A lithium primary battery with high discharge efficiency

一种放电效率、电池的技术,应用在一次电池的电极、一次电池的零部件、非水电解质电池等方向,能够解决存在安全陷患、反应消耗多、负极利用率下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

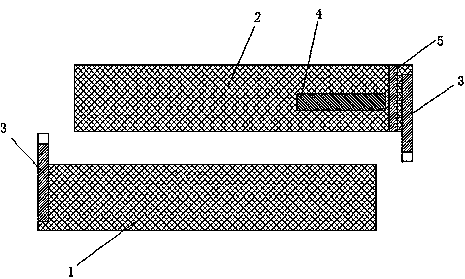

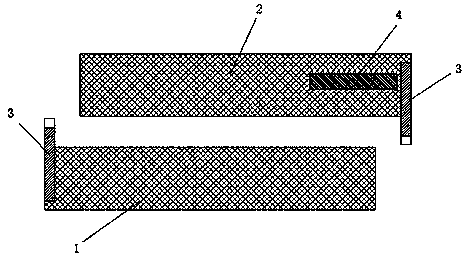

[0015] like figure 2 Shown: a lithium primary battery with high discharge efficiency, comprising a positive electrode sheet 1, a diaphragm, a lithium belt negative electrode sheet 2 and a tab 3 arranged on the positive and negative electrode sheet, the positive electrode sheet 1, the separator and the lithium belt negative electrode The sheet 2 is wound together with the tab end of the positive electrode sheet as the starting end, and a restraining reaction area is provided at the winding end of the lithium strip negative electrode sheet 2; the restraining reaction area is provided with a polymer tape sheet 4 ; Between the tabs 3 of the negative electrode sheet 2 of the lithium strip and the polymer adhesive tape sheet 4, there is a groove 5 for suspending the reaction. The formation of the positive electrode sheet is as follows: Weigh 1843g of heat-treated electrolytic manganese dioxide, 37g of graphite, 120g of conductive carbon black, and 72g of polytetrafluoroethylene sol...

Embodiment 2

[0017] The lithium strip positive electrode sheet 1 was prepared according to the method described in Example 1, and the figure 2 In the position shown, the length and width of the polymer tape sheet 4 are 25mm×4mm, and the length and width of the lithium tape negative sheet are 240mm×25mm. The length of the groove for stopping the reaction is 25 mm, and the depth of the groove 5 accounts for 40% to 90% of the thickness of the entire negative electrode sheet. The width of the groove 5 accounts for 0.1% to 7% of the length of the entire negative electrode sheet.

Embodiment 3

[0019] The lithium strip positive electrode sheet 1 was prepared according to the method described in Example 1, and the figure 2 In the position shown, the length and width of the polymer tape sheet 4 are 30mm×8mm, and the length and width of the lithium tape negative sheet are 240mm×25mm. The length of the groove for stopping the reaction is 25 mm, and the depth of the groove 5 accounts for 40% to 90% of the thickness of the entire negative electrode sheet. The width of the groove 5 accounts for 0.1% to 7% of the length of the entire negative electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com