Patents

Literature

61results about "Chamber furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

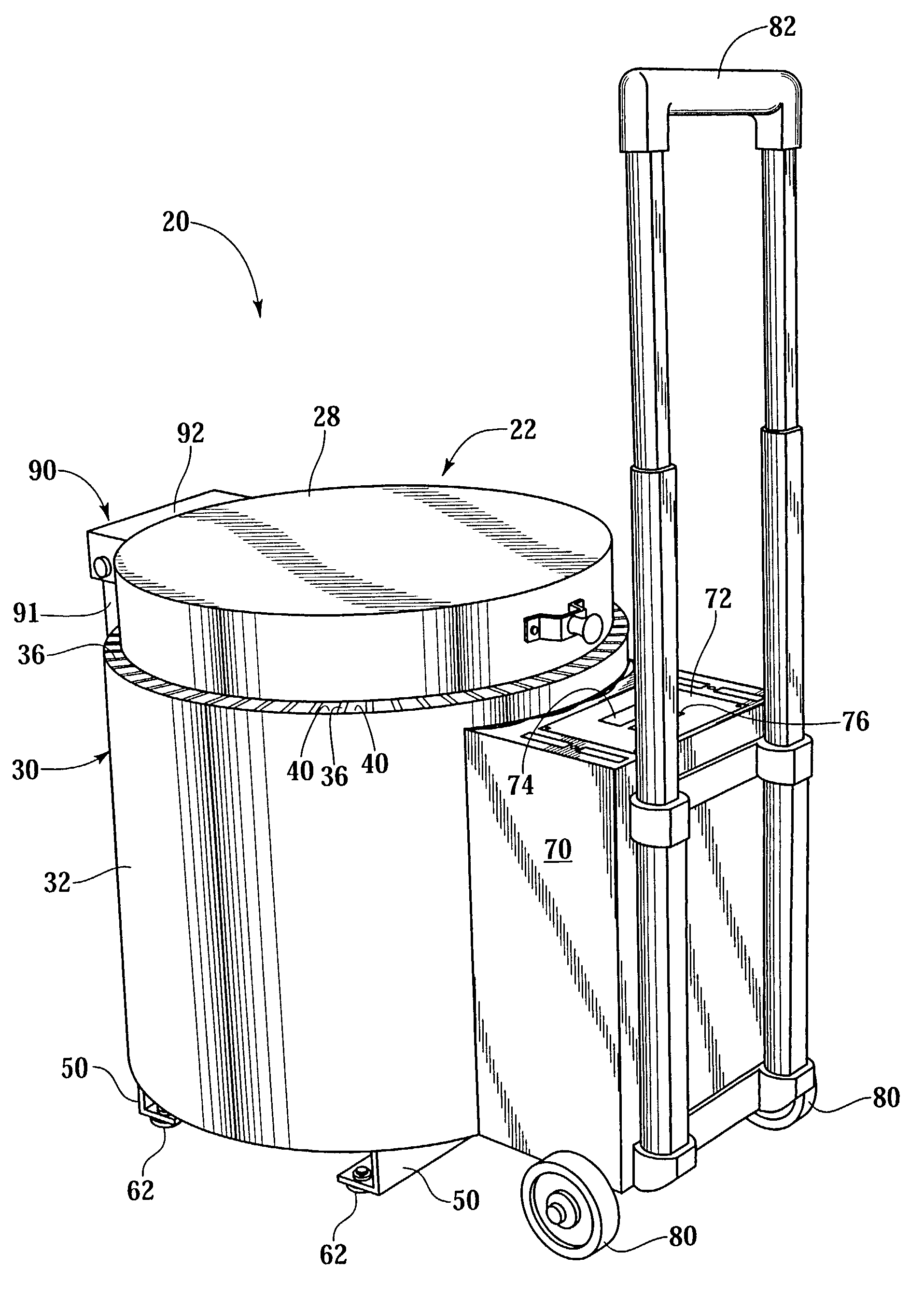

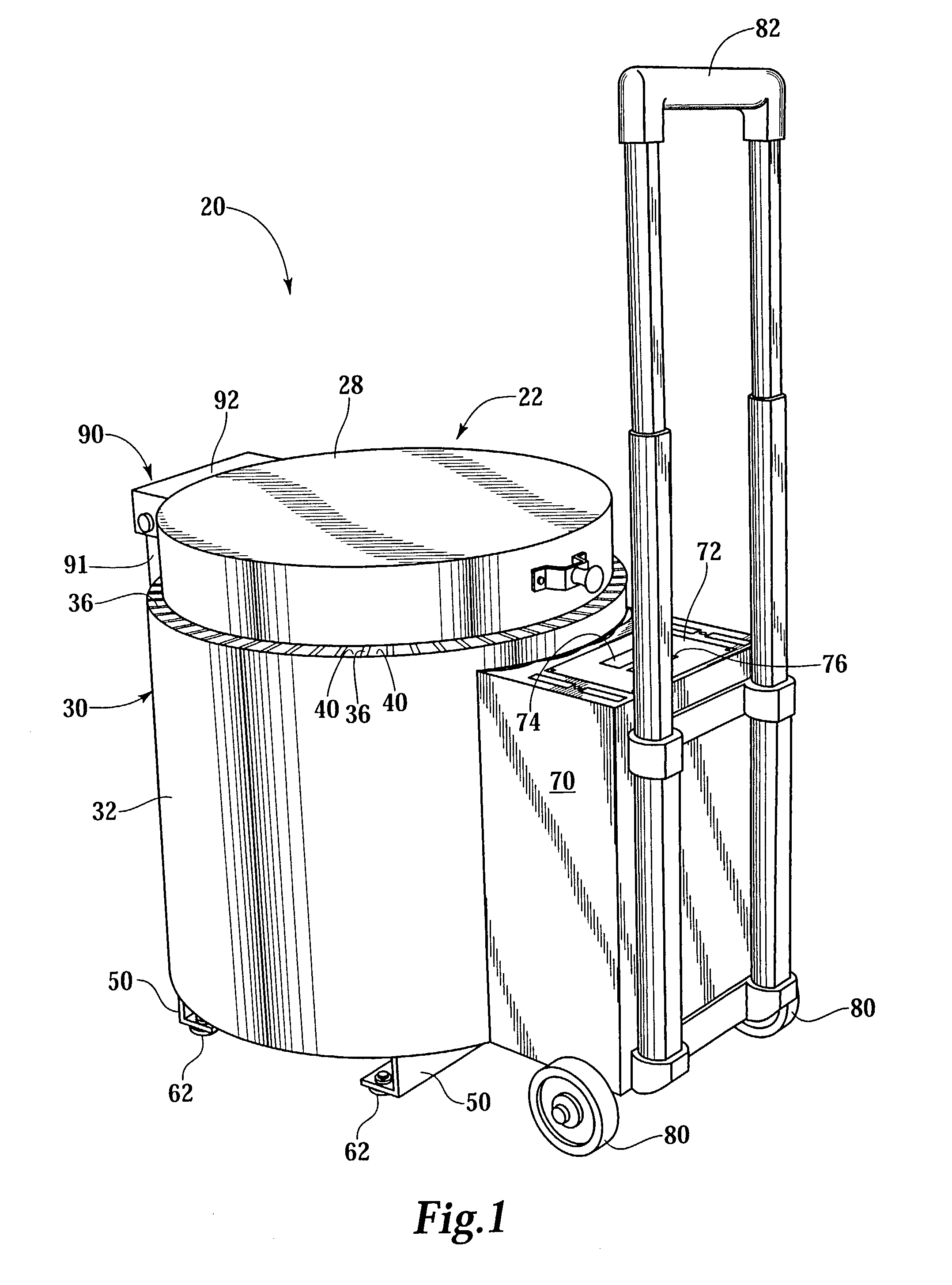

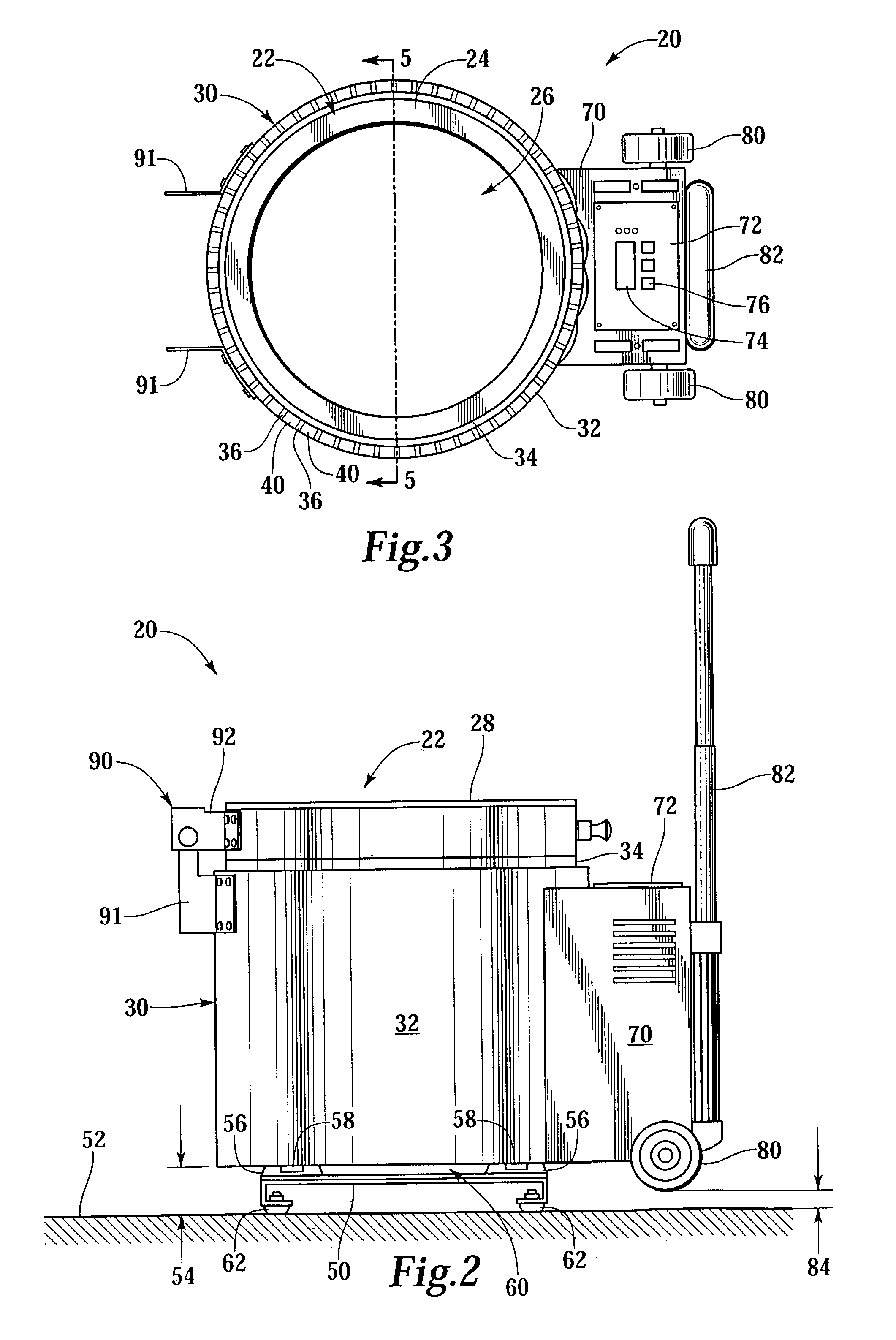

Portable kiln

ActiveUS7458809B2Limited range of activitiesChamber furnacesFurnace cooling arrangementsEngineeringMechanical engineering

A portable kiln has a set of wheels, a handle and a platform base. The wheels and the handle are attached on a first side of the kiln so that the kiln can be tilted and rolled on the wheels using the handle. The platform base provides a spaced distance between the wheels and the floor when the kiln is sitting upright in an operational position. The kiln may also include a metal outer shell wrapped about an oven portion. The outer shell has a shell sidewall radially spaced from the oven portion sidewall, which forms an annular air channel between the outer shell sidewall and the oven portion. The outer shell has a C-shaped cross-section and it has upper and lower vent openings for the air channel. A hinge assembly allows a lid of the kiln to rest in an open position.

Owner:HOHENSHELT

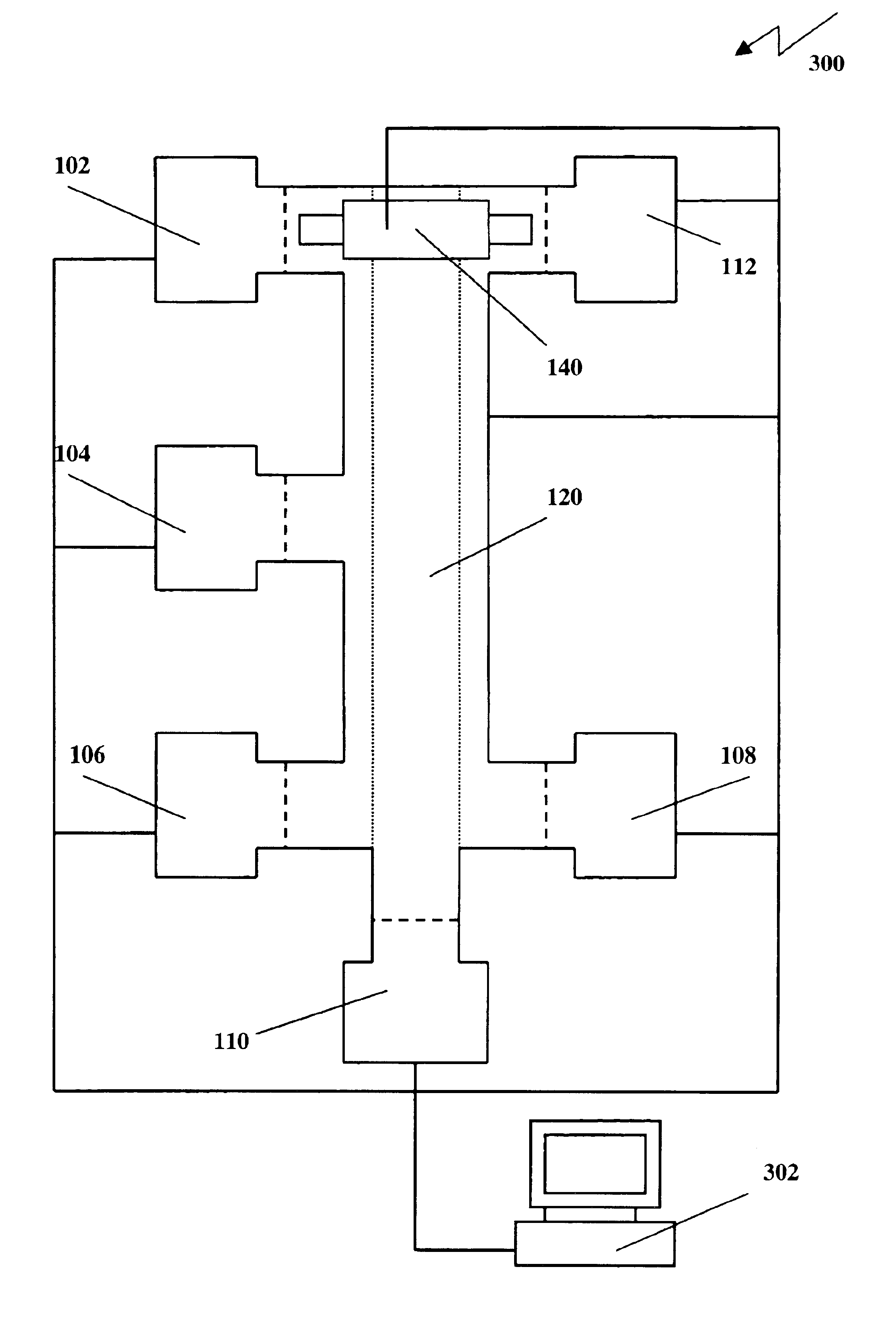

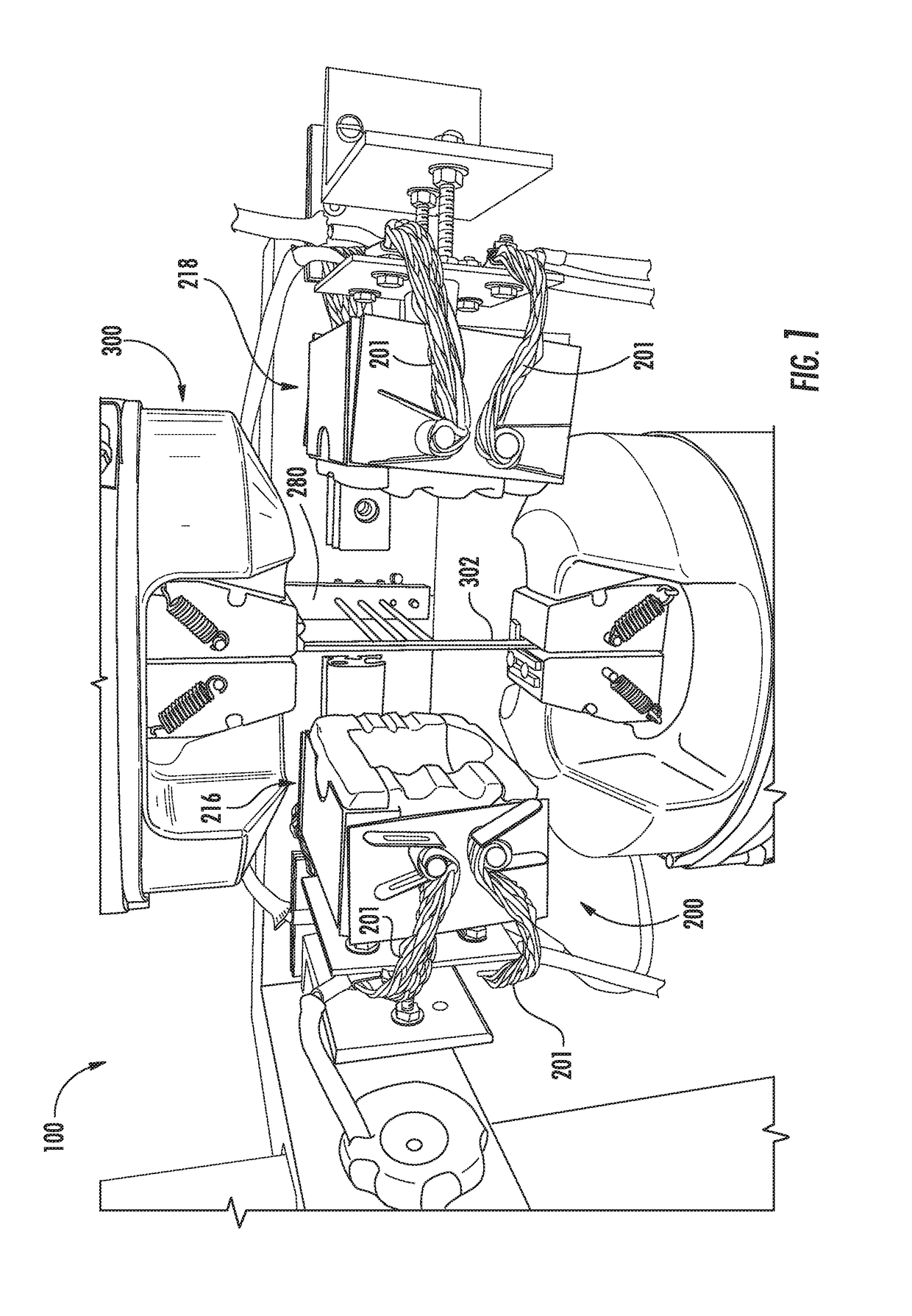

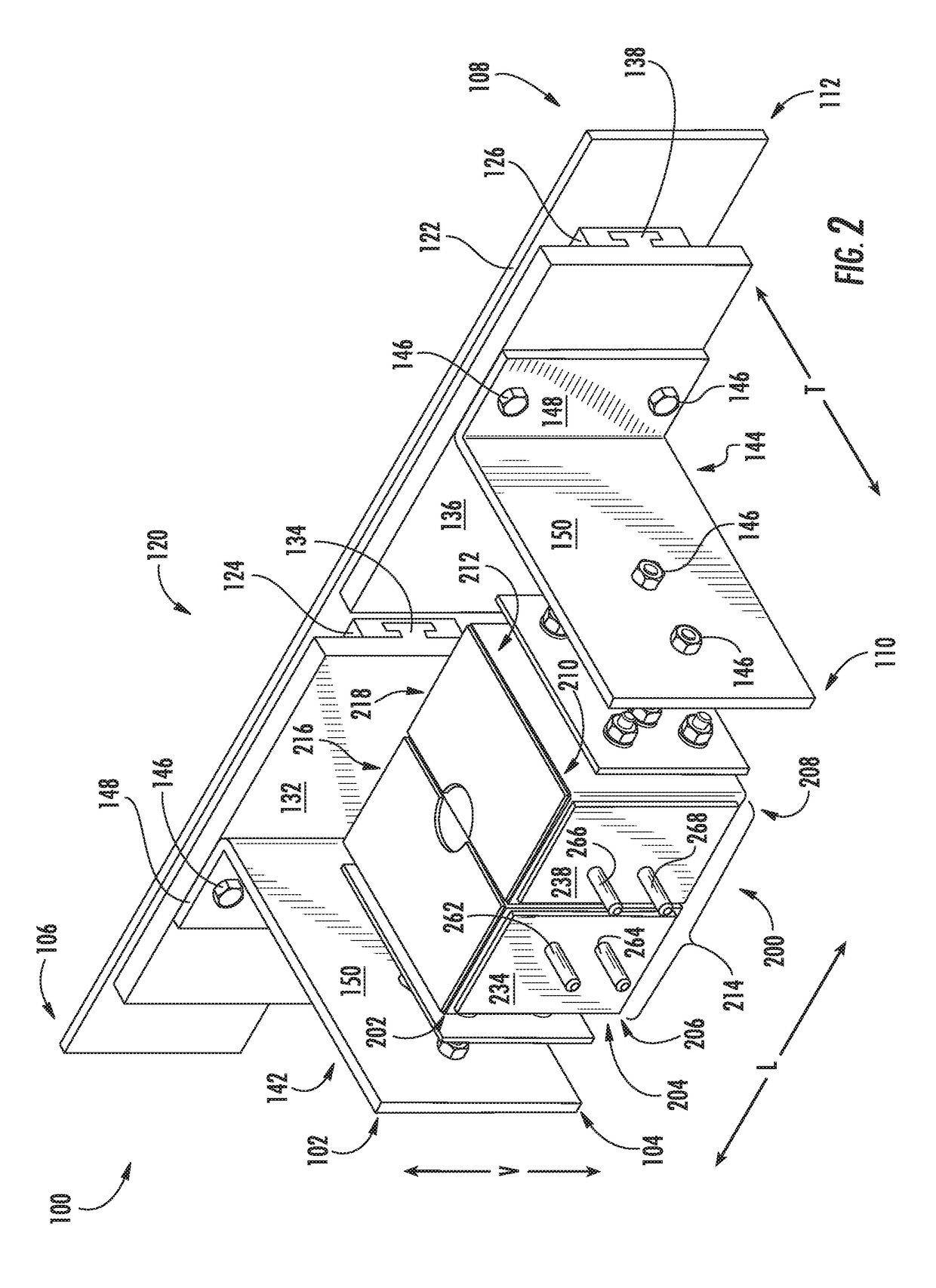

Multi-cell thermal processing unit

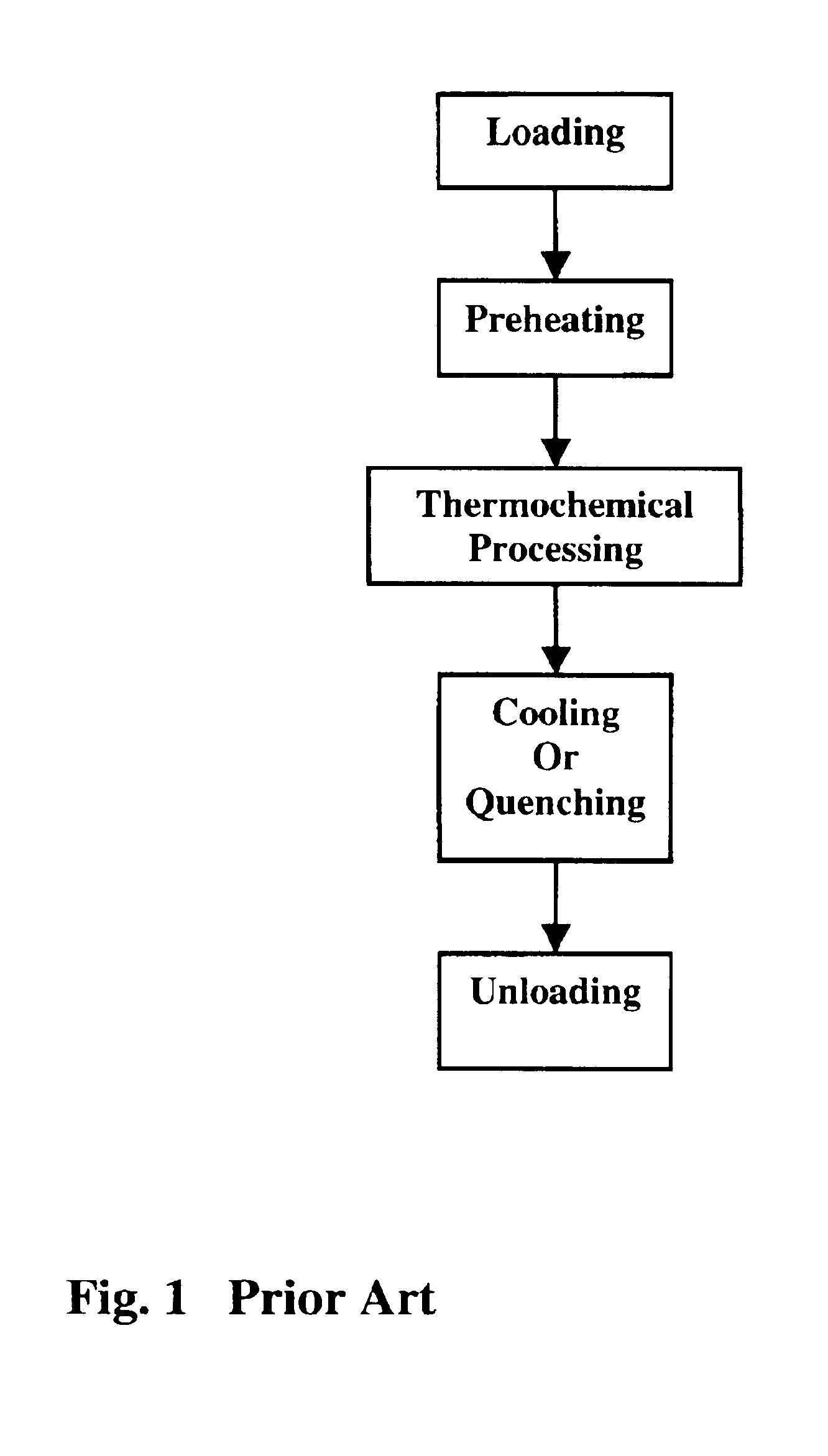

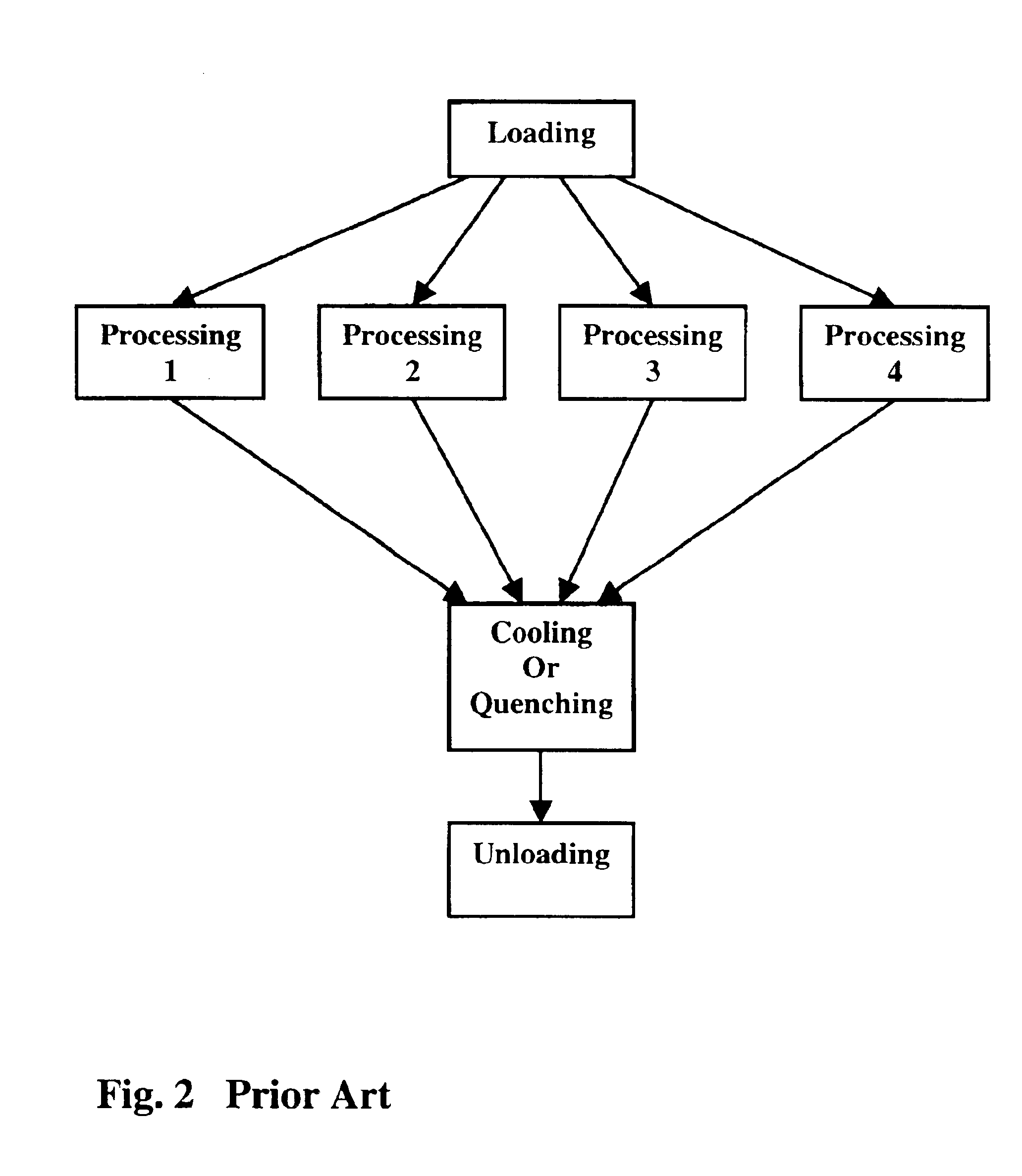

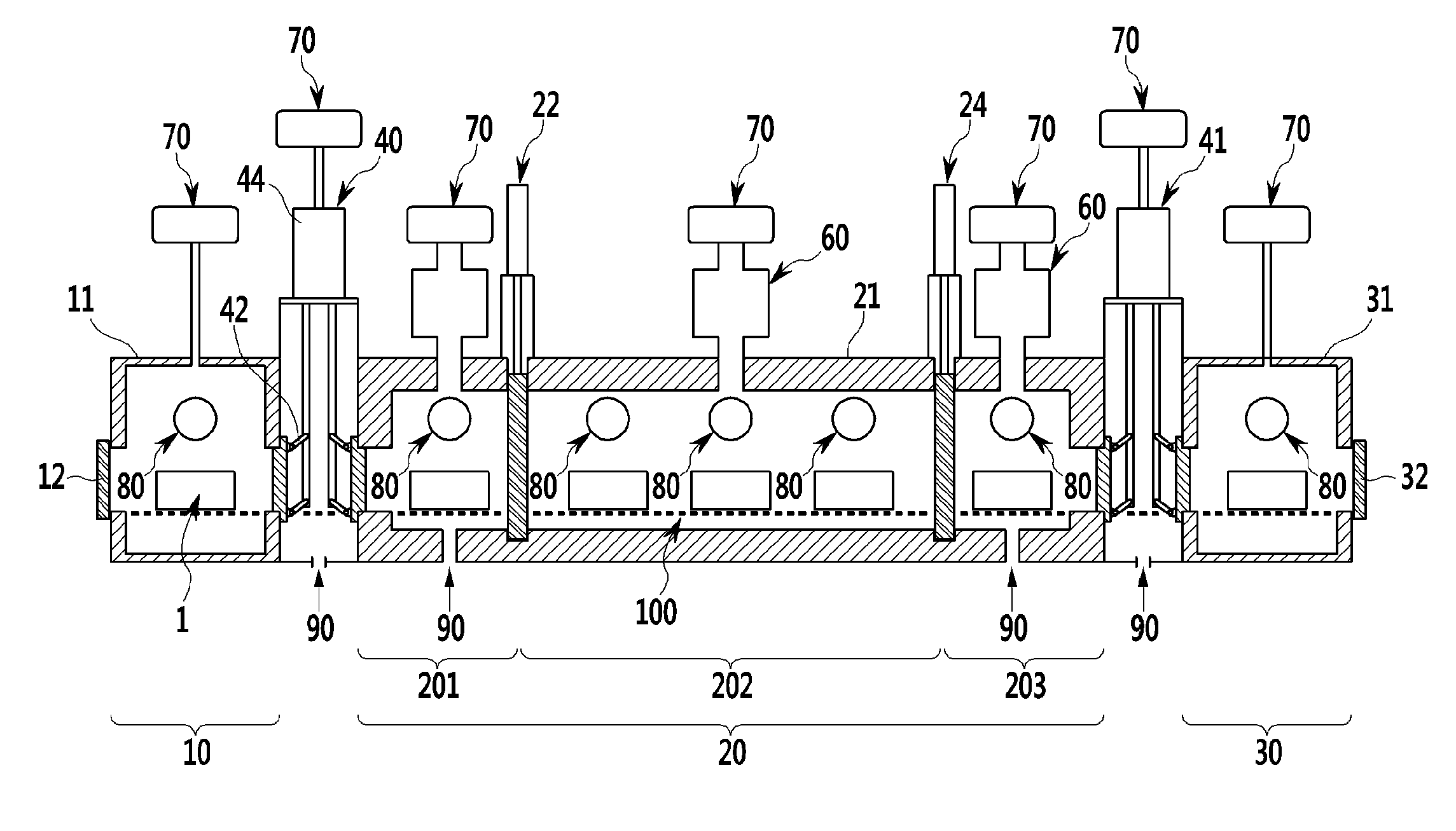

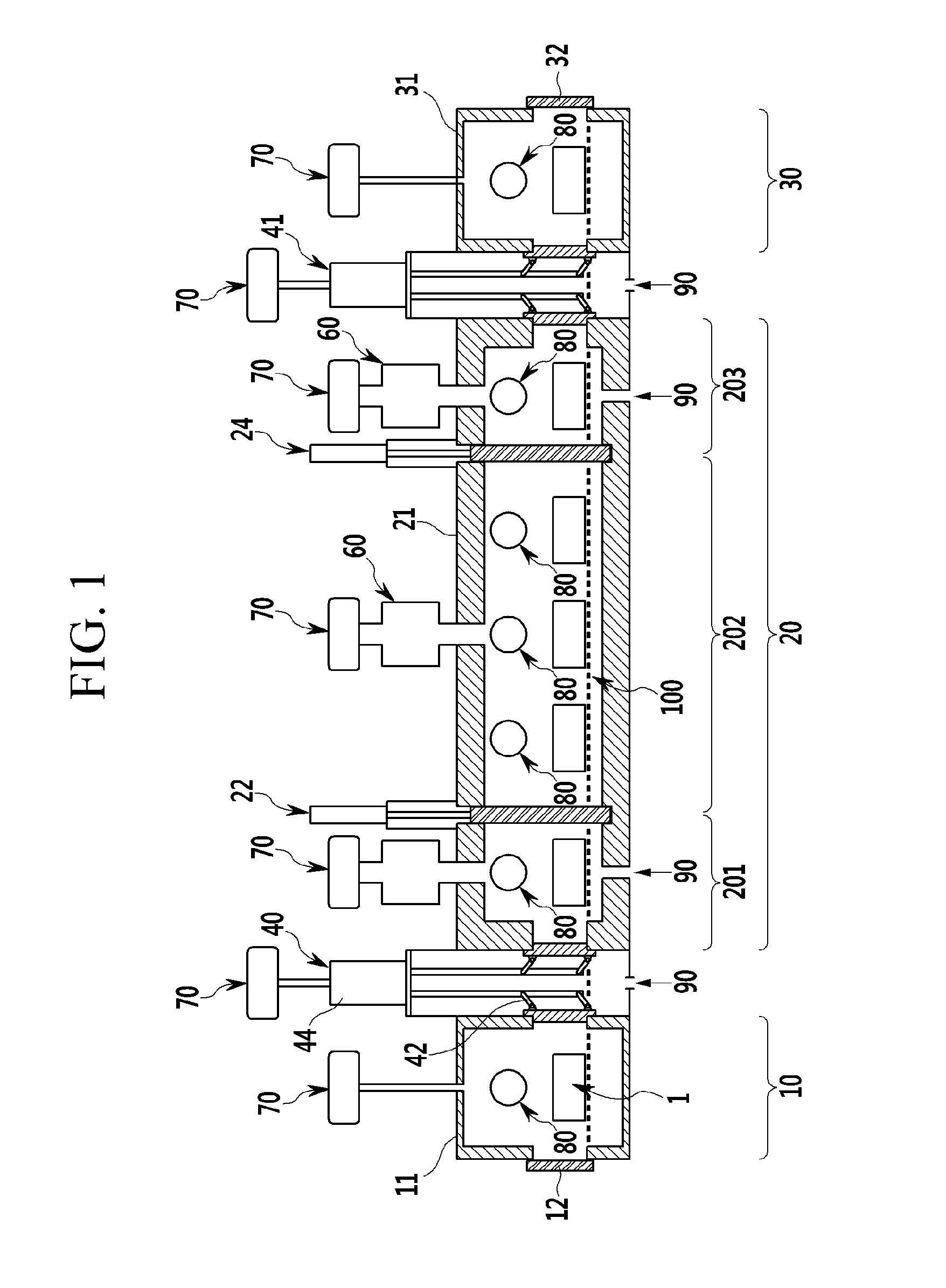

InactiveUS6902635B2Suitable for processingOptimize control functionMaintainance of heating chambersChamber furnacesChemical treatmentEngineering

Owner:NITREX METAL

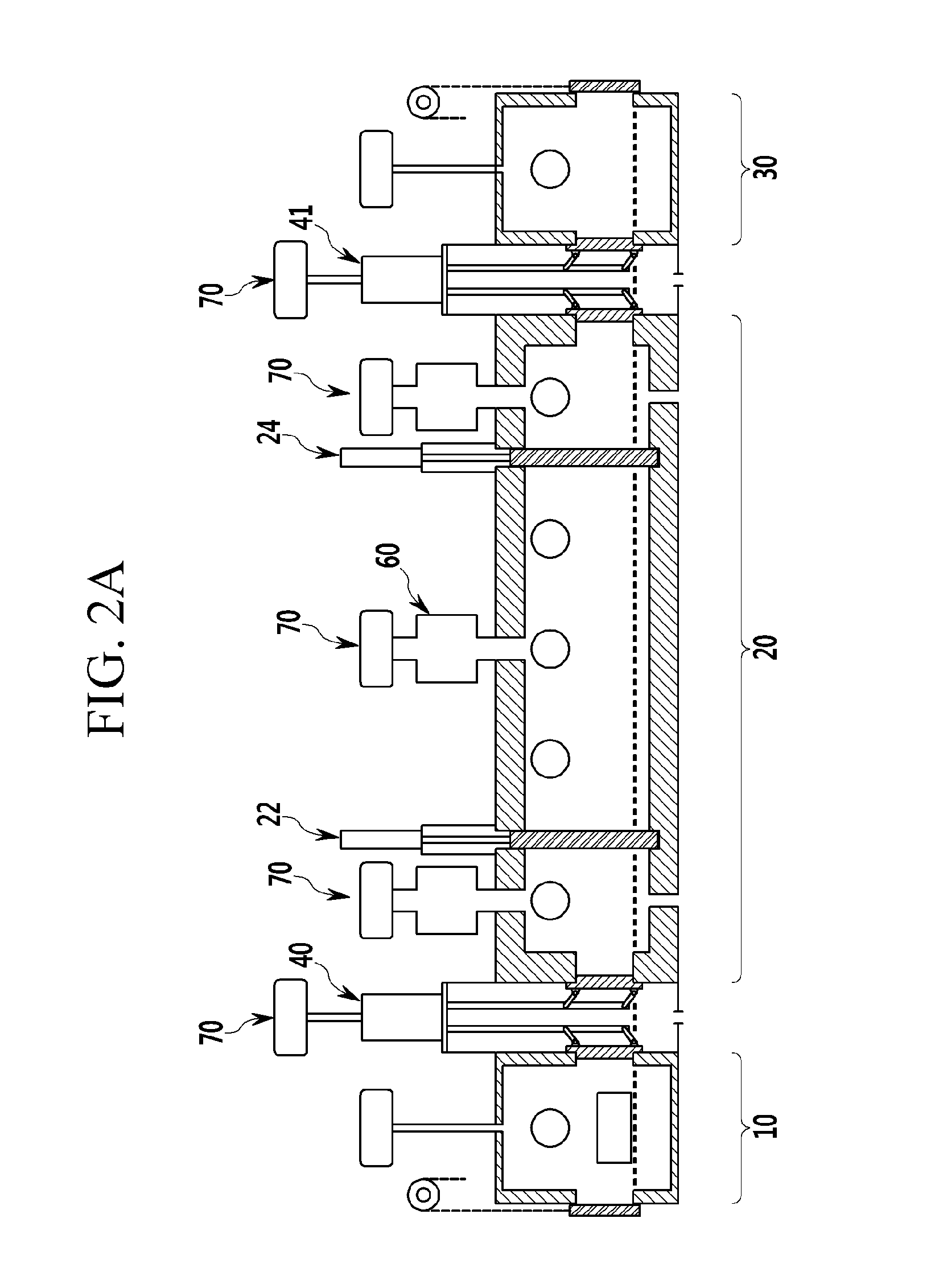

Thermal reduction apparatus for metal production, gate device, condensing system, and control method thereof

ActiveUS20160069615A1Maximize productivityContinuously and thermally reducedMaintainance of heating chambersCharge manipulationEngineeringMetal

Disclosed is a thermal reduction apparatus. The thermal reduction apparatus according to the exemplary embodiment includes: a preheating unit which preheats a to-be-reduced material and loads the to-be-reduced material into a reducing unit; the reducing unit which is connected to the preheating unit and in which a thermal reduction reaction of the to-be-reduced material occurs; a cooling unit which is connected to the reducing unit and from which the to-be-reduced material flowing into the cooling unit is unloaded to the outside; a gate device which is installed between the preheating unit and the reducing unit; a gate device which is installed between the reducing unit and the cooling unit; a condensing device which is connected to the reducing unit and condenses a metal vapor; a first blocking unit which is installed in the reducing unit; and a second blocking unit which is installed in the reducing unit so as to be spaced apart from the first blocking unit.

Owner:RES INST OF IND SCI & TECH

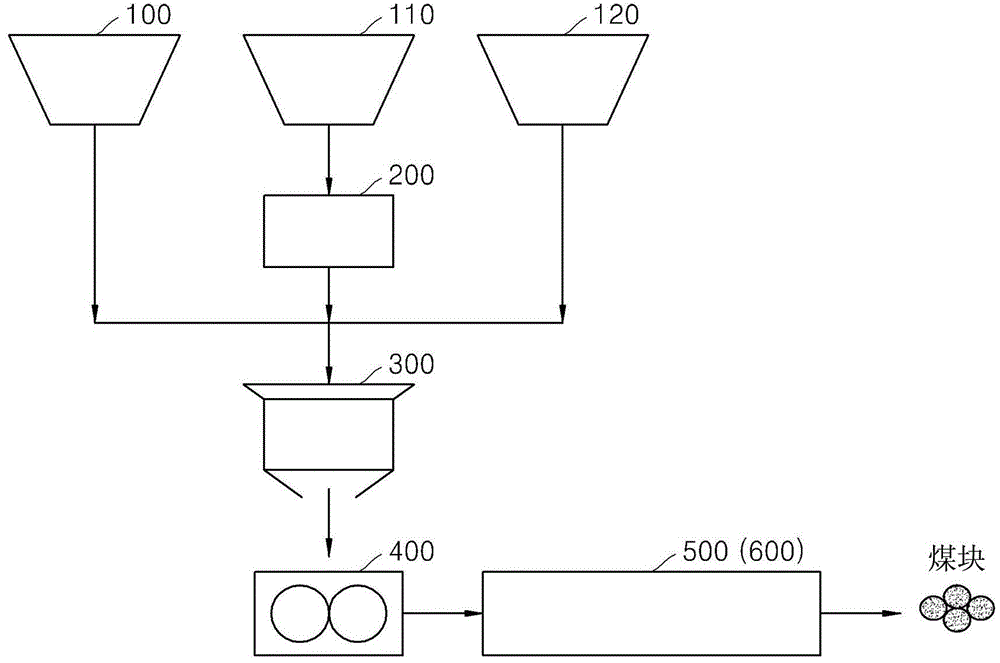

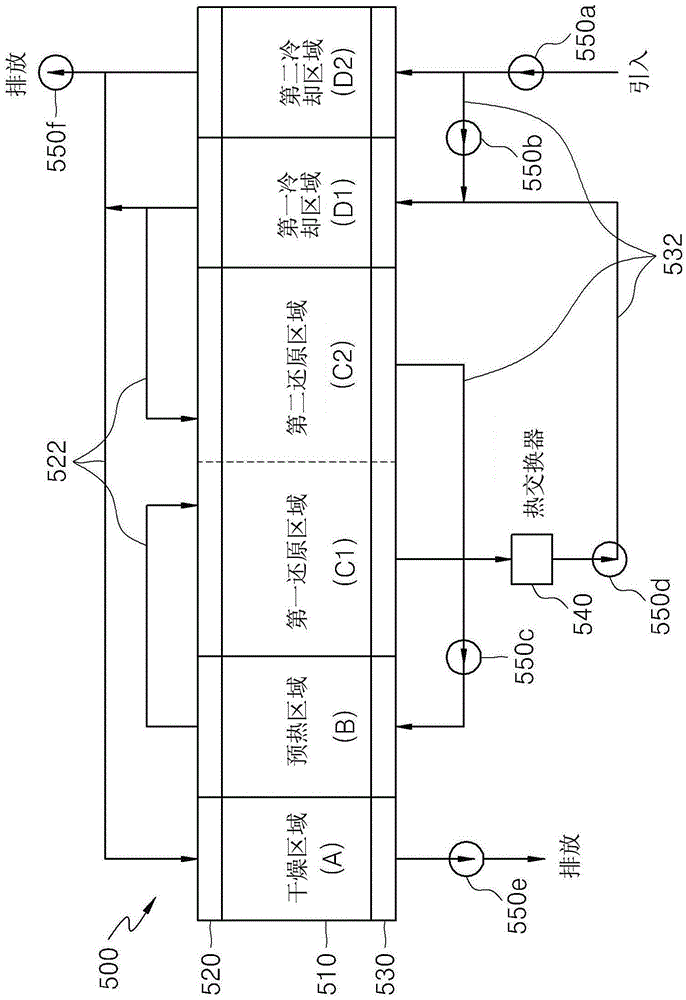

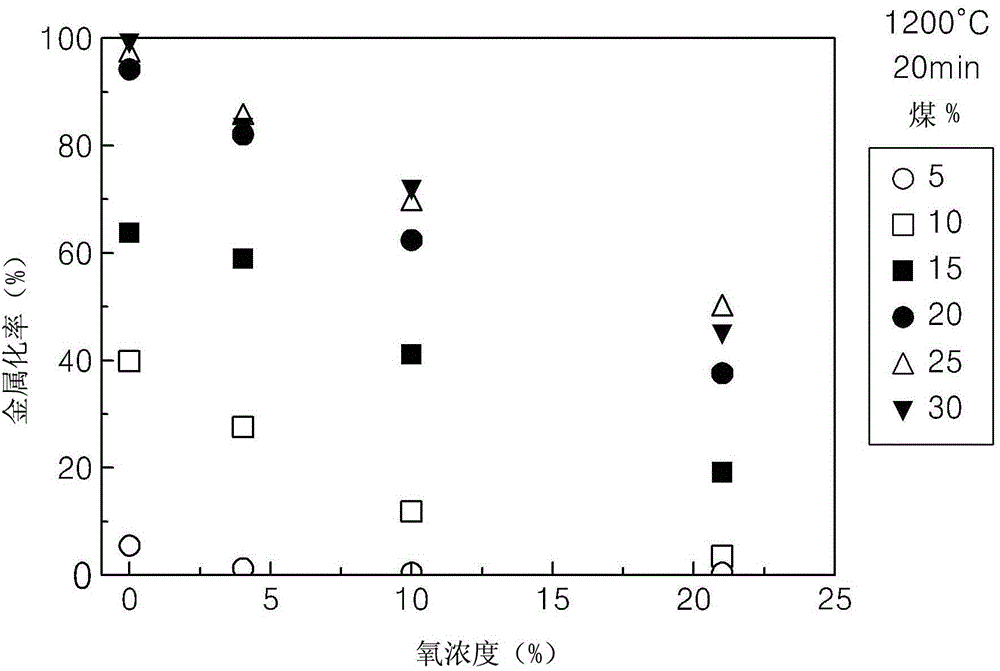

Burning Apparatus and Method for Manufacturing Reduced Iron Using the Same

The present invention relates to a burning apparatus and a method for manufacturing reduced iron using the same, and more particularly, to a burning apparatus heating a coal briquette to manufacture reduced iron, which includes a first burning furnace heating the coal briquette while moving the truck accommodating the coal briquette along a linear movement path; a second burning furnace connected to the other side of the first burning furnace, and heating the coal briquette while moving the coal briquette discharged from the truck along an annular path; and a cooling device connected to the second burning furnace, and cooling the reduced iron while moving reduced iron reduced in the second burning furnace along an annular path. The burning apparatus circulates exhaust gases generated in the burning furnace and cooling device to control a temperature and an oxygen concentration and thus improves a metallization rate of the reduced iron.

Owner:POHANG IRON & STEEL CO LTD

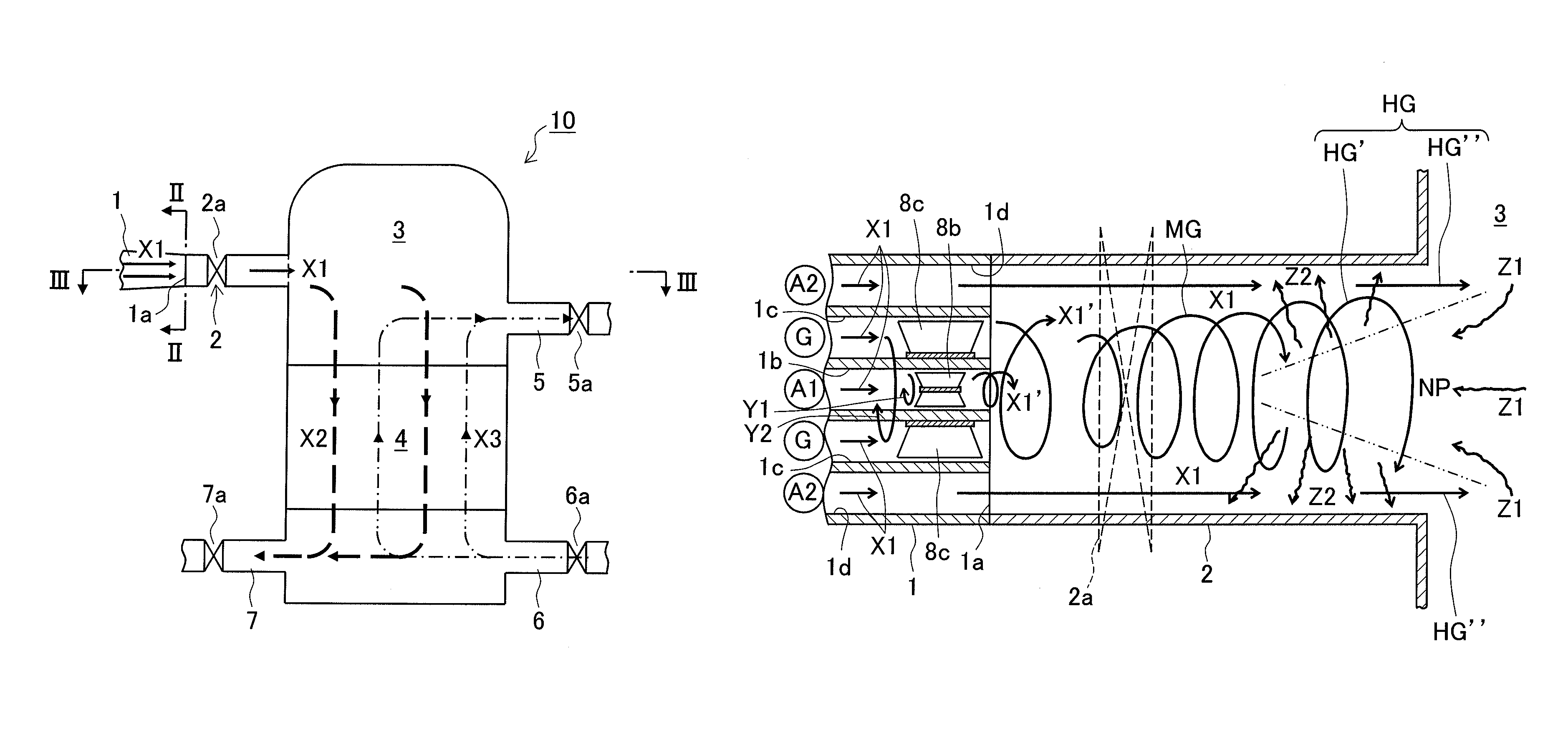

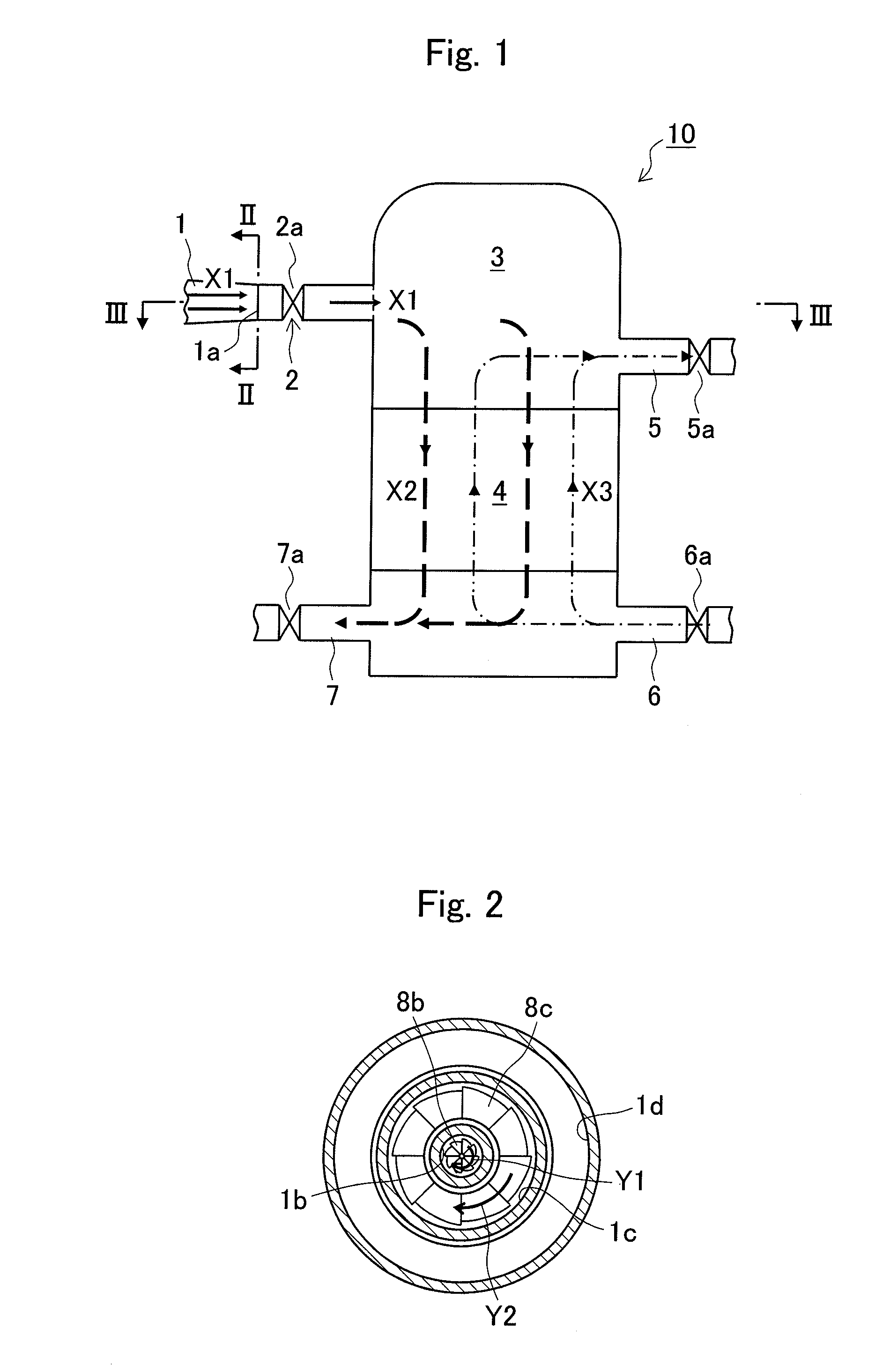

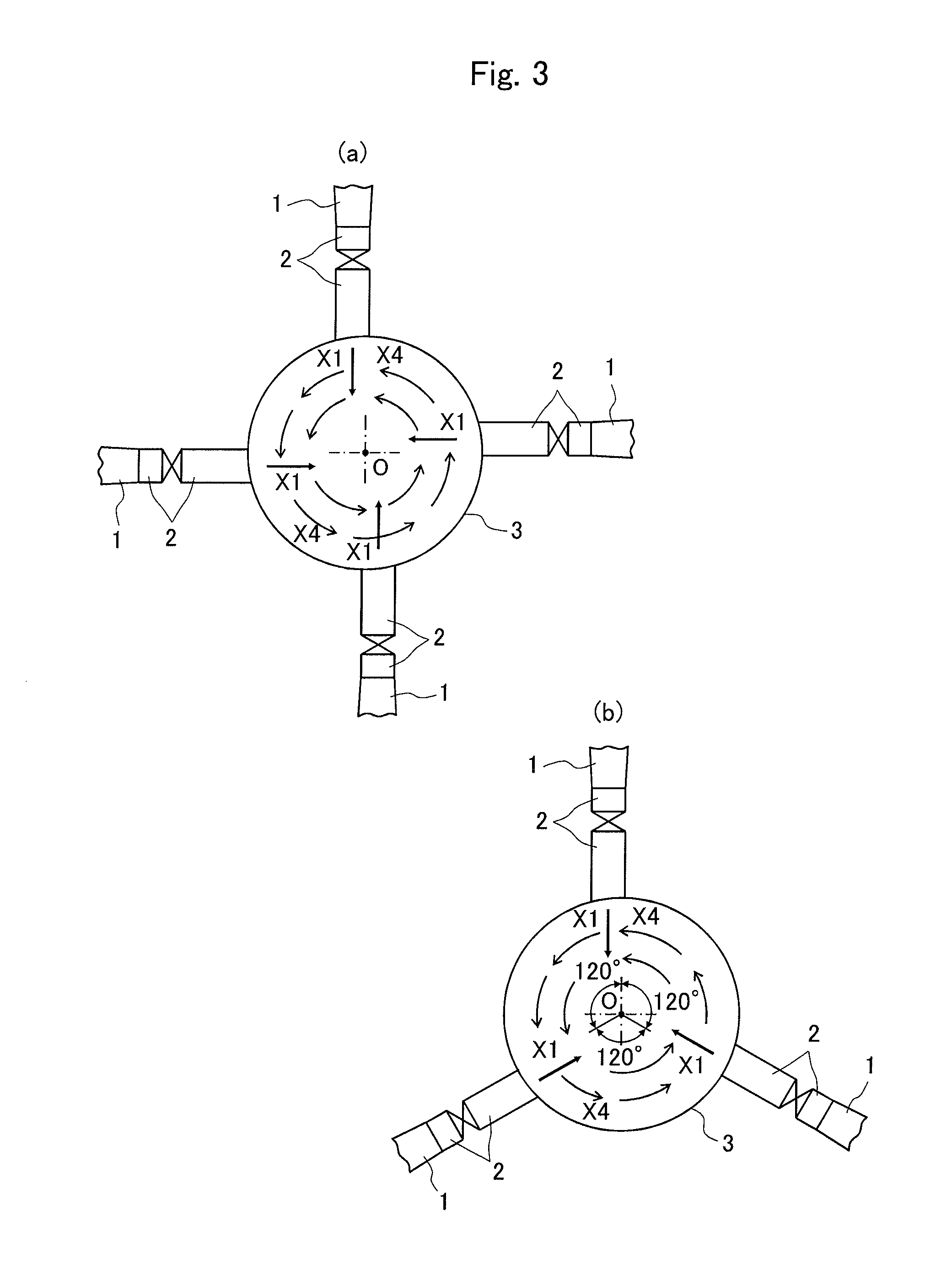

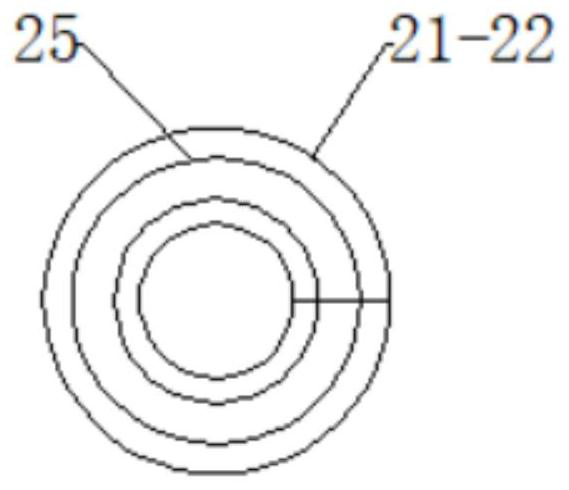

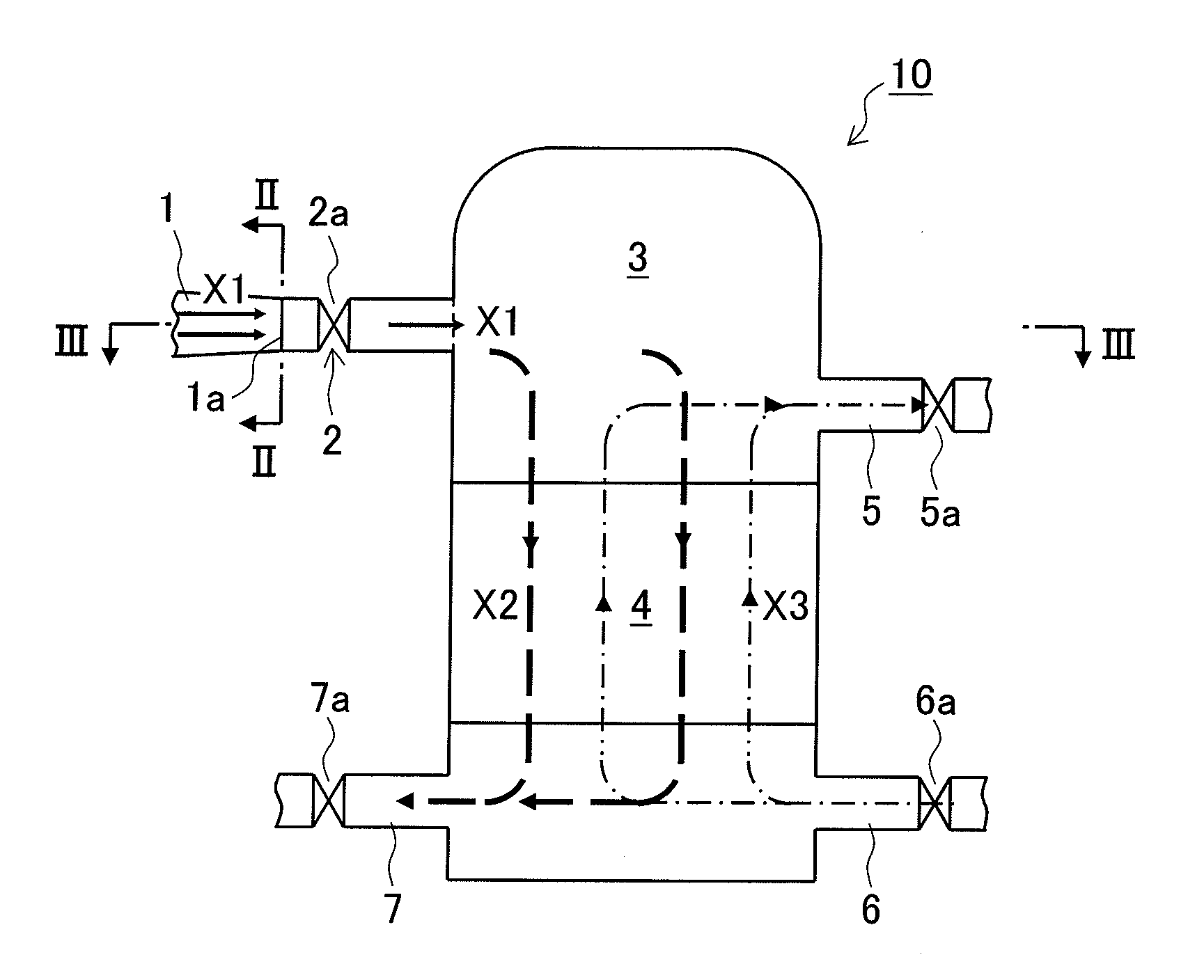

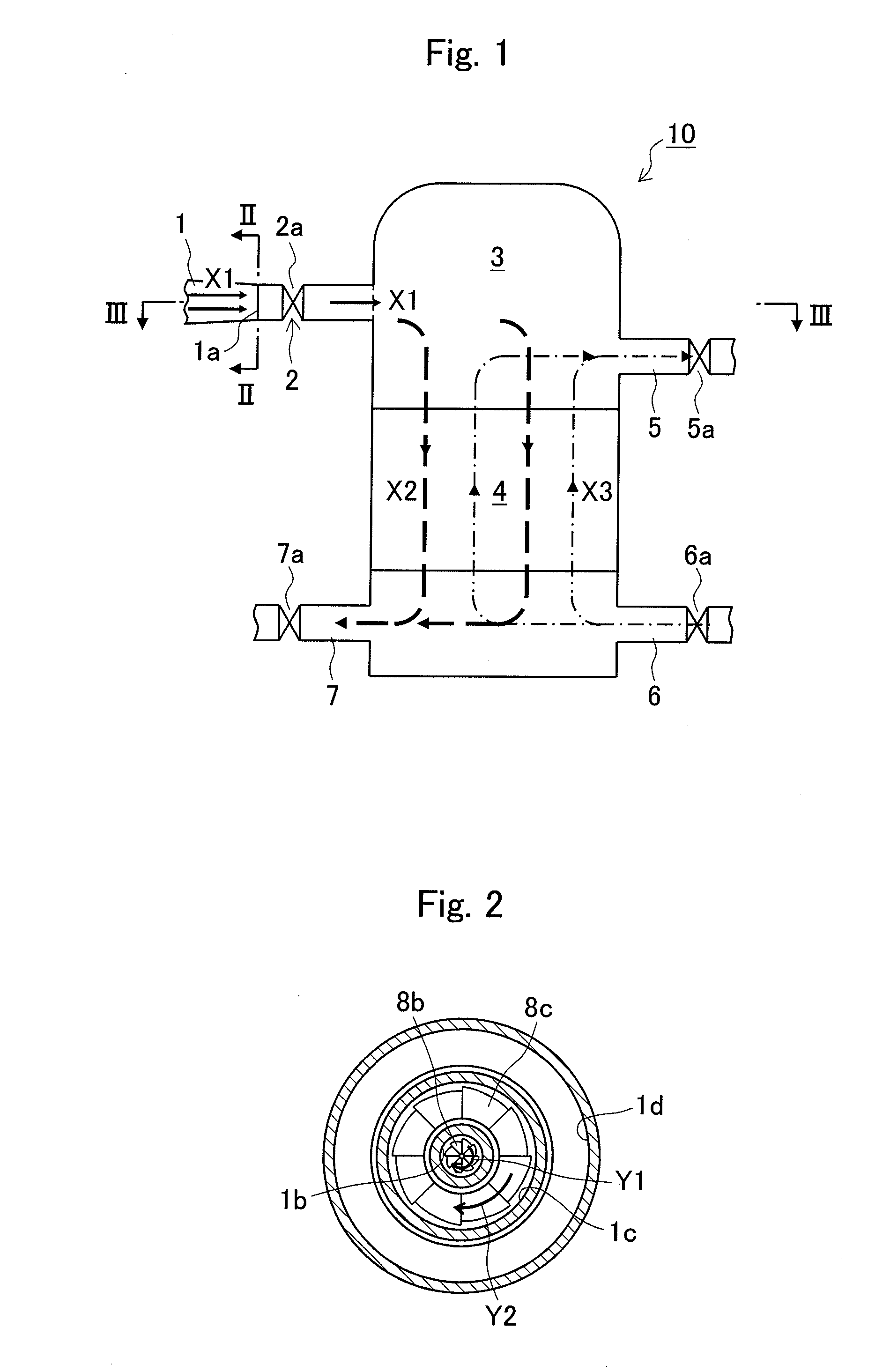

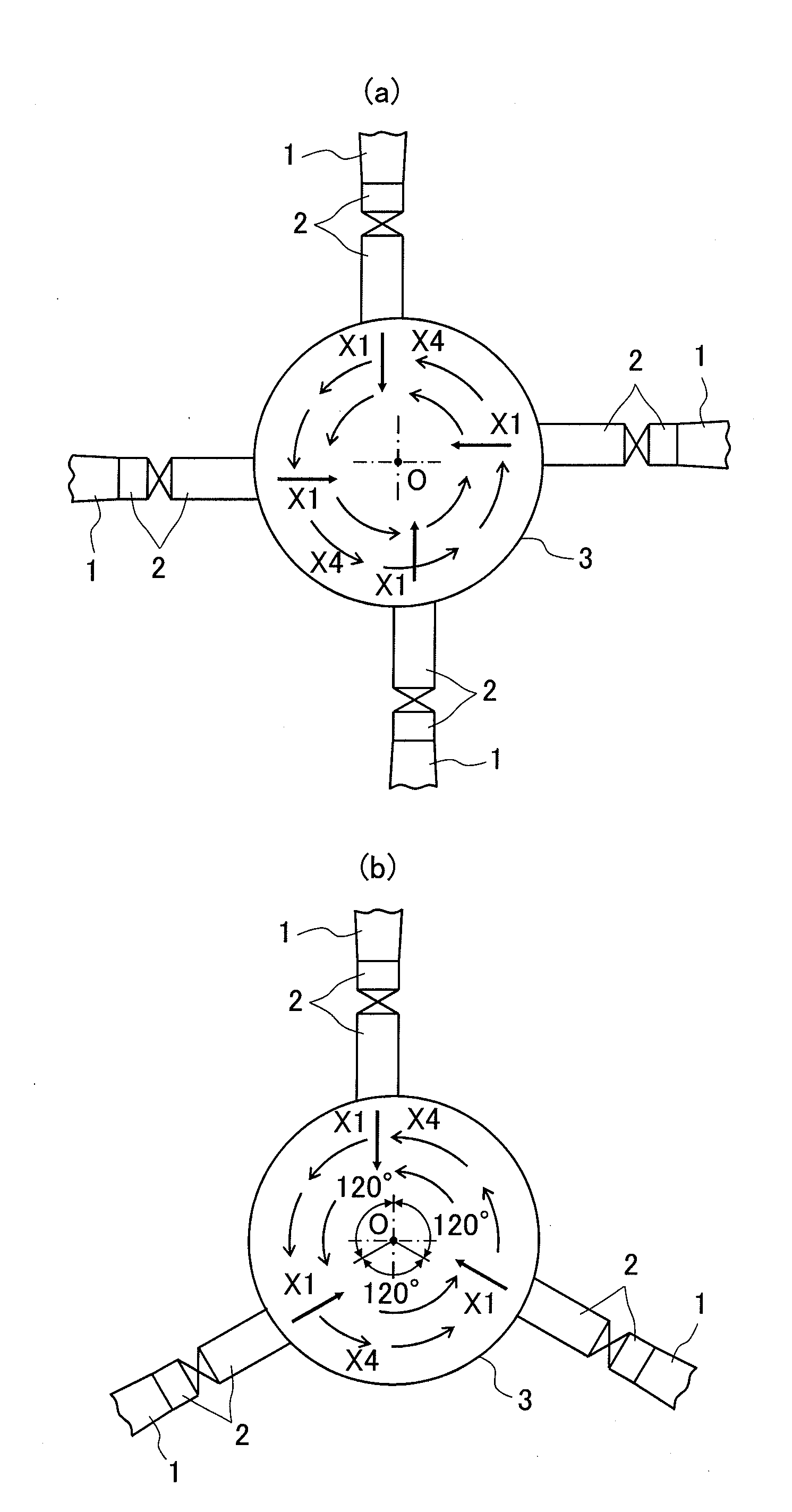

Top-firing hot blast stove

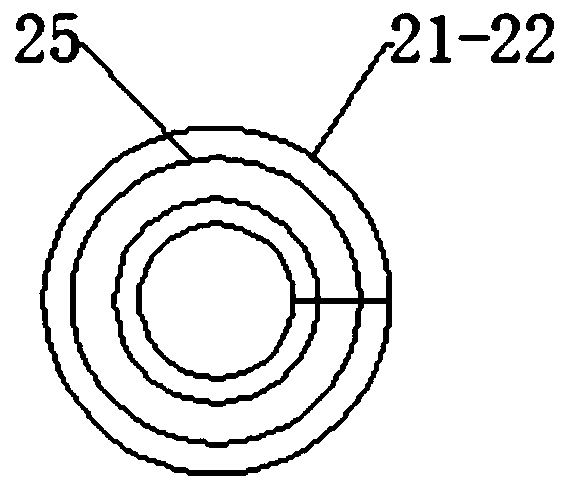

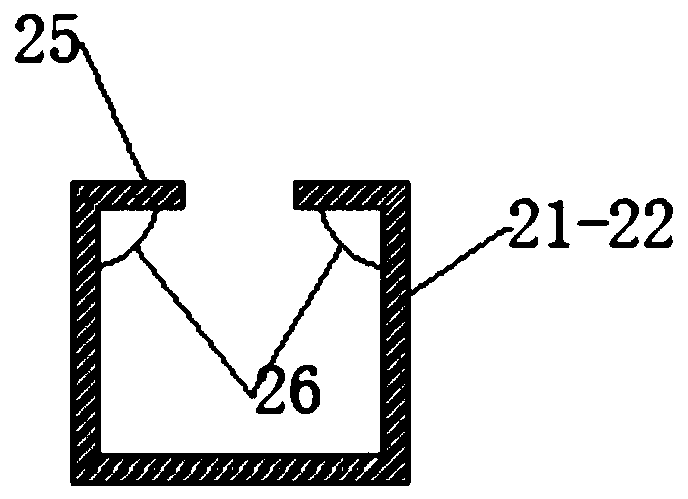

InactiveUS9017068B2Improve combustion efficiencyExcellent in hot-blast generating capabilityBlast furnace detailsChamber furnacesLinear componentCombustion chamber

There is provided a top-firing hot blast stove capable of enhancing combustion efficiency in burner system, supplying high-temperature combustion gas to an entire checker chamber, and suppressing damage on a refractory material on an inner wall of a burner duct.A top-firing hot blast stove 10 has a burner system including: a burner 1 for passing fuel gas or combustion air to each of three or more pipe lines in a multiple pipe line structure; and a burner duct 2. A core pipe line 1b and a central pipe line 1c include a swirling flow generating means provided for generating a swirling flow of the fuel gas or the combustion air, while an outermost pipe line 1d carries a linear flow of the fuel gas or the combustion air, so that combustion gas HG including a linear component HG″ and a swirling component HG′ is generated in the burner duct 2. The combustion gas HG is supplied to a combustion chamber 3 from at least one or more of the burner systems in an inflow direction which does not pass through a center position of the combustion chamber 3.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

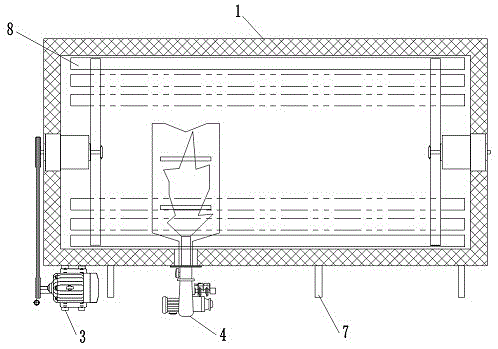

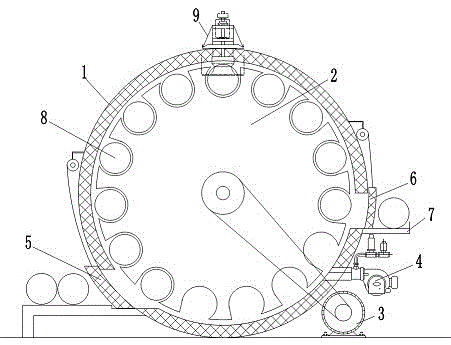

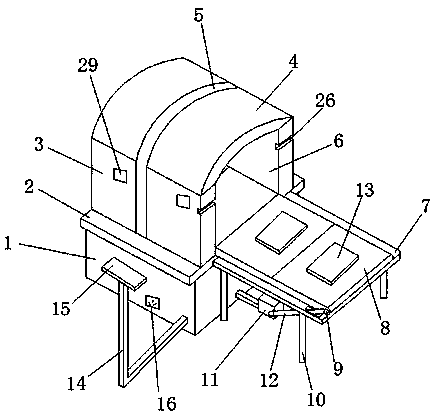

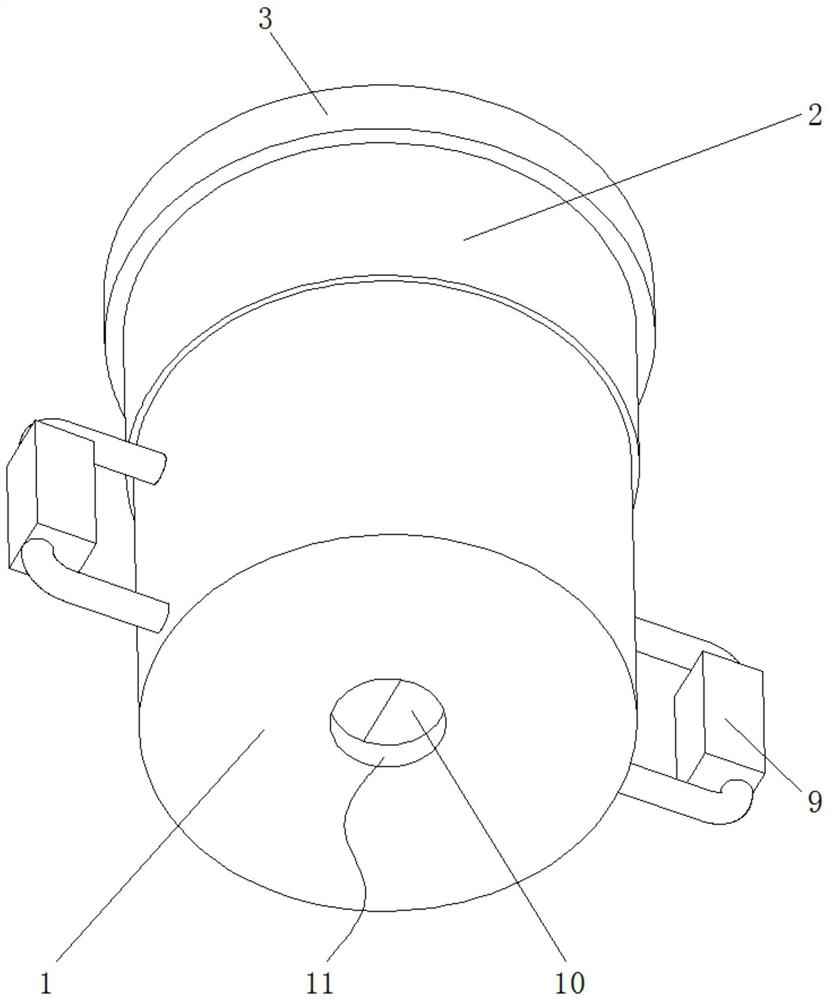

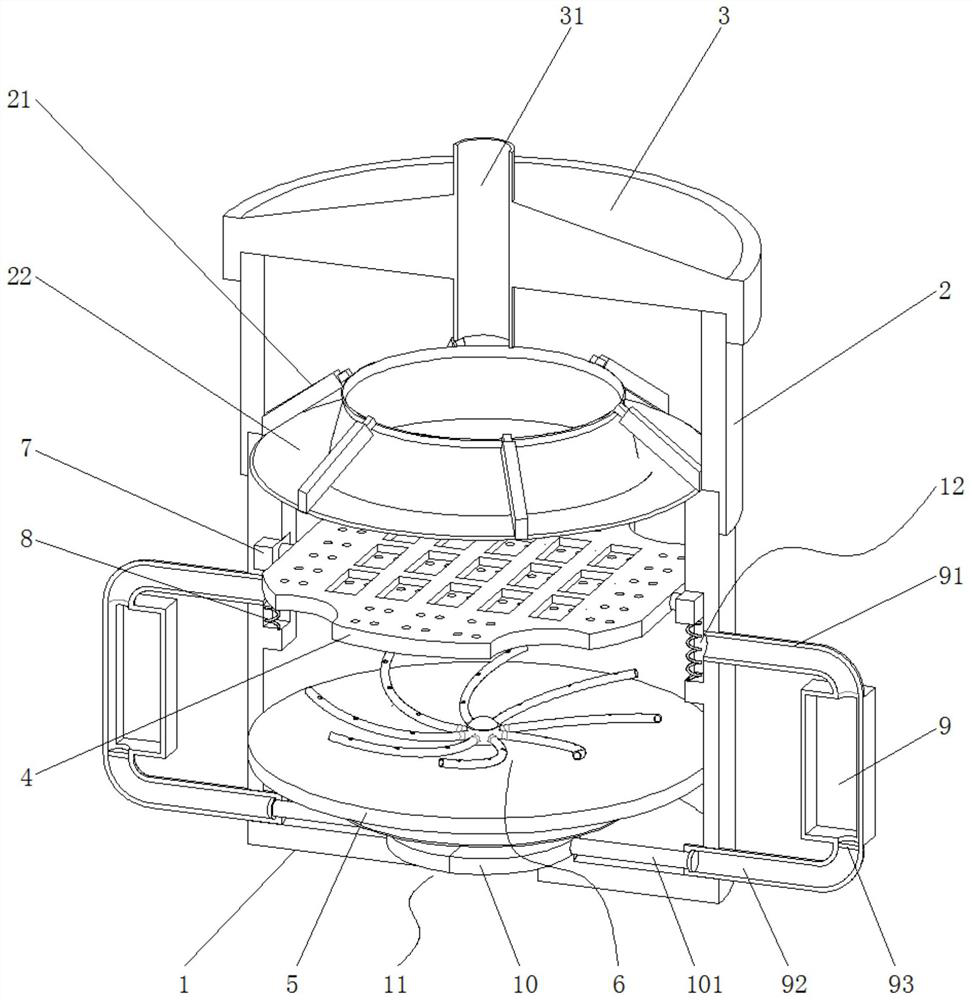

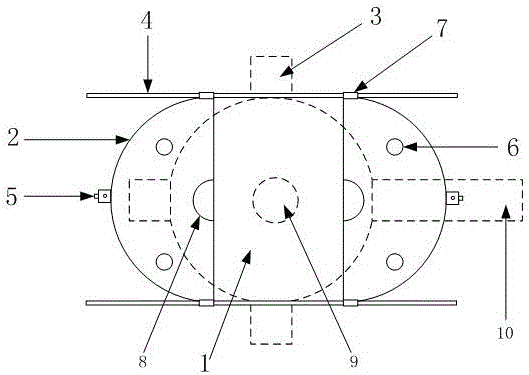

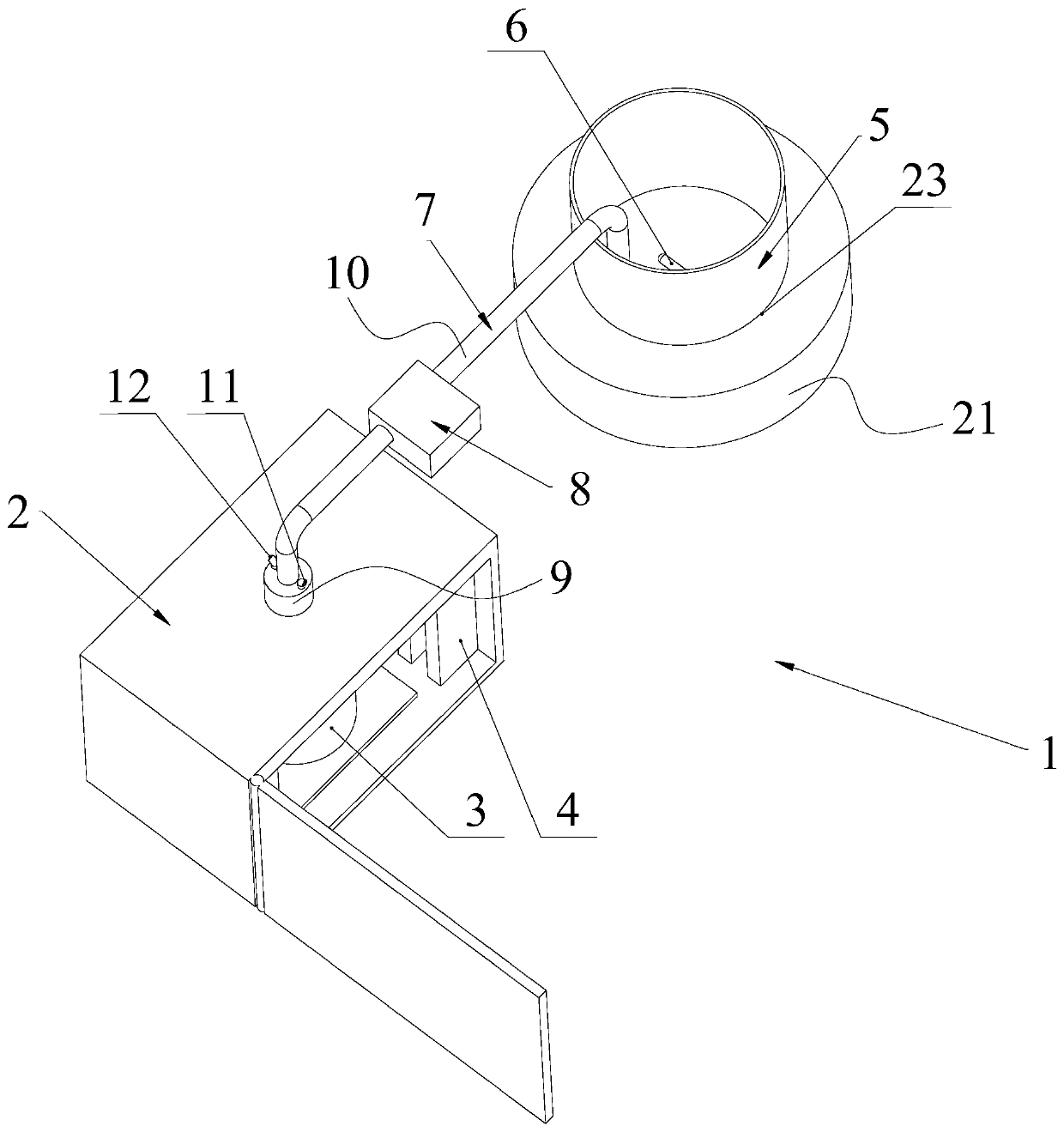

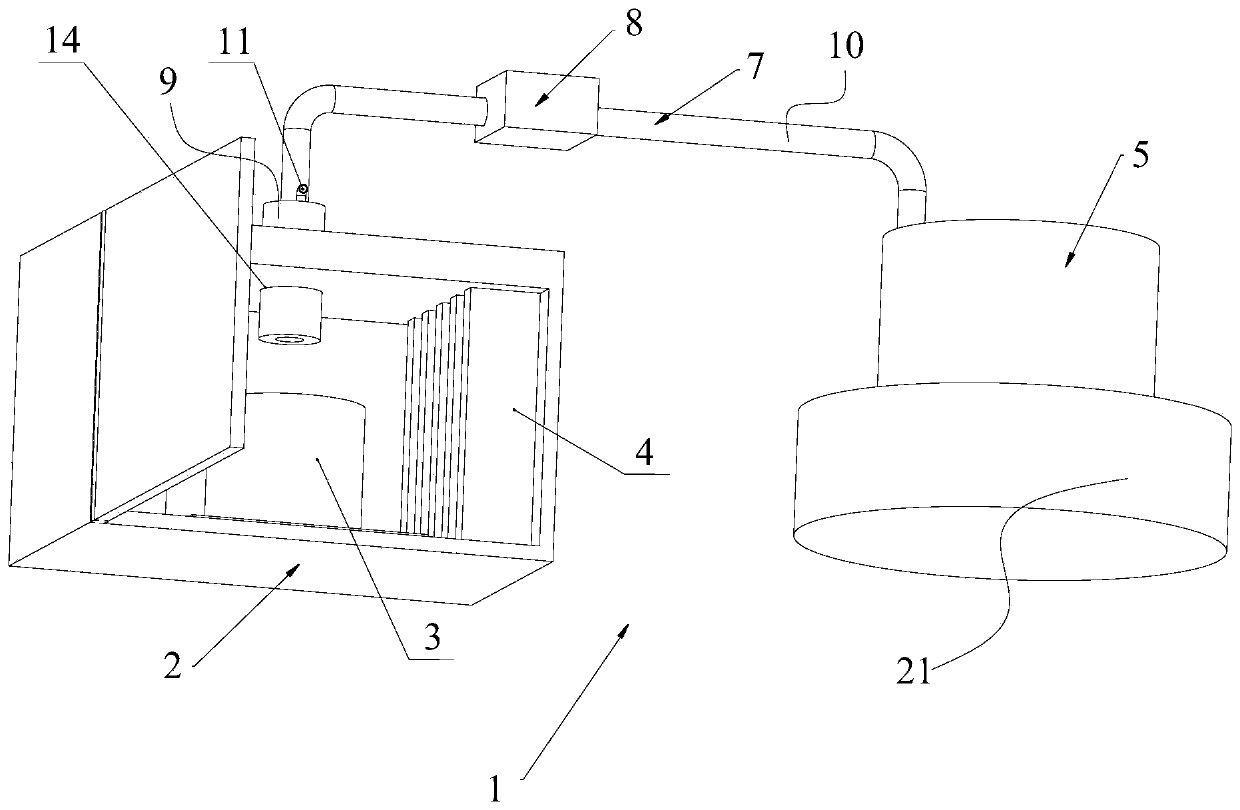

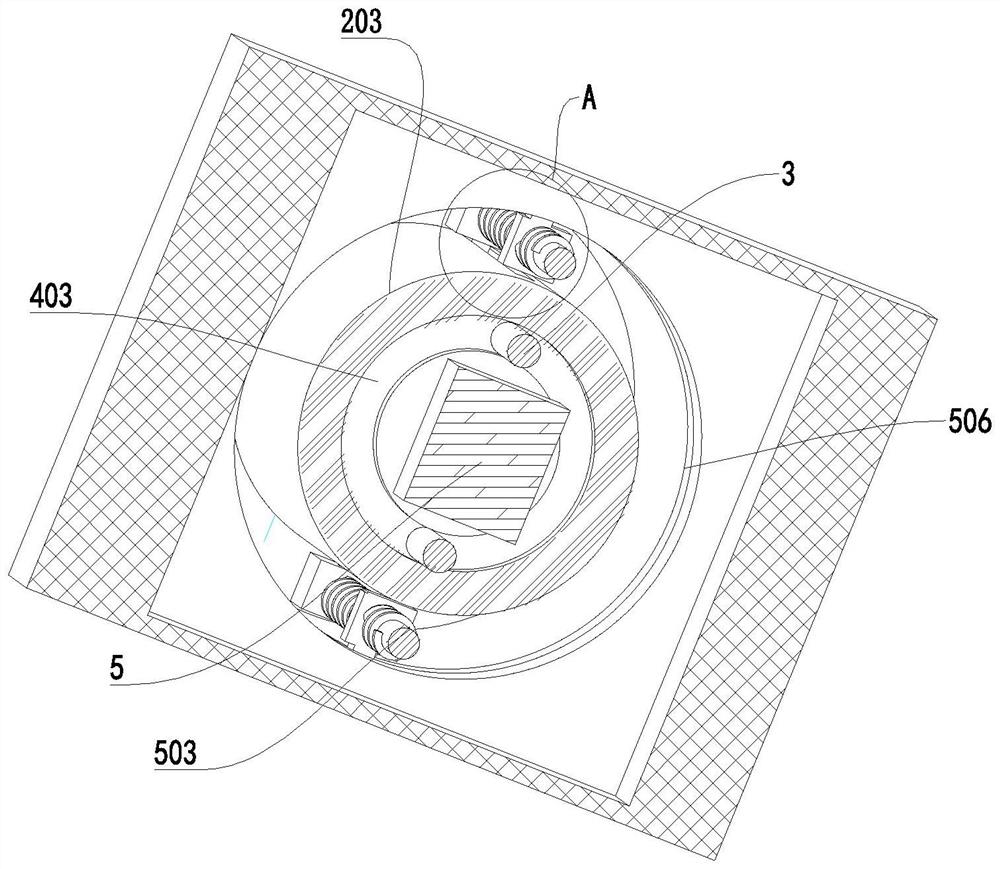

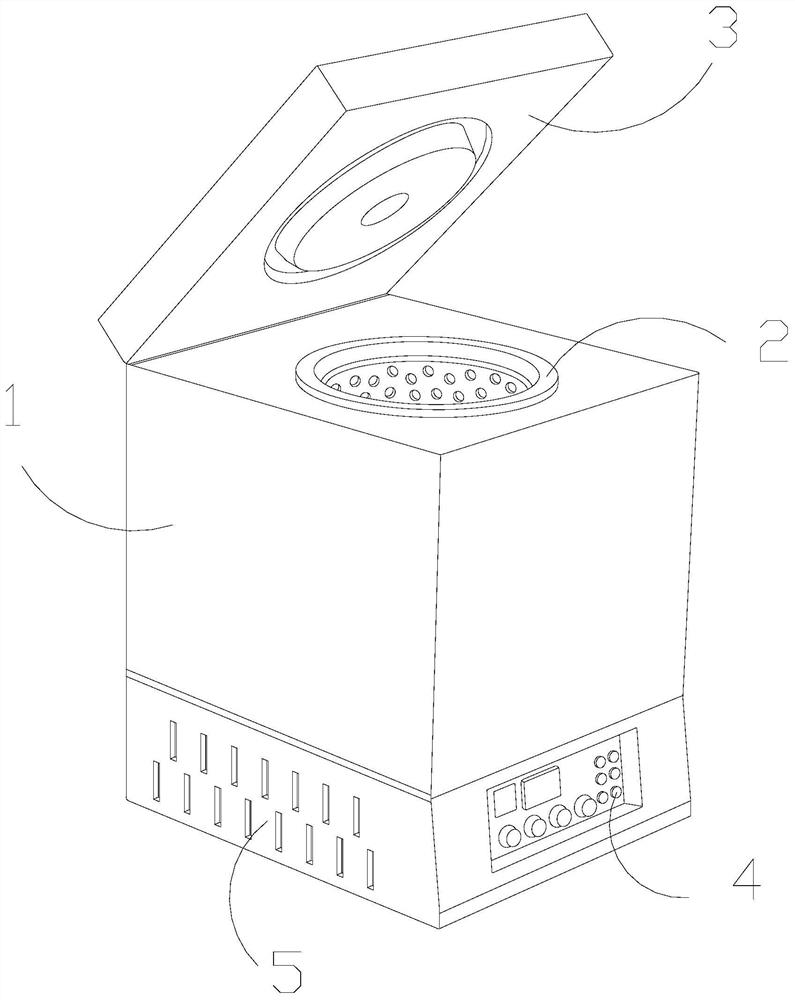

Circular rotary heating furnace for long aluminum bars

InactiveCN105588436AReduce energy consumptionEasy to operateCharge composition/stateChamber furnacesCombustorEngineering

The invention provides a circular rotary heating furnace for long aluminum bars. The circular rotary heating furnace comprises a cylindrical heating furnace body (1), a rotary bar placing plate (2), a rotary conveying system (3), a burner (4), a feeding furnace door (5), a discharging furnace door (6), a discharging platform (7) and an induced draft fan (9). The rotary bar placing plate (2) is arranged inside the furnace body. The rotary conveying system (3) is arranged outside the furnace body and connected with a central rotating shaft of the rotary bar placing plate (2). The burner (4) and the induced draft fan (9) both communicate with the furnace body. The circular heating furnace is easy and convenient to operate, small in space, compact in structure, high in automation degree and heating rate and low in energy consumption, and the aluminum bars are heated uniformly; in addition, the jamming phenomenon cannot occur, so that the service life is long.

Owner:XIAOGAN TIANMAO ALUMINUM IND CO LTD

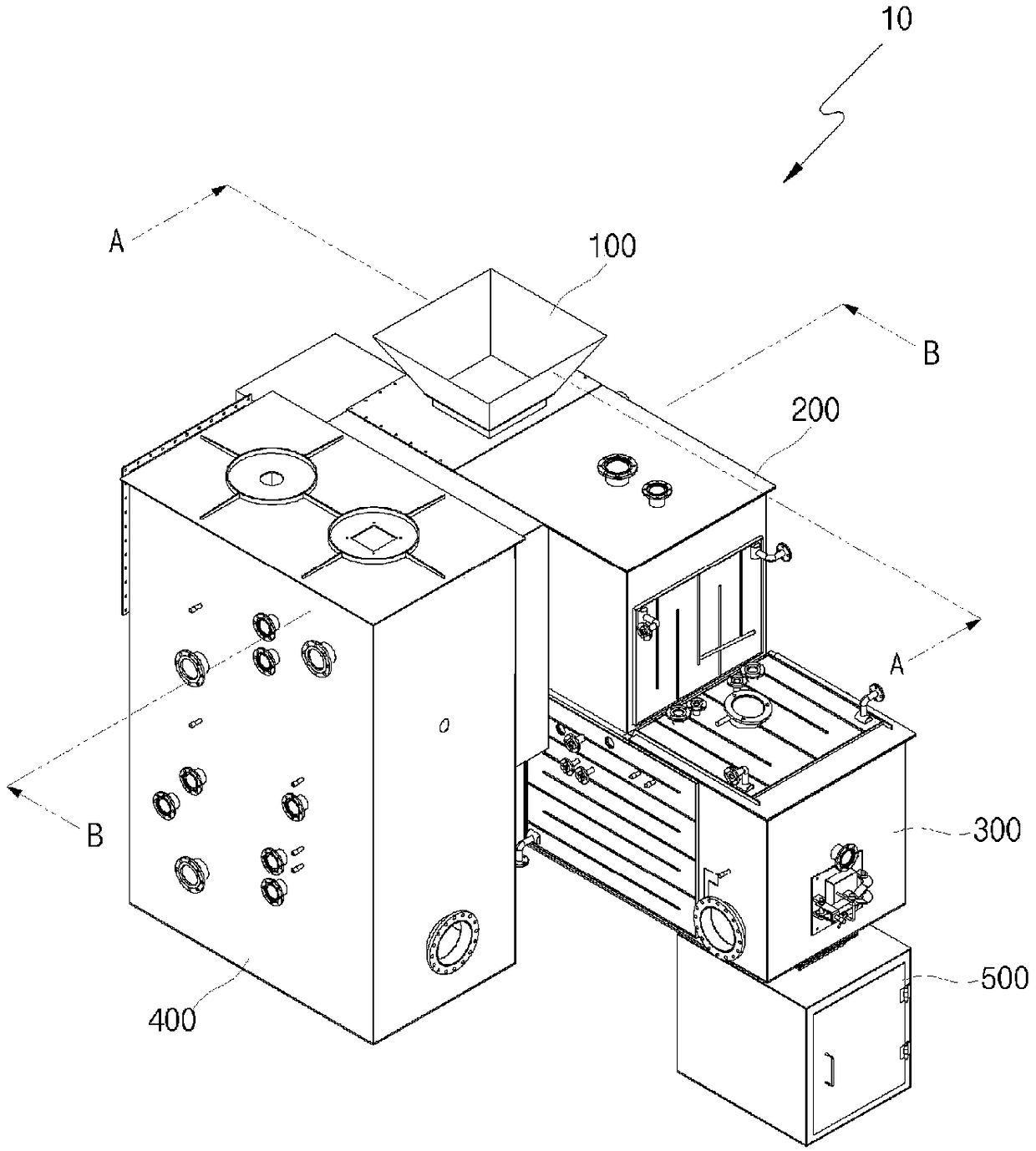

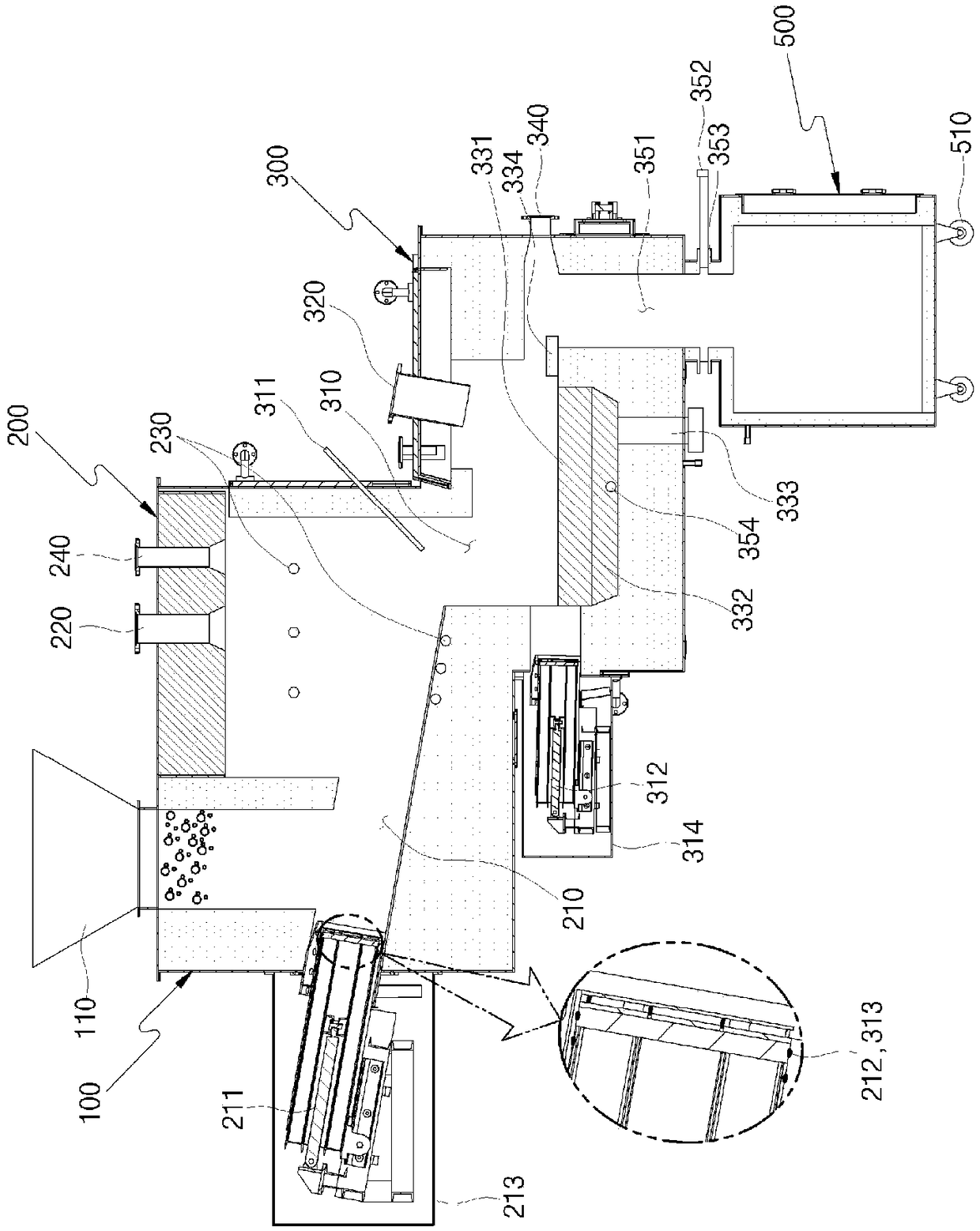

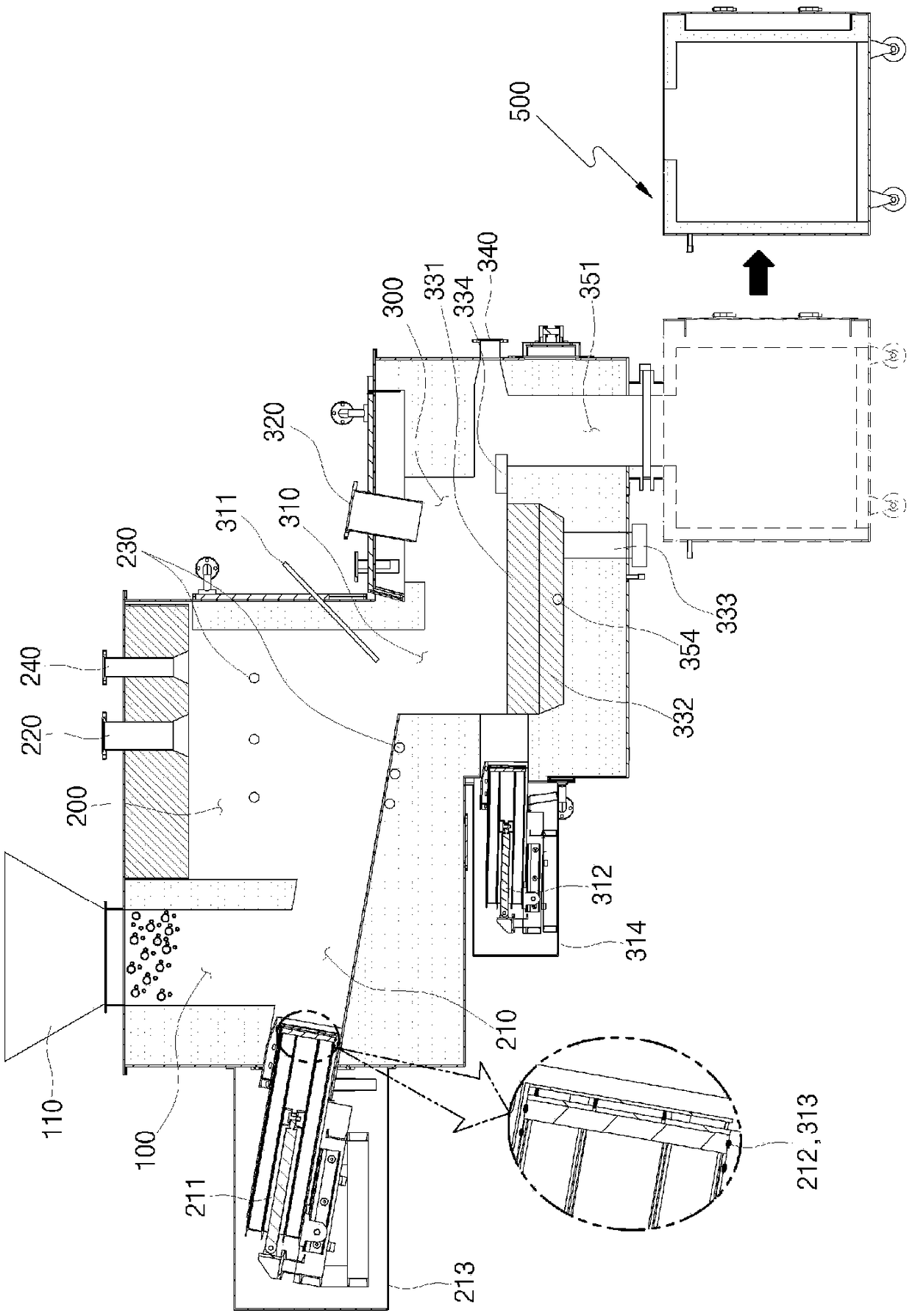

Sealed plasma melting furnace for treating medium- and low-level radioactive waste

InactiveCN109478438AReduce the possibility of leaksEasy to moveFurnace componentsWaste processingLiquid wasteCombustion chamber

The present invention relates to a sealed plasma melting furnace (10) for treating medium- and low-level radioactive wastes, which is capable of batch-processing the medium- and low-level radioactivewastes regardless of the types thereof according to the characteristics of each waste in a sealed state to thus minimize secondary pollutants. The sealed plasma melting furnace comprises: a waste supply chamber (100), provided with a hopper (110) on one side thereof in communication therewith, in which waste introduced from the hopper (110) is stacked in a vertical direction; a pyrolysis chamber channel (210) provided on one side of the waste supply chamber (100) and communicated with the waste supply chamber (100); a pyrolysis chamber (200) provided on one side of the pyrolysis chamber channel (210) and having a burner mounted thereon; a melting chamber channel (310), provided on one side of the pyrolysis chamber (200), which guides the waste conveyed from the pyrolysis chamber (200) communicating therewith and has a nozzle (311) for injecting liquid waste on one side thereof; a melting chamber (300), provided on one side of the melting chamber channel (310), which has a plasma torch(320) mounted on one side thereof and has a furnace inside for accommodating a molten material formed at a bottom surface thereof; a molten processed product discharging channel (350), provided at a lower portion of the melting chamber (300), for discharging the molten processed product generated in the melting chamber; a secondary combustion chamber channel (410), provided on one side of the pyrolysis chamber (200), for inducing and exhausting a flow of an exhaust gas generated in the melting chamber (300); and a secondary combustion chamber (400), provided on one side of the secondary combustion chamber channel (410), for inducing a complete combustion of the exhaust gas introduced from the secondary combustion chamber channel (410) communicating therewith.

Owner:TRIPLE +1

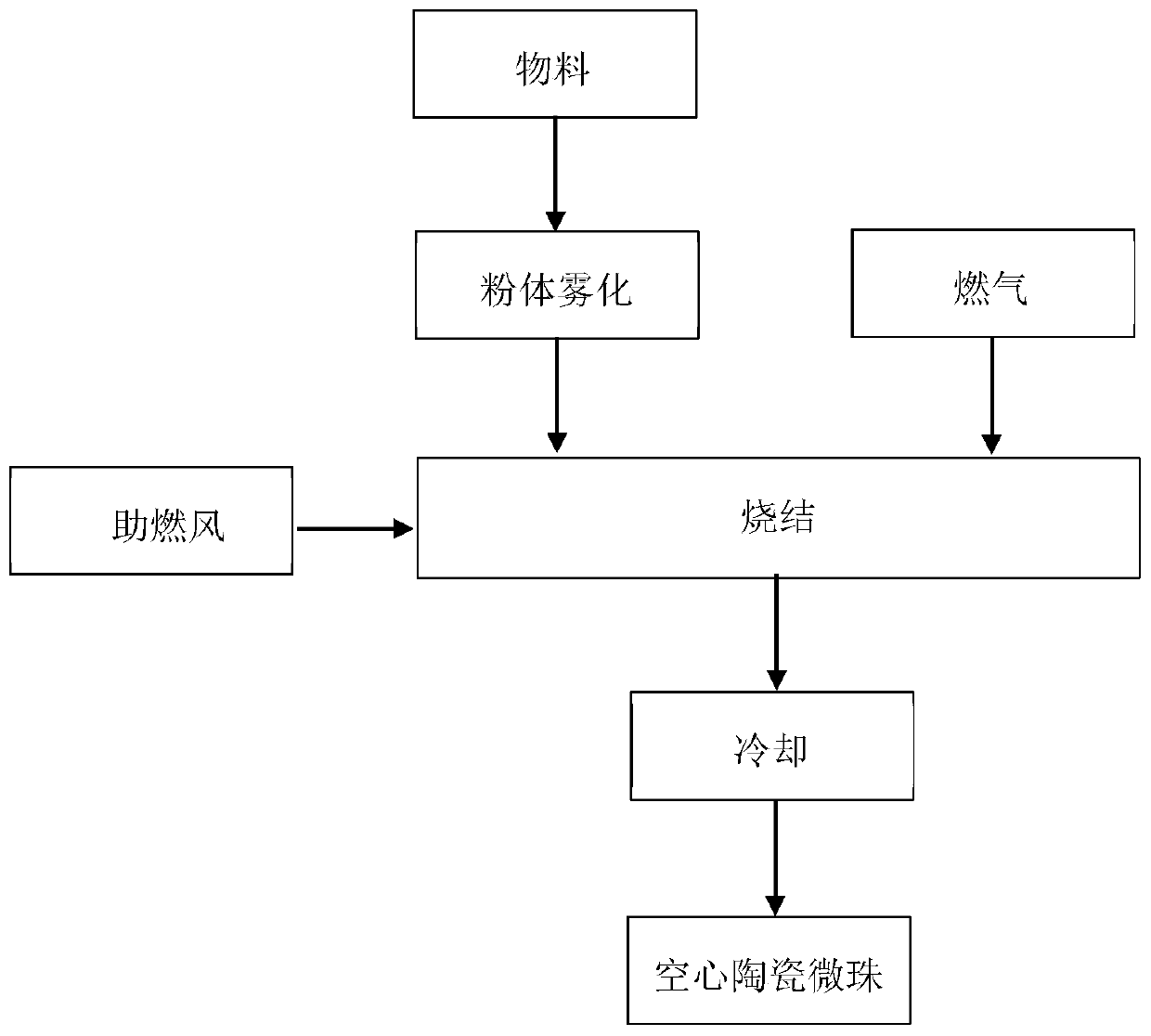

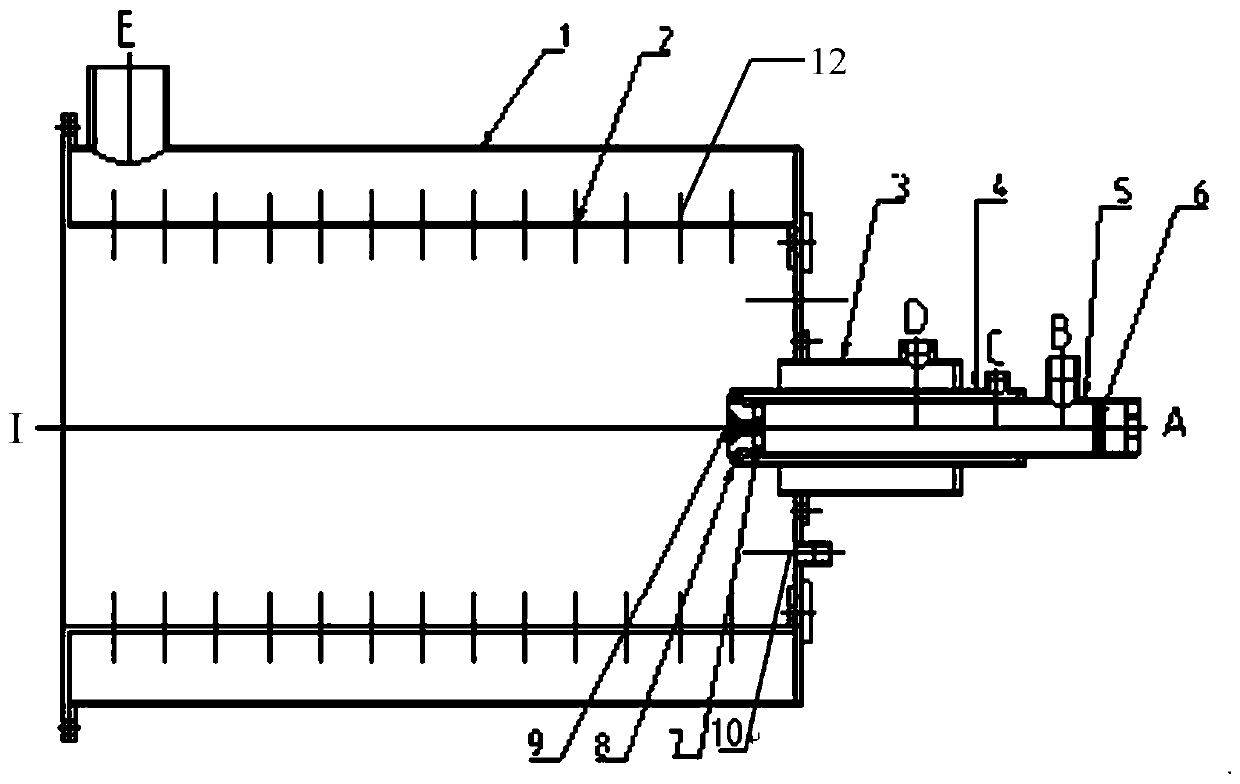

Method and device for sintering hollow ceramic microbeads

ActiveCN111517757ASolve the problem of energy consumptionSolve the problem of prone to wall adhesionChamber furnacesCharge treatment typeMicrosphereReaction zone

The invention discloses a method and a device for sintering hollow ceramic microspheres. The method comprises the following steps: step 1, rapidly mixing fuel gas with combustion-supporting air to react to form stable and continuous high-temperature flame, step 2, atomizing material particles and uniformly dispersing the atomized material particles into a flame reaction zone, and step 3, sinteringthe material with the high-temperature flame and then cooling to obtain a hollow ceramic microsphere product. The sintering device comprises a combustion-supporting air shell, a combustion cylinder,a powder conveying pipeline and a gas uniform dilution pipe, wherein the combustion-supporting air shell is communicated with a combustion-supporting air inlet pipe, the combustion cylinder is coaxially arranged in the combustion-supporting air shell, the combustion-supporting air shell is provided with a plurality of outlet pipes communicated with the combustion cylinder, the combustion cylinderis connected with an igniter, and the powder conveying pipeline and the fuel gas uniform dilution pipe are arranged at one end of the combustion cylinder. With application of the method, the hollow ceramic microbead product which is light in weight, high in strength, low in oil absorption rate, good in sound insulation, flame retardance and electrical insulation, low in heat conduction, wear-resistant and corrosion-resistant can be prepared at low cost.

Owner:HEBEI YL BANGDA NEW MATERIALS LTD CO

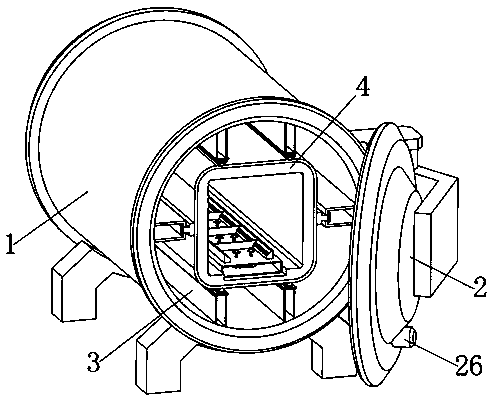

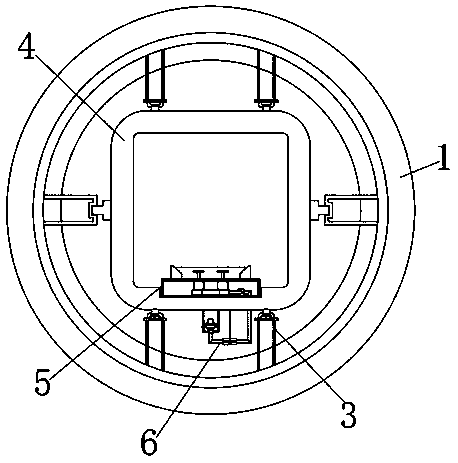

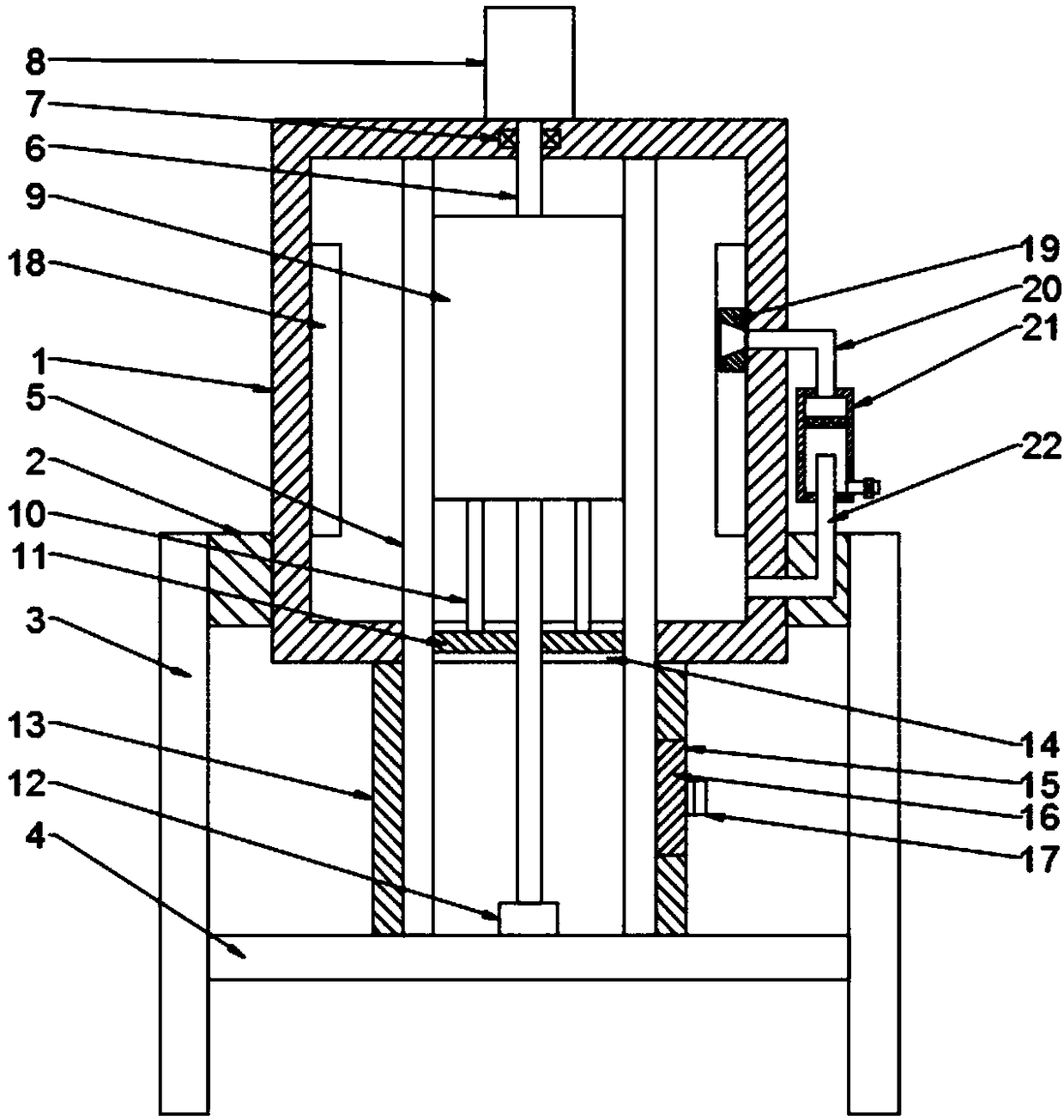

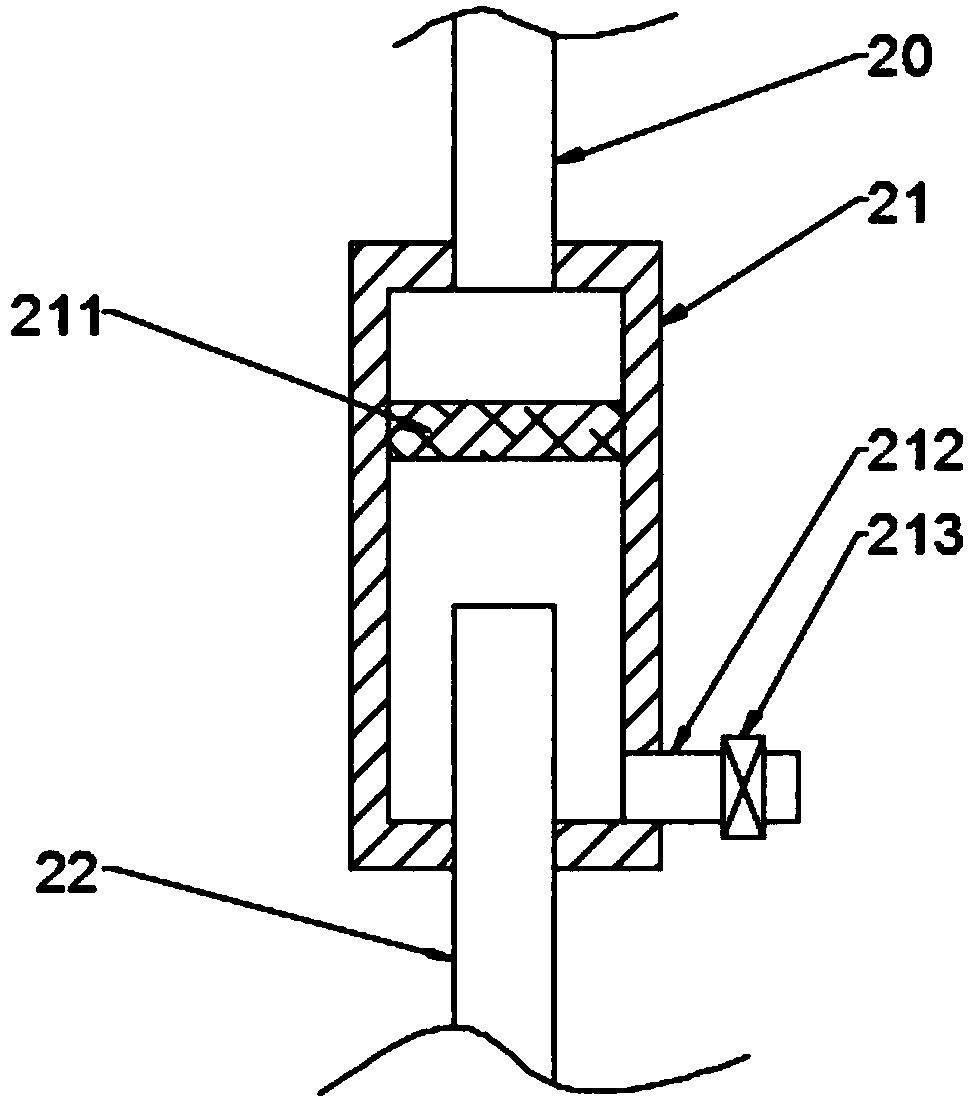

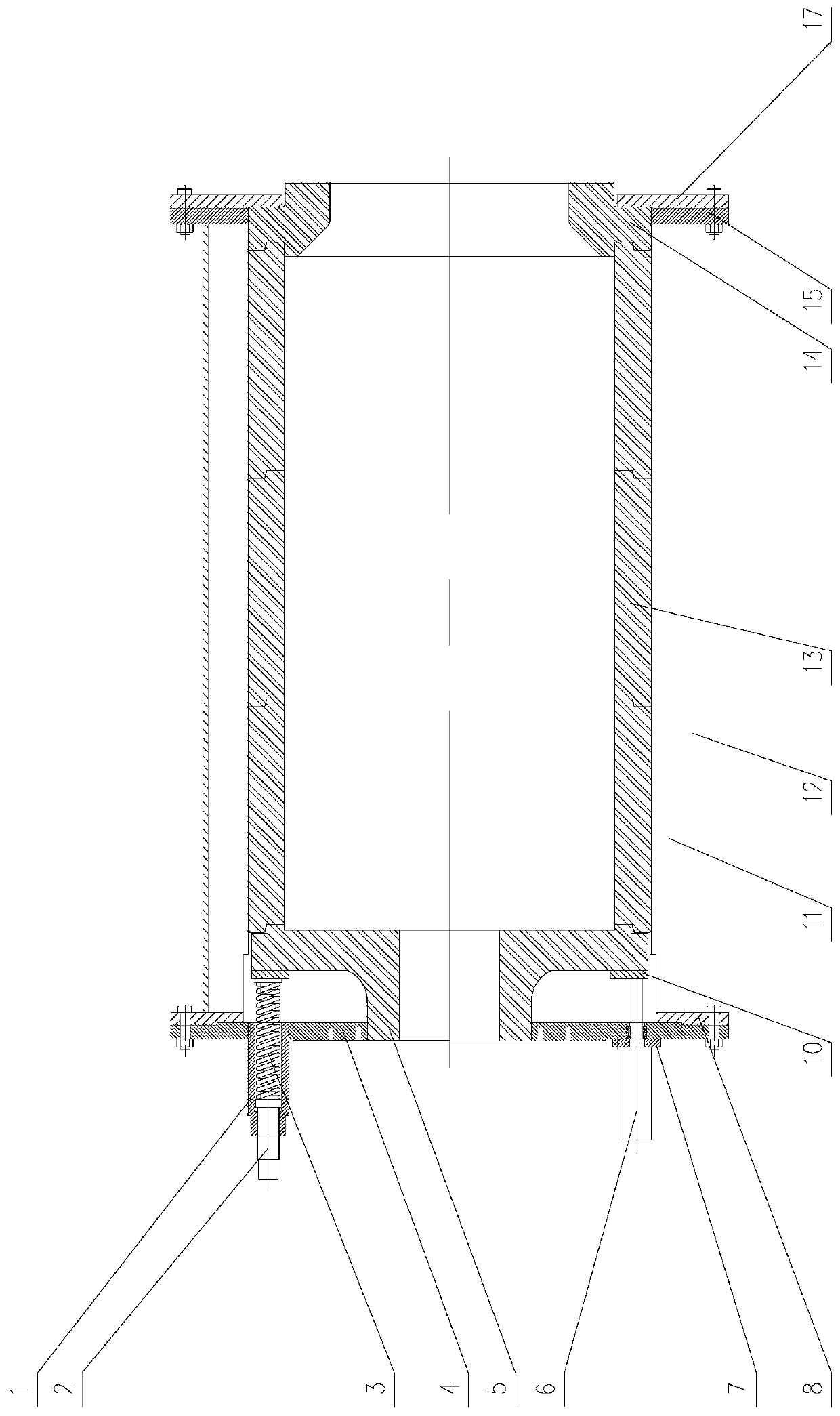

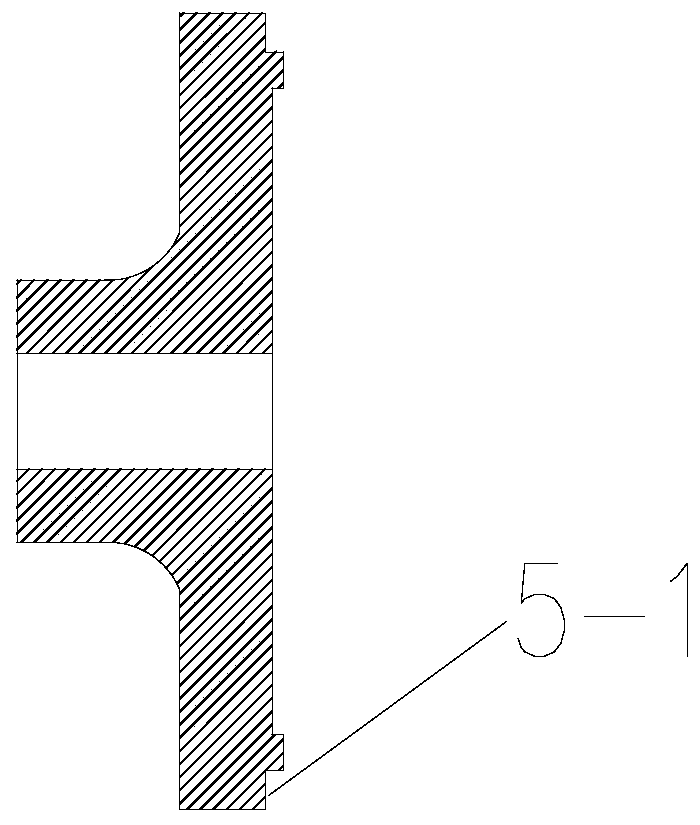

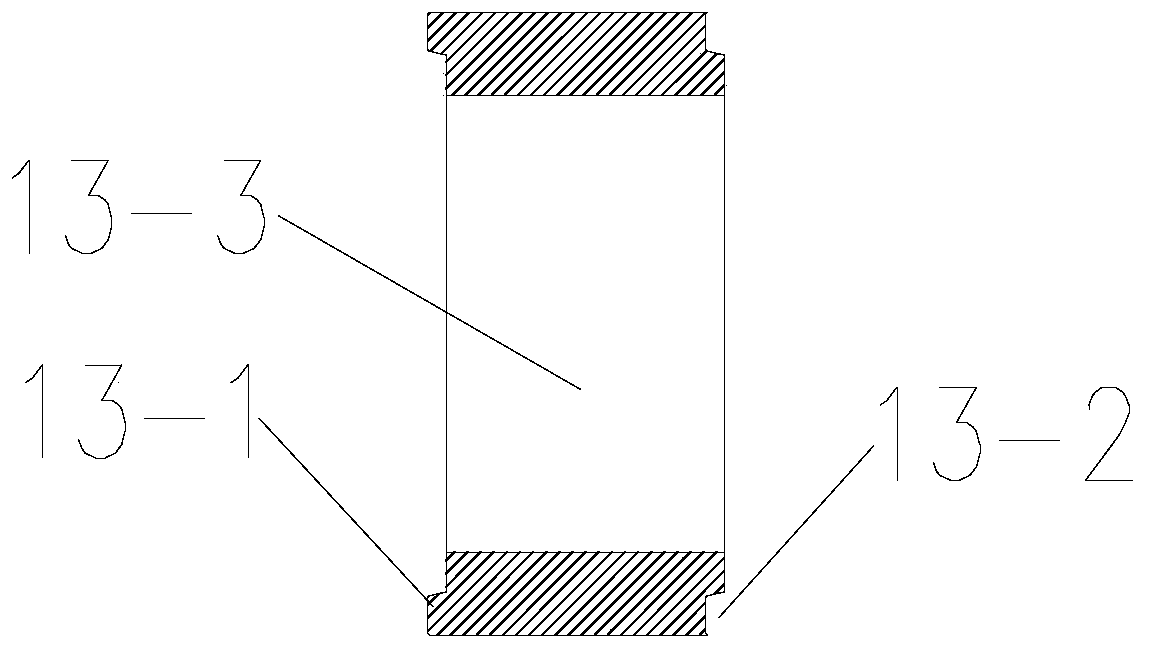

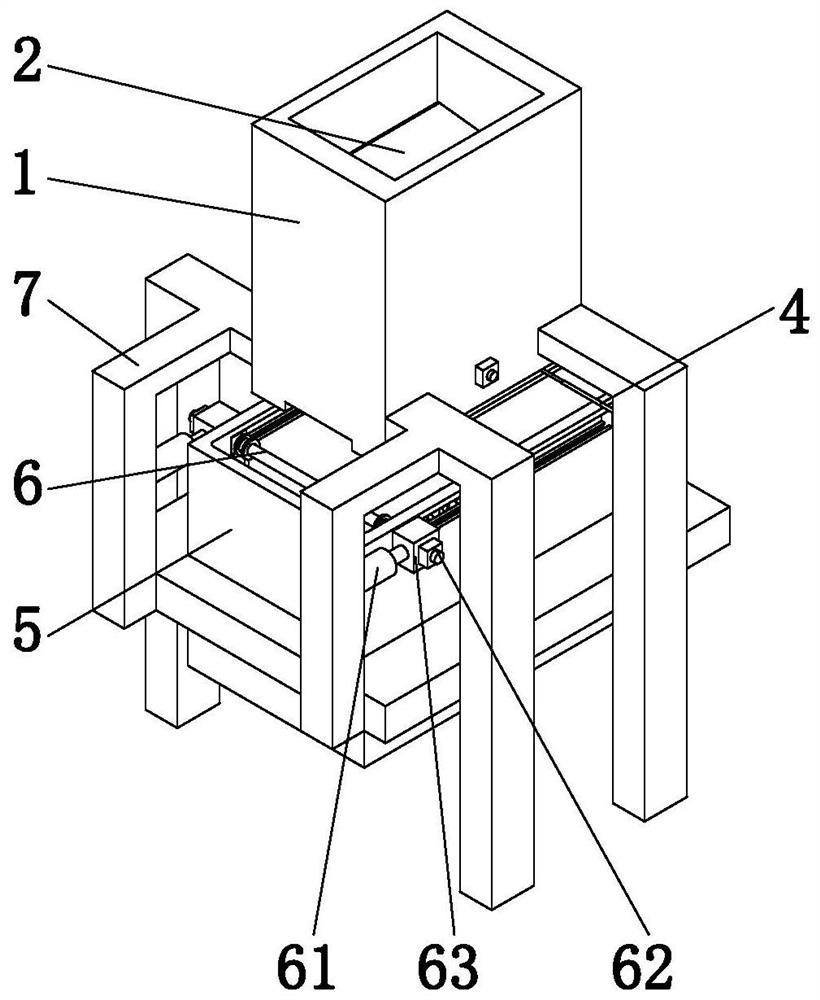

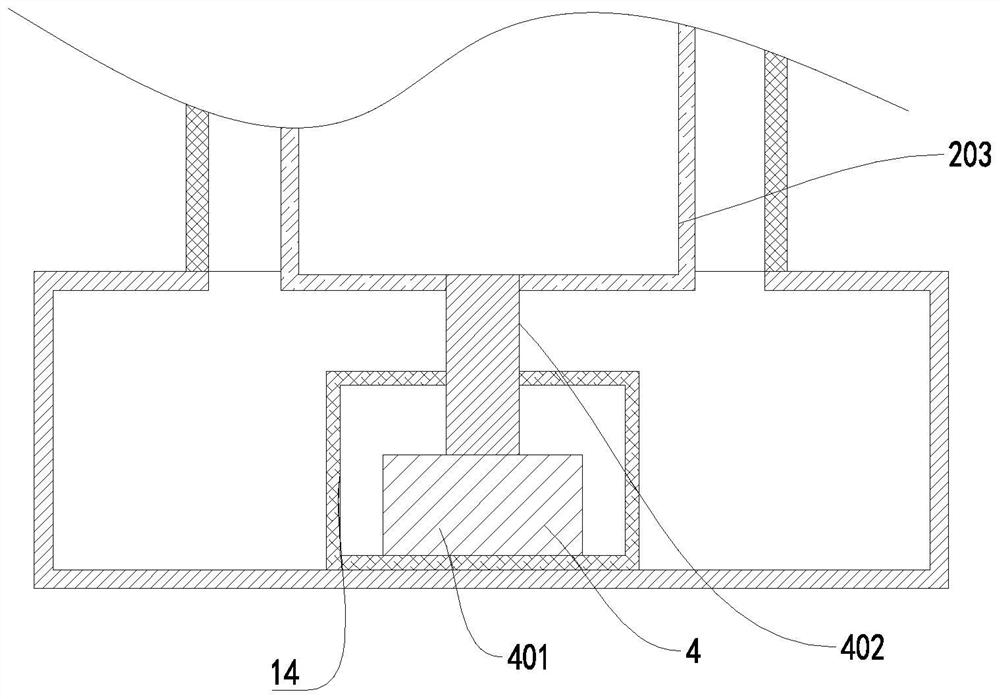

Forming device for bulletproof insert plate with complex curved surface

ActiveCN111322867AVolume Shrinkage and Deformation MonitoringTemperature controlCharge supportsChamber furnacesGreen bodyBoron carbides

The invention discloses a forming device for a bulletproof insert plate with a complex curved surface. The device comprises a furnace shell, a furnace cover, a supporting frame and a furnace barrel, wherein the furnace cover is arranged at the end port in the furnace shell through a rotating shaft frame, the furnace barrel is arranged in the furnace shell through a supporting frame, a setter plateassembly used for bearing boron carbide ceramic is placed in the furnace barrel, and the outer wall of the bottom of the furnace barrel is fixedly provided with a forming detecting assembly. According to the device, the setter plate in the furnace barrel is improved and optimized so that the volume shrinkage deformation of a boron carbide ceramic green body in the firing process can be monitoredthrough the setter plate; the reaction is performed by using a transmission part during shrinkage deformation of the green body so that the forming detecting assembly can detect the shrinkage deformation of the green body; and the temperature in a furnace is started to be controlled so that the temperature of the boron carbide ceramic during green body deformation in the firing process can be controlled, and the influence of over-high or over-low temperature on the green body firing quality is avoided.

Owner:浙江吉成新材股份有限公司

Improvement method and device for prolonging service life of graphite crucible

ActiveCN114105682AGood physical and chemical compatibilityPrevents oxidation and even breakageMolten spray coatingChemical industryPlasma sprayedGraphite crucible

The invention relates to the technical field of graphitization furnaces, in particular to an improvement method and device for prolonging the service life of a graphite crucible. The improvement method for prolonging the service life of the graphite crucible comprises the following steps that mixed powder is prepared, specifically, tungsten oxide, Si powder, C powder and chlorine salt are evenly mixed according to the mass part ratio of 45-60: 15-30: 10-25: 5-30, and the mixed powder is obtained; the graphite crucible base material is polished and pretreated, and an activated graphite crucible is obtained; primary bath: carrying out primary bath on the activated graphite crucible in the mixed powder to obtain a graphite crucible with a primary tungsten coating; and secondary spraying: spraying powder containing metal tungsten powder is subjected to plasma spraying on the surface of the graphite crucible with the primary tungsten coating, and the graphite crucible with the gradient tungsten coating is obtained. According to the method, the graphite crucible can be prevented from being oxidized and even fractured in the graphitization process; the service life is prolonged.

Owner:湖州启源金灿新能源科技有限公司

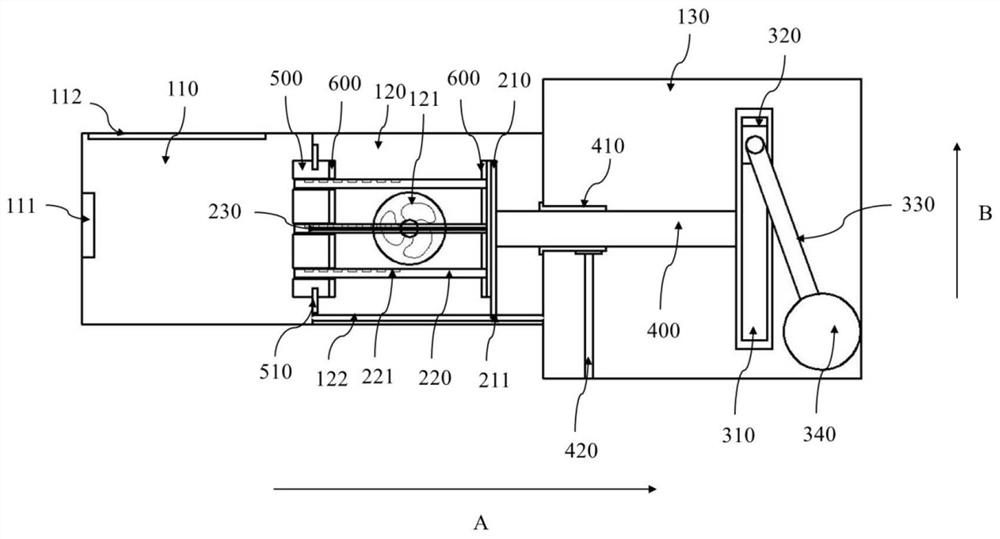

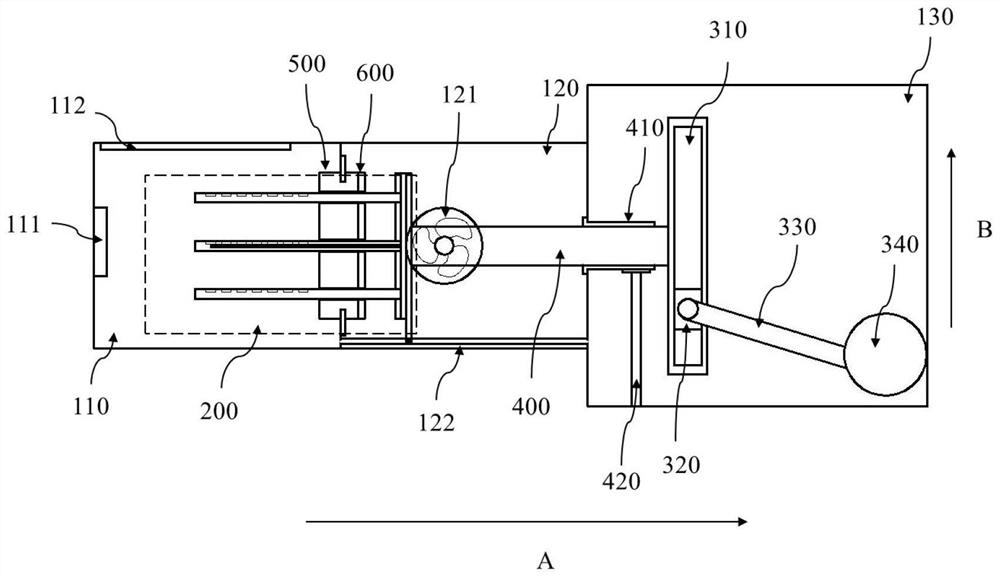

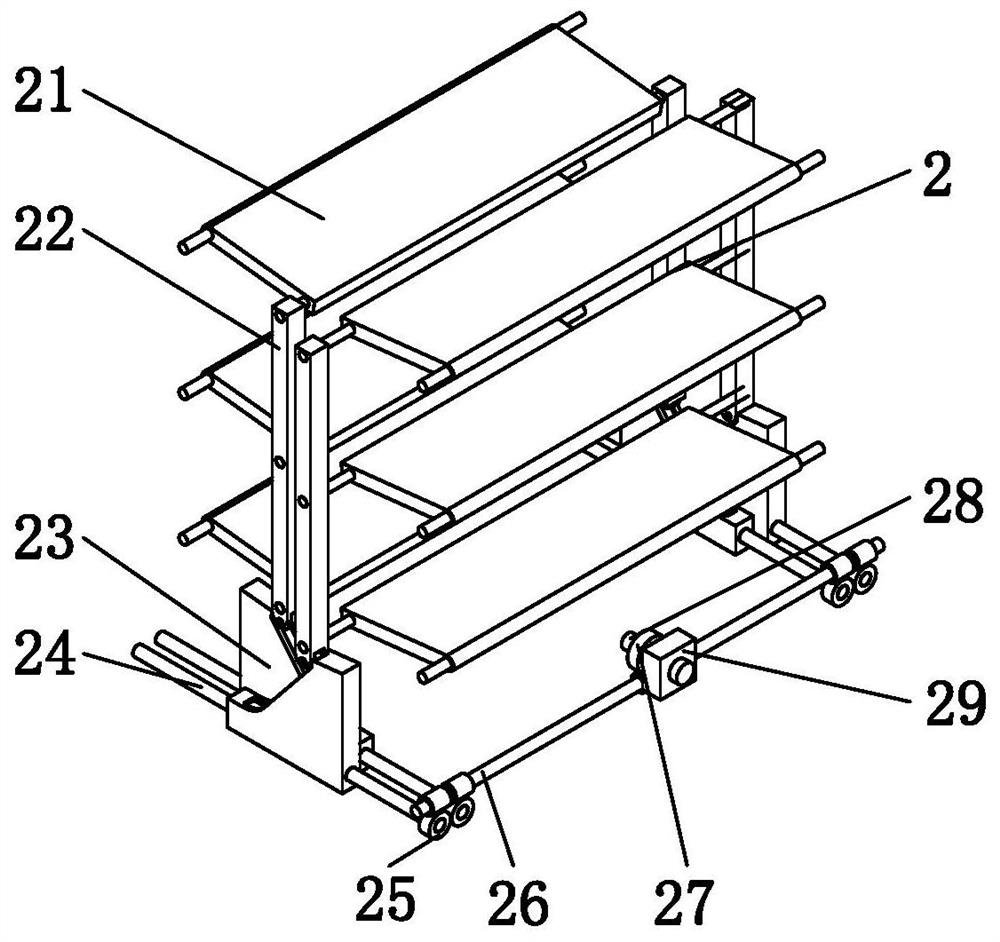

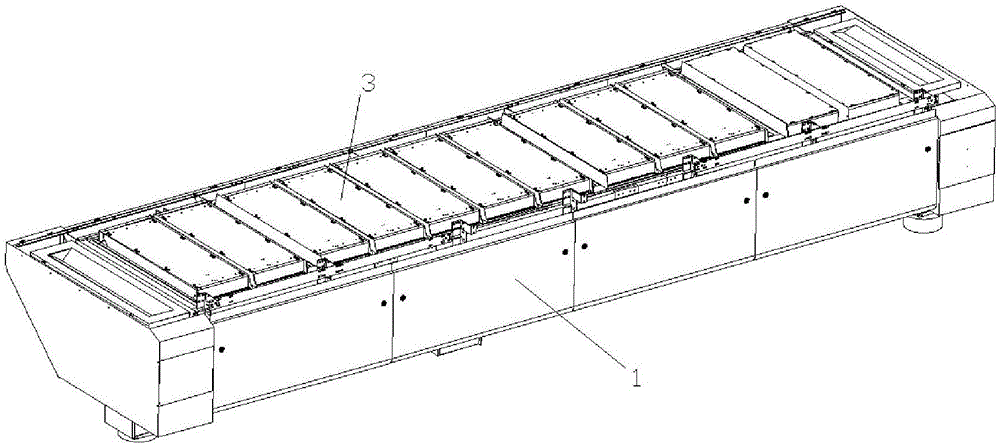

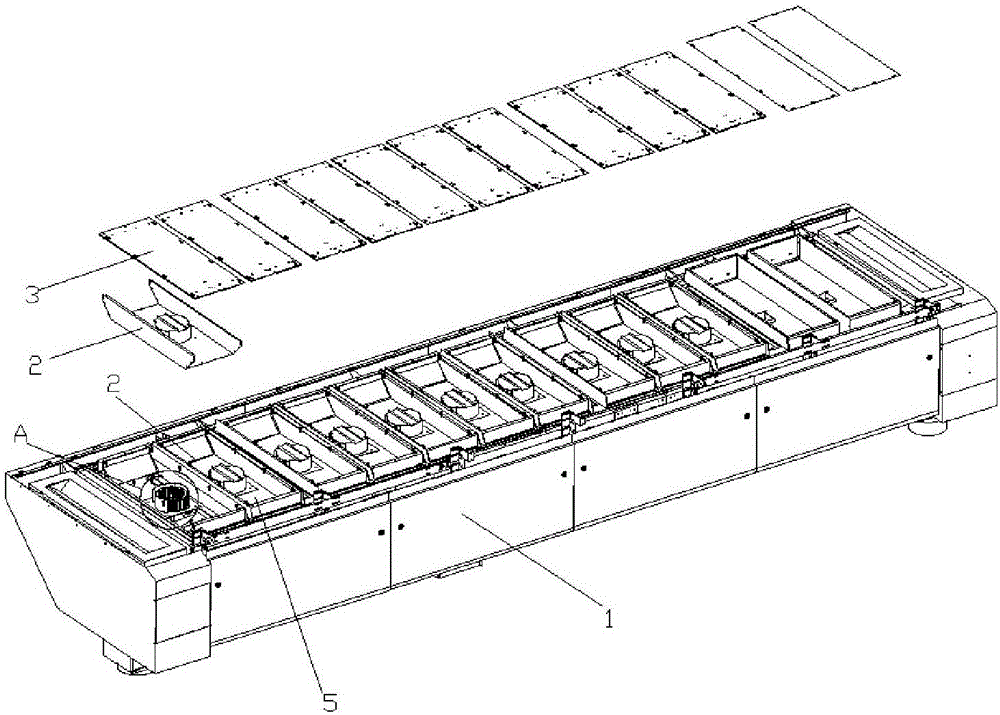

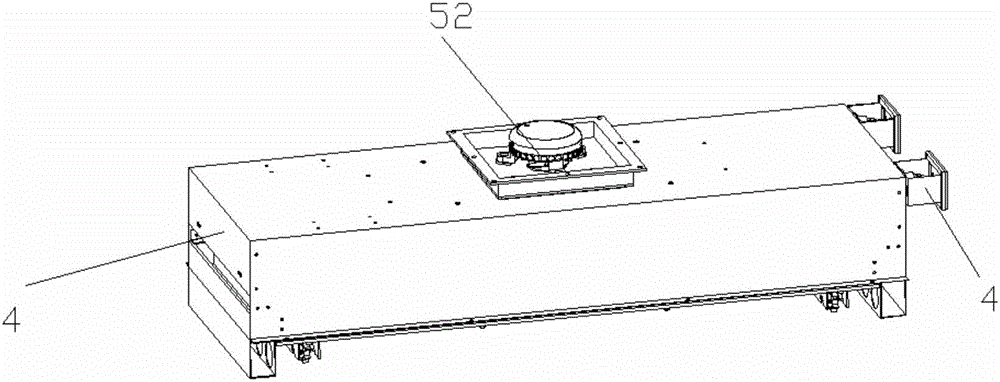

Horizontal circulating heating furnace

PendingCN112556428AImprove thermal shock performanceImprove detection efficiencyCharge manipulationChamber furnacesEngineeringHeat conservation

The invention discloses a horizontal circulating heating furnace, and relates to the related technical field of horizontal furnaces. The horizontal circulating heating furnace comprises a furnace body, a sample fixing device and a driving device, wherein, the furnace body is sequentially provided with a heating area, a cooling area and a control area which are arranged at intervals in the horizontal direction; the sample fixing device is provided with a first temperature sensor for monitoring the temperature of a to-be-detected sample; the driving device is arranged in the control area, is connected with the sample fixing device and drives the sample fixing device to circularly move between the heating area and the cooling area; when the temperature of the to-be-detected sample is lower than a threshold value, the driving device drives the sample fixing device to move to the heating area; and after the to-be-detected sample is subjected to heat preservation in the heating area at the preset temperature for preset time, the driving device drives the sample fixing device to move to the cooling area. According to the horizontal circulating heating furnace, the driving device is adopted to drive the sample fixing device to circularly move between the heating area and the cooling area so as to circularly heat and cool the to-be-detected sample, and the detection efficiency of the thermal shock performance of the to-be-detected sample is improved.

Owner:SHANGHAI ELECTRIC GAS TURBINE CO LTD

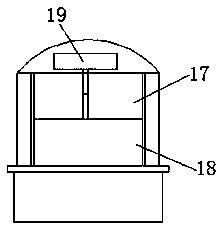

Vertical ceramic tile drying and sintering kiln capable of achieving feeding and discharging

InactiveCN108120286AReduce the impactKeep healthyCharge composition/stateChamber furnacesBrickWater vapor

The invention discloses a vertical ceramic tile drying and sintering kiln capable of achieving feeding and discharging. The kiln comprises a box body, the bottom end of the external circle face of thebox body is sleeved with a supporting frame, a plurality of supporting legs are evenly arranged on the external circle face of the supporting frame, a supporting plate is arranged among the supporting legs, a discharging cylinder is arranged at the top end of the supporting plate, the top end of the discharging cylinder is connected to the bottom end of the box body, a plurality of guide rail rods matched with the discharging cylinder are arranged in an inner cavity of the box body in a circular array mode, a lead screw is arranged among all the guide rail rods, and the lead screw is sleevedwith a drying box matched with the guide rail rods; the drying box is lowered through a motor, then, discharging and feeding are completed inside the discharging cylinder, the influence of high temperature of the kiln on workers is lowered due to the padding mode, and therefore the body health of the workers is ensured; by means of an internal circulation system formed between the box body and a water removal box, high temperature gas can bring away water vapor inside the box body constantly, so that the drying effect is improved, the high temperature gas can be recycled, and the thermal utilization rate is increased.

Owner:SHENZHEN SHENGTENG ENTERPRISE MANAGEMENT CO LTD

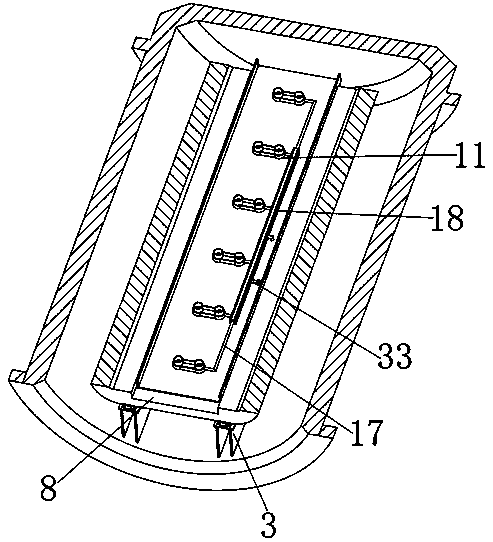

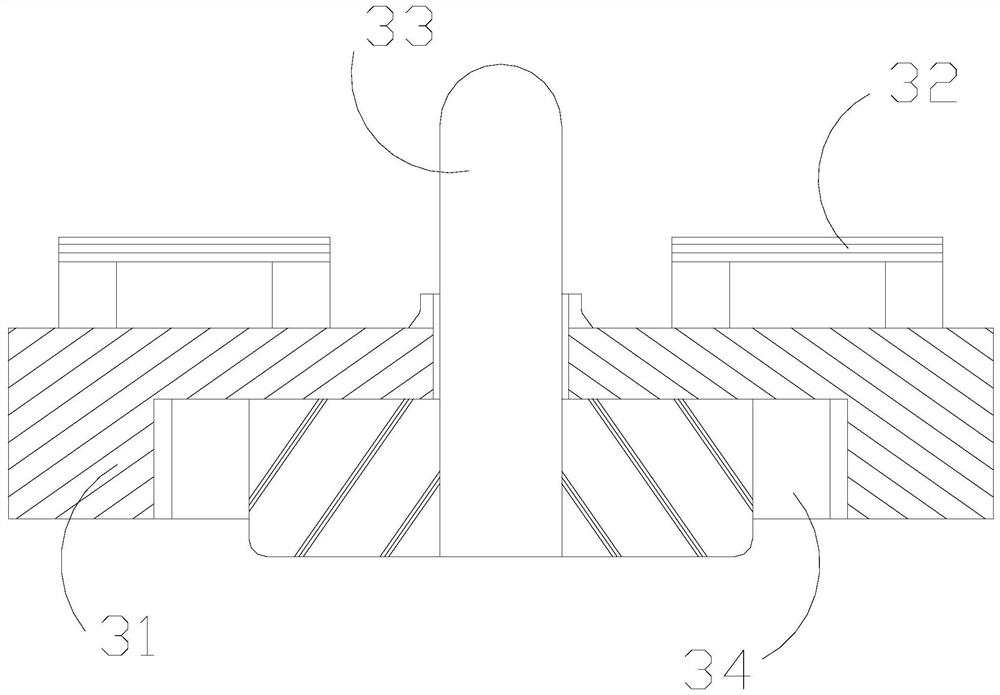

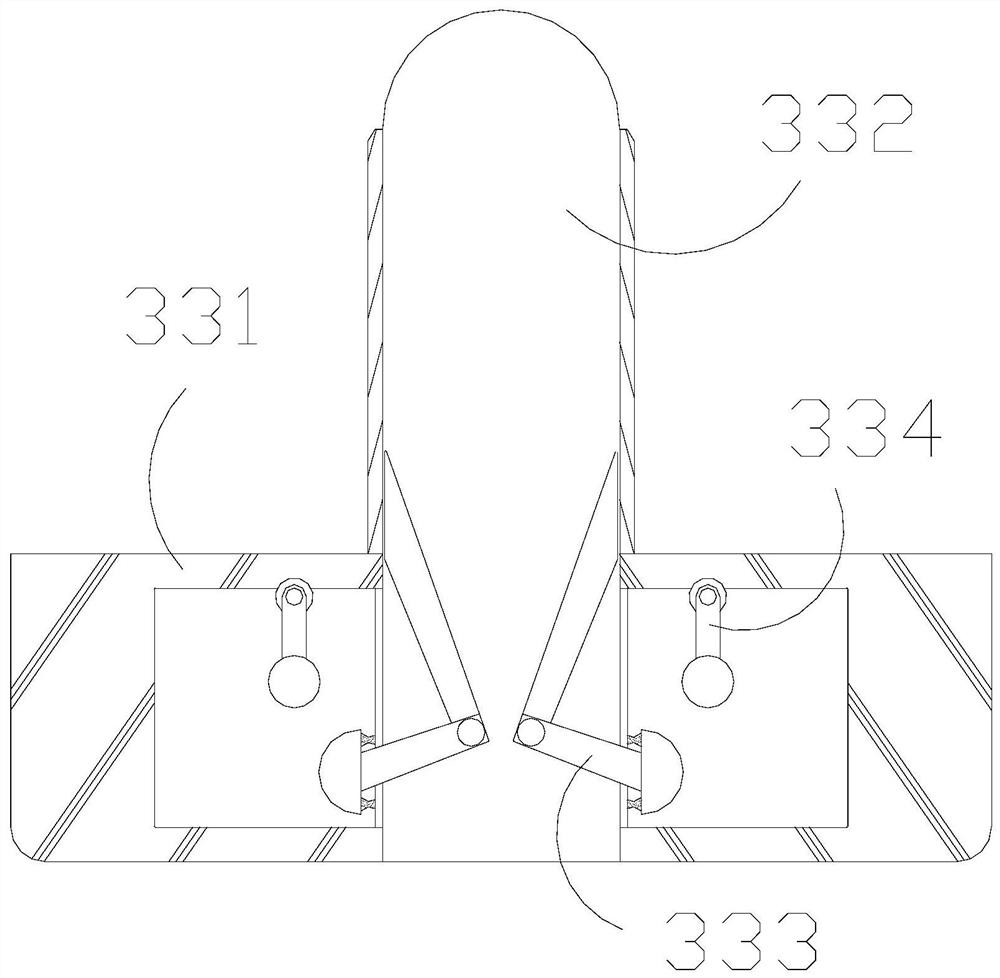

Mounting structure of ceramic liner rotary kiln

InactiveCN110375544AExtended service lifeIncrease productivityRotary drum furnacesChamber furnacesMetallurgyRotary kiln

The invention relates to a mounting structure of a ceramic liner rotary kiln. The mounting structure comprises a barrel. A ceramic liner is arranged in the barrel, the ceramic liner is of a split structure, an extruding device is arranged on one side of the ceramic liner, the barrel comprises an outer barrel, and insulating layers are arranged on the inner periphery of the outer barrel. An iron core is loaded and unloaded by using the mounting structure, so that the technical blank of compacting the ceramic liner of the rotary kiln at home is filled, zero metal pollution to a material in a heating process is realized, and the ceramic liner is long in service life, high in production efficiency and safe and reliable in compacting effect. The mounting structure is simple to operate, convenient to mount and simple in later maintenance, can improve the production efficiency and save the cost, and protects the environment.

Owner:JIANGSU FENGGU ENERGY SAVING TECH

Industrial kiln for ceramic material production

InactiveCN109059543AReduce pollutionReduce processing costsCharge composition/stateChamber furnacesPulp and paper industryControl table

The invention relates to an industrial kiln for ceramic material production. The industrial kiln comprises a base; a console is arranged at the top of the base; the console comprises a cooling furnace, a high-temperature furnace and an isolation device; the cooling furnace is connected with the high-temperature furnace through the isolation device; a kiln port is formed in one end of the high-temperature furnace; a conveying table is arranged at one end of the console; a conveying belt is arranged at the top of the conveying table; belt wheels are arranged on two sides of the conveying belt; support columns are arranged at the bottom of the conveying table; a motor is arranged at the bottom of the conveying table; linkage belts are arranged between the motor and the belt wheels; the motoris connected with the belt wheels through the linkage belts; a ceramic placing plate is arranged above the conveying belt; a control table is arranged on one side of the base; a switch controller is arranged at the top of the control table; and a power supply socket is arranged on one side of the bottom of the base. The industrial kiln reduces the environment pollution, reduces the machining cost,and achieves various functions and high practicability.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

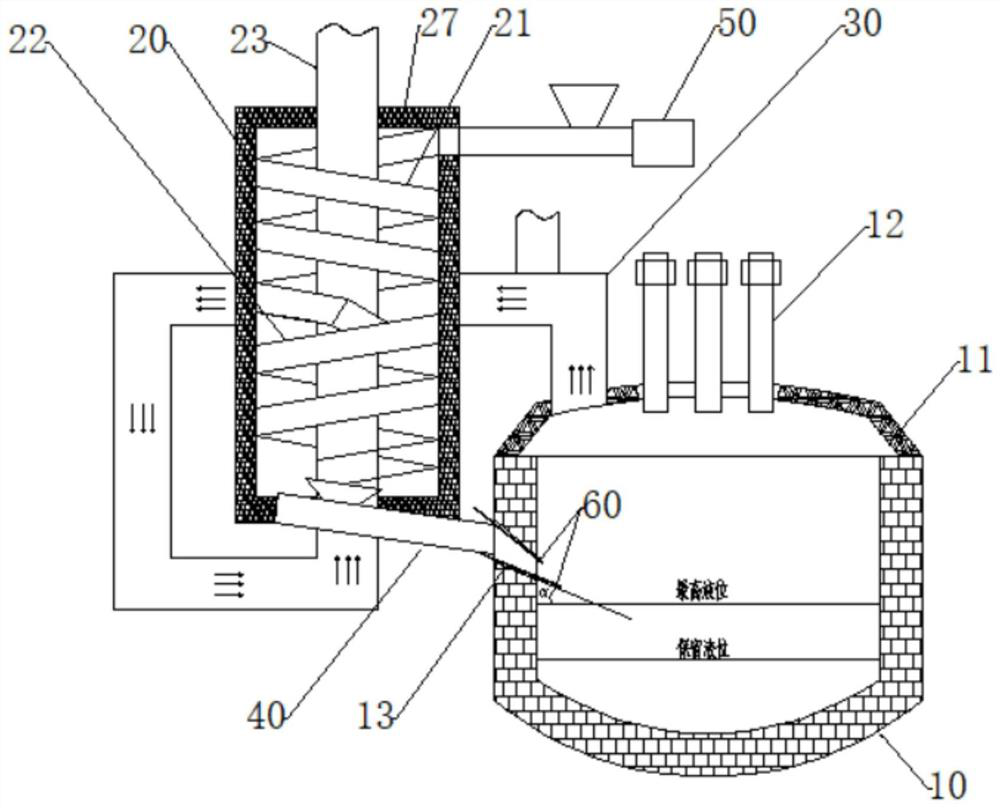

A high-stability fusion-cast zirconium corundum brick production process

ActiveCN111087231BImprove pass rateAvoid or reduce unevennessChamber furnacesPreheating chargesBrickMaterials science

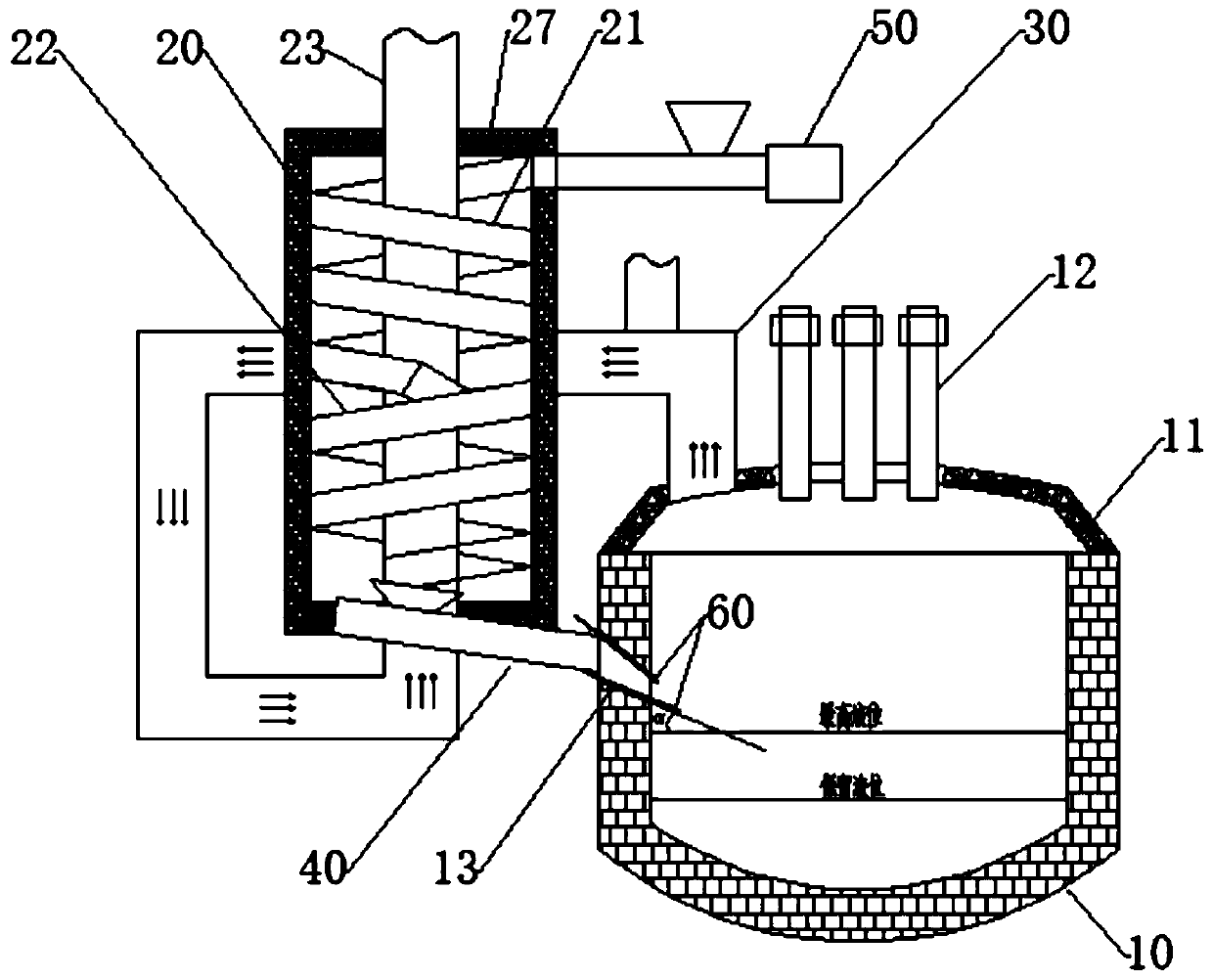

A high-stability fused-cast zirconium corundum brick production process, including mixture preparation, melting process, casting process, thermal insulation annealing process, demoulding processing process, and the ingredients are calculated by weight ZrO 2 +HfO 2 35‑40 parts, SiO 2 12‑14 parts, Na 2 O 1.2-1.6 parts, rare earth 0-3 parts, Al 2 o 3 Make up the batching to 100 parts by weight as the balance; include clinker and raw meal in the batching, the proportion of the two is the same, the clinker is a block, the particle size is 3-8cm, and the raw meal is a powder with a particle size of 0.05-1.5mm ;The proportion of clinker is 10‑30%; the melting process: keep 1 / 2‑3 / 5 of the molten material in the furnace body, and the clinker is directly poured into the center of the furnace body through the hopper; the raw material is microwaved before entering the furnace body Heating; the lowest point where the raw material enters the furnace body should be above the highest liquid level in the furnace body, and the distance between the lowest point and the highest liquid level is 1 / 2‑3 / 4 of the distance between the highest liquid level and the reserved liquid level; The angle α between the direction of the raw material entering the furnace body and the horizontal liquid level is 30-60 degrees. The process and equipment can effectively improve the melting efficiency, improve the uniformity of the material liquid components, and reduce energy consumption.

Owner:LUOYANG DAYANG HIGH PERFORMANCE MATERIAL

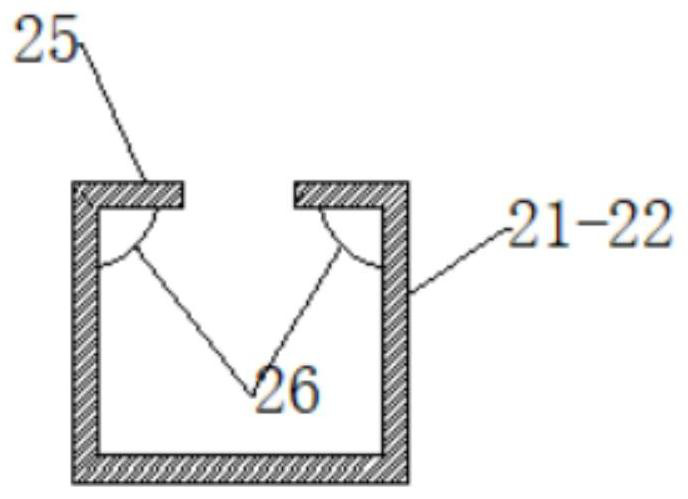

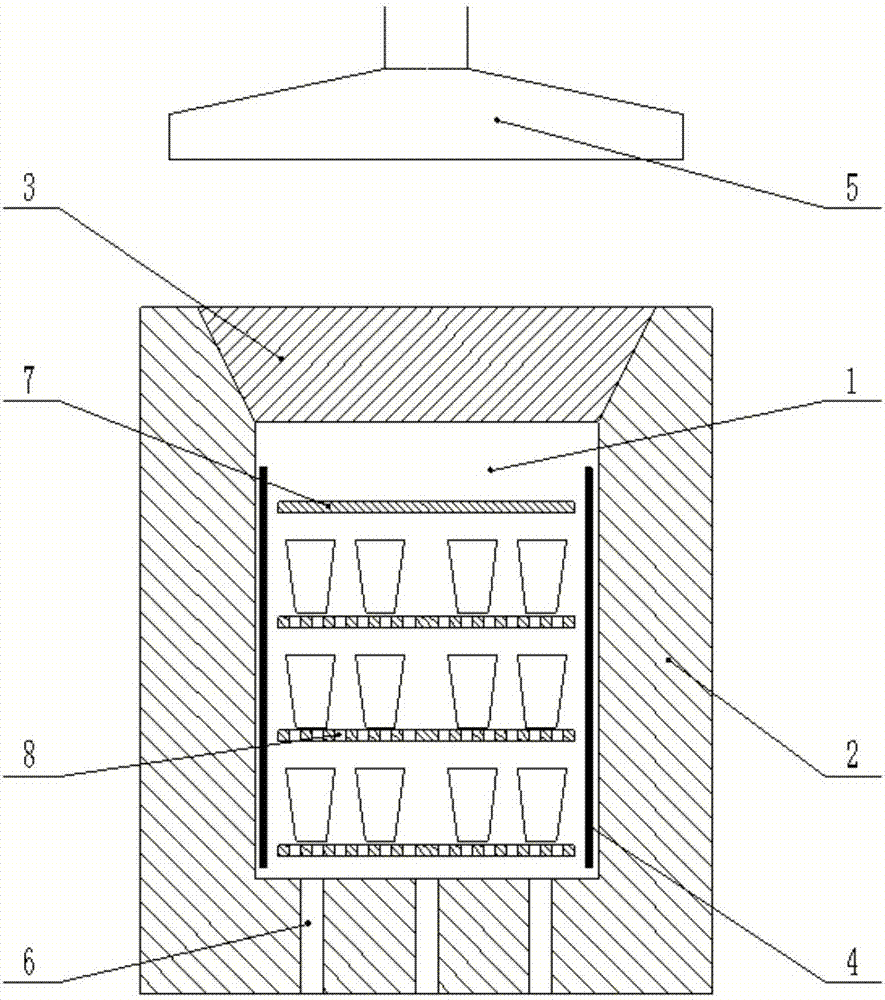

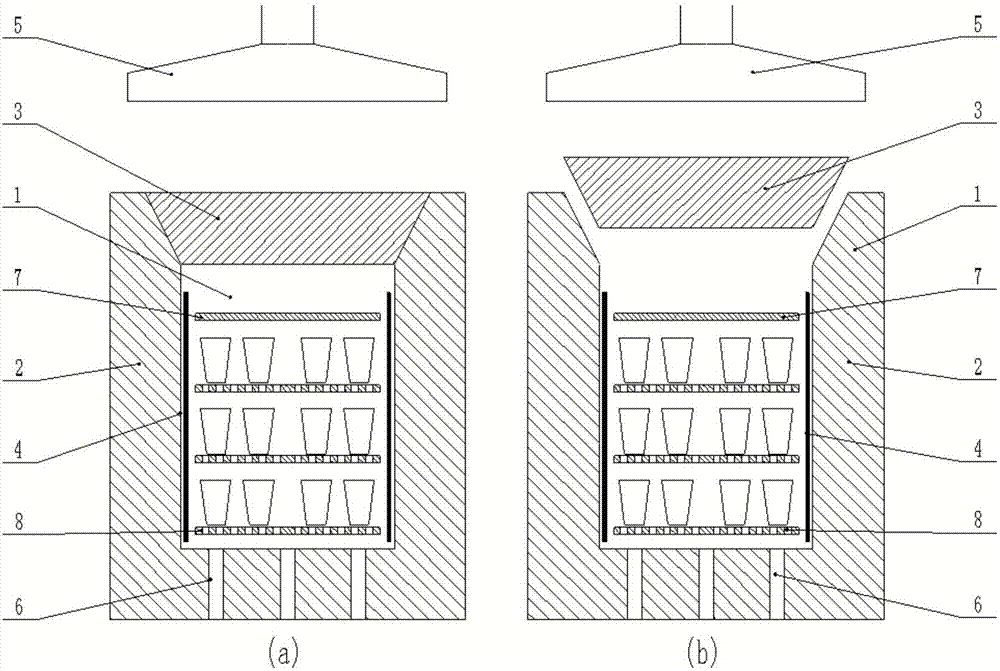

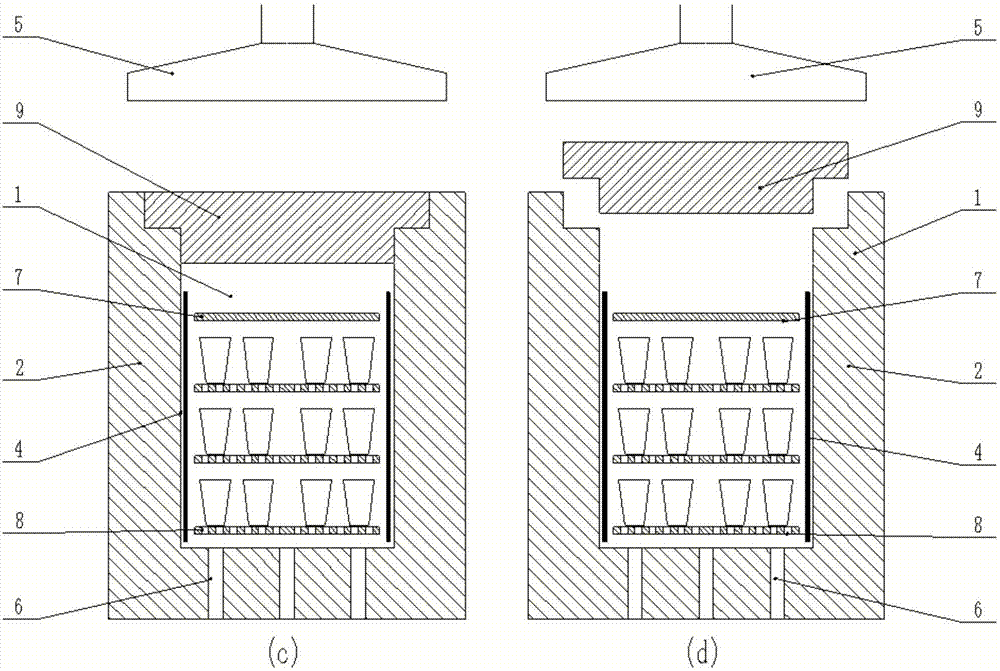

Ceramic kiln with cooling control structure

InactiveCN106885469ASolve the problem of extremely uneven temperature fieldReduced strengthRemovable covers for furnacesCharge composition/stateNatural convectionTop cap

The invention relates to a ceramic kiln with a cooling control structure, and belongs to the technical field of ceramic firing. The ceramic kiln comprises a hearth, a hearth outer wall, a liftable top cap, heaters, a smoke exhaust hood, a controlled air inlet pipeline, a soaking refractory slab and perforated ventilating refractory slabs, wherein the heaters are arranged on the walls of the hearth, and the perforated ventilating refractory slabs are arranged in the hearth longitudinally; a green body to be fired is arranged on the perforated ventilating refractory slabs, and the soaking refractory slab is located above the green body to be fired; the lower part of the hearth is provided with the controlled air inlet pipeline, and the upper part of the hearth is provided with the liftable top cap; the smoke exhaust hood is arranged above the top cap. The temperature in the ceramic kiln provided by the invention is controlled and reduced through controlling radiation quantity and natural convection quantity, and the liftable top cap is controlled; air enters from the bottom, and smoke is collected and exhausted from the top; a temperature field of a ceramic firing cooling stage and atmosphere uniformity are ensured. The ceramic kiln provided by the invention has the advantages of strong practicability and broad application prospect, and the ceramic production efficiency and the rate of finished products can be improved effectively.

Owner:杭州志在材料科技有限公司 +1

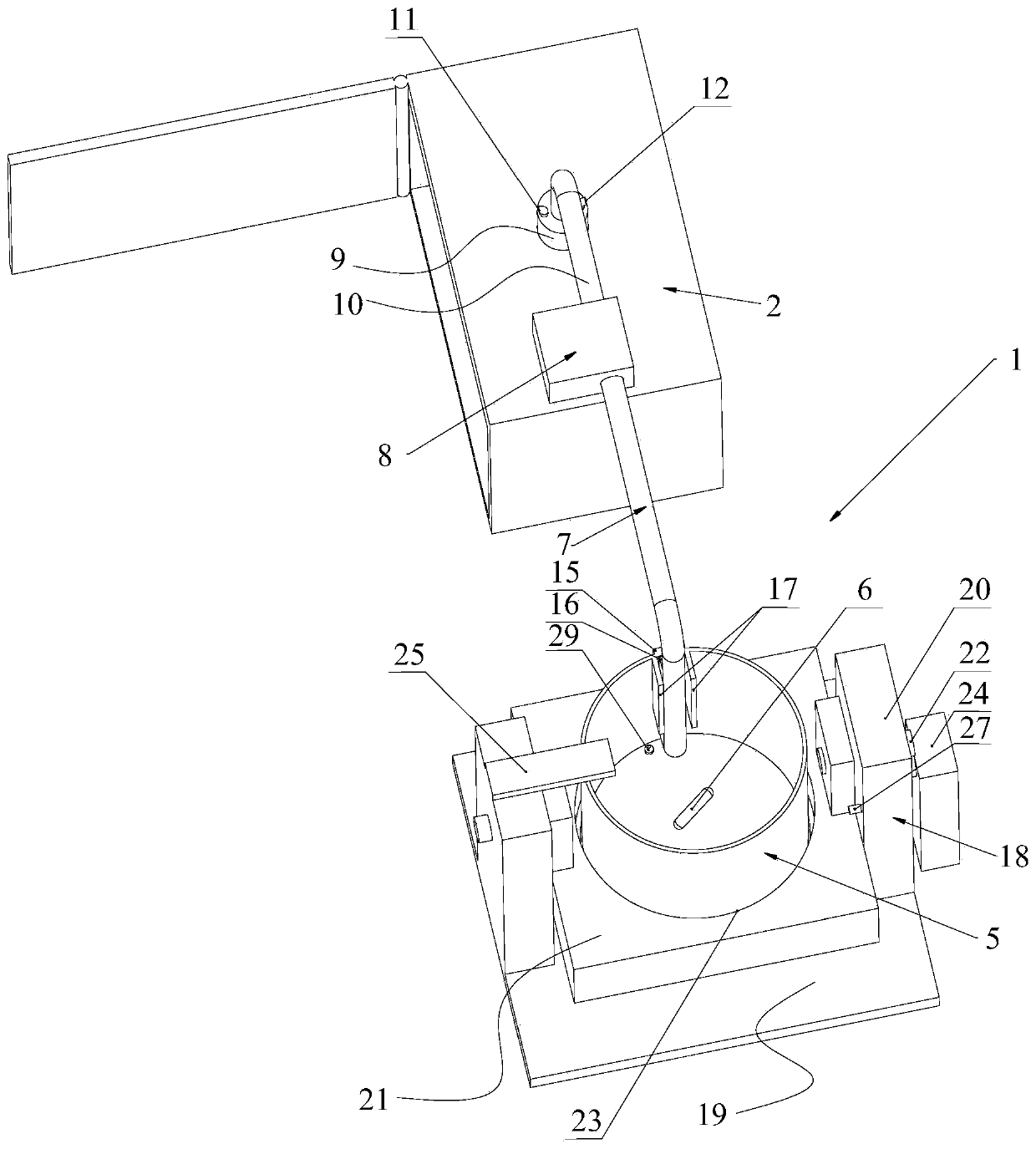

Multifunctional lanthanum calcium manganese oxygen ceramic sintering furnace

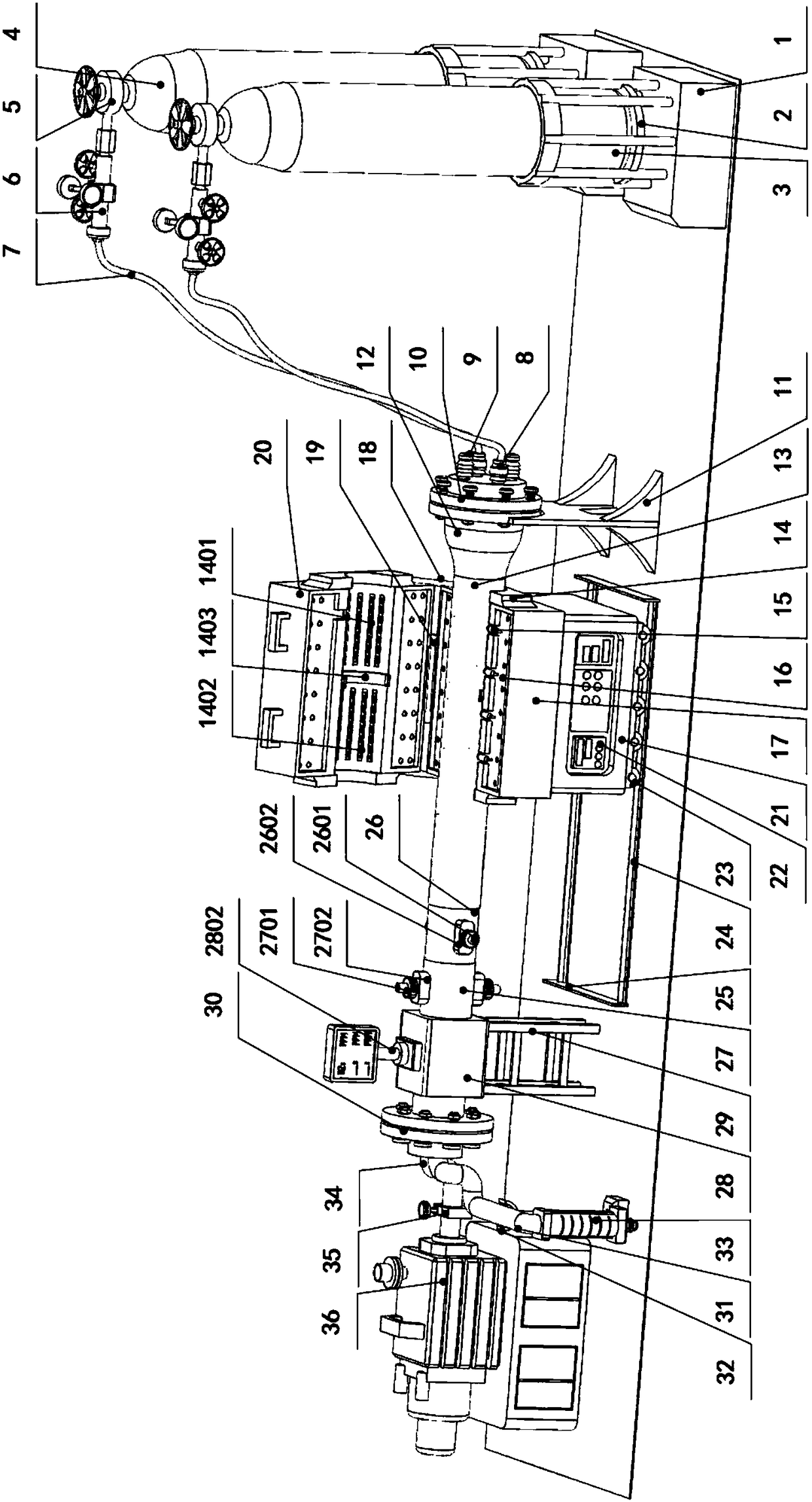

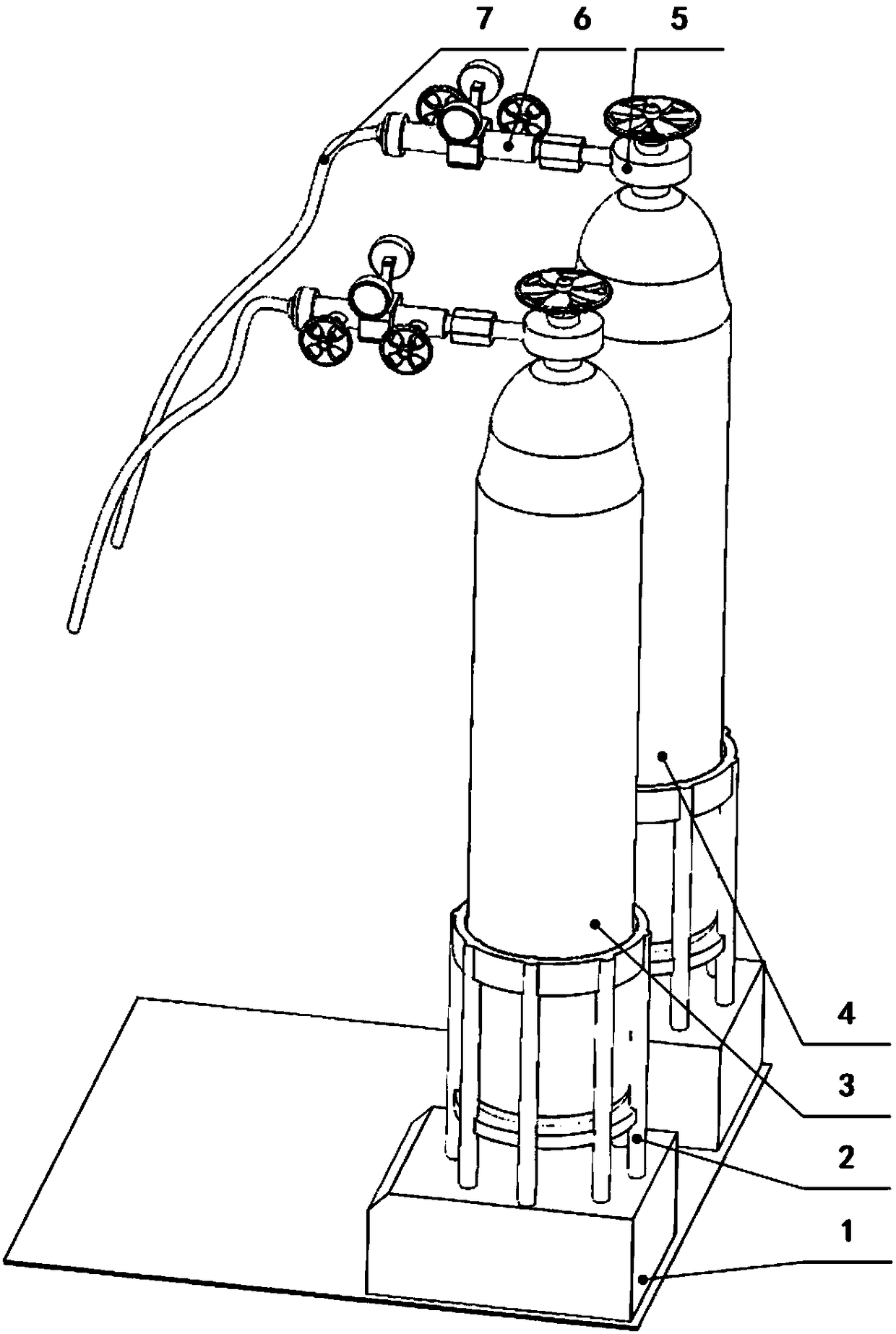

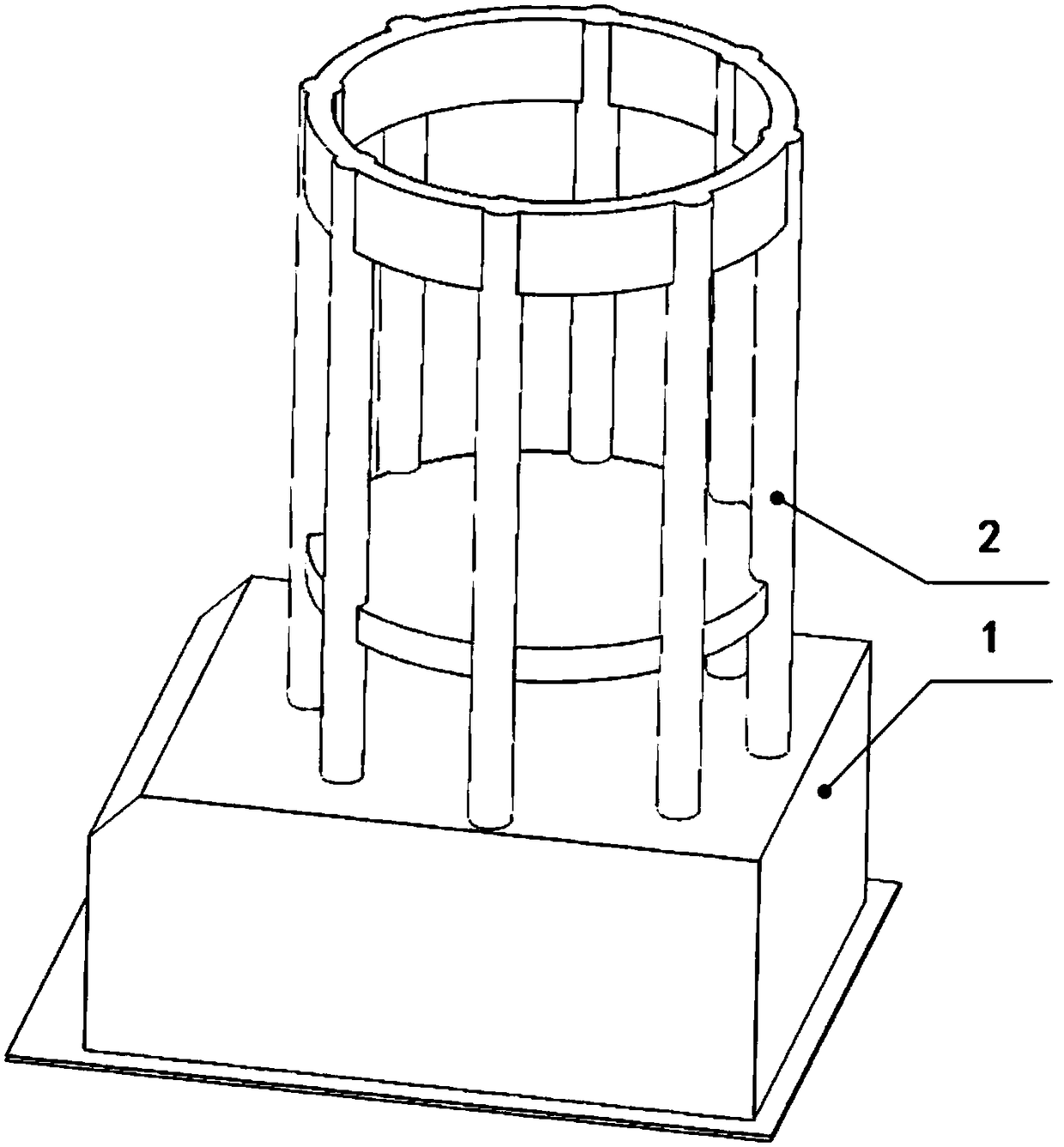

ActiveCN108398016AIncrease productivityPrecisely control the air volume in and outCharge composition/stateMaintainance of heating chambersCeramic sinteringLanthanum

The invention relates to a multifunctional lanthanum calcium manganese oxygen ceramic sintering furnace, and belongs to the technical field of electronic ceramic equipment. The multifunctional lanthanum calcium manganese oxygen ceramic sintering furnace comprises a first load-bearing table, a second load-bearing table, a first protective frame, a second protective frame, an oxygen cylinder, a nitrogen cylinder, a sintering pipeline, a supporting rib plate, a supporting frame, a sliding sintering system, a monitoring cavity and a vacuum pump machine. According to the multifunctional lanthanum calcium manganese oxygen ceramic sintering furnace, the lanthanum calcium manganese oxygen ceramic sintering efficiency can be improved, the gas inlet amount and the gas outlet amount are accurately controlled, the density of lanthanum calcium manganese oxygen ceramic sintering is improved, thus the ceramic performance is more excellent, a sintering pipe section is fixed, and a whole heating box can move freely along the sintering pipe.

Owner:KUNMING UNIV OF SCI & TECH

Ceramic brick sintering device for building

InactiveCN111998674AAvoid crackingReduce churnCharge composition/stateChamber furnacesBrickHeat conducting

The invention provides a ceramic brick sintering device for a building, and relates to the field of building equipment. The ceramic brick sintering device for the building comprises a kiln body, a tank body and a top cover, wherein an air inlet is formed in the center of the bottom of the kiln body, the tank body is arranged at the top of the kiln body, and the top cover is arranged at the top ofthe tank body. According to the ceramic brick sintering device for the building, a placing plate, a sliding block and a spring are matched with one another, after a blank is sintered into a ceramic brick, water is evaporated, the weight is reduced, so that an air pipe is exposed out of the upper body of the placing plate, and the detection effect is achieved; a storage bin, the air pipe, a water pipe and a heat conducting piece are matched, a piston rod is pushed by means of the heated transpiration of the liquid, so that two sealing plates are close to each other to seal the air inlet; the effect of automatically closing the air inlet after sintering is achieved; and then the sealing plates, an electric push rod and a heat insulation plate are matched, the kiln body is sealed, and the loss of hot air is reduced; and the situation that the ceramic brick cracks due to the fact that the temperature change is large because of the rapid loss of heat after sintering is avoided.

Owner:诸暨市仲达智能科技有限公司

Infrared baking device and electronic component baking method using same

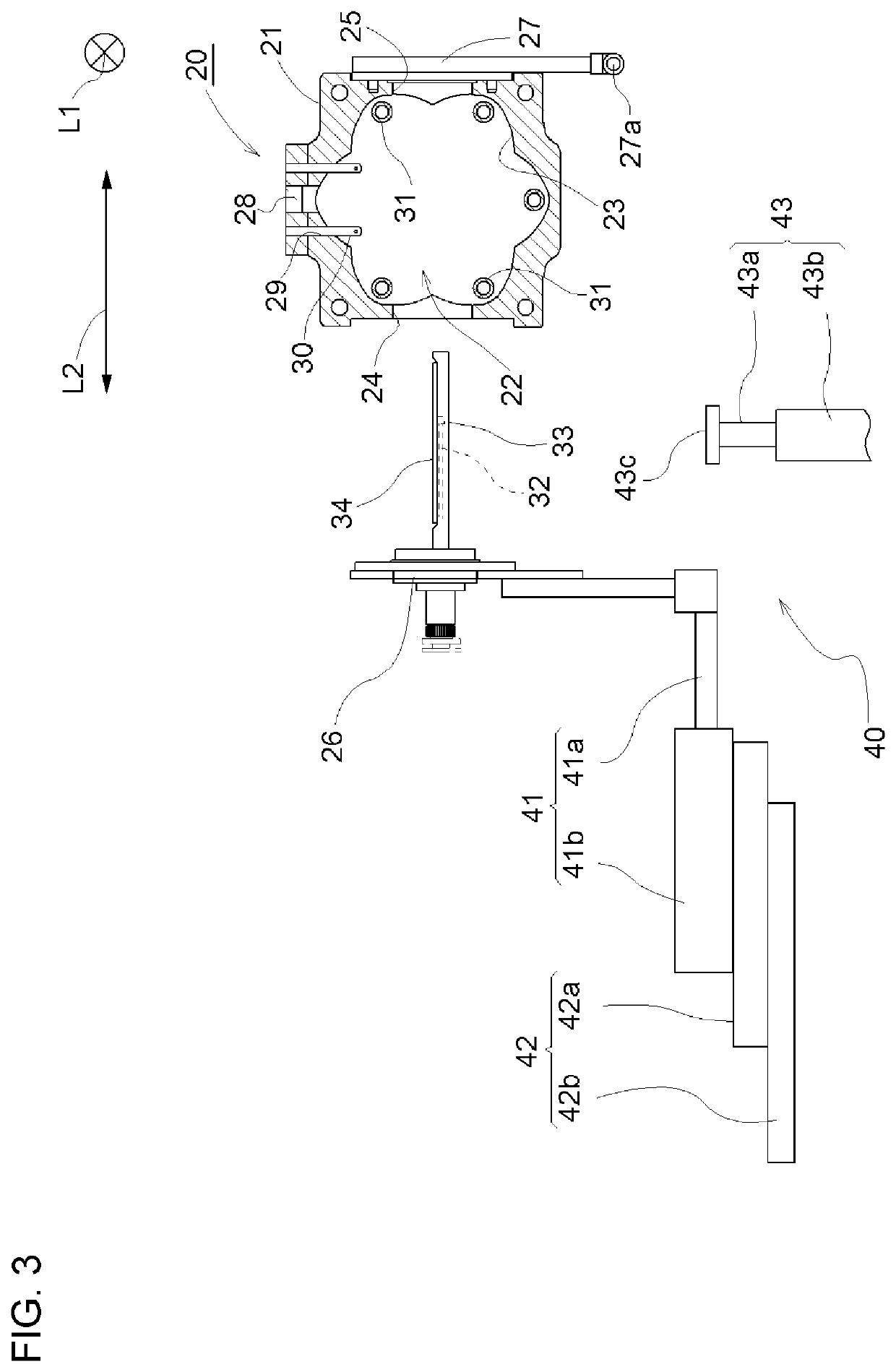

InactiveUS20200326128A1Accurate temperaturePrecise managementStacked capacitorsChamber furnacesInfraredEngineering

The infrared baking device includes: a furnace chamber having an opening openable / closable by an opening / closing cover and allowing an internal space thereof to be tightly sealed; a baking object placement portion on which a baking object is to be placed and which is extractable / insertable through the opening; a heater lamp for heating the heating object by infrared rays; and a thermocouple provided at the baking object placement tray. A furnace wall of the furnace chamber is configured so that infrared rays from the heater lamp are collected and radiated to the tray. The thermocouple is provided in a contactor to contact with the tray. The tray and the contactor are made of the same material which absorbs the infrared rays.

Owner:YONEKURA MFG +1

Round underground heat-insulating brick kiln

InactiveCN106247798AImprove utilization efficiencyIncrease the number of firings at one timeChamber furnacesFresh airEngineering

A round underground heat-insulating brick kiln comprises a round main kiln cavity with an opening at the top. The main kiln cavity is positioned underground, a cover plate is arranged at the top of the main kiln cavity, a pair of parallel guide rails are arranged at the opening of the top of the main kiln cavity, the cover plate can move along the guide rails to enable the top of the kiln cavity to be closed or opened, a heat-insulating layer is arranged in the cover plate, and a material and personnel passage is formed on the side wall of the kiln cavity; a burning area is arranged in the middle of the main kiln cavity, and a smoke hole corresponding to the burning area in position is formed in the cover plate. By adopting the round underground heat-insulating brick kiln, fuel heat utilization efficiency and one-time firing number are increased; vertical excavation and the top movable cover plate are adopted, so that earthwork load of the brick kiln is reduced; in order to substantially improve heat-insulating performance in the side wall direction of the kiln cavity, the top movable cover plate can be completely opened when ventilation and air feeding are needed, so that convenience is brought to quick cooling inside the kiln cavity and completion of fresh air exchange, and personnel is avoided being scalded or injured due to inhaling of toxic waste gas.

Owner:四川伊索新型节能材料有限公司

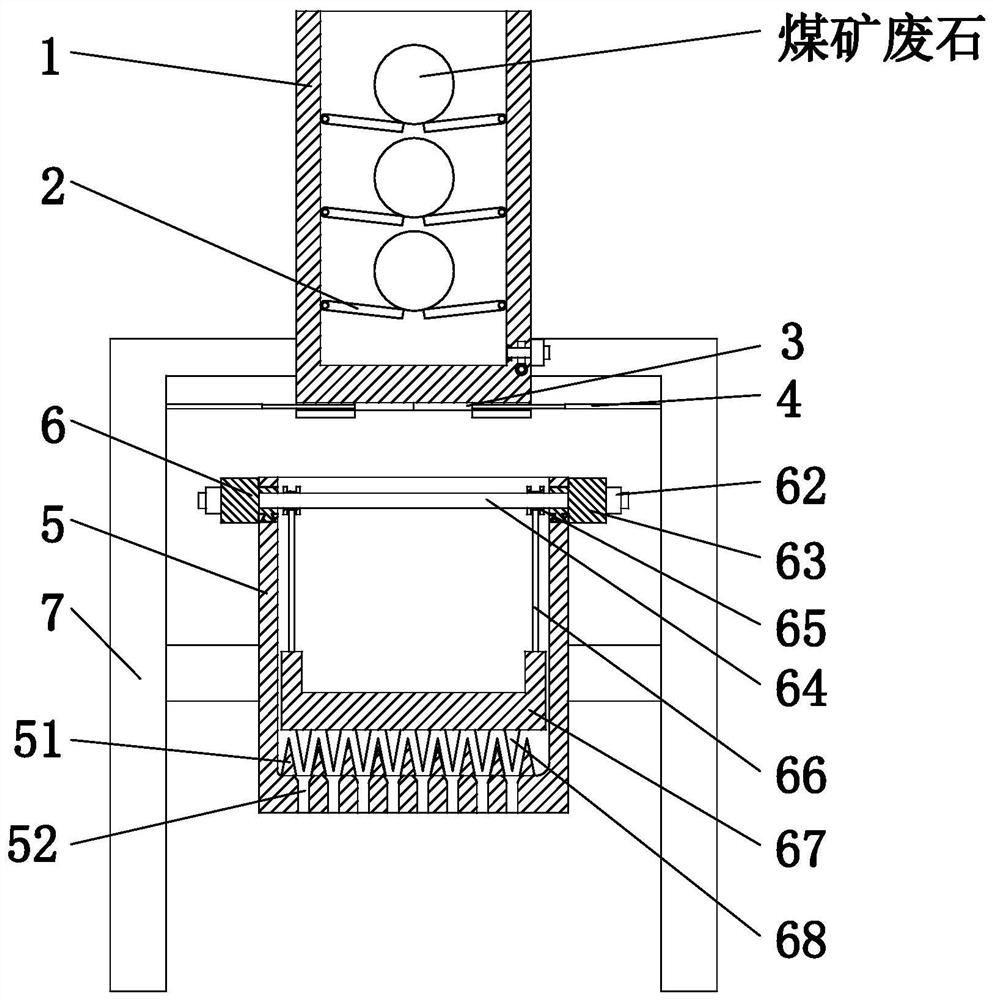

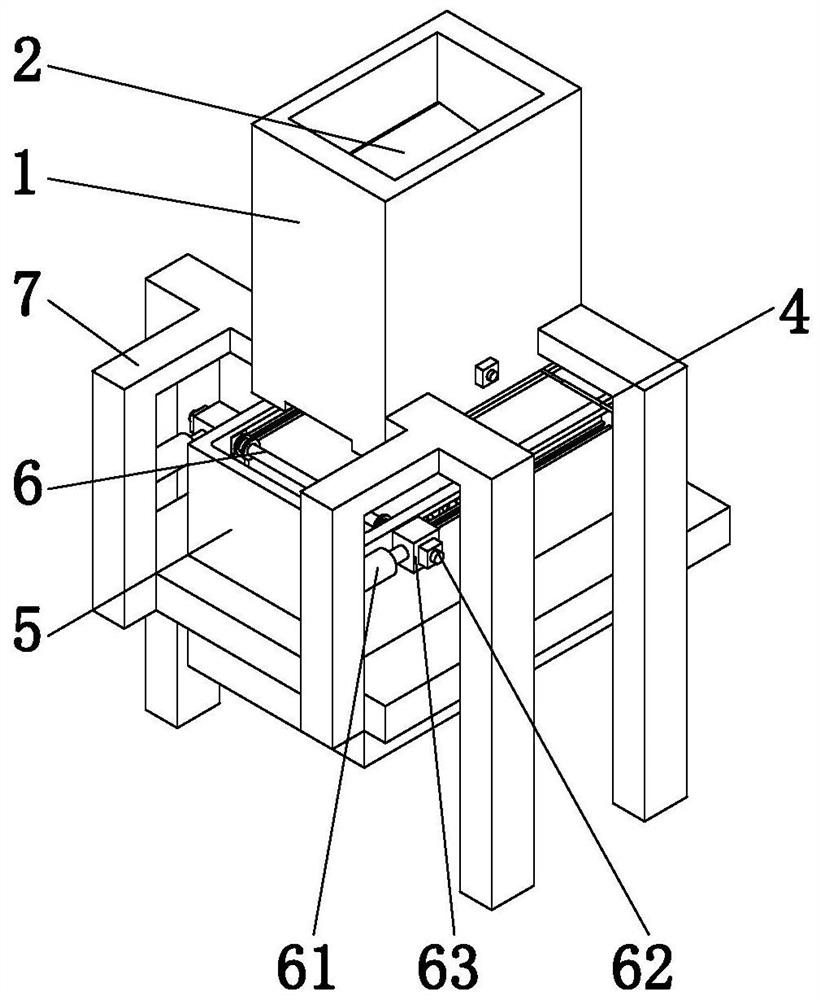

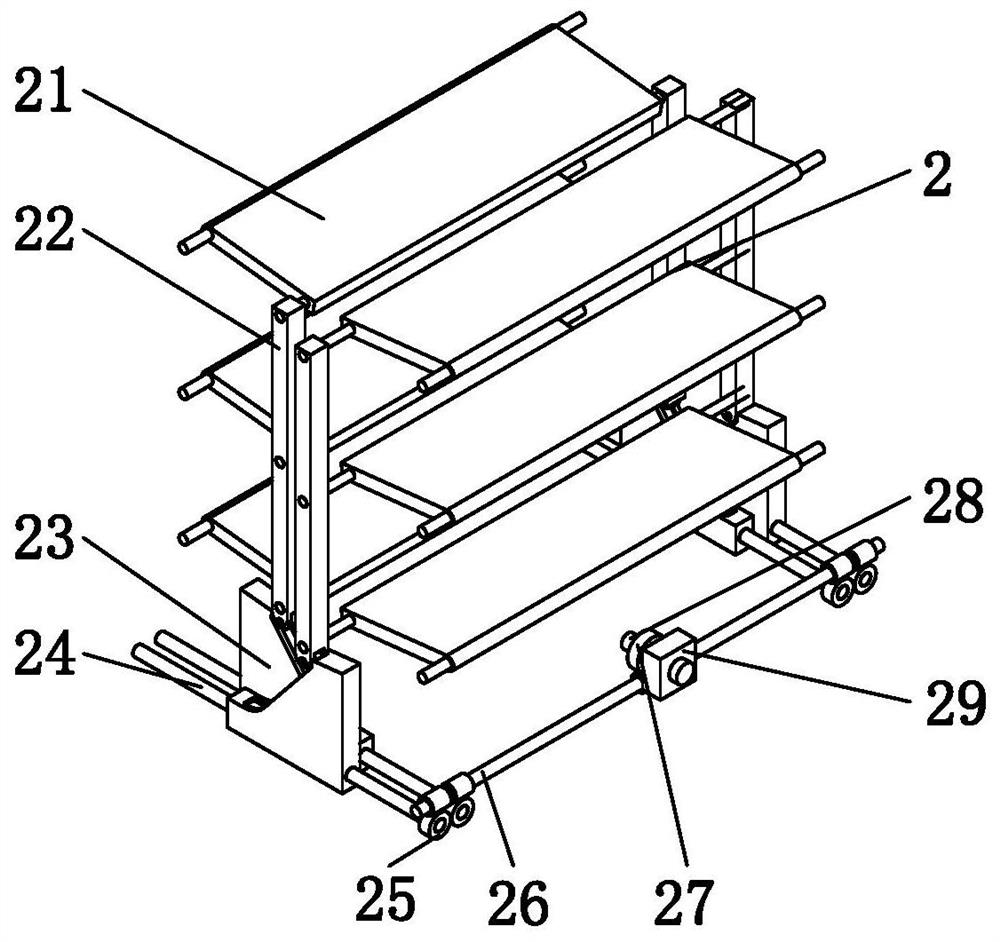

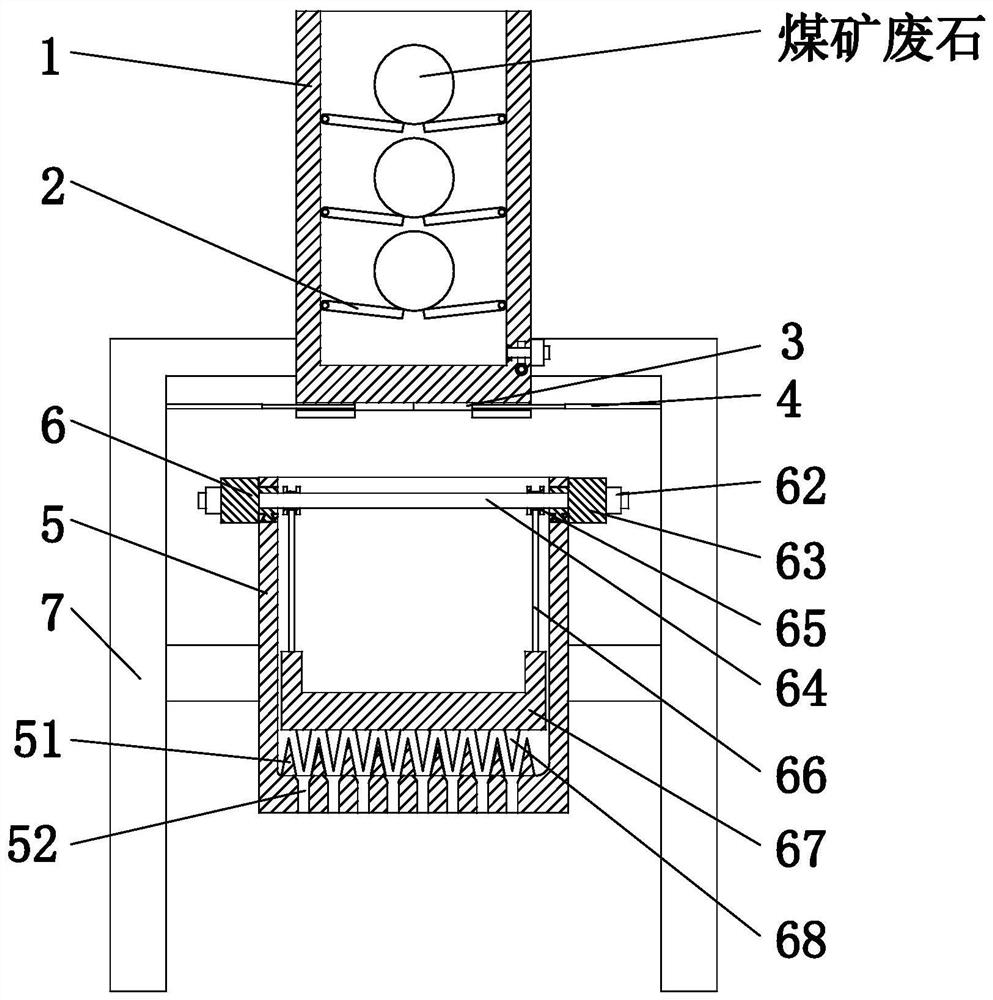

A coal mining waste rock solid material heating and crushing processing system

ActiveCN111795576BLow utilization efficiencyHigh labor costCharge manipulationChamber furnacesMining engineeringCrusher

The invention provides a heating and crushing processing system for waste rock solids in coal mining. The eating and crushing processing system comprises a calcinator, a calcining mechanism, a slidingplate, an electric push rod, a crushing box, a crushing mechanism and a supporting frame. The heating and crushing processing system can solve the following problems existing in the process of crushing and processing the waste rock solids in a coal mine: a, for coal mine waste rock crushing modes, in a traditional process, the coal mine waste rocks are conveyed into a crusher for stirring and rolling and decomposed into recyclable fine particles, no crushing pretreatment is conducted on the coal mine waste rocks in the traditional process, and it is difficult for the crusher to roll the coalmine waste rocks into small pieces; and b, generally, a traditional crusher is used for crushing the coal mine waste rocks, in this way, it is difficult to ensure that the coal mine waste rocks are 100% broken into required small pieces, the traditional crusher has low use efficiency and high labor cost, and it is often necessary to carry out secondary crushing on the broken waste rocks to ensurethat the broken small pieces can be used.

Owner:辽宁银盛水泥集团有限公司

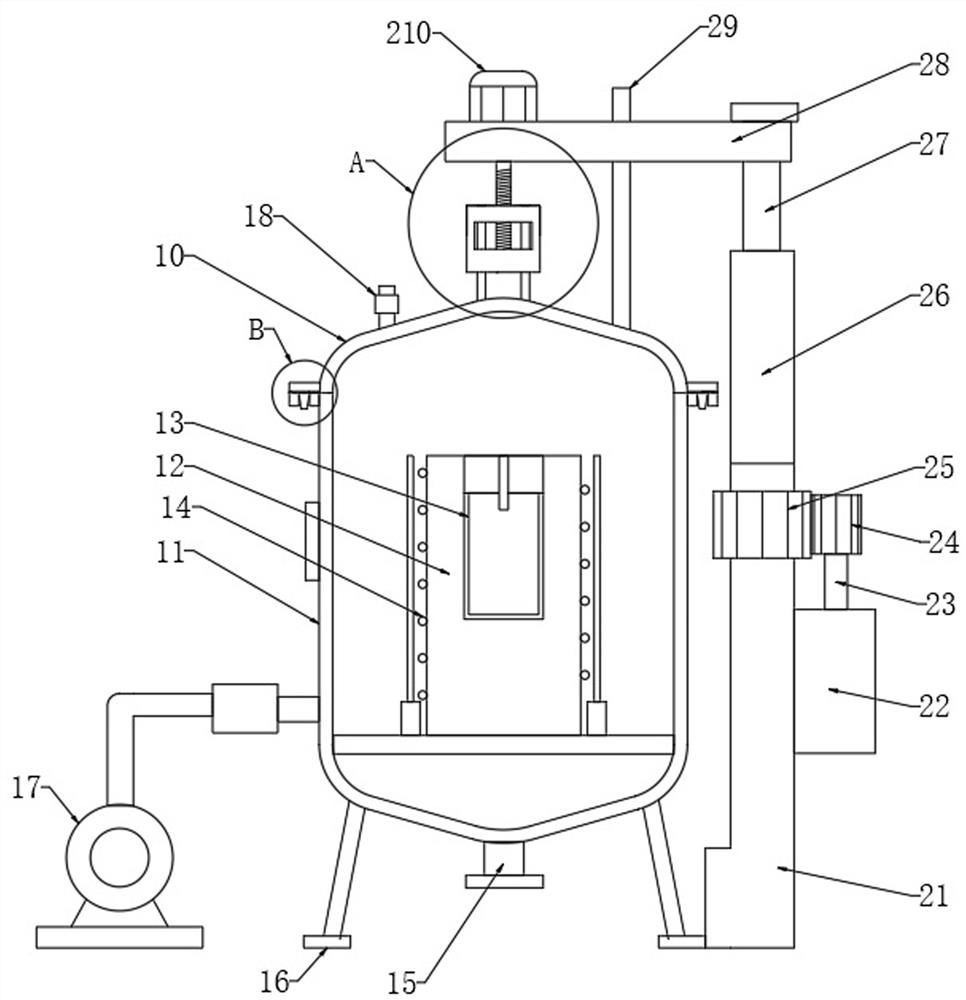

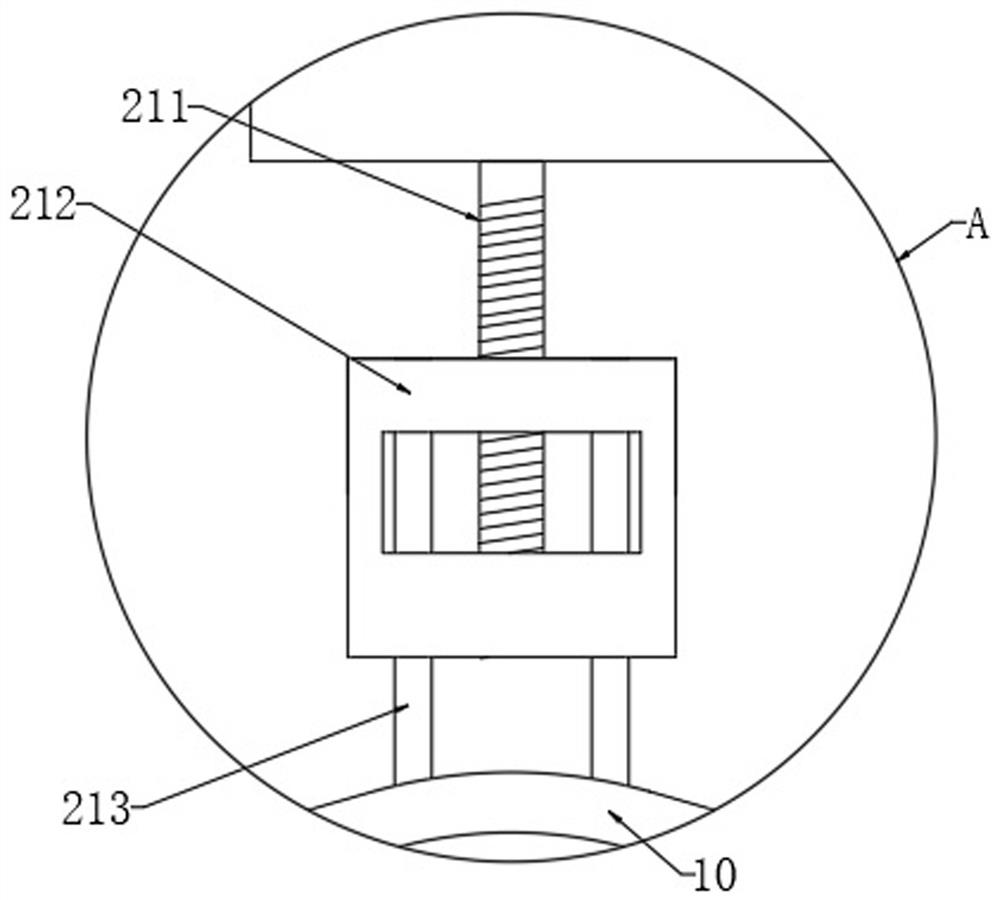

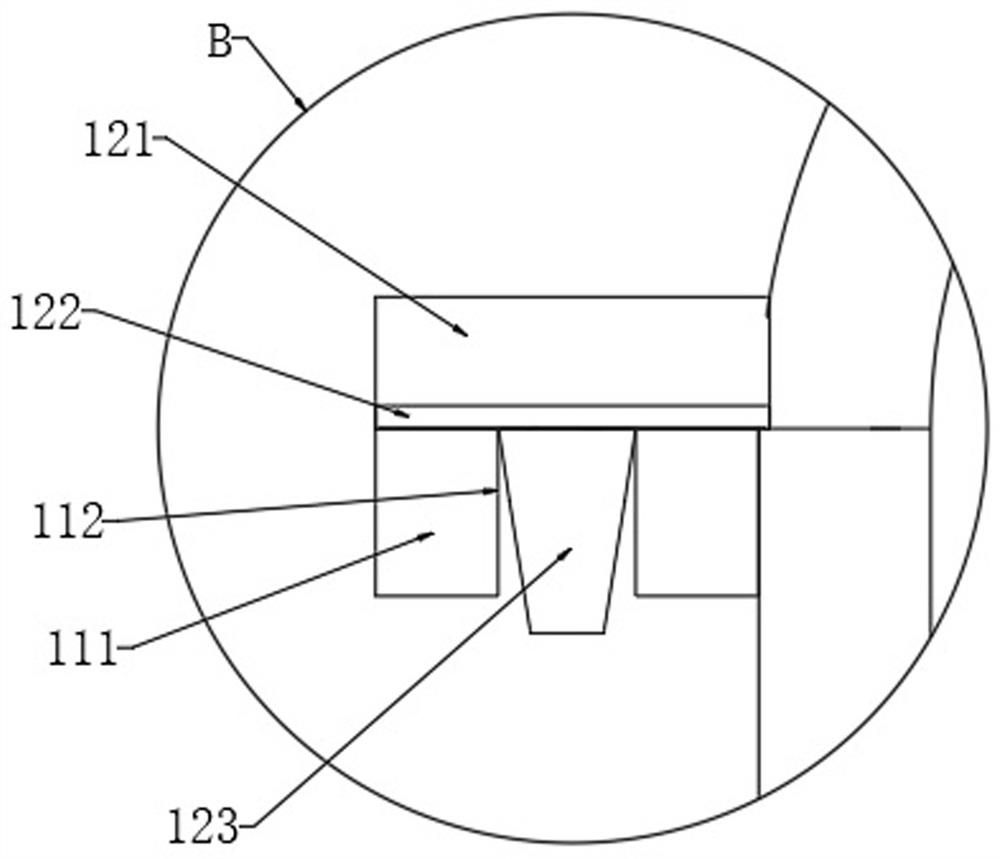

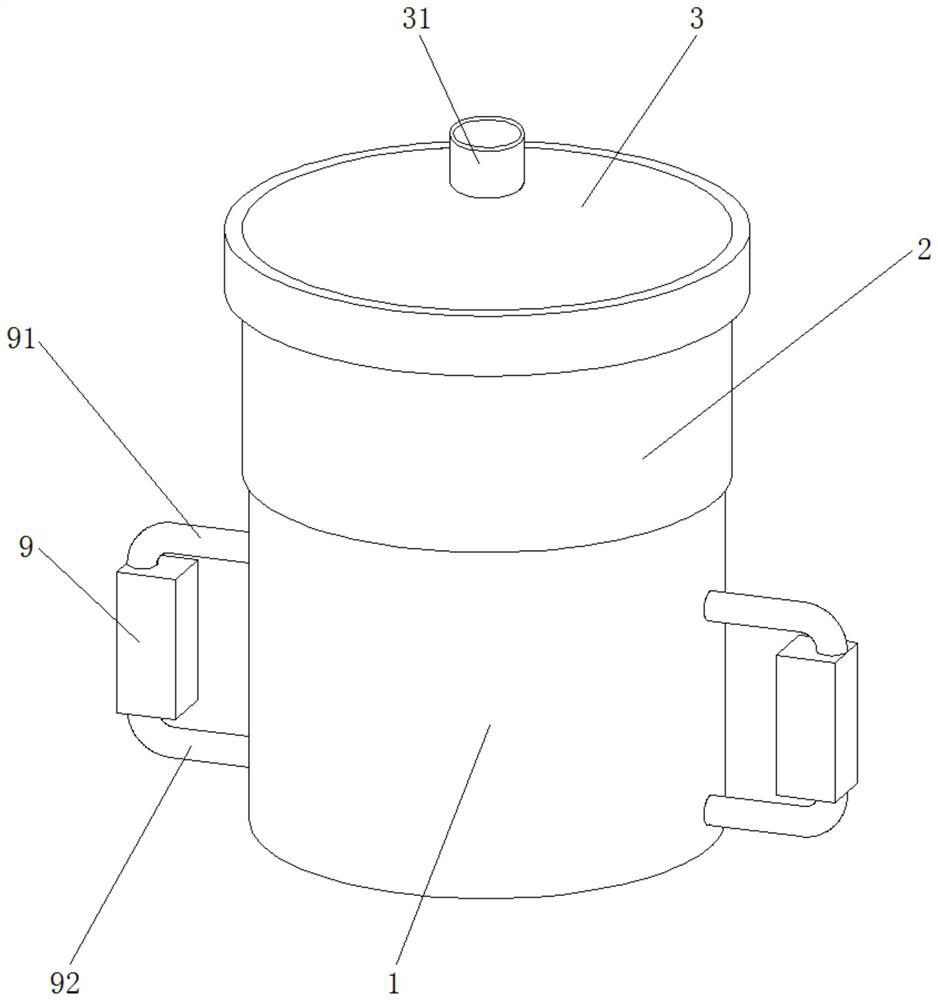

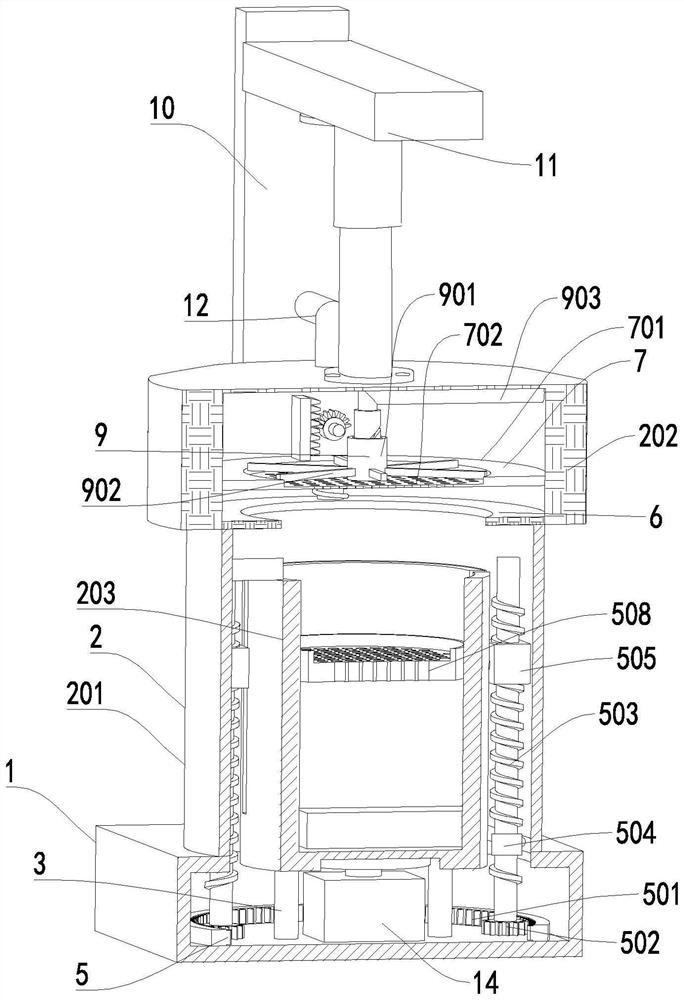

Hydration sintering device

PendingCN110274470AEvenly distributedGuaranteed uniformityCharge composition/stateChamber furnacesWater basedHydrolysis

The invention discloses a hydration sintering device. The hydration sintering device comprises a sintering furnace provided with a sintering container and a heating element inside, a storage container for storing water base pulp, a stirring element arranged in the storage container and used for stirring the water base pulp, a stirring driving element for driving the stirring element to rotate, a conveying pipeline for connecting the sintering furnace with the storage container, and a conveying device matched with the conveying pipeline and used for conveying the water base pulp in the storage container into the sintering container of the sintering furnace. The hydration sintering device can perform the hydrolysis operation; and when the water base pulp drops into the sintering container, water in each drop of the water base pulp is quickly evaporated, so that the sintering can be quickly implemented. The sintering temperature can be preferably lowered through the hydrolysis process; and compared with other traditional sintering methods, the insulation time is shorter.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Heating and crushing processing system for waste rock solids in coal mining

ActiveCN111795576ALow utilization efficiencyHigh labor costChamber furnacesCharge manipulationMining engineeringCrusher

The invention provides a heating and crushing processing system for waste rock solids in coal mining. The eating and crushing processing system comprises a calcinator, a calcining mechanism, a slidingplate, an electric push rod, a crushing box, a crushing mechanism and a supporting frame. The heating and crushing processing system can solve the following problems existing in the process of crushing and processing the waste rock solids in a coal mine: a, for coal mine waste rock crushing modes, in a traditional process, the coal mine waste rocks are conveyed into a crusher for stirring and rolling and decomposed into recyclable fine particles, no crushing pretreatment is conducted on the coal mine waste rocks in the traditional process, and it is difficult for the crusher to roll the coalmine waste rocks into small pieces; and b, generally, a traditional crusher is used for crushing the coal mine waste rocks, in this way, it is difficult to ensure that the coal mine waste rocks are 100% broken into required small pieces, the traditional crusher has low use efficiency and high labor cost, and it is often necessary to carry out secondary crushing on the broken waste rocks to ensurethat the broken small pieces can be used.

Owner:辽宁银盛水泥集团有限公司

Sintering kiln

PendingCN114877687AAvoid excessive air pressureAvoid situations where the spill goes directly to the outside without filteringCharge composition/stateChamber furnacesExhaust fumesKiln

The invention relates to the technical field of sintering furnaces, in particular to a sintering kiln. Comprising a bottom shell and a sintering furnace body, the sintering furnace body comprises a sintering furnace outer barrel, a machine cover and a sintering furnace inner container, the sintering furnace outer barrel is fixedly connected to the top end of the bottom shell, threaded surfaces are arranged inside the bottom end of the machine cover and outside the top end of the sintering furnace outer barrel, and the machine cover is in threaded connection with the top end of the sintering furnace outer barrel; through the designed filtering assembly, the reciprocating mechanism matched with the filtering assembly to work and the material spreading mechanism, combustion waste gas in the furnace can rapidly pass through filtered gas materials, and the problem that the gas pressure in the furnace is too large due to the fact that the waste gas overflows too slowly is solved; the sintering furnace is flexible, an operator can place materials to be sintered conveniently, and the working efficiency is improved.

Owner:严照旭

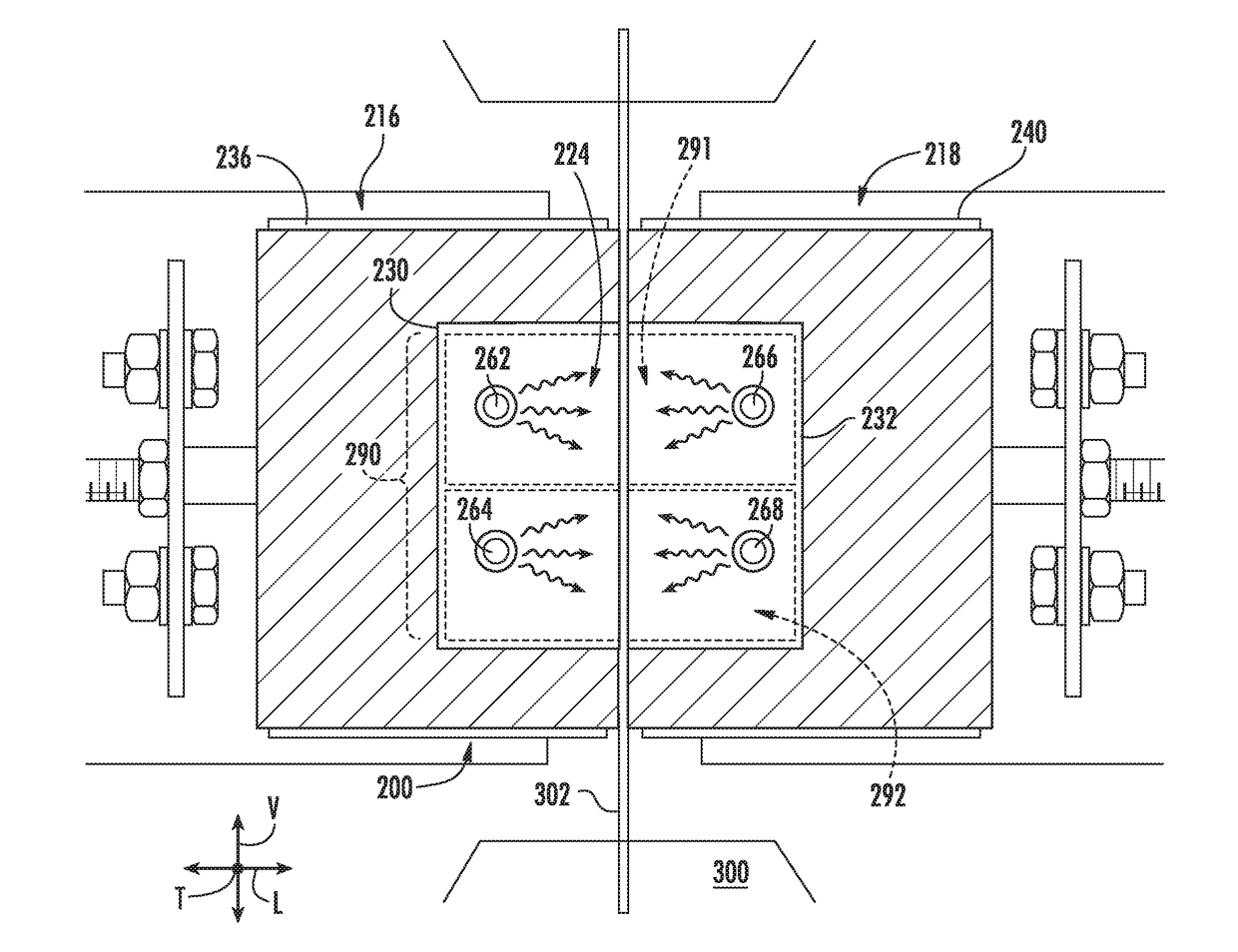

High temperature furnace

A high temperature furnace includes features that provide for multiple heating zones for heating a specimen extending at least partially through a heating chamber defined by the furnace. In one exemplary aspect, the furnace can include multiple heating elements extending at least partially through the heating chamber. Each heating element can be configured in a rod shape, which allows for multiple heating zone capability, better control over the temperature gradient, reduced current to achieve a desired temperature output, and a streamlined furnace shell.

Owner:GENERAL ELECTRIC CO

Functional ceramic preparation equipment

ActiveCN113267046AEasy to shake offPrevent adhesionChamber furnacesCharge treatment typeEngineeringMechanical engineering

The invention discloses functional ceramic preparation equipment. The functional ceramic preparation equipment is structurally provided with a box body, a sintering chamber, a top cover, a control panel and an operation box; upward thrust is generated on a connecting frame through air flow, the connecting frame is made to swing and fold, an arc block is driven to assist an elastic block to generate power, reverse elastic jacking is generated immediately under the elastic property of the arc block, the elastic block can continuously bounce and circularly eject the arc block under the elastic assistance of the elastic block and the telescopic elastic cooperation of a sleeve frame, and therefore, the sliding block can integrally do displacement movement to a greater extent to drive a movable body to move in a longer area, and a shovel plate can shovel and scrape the inner wall of a cigarette cavity better. A collision block sinks into the inner side of the shovel plate under the telescopic connection of a connecting rod through the magnetism of the arc block and the repulsive magnetic force of the movement assisting body, collision force is generated on the shovel plate to enable substances shoveled and scraped from the end face of the shovel plate to be shaken off conveniently, and therefore, the situation that hot gas drives part of particle molecules to be drained and attached to the wall face of a smoke cavity is avoided.

Owner:怀仁县恒益陶瓷有限公司

Heating furnace convenient to clean and maintain and high in energy efficiency

PendingCN106802082AEasy to disassembleEasy to installChamber furnacesElectric heating for furnacesProcess engineeringDirect heating

The invention discloses a heating furnace convenient to clean and maintain and high in energy efficiency. The heating furnace comprises a furnace platform of which the feeding end and the discharging end are the same in structure. A plurality of heating furnace cavities are formed in the upper plane of the furnace platform at intervals. A partition plate which can be slidably opened or slidably clamped covers the upper end of each heating furnace cavity. The bottom of each heating furnace cavity is provided with a heating pipe assembly which can be horizontally pulled out from or horizontally pushed into the bottom of the heating furnace cavity to be clamped. The bottom of each heating furnace cavity and the corresponding heating pipe assembly are partitioned through a heat dissipation plate. By means of the structure design, easy disassembling and assembling can be achieved without the step of disassembling screws. According to the heating furnace convenient to clean and maintain and high in energy efficiency, heating pipes which can be horizontally inserted and installed are designed and directly heat air in heating pipe installation cavities; hot air is brought to the heating cavities through heat dissipation fans; through the air direct heating mode, the steps that the partition plates are heated at first, and then heat energy is transmitted to air are not needed, and the heat energy utilization rate is higher; and in addition, the heating pipes are convenient to disassemble and can be timely cleaned and replaced.

Owner:东莞市创威自动化科技有限公司 +1

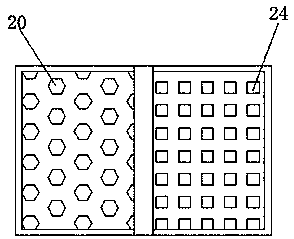

Production process and production equipment of high-stability fused cast zirconia-corundum brick

ActiveCN111087231AImprove pass rateAvoid or reduce unevennessChamber furnacesPreheating chargesGrogBrick

The invention discloses a production process and production equipment for a high-stability fused cast zirconia-corundum brick. The preparation method comprises the following steps: preparing a mixture, melting, casting, and carrying out heat preservation annealing, and demolding, wherein the ingredients comprise the following components in parts by weight: 35-40 parts of ZrO2+HfO2, 2-14 parts of SiO2, 1.2-1.6 parts of Na2O, 0-3 parts of rare earth and the balance of Al2O3, and the total weight parts of the ingredients are 100 parts; the ingredients comprise clinker and raw materials in the same proportion, the clinker is a block, the particle size of the clinker is 3-8cm, and the raw materials are powder with the particle size of 0.05-1.5 mm; the clinker accounts for 10-30%; in the meltingprocess, 1 / 2-3 / 5 of molten materials are reserved in a furnace body, and the clinker is directly poured into the center of the furnace body through a hopper; the raw materials are subjected to microwave heating before entering the furnace body; the lowest point of the raw materials entering the furnace body should be above the highest liquid level in the furnace body, and the distance between thelowest point and the highest liquid level is 1 / 2-3 / 4 of the distance between the highest liquid level and the reserved liquid level; and the included angle [alpha] between the direction of the raw materials entering the furnace body and the horizontal liquid level is 30-60 degrees. According to the production process and production equipment, the melting efficiency can be effectively improved, the uniformity of feed liquid components is improved, and the energy consumption is reduced.

Owner:LUOYANG DAYANG HIGH PERFORMANCE MATERIAL

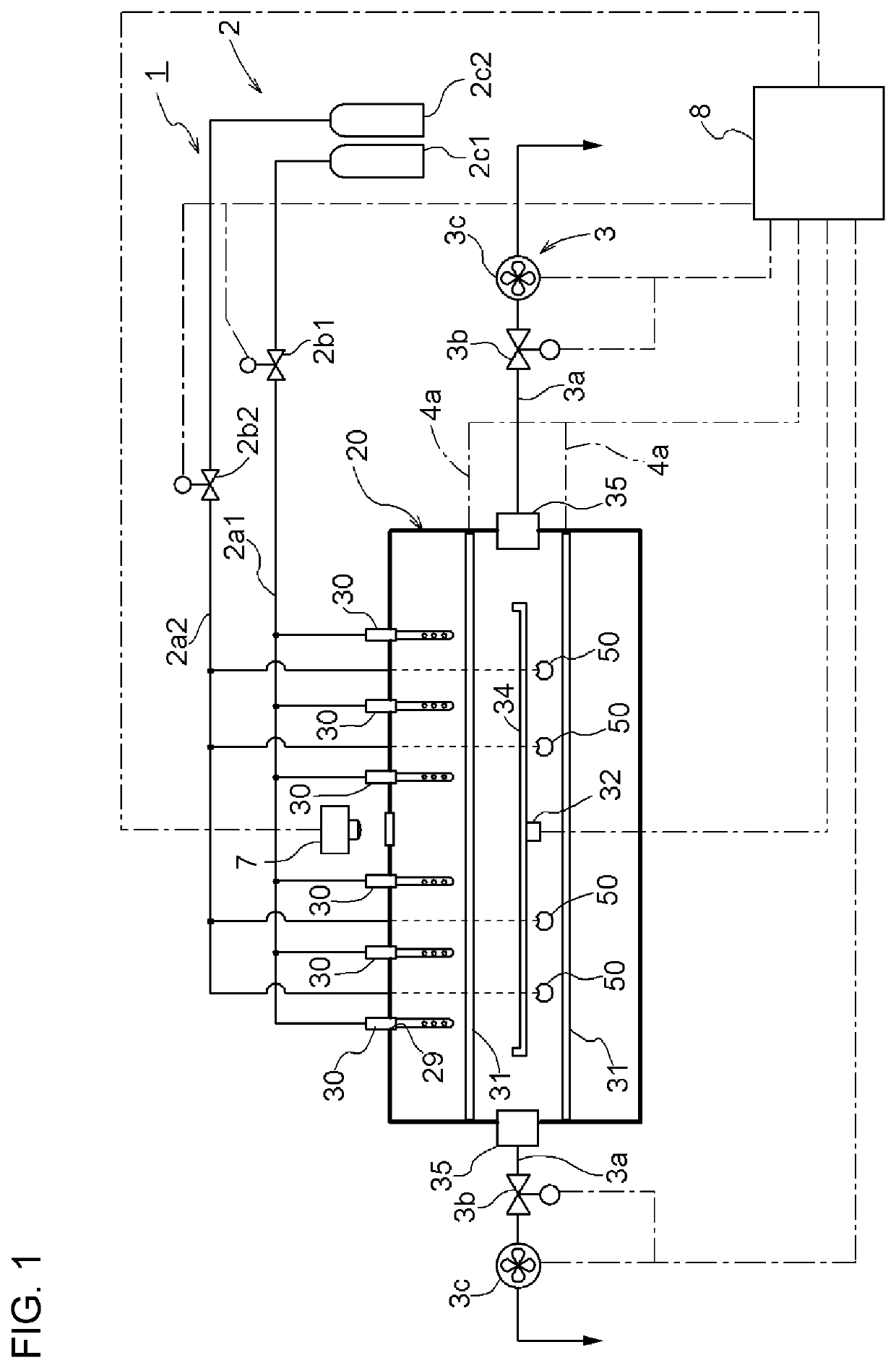

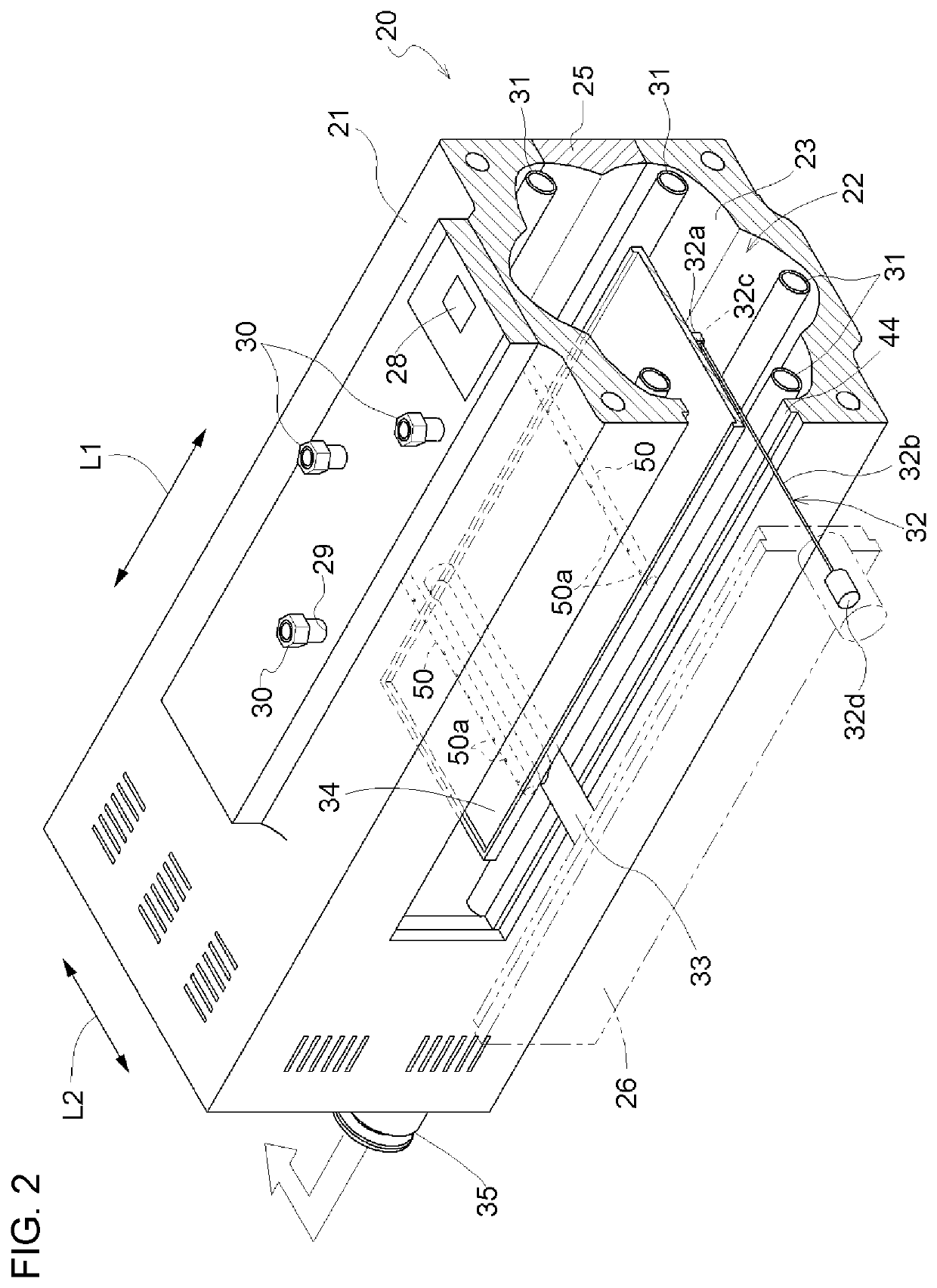

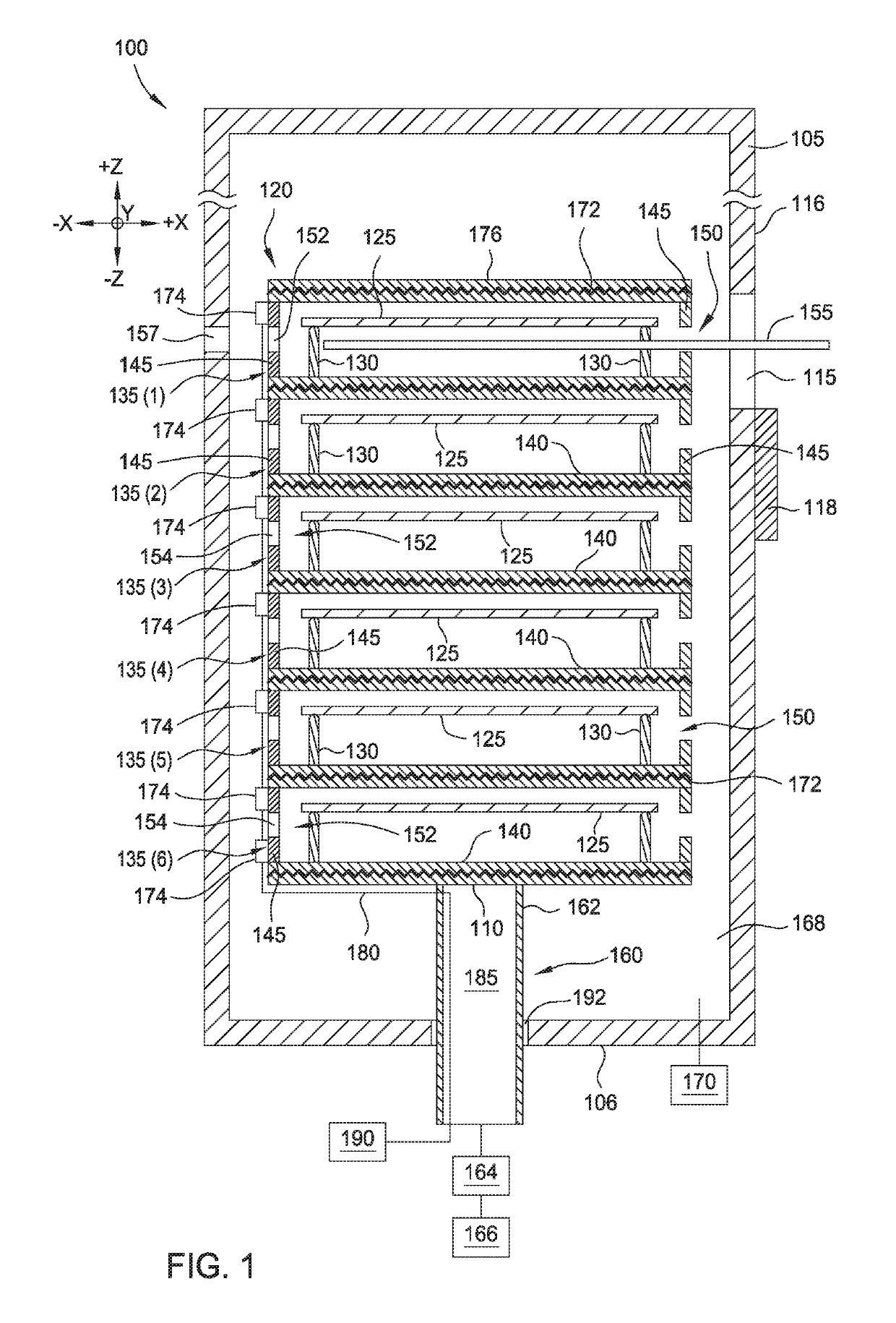

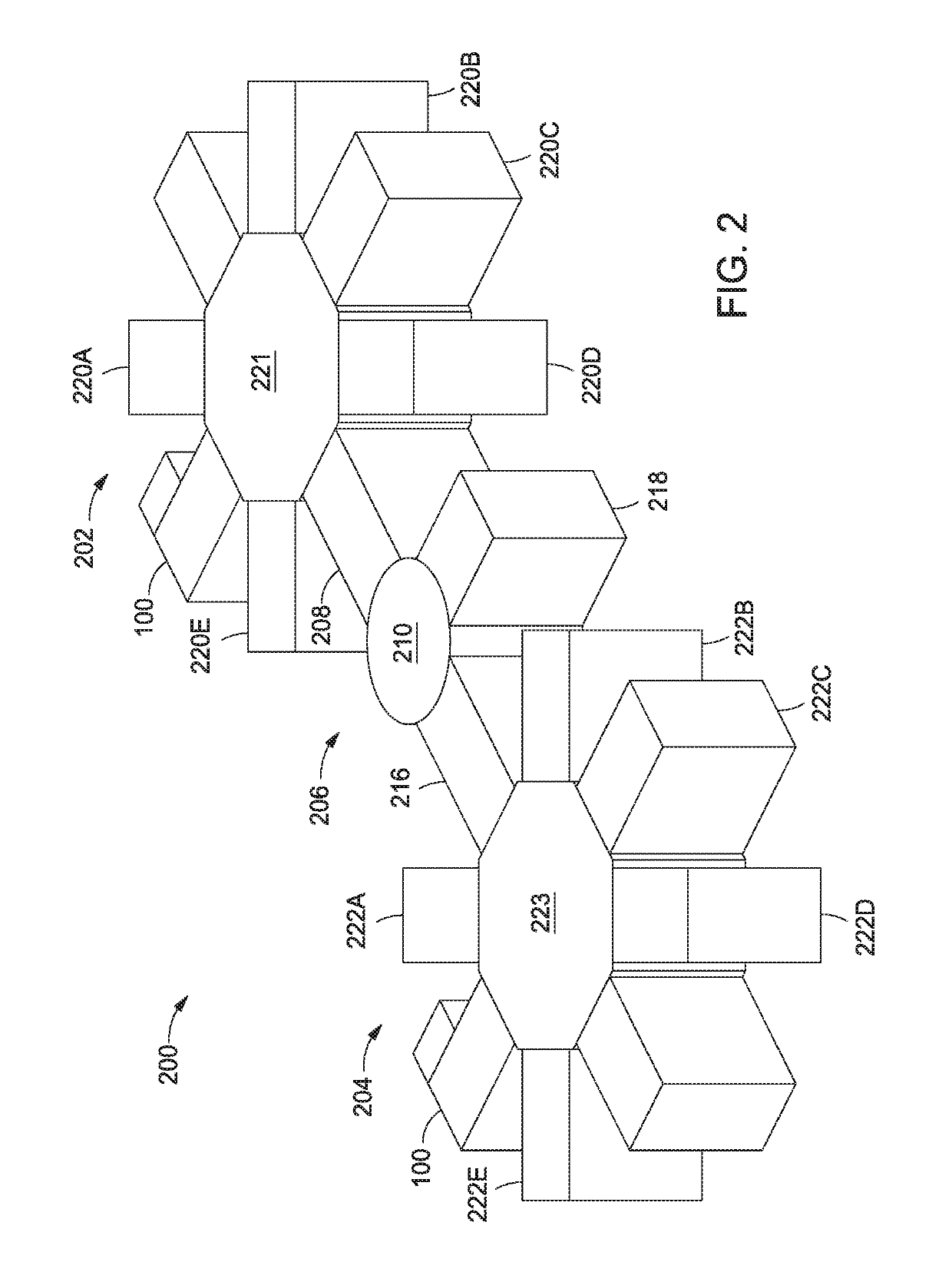

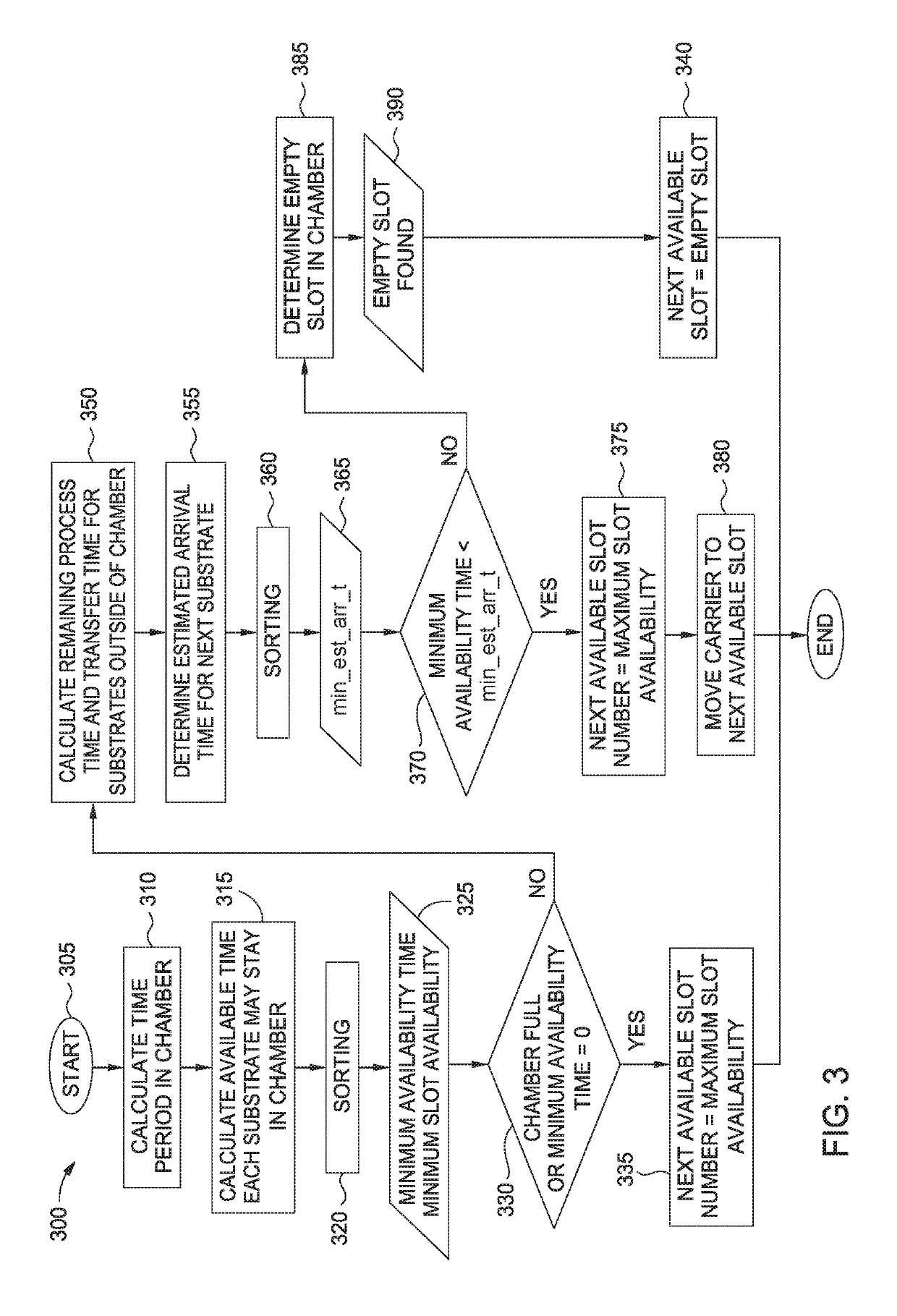

Method and apparatus for substrate transfer in a thermal treatment chamber

ActiveUS10460922B2Semiconductor/solid-state device manufacturingChamber furnacesEngineeringThermal treatment

The present disclosure generally relates to methods and apparatus for heating a substrate as well as a slot management method for a thermal treatment chamber that in one embodiment includes providing a first substrate to a first slot of a carrier in the thermal treatment chamber via a transfer opening formed in the thermal treatment chamber, the first substrate having a specified anneal time, heating the substrate, moving the carrier to a lowermost position in the thermal treatment chamber using an elevator mechanism coupled to the carrier, and moving the carrier such that the first slot is in a position adjacent to the transfer opening using the elevator mechanism within a carrier transfer time period and transferring the first substrate out of the thermal treatment chamber at a determined time period for anneal.

Owner:APPLIED MATERIALS INC

Top-firing hot blast stove

InactiveUS20140011152A1Improve combustion efficiencyExcellent in hot-blast generating capabilityChamber furnacesBlast furnace detailsLinear componentCombustor

There is provided a top-firing hot blast stove capable of enhancing combustion efficiency in burner system, supplying high-temperature combustion gas to an entire checker chamber, and suppressing damage on a refractory material on an inner wall of a burner duct.A top-firing hot blast stove 10 has a burner system including: a burner 1 for passing fuel gas or combustion air to each of three or more pipe lines in a multiple pipe line structure; and a burner duct 2. A core pipe line 1b and a central pipe line 1c include a swirling flow generating means provided for generating a swirling flow of the fuel gas or the combustion air, while an outermost pipe line 1d carries a linear flow of the fuel gas or the combustion air, so that combustion gas HG including a linear component HG″ and a swirling component HG′ is generated in the burner duct 2. The combustion gas HG is supplied to a combustion chamber 3 from at least one or more of the burner systems in an inflow direction which does not pass through a center position of the combustion chamber 3.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com