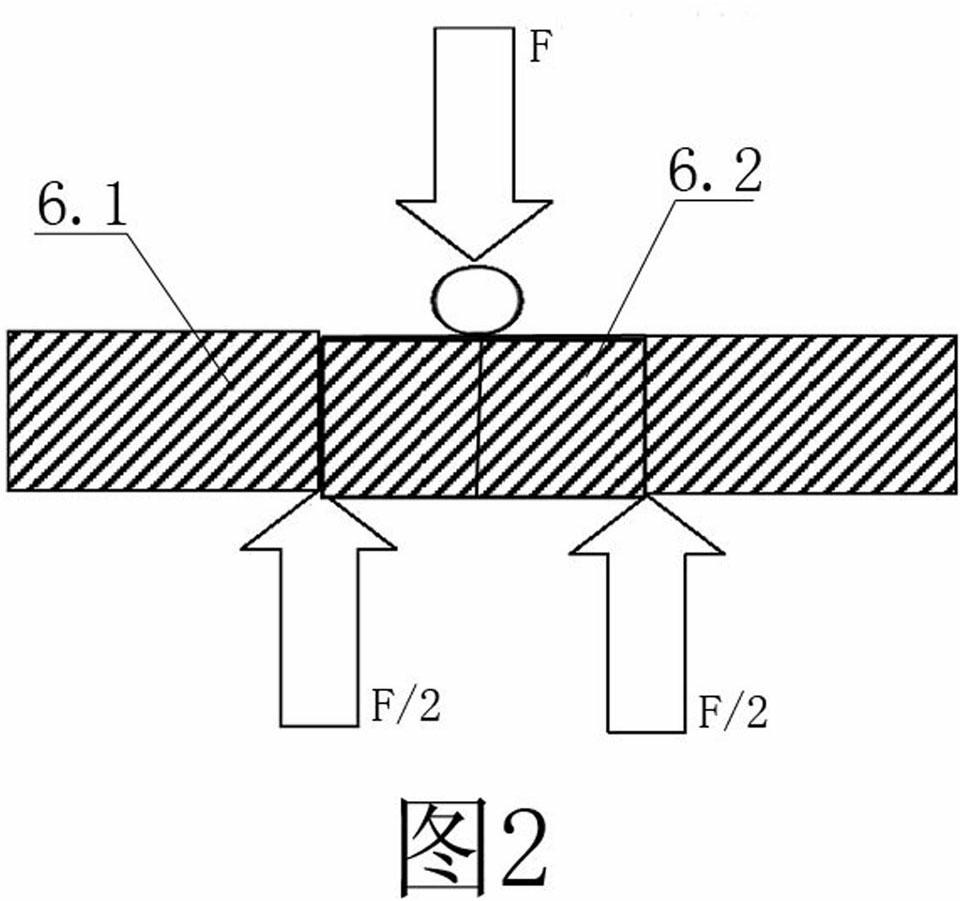

[0033] Step 3, gradually increase the tensile force until the flexural test piece 6 is broken by the supporting section 6.1 and the broken section 6.2, see figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com