Machine learning-based image recognition algorithm for aviation aluminum alloy surface cracking

An aluminum alloy surface and machine learning technology, applied in the field of image recognition algorithms based on machine learning, can solve problems that do not meet the real-time requirements in the aviation field, are easily ignored, and have a large time cost, so as to prevent aircraft structure failure and reduce Security incidents, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

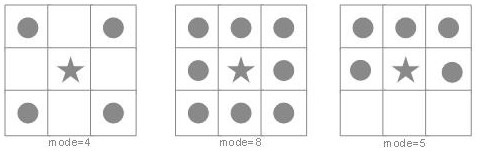

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to figure 1 , an image recognition algorithm based on machine learning for surface cracking of aerospace aluminum alloys, including the following steps:

[0019] S1. Use an adaptive filtering algorithm based on semi-supervised learning to process the image, which specifically includes two parts of learning content: the first learning process, firstly filter every 50 gray values from 0-255, and compare To analyze all the learning results and determine the best gray value interval, we use 500 samples, of which 200 are used as learning samples and 300 are used as testing samples. Divide 255 pixels equally every 50 pixels into 52 gray values, 0, 50, 100, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com