Full-dry-type prefabricated concrete slab column structure system

A prefabricated assembly, slab-column structure technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of structural failure, long construction period of wet connection, etc., achieve high prefabrication rate, excellent seismic performance, simple and fast construction project Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

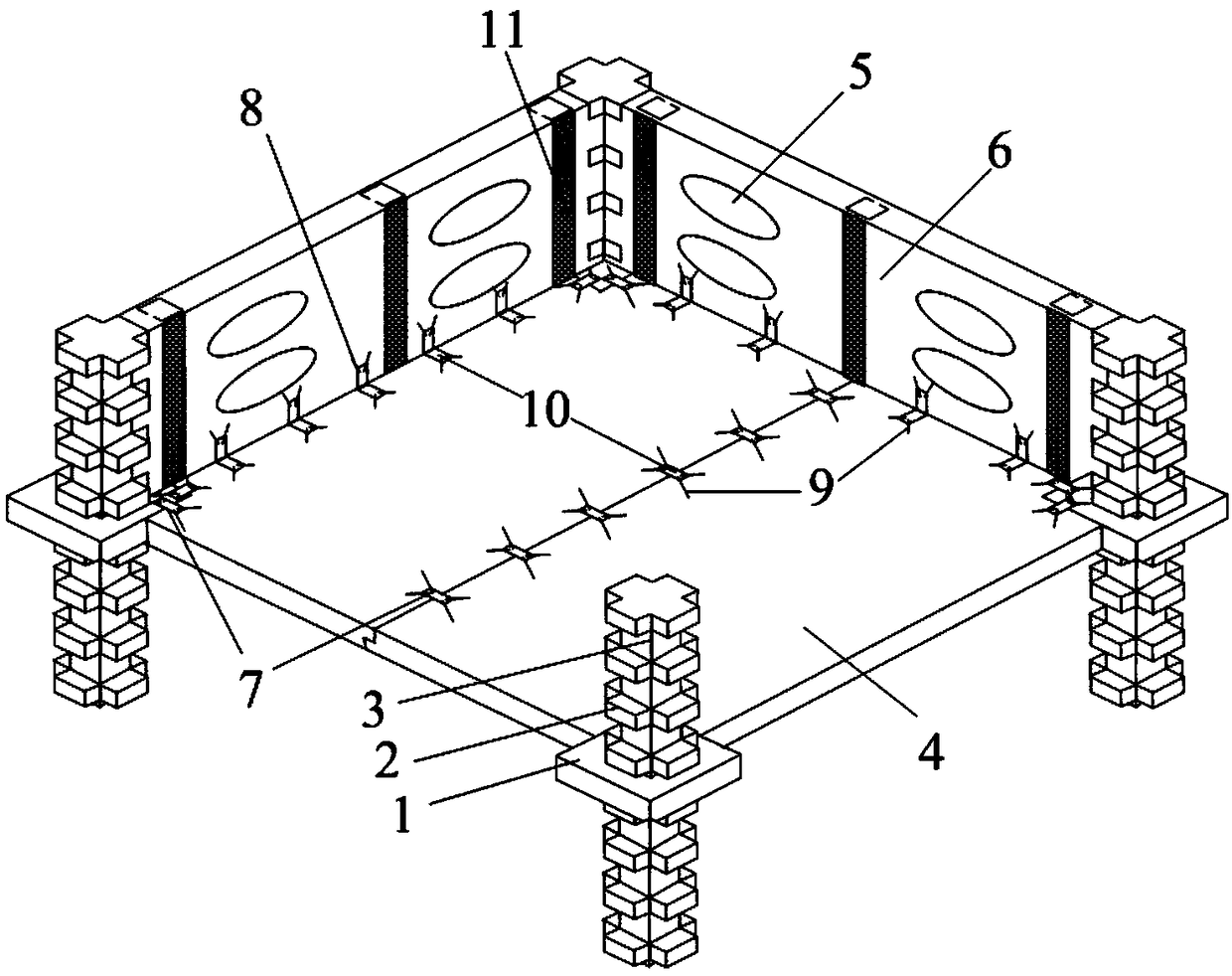

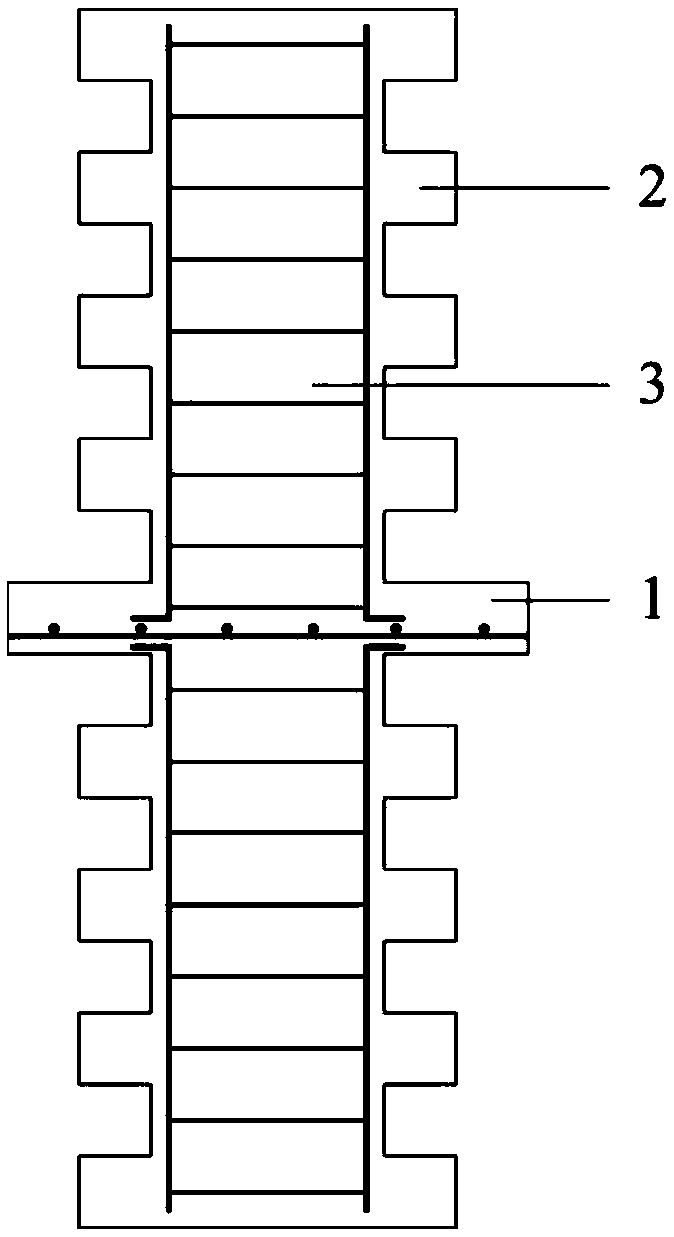

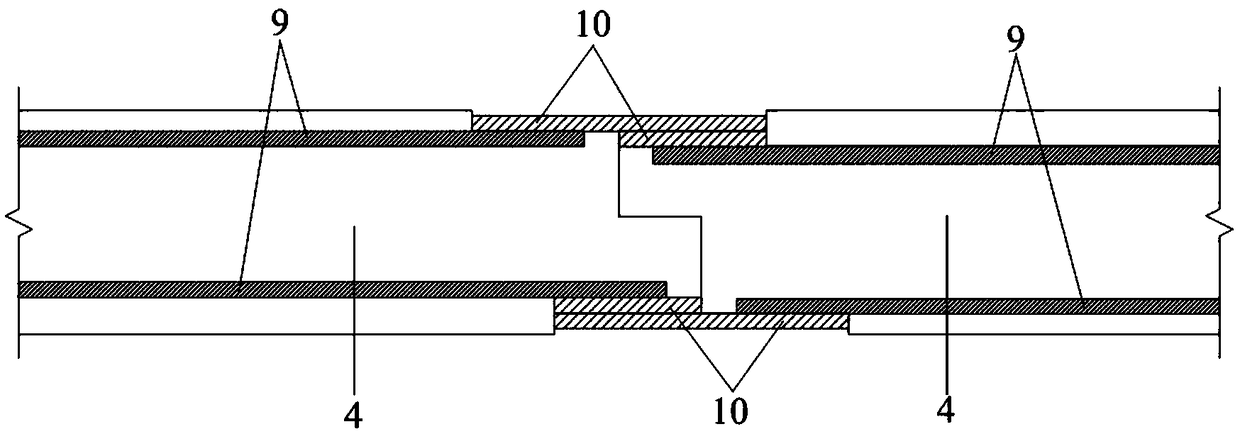

[0036] A fully dry prefabricated concrete slab-column structure system, with prefabricated columns 3 connecting slabs 1, prefabricated floor slabs 4 and prefabricated wall panels 6 are all prefabricated and connected by slab-slab connectors 7 and wall-slab connectors 8 In this way, a whole is formed and a dry connection is realized. The connecting parts are all welded by the anchor plate 10 to realize the connection function. The force transmission is reliable and the construction is simple and fast, which reduces the workload on site, avoids the concrete curing time, and grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com