Functional ceramic preparation equipment

A technology for functional ceramics and equipment, which is applied in the field of functional ceramics preparation equipment, can solve the problems of reducing diameter and width, and unsmooth exhaust of flue gas, and achieves good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 To attach Image 6 Shown:

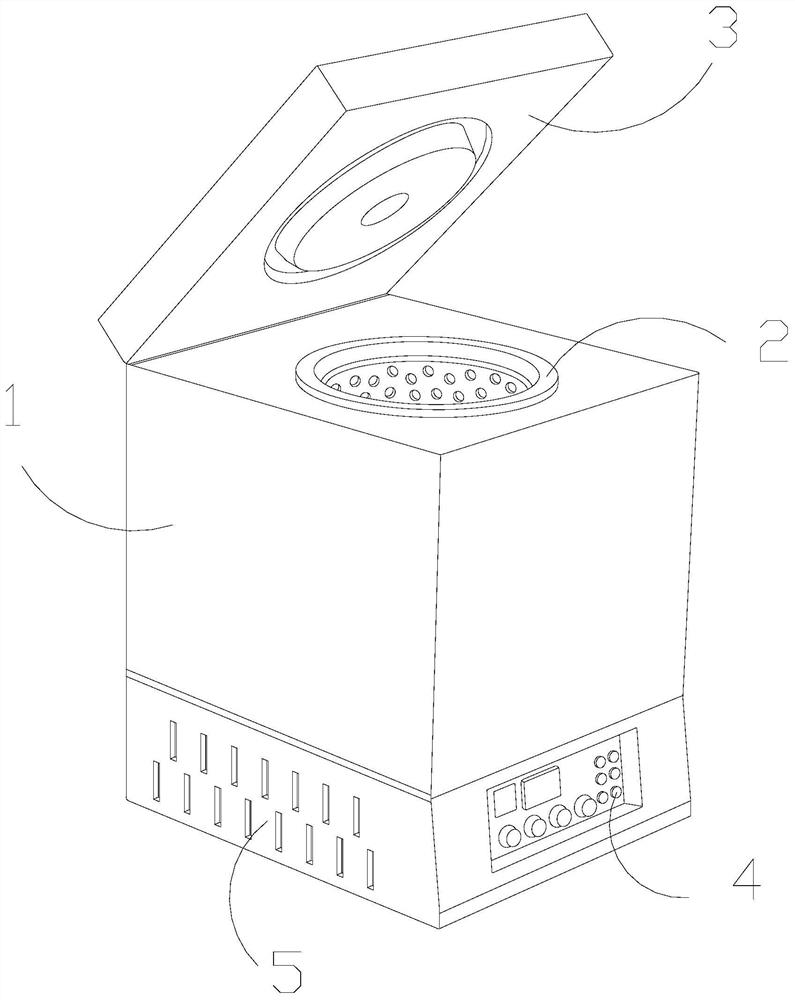

[0032] The present invention provides a kind of functional ceramic preparation equipment, its structure is provided with box body 1, sintering chamber 2, top cover 3, control panel 4, operation box 5, and described sintering chamber 2 and box body 1 are integrated structure and are arranged in At the middle end position, the top cover 3 is hingedly connected to the top of the box body 1, the top cover 3 is movably engaged above the sintering chamber 2, the operation box 5 is located at the bottom end of the box body 1, and the control The panel 4 is arranged at the lower end of the outer side of the box body 1 .

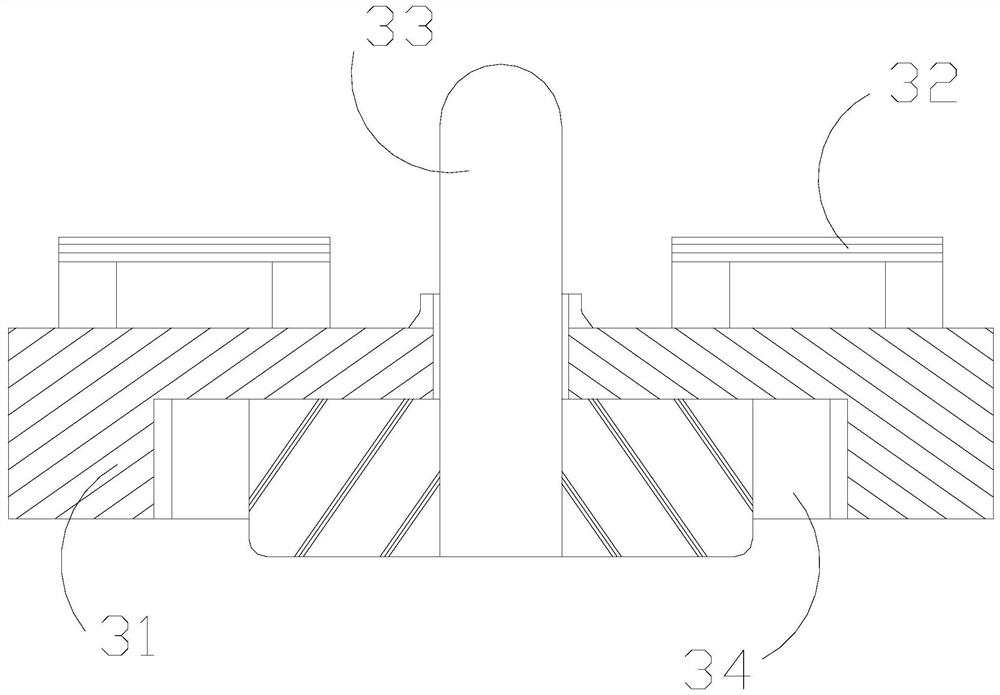

[0033] The top cover 3 is provided with a solid plate 31, a handle 32, a smoke exhaust device 33, and a draw-in groove 34. The draw-in groove 34 and the solid plate 31 are integrated structures and are embedded in the inner side thereof. The handle 32 is embedded Fixedly installed on the top of the solid boar...

Embodiment 2

[0040] as attached Figure 7 To attach Figure 9 Shown:

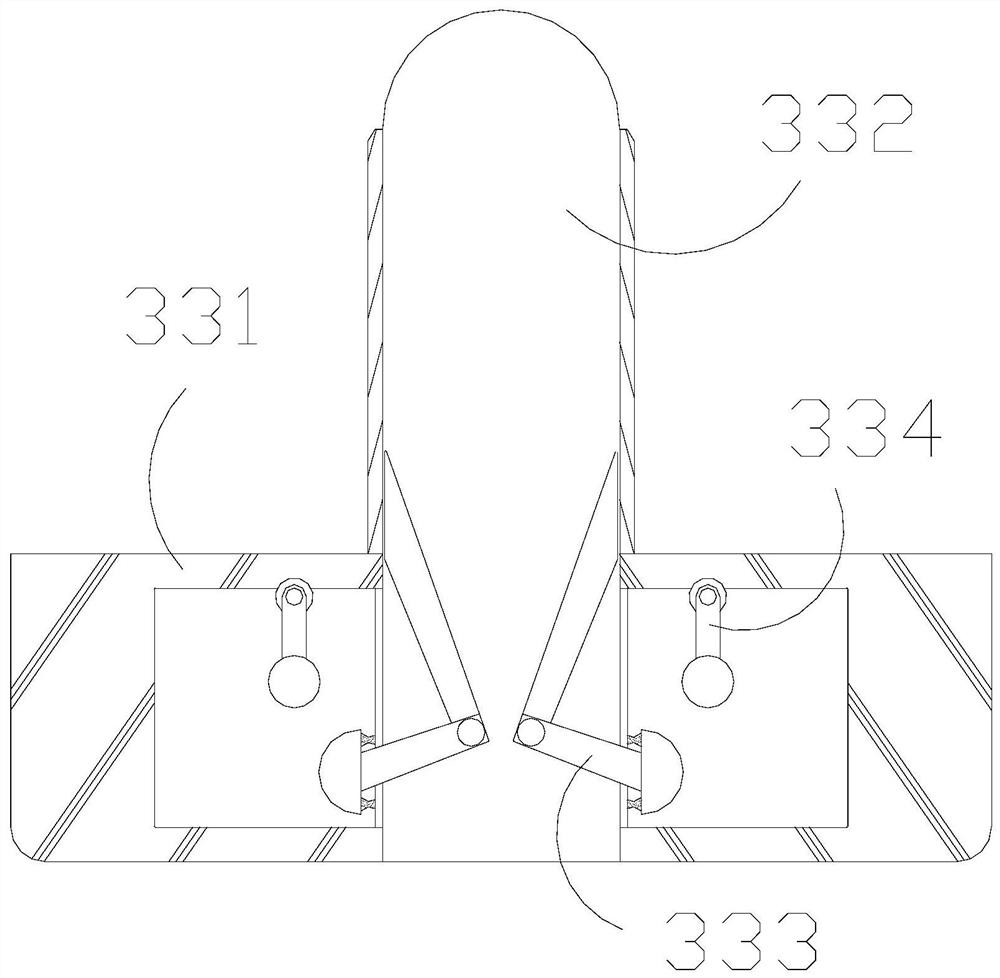

[0041] Wherein, the moving aid body 334 is provided with a folding rod b1, a variable ball b2, and a plug b3. The plug b3 is interpenetrated and movably matched. The folding rod b1 is a stretchable plate. The changing ball b2 is a circular structure with magnetic force and can be deformed in size. The changing ball b2 is Next, the displacement transformation is carried out with the assistance of the folding rod b1.

[0042] Wherein, the variable ball b2 is provided with an outer ring b21, a fixed ring b22, and a telescopic frame b23, the fixed ring b22 is located inside the outer ring b21, and the telescopic frame b23 is connected between the outer ring b21 and the fixed ring b22 and moves Cooperate, the outer ring b21 has a ring structure, the fixed ring b22 is a ring with a fixed diameter, and the telescopic frame b23 is flexible, and the outer ring b21 is ring-shaped under the telescopic cooperation of the telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com