Crushing and screening grading device for active carbon

A crushing, screening and grading device technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of reducing processing efficiency, low degree of automation, and good crushing effect, so as to realize automatic processing, improve processing efficiency, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

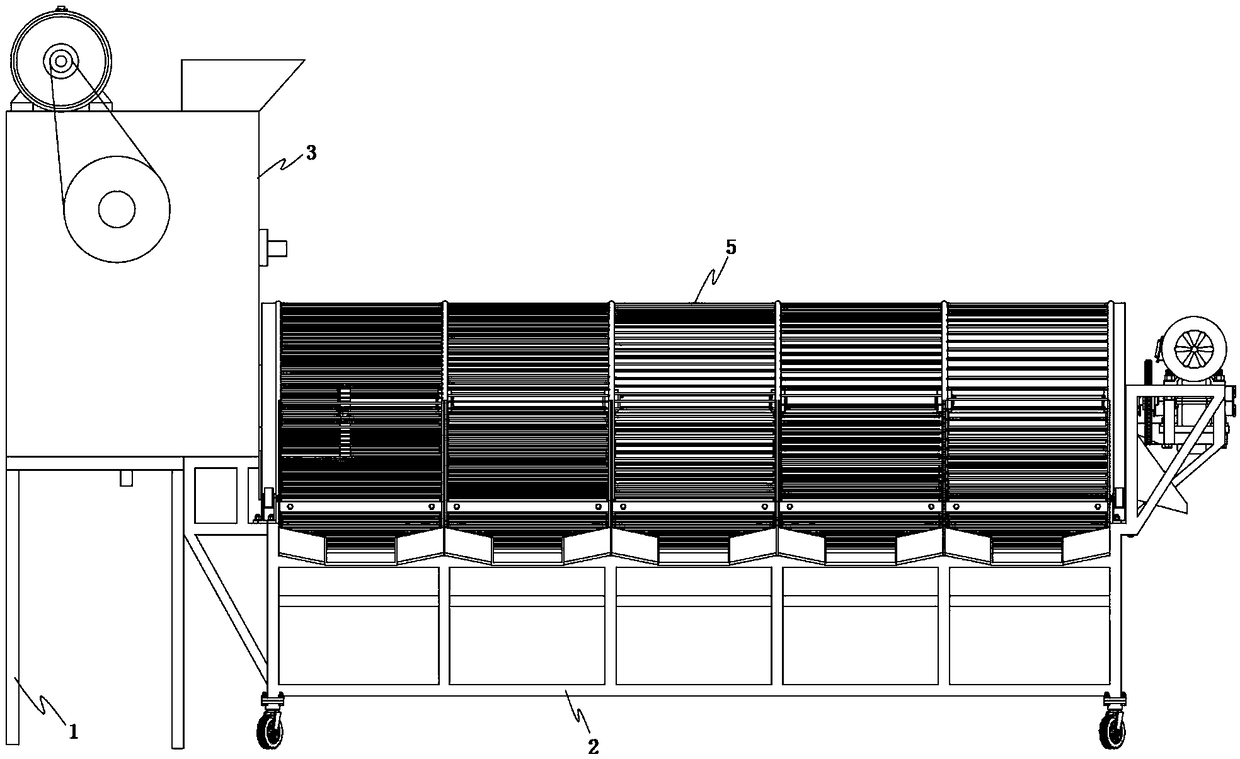

Embodiment 1

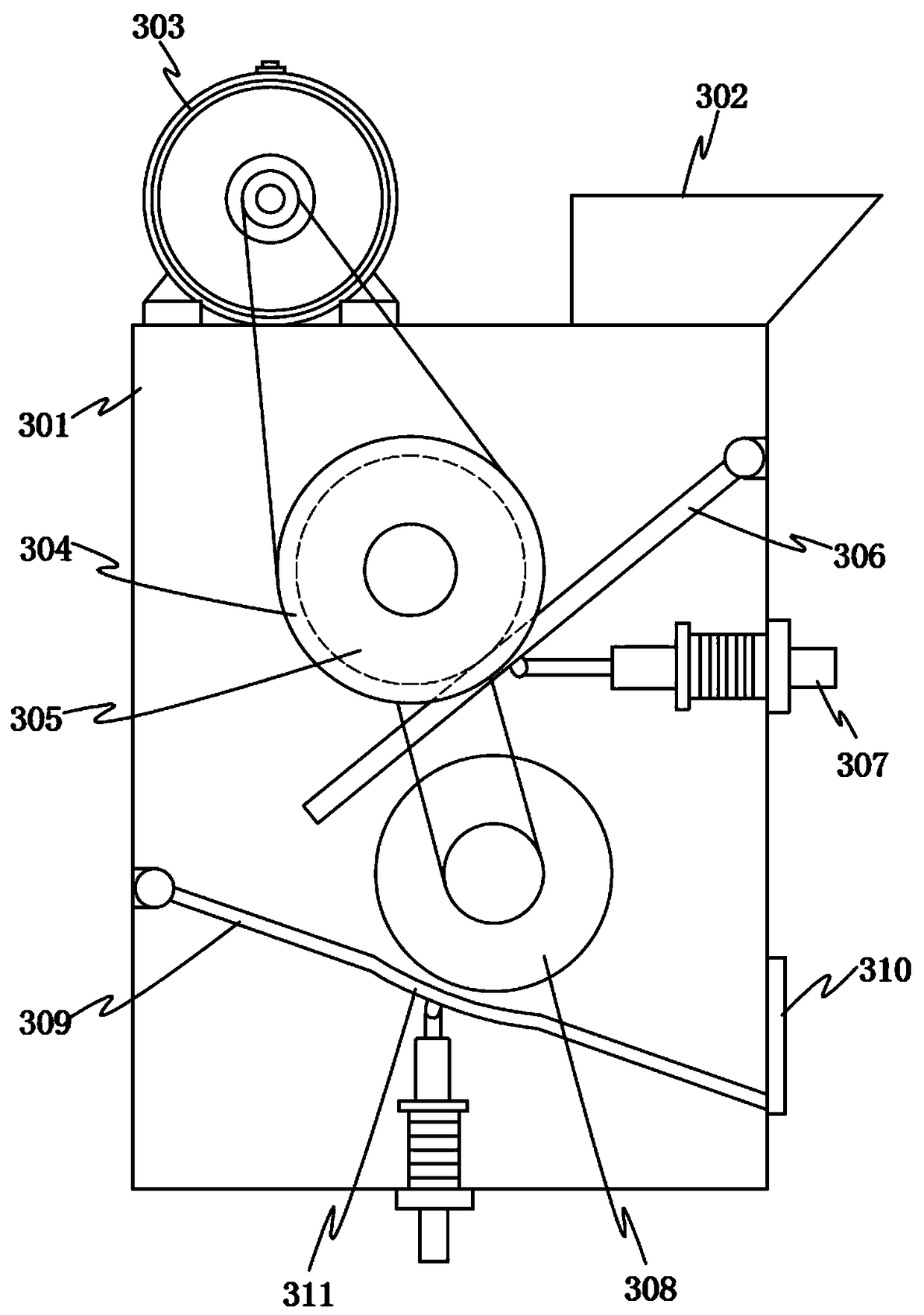

[0024] When this crushing, screening and classifying device crushes activated carbon, the activated carbon is first added from the activated carbon feed port 302 at the upper end of the crushing box 301, and at the same time, the crushing drive motor 303 at the top of the crushing box 301 is started, and the crushing drive motor 303 drives the rotating gear The roller I305 and the rotating toothed roller II308 rotate, and after the activated carbon is added into the crushing box 301, it rolls down along the crushing jaw plate I306, and the activated carbon on the crushing jaw plate I is rolled and crushed by the rotating toothed roller I305. After crushing, the activated carbon rolls down along the crushing jaw plate I onto the crushing jaw plate II 309, and when the activated carbon rolls into the crushing groove 311 in the middle of the crushing jaw plate II 309, the activated carbon is secondary crushed by the rotating gear roller II 308, and the activated carbon is After ro...

Embodiment 2

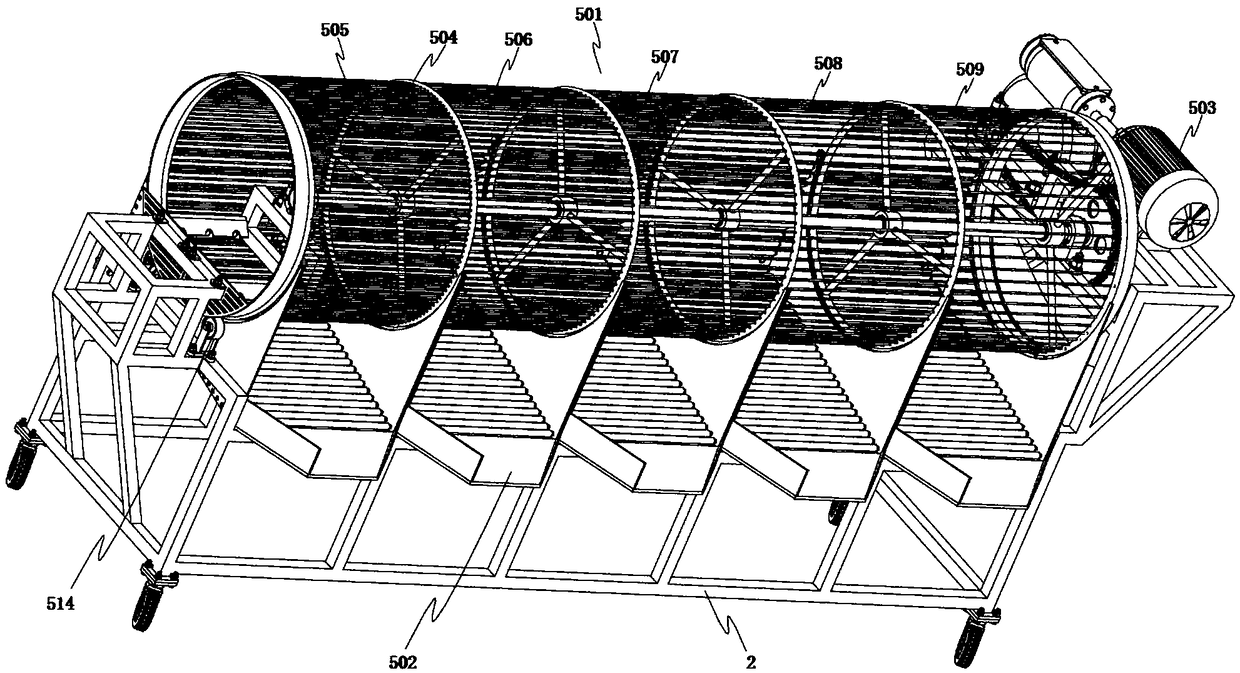

[0026]After the activated carbon is crushed, the activated carbon discharged from the output port 310 enters the screening and grading mechanism 5 from the sorting drum 501. At the same time, the sorting drum 501 is driven by the driving motor I503 fixed on the second frame 2 and through the transmission chain and The transmission of the driving gear 512 at the end of the rotating shaft 511 drives the sorting drum 501 to rotate on the second frame 2, and the activated carbon that enters the sorting mechanism 5 rolls and precesses under the rotating drive of the sorting drum 501, and the water chestnuts During the process of rolling and precessing, the activated carbon moves from the steel bars of sorting unit I505, sorting unit II506, sorting unit III507, sorting unit IV508 and sorting unit X509 of sorting drum 501 in order of particle size from small to large. The slits drop into the discharge port 502 of the lower part in turn, and output along the discharge port 502, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com