Patents

Literature

36results about How to "Avoid structural failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

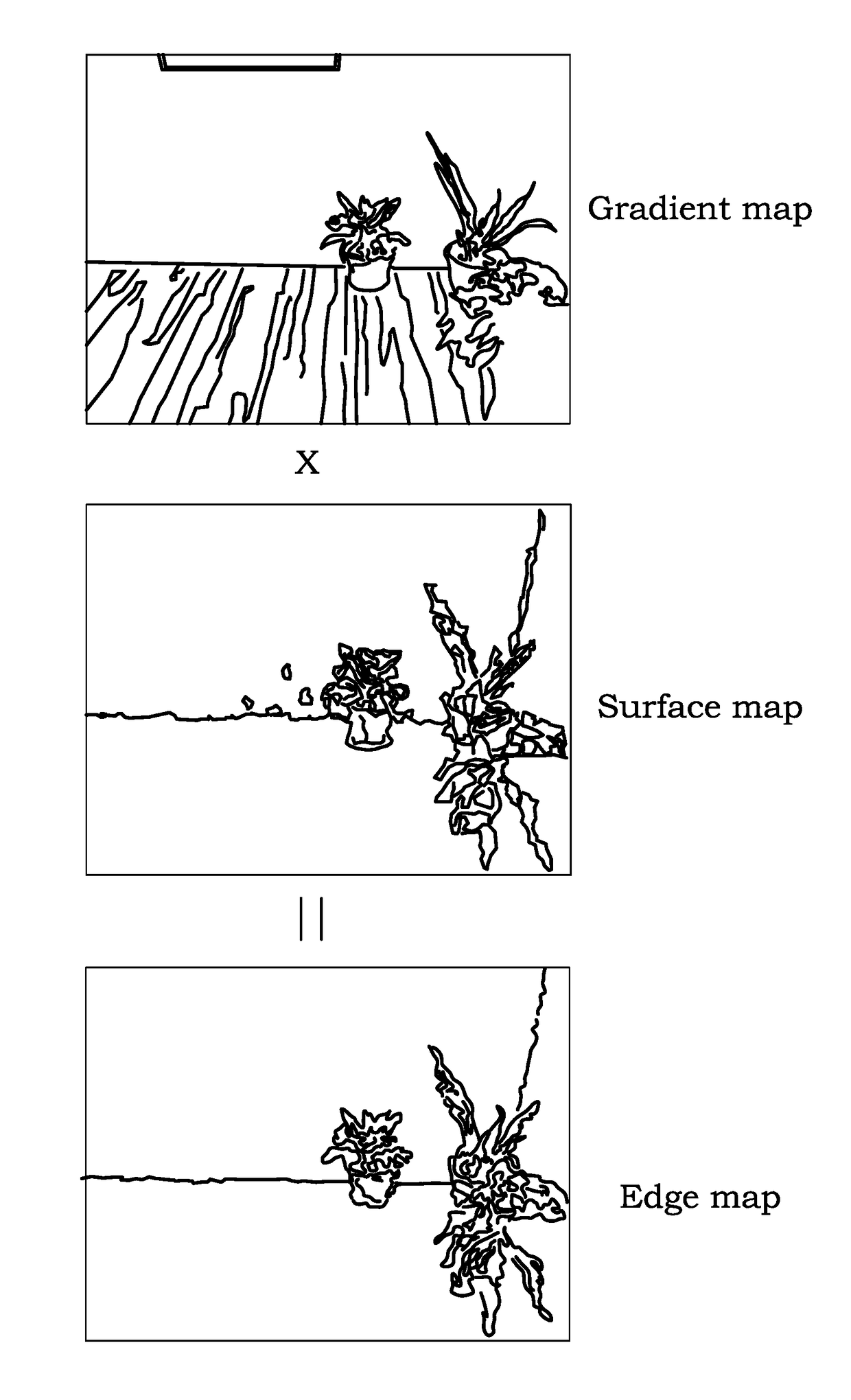

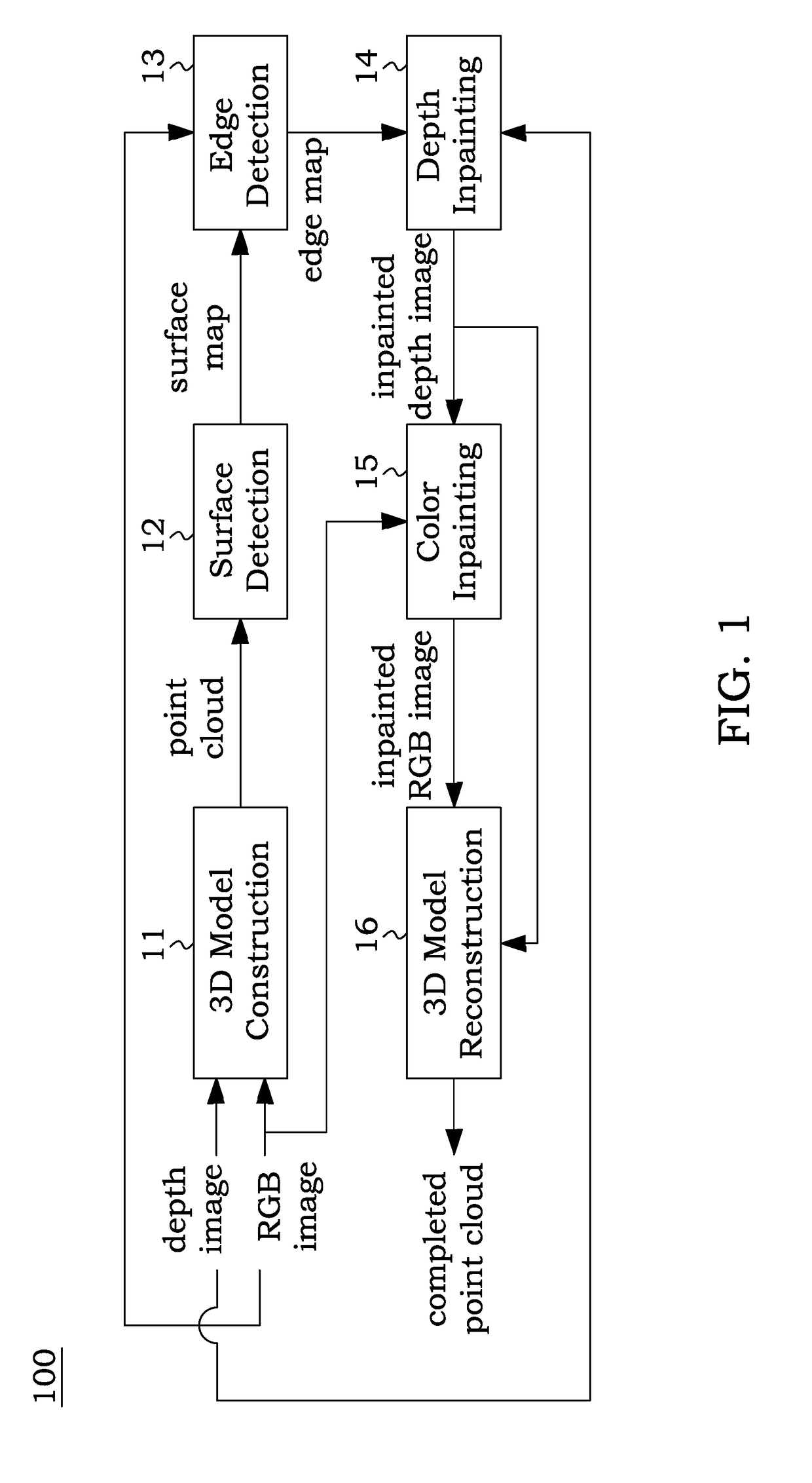

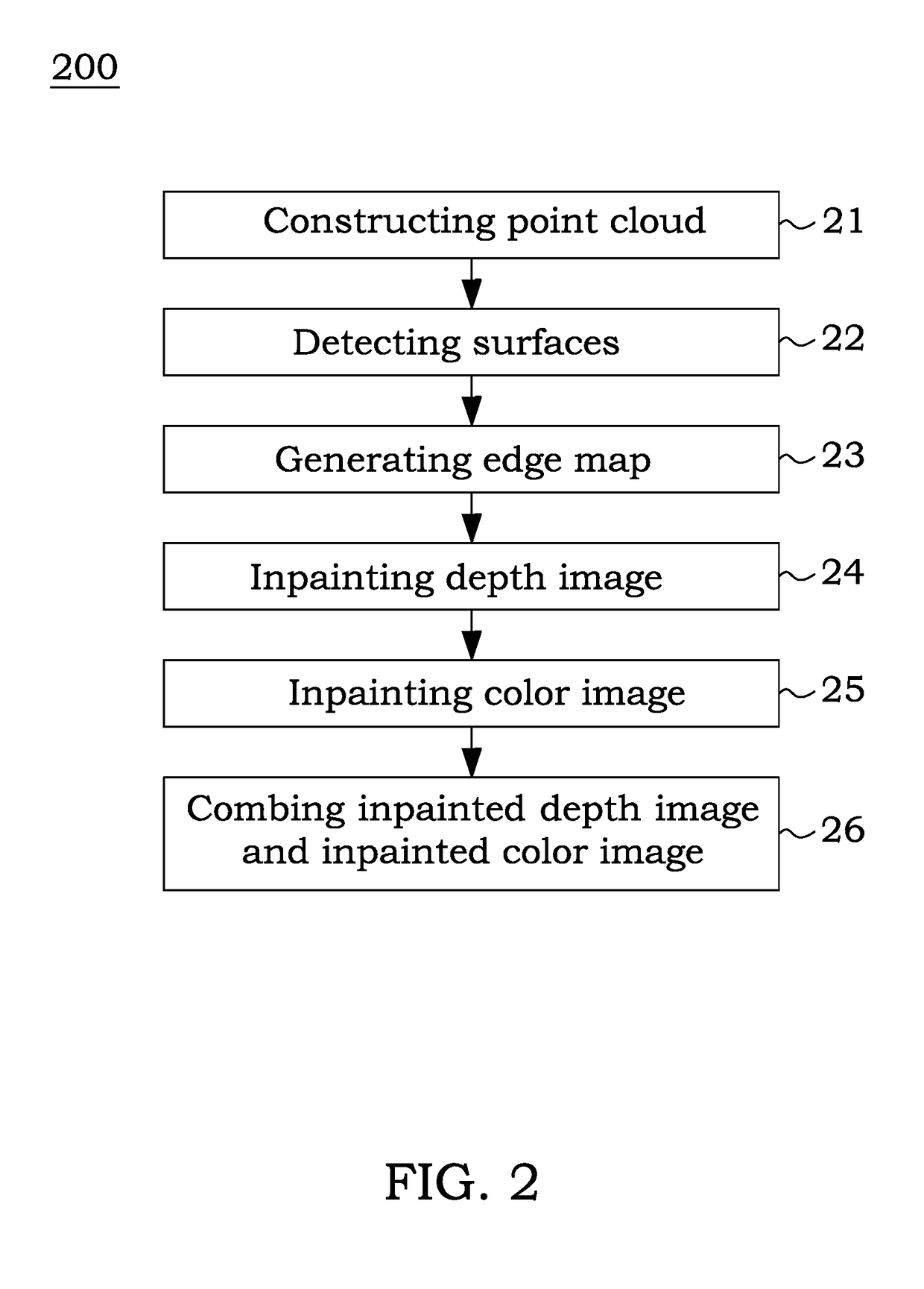

System and a method of restoring an occluded background region

InactiveUS20180300937A1Realistic colorsReal structureDetails involving processing stepsImage enhancementColor imagePoint cloud

A system and method of restoring an occluded background region includes detecting surfaces of a point cloud, thereby resulting in a surface map; substantially enhancing edges between detected surfaces according to a gradient map and the surface map, thereby generating an edge map; inpainting a depth image, thereby generating in an inpainted depth image; and inpainting a color image, thereby generating an inpainted color image.

Owner:NAT TAIWAN UNIV +1

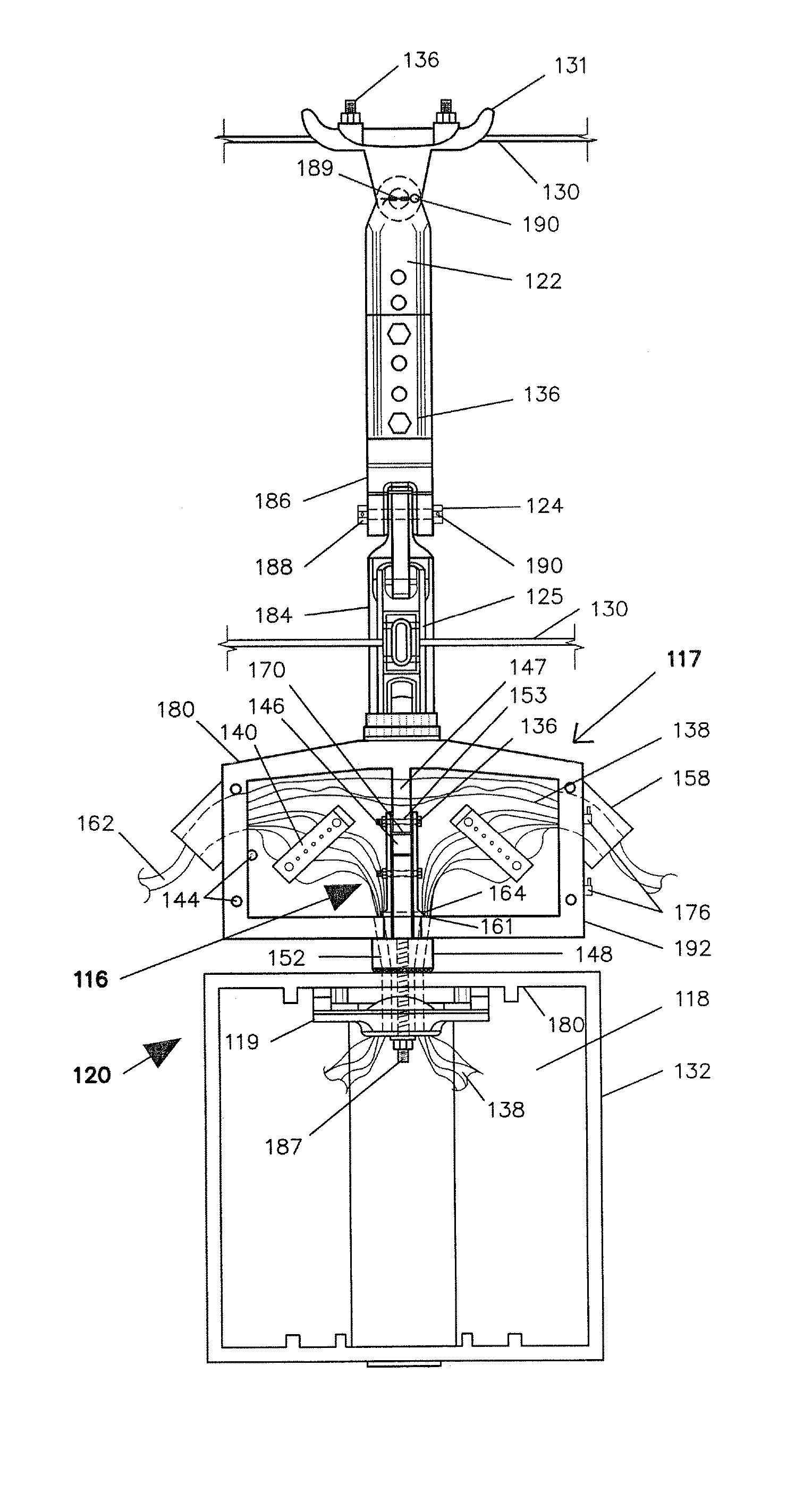

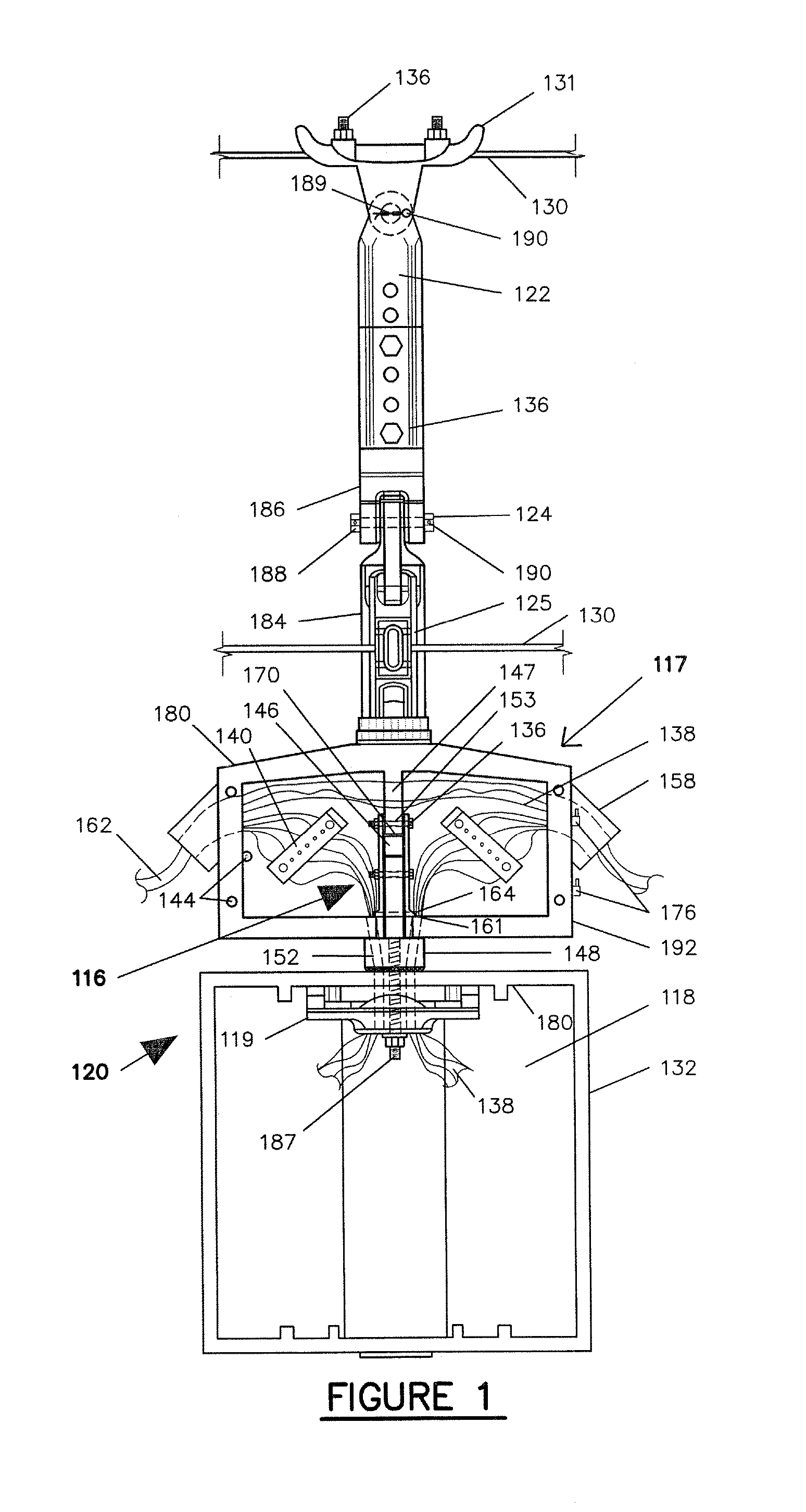

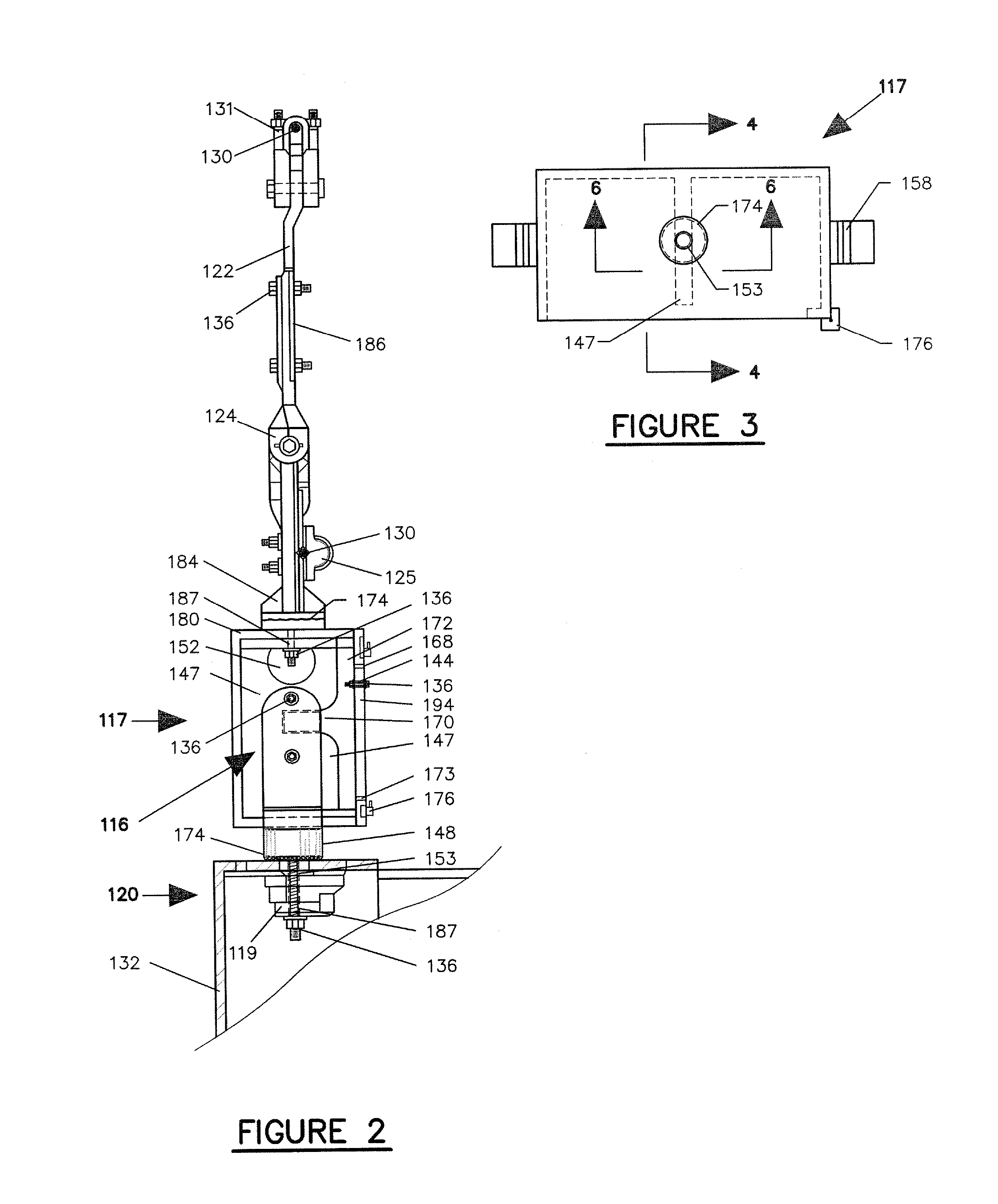

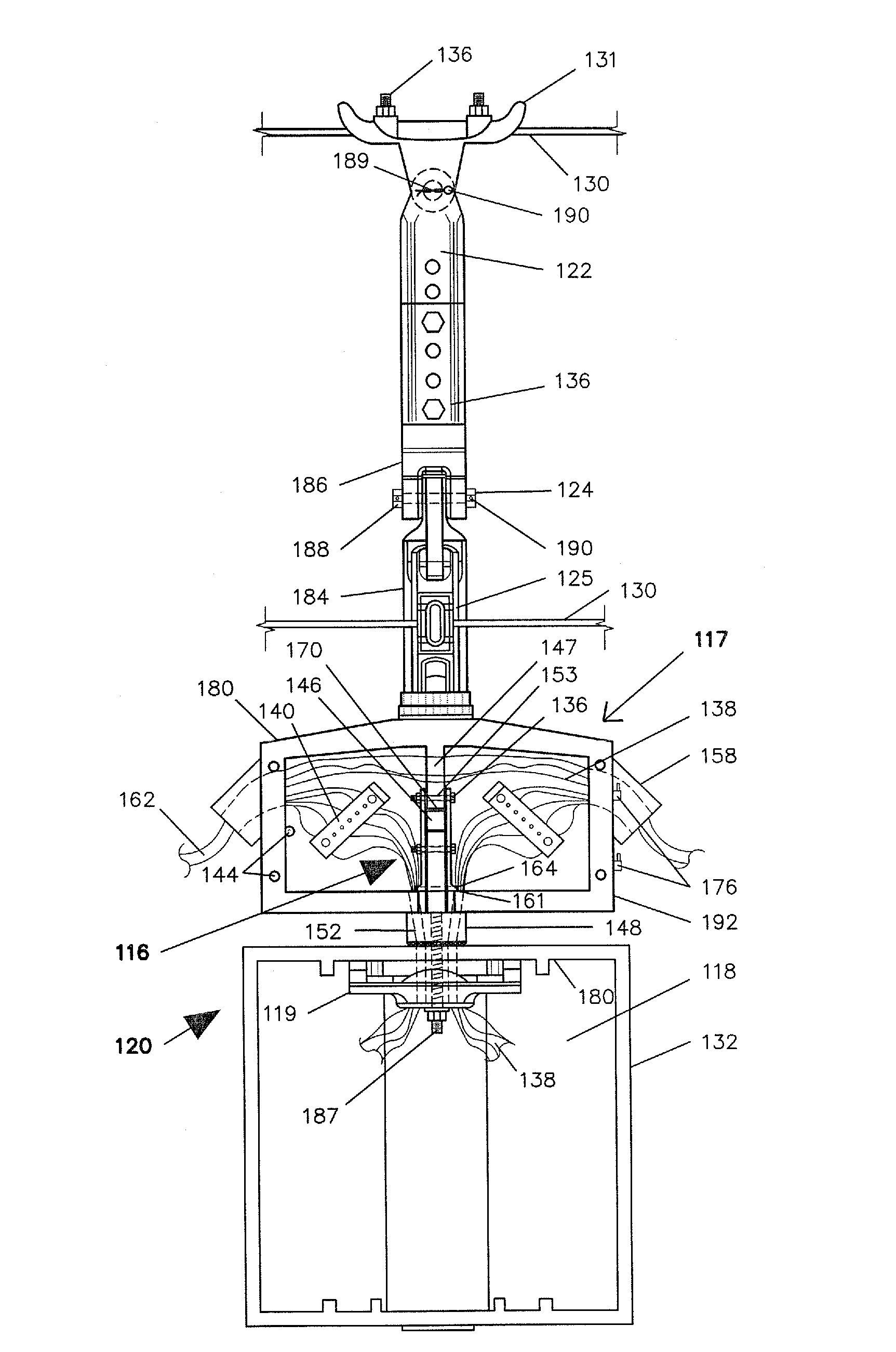

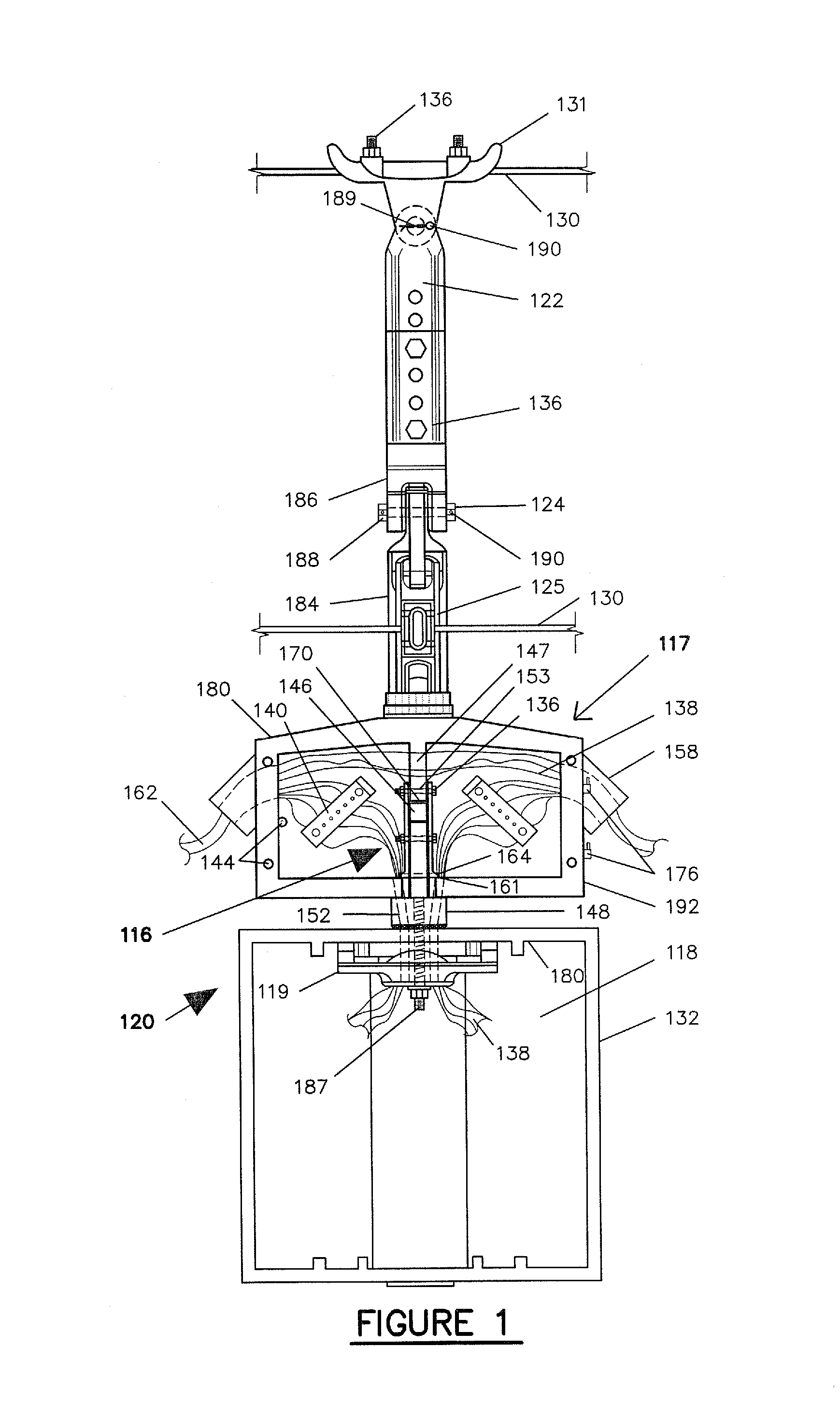

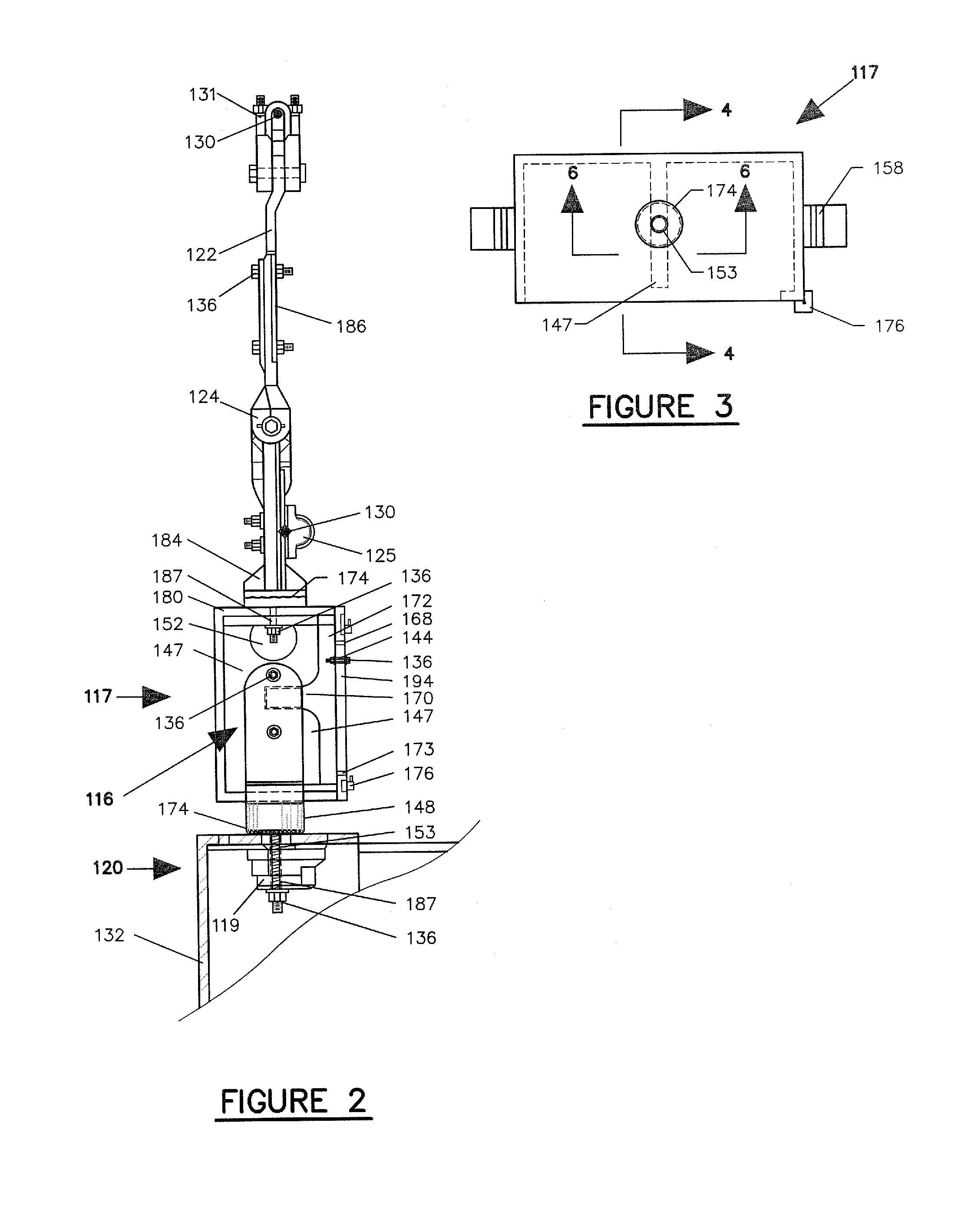

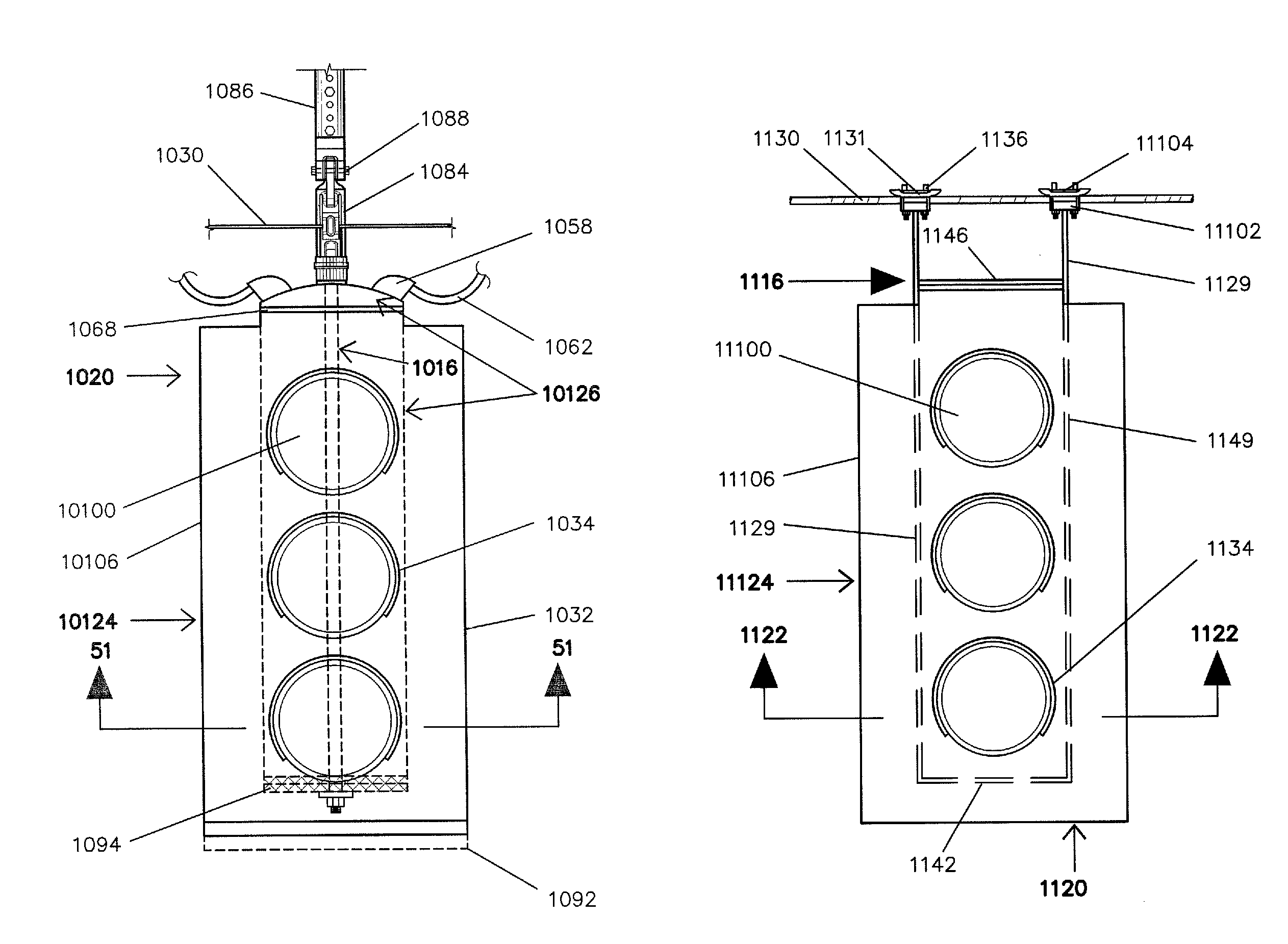

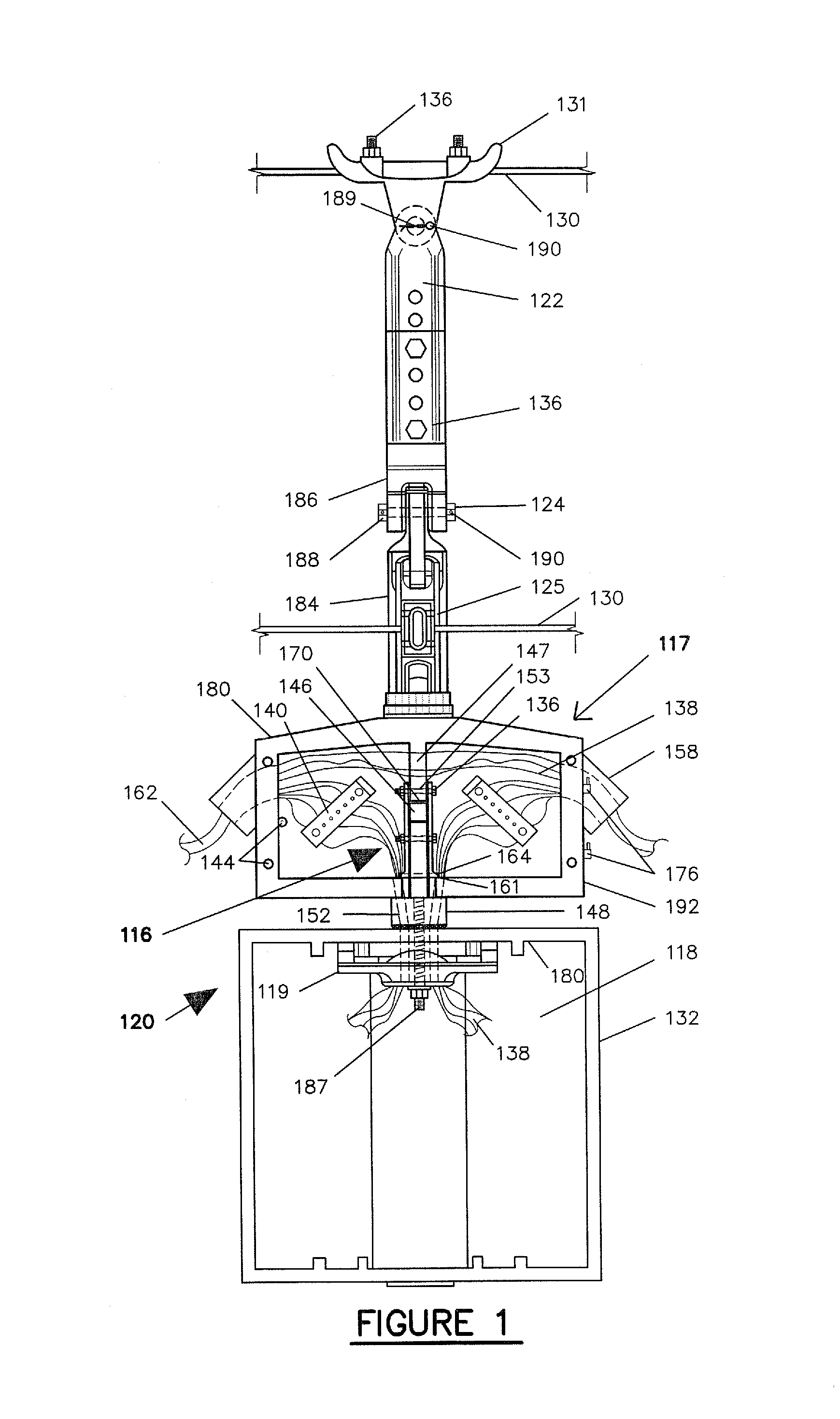

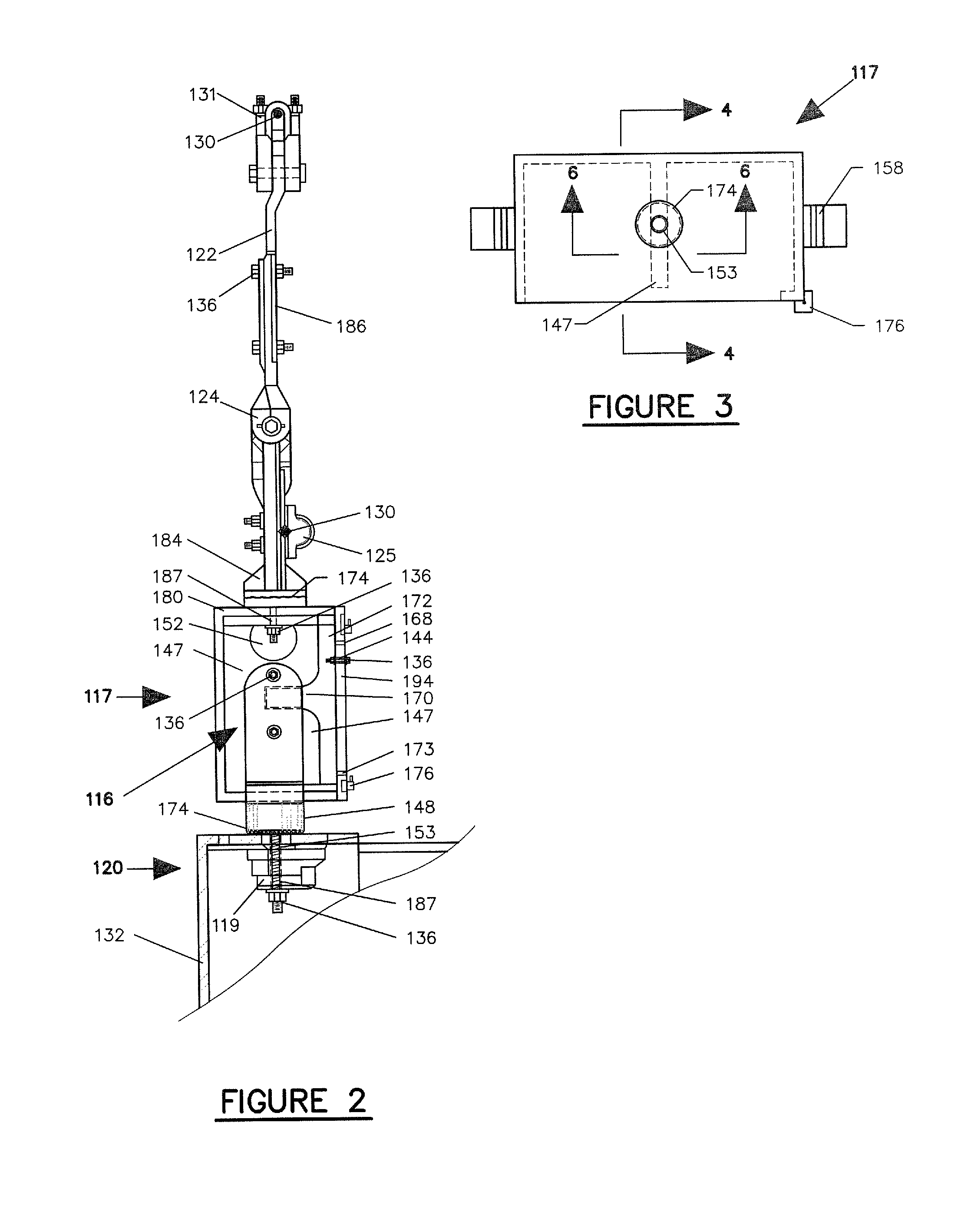

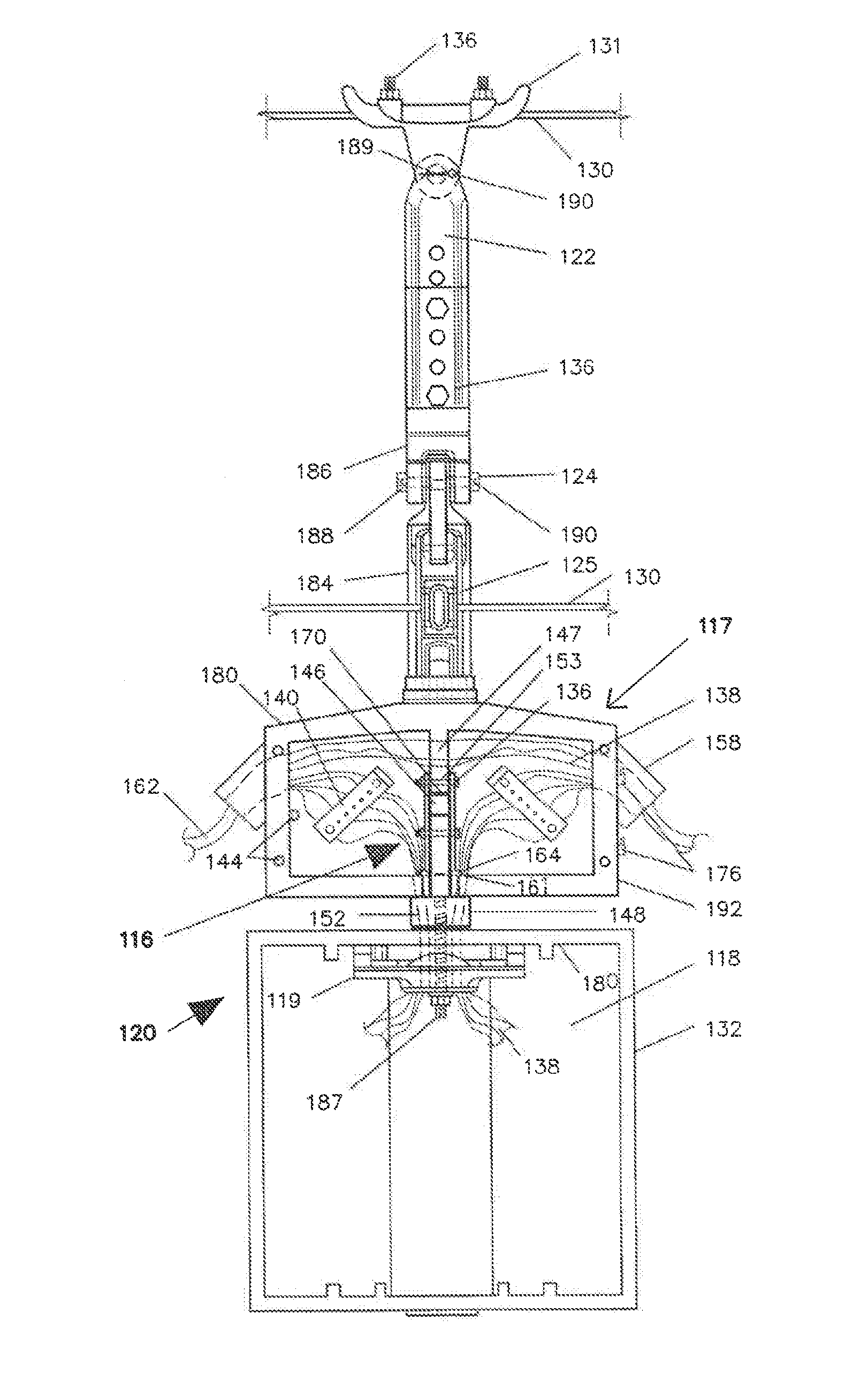

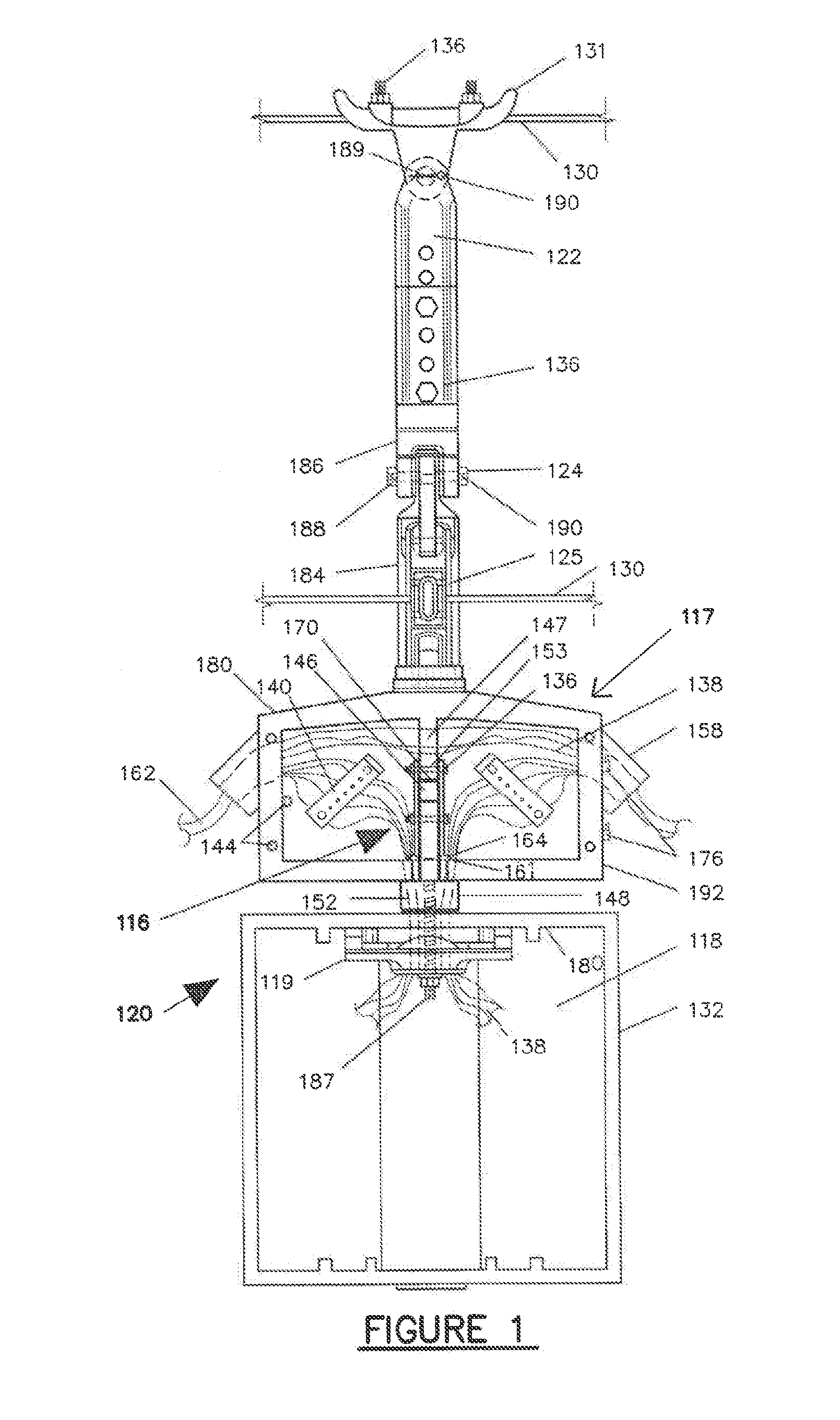

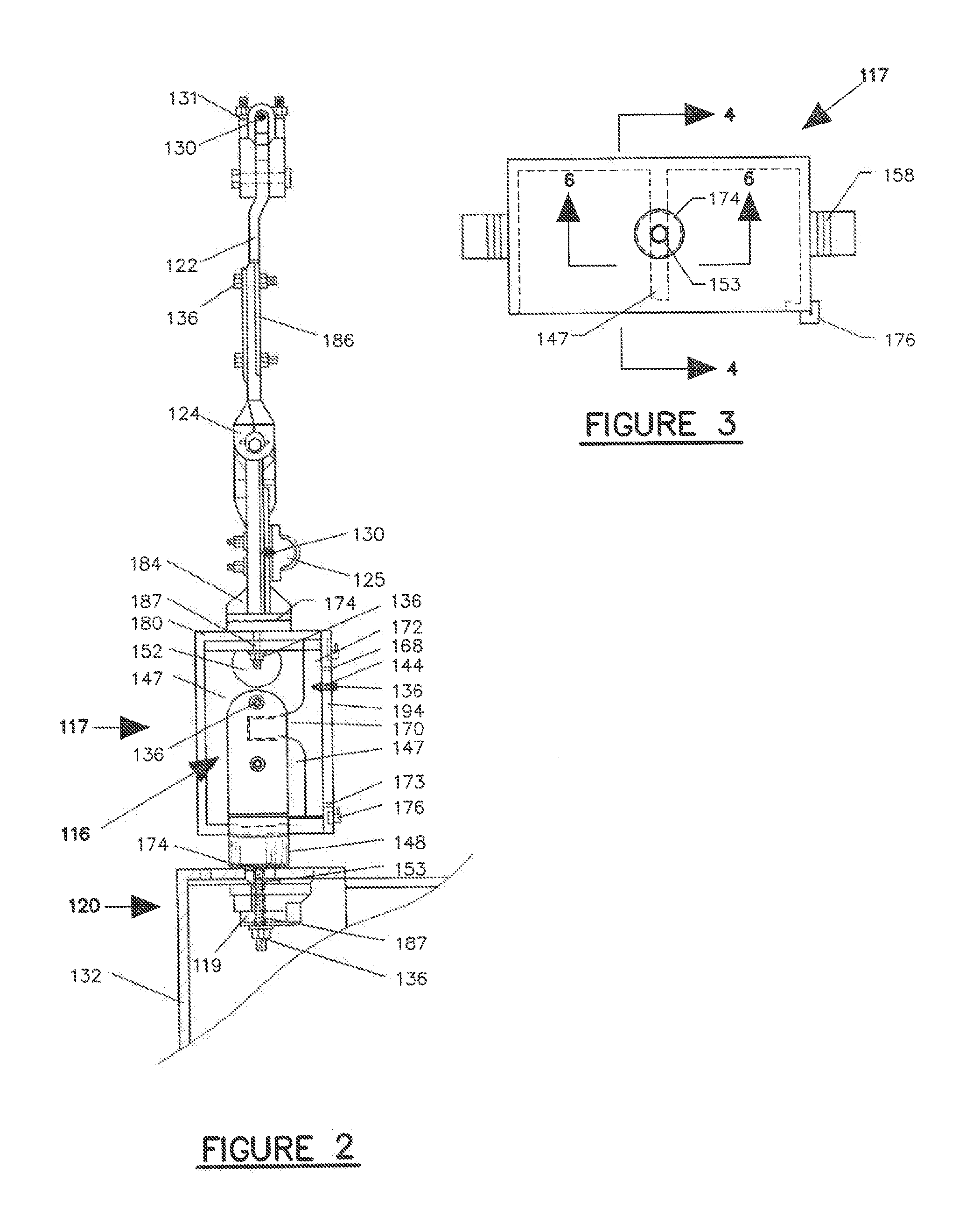

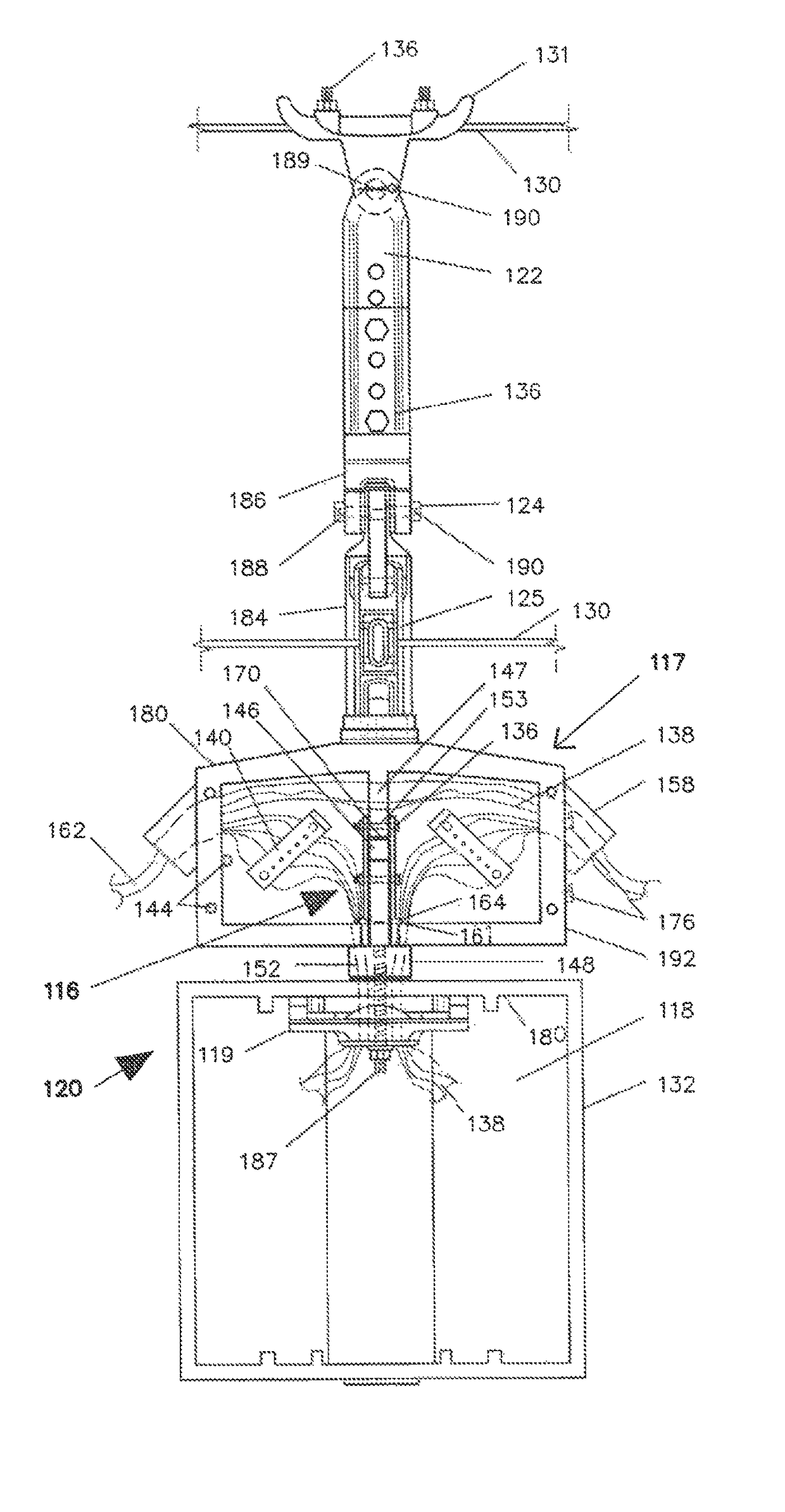

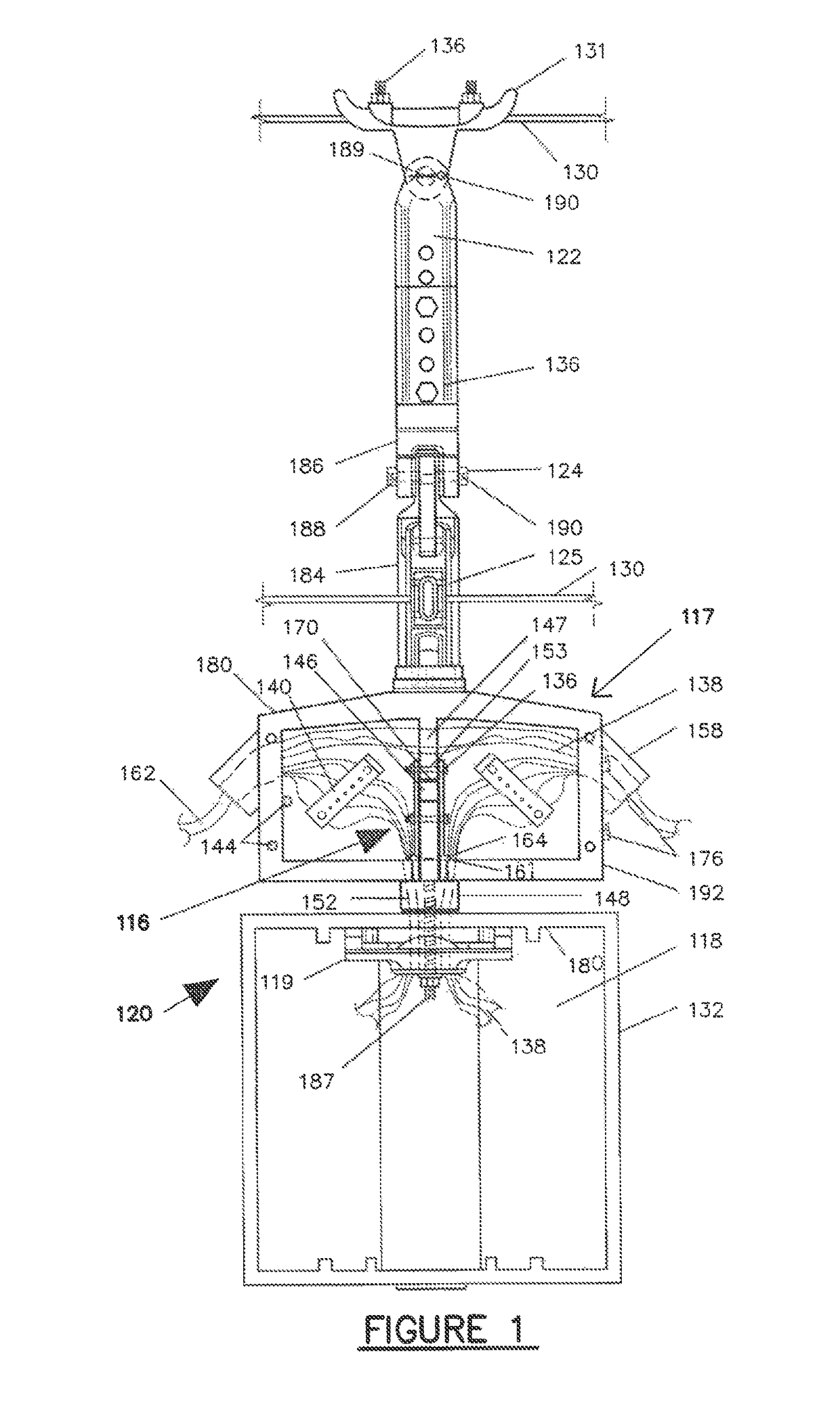

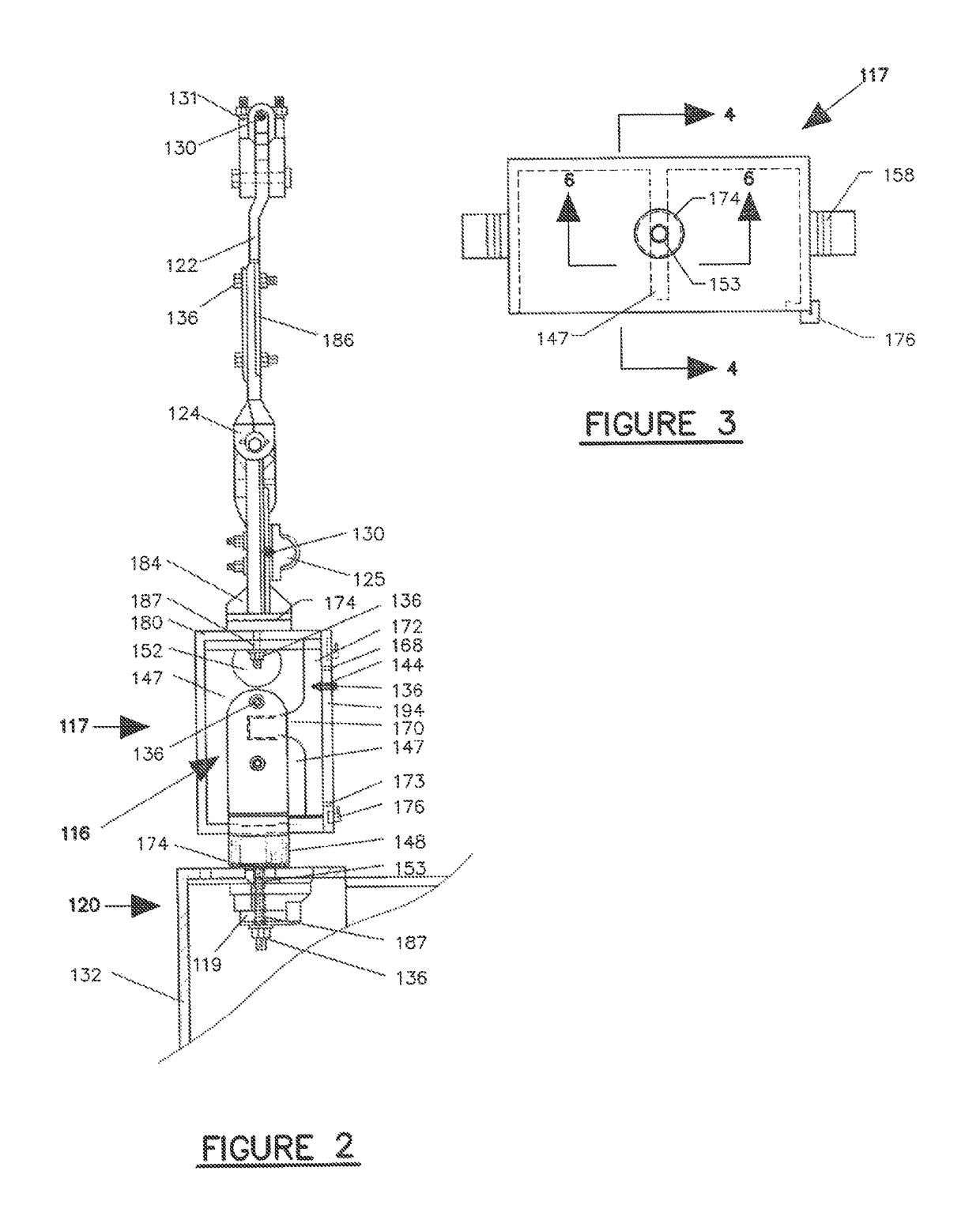

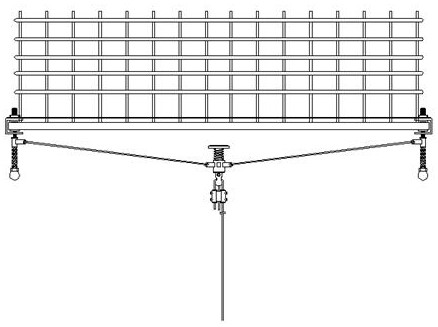

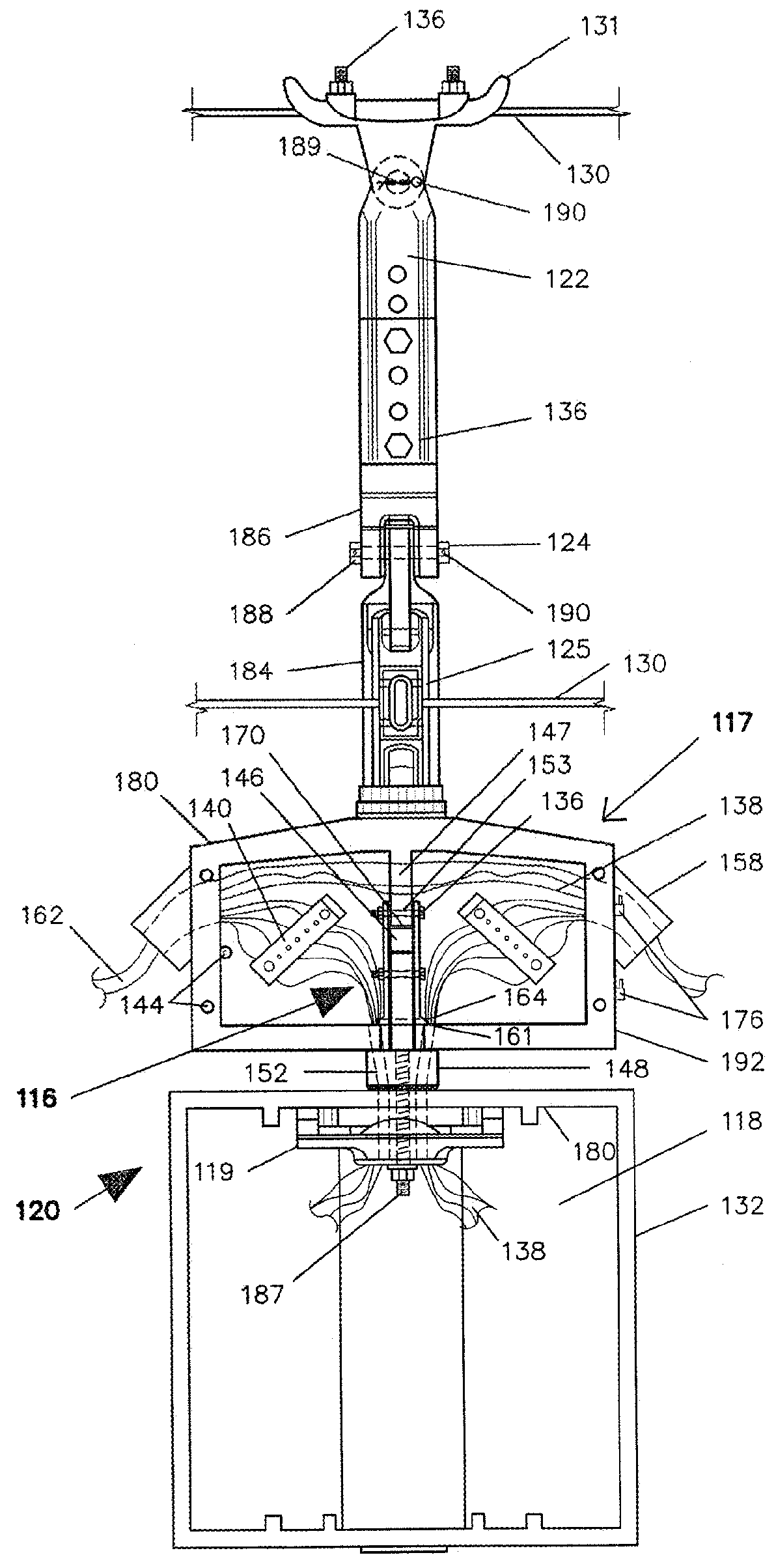

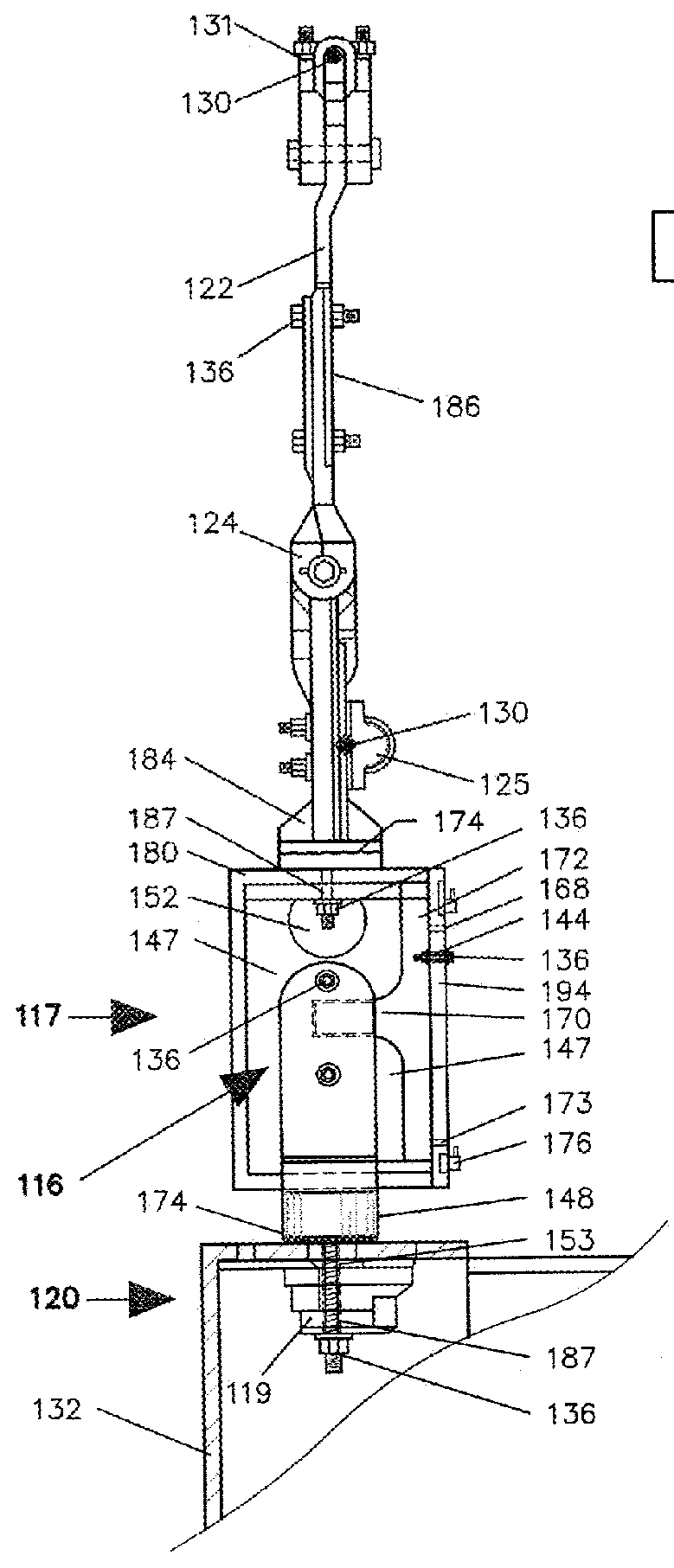

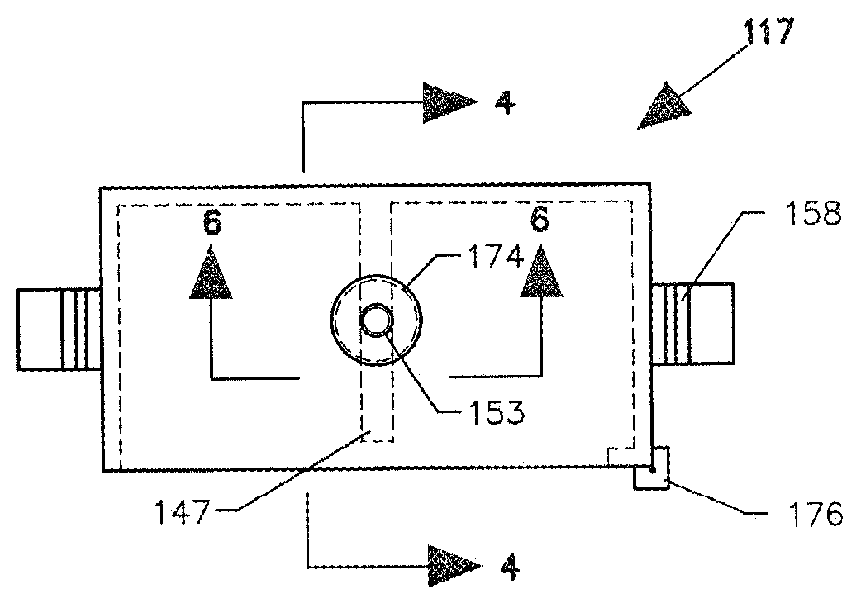

Devices and systems for improved traffic control signal assembly

ActiveUS20130248673A1Avoid structural failureEnhanced control signalLighting support devicesRoad vehicles traffic controlSupporting systemTraffic signal

Methods and apparatuses are provided for improved traffic control devices including a continuous central hanger support system that is integral to the traffic control device and provides a central load path. In an embodiment of the invention, the terminal housing and traffic signal housing of the traffic control device can be included in a single unit housing. A single unit housing can also include an integral backplate. Embodiments with an integral backplate can provide a solar energy generation system that utilizes a traffic signal's exterior surface as a substratum to secure thin-film photo cell laminates (TFPVL). The continuous central hanger integrated with the single unit housing can provide the traffic control device with improved securement of electrical components and structural stability for survivability during high wind events as compared to conventional traffic signal devices.

Owner:TOWNSEND ROBERT E JR

Devices and systems for improved traffic control signal assembly

InactiveUS20130095710A1Avoid structural failureEliminate needEngagement/disengagement of coupling partsElectrically conductive connectionsSupporting systemSurvivability

Methods and apparatuses are provided for improved traffic control devices including a continuous central hanger support system that is integral to the traffic control device and provides a central load path. In an embodiment of the invention, the terminal housing and traffic signal housing of the traffic control device can be included in a single unit housing. A single unit housing can also include an integral backplate. Also provided are span wire clamps, tether clamps, and mast arm clamps that can be used to affix the continuous central hanger of the traffic control device to various fixtures such as a single span wire, two span wires, a pole or a mast arm. The continuous central hanger integrated with the single unit housing can provide the traffic control device with improved securement of electrical components and structural stability for survivability during high wind events as compared to conventional traffic signal devices.

Owner:TOWNSEND JR ROBERT E

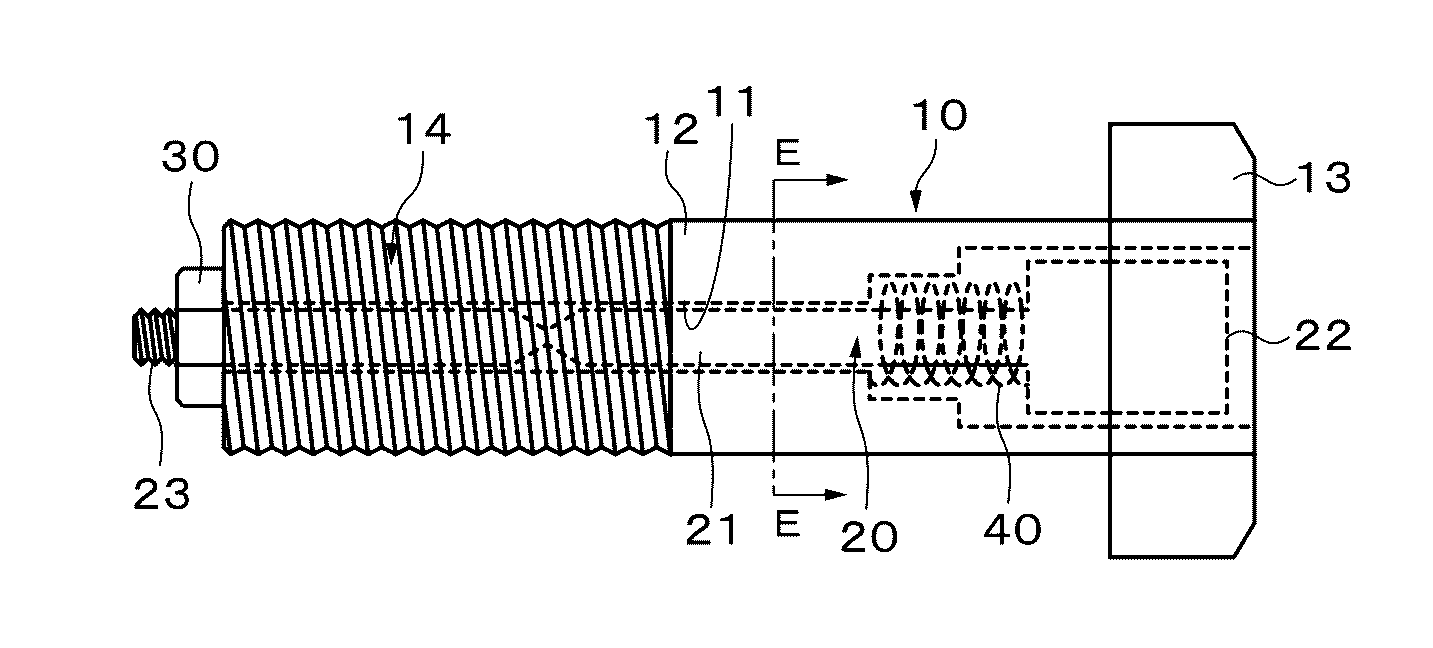

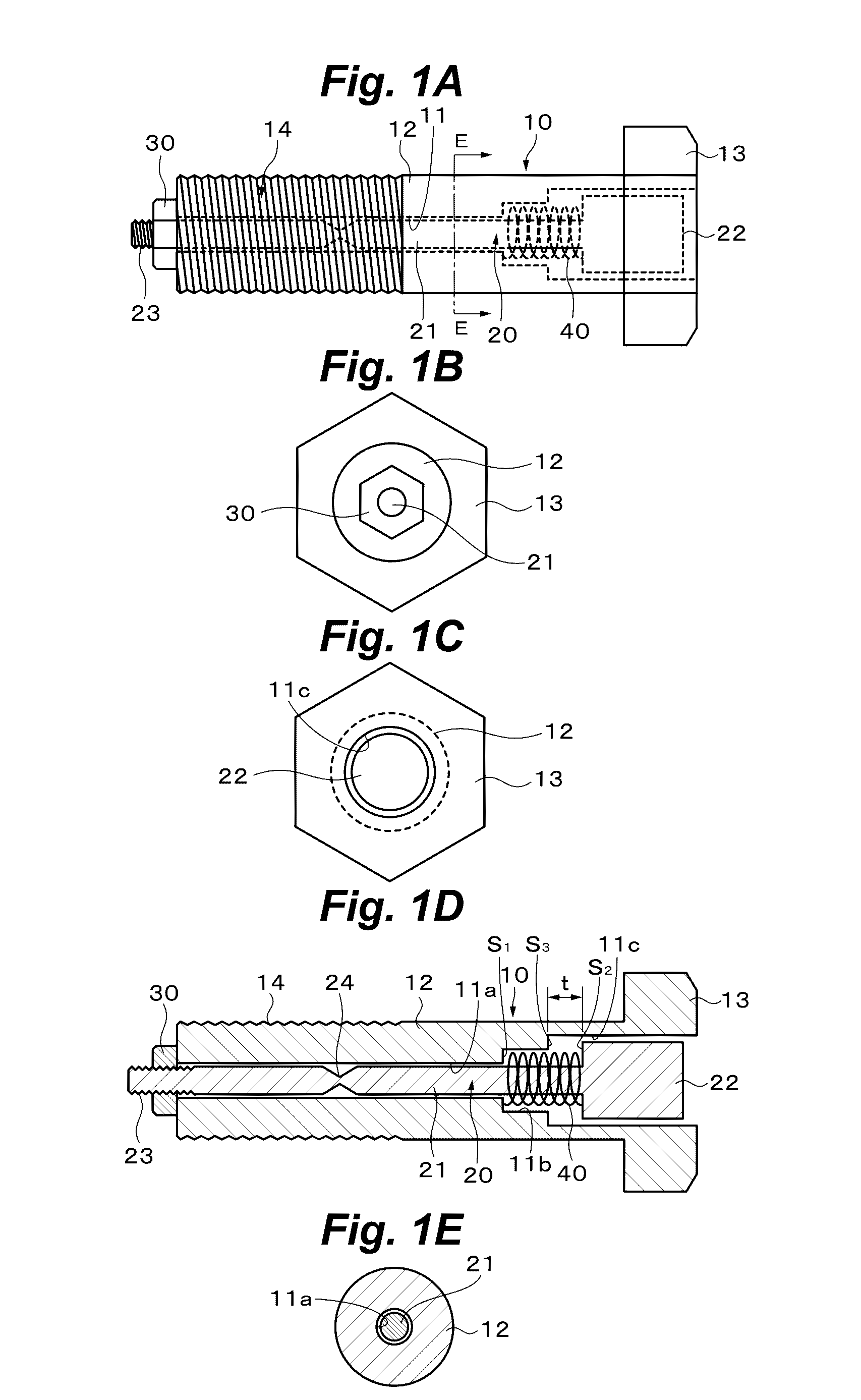

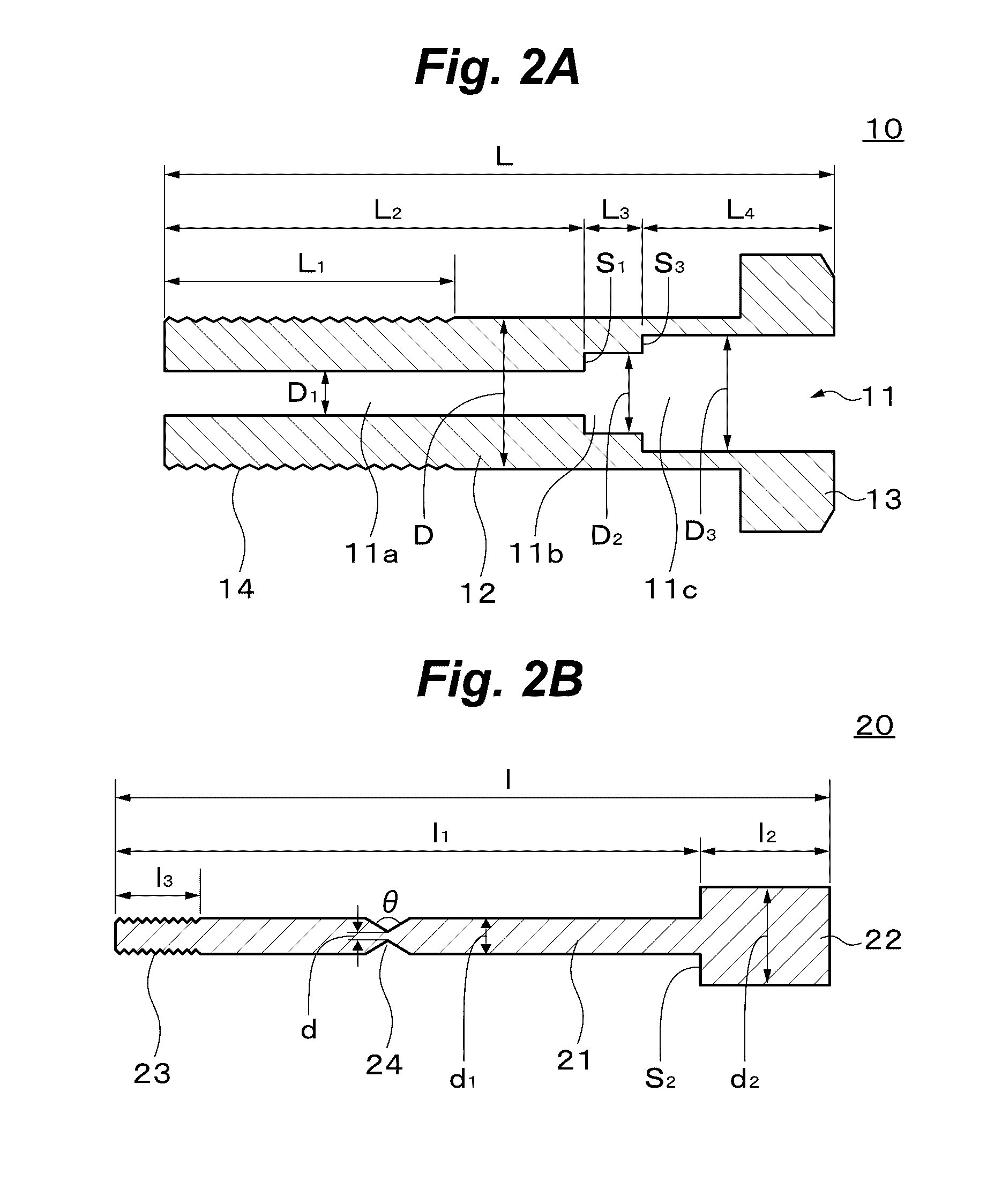

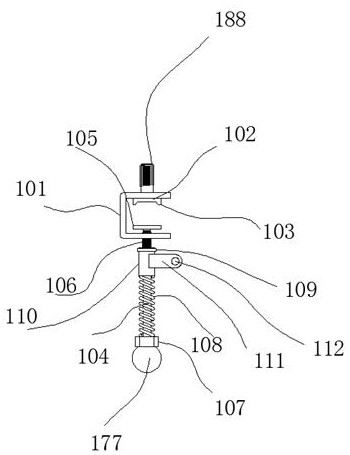

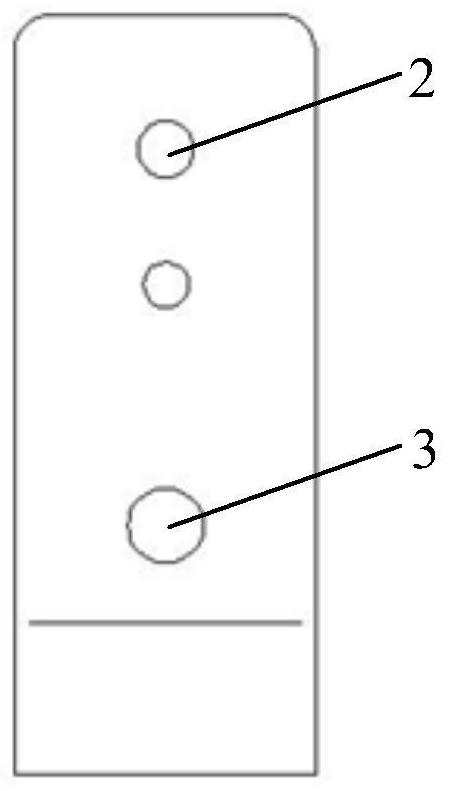

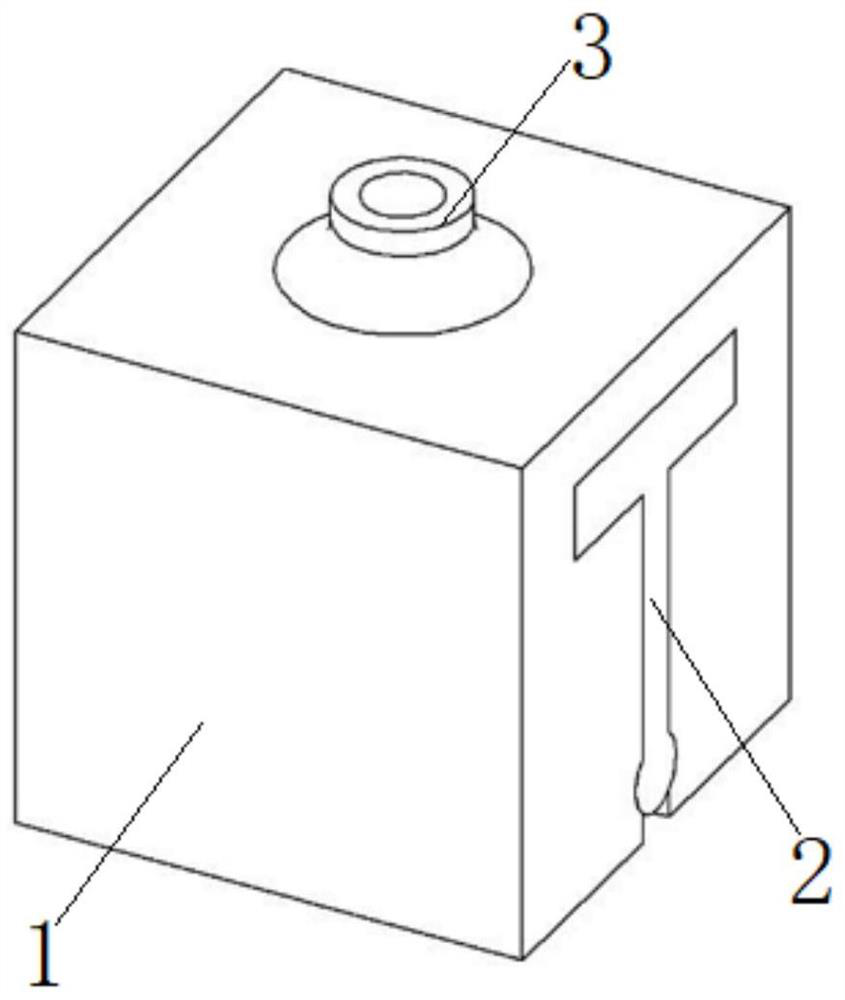

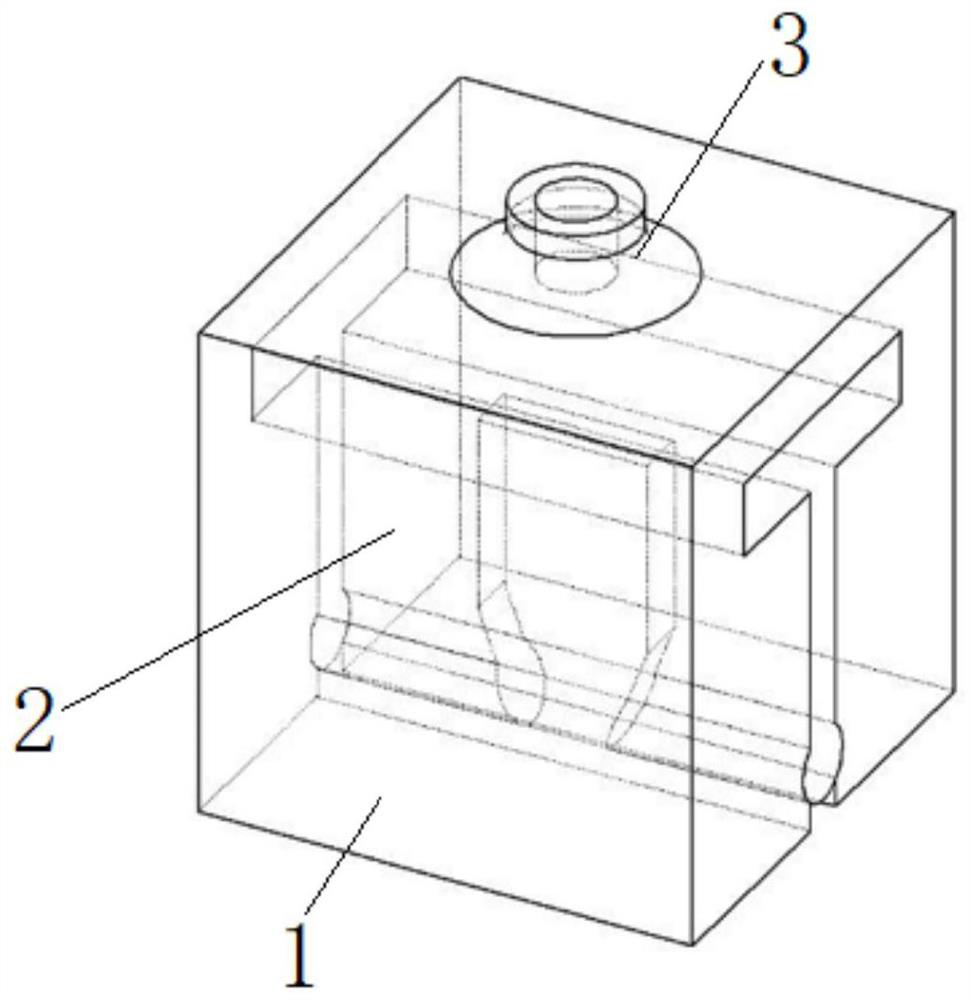

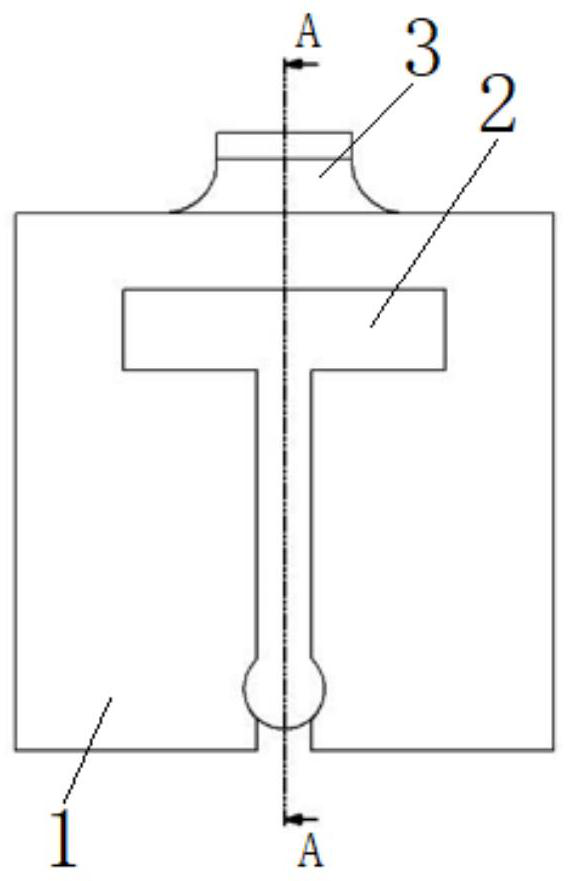

Failure detection sensor, failure detection system, and structure

ActiveUS20160370268A1Easy to detectLow priceLoad modified fastenersMaterial strength using tensile/compressive forcesStress concentrationPull force

Provided is a failure detection sensor which, when attached to structural members of various structures such as buildings can easily detect the risk of the failure of the structural members, and thus the structure, before such failure occurs and has a simple structure, which leads to realization at a low price.The failure detection sensor comprises: the first member 10 and the second member 20 provided in parallel with the first member 10 such that one end of the second member 20 is fixed to or restricted by the first member 10 and the other end of the second member 20 is not fixed to or restricted by the first member 10, having fracturing characteristics such that the second member 20 fractures during elastic deformation or plastic deformation of the first member 10. The failure detection sensor may have a compression coil spring 40 which applies a tensile force to the other end of the second member 20 on the opposite side of the one end. The first member 10 and the second member 20 are constituted of, for example, a round rod or a square rod and the first member 10 is constituted of, for example, a hollow rod. The second member 20 has a notch 24 which is a stress concentration site between the one end and the other end. The second member 20 is made of brittle materials.

Owner:HIEI KENSETSU

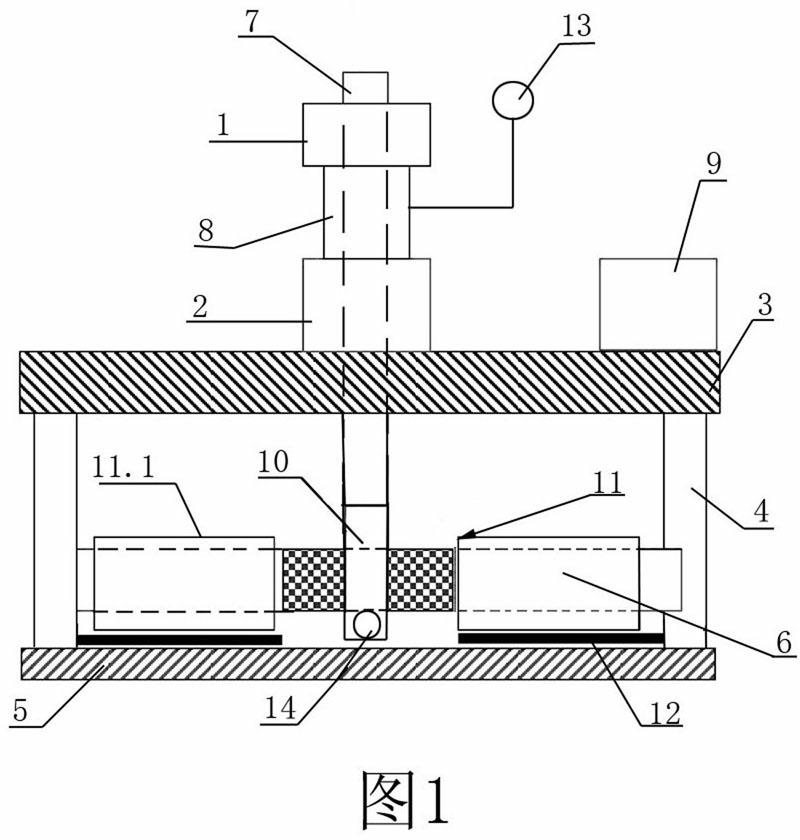

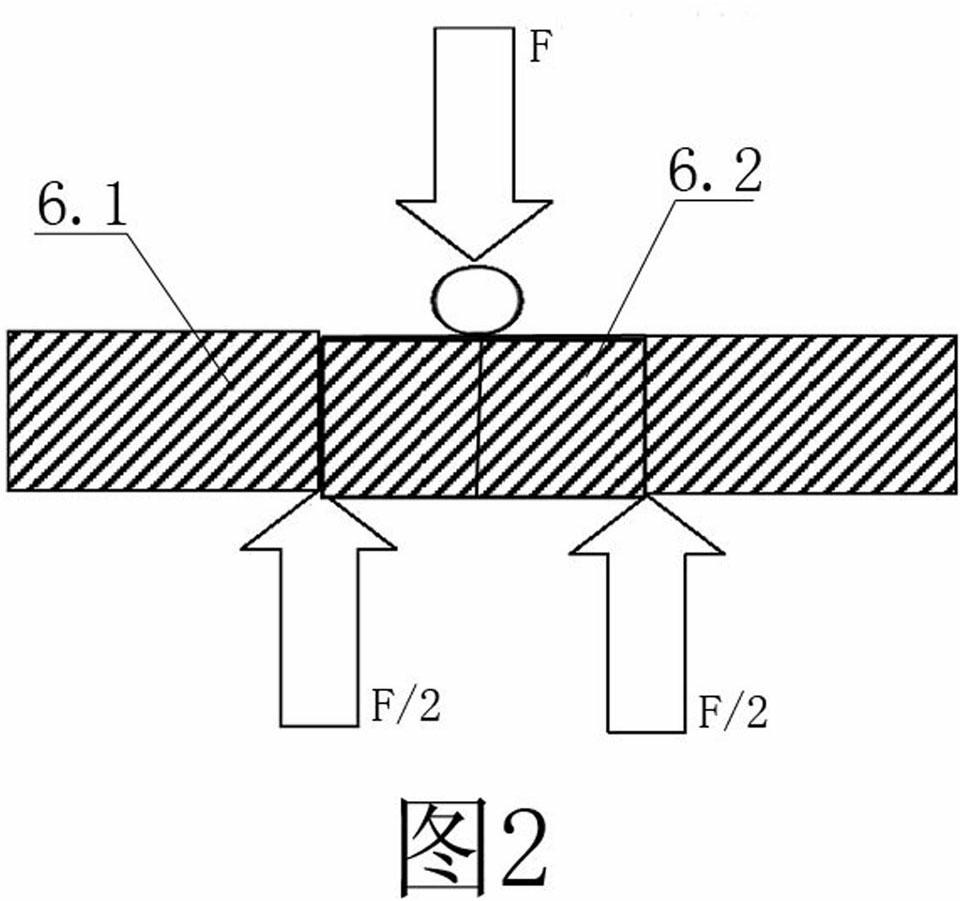

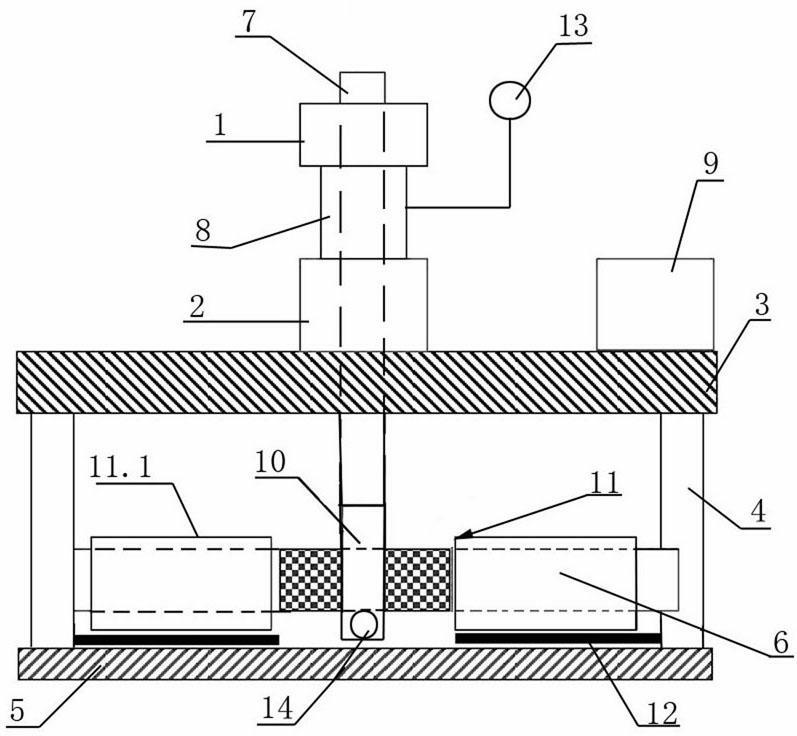

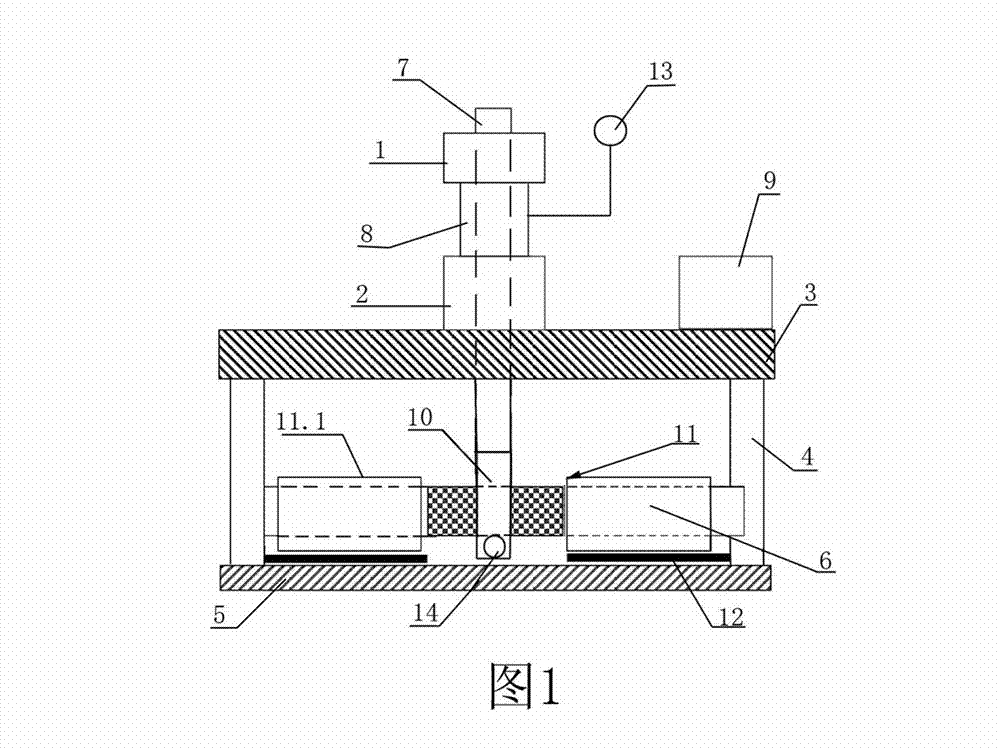

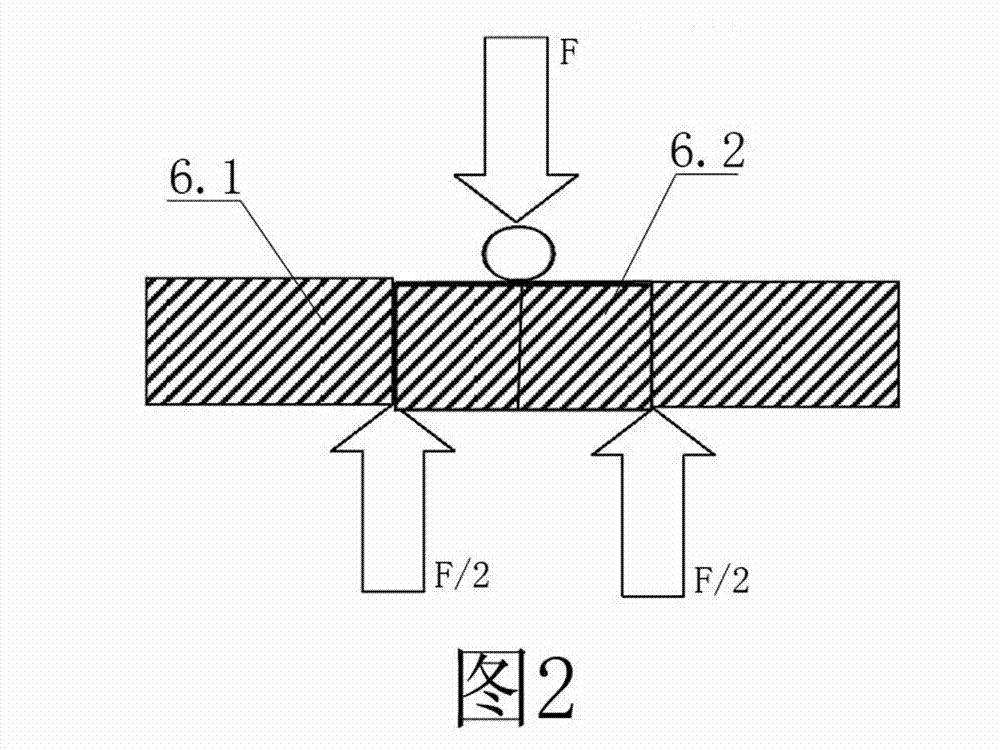

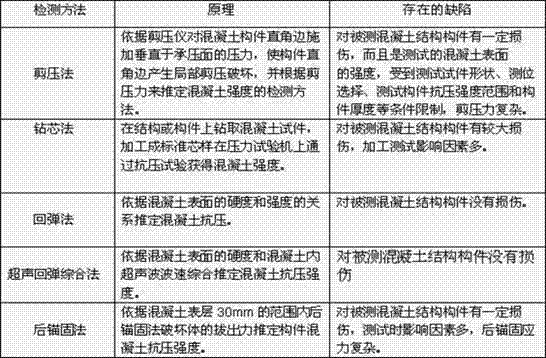

Method and device for detecting compressive strength of concrete by bending method

InactiveCN102435499AAvoid damageFew influencing factorsMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a method and a device for detecting the compressive strength of concrete by a bending method. The method comprises the following steps of: recording rupture load during damage of the concrete and an area of a damaged section to calculate bending strength; and establishing a correlativity between the bending strength and the corresponding strength of a cubic test piece with the side length of 150mm to deduce the compressive strength of the concrete. By applying fracture resistance force to a test piece, influencing factors in the testing process are reduced and the testing accuracy is improved; moreover, the testing process is simple and feasible. The invention can be widely applied to detection of strength of concrete structure entities in the building industry, railway industry, traffic industry, water transportation industry, harborwork industry and the like.

Owner:王文明

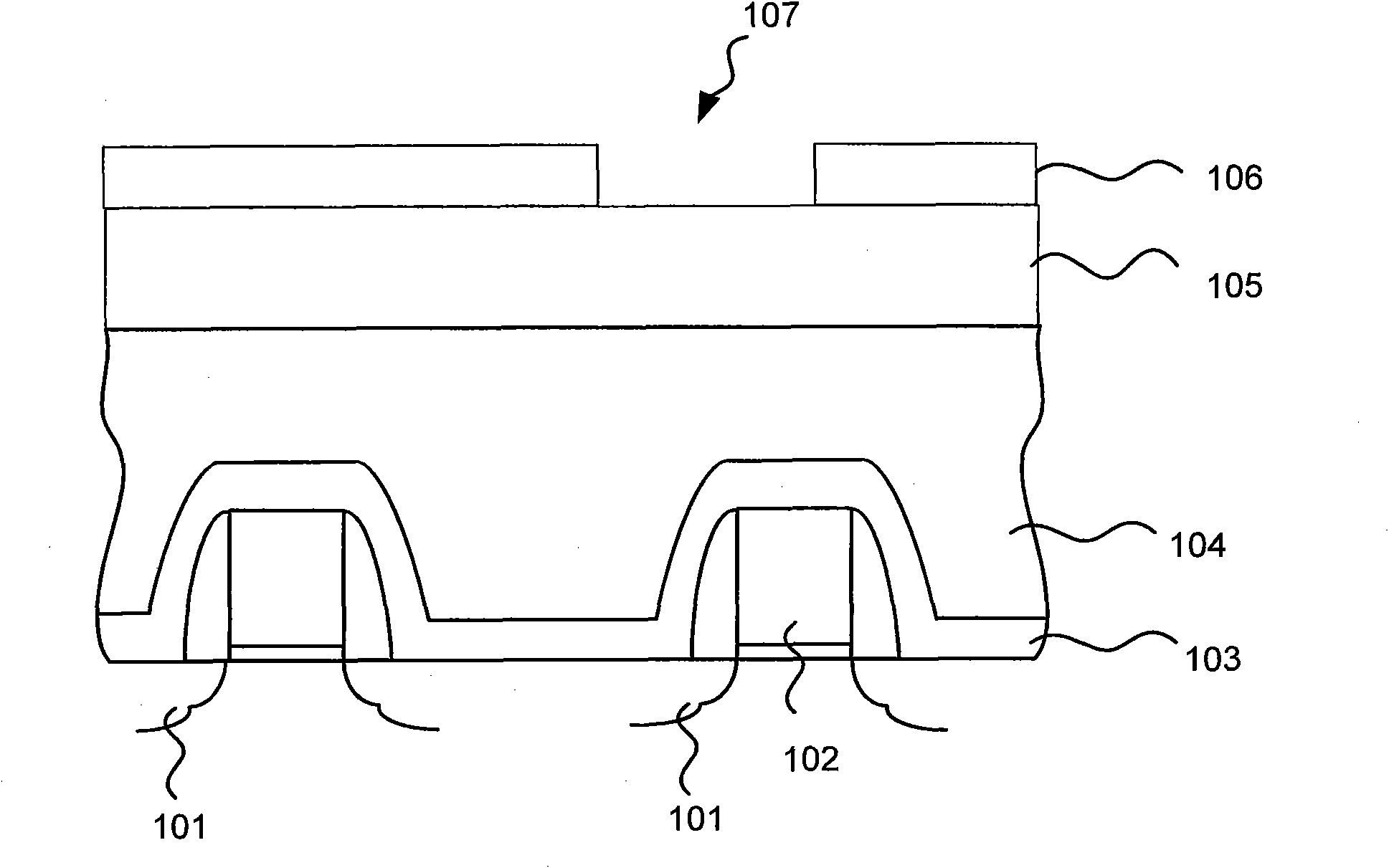

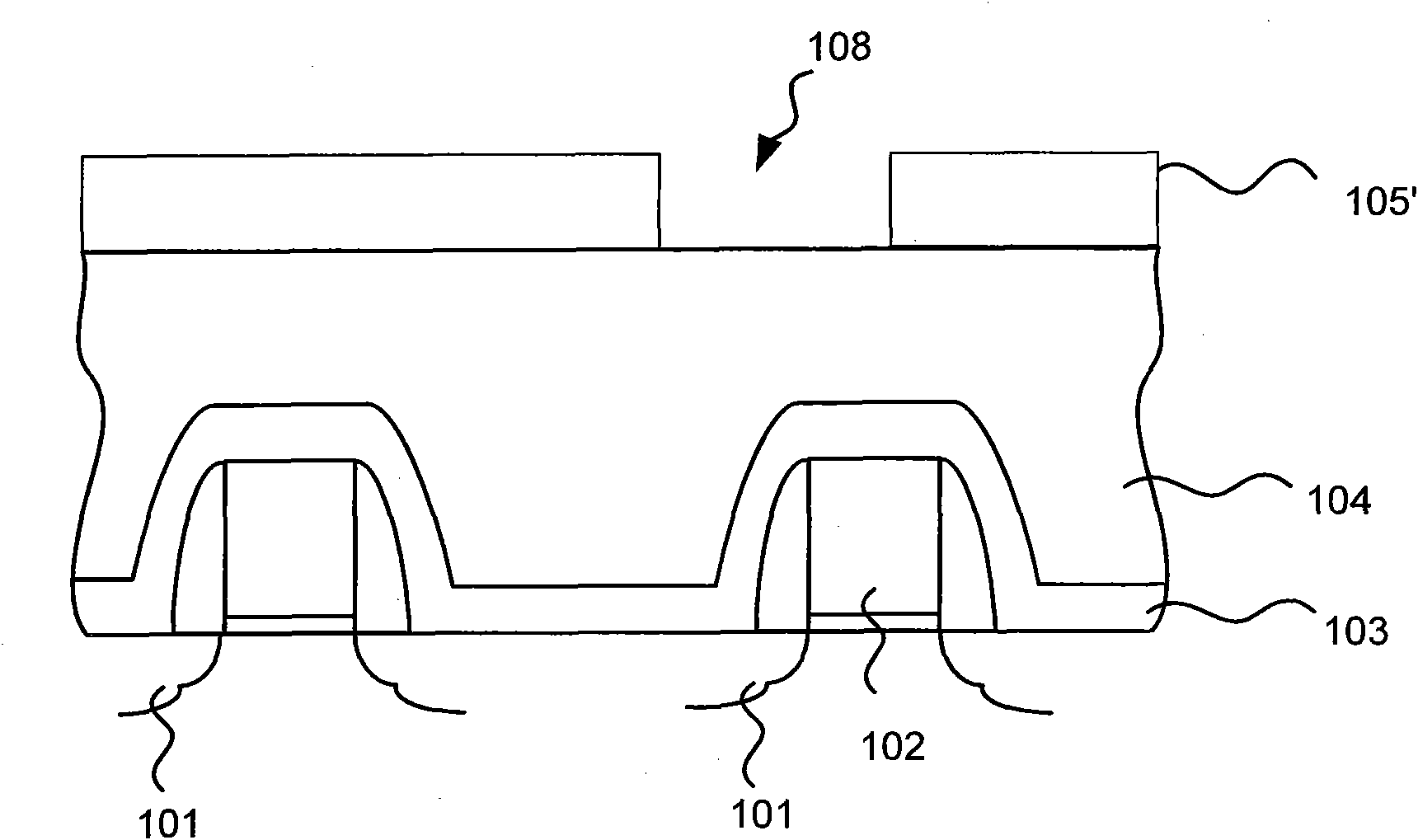

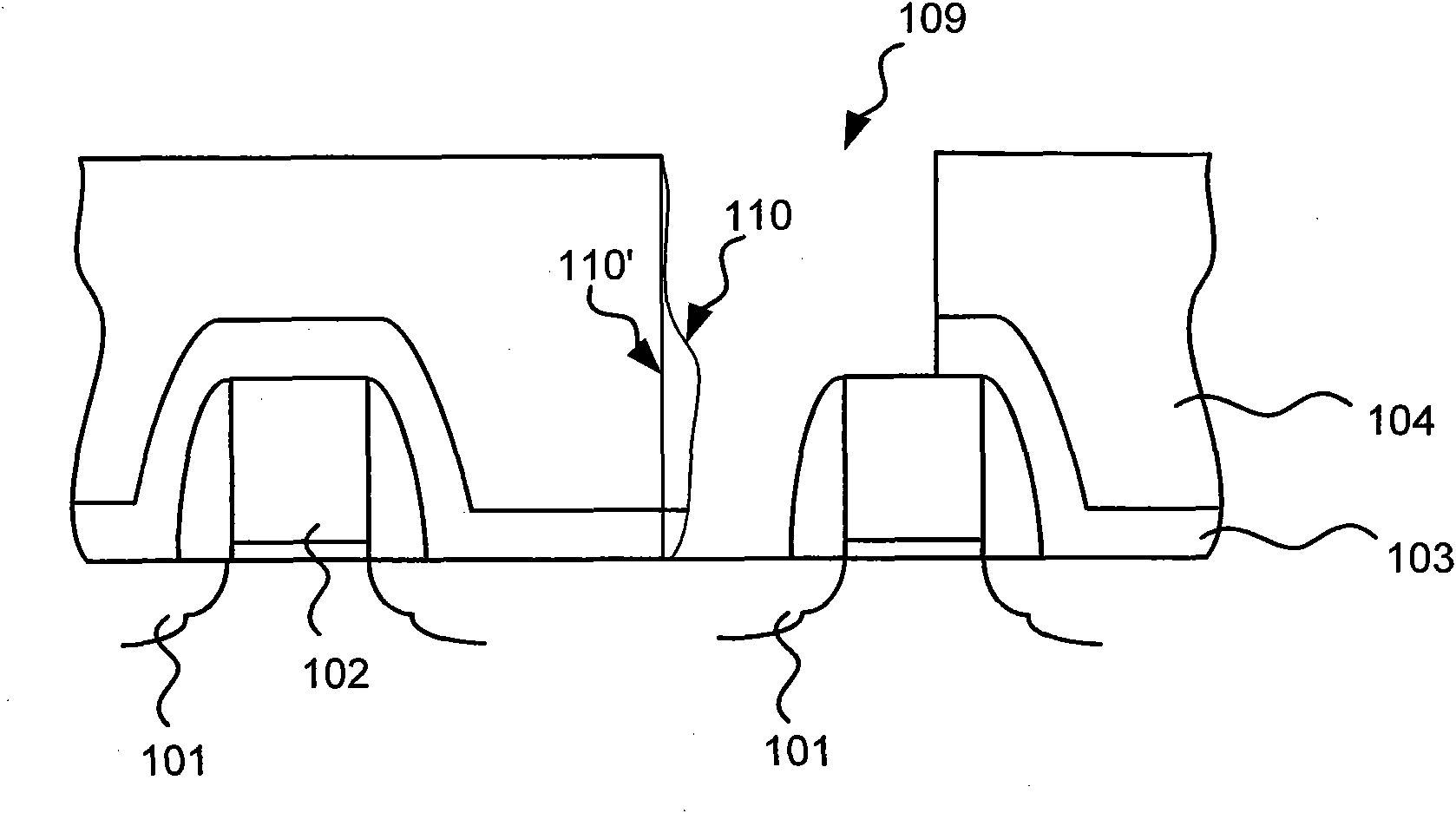

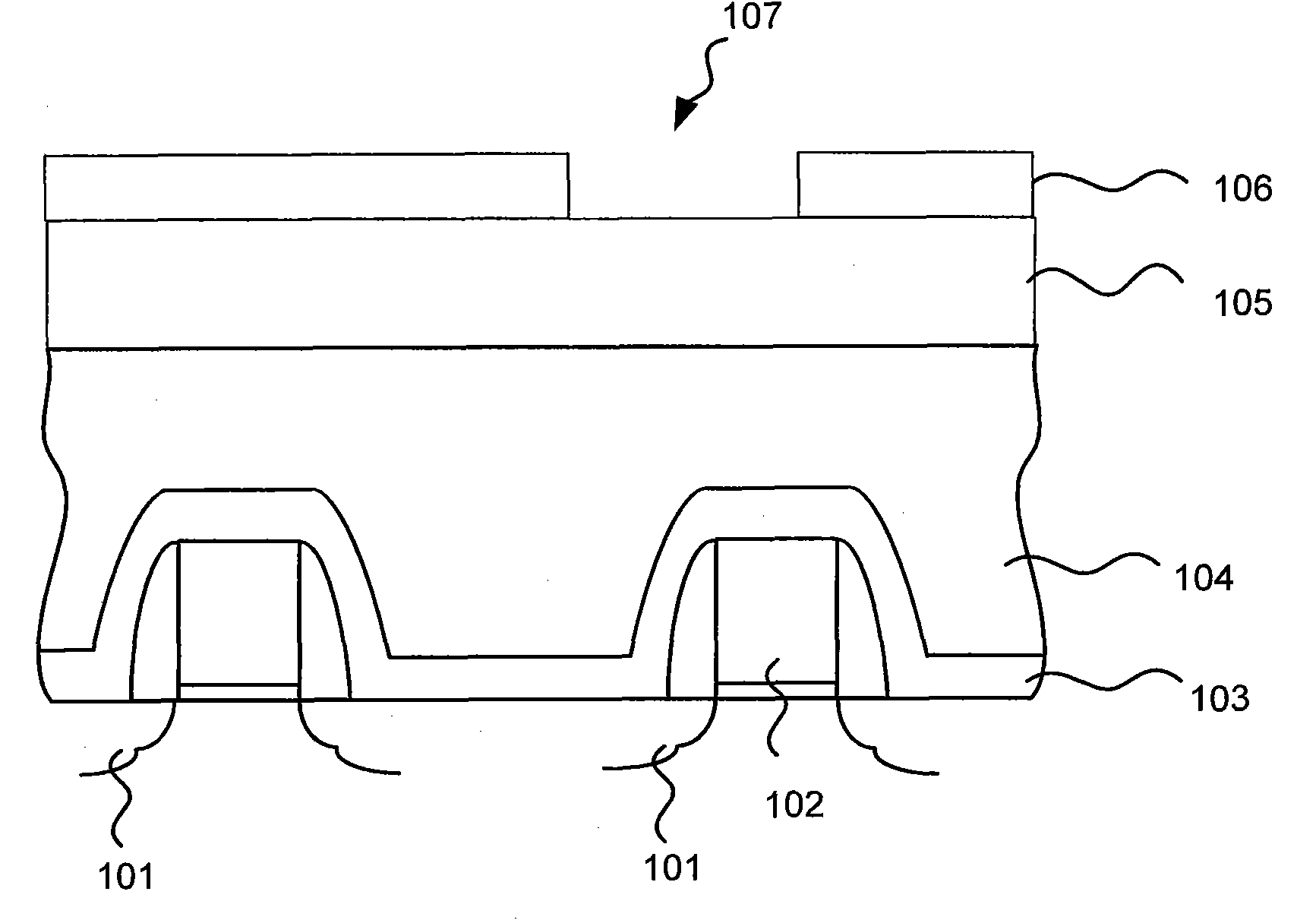

Method for manufacturing structure of semiconductor device

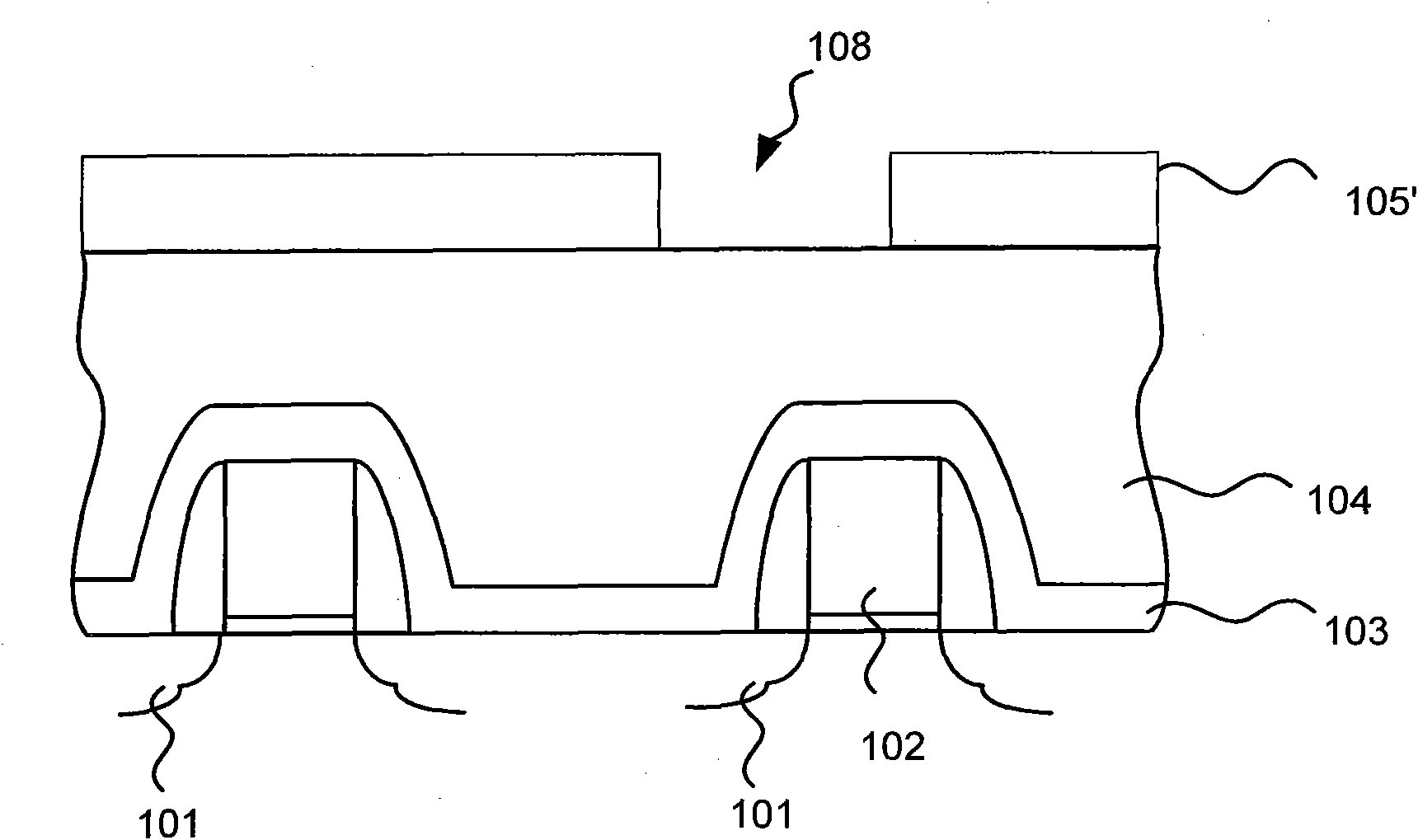

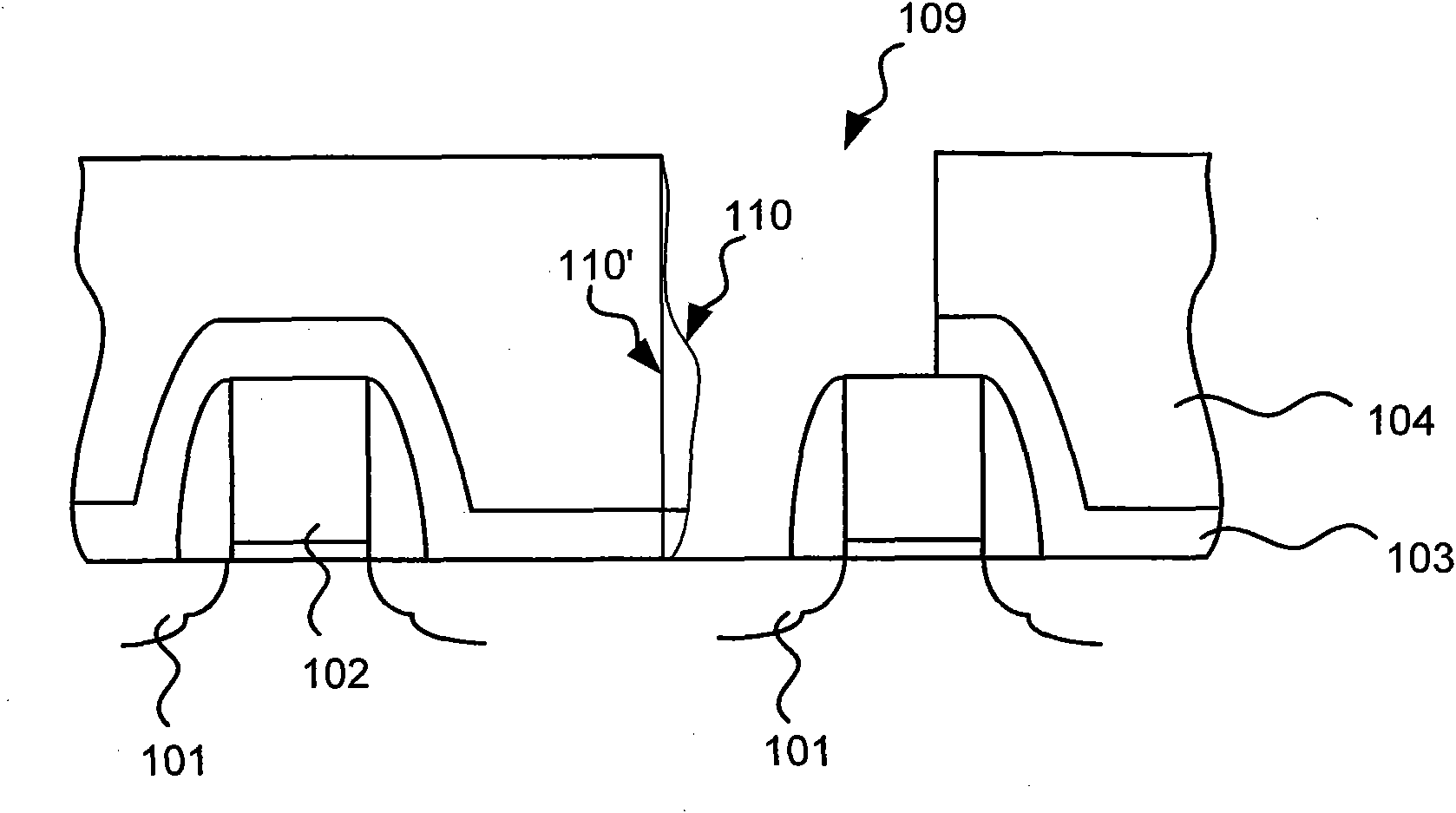

ActiveCN102386127AAvoid structural failureImprove yield rateSemiconductor/solid-state device manufacturingBit lineMedia layer

The invention provides a method for manufacturing the structure of a semiconductor device, which comprises the steps of: providing a front-end device layer structure, wherein the front-end device layer structure is provided with liners and grid electrode structures positioned above the liners, the liner at two sides of each grid electrode structure is internally provided with active regions, the surface of the liner is sequentially provided with an etching stopping layer, an interlayer medium layer and a patterned mask film layer, the patterned mask film layer is provided with a first opening which correspondingly needs to manufacture a bit line contact hole, and the surface of the interlayer medium layer is exposed out of the first opening; firstly etching the interlayer medium layers under the first openings by the means that the patterned mask film layers are taken as mask films, and secondly etching the residual interlayer medium layers, so that the interlayer medium layers are wholly removed, and the active regions and the etching stopping layers above the grid electrode structures are exposed; and thirdly etching the exposed etching stopping layers, so that the exposed etching stopping layers are wholly removed, and the bit line contact holes are formed. The method guarantees the contact holes to have ideal appearance outlines.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Devices and systems for improved traffic control signal assembly

InactiveUS8540392B2Avoid structural failureEliminate needEngagement/disengagement of coupling partsRoad vehicles traffic controlSupporting systemTraffic signal

Methods and apparatuses are provided for improved traffic control devices including a continuous central hanger support system that is integral to the traffic control device and provides a central load path. In an embodiment of the invention, the terminal housing and traffic signal housing of the traffic control device can be included in a single unit housing. A single unit housing can also include an integral backplate. Also provided are span wire clamps, tether clamps, and mast arm clamps that can be used to affix the continuous central hanger of the traffic control device to various fixtures such as a single span wire, two span wires, a pole or a mast arm. The continuous central hanger integrated with the single unit housing can provide the traffic control device with improved securement of electrical components and structural stability for survivability during high wind events as compared to conventional traffic signal devices.

Owner:TOWNSEND JR ROBERT E

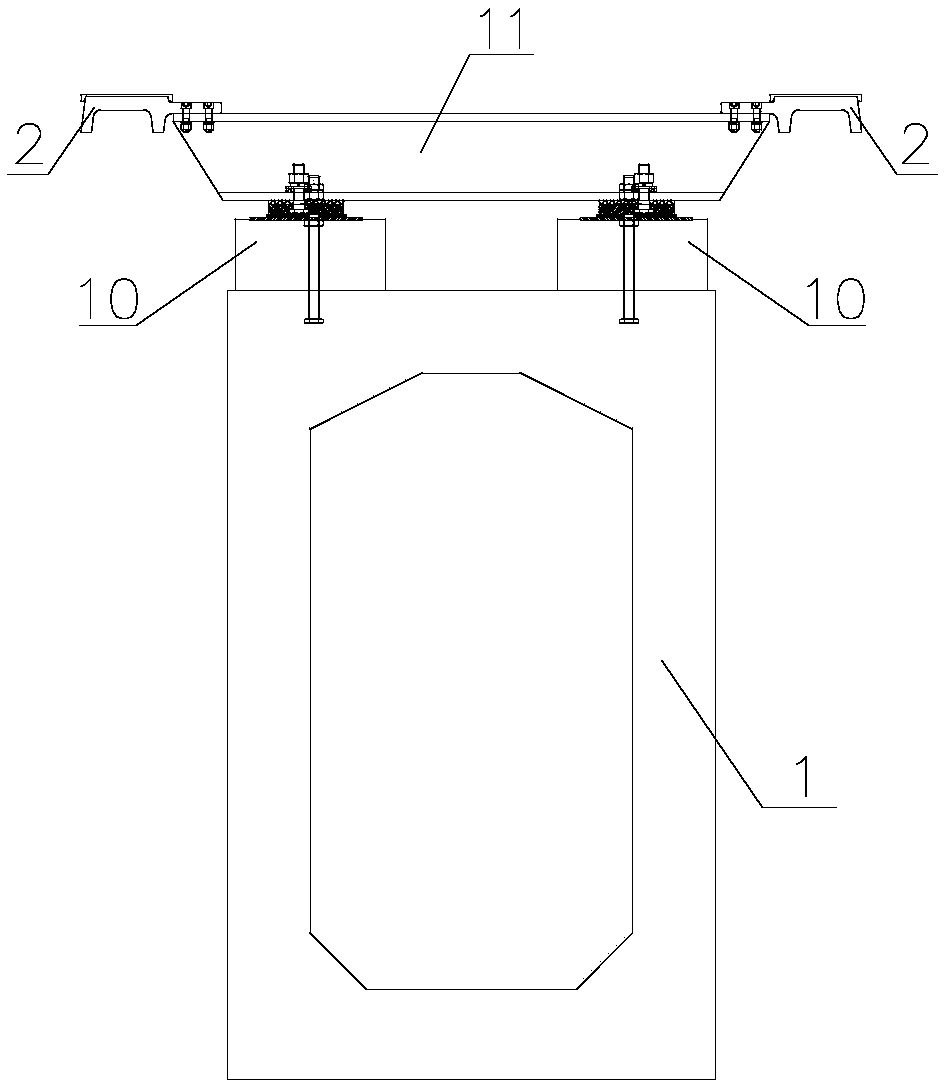

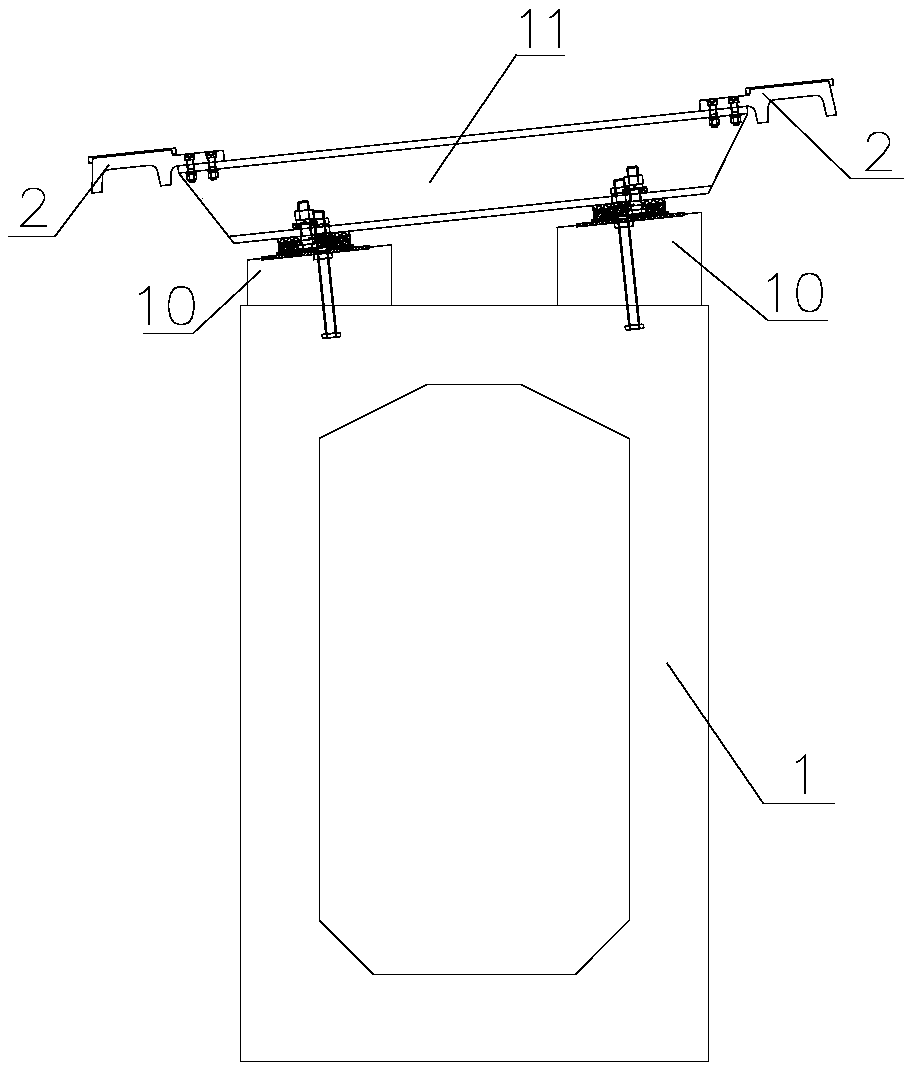

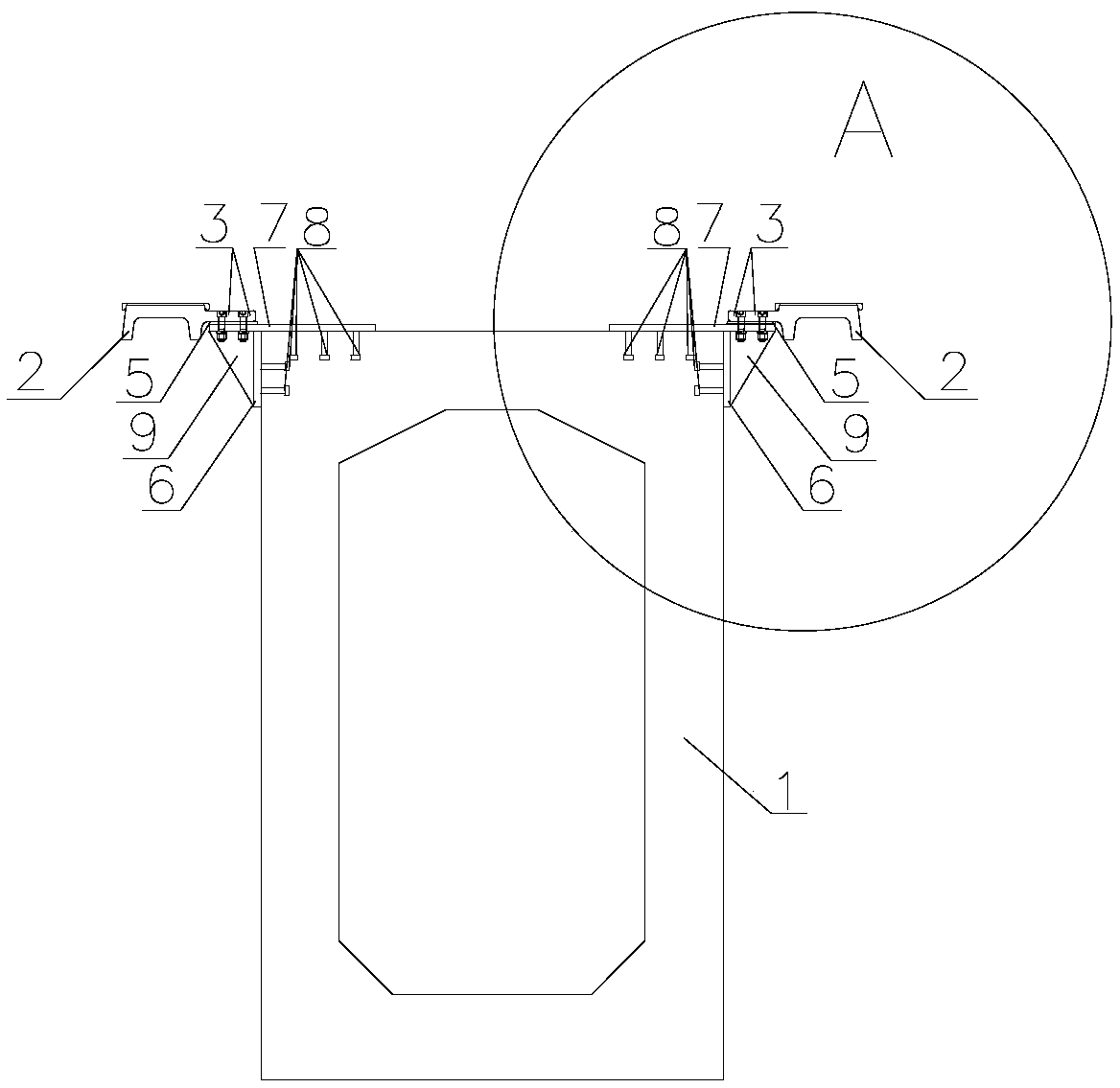

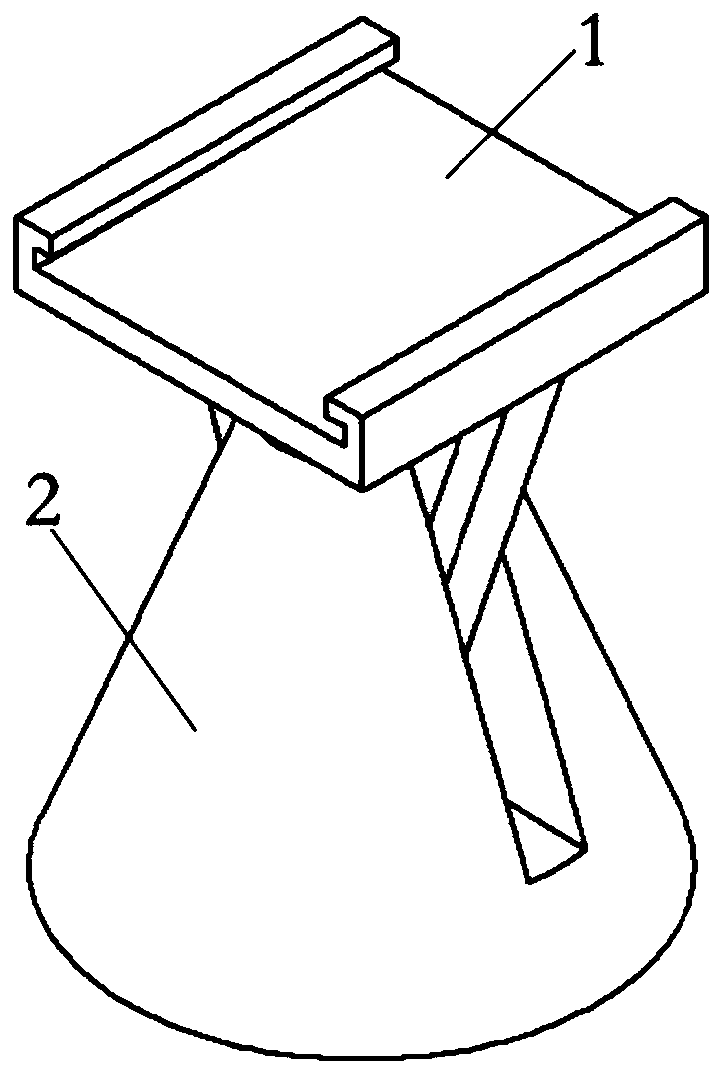

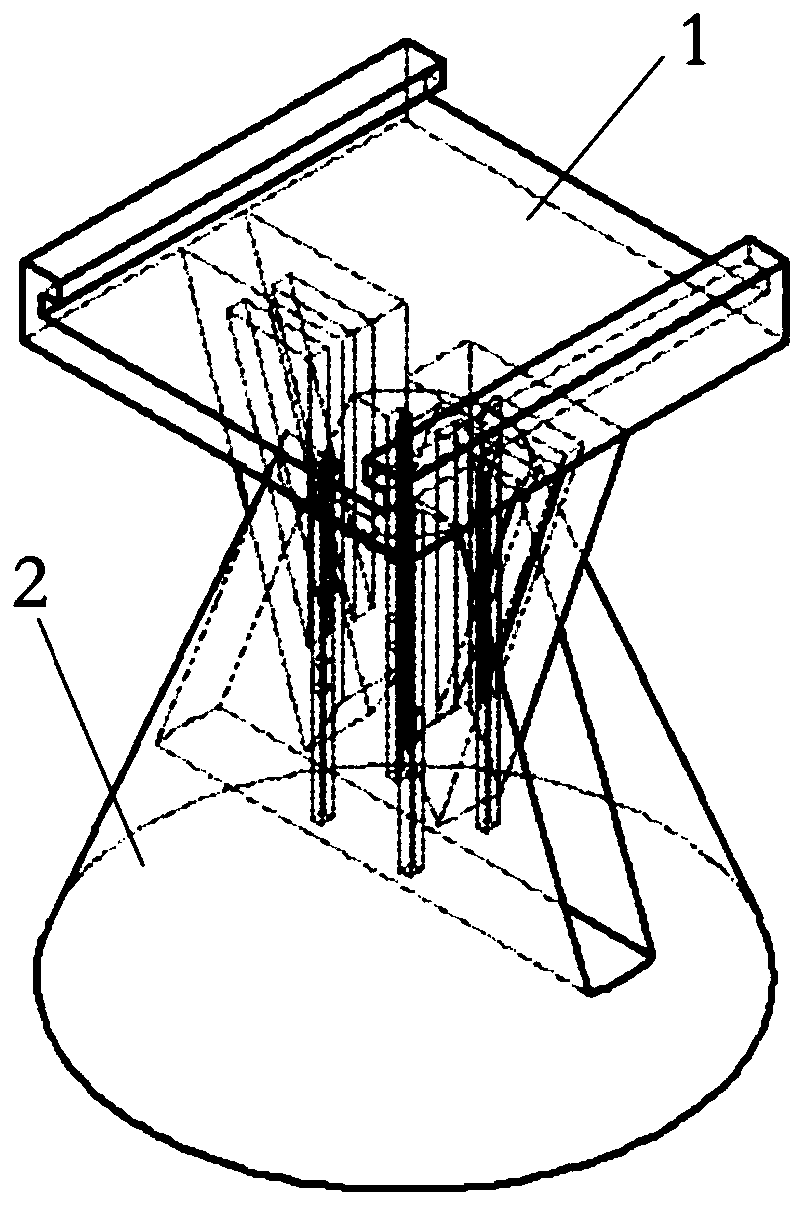

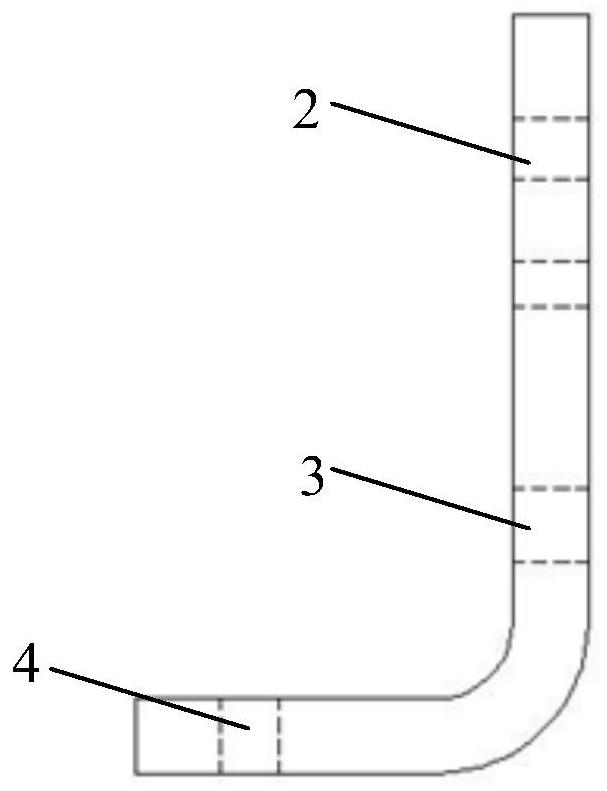

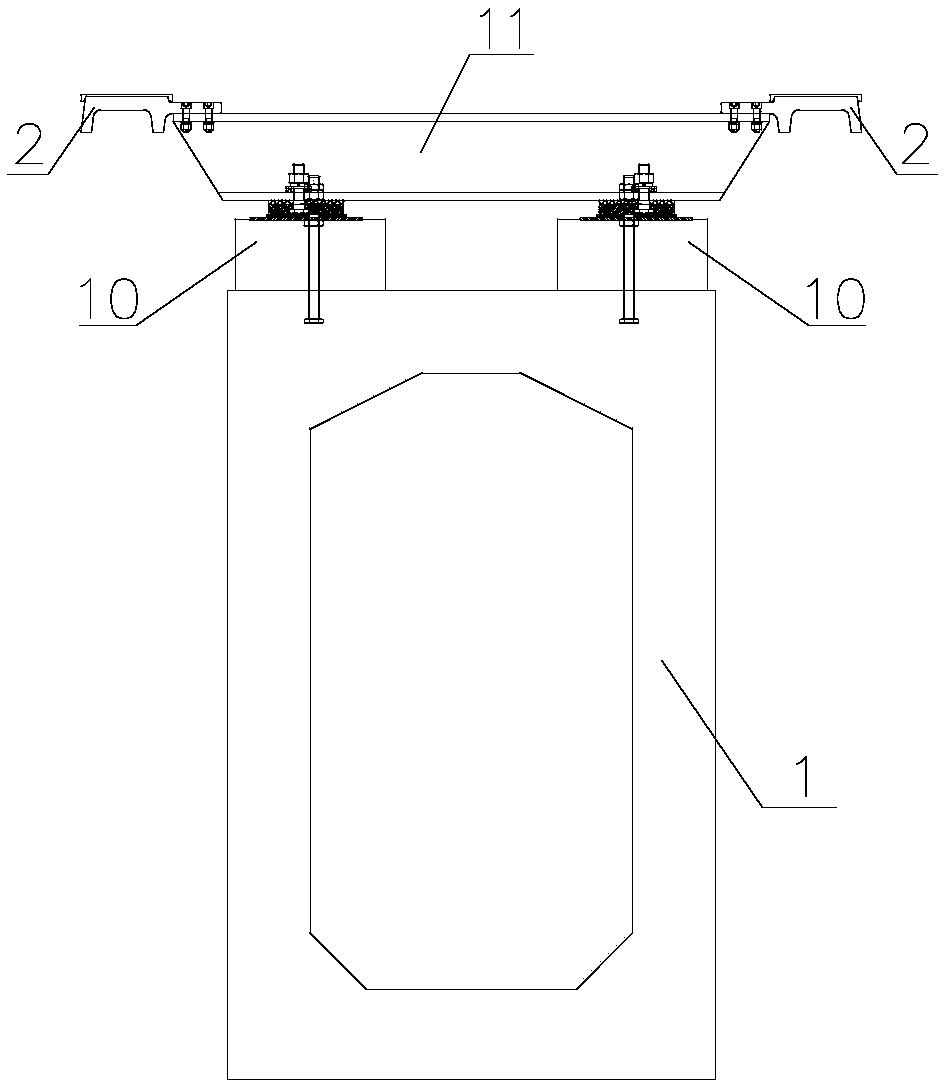

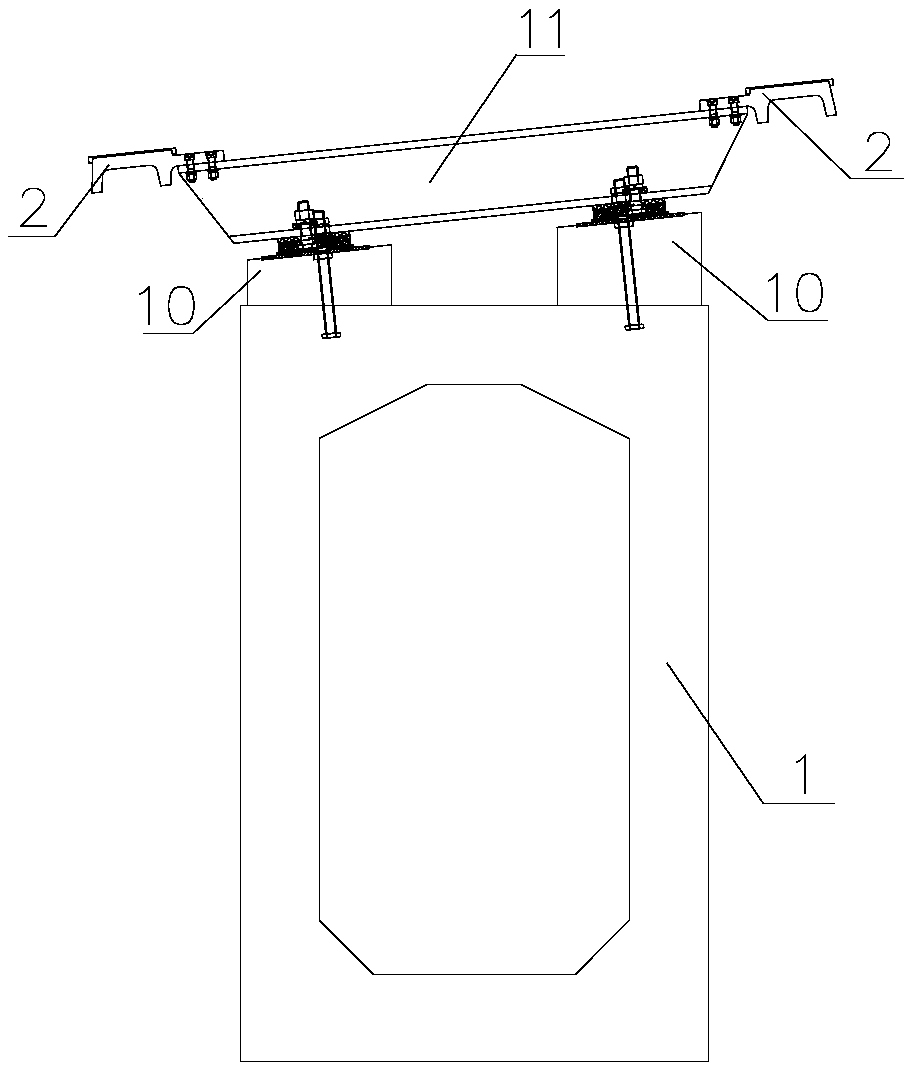

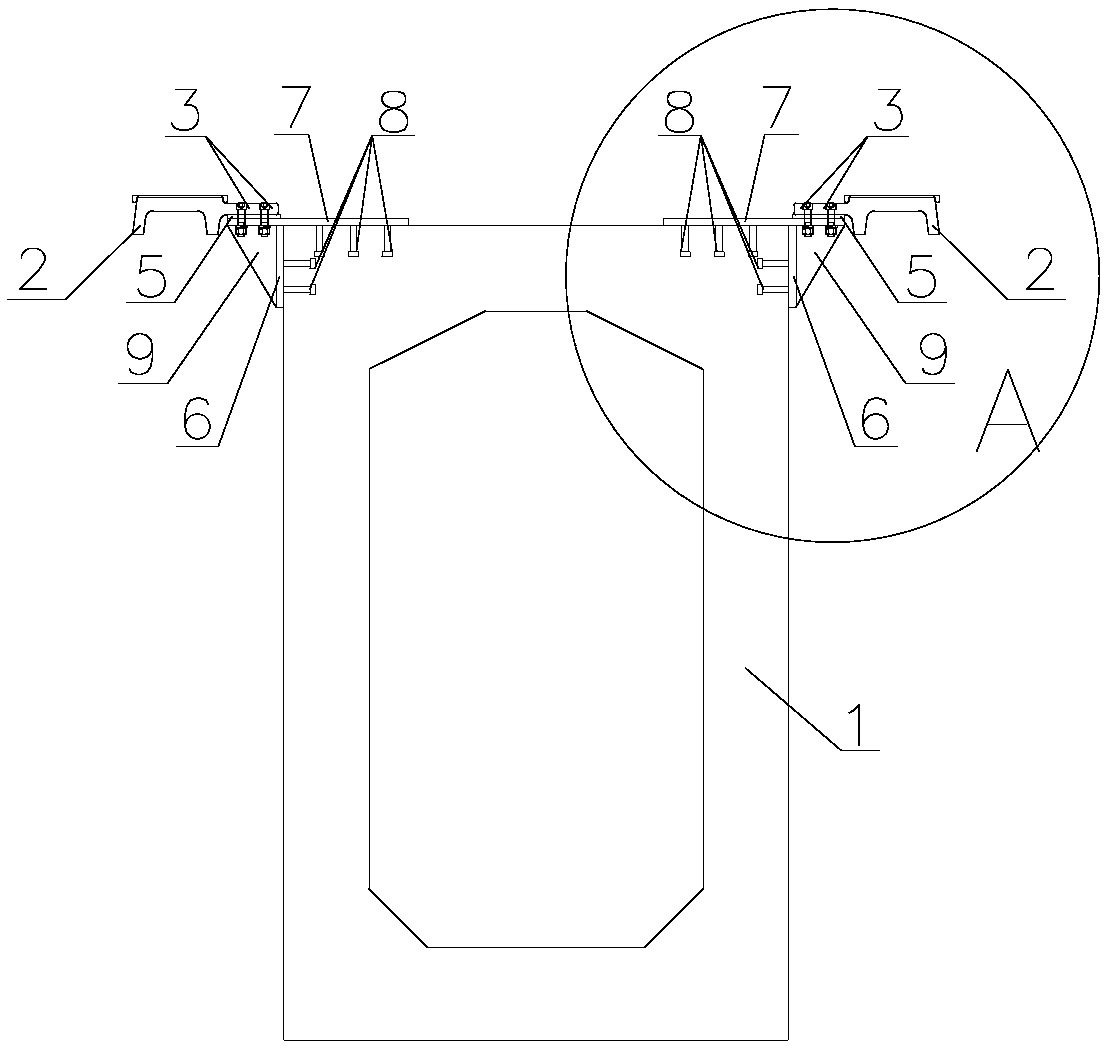

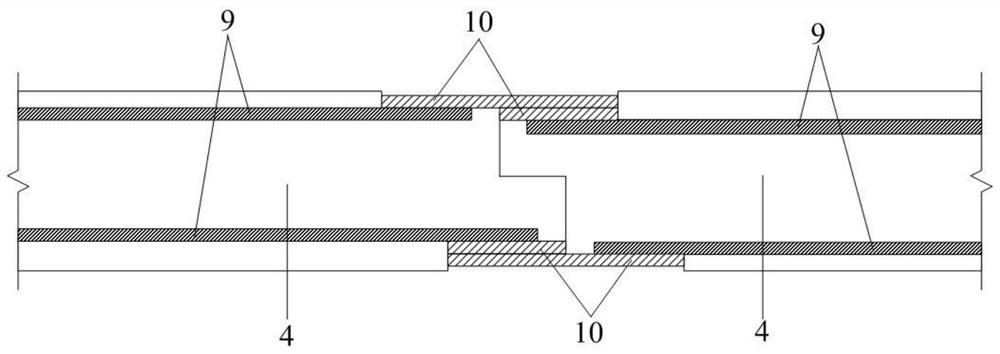

Beam-rail integrated medium-and-low speed maglev track beam

PendingCN109235167ALower the altitudeImprove transfer efficiencyRailway tracksLow speedConcrete beams

The invention discloses a beam-rail integrated medium-and-low speed maglev track beam, which comprises a concrete beam (1), an F rail (2) and a connecting device, wherein that connecting device comprises a bolt (3), a first connector (6), a second connector (7) and a shear nail (8), and a plurality of stiffened plates (9) are arrange on a side of the T-shaped connecting structure adjacent to the Frail (2) along the length direction of the rail beam. The rail integration medium and low speed maglev rail beam eliminates the existing steel beam, fasteners, bearing platform and support structureof the medium and low speed maglev rail beam, greatly reduces the height of the whole rail beam structure, and the load such as car body movement borne by the F rail directly passes through the beam.Transfer of rail-integrated structure, in addition to the super-high section of the beam in the curve. The rail-integrated structure directly bears the transverse shear force caused by the rail inclination, which not only improves the performance of the rail, but also improves the stability of the rail. The transfer efficiency of the force between the beams, and effectively avoid the load caused by rail structural failure between beams.

Owner:CHINA RAILWAY MAGLEV TRANSPORTATION INVESTMENT CONSTR CO LTD

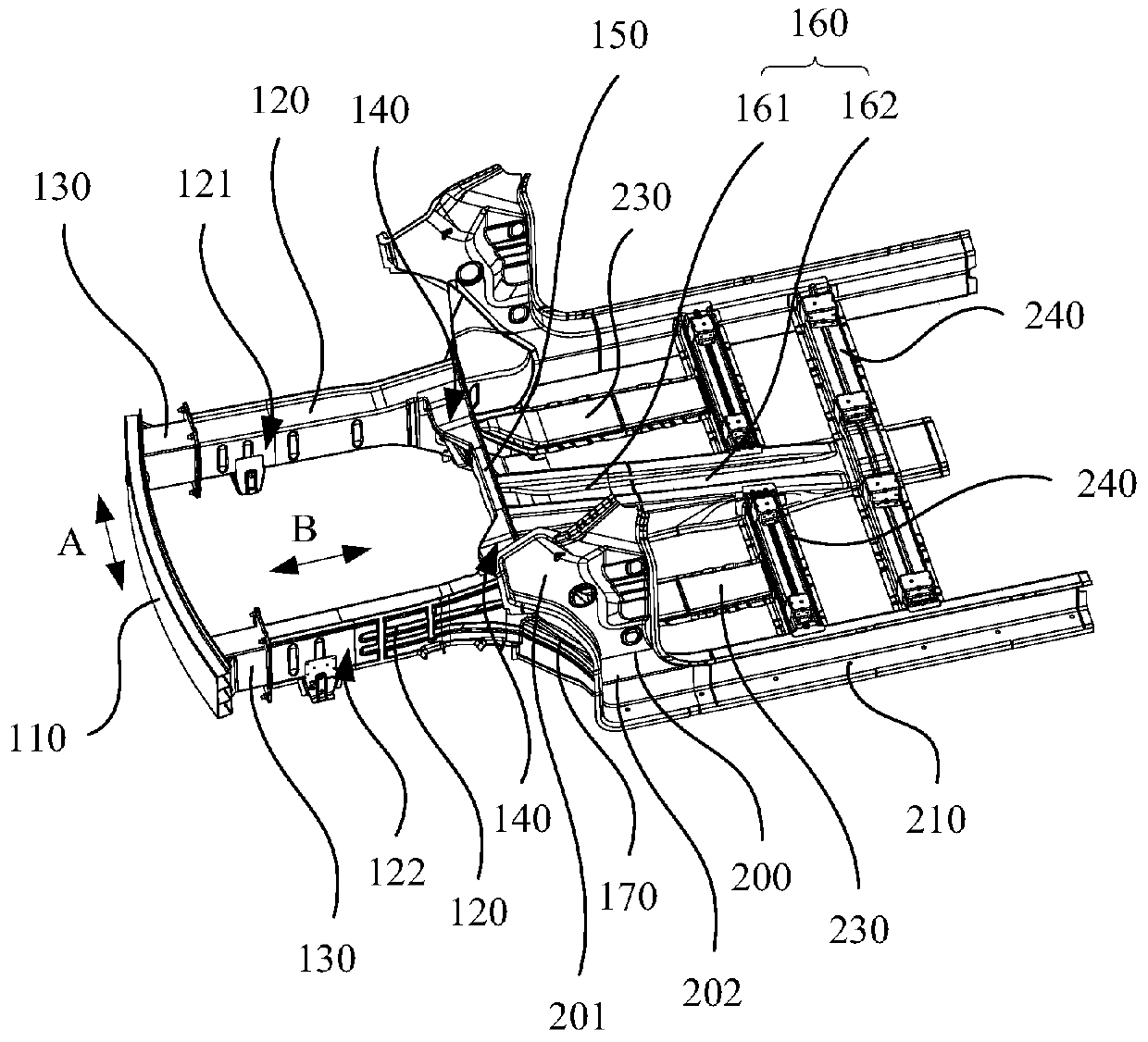

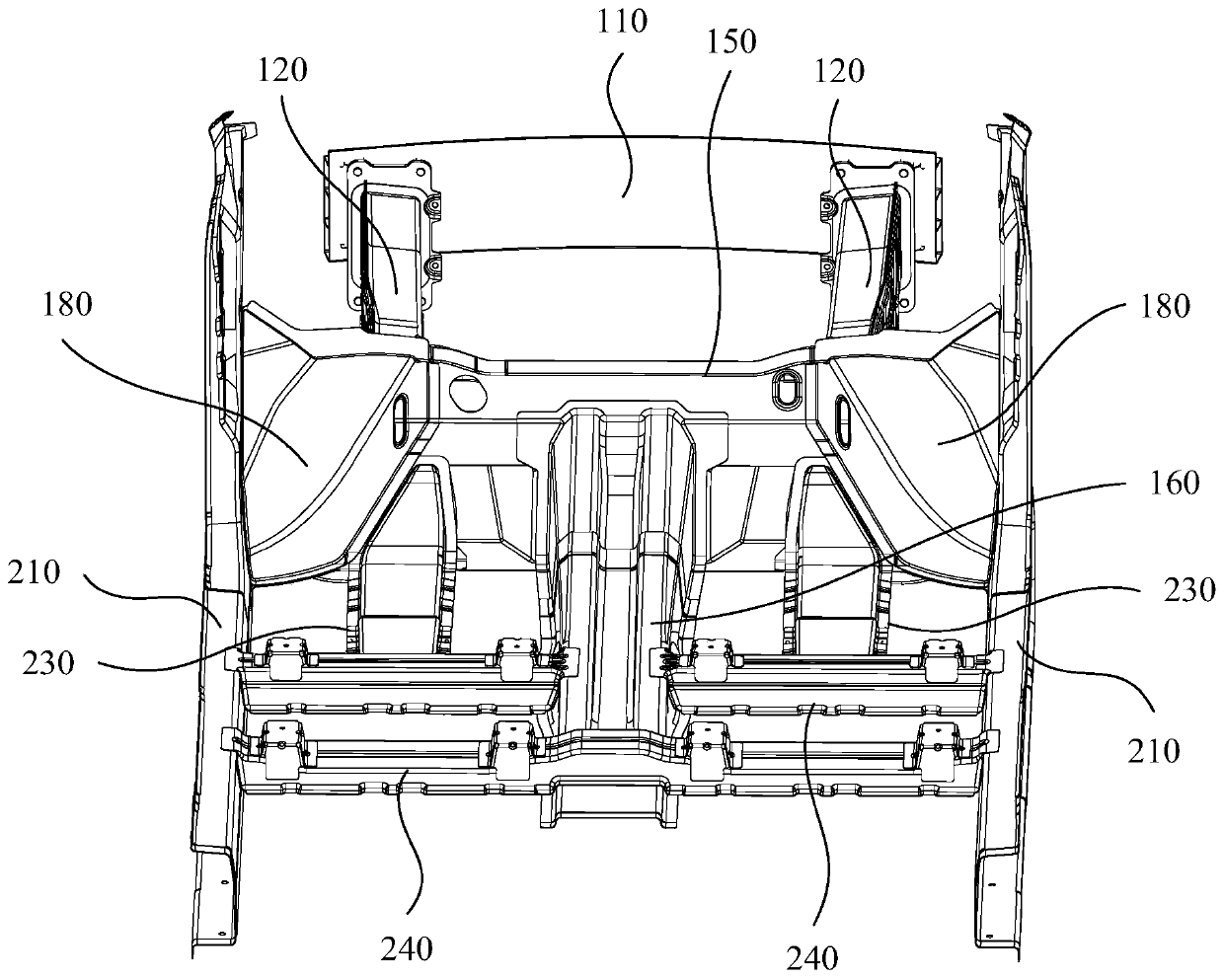

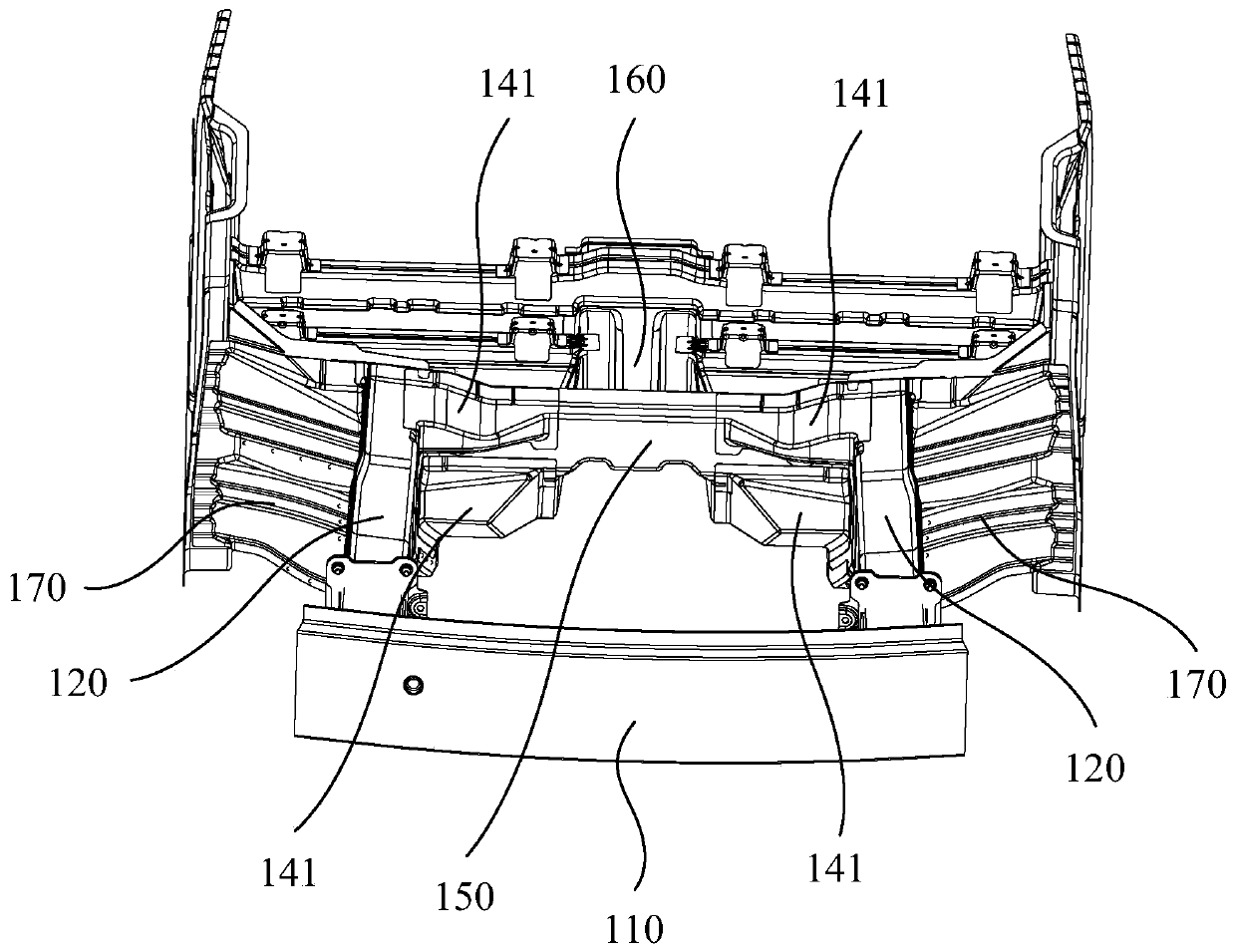

Vehicle, vehicle body and force transmission structure thereof

PendingCN111547134AAvoid destructionEnsure safetyUnderstructuresControl theoryMechanical engineering

The invention relates to a vehicle, a vehicle body and a force transmission structure of the vehicle body. The force transmission structure of the vehicle body comprises a front anti-collision beam, afront longitudinal beam, a first connecting part, a dash panel cross beam, a middle channel, a second connecting part, a footrest, a torsion box, an A column inner plate and a threshold. The front anti-collision beam, the front longitudinal beam, the first connecting part, the dash panel cross beam and the middle channel can conduct force transmission and are matched to form a first force transmission path, and the front anti-collision beam, the front longitudinal beam, the second connecting part, the footrest, the torsion box, the A column inner plate and the threshold can conduct force transmission and are matched to form a second force transmission path. According to the vehicle, the vehicle body and the force transmission structure of the vehicle body, compared with a traditional force transmission structure with a single transmission path, structural failure caused by the single transmission path can be avoided, collision force can be dispersed, stress concentration is avoided, damage to the vehicle body structure of a passenger compartment part in the collision force transmission process is avoided, and the passenger safety is guaranteed.

Owner:合创汽车科技有限公司

Devices and Systems for Improved Traffic Control Signal Assembly

InactiveUS20150115122A1Avoid structural failureEnhanced control signalLighting support devicesRoad vehicles traffic controlStructural stabilityBackplane

Methods and apparatuses are provided for improved traffic control devices including a continuous central hanger support system that is integral to the traffic control device and provides a central load path. In an embodiment of the invention, the terminal housing and traffic signal housing of the traffic control device can be included in a single unit housing. A single unit housing can also include an integral backplate. Also provided are span wire clamps, tether clamps, and mast arm clamps that can be used to affix the continuous central hanger of the traffic control device to various fixtures such as a single span wire, two span wires, a pole or a mast arm. The continuous central hanger integrated with the single unit housing can provide the traffic control device with improved securement of electrical components and structural stability for survivability during high wind events as compared to conventional traffic signal devices.

Owner:TOWNSEND JR ROBERT E

Devices and systems for improved traffic control signal assembly

InactiveUS9765953B2Avoid structural failureEliminate needMachine supportsLighting support devicesSupporting systemTraffic signal

Methods and apparatuses are provided for improved traffic control devices including a continuous central hanger support system that is integral to the traffic control device and provides a central load path. In an embodiment of the invention, the terminal housing and traffic signal housing of the traffic control device can be included in a single unit housing. A single unit housing can also include an integral backplate. Also provided are span wire clamps, tether clamps, and mast arm clamps that can be used to affix the continuous central hanger of the traffic control device to various fixtures such as a single span wire, two span wires, a pole or a mast arm. The continuous central hanger integrated with the single unit housing can provide the traffic control device with improved securement of electrical components and structural stability for survivability during high wind events as compared to conventional traffic signal devices.

Owner:TOWNSEND JR ROBERT E

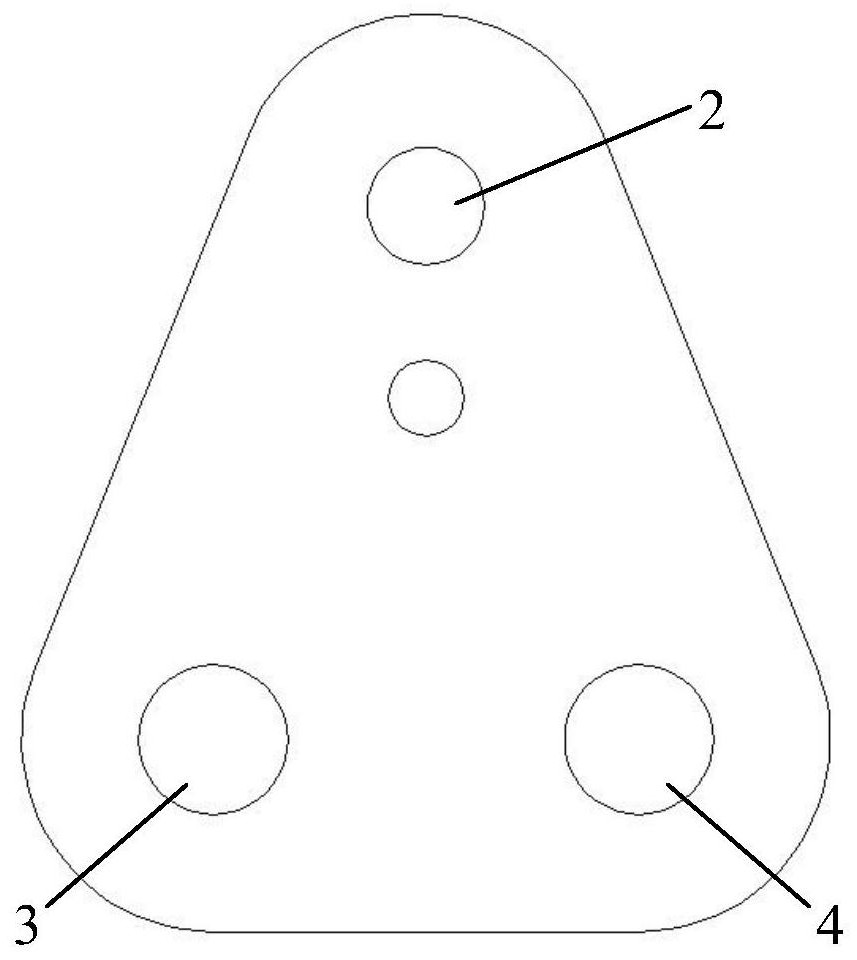

Compression type concrete uniaxial tensile test fixture and test method

ActiveCN111504787AAvoid breakingSure breakMaterial strength using tensile/compressive forcesStress concentrationArchitectural engineering

The invention discloses a compression type concrete uniaxial tensile test fixture and a test method. The compression type concrete uniaxial tensile test fixture comprises a lower pressing piece and anupper jacking piece, the upper end of the lower pressing piece is fixedly connected with an upper pressing plate of the hydraulic machine, and the lower end of the lower pressing piece is slidably inserted into the upper ejecting piece which is arranged on a workbench of the hydraulic machine. The concrete test piece is arranged between the lower pressing piece and the upper jacking piece, the upper end of the concrete test piece is in tight contact connection with the upper end surface of the upper jacking piece, and the lower end of the concrete test piece is in tight contact connection with the lower end surface of the lower pressing piece; according to the invention, the upper clamping end of the concrete test piece is in close contact with the upper end surface of the upper jacking piece; the lower clamping end of the concrete test piece is in contact with the lower end surface of the lower pressing piece; the stress concentration between the clamp and the concrete test piece iseffectively eliminated, the root of the concrete test piece is prevented from being broken due to damage to the interior of the concrete test piece in the early stage of the test, the tensile fracturesurface of the concrete test piece is ensured to occur in the middle of the concrete test piece, and the accuracy of test results is effectively improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

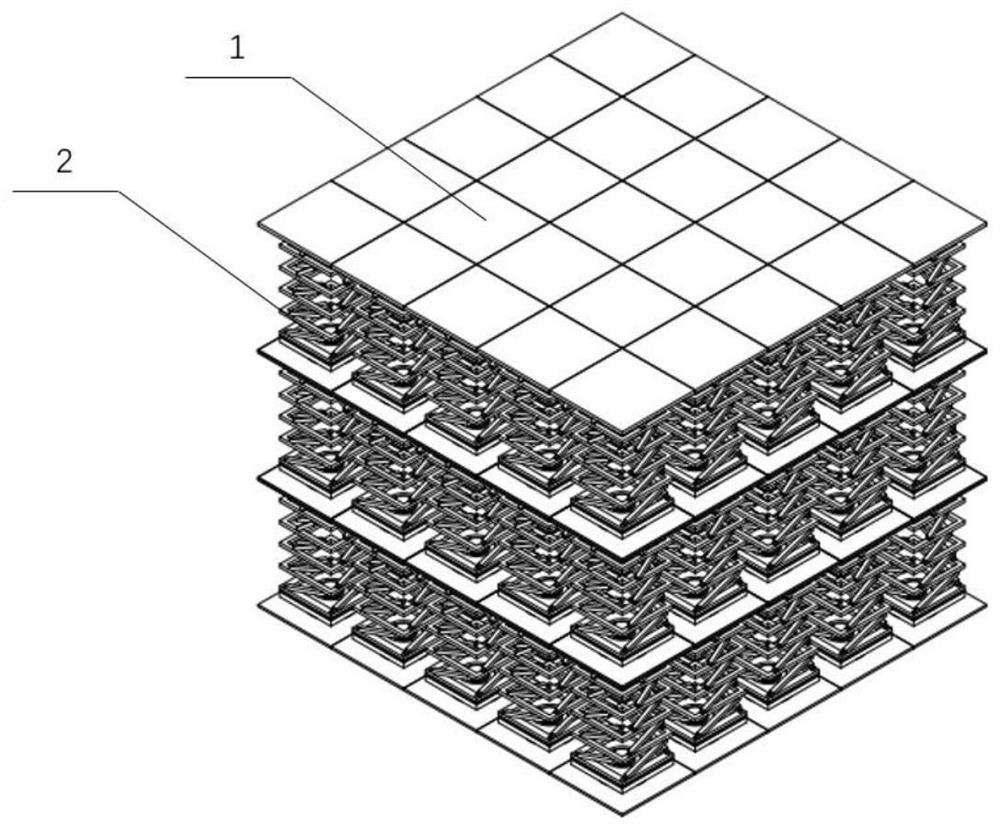

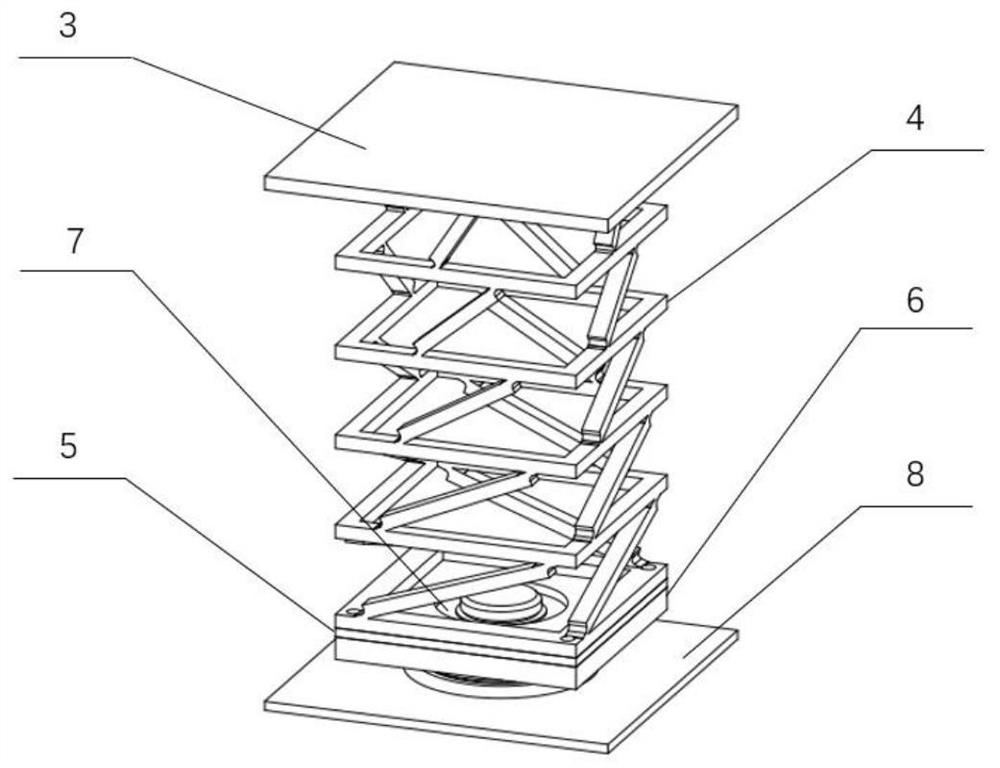

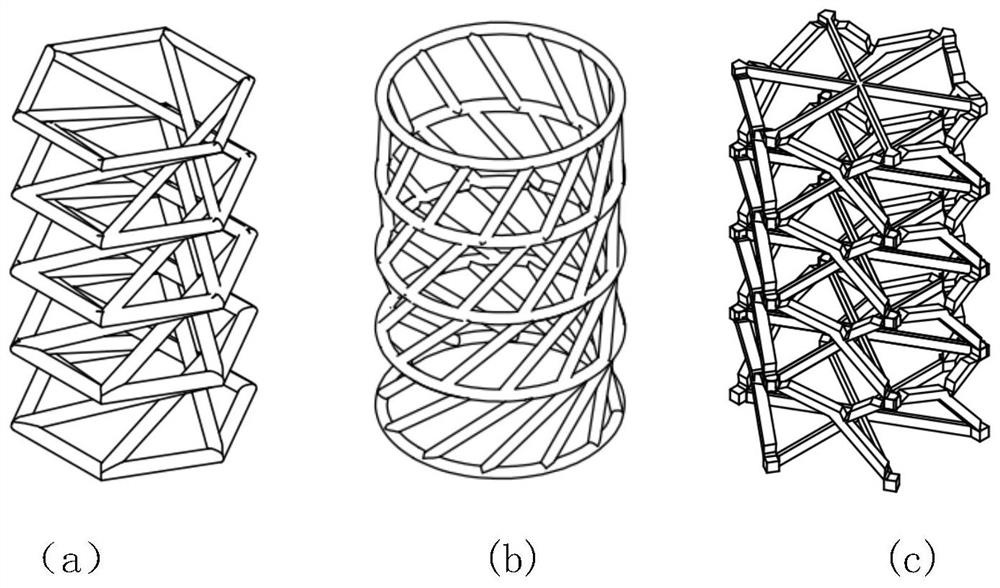

Gradient pressure-torsion energy storage and vibration reduction structure

ActiveCN113738802ALow densityImprove vibration damping abilitySpringsShock absorbersEnergy absorptionLower face

The invention discloses a gradient pressure-torsion energy storage and vibration reduction structure. The structure is characterized in that a plurality of pressure-torsion unit cells can rotate the load direction when being subjected to load, the pressure-torsion unit cells are arranged to form a layer of energy storage and vibration reduction unit in an array, and a plurality of layers of energy storage and vibration reduction units are sequentially overlapped to form the gradient pressure-torsion energy storage and vibration reduction structure; each pressure-torsion unit cell sequentially comprises an upper face plate, a plurality of pressure-torsion structures, a lower face plate and a bottom plate from top to bottom, and the pressure-torsion structures are arranged between the upper face plates and the lower face plates in an overlapped mode. Impact energy is converted into structure rotation energy and counterweight rotation energy, the energy absorption efficiency of a traditional structure is greatly improved, meanwhile, the structure can further absorb the rotation energy through a transmission means in the rotation process, the structure is high in designability, and the rigidity and the strength of the structure can be improved by increasing the number of inclined rods of the unit cells, so that the structure has a wider application space.

Owner:XI AN JIAOTONG UNIV

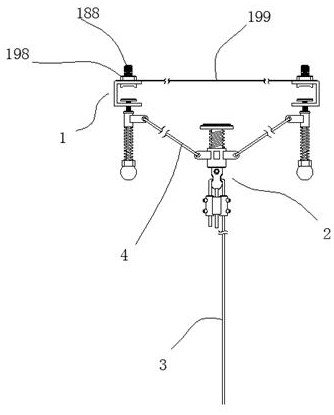

Safety device for building external wall construction

ActiveCN112031388AEasy to operateHave a balancing effectBuilding support scaffoldsArchitectural engineeringHanging basket

The invention discloses a safety device for building external wall construction. The safety device comprises connecting structures arranged on the periphery of the exterior of a hanging basket, a center hanging and pulling structure matched with the multiple connecting structures and a pulling cable connected with the center hanging and pulling structure, wherein steel cables are connected betweenthe connecting structures and the center hanging and pulling structure. The safety device can conduct auxiliary positioning on the hanging basket on the ground.

Owner:新昌县杨辉网络科技有限公司

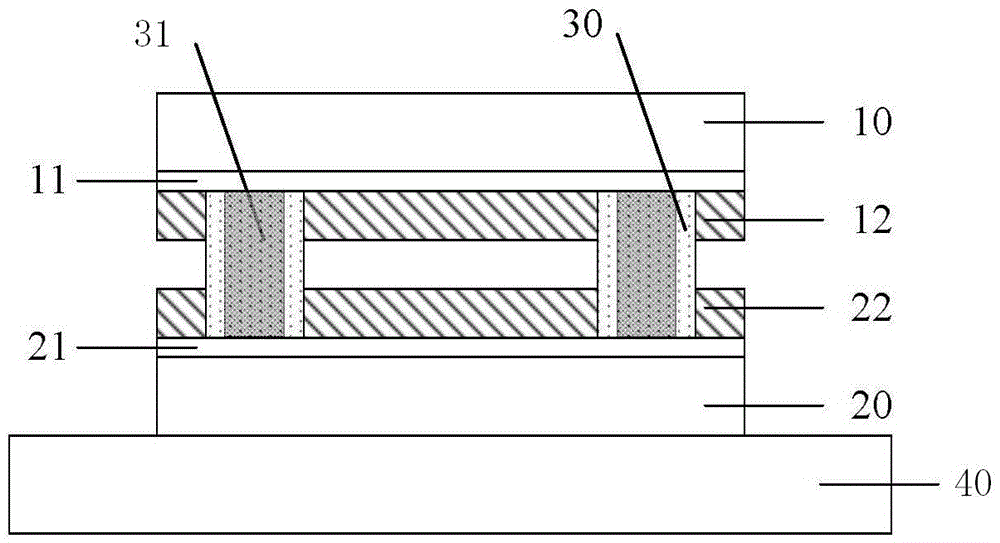

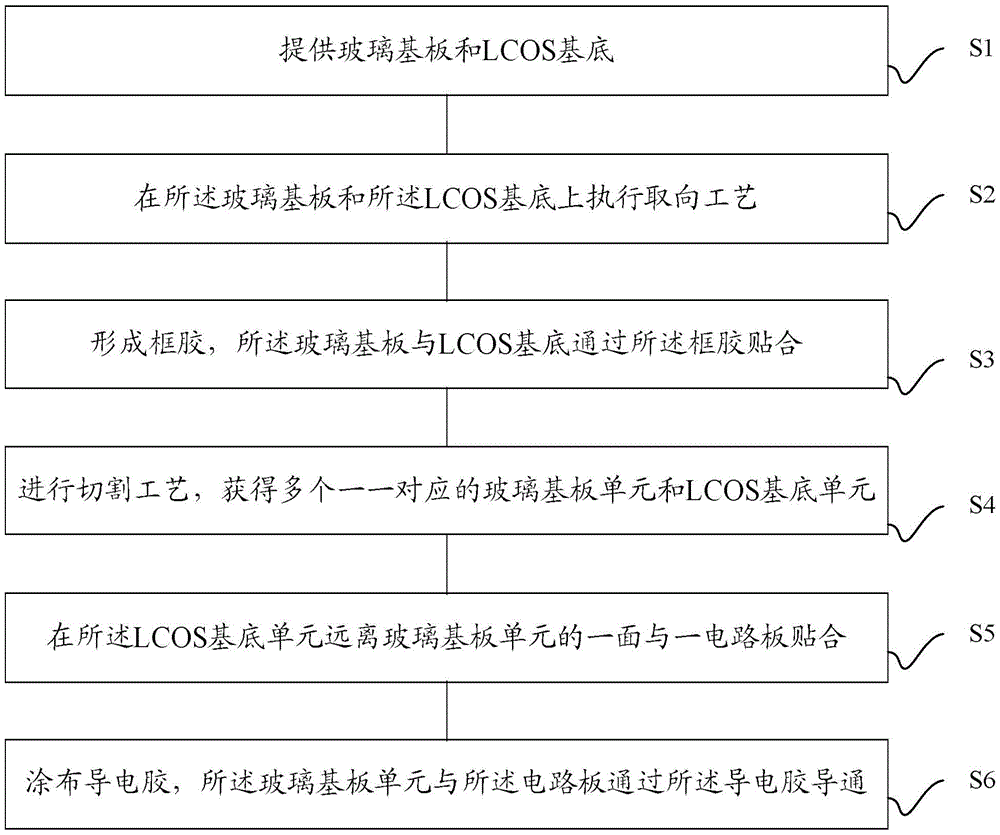

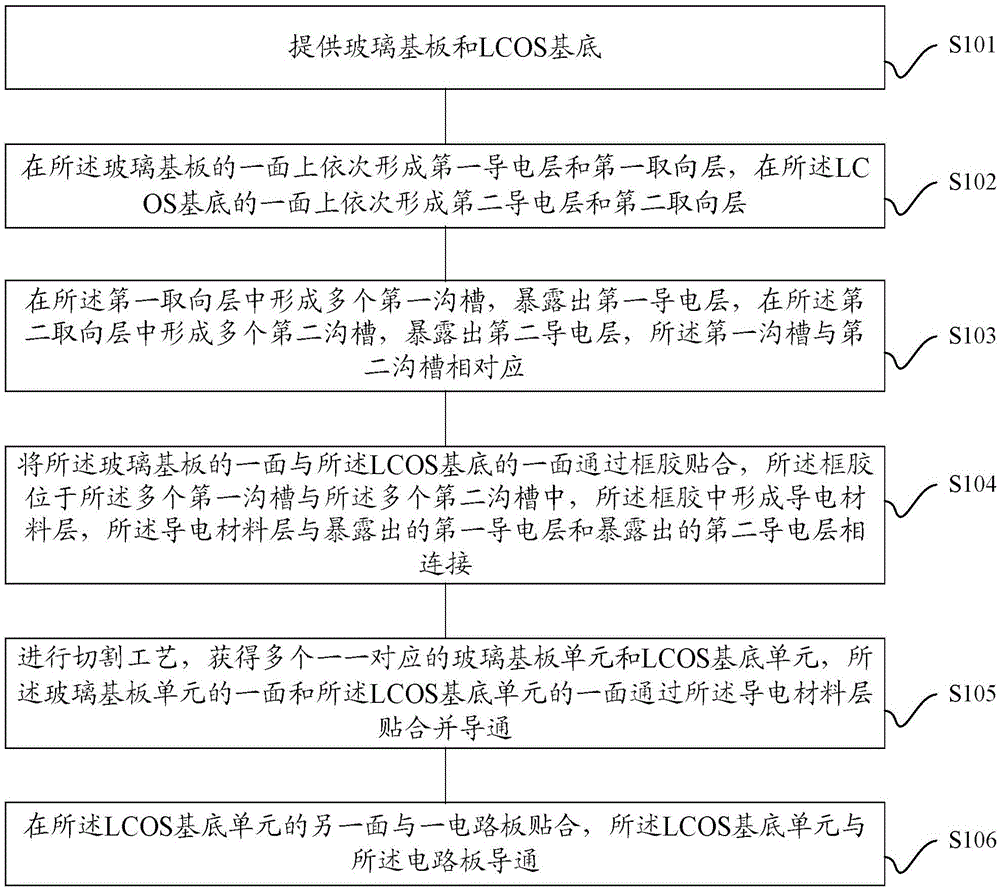

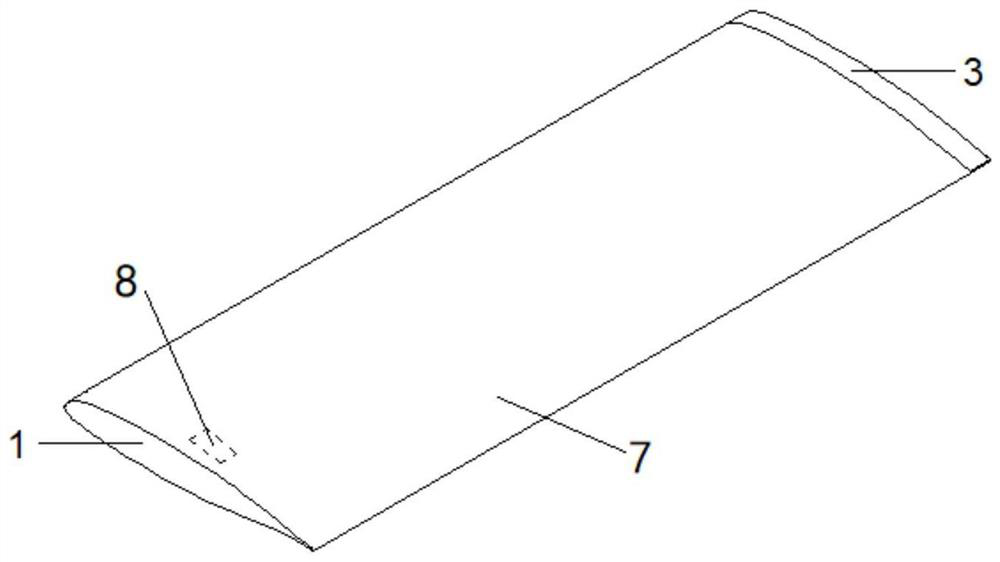

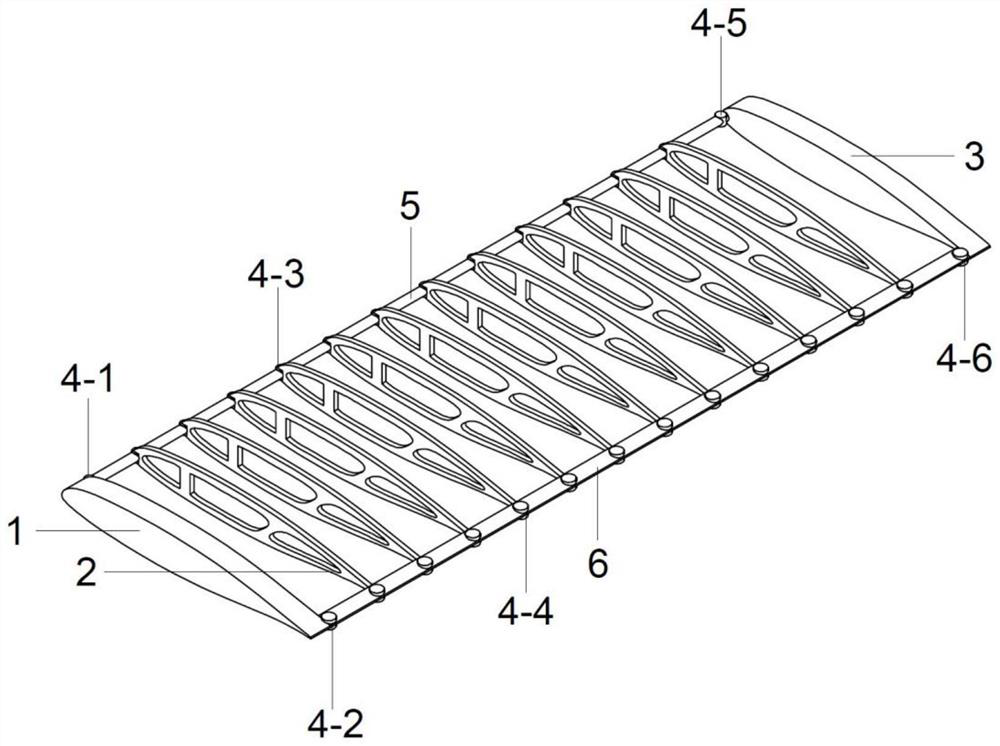

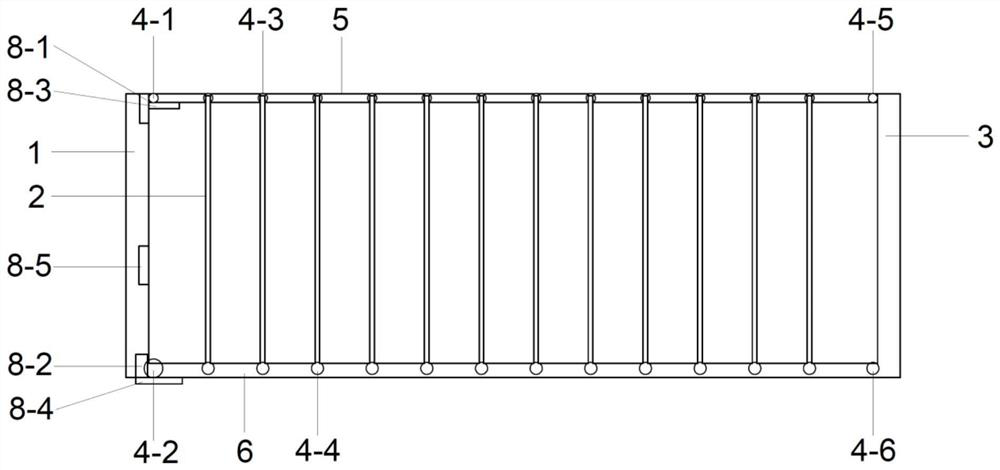

LCOS structure and manufacturing method

InactiveCN105629550AAvoid structural failureSimple preparation processNon-linear opticsSealantLiquid crystal on silicon

The invention provides a liquid crystal on silicon (LCOS) structure and a manufacturing method. The manufacturing method for the LCOS structure comprises a step of forming a conducting material layer in a sealant, thereby utilizing the conducting material layer to implement the conduction between a glass substrate unit and a circuit board through an LCOS substrate unit. The invention further provides an LCOS structure manufactured by utilizing the manufacturing method for the LCOS structure. Compared with the prior art, the manufacturing method for the LCOS structure not only can effectively shorten a manufacturing process of LCOS products, but also can solve the technical problems that conducting resin is removed or broken and the conducting resin is easy to oxidize in the prior art.

Owner:HUA WEI SEMICONDUCTOR (SHANGAHAI) CO LTD

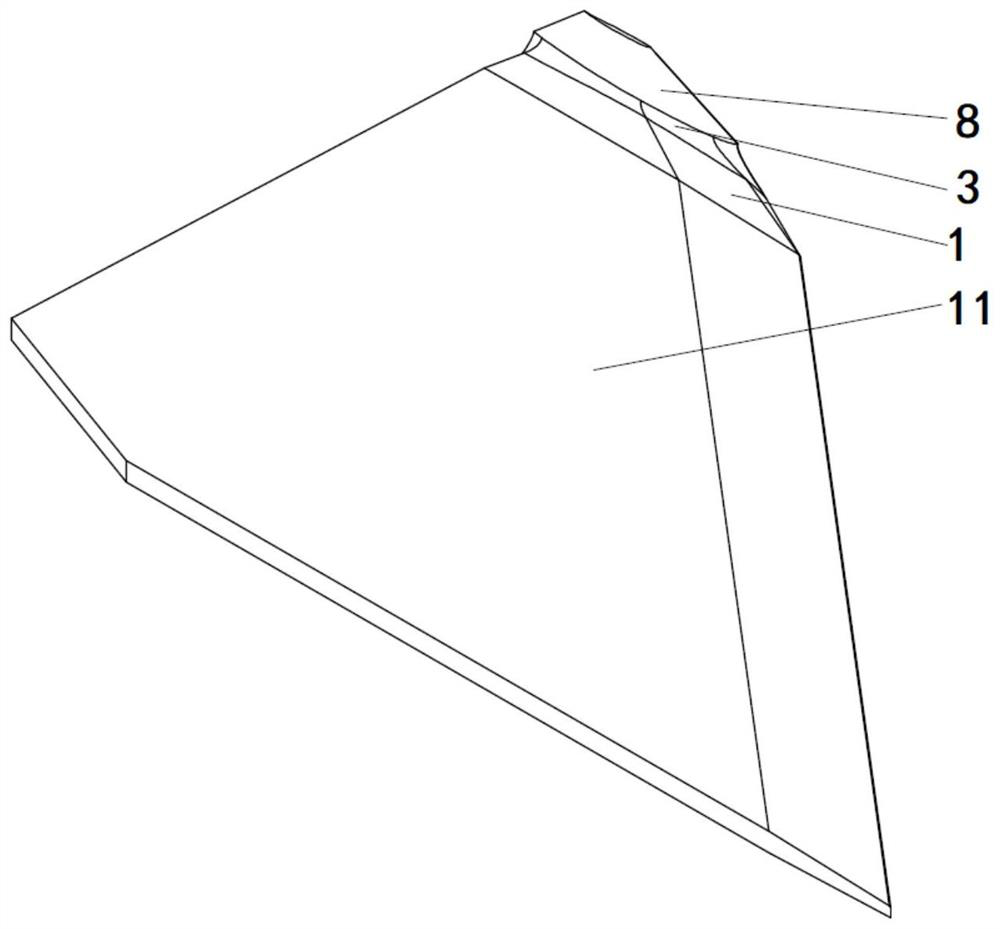

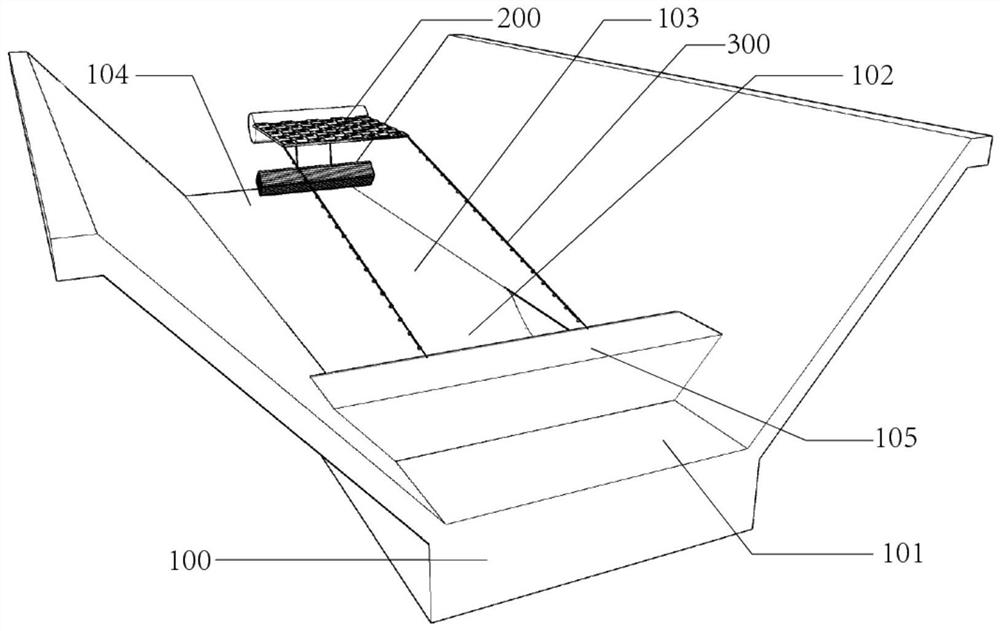

Flexible foldable wing

PendingCN113734421AAchieve foldingReasonable structural designWing adjustmentsLeading edgeFlight vehicle

The invention discloses a flexible foldable wing, and belongs to the technical field of aircraft devices. One side of the wing base is connected with the root of an aircraft wing, the front end of the other side of the wing base is rotationally connected with the root of the leading edge main beam, the rear end of the other side of the wing base is rotationally connected with the root of the trailing edge auxiliary beam, and the folding servo transmission system is connected with the root of the leading edge main beam and the root of the trailing edge auxiliary beam. The tip of the front edge main beam is hinged to the wingtip base, and the tip of the rear edge auxiliary beam is hinged to the wingtip base; two ends of the plurality of wing ribs are respectively hinged with the leading edge main beam and the trailing edge auxiliary beam; the wing base, the wingtip base, the front edge main beam, the rear edge auxiliary beam and the wing ribs are wrapped with the flexible skin, and a complete pneumatic wing shape is formed. The aircraft wing can be highly folded, the size of the aircraft in storage and transportation is reduced, the flexibility of the aircraft is improved, and miniaturization of the aircraft is achieved.

Owner:XI AN JIAOTONG UNIV

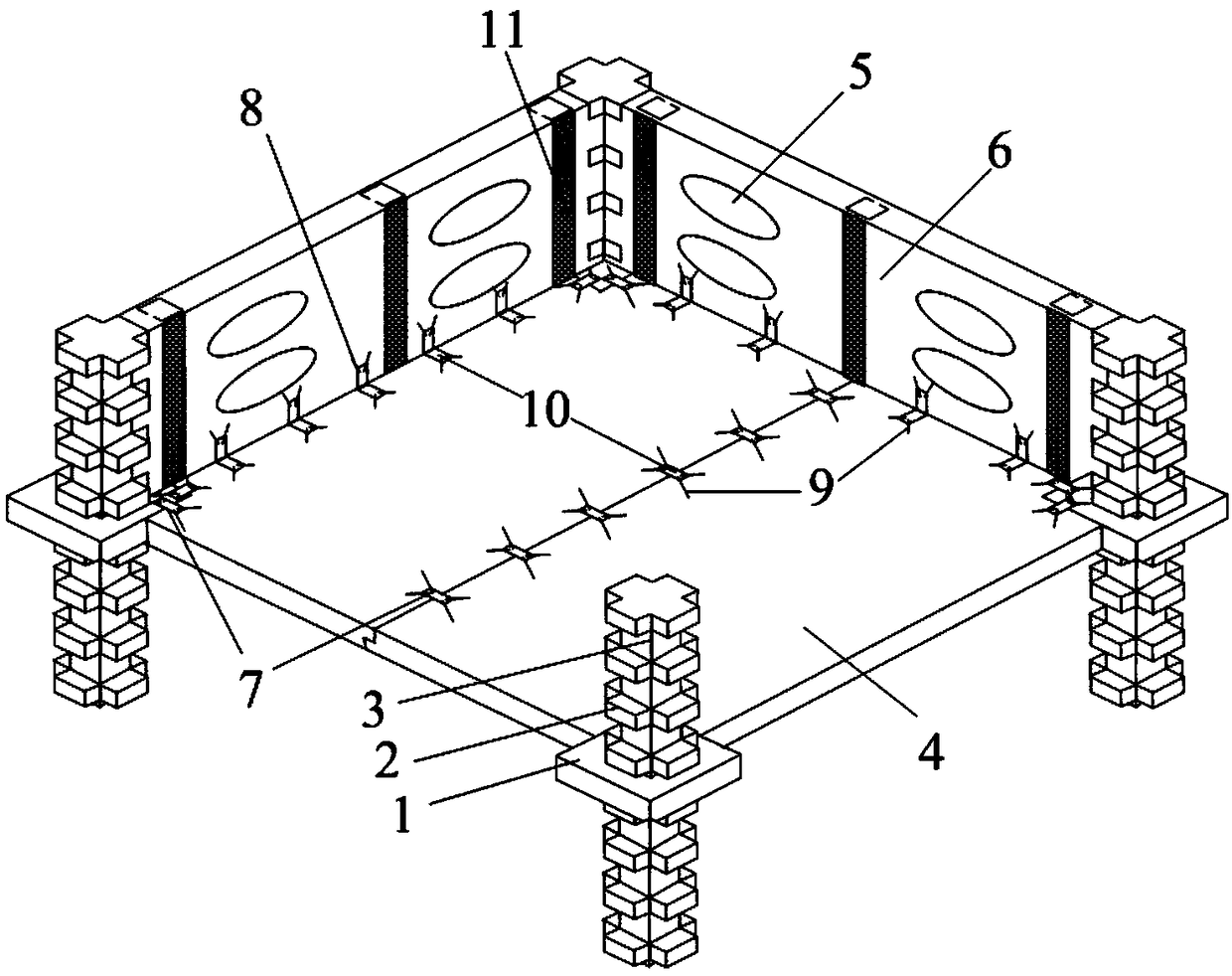

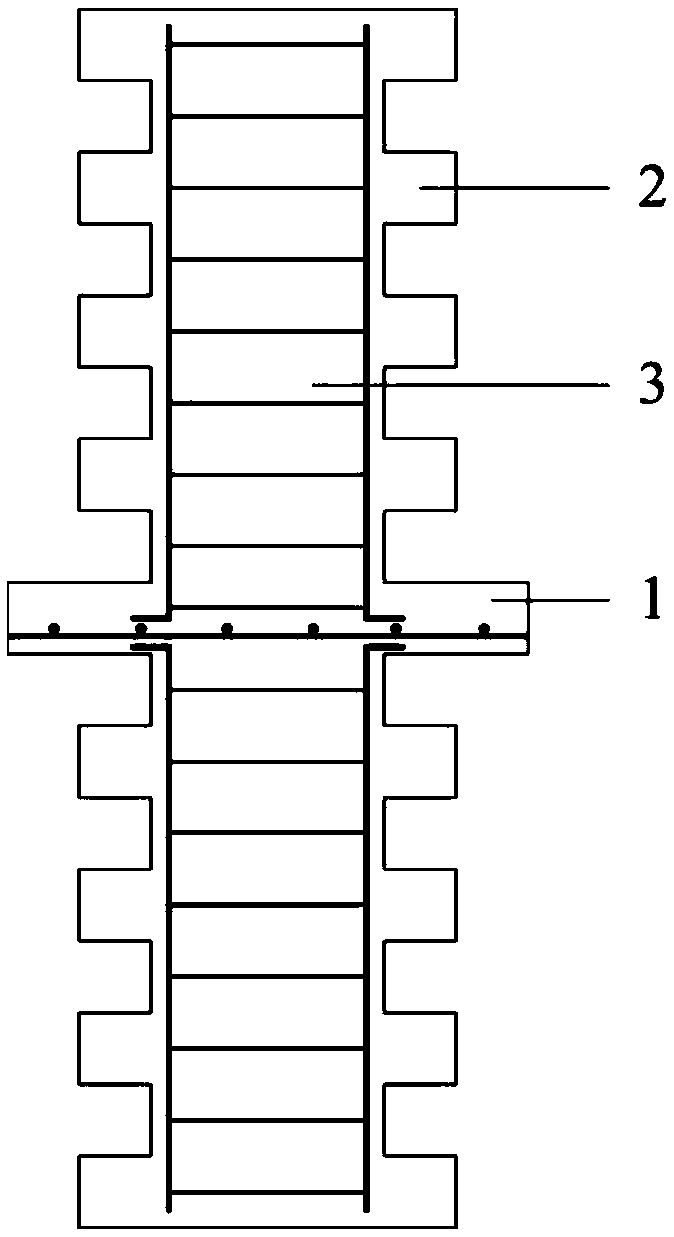

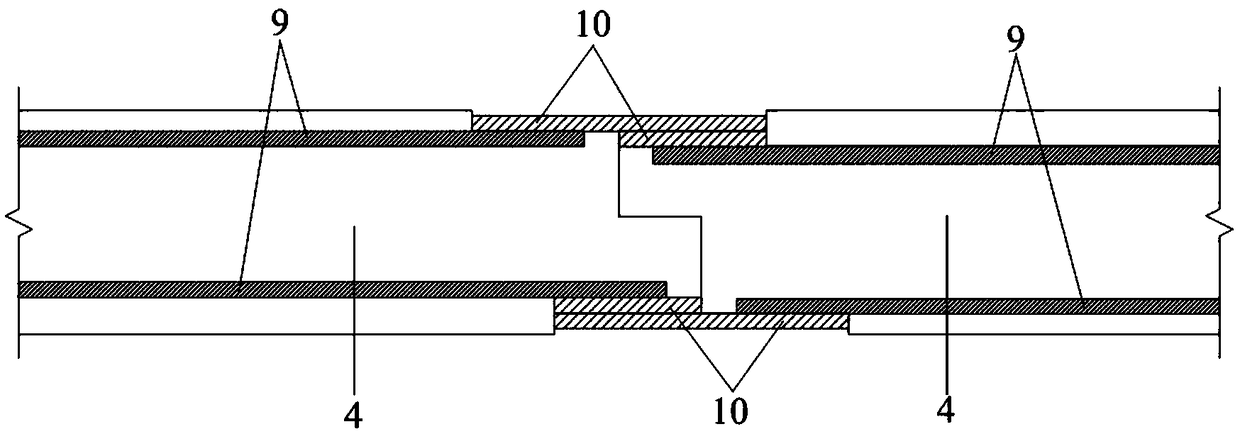

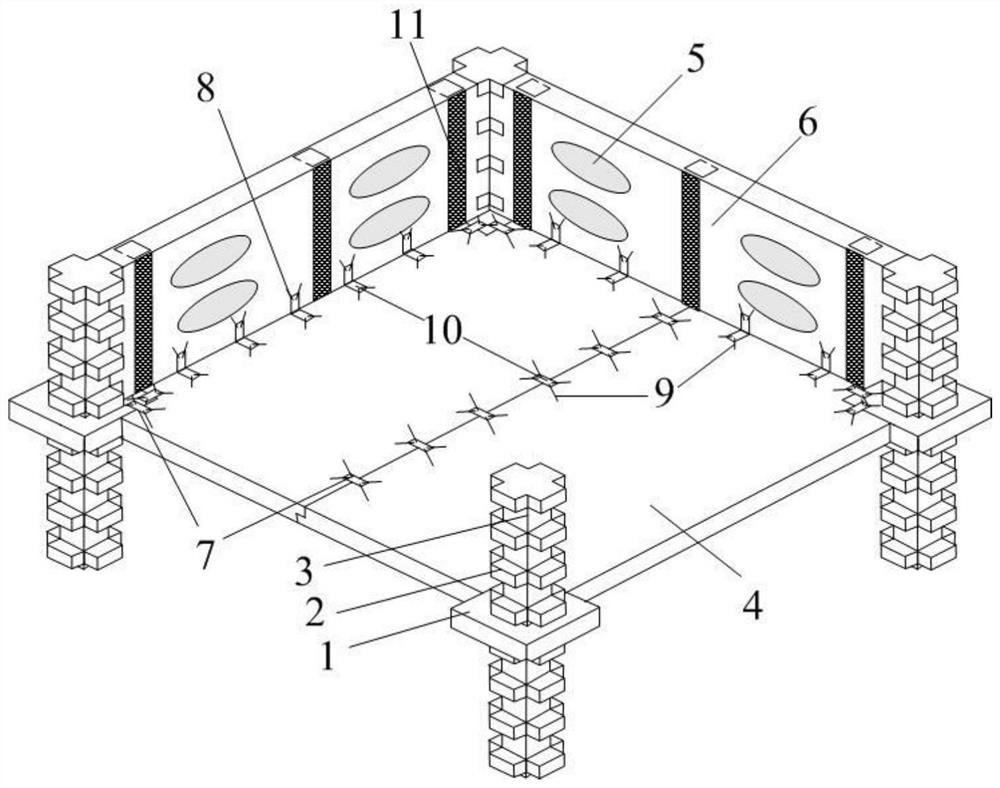

Full-dry-type prefabricated concrete slab column structure system

ActiveCN109440992AImprove seismic performanceEasy and fast constructionFloorsClimate change adaptationCold formedFloor slab

The invention discloses a full-dry-type prefabricated concrete slab column structure system, and belongs to the field of building structure technologies and structural seismic resistance and reduction. The full-dry-type prefabricated concrete slab column structure system comprises prefabricated columns with connecting flat plates and combed joints, prefabricated floor slabs, prefabricated wall plates provided with elliptical holes filled with ECC materials, plate-plate connecting pieces, wall-plate connecting pieces and the like; the prefabricated columns and the connecting flat plates are overall poured, the prefabricated floor slabs are matchboards, the prefabricated wall plates are cold-formed thin-walled steel composite wall plates, and the connecting flat plates, the prefabricated floor slabs and the prefabricated wall plates are connected through the connecting pieces; and the plate-plate connecting pieces and the wall-plate connecting pieces are both composed of anchor plates and anchor bars, poured with components integrally, and anchor plate connecting components are welded on a construction site. According to the full-dry-type prefabricated concrete slab column structuresystem, full-dry-type construction is achieved, wet operation is omitted, construction is easy and convenient, the prefabrication rate is high, the construction efficiency is greatly improved, the cost is low, and the full-dry-type prefabricated concrete slab column structure system has the characteristics of safety, reliability and good seismic resisting performance.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Devices and systems for improved traffic control signal assembly

ActiveUS20160033116A9Avoid structural failureEliminate needLighting support devicesRoad vehicles traffic controlSupporting systemTraffic signal

Owner:TOWNSEND ROBERT E JR

Method and device for detecting stress strength of concrete by bending method

InactiveCN102435499BAvoid damageFew influencing factorsMaterial strength using tensile/compressive forcesEngineeringStress strength

Owner:王文明

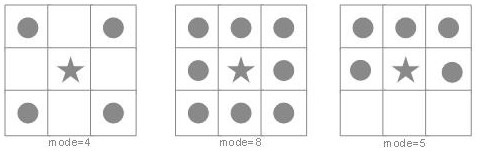

Machine learning-based image recognition algorithm for aviation aluminum alloy surface cracking

PendingCN112016555AAvoid structural failureAvoid failureImage analysisCharacter and pattern recognitionAviationAdaptive filtering algorithm

The invention relates to the technical field of aviation aluminum alloy, in particular to a machine learning-based image recognition algorithm for aviation aluminum alloy surface cracking, which comprises the following steps: S1, processing an image by adopting a semi-supervised learning-based adaptive filtering algorithm; s2, segmenting the image by adopting a morphological processing method, anddetermining the initiation edge of the crack; s3, introducing a morphological concept into a connected algorithm of region growth based on image growth to locate the position of a crack; the method aims at overcoming the defects of poor accuracy and real-time performance of aircraft surface material crack image recognition in the aviation field in the prior art. The crack recognition algorithm ishigh in speed and high in precision, can monitor whether cracks appear on the aluminum alloy material on the surface of the aircraft and the lengths of the cracks in real time, and can prevent aircraft structure failure and reduce safety accidents caused by aircraft surface material failure.

Owner:CIVIL AVIATION UNIV OF CHINA

Conducting bar, junction box for high-voltage doubly-fed wind generator and installation method of junction box

PendingCN112039267ACompact designSmall footprintCoupling device connectionsWindingsElectrical resistance and conductanceElectric machine

The invention belongs to the technical field of high-voltage doubly-fed wind generators, and relates to a conducting bar, a junction box for a high-voltage doubly-fed wind generator and an installation method of the junction box. The conducting bar simultaneously meets the assembly requirements of a motor side and a user cable. According to the junction box, three-phase conducting bars are respectively positioned on an insulating column bracket according to the position layout of the three-phase conducting bars, a distance between every two adjacent conducting bars is more than or equal to 220mm, and every two conducting bars are arranged to be compact and are small in occupied space. When the junction box is installed, a stator leading-out wire freely overhangs in a stator junction box,so on one hand, the bending radius of the stator leading-out wire is ensured, and the use reliability of the cable can be improved; and on the other hand, the insulation resistance of the surface of the cable can be increased by lengthening the effective length of the cable, thereby enhancing the insulation performance of the cable.

Owner:CRRC XIAN YONGE JIELI WIND ENERGY CO LTD

A concrete uniaxial tensile test fixture and test method

ActiveCN112611635BRealize clamping and fixingEnsure tensile fracture surfacePreparing sample for investigationMaterial strength using tensile/compressive forcesStress concentrationArchitectural engineering

The invention provides a concrete uniaxial tensile test fixture and test method, which include two clamp bodies with the same structure, the two clamp bodies are respectively arranged at the two ends of the concrete test piece, and there is a gap between the clamp body and the concrete test piece The specimen clamping part is horizontally embedded in the clamp body; the specimen clamping part is provided with a specimen installation groove, and the clamping end of the concrete specimen is fitted in the specimen installation groove; the concrete specimen The clamping end of the specimen is in close contact with the mounting groove surface of the test piece, and the two sides of the clamping end of the concrete specimen are in contact with the surface of the clamping body; in the present invention, the clamping end of the specimen is in contact with the mounting groove surface of the specimen Close fit, using the geometric constraints of the clamp body and the specimen clamping piece, to achieve the clamping and fixing of the specimen, avoiding the local stress concentration at the clamping end of the concrete specimen, and reducing the occurrence of cracks and slowing at the clamping end of the specimen. Variable and other additional damage ensures that the tensile fracture surface occurs in the middle of the specimen, improving the reliability and stability of the test process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

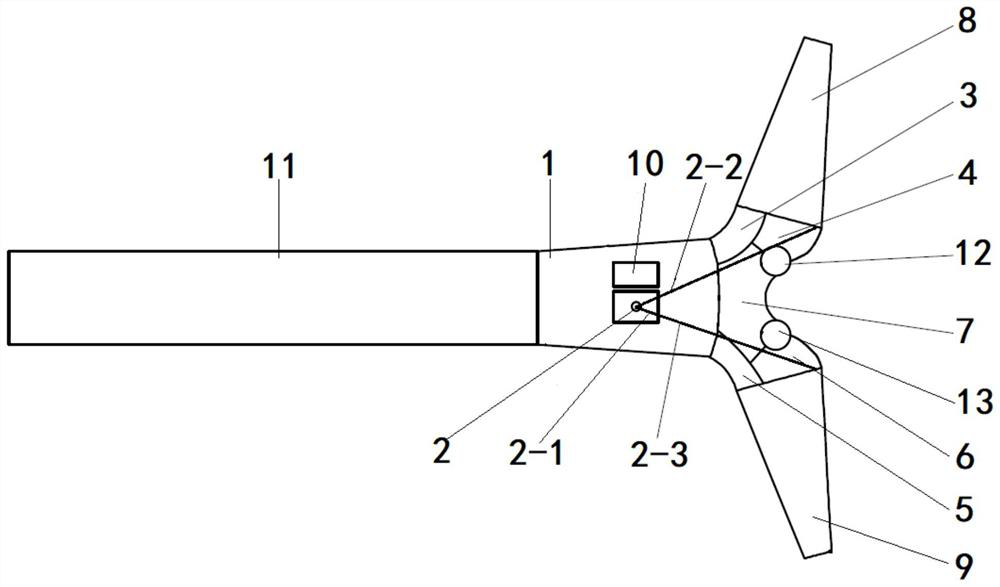

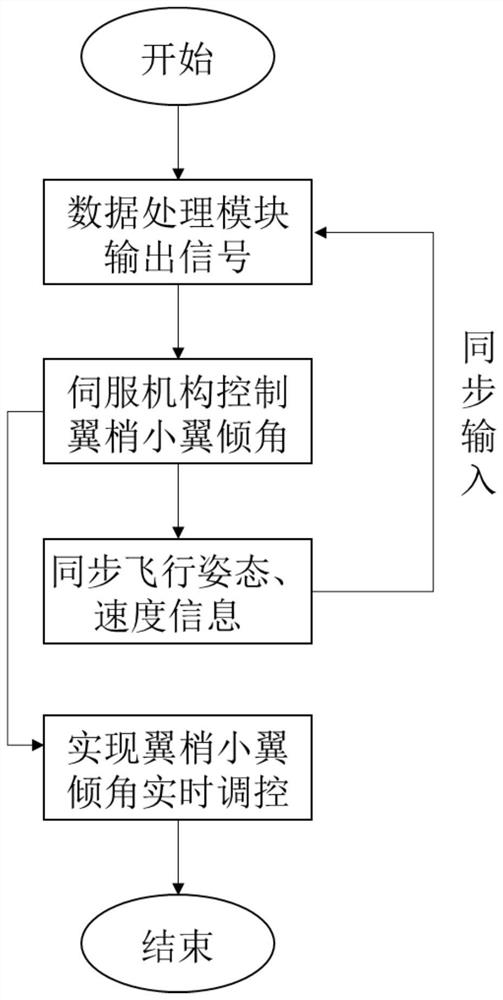

Double-feather winglet device with variable inclination angle

ActiveCN113306698AIncrease flexibilityStrong penetrating powerWing adjustmentsDrag reductionFree flightFlight vehicle

The invention discloses a double-feather winglet device with a variable inclination angle, and belongs to the technical field of aircraft devices. A winglet base is connected with the wing spanwise tail end of an aircraft through a wing transition section; a first winglet and a second winglet are arranged at the two sides of the winglet base respectively. The first winglet and the second winglet are connected with the wing transition section through a flexible connection section, and connected with a rigid connection section, and the rigid connection section is hinged to the winglet base; a servo transmission system is connected with a control system, and the servo transmission system is connected with the first winglet and the second winglet; and the control system is in communication connection with an aircraft control center. The double-feather winglet device does not generate extra additional force during attack-angle-free flight, is suitable for various wing layouts, can adjust the inclination angles of the first winglet and the second winglet in real time according to flight parameters of an aircraft, reduces the influence of wingtip vortexes, improves the flexibility and penetration performance of the aircraft, a and is suitable for executing maneuvering complex flight missions.

Owner:XI AN JIAOTONG UNIV

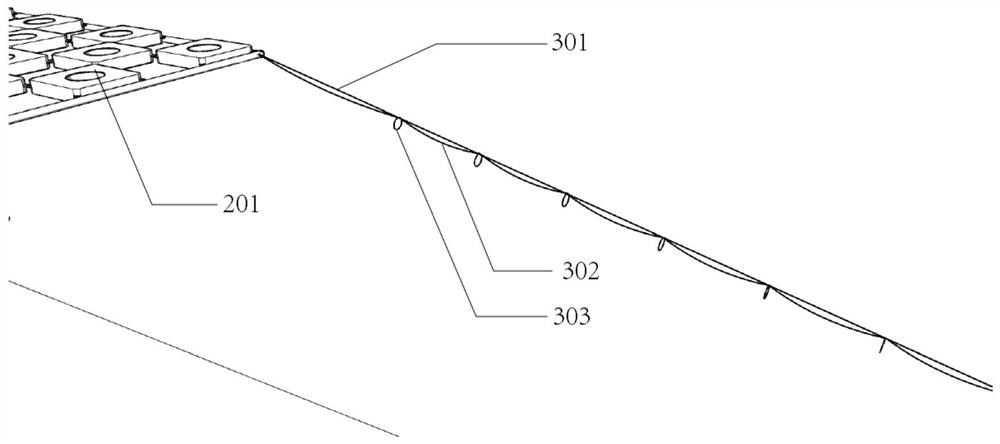

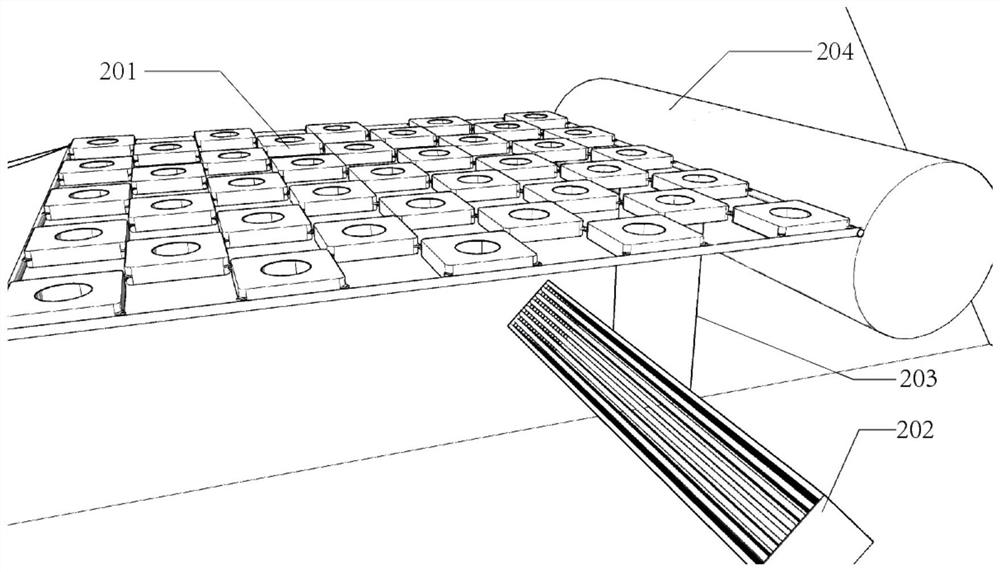

Ecological river floating bed system

ActiveCN113264635AImprove purification effectReduce lossesSpecific water treatment objectivesBiological treatment apparatusMicroorganismWater storage

The invention discloses an ecological river floating bed system which comprises a channel foundation part and a purification device. The end face of the channel foundation part is in an isosceles trapezoid shape, the upper end opening is large, and the lower end is tightened. The channel foundation part is sequentially divided into a water stopping section, a washing section, a uniform flowing section and a silting section in the water flow direction. A micro water retaining dam is arranged between the water stopping section and the scouring section; the bottom surface of the washing section is sunken downwards to form a water storage pit; the purification device comprises a plant floating bed and an iron-carbon purification device, the purification device is connected with the channel foundation part through a first connecting rope, and the purification device is located at the downstream of the micro retaining dam; the plant floating bed is connected with the iron-carbon purification device through a second connecting rope, and the balance iron-carbon purification device is located below the plant floating bed; and floaters are arranged on the plant floating bed. And water purification plants are planted in water purification plant planting baskets of the plant floating bed. The nitrogen and phosphorus polluted water body is gradually digested under the action of plants, microorganisms and iron-carbon micro-electrolysis, and the purification effect is very good.

Owner:HOHAI UNIV

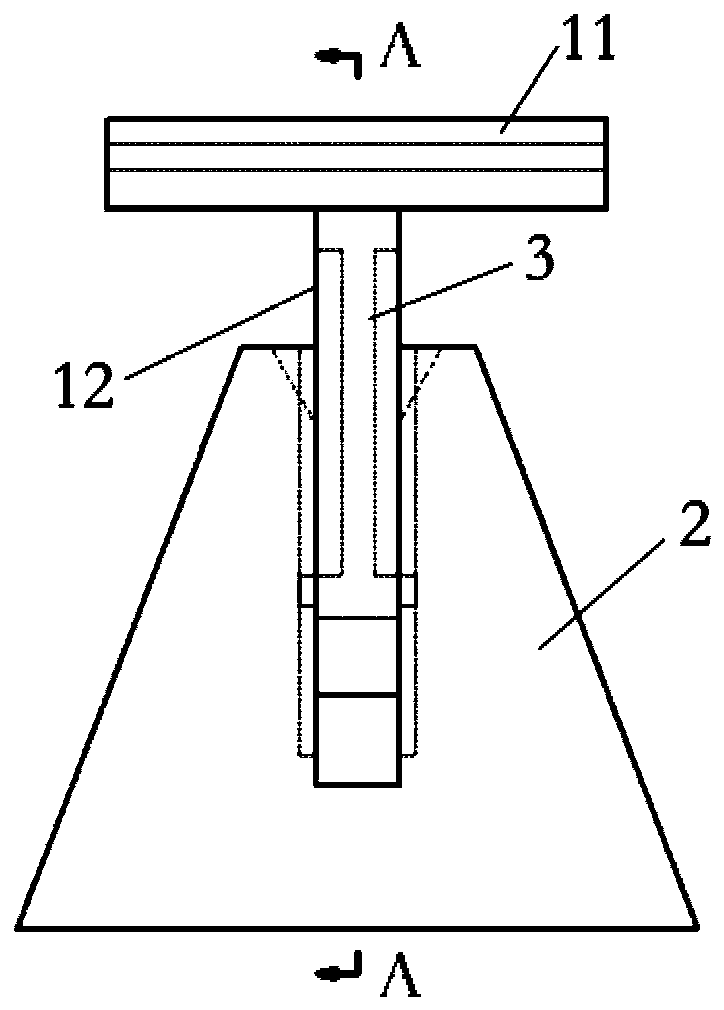

Beam-rail integrated structure and medium-low speed maglev track beam with same

PendingCN109235168ALower the altitudeImprove transfer efficiencyRailway tracksLow speedConcrete beams

The invention discloses a beam-rail integrated structure, which comprises an f rail and a concrete beam, wherein the f rail is arranged between the f rail and the concrete beam (1); the connecting device comprises parallel and perpendicular to the concrete beam (1) is arranged on the top of the concrete beam or pre-buried in the concrete beam (1) a first connecting piece and a second connecting piece, wherein the first connecting piece is used for fixing the f rail and the first connecting piece. The invention further discloses a medium and low speed magnetic levitation track beam with the beam and rail integrated structure. According to the beam and rail integrated structure, the height of the whole rail beam structure is greatly reduced, the motion of a vehicle body borne by the f rail and the like are directly transmitted through an integrated structure of the beam and rail, and the curve ultrahigh-section beam. The rail integrated structure directly bears the transverse shearing acting force caused by inclination of the rail, so that not only is the rail improved, but also the rail. The force transmission efficiency of the beams is improved, and the structure faults among the rail beams caused by the load action are effectively avoided.

Owner:CHINA RAILWAY MAGLEV TRANSPORTATION INVESTMENT CONSTR CO LTD

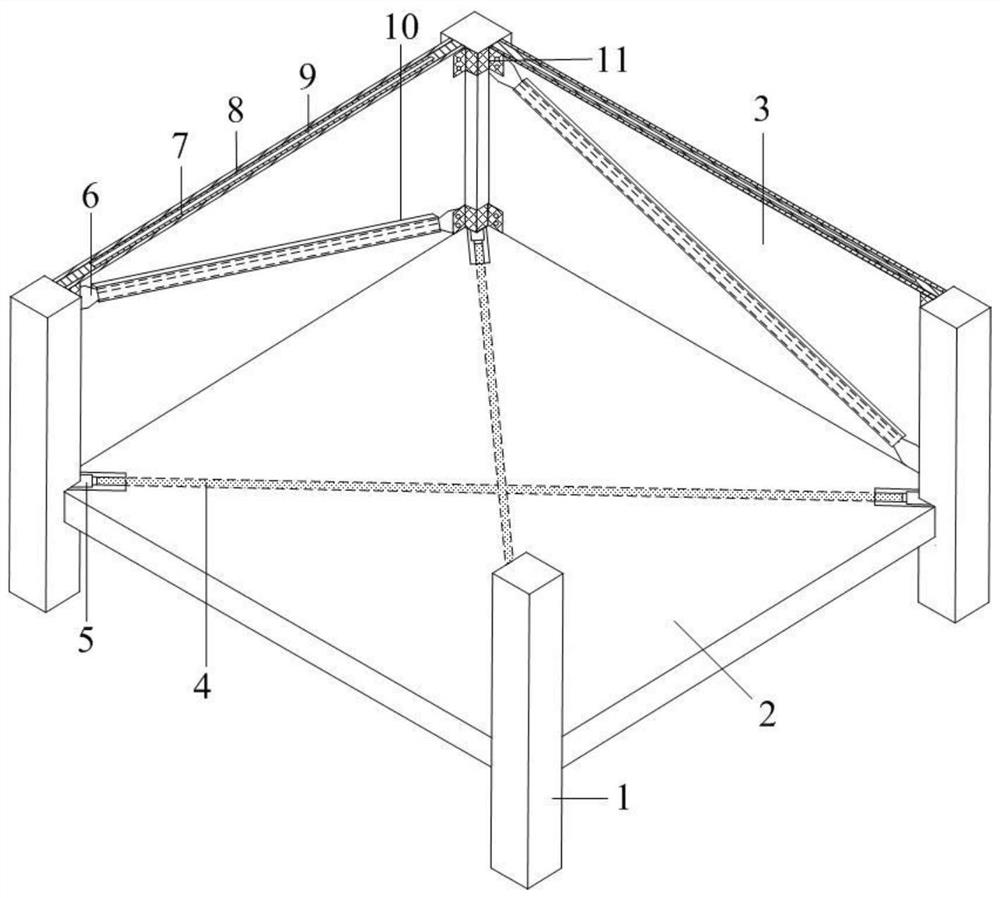

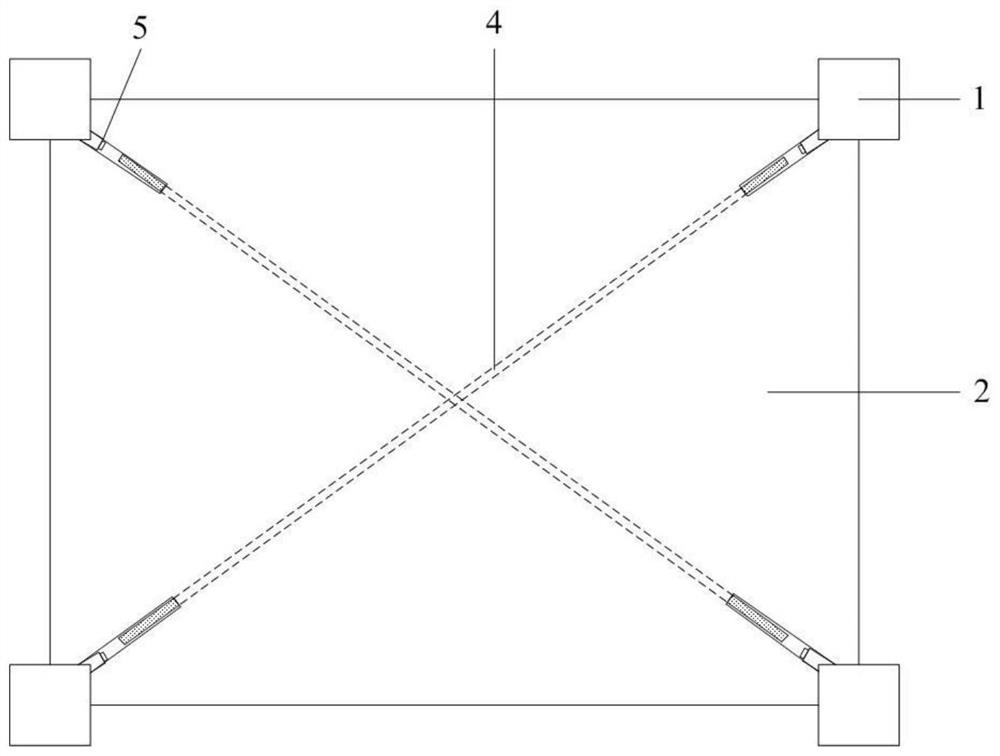

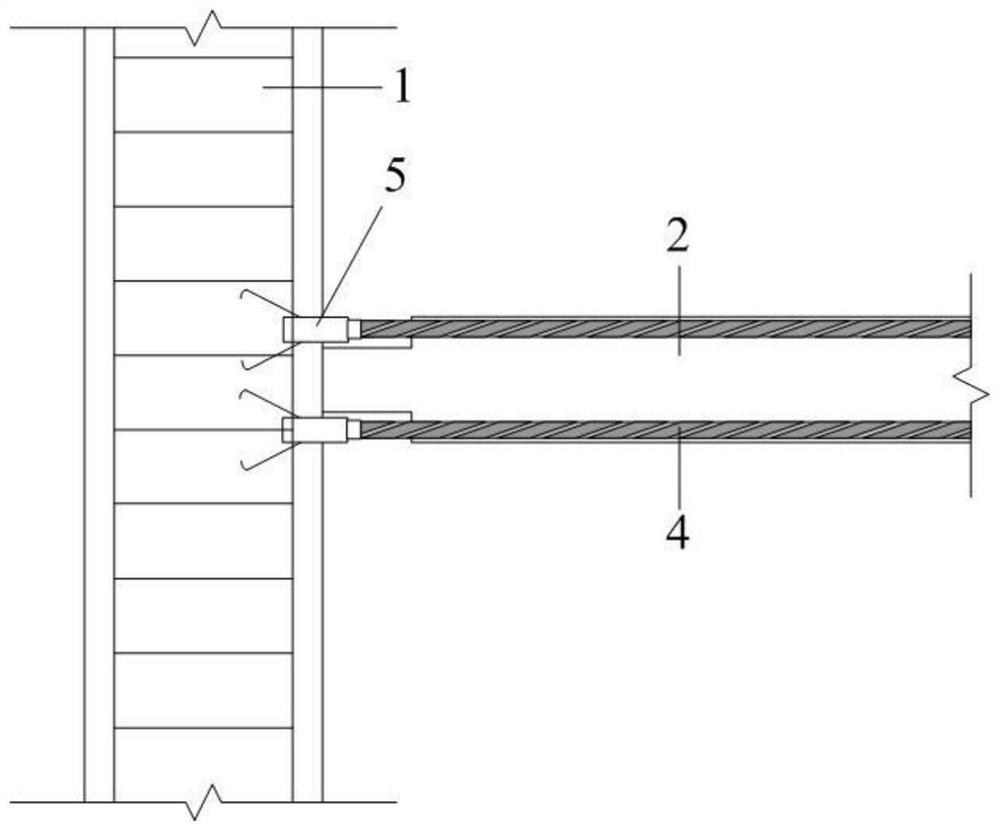

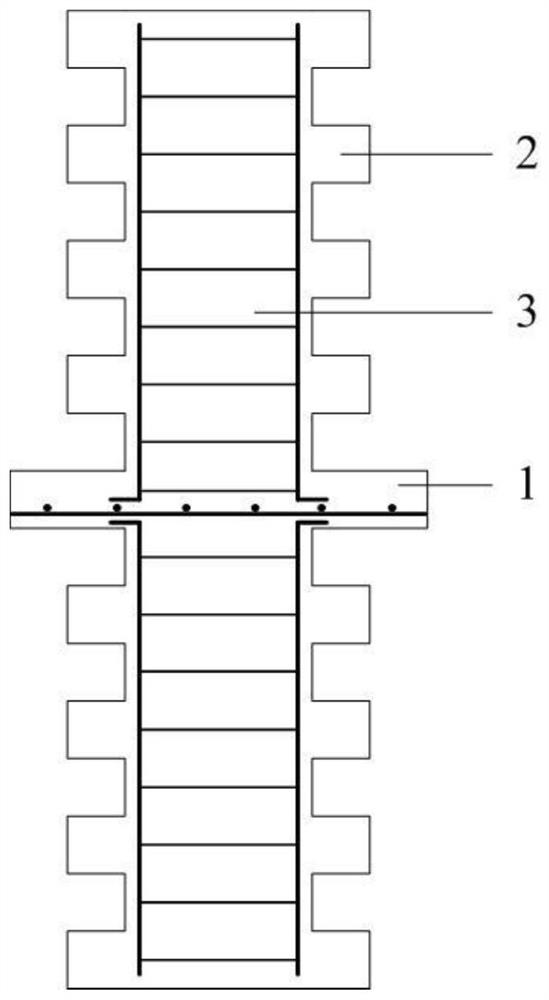

A fabricated slab-column system using prestressed steel rods and inner core curved buckling-resistant bracing

ActiveCN109235733BAvoid pollutionShort maintenance timeFloorsProtective buildings/sheltersFloor slabPre stress

The invention discloses an assembly type slab column system adopting prestressed steel bars and inner core bending type buckling-restrained braces, and belongs to the field of building structure technology and structure seismic shock absorption. The system mainly comprises precast columns, precast floor slabs, precast wall boards, the prestressed steel bars for concrete, prestressed anchors, the inner core bending type buckling-restrained braces, heat-preservation and sound-insulation wall boards, external wall boards, gaps between the inner core bending type buckling-restrained braces and theheat-preservation and sound-insulation wall boards, column-wall connecting pieces and the like. The prestressed anchors arranged on the column corners, the prestressed steel bars for concrete are arranged in prestressed ducts in the precast floor slabs, and slab column joints are connected with the prestressed anchors through the prestressed steel bars for concrete. The inner core bending type buckling-restrained braces are arranged in the precast wall boards, the anti-lateral rigidity and bearing capacity of the structure are improved, and meanwhile the system energy-dissipating capacity isenhanced. Accordingly, all dry type construction is achieved, wet method operation is omitted, construction is easy, the prefabricated rate is high, the slab column joint is stable and reliable, and the structural system anti-seismic property is good.

Owner:BEIJING UNIV OF TECH

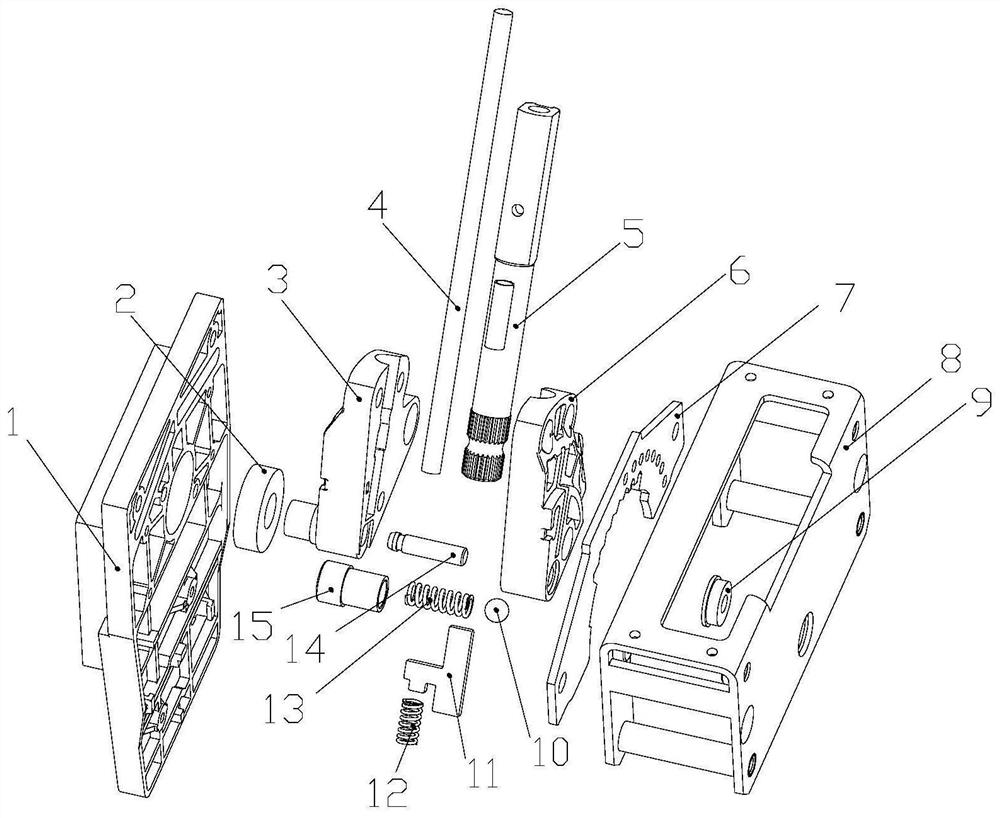

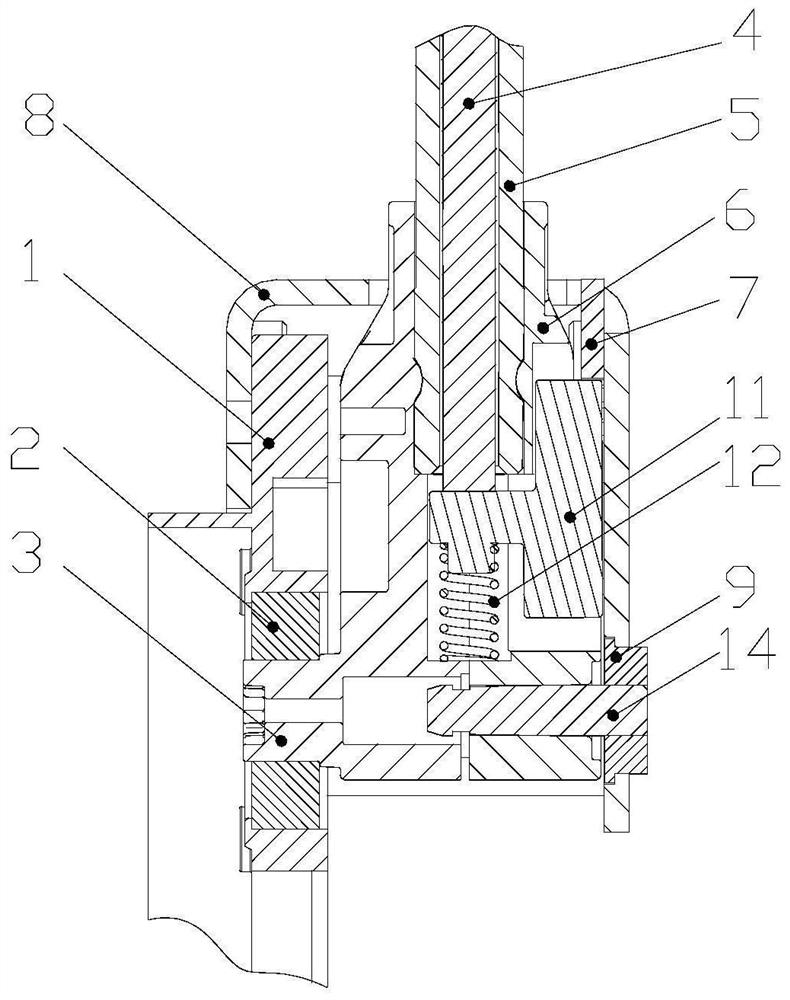

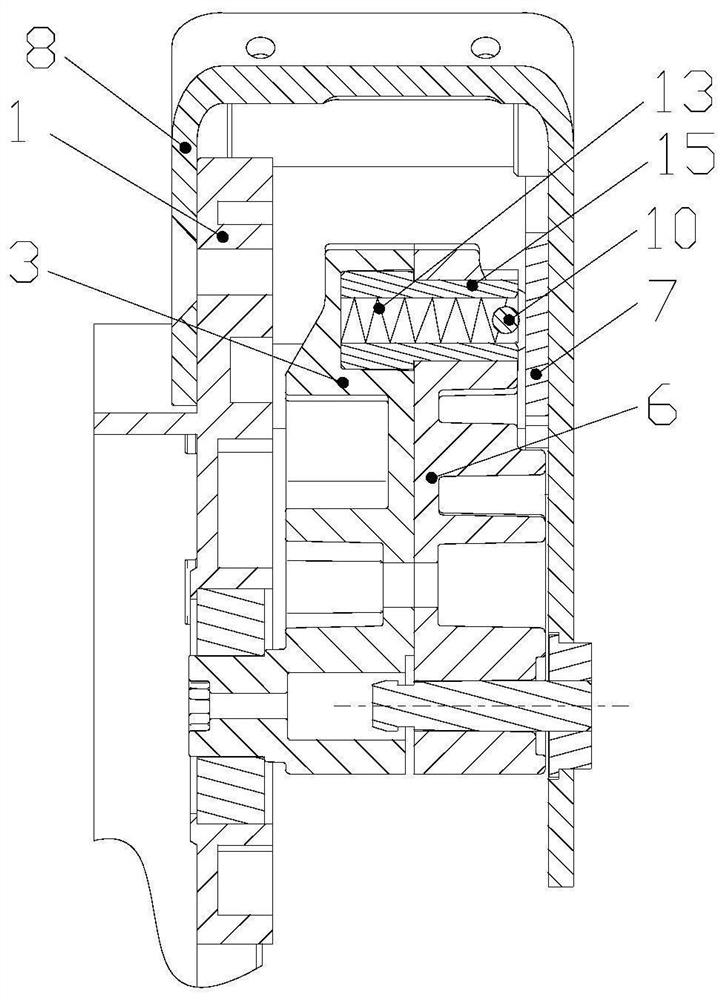

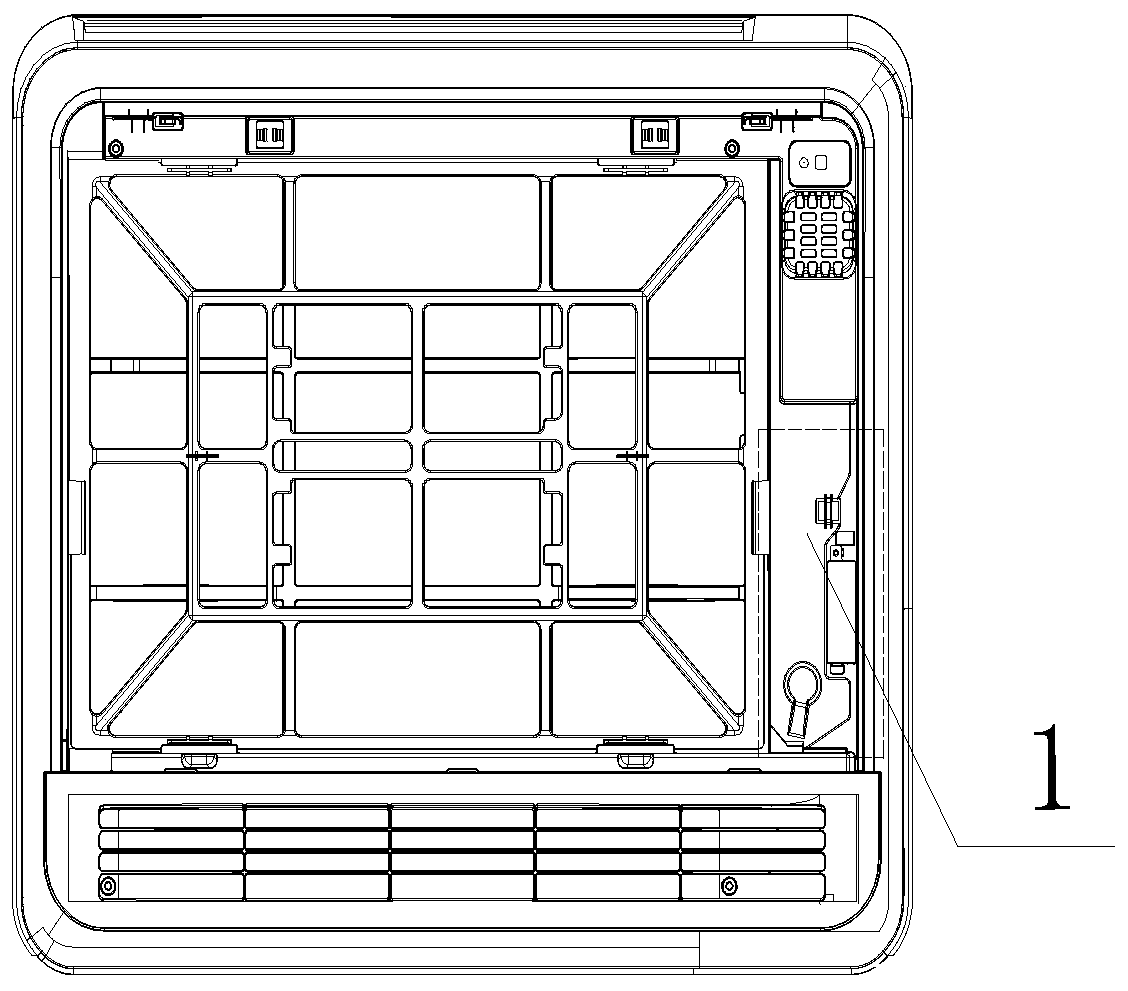

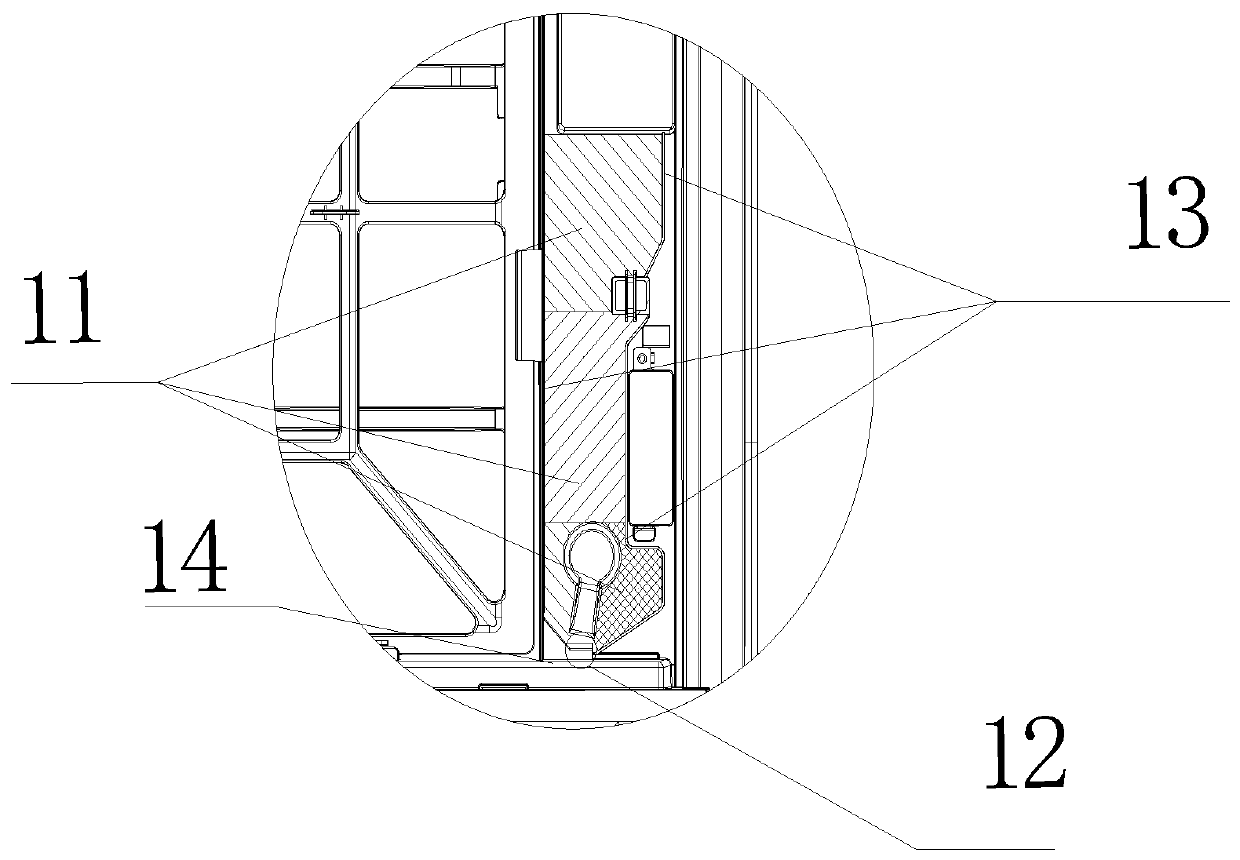

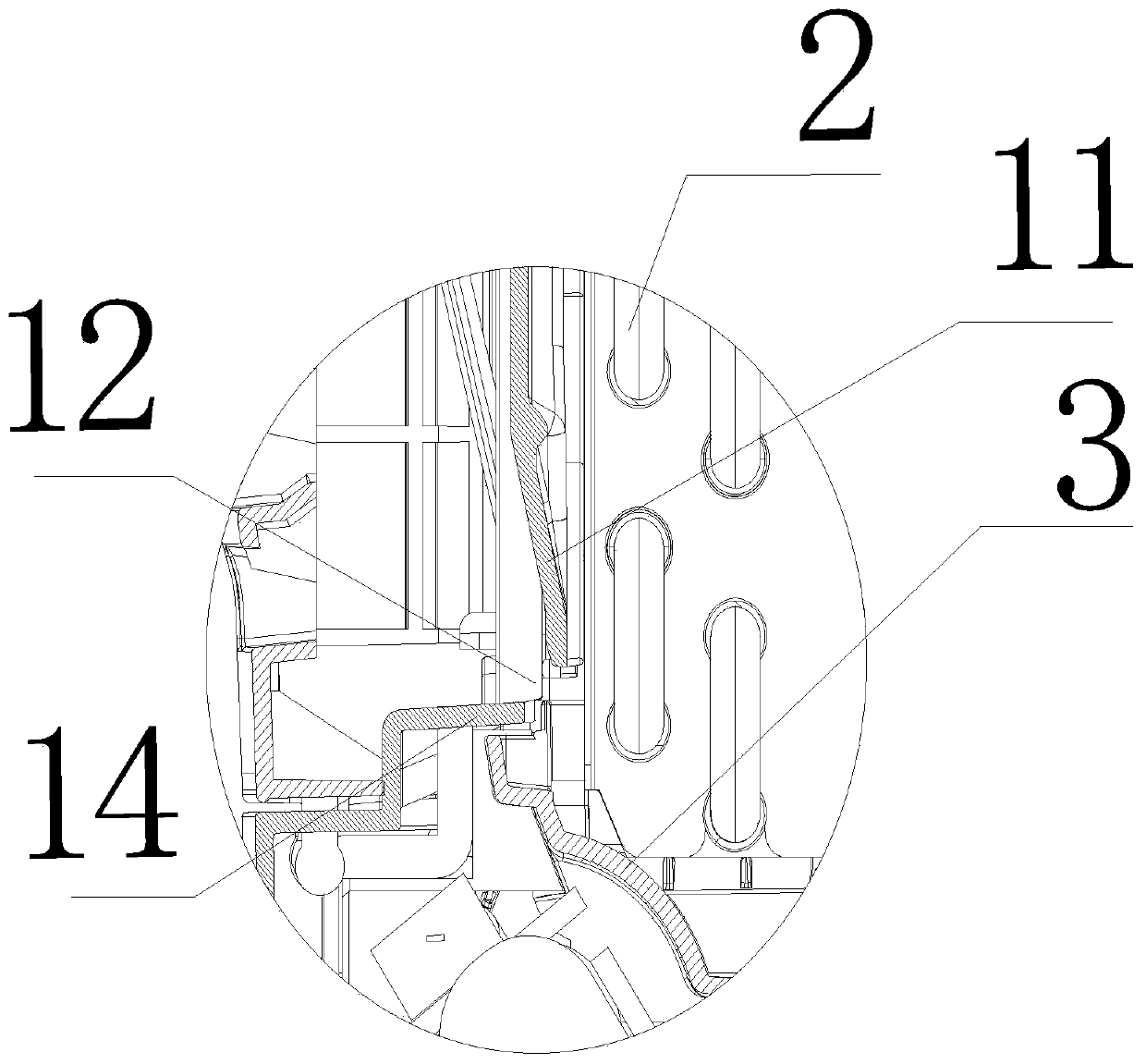

High-reliability gear shifter core device

The invention discloses a high-reliability electronic gear shifter core structure. The high-reliability electronic gear shifter core structure comprises a support, a side plate, a tooth-shaped plate and a gear shifting assembly; the gear shifting assembly comprises a left gear shifting block, a gear shifting rod, a right gear shifting block, a steel ball, a locking plate, a locking spring, a gear spring and a sleeve; and the gear shifting rod is clamped and fixed through the left gear shifting block and the right gear shifting block, a cylindrical boss of the left gear shifting block is in close fit with an inner round hole of a large bearing, a pin shaft hole of the right gear shifting block is in close fit with a pin shaft, and the pin shaft is in close fit with an inner round hole of a small bearing. The locking spring and the locking piece slide in inner cavities of the left gear shifting block and the right gear shifting block, the steel ball and the gear spring move in an inner circular hole of the sleeve and are in sliding connection with the tooth-shaped plate, and an unlocking rod slides in the gear shifting rod. The gear shifting operation hand feeling is enhanced, the service life of a gear shifter is prolonged, the use strength and the structural reliability of the gear shifter are improved, and the misoperation risk is avoided through the locking function.

Owner:NANJING AOLIAN AE&EA

Method for manufacturing structure of semiconductor device

ActiveCN102386127BAvoid structural failureImprove yield rateSemiconductor/solid-state device manufacturingBit lineEngineering

The invention provides a method for manufacturing the structure of a semiconductor device, which comprises the steps of: providing a front-end device layer structure, wherein the front-end device layer structure is provided with liners and grid electrode structures positioned above the liners, the liner at two sides of each grid electrode structure is internally provided with active regions, the surface of the liner is sequentially provided with an etching stopping layer, an interlayer medium layer and a patterned mask film layer, the patterned mask film layer is provided with a first opening which correspondingly needs to manufacture a bit line contact hole, and the surface of the interlayer medium layer is exposed out of the first opening; firstly etching the interlayer medium layers under the first openings by the means that the patterned mask film layers are taken as mask films, and secondly etching the residual interlayer medium layers, so that the interlayer medium layers are wholly removed, and the active regions and the etching stopping layers above the grid electrode structures are exposed; and thirdly etching the exposed etching stopping layers, so that the exposed etching stopping layers are wholly removed, and the bit line contact holes are formed. The method guarantees the contact holes to have ideal appearance outlines.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A fully dry prefabricated concrete slab-column structure system

ActiveCN109440992BReduce typesImprove prefabrication rateClimate change adaptationFloorsEarthquake resistanceFloor slab

The invention discloses a full-dry-type prefabricated concrete slab column structure system, and belongs to the field of building structure technologies and structural seismic resistance and reduction. The full-dry-type prefabricated concrete slab column structure system comprises prefabricated columns with connecting flat plates and combed joints, prefabricated floor slabs, prefabricated wall plates provided with elliptical holes filled with ECC materials, plate-plate connecting pieces, wall-plate connecting pieces and the like; the prefabricated columns and the connecting flat plates are overall poured, the prefabricated floor slabs are matchboards, the prefabricated wall plates are cold-formed thin-walled steel composite wall plates, and the connecting flat plates, the prefabricated floor slabs and the prefabricated wall plates are connected through the connecting pieces; and the plate-plate connecting pieces and the wall-plate connecting pieces are both composed of anchor plates and anchor bars, poured with components integrally, and anchor plate connecting components are welded on a construction site. According to the full-dry-type prefabricated concrete slab column structuresystem, full-dry-type construction is achieved, wet operation is omitted, construction is easy and convenient, the prefabrication rate is high, the construction efficiency is greatly improved, the cost is low, and the full-dry-type prefabricated concrete slab column structure system has the characteristics of safety, reliability and good seismic resisting performance.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Water guide structure of air conditioner panel

InactiveCN110530002ASimple designAvoid savingsCondensate preventionLighting and heating apparatusEngineeringCondensed water

The invention discloses a water guide structure of an air conditioner panel. The water guide structure comprises a condensate water plate, water guide ribs, water guide ports and a bottom barrier strip. The condensate water plate is an area, close to the condensation pipeline, on the air conditioner panel; the water guide ribs are arranged on the left side and the right side of the condensate water plate; the water guide ports are formed between the left side and the right side of the water guide ribs and communicated with the water pan; the bottom barrier strip is arranged on the lower side of the water guide ports and tilts upwards by a certain angle. When the water guide structure of the air conditioner panel is used, the condensate water plate on the air conditioner panel can generatecondensate water under the action of the condenser; under the combined action of gravity and surface tension, condensed water starts to flow; no matter which path the condensed water flows along, thecondensed water is limited in the condensate water plate by the water guide ribs and finally gathered on the bottom barrier strip, and the condensed water is introduced into the water guide ports under the upwarping design of the bottom barrier strip and finally flows into the water pan, so that the drainage process of the condensed water is completed, the subsequent problem caused by condensed water accumulation is avoided, and the problem caused by sponge falling off is avoided.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com