Patents

Literature

36results about How to "Sure break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

GH3600 alloy fine thin-walled seamless pipe manufacturing method

The invention relates to a GH3600 alloy fine thin-walled seamless pipe manufacturing method, which comprises: adopting methods of vacuum induction smelting and electroslag remelting smelting to smelt a casting ingot meeting requirements; adopting a 2000 or 4000 ton rapid forging and 1300 ton radial forging thermal combined forging process to carry out cogging on the casting ingot so as to ensure complete crushing of the thick and large structure of the casting ingot, produce the round pipe billet with the uniform structure, increase the plasticity of material, and saves energy consumption; adopting a hot extrusion process to produce a lateral so as to ensure the uniformity of the internal structure of the lateral and the high quality of the external surface of the lateral, and make the performance of the produced finished product pipe excellent; and adopting a multi-pass cold rolling and cold drawing process and the matched heat treatment process, and assistedly adopting the special lubrication process and the cleaning process to control the structure and the high performance of the pipe so as to finally obtain the GH3600 alloy fine thin-walled pipe with characteristics uniform and fine pipe structure and high comprehensive performance.

Owner:宝武特种冶金有限公司

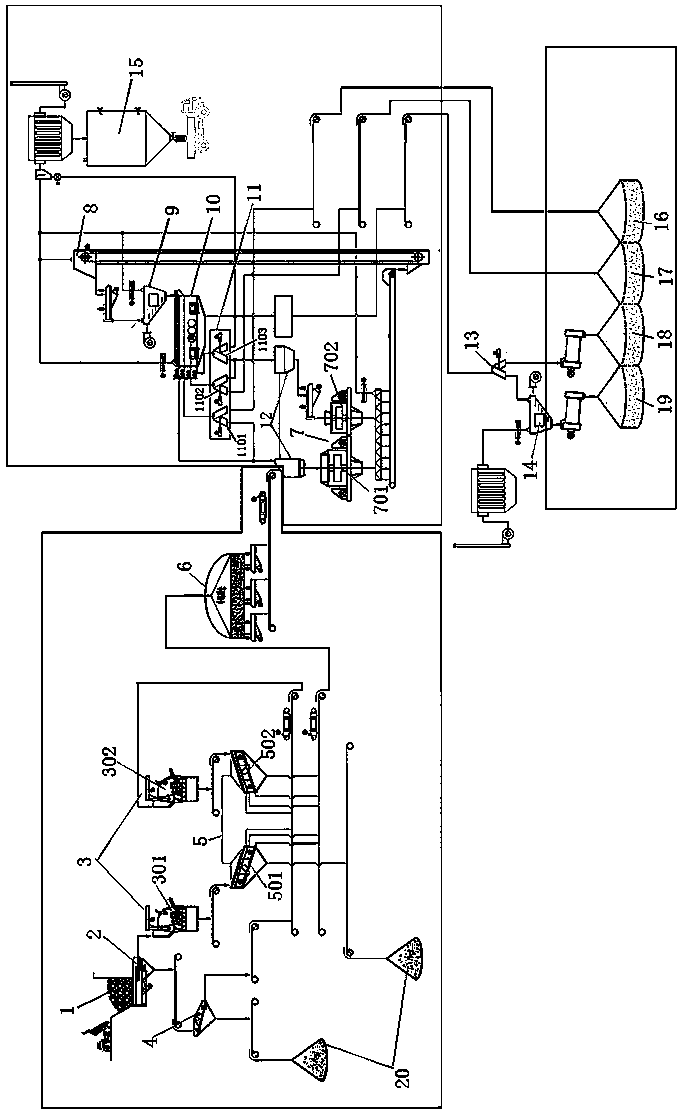

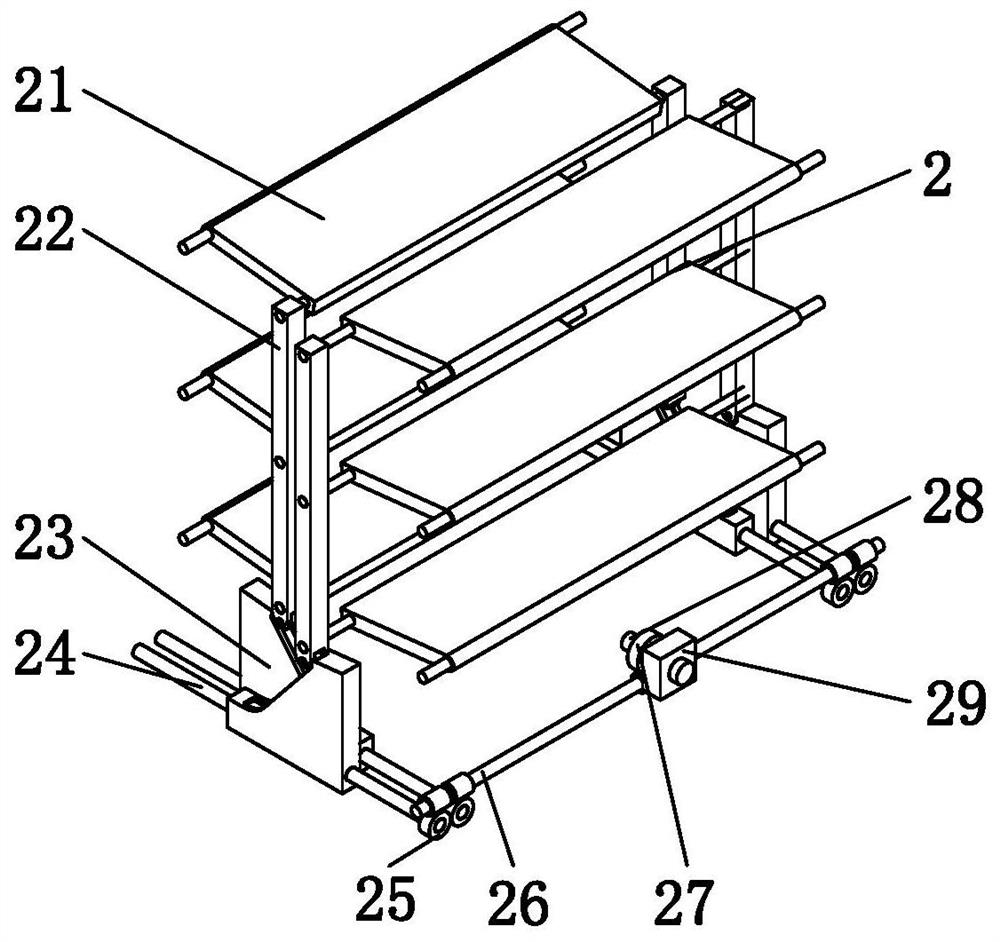

Five-double full-dry method crushing production line and processing method for high-quality sandstone aggregates

PendingCN109731661AGuaranteed cleanlinessGuaranteed growthGrain treatmentsSolid waste managementProduction linePre treatment

The invention discloses a five-double full-dry method crushing production line and processing method for high-quality sand aggregates. The production line comprises a material pretreatment system. A discharge port of the material pretreatment system is connected with a feed port of double-impact crushing equipment of a fine coarse aggregate processing system, a discharge port of the material pretreatment system is connected with a primary classifier, and a discharge port of the primary classifier is connected with a finished product screening and proportion adjusting circulation system. A super-particle-size material outlet of the finished product screening and proportion adjusting circulation system is circularly connected to a feed inlet of double-speed double-frequency crushing sand making equipment. The fine sand aggregates are connected to corresponding finished product bins or are circularly connected to the feed inlet of the double-speed double-frequency crushing sand making equipment, and multi-stage powder selecting equipment is arranged below a fine sand outlet. According to the production line, the production line with multi-stage desliming, double-countering-impact crushing, double-vertical-shaft impact crushing shaping sand making, multi-stage powder selecting and multi-stage circulation is adopted, so that the system productivity and the quality of the finished sand aggregates are improved effectively, the efficient and energy-saving effects are realized, and the practicability is high.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

Manufacturing method for UNSN08810 iron-nickel-base alloy large-diameter seamless pipe for high temperature heating furnace

Disclosed is a manufacturing method for a UNSN08810 iron-nickel-base alloy large-diameter seamless pipe for a high temperature heating furnace. The manufacturing method comprises the following steps that firstly, a square ingot which meets requirements is directly continuous-casted by using an electric arc smelting method, then the square ingot is cogged, then a hollow billet is produced by usinga hot piercing process, finally, through a cold machining process, a matched heat treatment process and a supplemented pipe surface treatment process, and the texture of the pipe is controlled to be uniform, so that the pipe has high performance and high surface quality. The microscopic structure of the pipe is isometric crystal, the grain size is 3-5 grades, the tensile properties of a finished pipe at room temperature are that the tensile strength is equal to or greater than 500 MPa, the yield strength is equal to or greater than 210 MPa, and the elongation is equal to or greater than 50%, and the tensile properties at 650 DEG C are that the tensile strength is equal to or greater than 400 MPa, the yield strength is equal to or greater than 120 MPa, and the elongation is equal to or greater than 50%.

Owner:宝武特种冶金有限公司

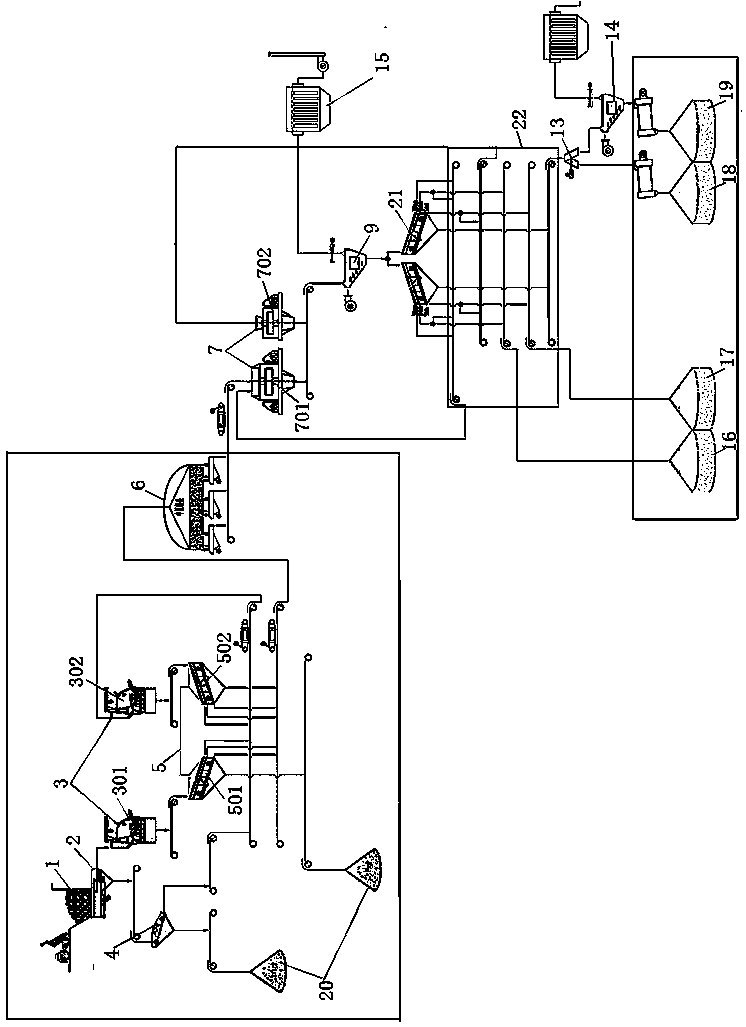

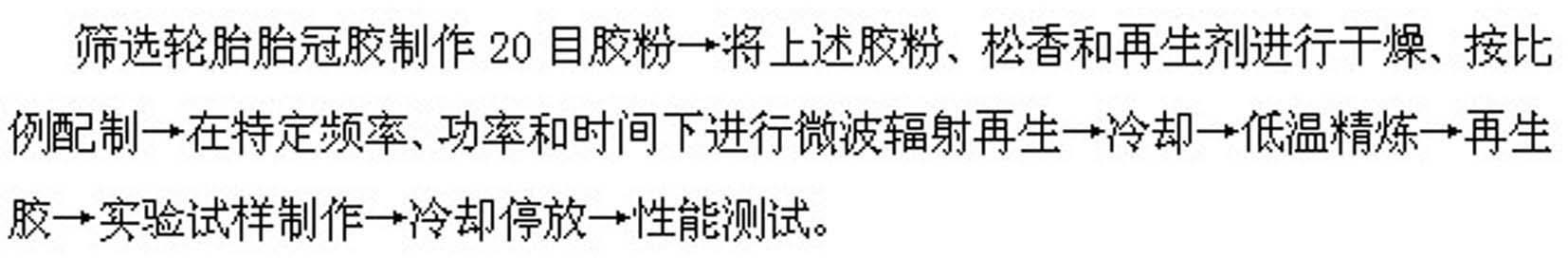

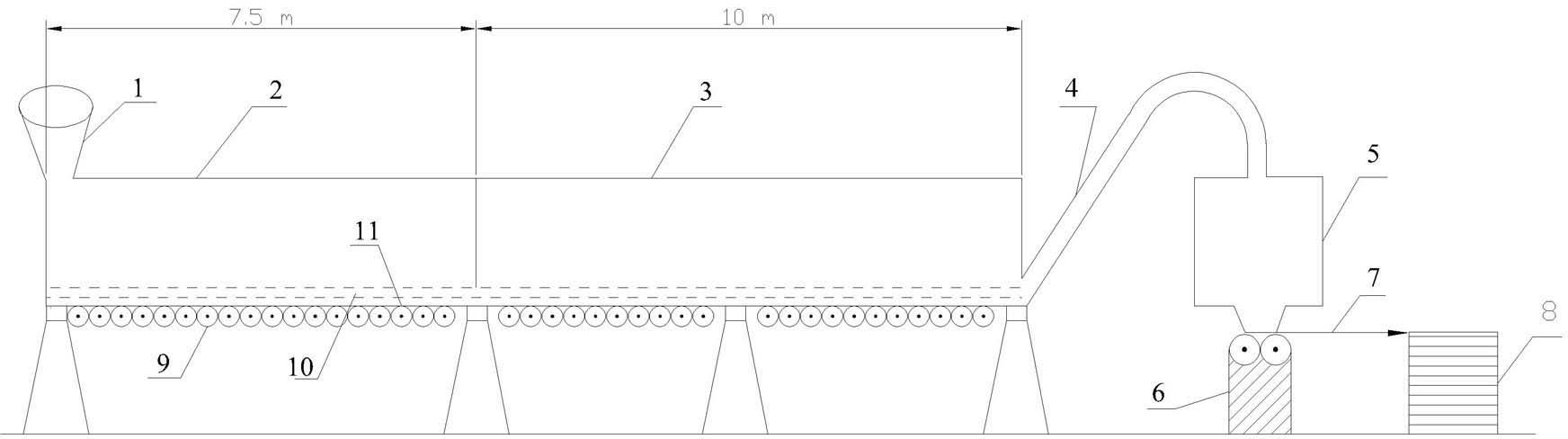

Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

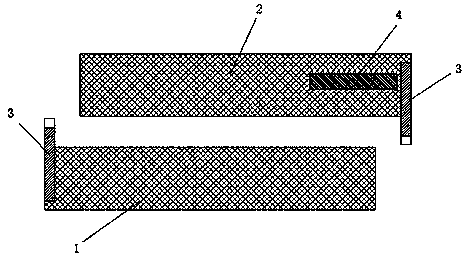

InactiveCN102634056AProtection from destructionSure breakPlastic recyclingRubber materialWaste rubber

The invention discloses a microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber, and belongs to the technical field of waste rubber reclaiming. The method comprises the following steps of: mixing waste rubber outer tire crown powder with the particle size of 20 meshes, rosin and dipentene according to a certain proportion; uniformly feeding the materials with a certain thickness on a roller way conveying device; determining the length of a roller way according to microwave radiation time; arranging a high-frequency microwave radiation device on the roller way; conveying the materials on the roller way for reclaiming the materials by microwave radiation during conveying; continuously putting the reclaimed rubber materials into a cooling device through the roller way; directly discharging the cooled materials to an open mill for performing refining, wherein the refining temperature is controlled to be 35-50 DEG C; and refining at low temperature on the open mill for 20 minutes to obtain a refined rubber sheet with smooth surface and uniform texture. A test result shows that the tensile strength of the reclaimed rubber is more than 18MPa, the breaking elongation is over 400%, and the Weigert plasticity is 0.35-0.45. The microwave radiation reclaiming method has the advantages of environment friendliness, short reclaiming time, low reclaiming temperature, energy conservation and high production efficiency.

Owner:XUZHOU COLLEGE OF INDAL TECH

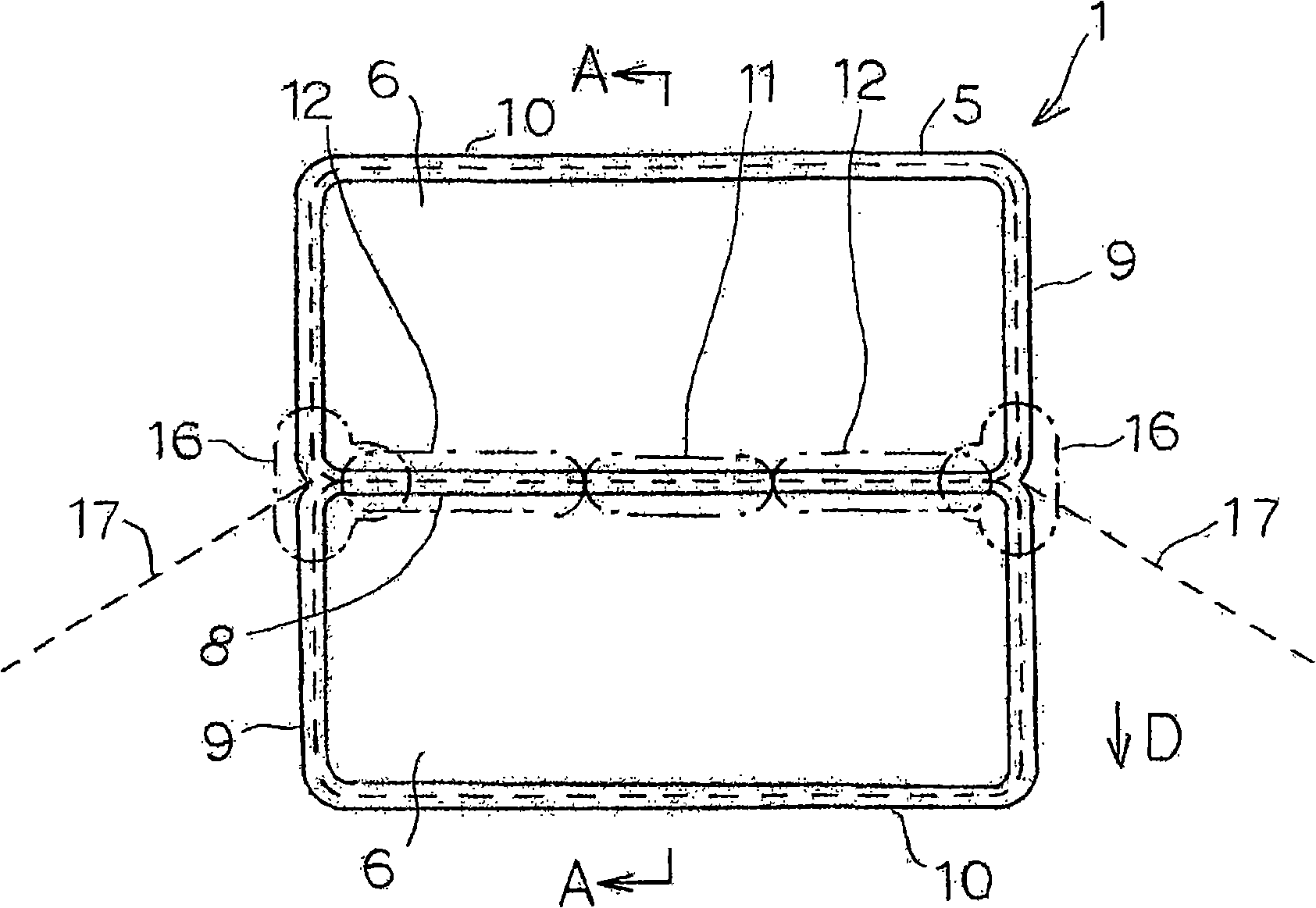

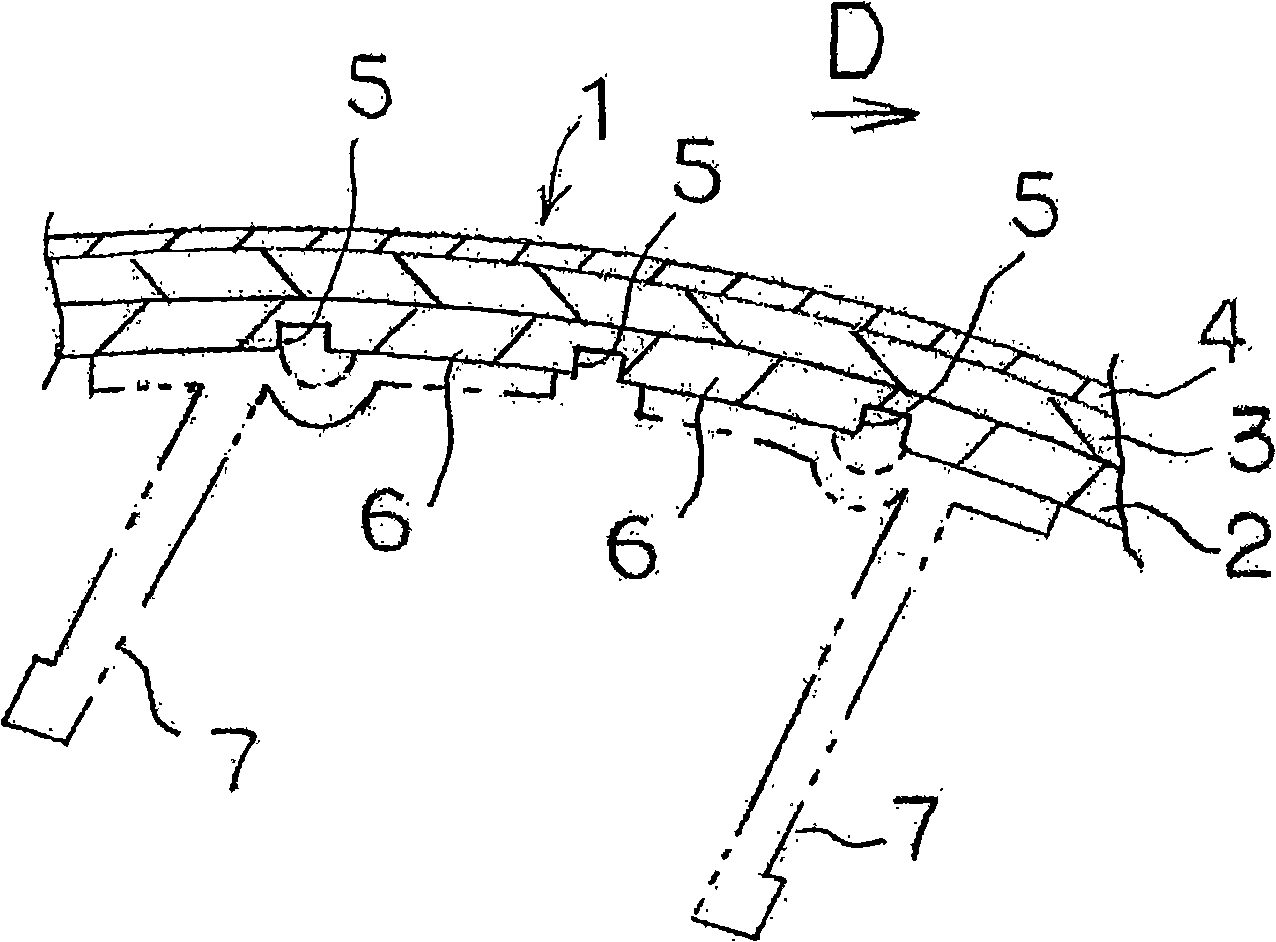

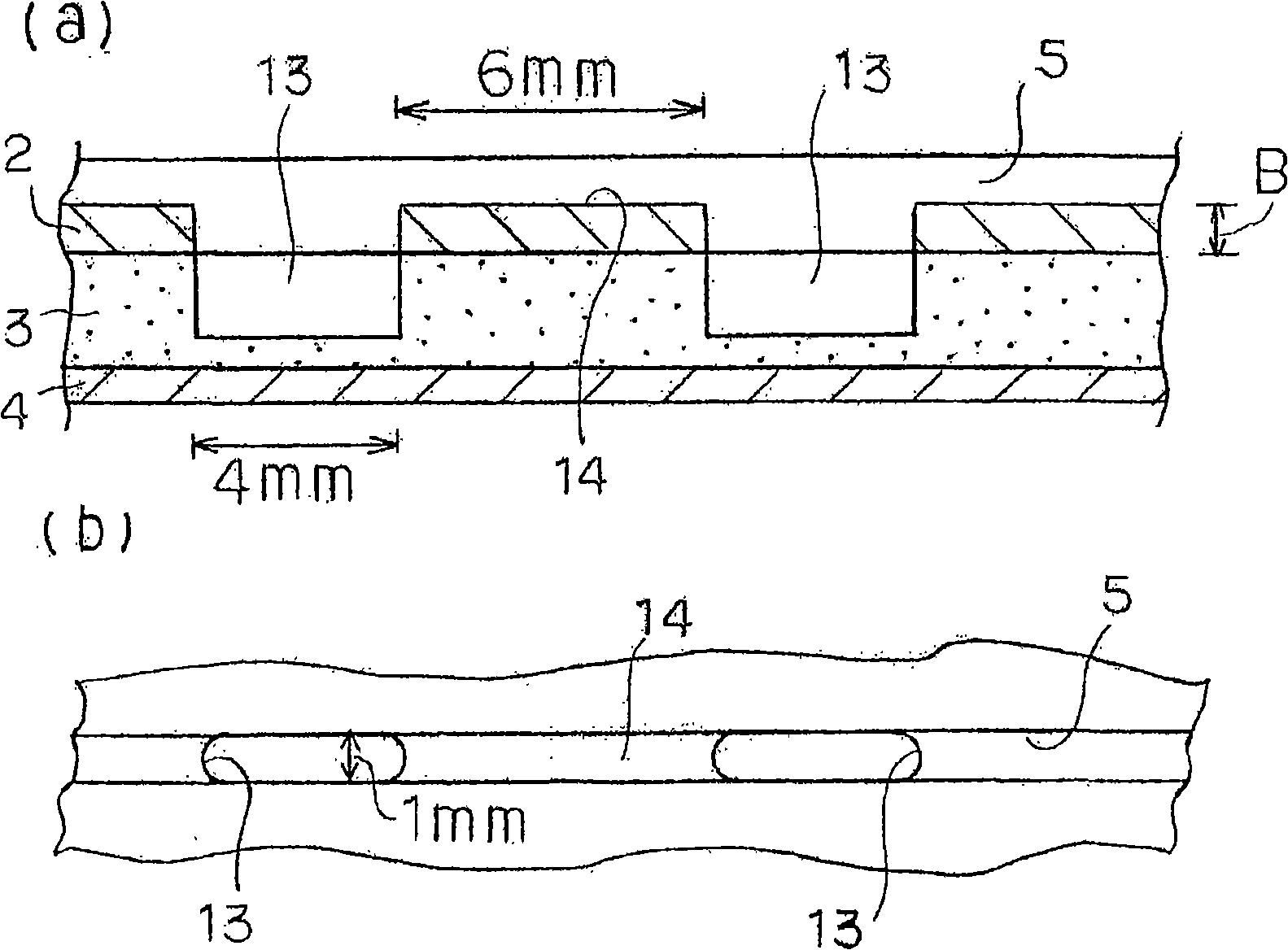

Airbag door, method of controlling breakage of tear line, and method of expanding airbag

InactiveCN101495345ASure breakSustain control effect of fracturePedestrian/occupant safety arrangementDashboardsEngineeringAirbag

A tear groove with a shape of an airbag door is formed in the back side of a base, the residual thickness of the base measured at the center line of the groove is set smaller than the thickness of the remaining portion of the base, and dotted tear holes for selectively breaking a skin are formed in the centerline portion and near a portion where a side line and the centerline meet. Consequently, when an airbag is inflated and expanded, the base and the skin of the airbag door are synchronously broken in an appropriate order on a portion by portion basis.

Owner:TOYOTA SHATAI KK

YE JIAN dark tea and processing method thereof

The invention discloses YE JIAN dark tea and a processing method thereof. By adopting high-tenderness single-bud and / or one-bud and one-leaf tea as a raw material, through steps of activated aroma enhancement, slight water removing, twisting, deblocking and tea strip tidying, intermittent temperature-controlled alcoholization, pile fermentation, deblocking and tea strip tidying and low-temperature drying, the technical problems that dark tea processed by taking high-tenderness tea as the raw material cannot be easily processed, is sour and rancid in smell and is sapropelic in leaf bottom are solved. The dark tea processed by the processing method disclosed by the invention is exquisite in appearance and is glossy and bright, is pure in aroma, red, bright and glossy in liquor color and mellow in taste after being brewed, and the leaf bottom is complete and elastic.

Owner:湖南省怡清源茶业有限公司

Forming method of precise high-temperature alloy pipe with small caliber and thick wall for aviation

The invention discloses a forming method of a precise high-temperature alloy pipe with small caliber and thick wall for aviation. The forming method comprises the following steps: S1: cold rolling: carrying out multi-pass cold rolling on a qualified seamless tube to obtain a tube blank in transitional specification, wherein the outer diameter of the tube blank in the transitional specification is 1.14-1.17 times of that of a finished tube, the wall thickness of the tube blank is 0.97-0.985 times of that of the finished tube, and the dimensional deviation is controlled within a range of plus or minus 0.03mm; S2: manufacturing a pointed end: carrying out degreasing, heat treatment, acid cleaning, straightening and UT (ultrasonic) flaw detection on the tube blank with transitional specification sequentially, selecting the qualified tube blank obtained after UT flaw detection, and welding a pointed end with conicity at the end part of the qualified tube blank; S3: empty sinking: drawing the tube blank by the pointed end and deforming the tube blank under the extrusion of an outer mold to obtain a finished tube. The forming method makes up the technical gap of domestically producing the precise high-temperature alloy pipe with small caliber and thick wall, and has important economic benefit on the research and the production of a domestic aero-engine.

Owner:宝武特冶航研科技有限公司

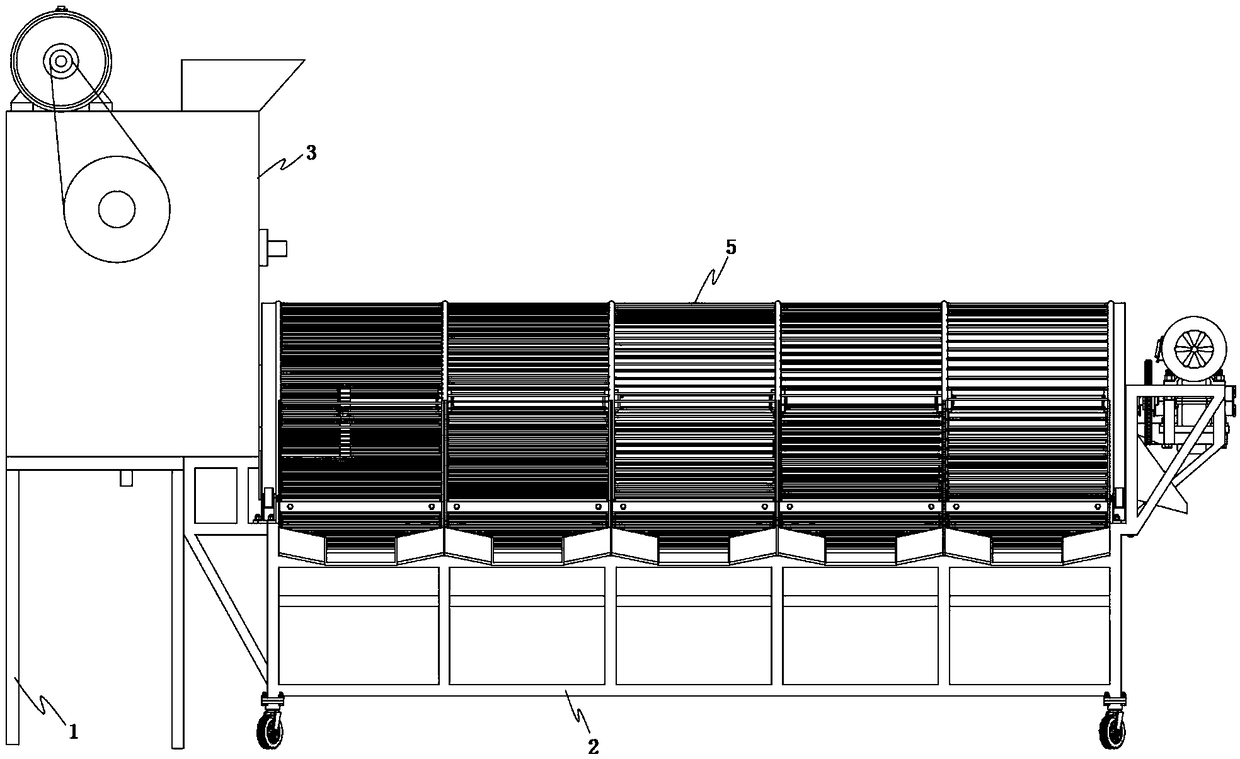

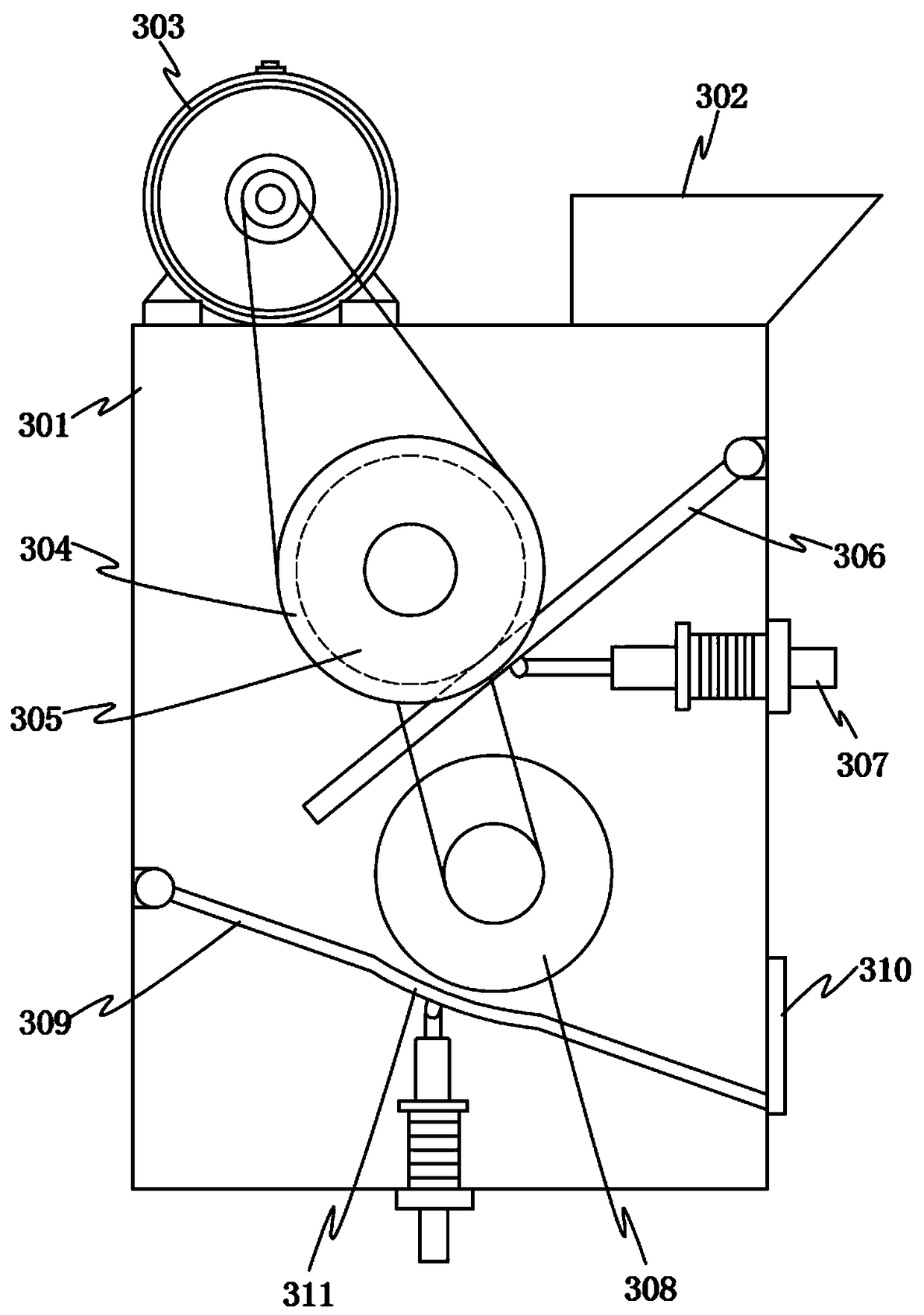

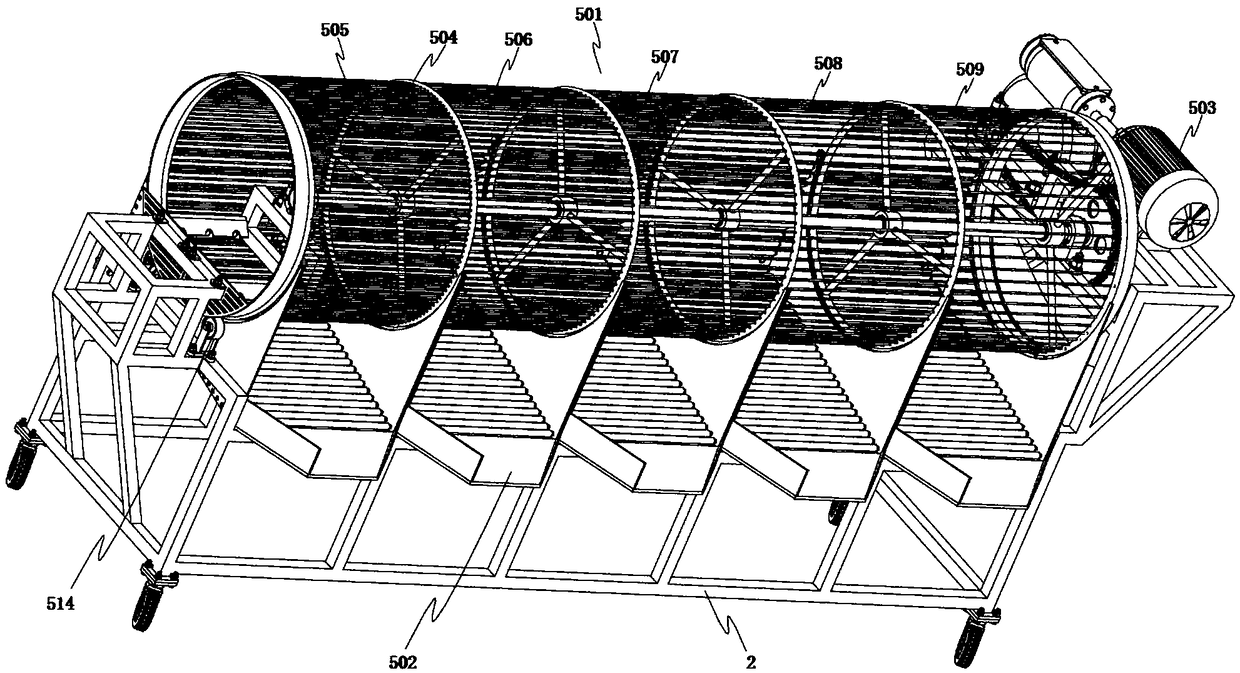

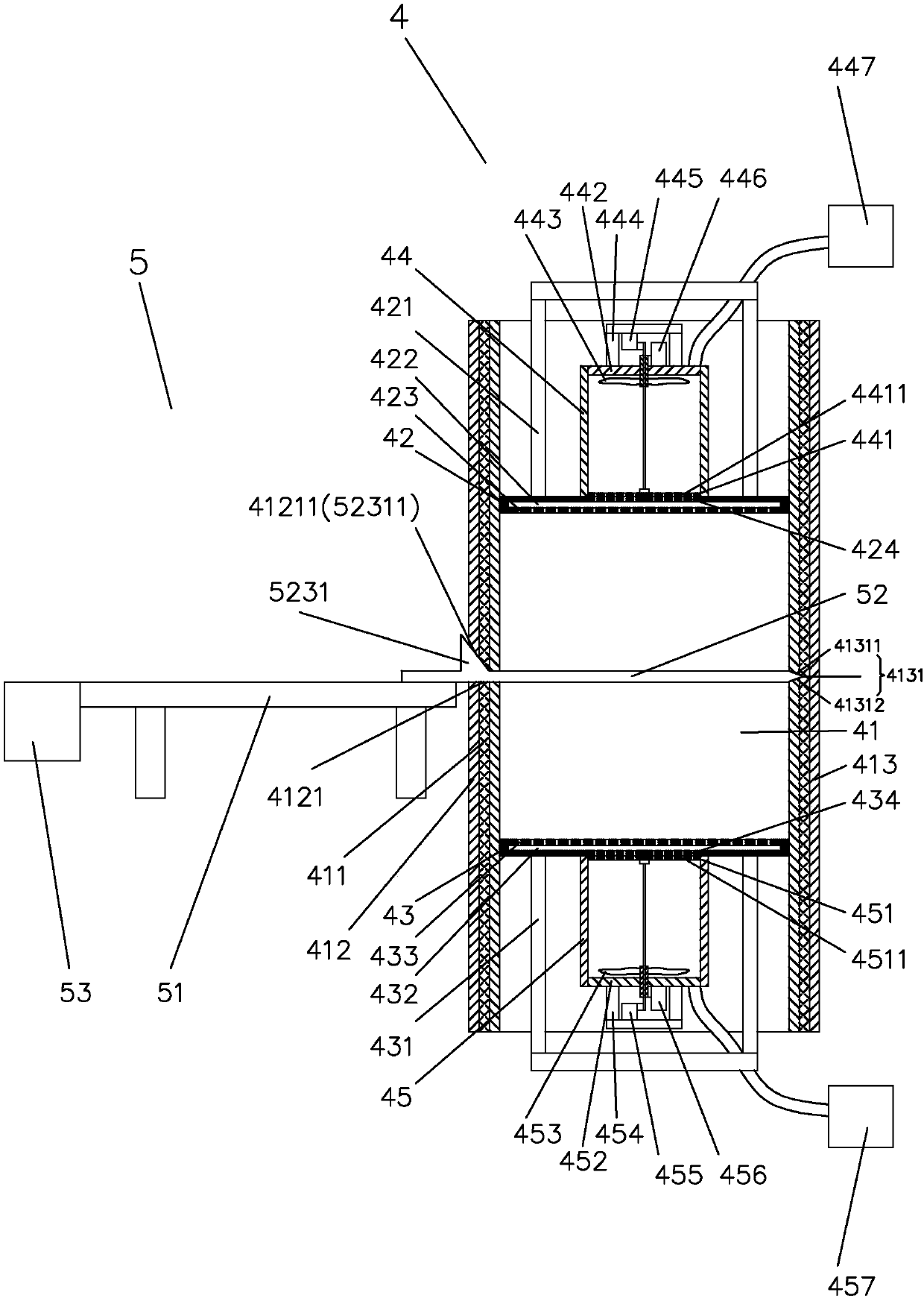

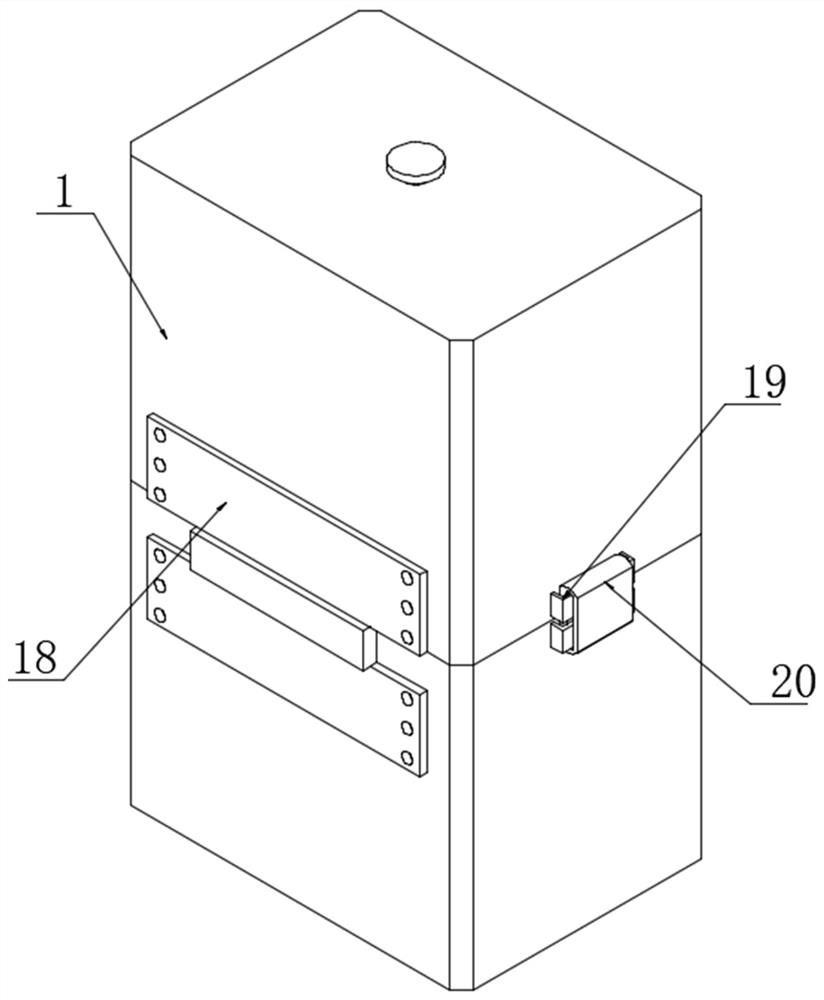

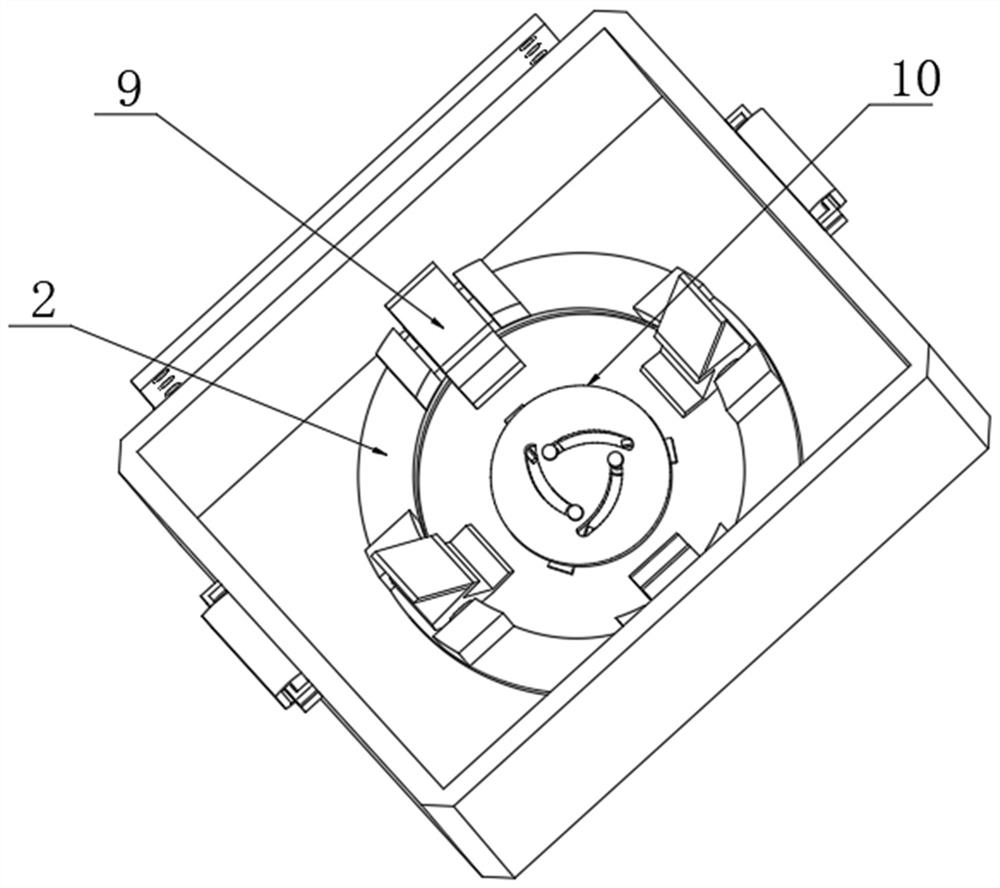

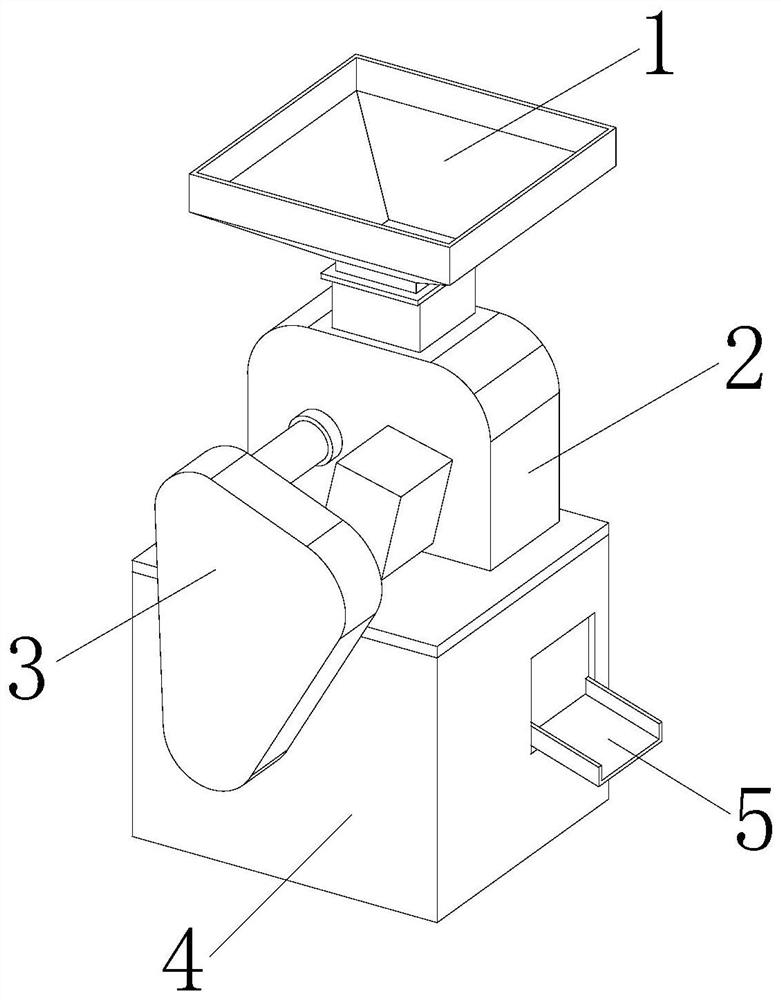

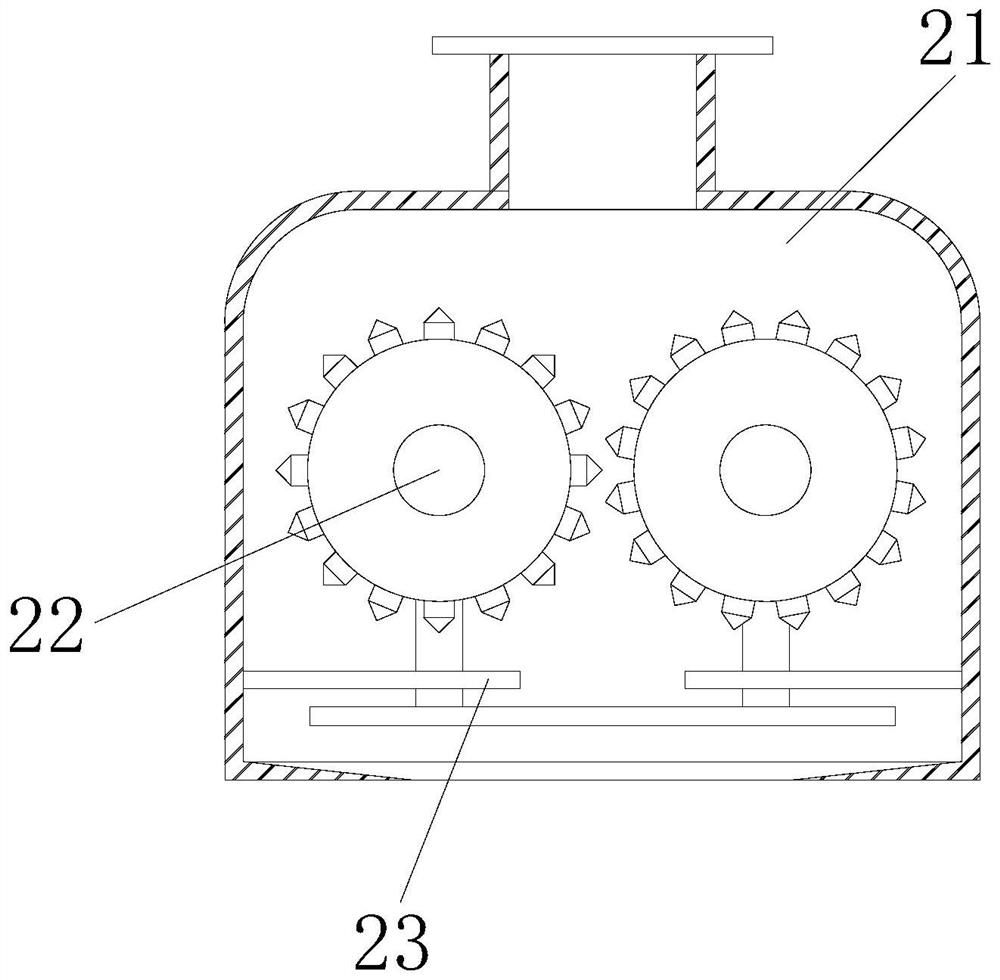

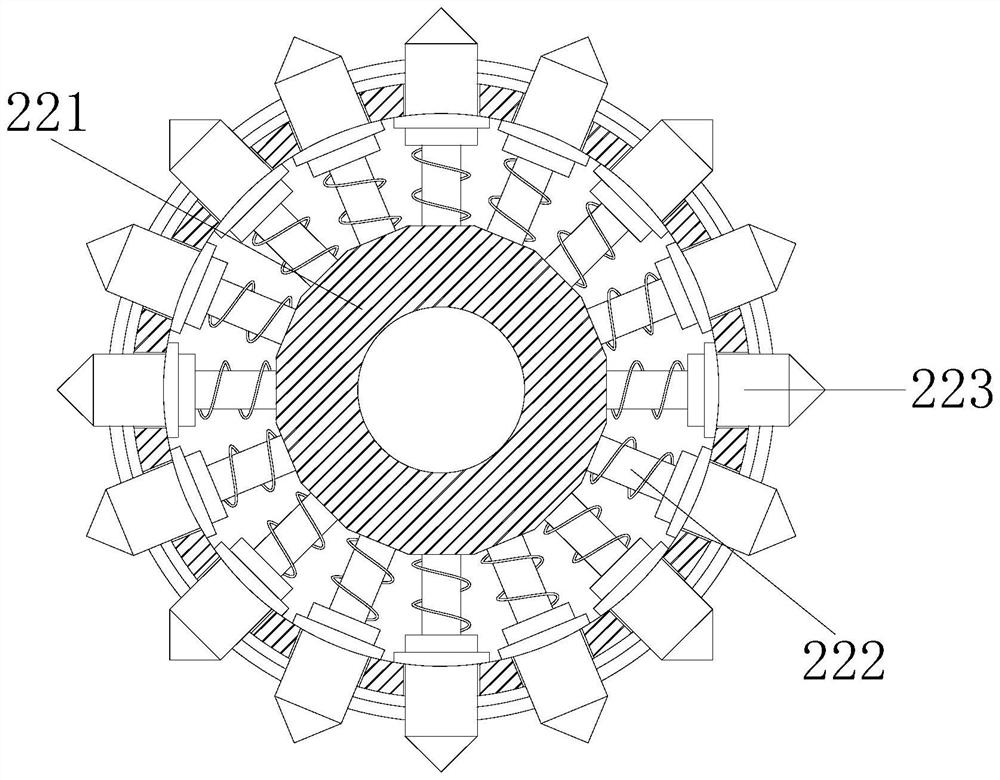

Crushing and screening grading device for active carbon

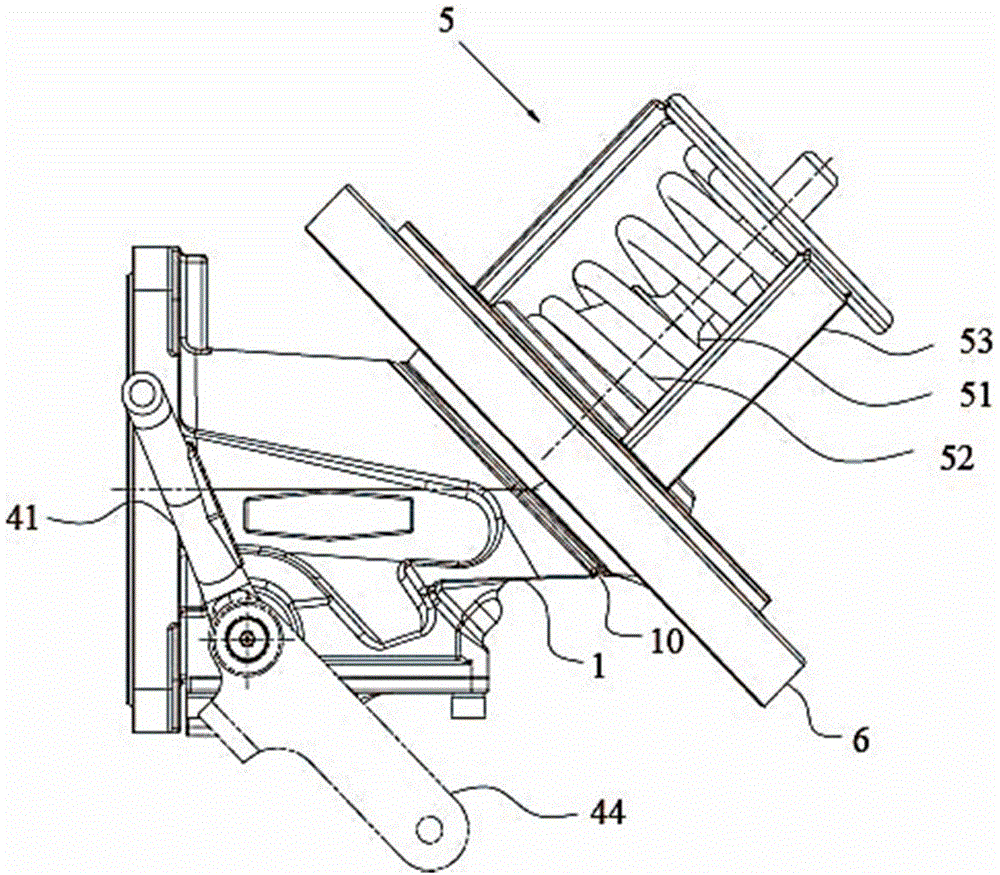

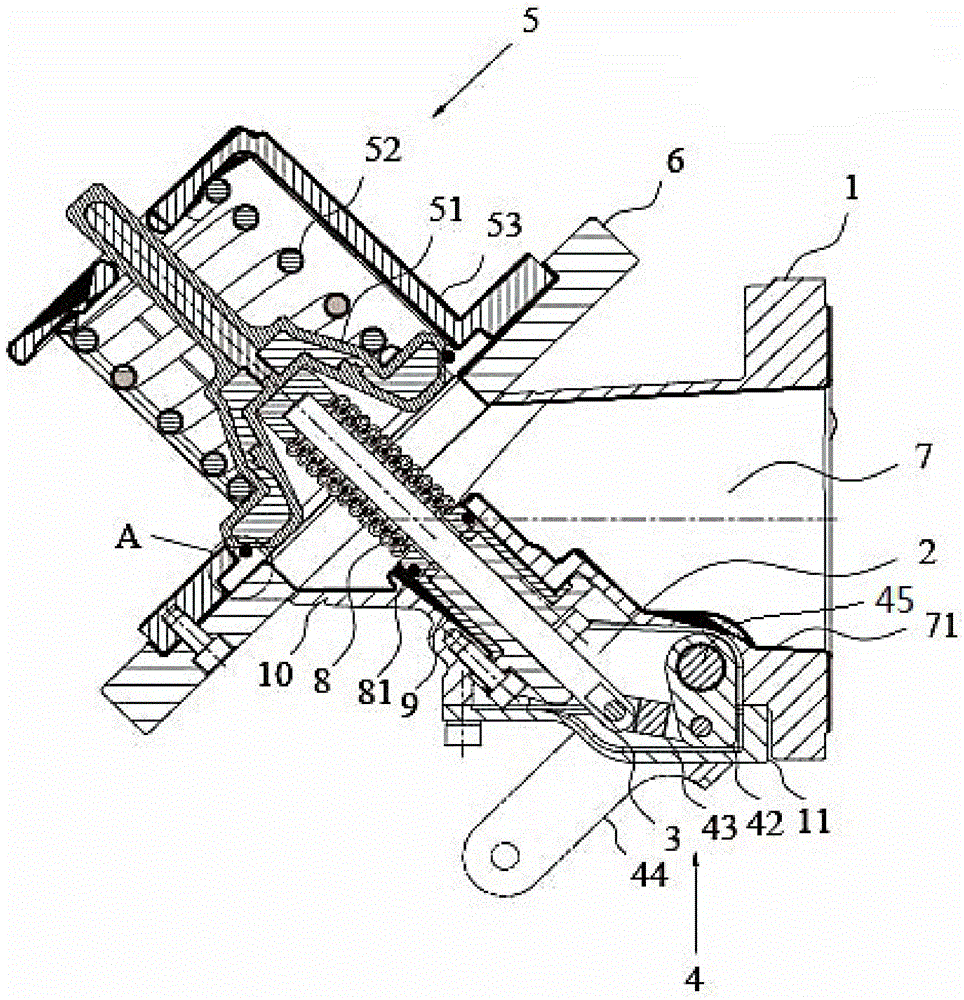

InactiveCN108704711ASure breakImprove crushing effectSievingScreeningScreening proceduresActivated carbon

The invention relates to a crushing and screening grading device for active carbon. The crushing and screening grading device comprises a first underframe, a second underframe, a crushing mechanism fixed to the first underframe and a screening grading mechanism fixed to the second underframe. The crushing mechanism is used for crushing the active carbon and can crush the active carbon twice. The screening grading mechanism is used for screening the crushed active carbon according to the granularity. The crushing and screening grading device has the function of crushing the active carbon and the function of graded screening of the crushed active carbon, and the crushing mechanism and the screening mechanism for the active carbon are integrated to replace a traditional processing mode that the crushing procedure of active carbon and the graded screening procedure of the active carbon are separated, so that the processing cost of the active carbon is reduced, automatic crushing and gradedscreening of the active carbon are achieved, and the processing efficiency is improved.

Owner:SONGYANG TONGDA ACTIVATED CARBON CO LTD

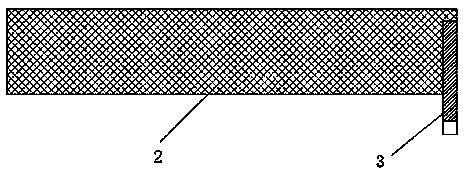

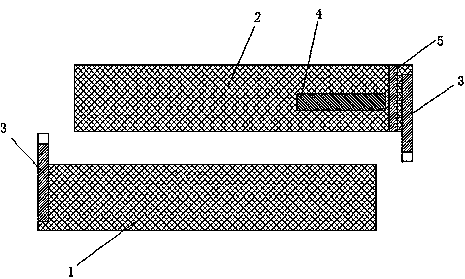

Primary lithium battery with high discharging efficiency

ActiveCN107681171AEnsure safetyImprove discharge capacityNon-aqueous electrolyte cellsPrimary cell electrodesDischarge efficiencyPolymer adhesive

The invention relates to the technical field of batteries, in particular to a primary lithium battery with high discharging efficiency. The primary lithium battery comprises a positive plate, a diaphragm, a lithium belt negative plate and lugs arranged on the positive plate and the negative plate, wherein the positive plate, the diaphragm and the lithium belt negative plate are mutually wound together by taking the lug end of the positive plate as a beginning end, and an inhibition reaction region is arranged at the winding tail end of the lithium belt negative plate; a polymer adhesive tape plate is arranged on the inhibition reaction region; and a groove for stopped reactions is arranged between the lug of the lithium belt negative plate and the polymer adhesive tape plate. The inhibition reaction region of the structure can guarantee that regular discharge of the battery is sufficient and effective, and the groove for stopped reactions can guarantee that the lithium belt is broken under overdischarge and forced discharge conditions of the battery, so that the safety of the battery is guaranteed, and the primary lithium battery is high in discharge capacity and excellent in safety performance.

Owner:HUIZHOU HUIDERUI LITHIUM BATTERY TECHNOLOGY CO LTD

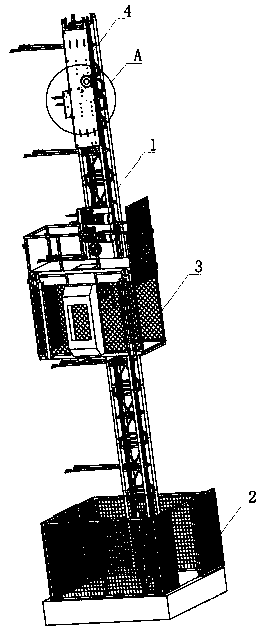

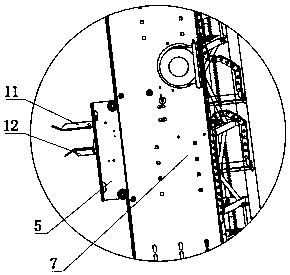

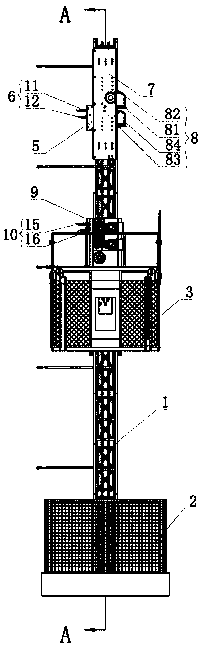

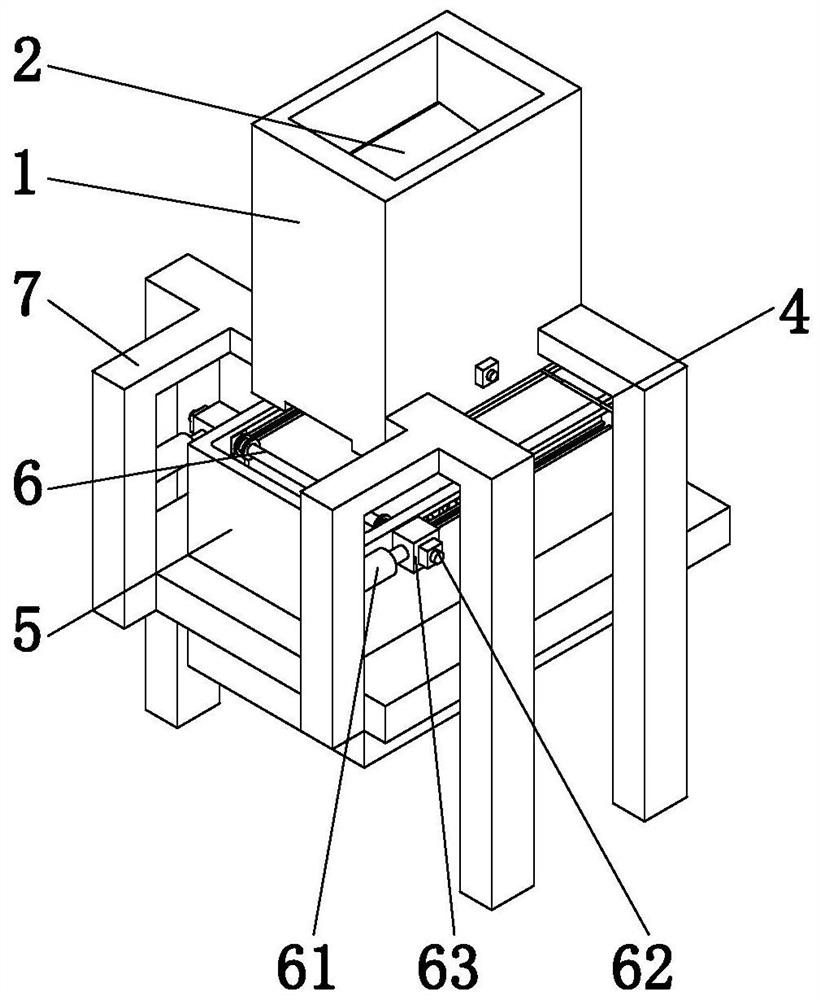

Lifting device and use method thereof

Owner:CHONGQING IND POLYTECHNIC COLLEGE

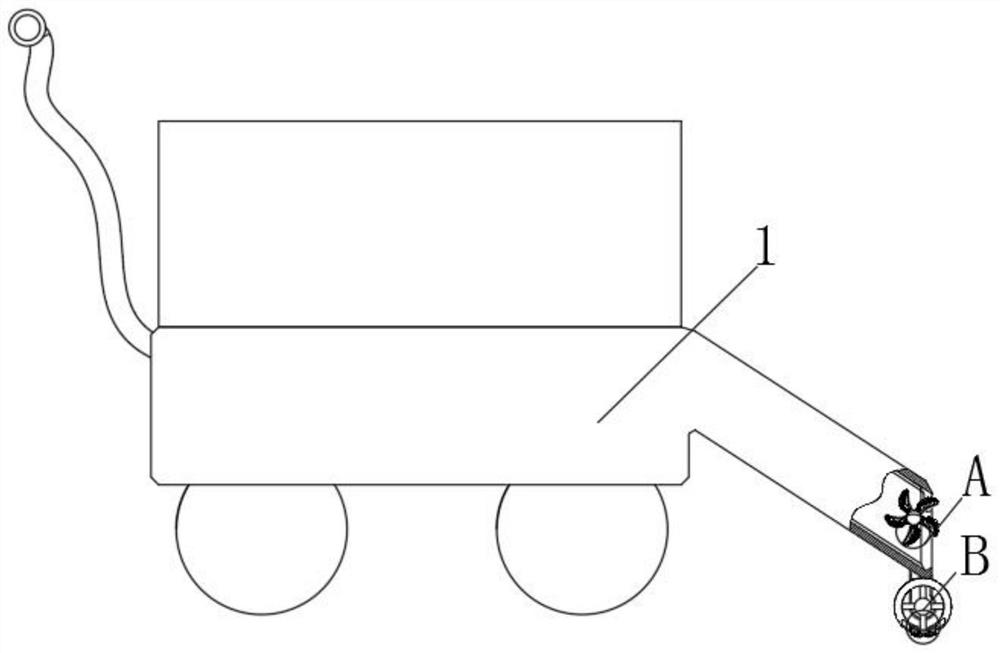

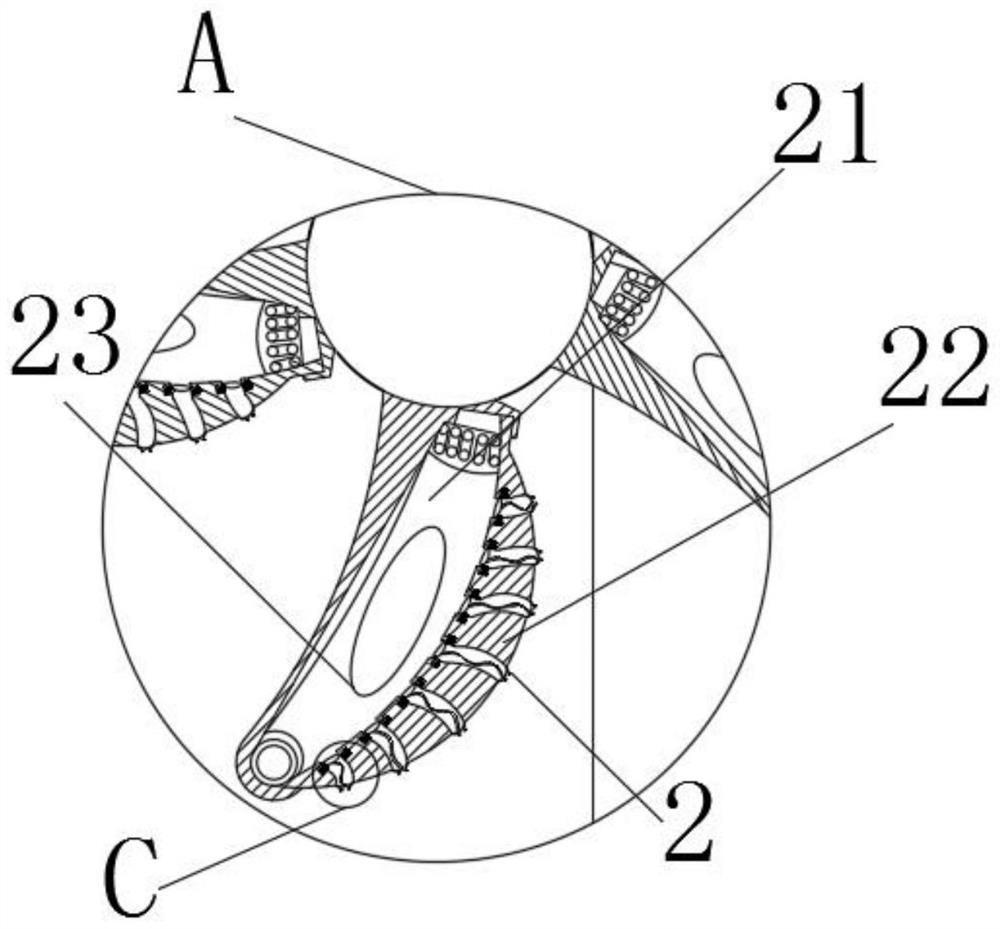

Snow and ice removing device for campus playground runway in winter

ActiveCN112878267AClear ice and snow to ensureConducive to speed upSnow cleaningSnow removalEngineering

The invention discloses a snow and ice removing device for a campus playground runway in winter, and relates to the technical field of playground cleaning. The snow and ice removing device for the campus playground runway in winter comprises a runway snow removing mechanism used for removing snow on the runway, an air bag crushing mechanism used for crushing an air bag, an elastic extruding mechanism used for elastic extruding, a magnetic ice breaking mechanism used for magnetic ice breaking and a rotary ice breaking mechanism used for rotating ice breaking, a snow remover is arranged in the runway snow removing mechanism, and an air bag crushing mechanism is arranged in the snow remover of the runway snow removing mechanism. According to the snow and ice removing device for the campus playground runway in winter, under the condition that a screw rod is extruded, the screw rod is attached to the ground to remove ice and snow, the screw rod rotates spirally to drive the ice and snow to move so as to ensure that the ice and snow are removed, and the rotation of a rotating paddle can smash the ice and snow, so that the ice and snow are prevented from being accumulated too high, and the collection of ice and snow is ensured.

Owner:梁子禹

Golden flower loose tea dark tea and processing method of golden flower loose tea dark tea

The invention discloses golden flower loose tea dark green tea and a processing method of the golden flower loose tea. High-tenderness single buds and / or tea with one bud and one leaf are / is used as raw materials, raw dark green tea is prepared through steps of activation fragrance enhancement, slight water removing, twisting, deblocking, strip sorting, intermittent juice adding alcoholization, pile fermentation, secondary deblocking and strip sorting, low-temperature drying and the like, then, the raw dark green tea is used for further floating, the golden flower loose tea is prepared, the strip shape of the loose tea is maintained, and the characteristics of golden flower are also realized.

Owner:湖南省怡清源茶业有限公司

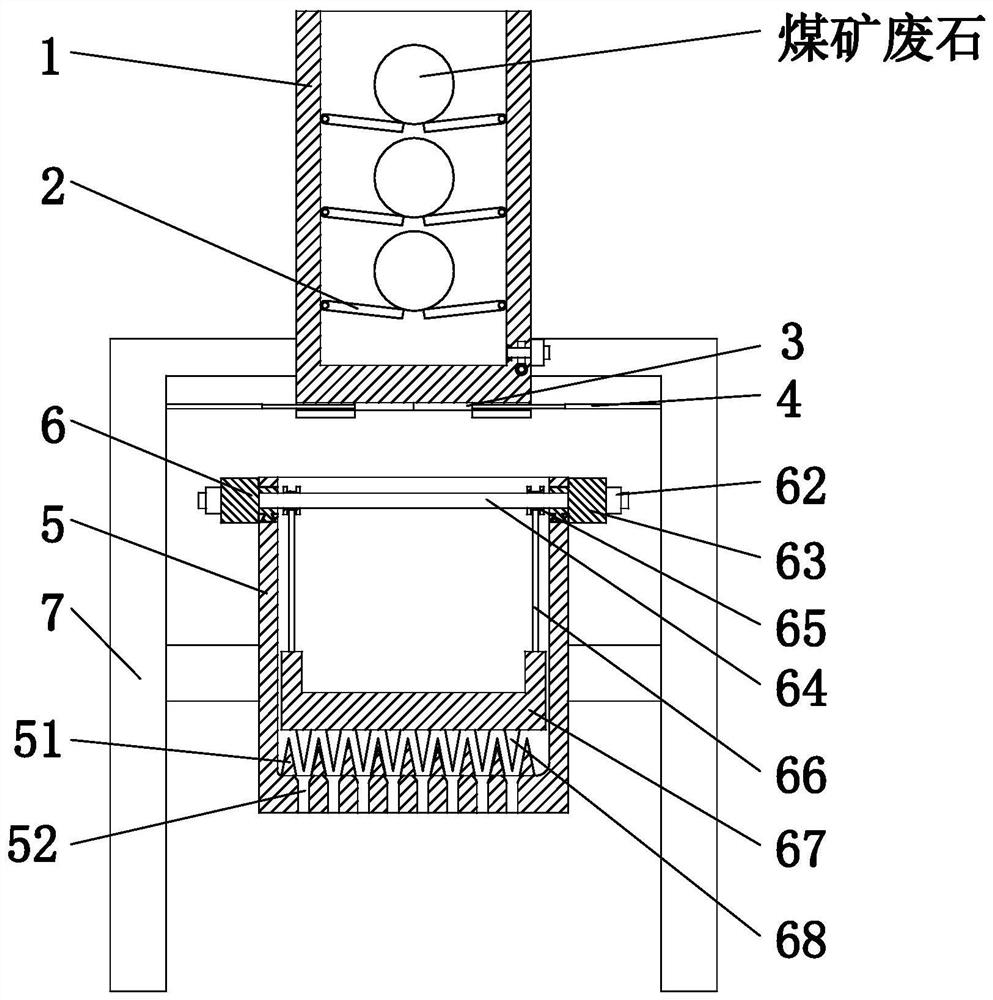

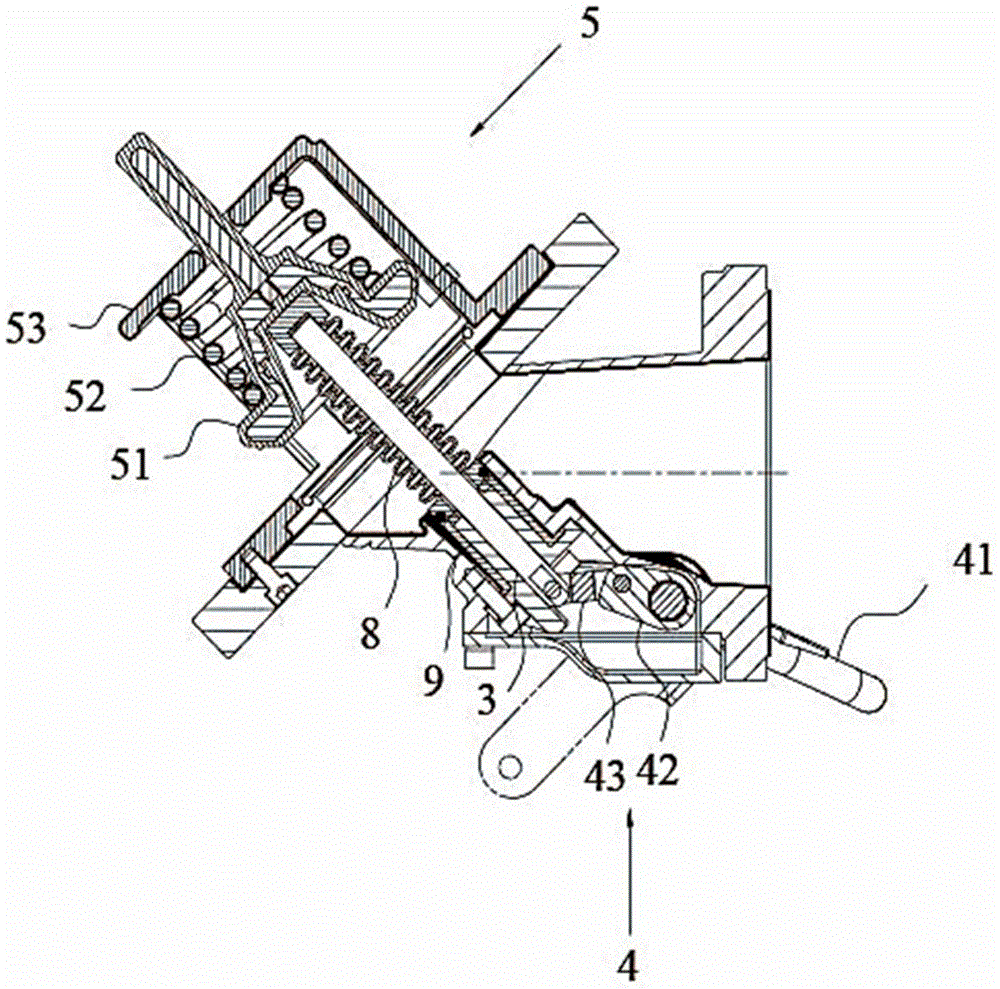

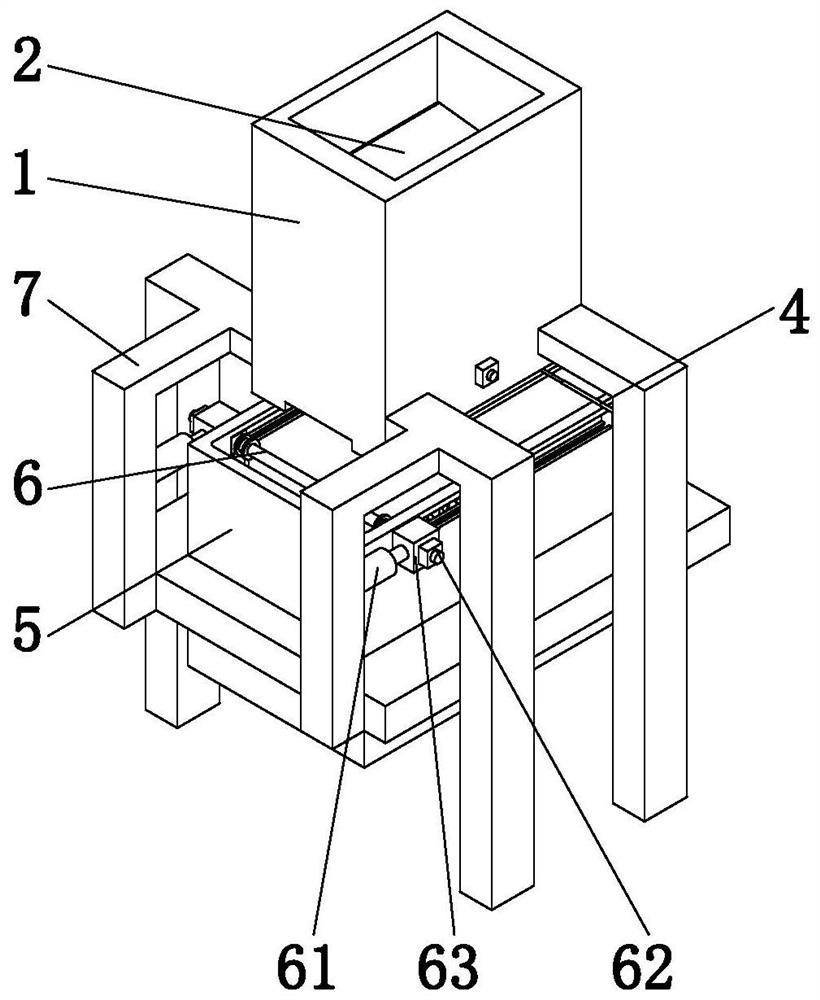

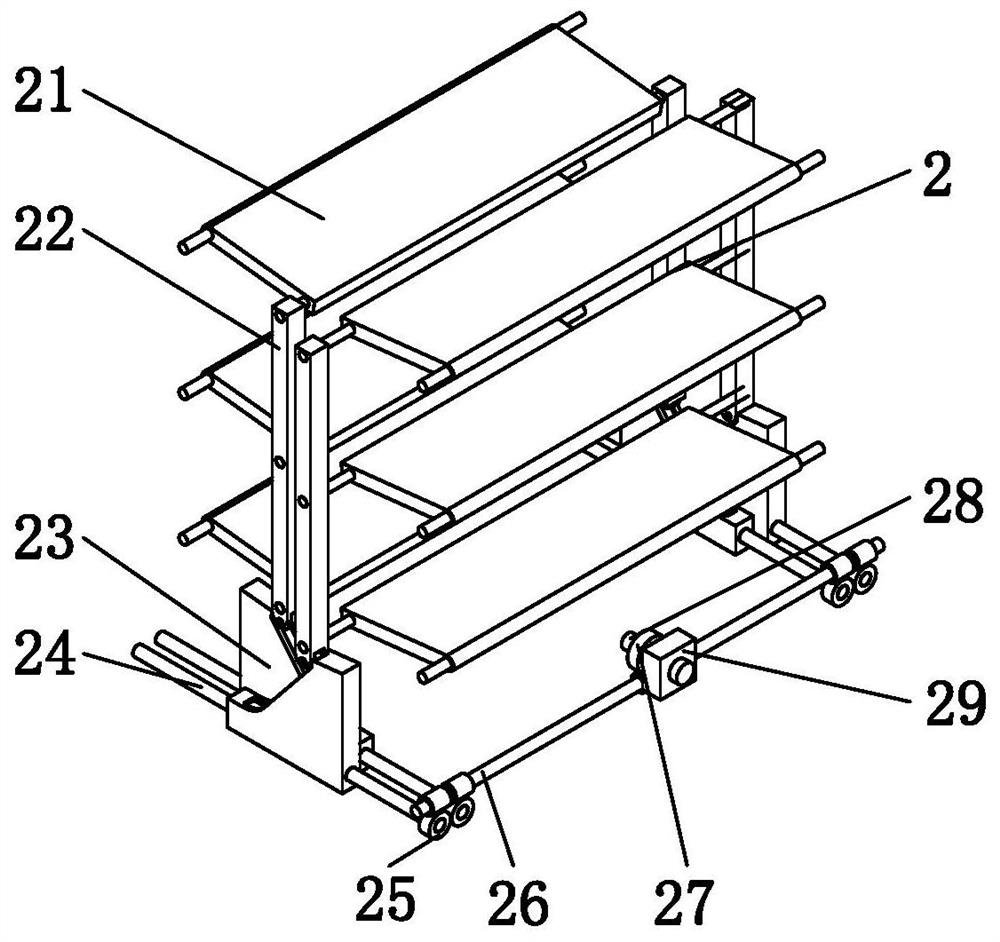

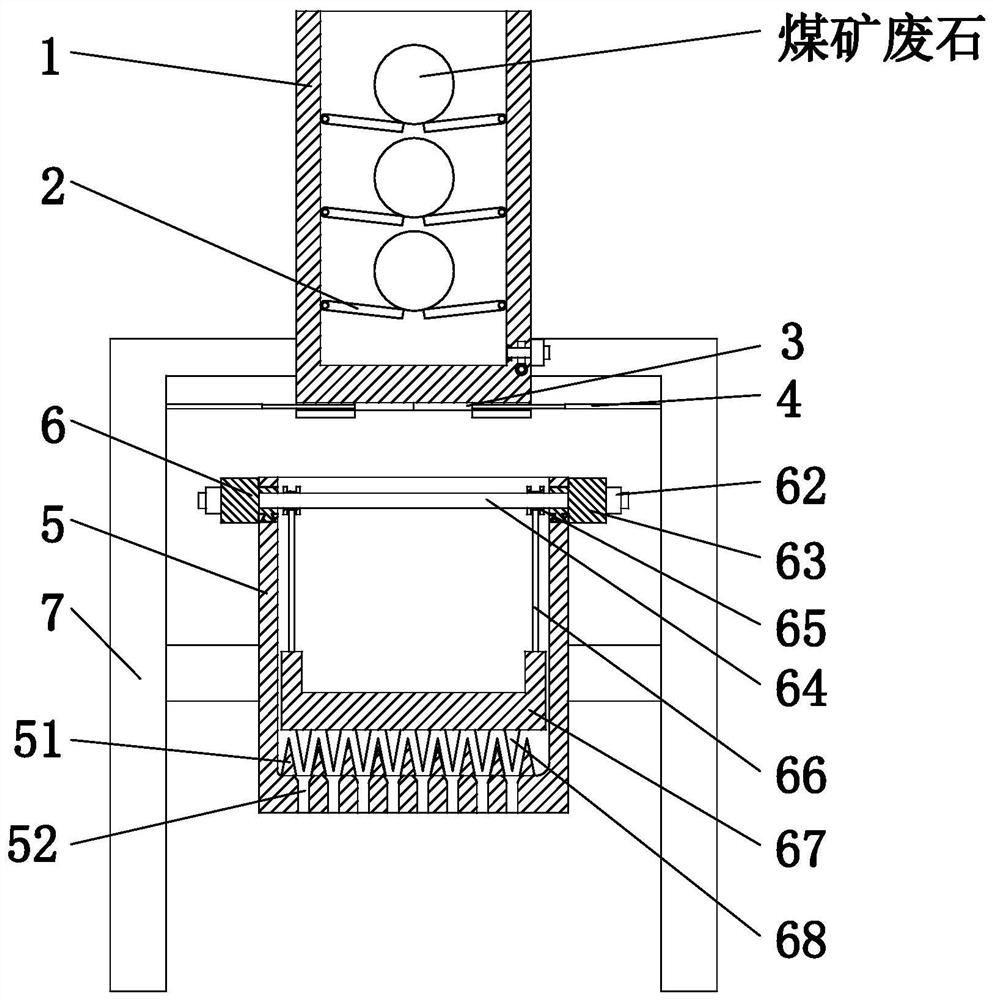

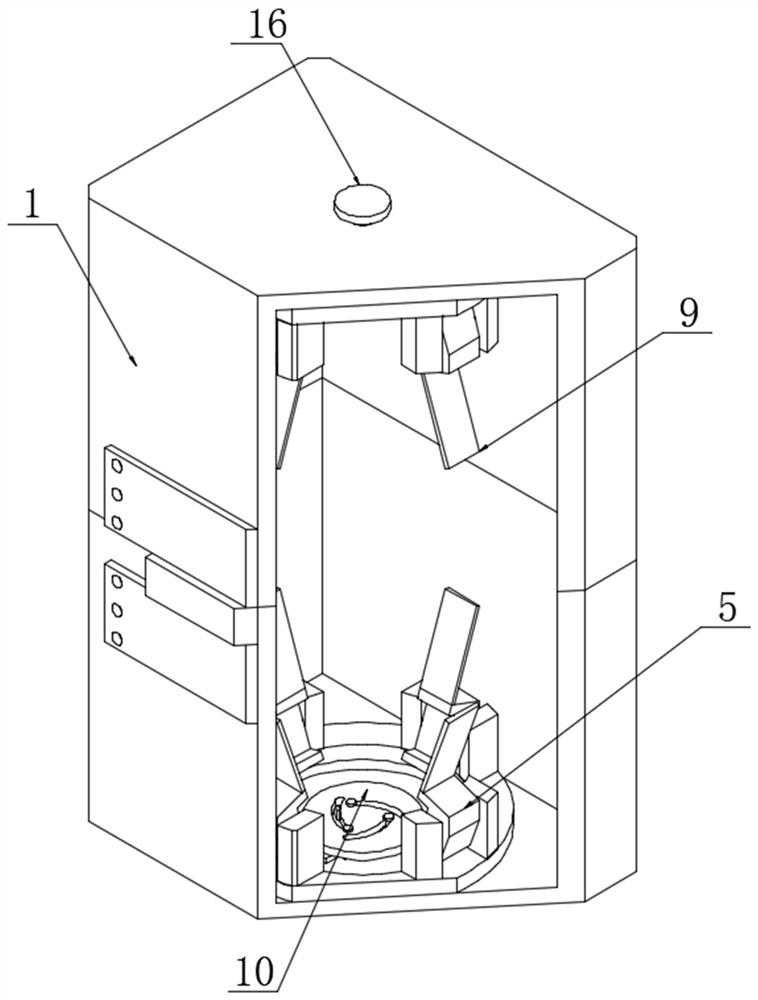

Heating and crushing processing system for waste rock solids in coal mining

ActiveCN111795576ALow utilization efficiencyHigh labor costChamber furnacesCharge manipulationMining engineeringCrusher

The invention provides a heating and crushing processing system for waste rock solids in coal mining. The eating and crushing processing system comprises a calcinator, a calcining mechanism, a slidingplate, an electric push rod, a crushing box, a crushing mechanism and a supporting frame. The heating and crushing processing system can solve the following problems existing in the process of crushing and processing the waste rock solids in a coal mine: a, for coal mine waste rock crushing modes, in a traditional process, the coal mine waste rocks are conveyed into a crusher for stirring and rolling and decomposed into recyclable fine particles, no crushing pretreatment is conducted on the coal mine waste rocks in the traditional process, and it is difficult for the crusher to roll the coalmine waste rocks into small pieces; and b, generally, a traditional crusher is used for crushing the coal mine waste rocks, in this way, it is difficult to ensure that the coal mine waste rocks are 100% broken into required small pieces, the traditional crusher has low use efficiency and high labor cost, and it is often necessary to carry out secondary crushing on the broken waste rocks to ensurethat the broken small pieces can be used.

Owner:辽宁银盛水泥集团有限公司

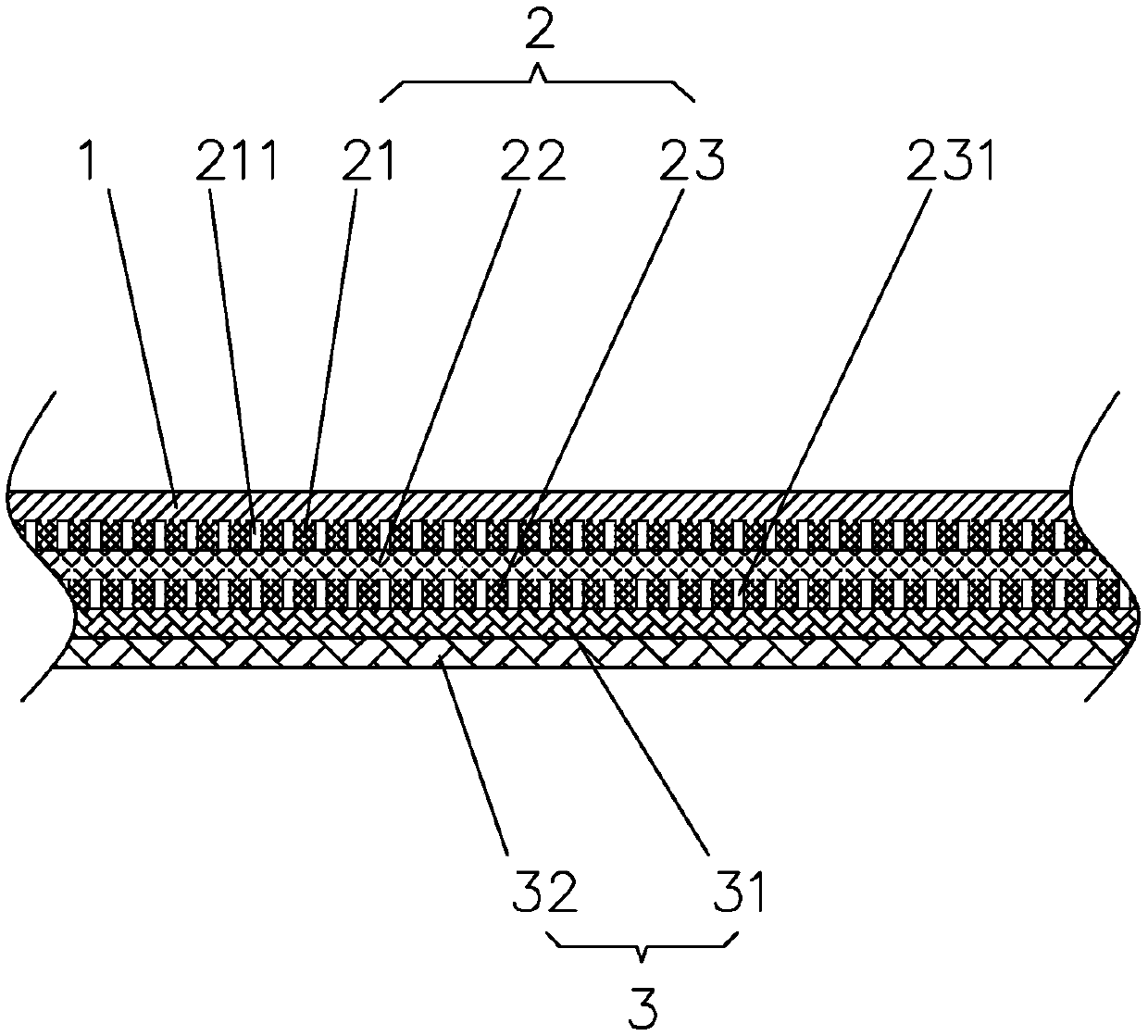

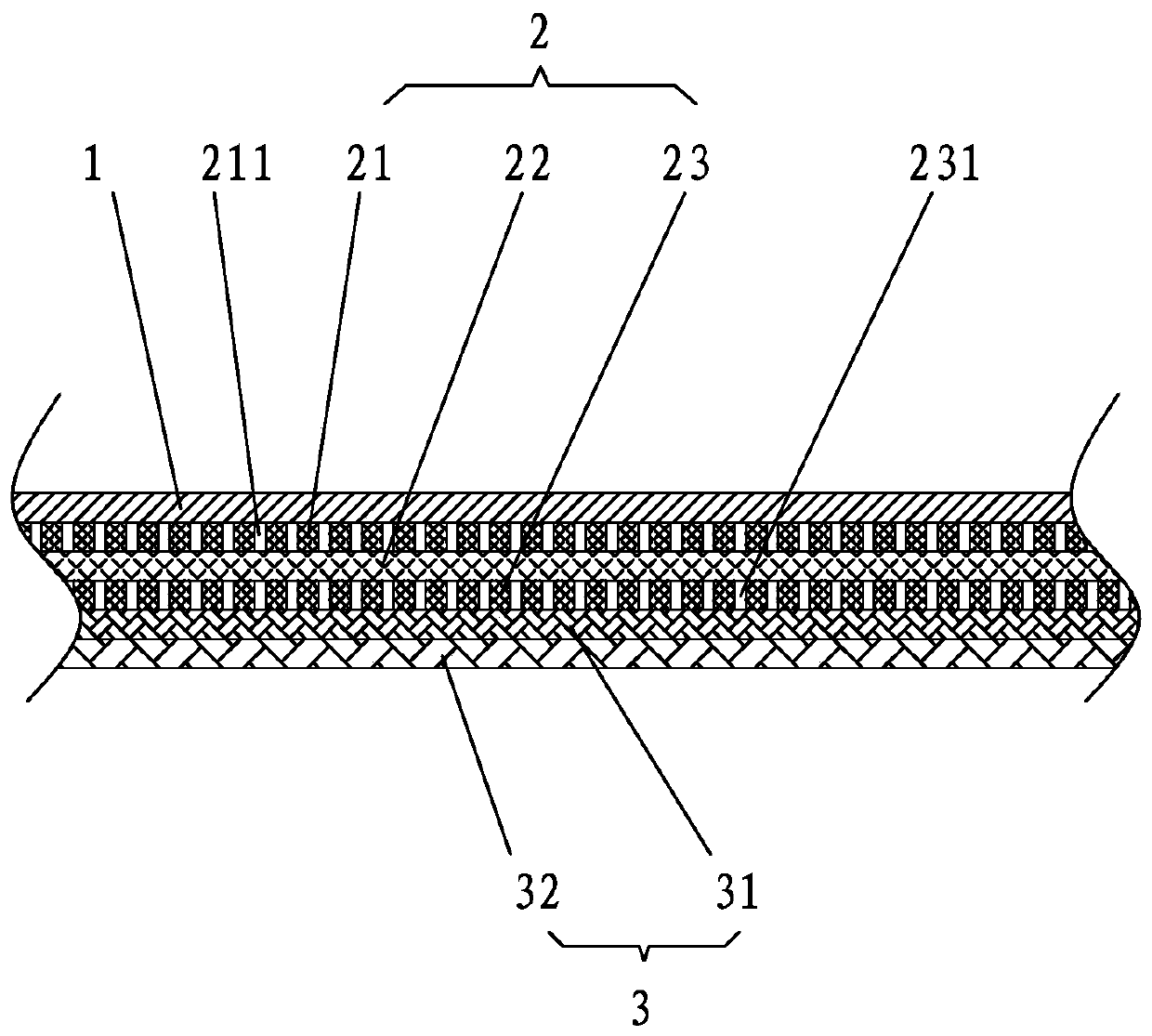

Hot air non-woven fabrics capable of fast and efficiently guiding flow and inhibiting bacteria and production method thereof

InactiveCN107696648AImprove permeabilityStrong capillaritySynthetic resin layered productsLaminationCompound aMoisture absorption

The invention provides hot air non-woven fabrics capable of fast and efficiently guiding flow and inhibiting bacteria. A fiber composite layer is formed by compounding an upper latex layer, a mixed fiber layer and a lower latex layer, and the lower fiber layer is formed by compounding a compact fiber layer at the inside and a sparse fiber layer at the outside, the mixed fiber layer is formed by uniformly mixing bamboo charcoal fibers and thermoplastic synthetic fibers with stirring, the formed lower fiber layer has strong permeability due to the sparse fiber layer, the dense fiber layer has astrong capillary phenomenon, the sparse fiber layer can quickly guide a flow of water and other liquids, the dense fiber layer can quickly absorb and firmly grasp water and other liquids, and thus thecompact fiber layer and the sparse fiber layer cooperate with each other to achieve efficient and fast flow guiding and absorption purposes of liquids. The mixed fiber layer has bacterium inhibitingand resisting effects, environment protection effects and high liquid and moisture absorption effects of bamboo charcoal fibers. The present invention also provides a production method for the hot airnon-woven fabrics capable of fast and efficiently guiding a flow and inhibiting bacteria.

Owner:福建金坛实业有限公司

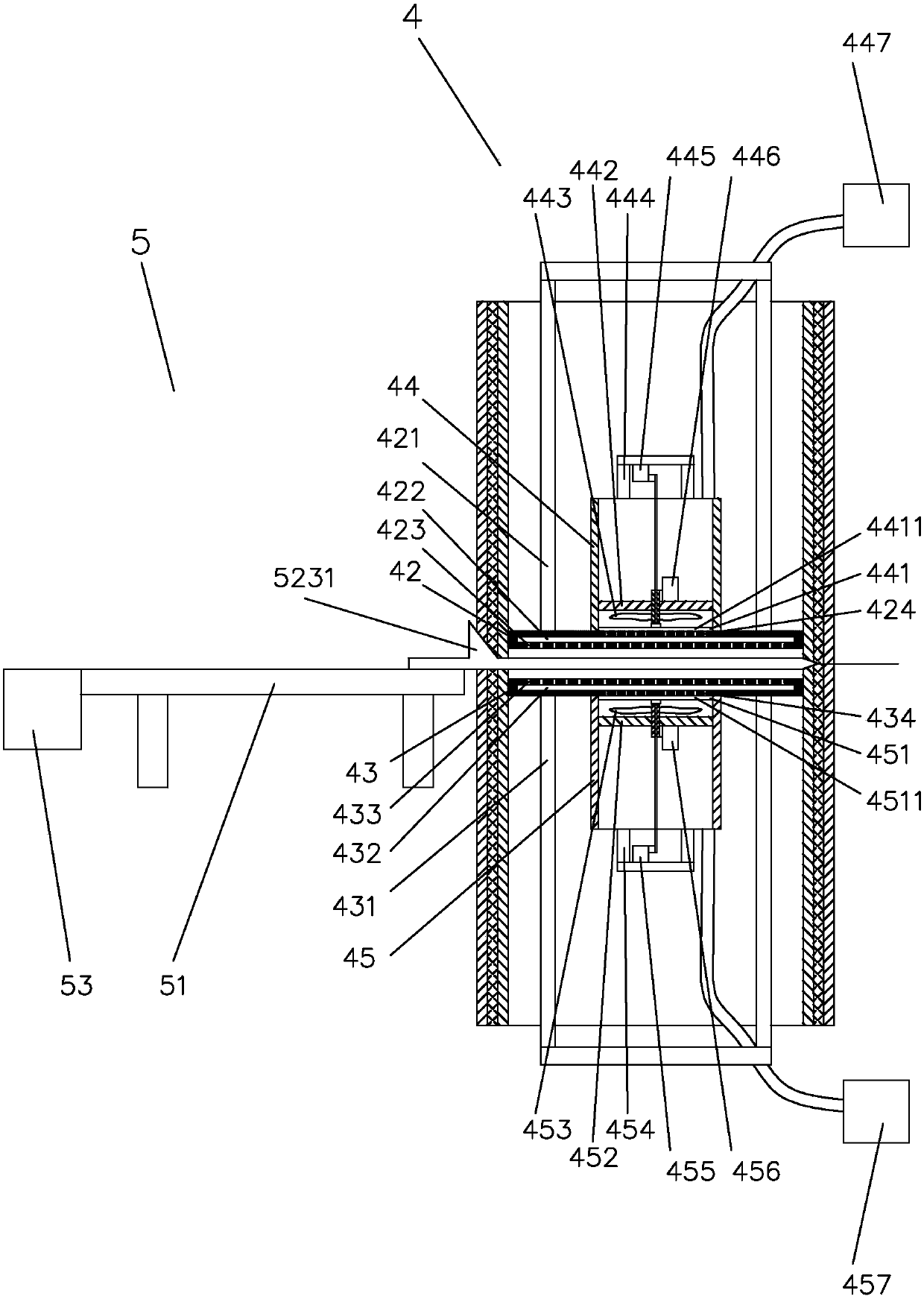

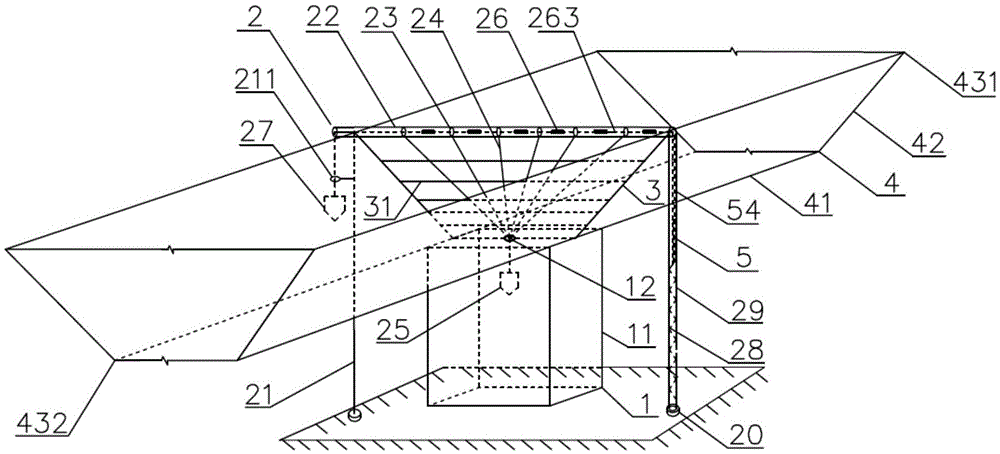

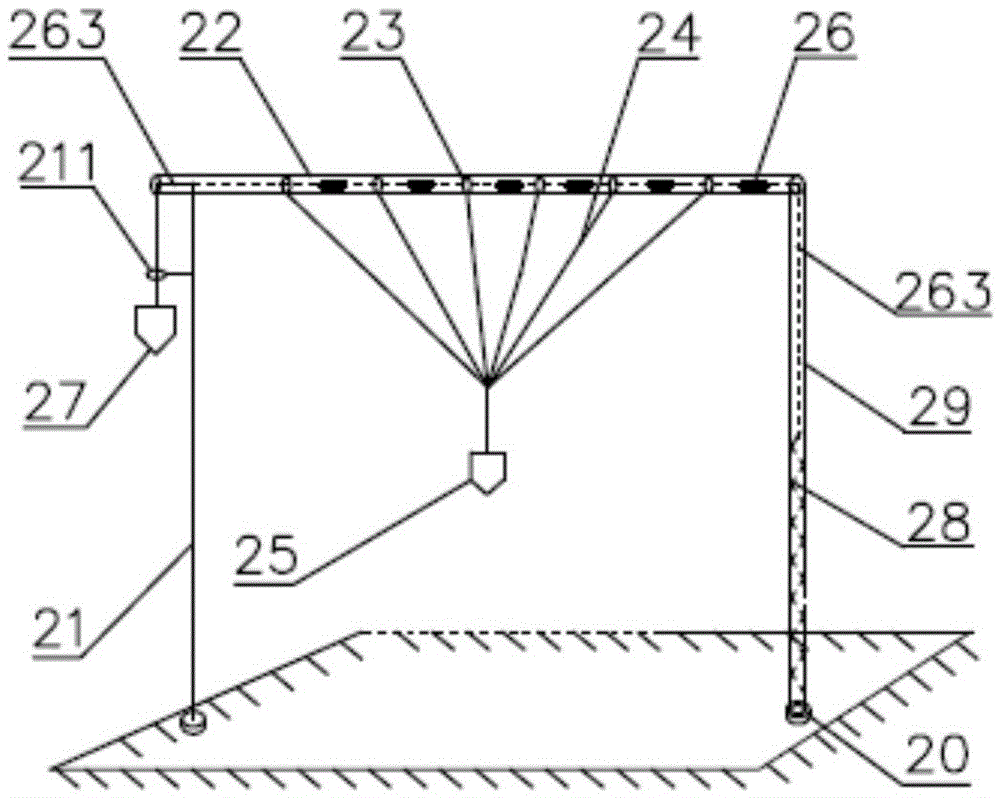

Simulation device of instant unstable burst of dam under extreme load condition and operation method

The invention discloses a simulation device of instant unstable burst of a dam under an extreme load condition and an operation method, relates to the technical field of dam burst, and is a test device and a method suitable for researching instant burst of the dam caused by instability of a dam shoulder. The simulation device of instant unstable burst of the dam under extreme load condition comprises a leakage preventing unit, a fixed platform, the dam, a water tank and an unstable unit. The dam consists of multiple baffle plates, and is kept in a stable state under combined action of the fixed platform, the water tank and related parts in the leakage preventing unit and the unstable unit. The instability of the dam shoulder is realized through fusing of a copper wire by heating of a resistance wire in the unstable unit; and the instant burst test effect of the dam is realized through unbalanced stress of the dam and collapse and water rushing destroy of the baffle plates caused by unstable dam shoulder. The simulation device provides the test theory and method for research on instant dam burst mechanism and instant burst water current moving rules caused by unstable dam shoulder.

Owner:ANHUI UNIV OF SCI & TECH

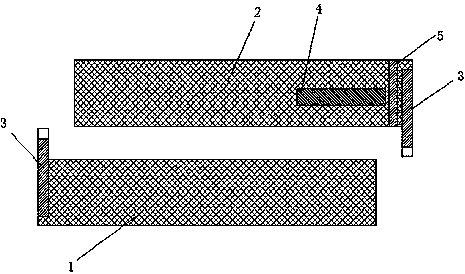

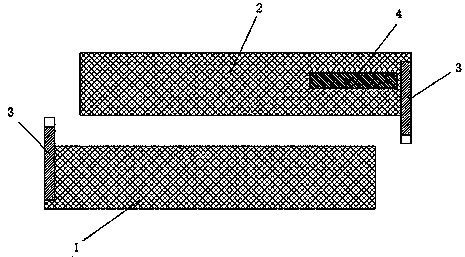

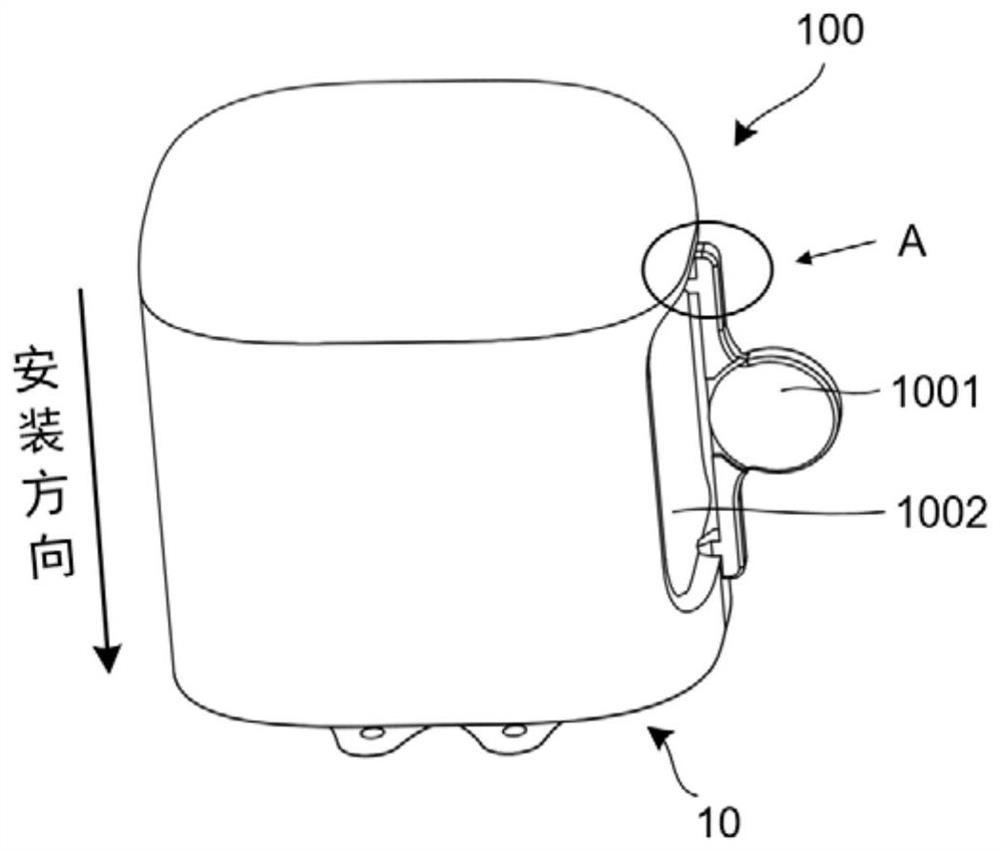

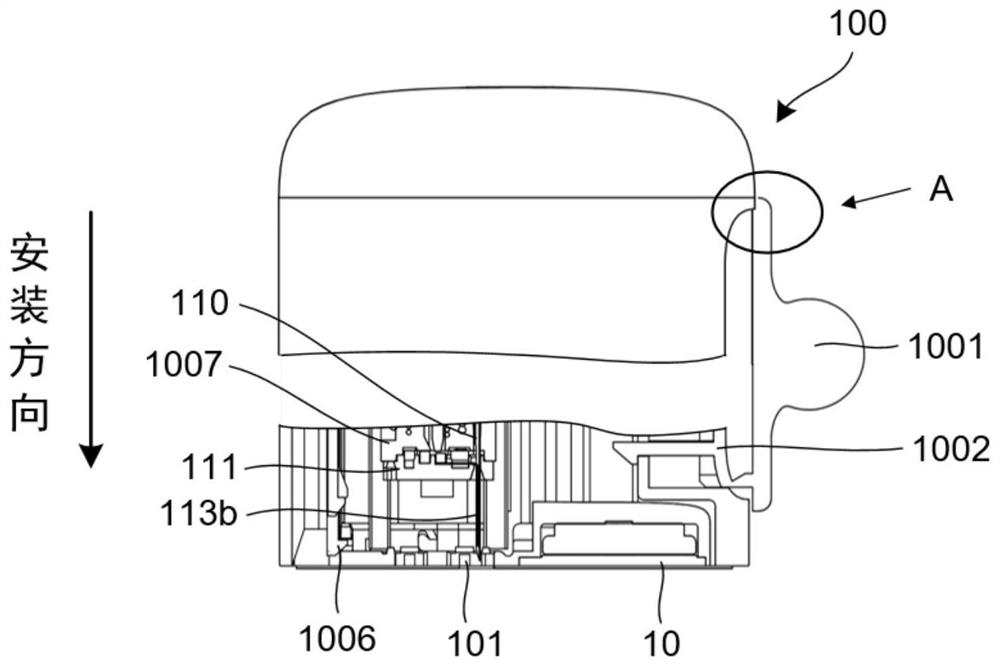

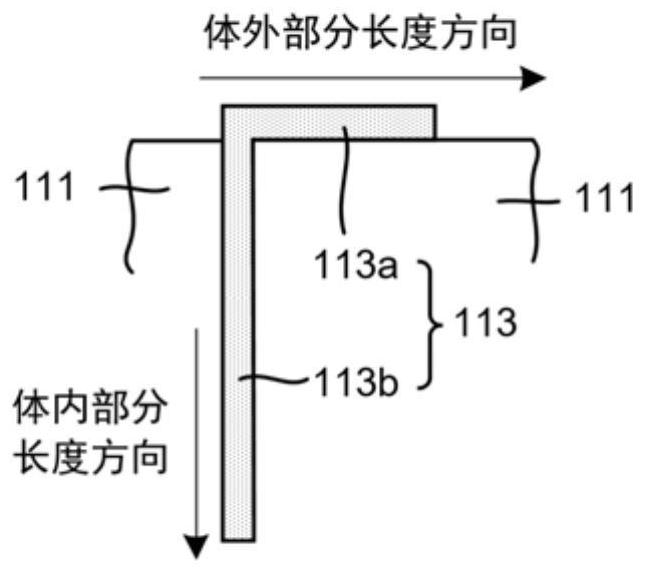

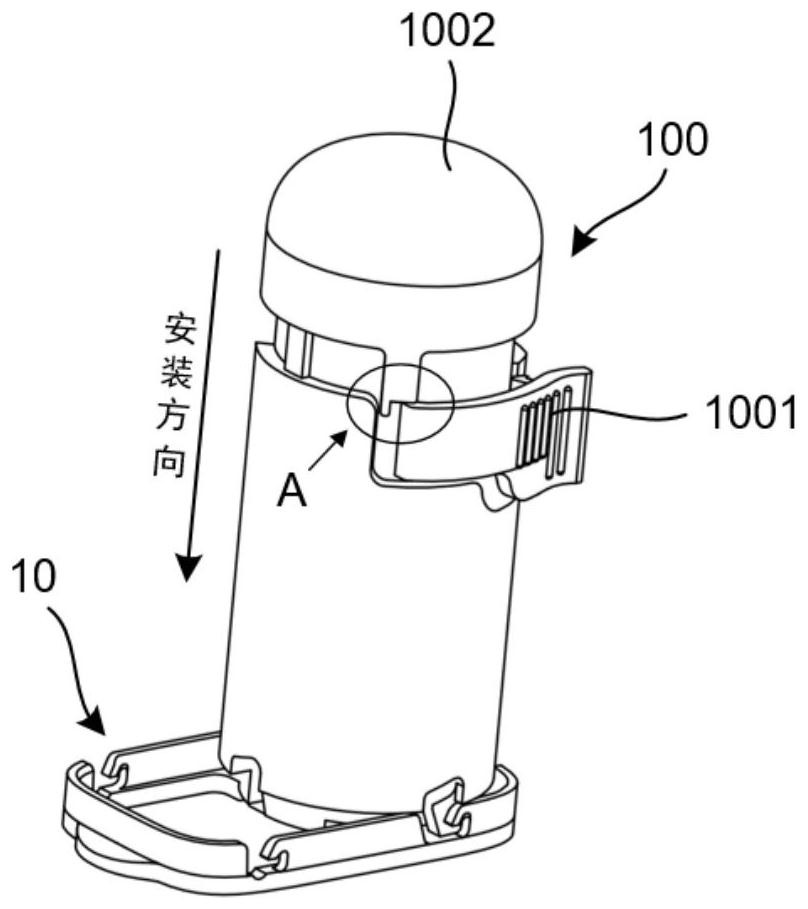

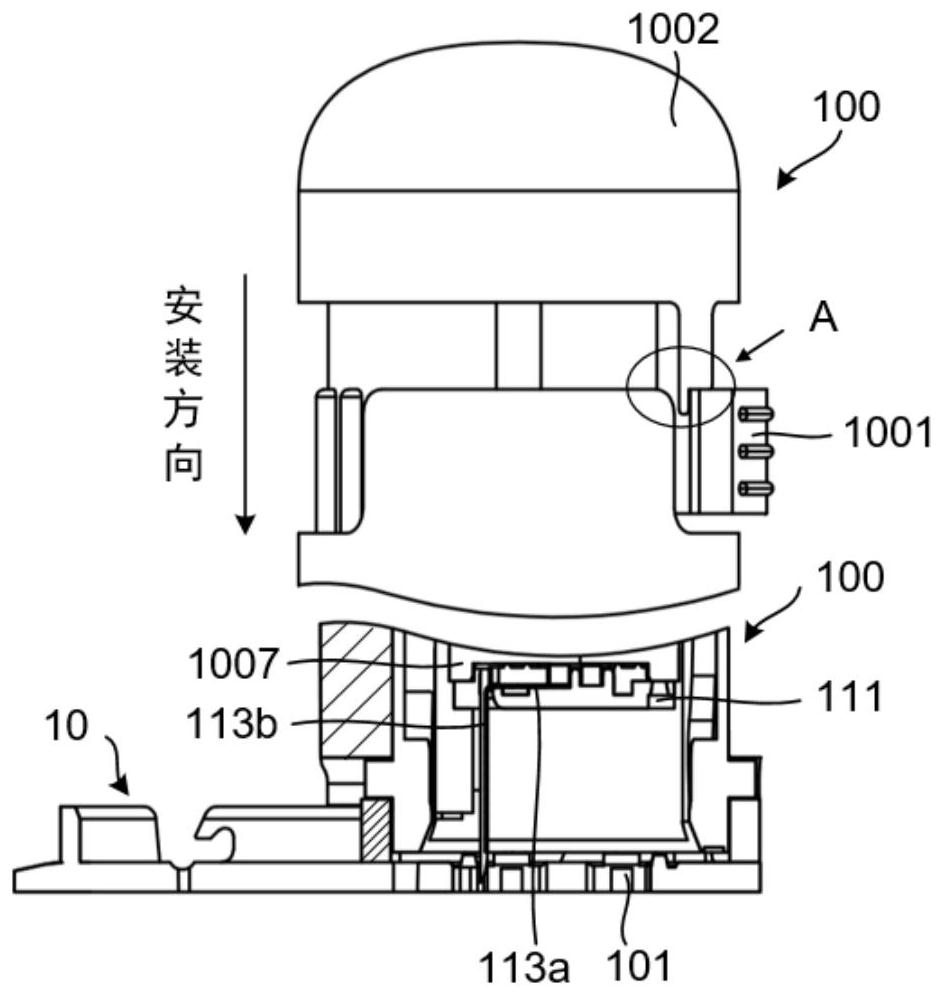

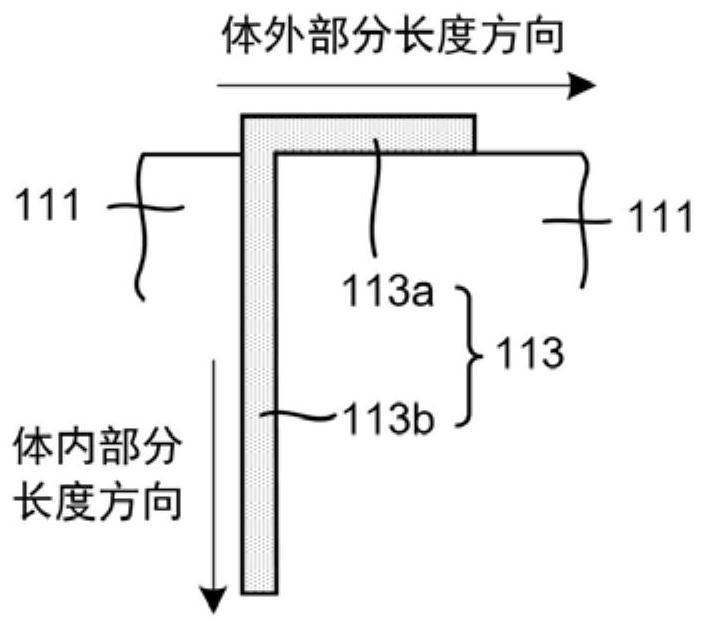

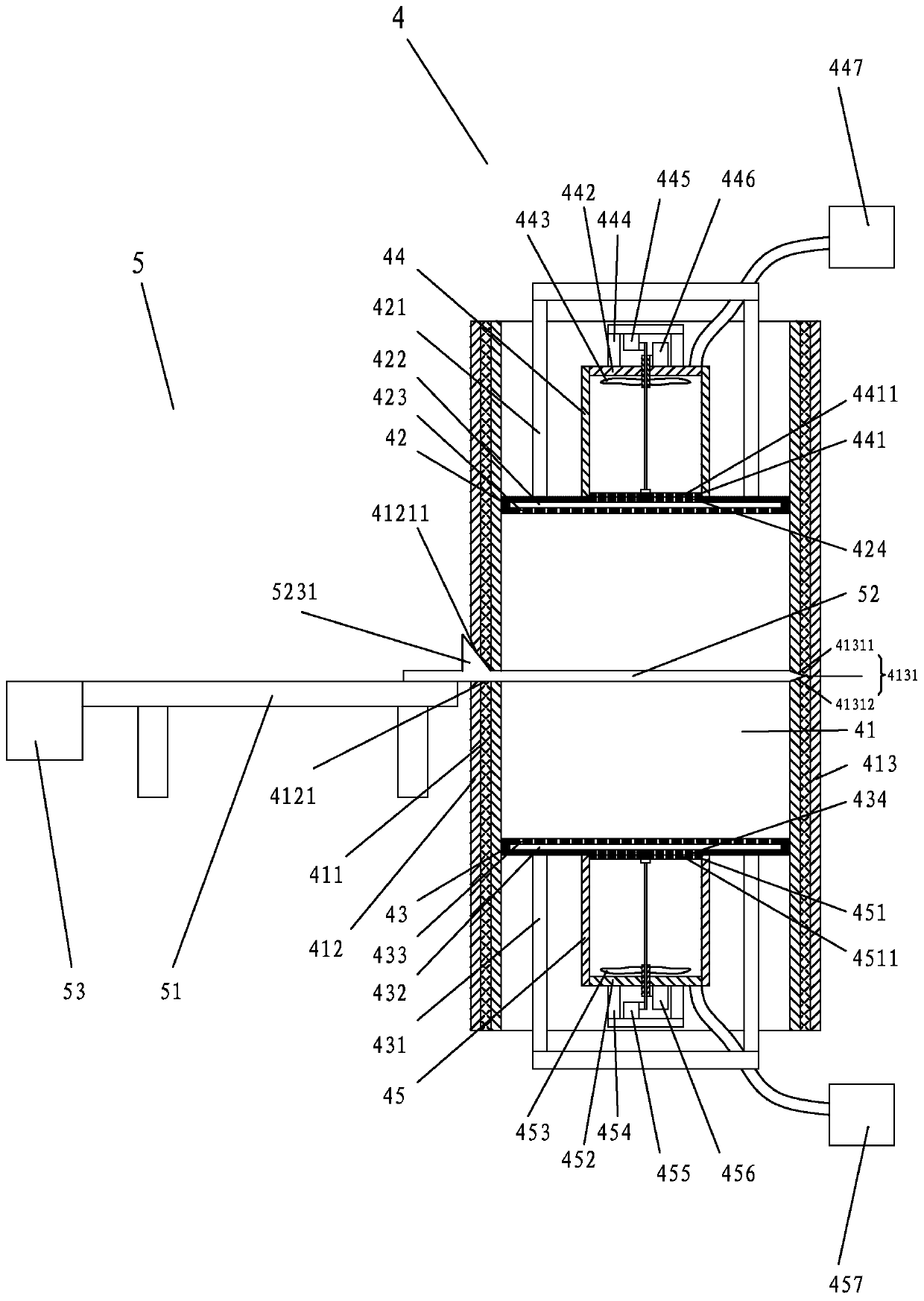

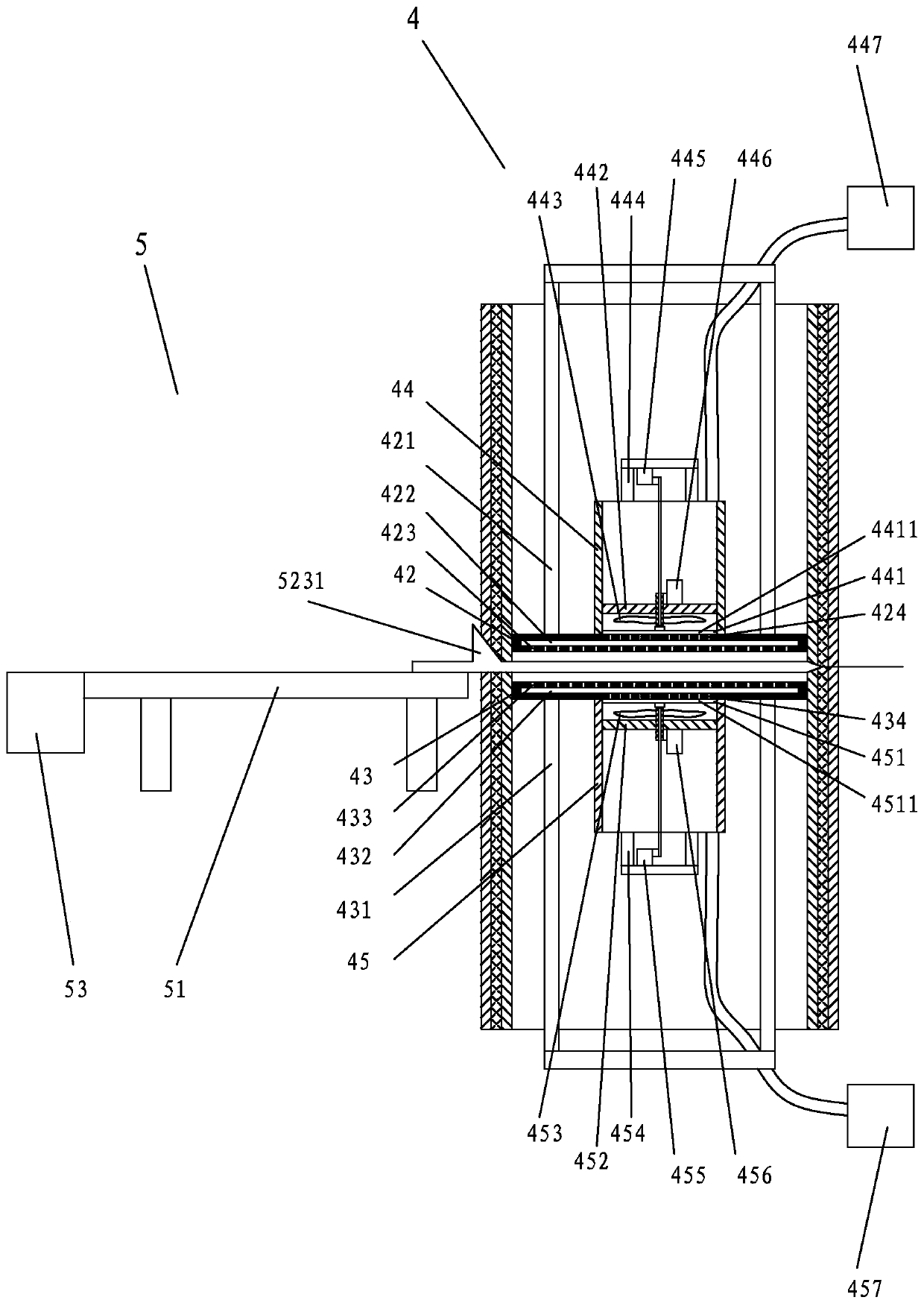

Mounting unit and mounting method of analyte detection device

PendingCN113274014AImprove reliabilityReduced Thickness DimensionsCatheterDiagnostic recording/measuringAnalyteEngineering

The invention discloses a mounting unit of an analyte detection device. The mounting unit comprises an auxiliary mounting structure, a sensor unit, a triggering part and a base, wherein the auxiliary mounting structure is arranged at the rear end of the mounting unit; the sensor unit is arranged close to the front end of the mounting unit; the sensor unit comprises a pedestal and a sensor arranged on the pedestal; the sensor comprises an in-vivo part and an in-vitro part; the in-vitro part is bent or buckled towards the top of the pedestal, and the in-vitro part is located at a working position; before the triggering part is started, the auxiliary mounting structure does not implement the mounting action; and the base is embedded into the mounting unit from the front end of the mounting unit. In the whole installation process, the shape of the in-vitro part of the sensor is not changed, an electrode or an electrode lead on the surface of the sensor is prevented from being broken, normal detection is ensured, and the reliability of the analyte detection device is improved.

Owner:MEDTRUM TECH

Mounting unit and mounting method of analyte detection device

The invention discloses a mounting unit of an analyte detection device. The mounting unit comprises an auxiliary mounting structure, a sensor unit, a triggering part and a first clamping part, wherein the auxiliary mounting structure is arranged at the rear end of the mounting unit; the sensor unit is arranged close to the front end of the mounting unit; the sensor unit comprises a base and a sensor arranged on the base; the sensor comprises an in-vivo part and an in-vitro part, the in-vitro part is bent or buckled towards the top of the base, and the in-vitro part is located at a working position; before the triggering part is started, the auxiliary mounting structure does not implement the mounting action; and the first clamping part is arranged at the front end of the mounting unit. In the whole installation process, the shape of the in-vitro part of the sensor is not changed, an electrode or an electrode lead on the surface of the sensor is prevented from being broken, normal detection is ensured, and the reliability of the analyte detection device is improved.

Owner:MEDTRUM TECH

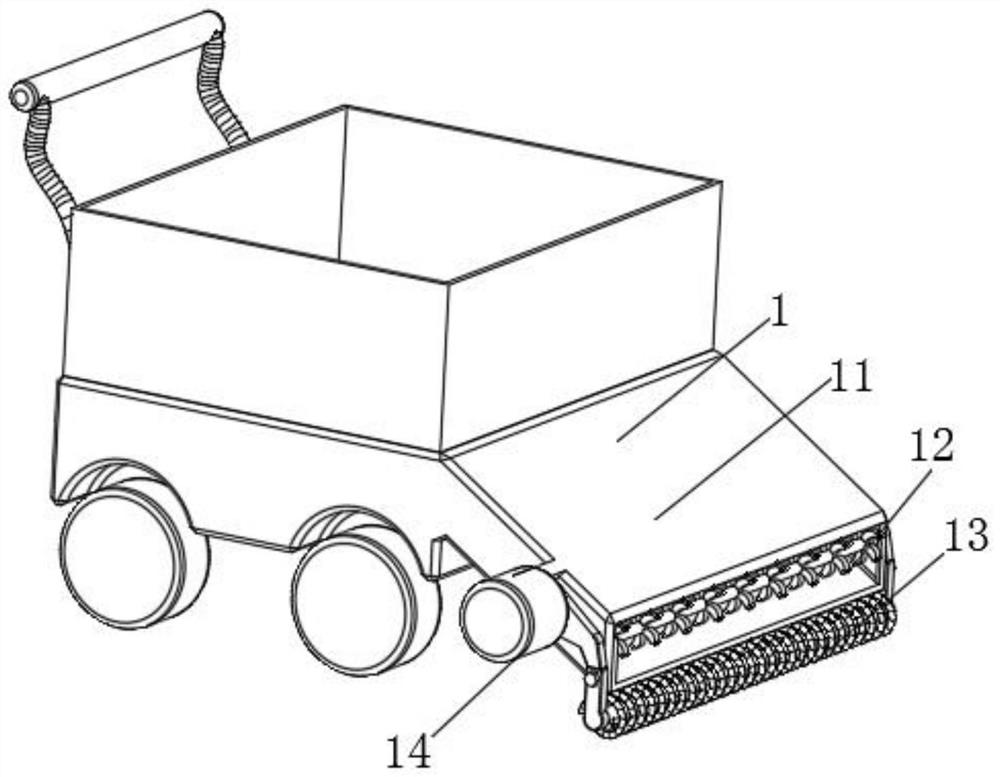

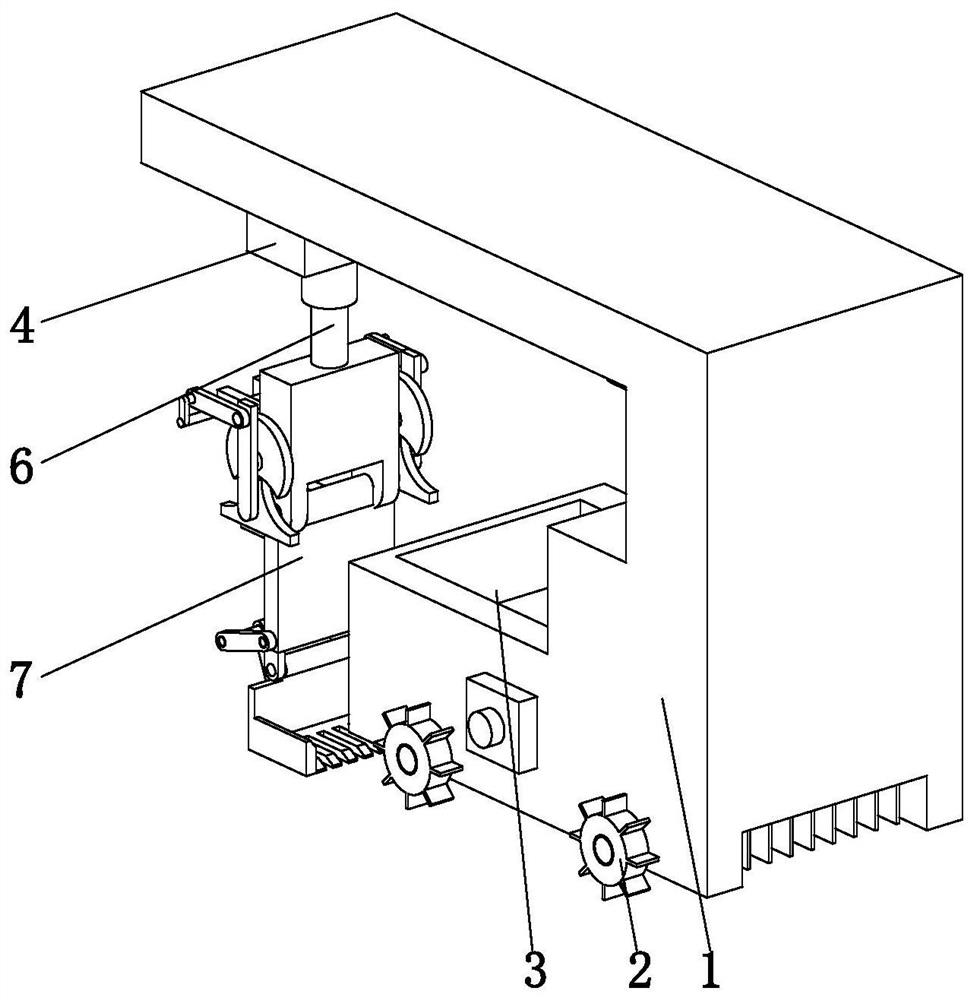

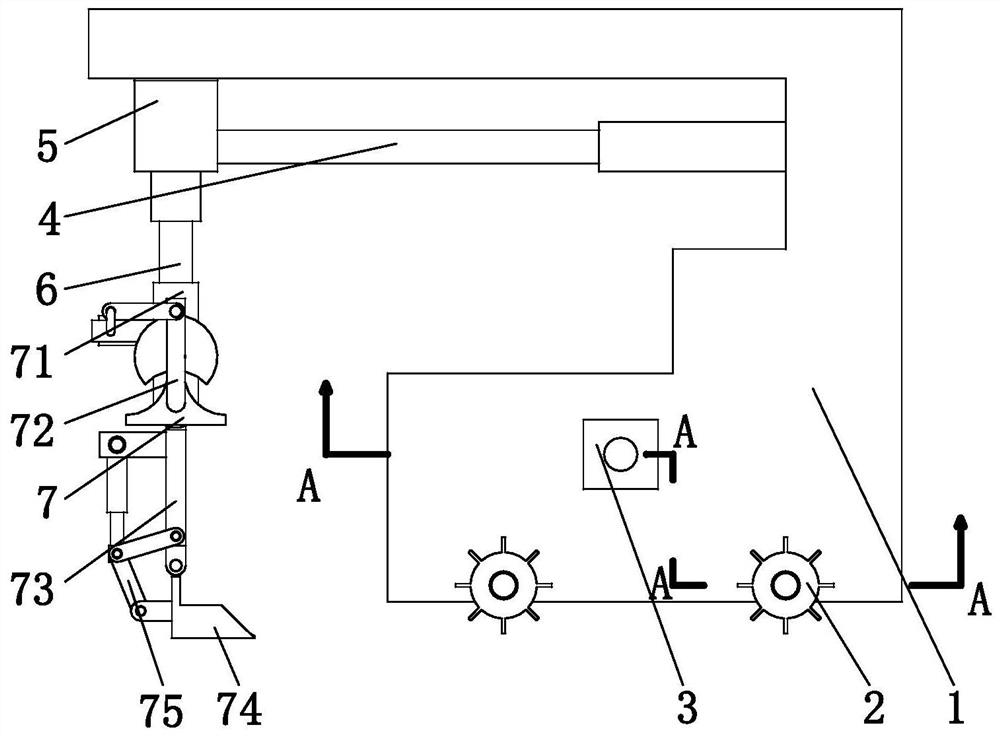

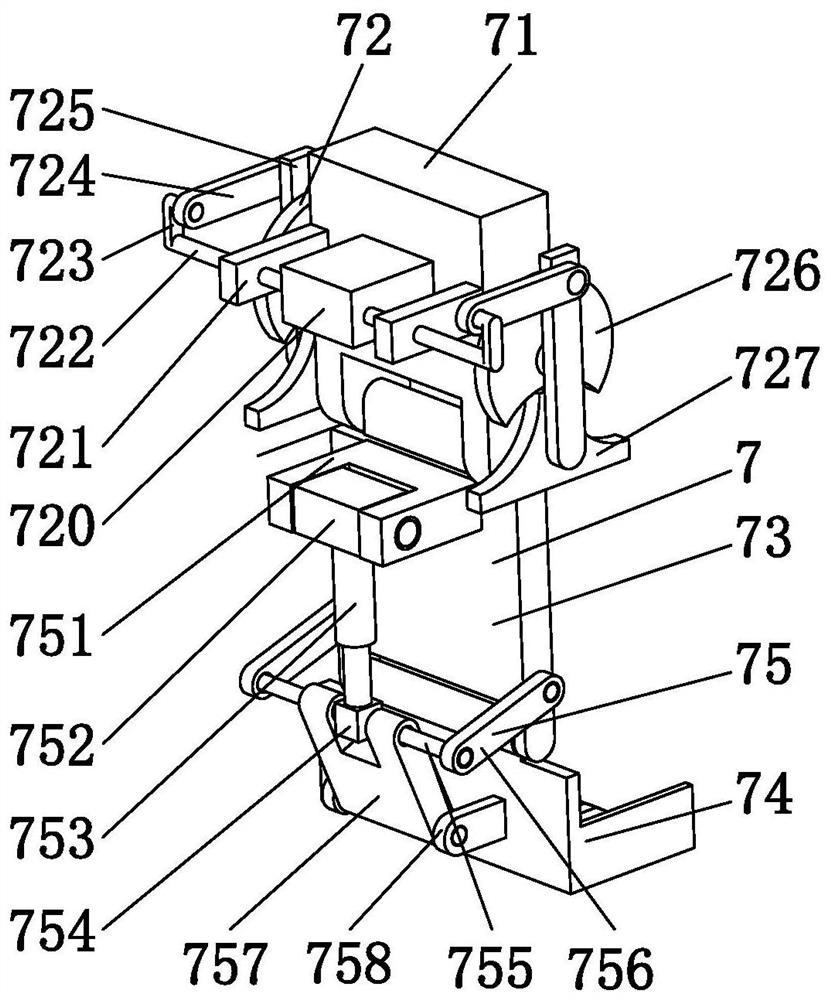

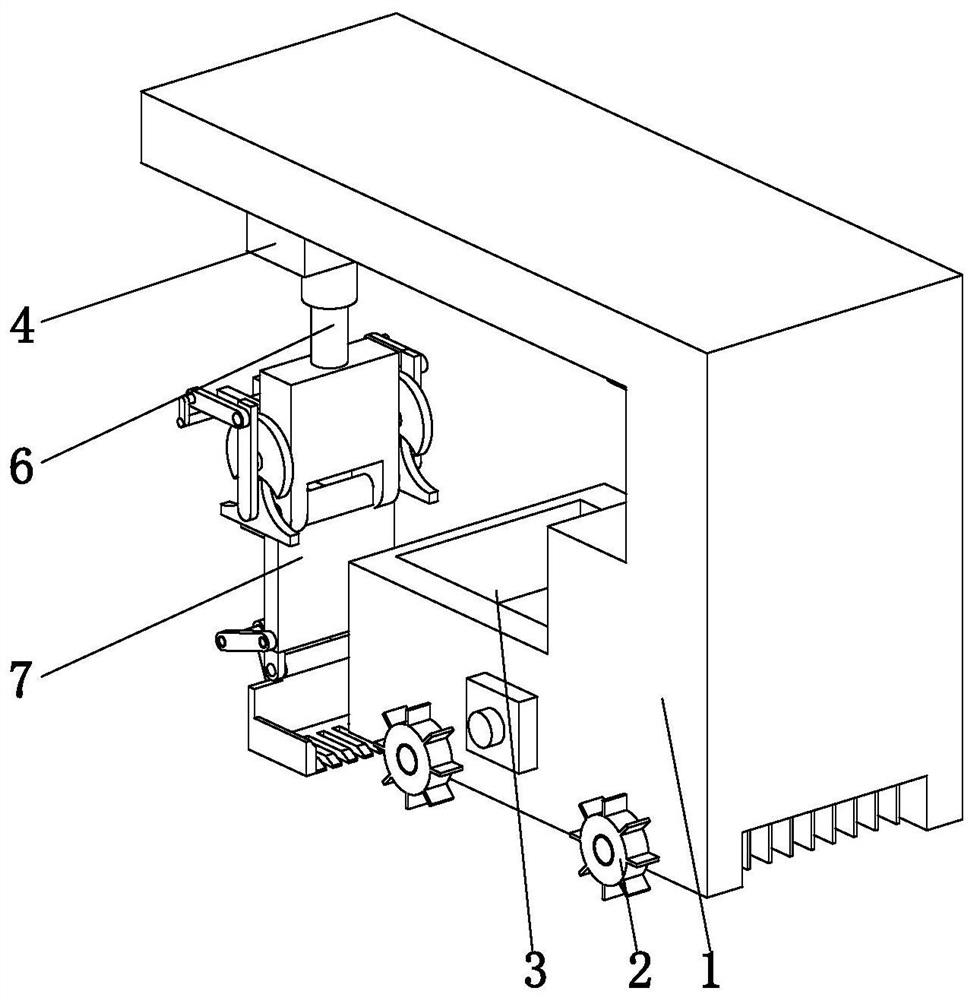

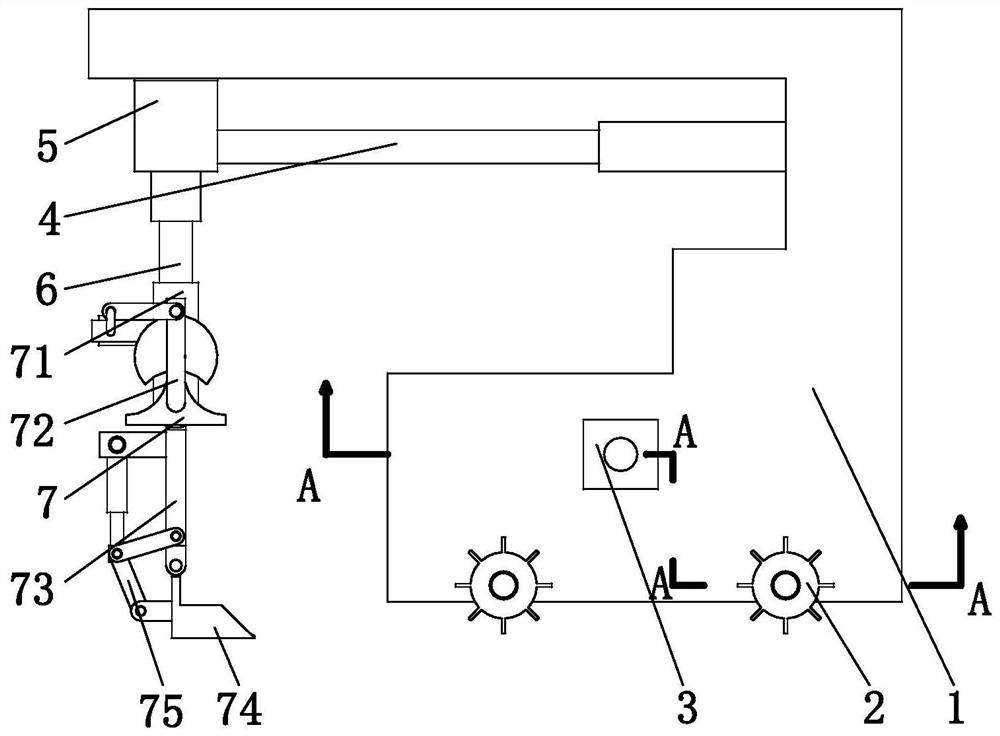

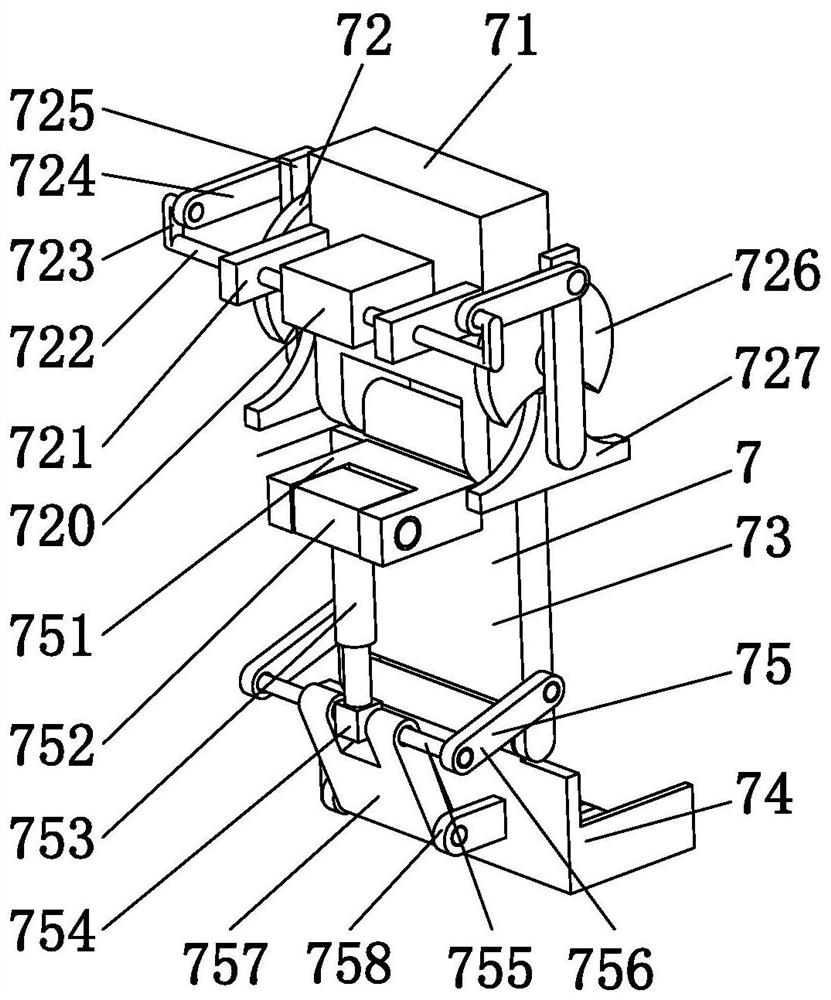

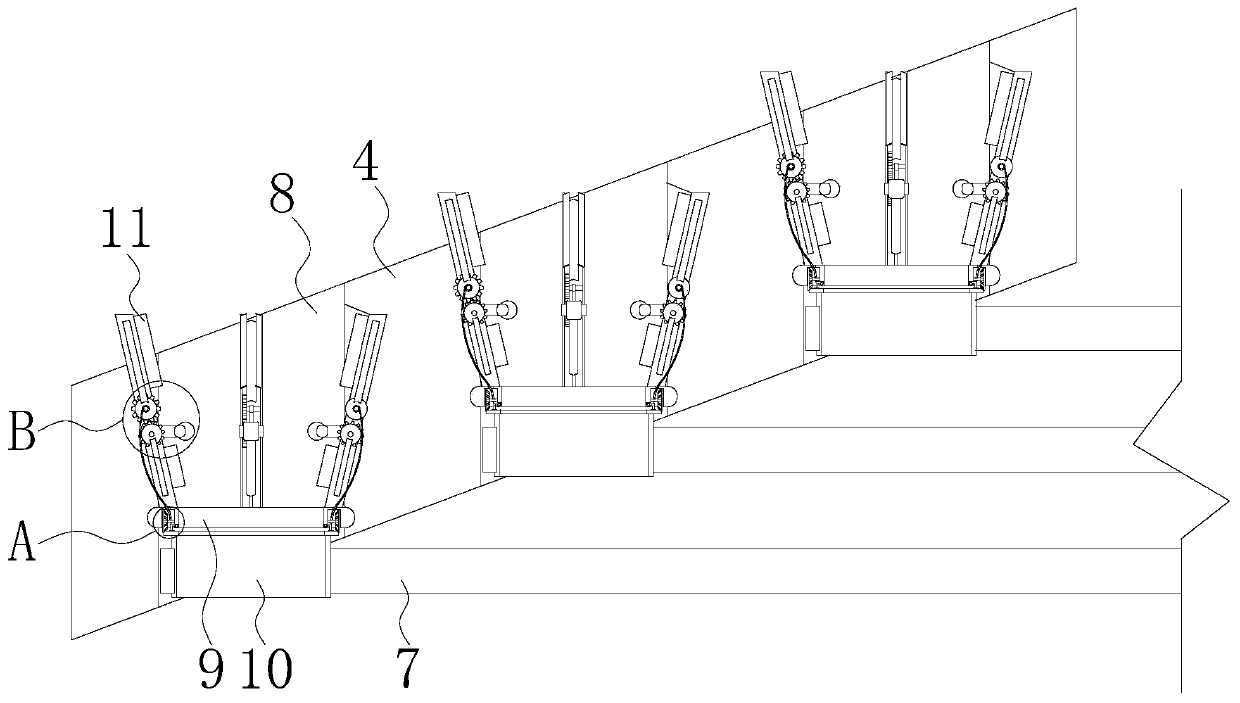

A soil breaking device for planting ground

ActiveCN111886946BNo reduction in intensitySwing back and forthSpadesPloughsAgricultural scienceAgricultural engineering

Owner:WEIFANG UNIVERSITY

Soil breaking and loosening device for planting lands

ActiveCN111886946ANo reduction in intensitySwing back and forthSpadesPloughsAgricultural engineeringStructural engineering

The invention provides a soil breaking and loosening device for planting lands. The soil breaking and loosening device comprises a rack, rollers, a soil loosening mechanism, a first air cylinder, a movable sliding block, a lifting air cylinder and a soil breaking mechanism. The soil breaking and loosening device for the planting lands can solve the following problems existing in a soil breaking and loosening process of the planting lands: a, traditional soil breaking and loosening of the planting lands are carried out by simple tools manually in general, and the tillage mode is high in labor intensity, needs to consume a large amount of time and is not suitable for large-area soil breaking and loosening; and b, soil loosening equipment in the current market is expensive and relatively single in function, the equipment which can often loosen soil cannot break and refine the soil and cannot effectively remove weeds in the soil, and the weeds in a place subjected to soil breaking and loosening often still grow in the place and need to be manually cleaned, so that the labor intensity is not reduced.

Owner:WEIFANG UNIVERSITY

YE JIAN dark tea and processing method thereof

The invention discloses YE JIAN dark tea and a processing method thereof. By adopting high-tenderness single-bud and / or one-bud and one-leaf tea as a raw material, through steps of activated aroma enhancement, slight water removing, twisting, deblocking and tea strip tidying, intermittent temperature-controlled alcoholization, pile fermentation, deblocking and tea strip tidying and low-temperature drying, the technical problems that dark tea processed by taking high-tenderness tea as the raw material cannot be easily processed, is sour and rancid in smell and is sapropelic in leaf bottom are solved. The dark tea processed by the processing method disclosed by the invention is exquisite in appearance and is glossy and bright, is pure in aroma, red, bright and glossy in liquor color and mellow in taste after being brewed, and the leaf bottom is complete and elastic.

Owner:湖南省怡清源茶业有限公司

An emergency cut-off valve

InactiveCN105370949AGood chemical compatibilityWith emergency cut-off functionOperating means/releasing devices for valvesEqualizing valvesEngineeringVALVE PORT

The invention provides an emergency cut-off valve used for transportation of high-danger chemicals. The emergency cut-off valve comprises an angular valve body, an accommodating cavity in the valve body, a push rod disposed in the accommodating cavity and extended out of the accommodating cavity, a drive device used for driving the push rod to slide in the accommodating cavity, a valve plate device, an inlet flange, and a runner in the valve body. The outer surface at the corner of the valve body is annularly provided with a concave cutting groove. The emergency cut-off valve also comprises a sealing corrugated pipe sleeving the head end of the push rod, and a push rod guide rail arranged in the accommodating cavity and fixedly connected with the valve body; the head end of the sealing corrugated pipe is pressed against the valve plate device and the tail end of the sealing corrugated pipe is embedded in the accommodating cavity hermetically; the push rod guide rail is embedded between the push rod and the tail end of the sealing corrugated pipe. The emergency cut-off valve is great in corrosion resistance and airtightness, is suitable for the transportation of high-danger chemicals, has an emergency cut-off function and is highly safe.

Owner:FORT VALE ENG SHANGHAI LTD

A coal mining waste rock solid material heating and crushing processing system

ActiveCN111795576BLow utilization efficiencyHigh labor costCharge manipulationChamber furnacesMining engineeringCrusher

The invention provides a heating and crushing processing system for waste rock solids in coal mining. The eating and crushing processing system comprises a calcinator, a calcining mechanism, a slidingplate, an electric push rod, a crushing box, a crushing mechanism and a supporting frame. The heating and crushing processing system can solve the following problems existing in the process of crushing and processing the waste rock solids in a coal mine: a, for coal mine waste rock crushing modes, in a traditional process, the coal mine waste rocks are conveyed into a crusher for stirring and rolling and decomposed into recyclable fine particles, no crushing pretreatment is conducted on the coal mine waste rocks in the traditional process, and it is difficult for the crusher to roll the coalmine waste rocks into small pieces; and b, generally, a traditional crusher is used for crushing the coal mine waste rocks, in this way, it is difficult to ensure that the coal mine waste rocks are 100% broken into required small pieces, the traditional crusher has low use efficiency and high labor cost, and it is often necessary to carry out secondary crushing on the broken waste rocks to ensurethat the broken small pieces can be used.

Owner:辽宁银盛水泥集团有限公司

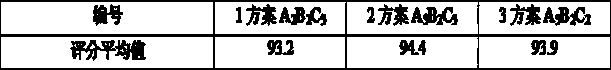

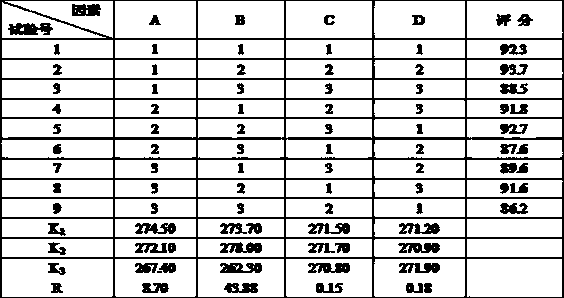

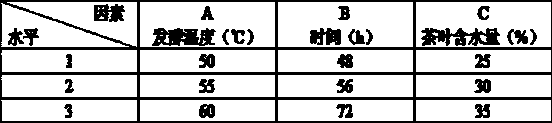

Method for selecting optimal microwave radiation power of environmental-friendly high-tenacity regenerated rubber

InactiveCN102634059AProtection from destructionSure breakPlastic recyclingEnvironmental resistanceProcess engineering

The invention discloses a method for selecting the optimal microwave radiation power of environmental-friendly high-tenacity regenerated rubber, belonging to the field of waste rubber regeneration. The method comprises the following steps of: flatly laying rubber to be processed 2 cm in thickness; then, carrying out microwave regeneration processing on the rubber; under the condition that the microwave radiation frequency is 2450 Hz, respectively setting the power into seven power points: 320 W, 400 W, 480 W, 560 W, 640 W, 720 W and 800 W power points, respectively setting the radiation time into seven time points: 60 s, 70 s, 80 s, 90 s, 100 s, 110 s, 120 s time points, and carrying out microwave radiation processing on the rubber for seven times under each power point; and respectively carrying out low-temperature regeneration on 49 rubbers subjected to microwave radiation for 20 min on a low-temperature roll mill under each power point and each time point. Through carrying out testing on the physical mechanical properties and manufacturing process properties of the rubber prepared according to a national standard formula, the radiation power corresponding to the rubber with the optimal comprehensive property is determined as the optimal microwave radiation power. The method has the beneficial effects of saving the radiation energy and improving the properties of the regenerated rubber.

Owner:XUZHOU COLLEGE OF INDAL TECH

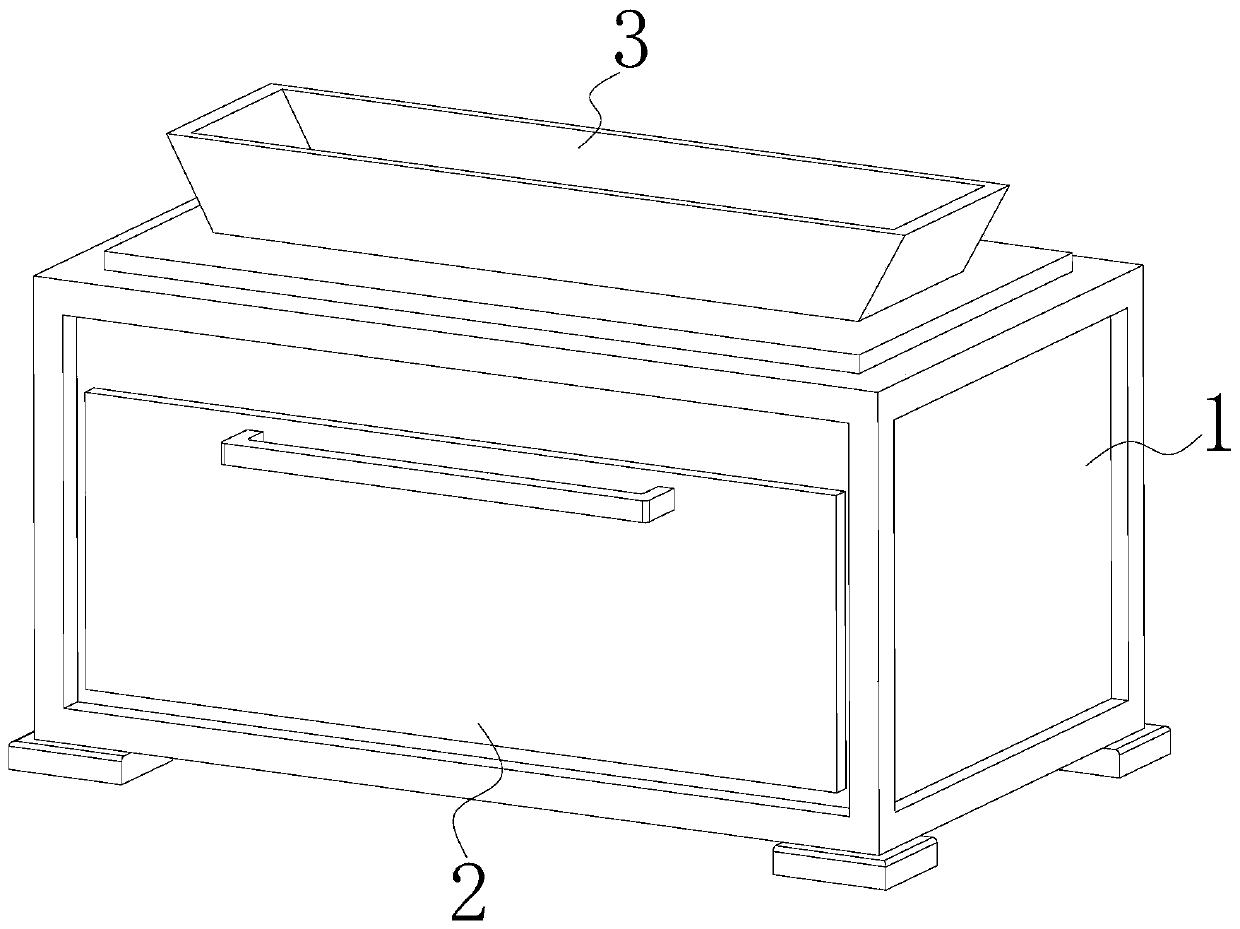

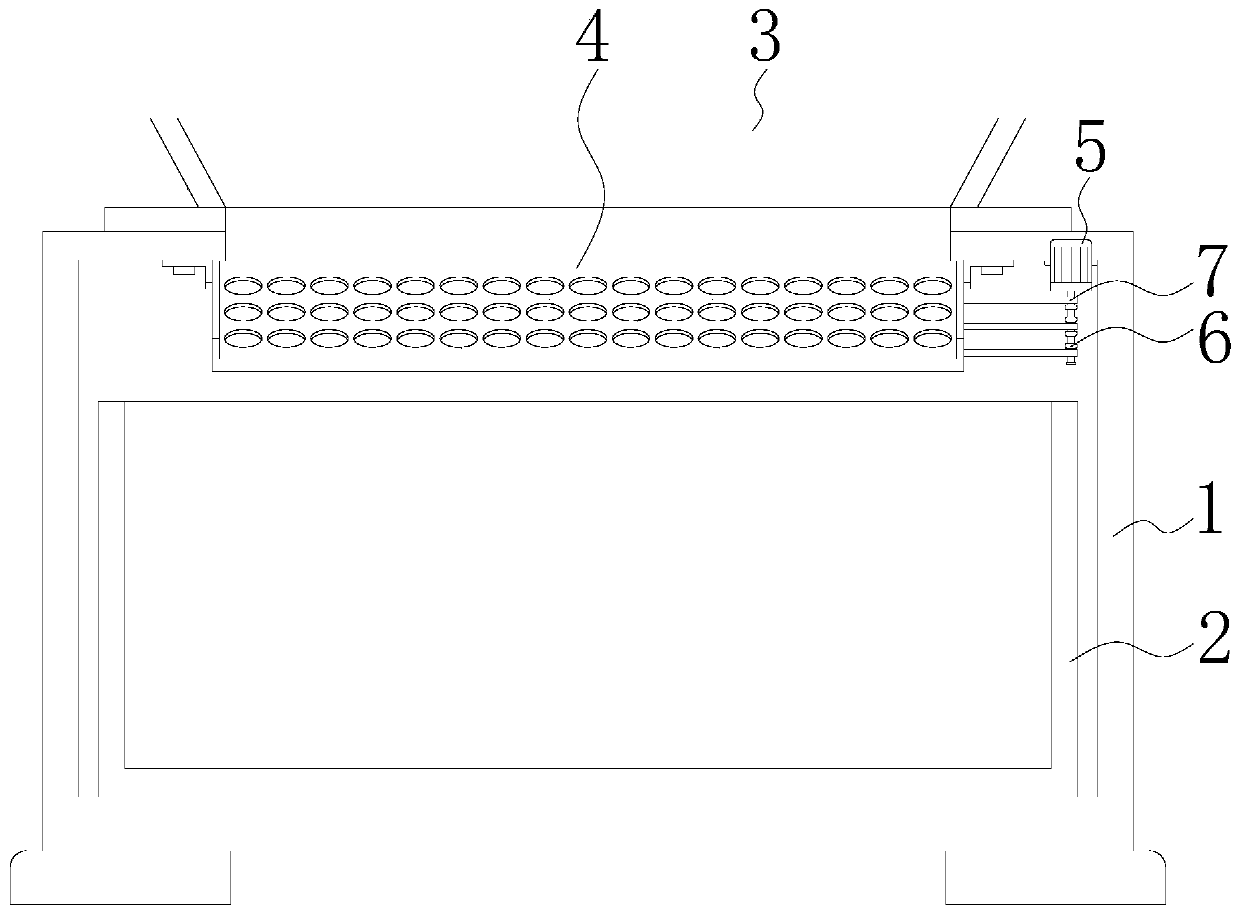

Brown rock sugar special crushing machine in multicrystal rock sugar processing process

The invention discloses a brown rock sugar special crushing machine in the multicrystal rock sugar processing process, and relates to the technical field of sugar crushing. The brown rock sugar special crushing machine in the multicrystal rock sugar processing process comprises a machine body, a collection box and a feeding frame. The bottom of the collection box is connected with the inner bottomof the machine body in a sliding manner. The front face of the collection box penetrates through the front face of the machine body. The feeding frame is fixedly connected to the middle portion of the top of the machine body. An inner cavity of the feeding frame communicates with an inner cavity of the machine body. The top of the collection box is in an opening shape. An inclined plate is arranged below the communicating position of the feeding frame and the machine body. According to the brown rock sugar special crushing machine in the multicrystal rock sugar processing process, conical gears are driven by conical gear rings to rotate so that rotating shafts can rotate and pull traction ropes downwards, every two corresponding crushing knives are made to oppositely rotate due to opposite rotation directions, rock sugar falling into crushing openings can be effectively limited through soft bags at the same time, and the crushing knives in four directions can effectively clamp the rock sugar to adapt to the irregular shapes of the rock sugar.

Owner:赵苗

Packaging body of medical instrument

ActiveCN114671131AEasy to operateAchieve clampingContainers to prevent mechanical damageInternal fittingsApparatus instrumentsBiomedical engineering

The invention discloses a medical instrument packaging body, and particularly relates to the technical field of medical instruments, the medical instrument packaging body comprises packaging shell main bodies arranged at the two ends of a medical instrument in a sleeving mode respectively, the inner space of each packaging shell main body is matched with the outer side area of the medical instrument, and protective supporting connecting mechanisms are arranged on one sides of the inner walls of the two packaging shell main bodies; a self-locking limiting mechanism is arranged in the protection supporting connecting mechanism, and the protection supporting connecting mechanism comprises a reinforcing mounting ring. According to the device, through the mutual influence effect of all the structures, integrated synchronous operation of supporting, fixing and limiting of medical instruments and subsequent storing and taking of the medical instruments is achieved, so that the more efficient protection performance of the medical instruments is achieved, the situation that a packaging body and the medical instruments are broken under external pressure or violent transportation can be effectively avoided, and the safety of medical instruments is improved. And meanwhile, subsequent storage and taking are easier, and use is convenient.

Owner:国创医疗科技(江苏)有限公司

A lithium primary battery with high discharge efficiency

ActiveCN107681171BEnsure safetyImprove discharge capacityNon-aqueous electrolyte cellsPrimary cell electrodesDischarge efficiencyEngineering

The invention relates to the technical field of batteries, in particular to a lithium primary battery with high discharge efficiency. It includes a positive electrode sheet, a separator, a lithium strip negative electrode sheet and tabs arranged on the positive and negative electrode sheets. Together, the winding tail end of the lithium strip negative electrode sheet is provided with an inhibition reaction zone; the described inhibition reaction area is provided with a polymer tape sheet; a stop is provided between the tab of the lithium strip negative electrode sheet and the polymer tape sheet React groove. The inhibiting reaction region of this structure can ensure that the normal discharge of the battery is sufficient and effective, and the stop reaction notch can ensure that the lithium ribbon of the battery is broken under the condition of overdischarge and forced discharge, thereby ensuring the safety of the battery, so the lithium primary battery of the present invention has high discharge capacity, Excellent safety performance.

Owner:HUIZHOU HUIDERUI LITHIUM BATTERY TECHNOLOGY CO LTD

An agricultural cotton dehulling machine

ActiveCN112971160BImprove crushing effectGuaranteed to workSaving energy measuresHuskingAgricultural scienceAgricultural engineering

The invention discloses an agricultural cotton hulling machine. Its structure includes a feeding hopper, a hulling device, a transmission box, a discharging box and a discharging plate. The front surface of the device is provided with a transmission box and is connected by transmission. The crushing head is driven by a spring rod to perform telescopic extrusion, so as to prevent the cotton from shrinking during extrusion and crushing, and improve the crushing ability of the cotton shell. Sliding, elastic force is generated during the movement of the frame plate, so that the cotton stuck between the crushing heads is ejected out. When the roller body rotates, the cam pushes down the lower pressure rod, and the lifting rod is carried out inside the fixed frame. The vertical lift drives the fixed rod and the connecting frame to squeeze down, the torsion shaft makes the pendulum rotate slightly, and the lower end of the pendulum is squeezed down, so as to press down on the fluffy cotton after shelling to avoid Fluffy cotton is jammed inside the lower end of the separation box.

Owner:溧阳市捌伍叁科技有限公司

A kind of high-efficiency rapid diversion antibacterial hot air non-woven fabric and production method thereof

InactiveCN107696648BImprove permeabilityStrong capillaritySynthetic resin layered productsLaminationEnvironmental resistanceCompound a

Owner:福建金坛实业有限公司

A nickel-based corrosion-resistant alloy pipe and its manufacturing method

The invention discloses a nickel-base anti-corrosion alloy pipe for a high-temperature gas-cooled reactor steam generator and a manufacturing method of the nickel-base anti-corrosion alloy pipe. The nickel-base anti-corrosion alloy pipe comprises the components of, by weight, 0.03-0.04% of C, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 20.0-23.0% of Cr, greater than or equal to 58.0% of Ni, 8.5-9.5% of Mo, 3.3-3.8% of Nb, 0.35-0.60% of Al, 0.35-0.60% of Ti, 0.002-0.005% of Mg, 3.0-5.0% of Fe, 0.90-1.0% of Al and Ti, and the balance unavoidable impurities. According tothe nickel-base anti-corrosion alloy pipe, the pipe structure is even, the grain size reaches 3-5 grades, the tensile strength at the room temperature is higher than or equal to 700 MPa, the yield strength is higher than or equal to 300 MPa, and the ductility is higher than or equal to 40%; the high-temperature strength at the temperature of 750 DEG C is higher than or equal to 500 MPa, the yieldstrength is higher than or equal to 210 MPa, and the ductility is higher than or equal to 90%; flattening is conducted till the inner wall distance is two times of the wall thickness, cracks cannot be generated on a sample after flattening is conducted, pipes are subjected to the hydrostatic test under the water pressure being 20 MPa one by one, and the phenomenon of water leakage or sweating cannot occur; and the pipes are subjected to liquid permeation testing one by one, the permeation defect is not allowed to occur on the surface, extrapolation is conducted for 105 hours at the temperature of 750 DEG C and the endurance strength is higher than or equal to 75.3 MPa, and the manufacturing requirements of the high-temperature gas-cooled reactor steam generator are met.

Owner:宝武特种冶金有限公司

A kind of manufacturing method of gh3600 alloy fine thin-walled seamless pipe

The invention relates to a GH3600 alloy fine thin-walled seamless pipe manufacturing method, which comprises: adopting methods of vacuum induction smelting and electroslag remelting smelting to smelt a casting ingot meeting requirements; adopting a 2000 or 4000 ton rapid forging and 1300 ton radial forging thermal combined forging process to carry out cogging on the casting ingot so as to ensure complete crushing of the thick and large structure of the casting ingot, produce the round pipe billet with the uniform structure, increase the plasticity of material, and saves energy consumption; adopting a hot extrusion process to produce a lateral so as to ensure the uniformity of the internal structure of the lateral and the high quality of the external surface of the lateral, and make the performance of the produced finished product pipe excellent; and adopting a multi-pass cold rolling and cold drawing process and the matched heat treatment process, and assistedly adopting the special lubrication process and the cleaning process to control the structure and the high performance of the pipe so as to finally obtain the GH3600 alloy fine thin-walled pipe with characteristics uniform and fine pipe structure and high comprehensive performance.

Owner:宝武特种冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com