Airbag door, method of controlling breakage of tear line, and method of expanding airbag

A control method and airbag door technology, which is applied in vehicle safety arrangements, instrument panels, pedestrian/passenger safety arrangements, etc., can solve the problems of hindering the breakage of the base material, damaging the airbag, and incomplete breakage of the base material, so as to achieve the effect of ensuring the breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] (airbag door in Embodiment 1)

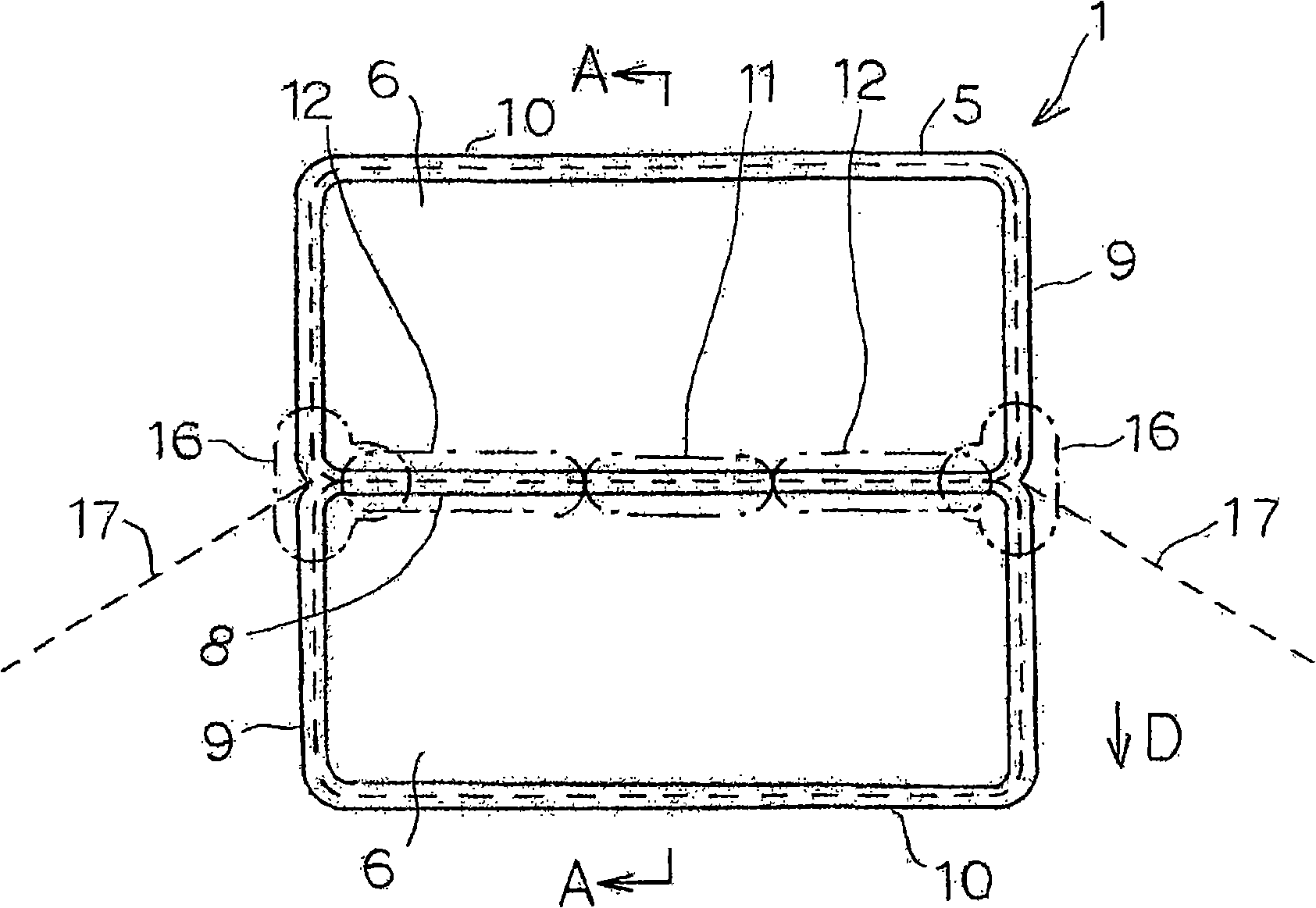

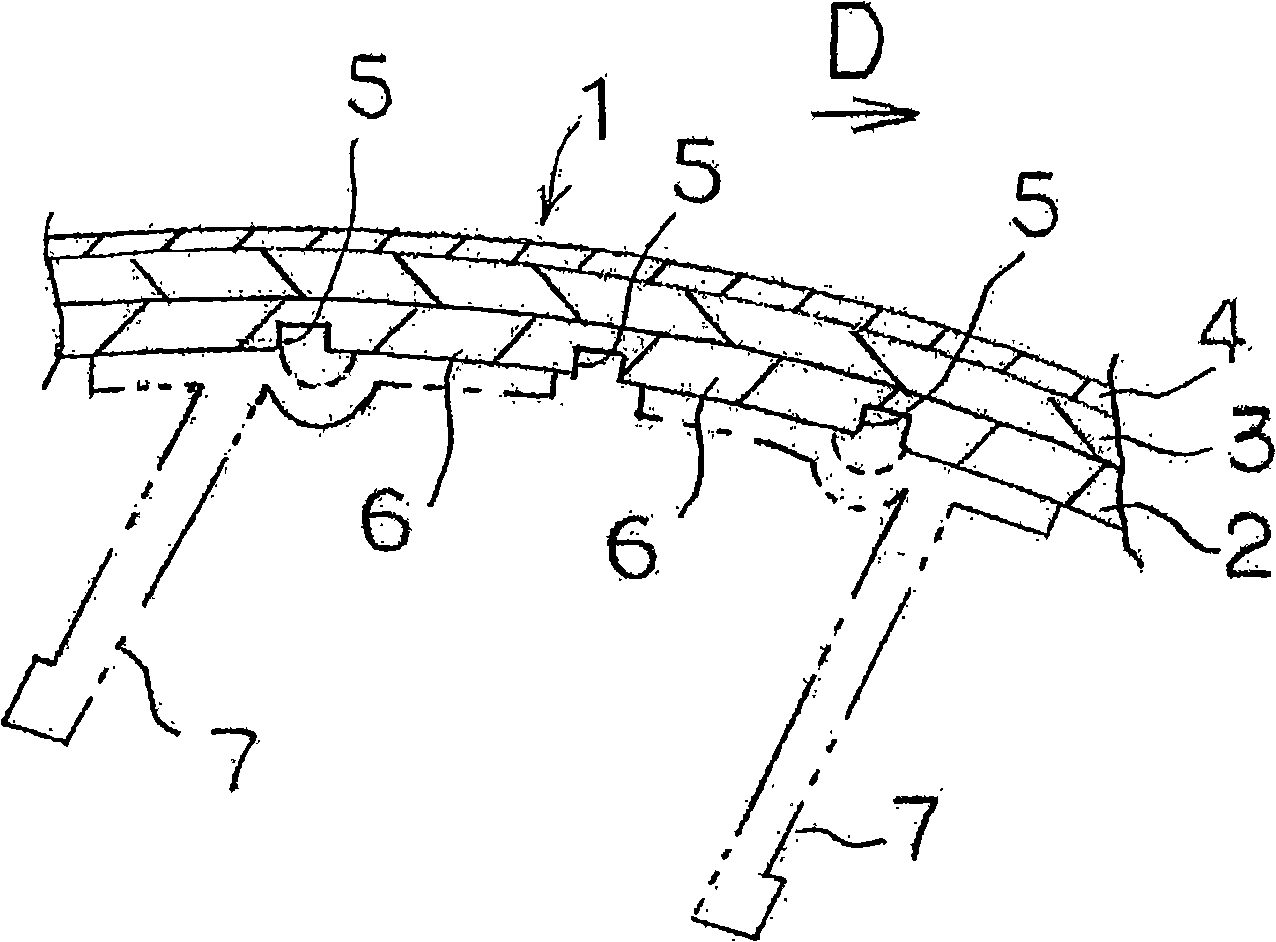

[0136] The airbag door 1 of the present embodiment is formed on an instrument panel of a motor vehicle. figure 1 Indicates the airbag door 1 seen from the back side of the instrument panel, figure 2 means along figure 1 Sectional view of line A-A.

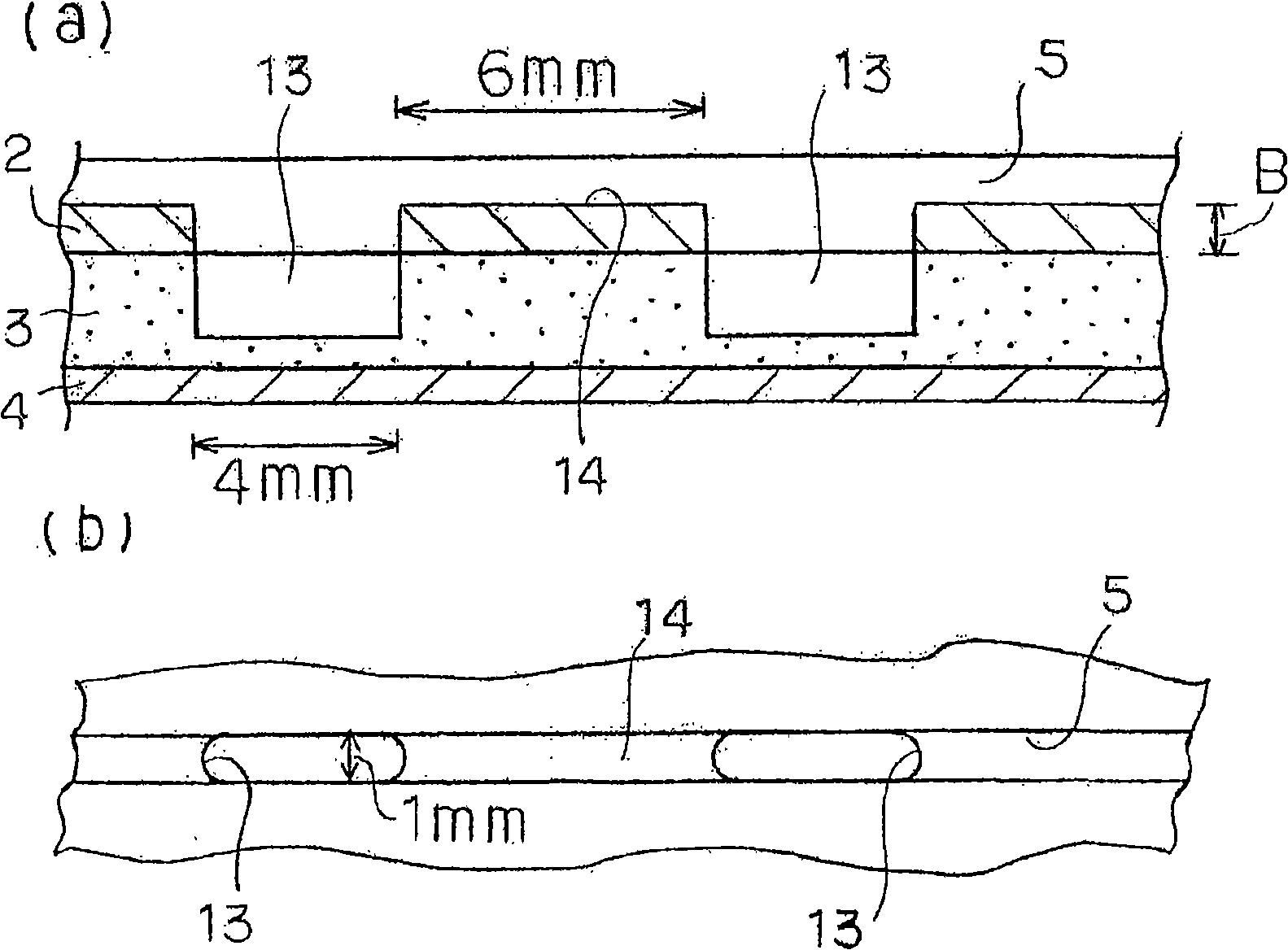

[0137] Depend on figure 2 It can be seen that the instrument panel is a laminated structure in which the foam material layer 3 and the skin 4 are formed on the base material 2 . The base material 2 constituting the back of the instrument panel was made of polypropylene and had a thickness of 3 mm. The foam material layer 3 is in contact with the substrate 2 and is made of foamed polypropylene with a thickness of about 2mm. The skin 4 adjoining the layer of foamed material 3 forms the surface of the instrument panel, is made of polyolefin and has a thickness of approximately 0.6 mm.

[0138] Such as figure 1 As shown, on the back of the base material 2, tear grooves 5 are continuously ...

Embodiment 2

[0155] In this example, if Figure 7 As shown, the structure is the same as that of Example 1, except that the tear line 17' for breaking the skin extends linearly from the center line 8 without being bent. The effect of embodiment 2, effect, except not having above-mentioned Figure 6 (a) and Figure 6Except for the action and effect shown in (b), it is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com