Improved textile waterproof performance detection device and detection method

A detection equipment and textile technology, applied in the field of improved textile waterproof performance detection equipment, can solve the problems of cumbersome operation, inability to realize gripper beating, poor practicability, etc., and achieve the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

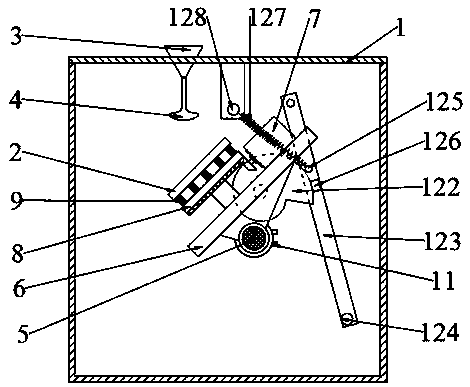

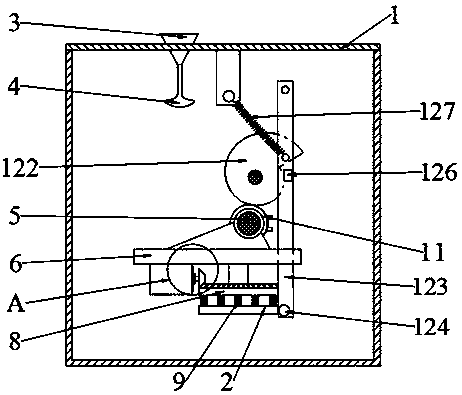

[0060] Such as Figure 1-4 As shown, in the improved textile waterproof performance testing equipment of Example 1, a funnel 3 is arranged in the through hole on the top surface of the box body 1, the bottom end of the funnel 3 is connected with a nozzle 4, and a rotating shaft is arranged between the opposite side walls of the box body 1 5. A base 6 is fixedly installed on the rotating shaft 5, and the surface of the base 6 is sequentially provided with a rotary driving member 7, a rotary supporting plate 8, an elastic connector 9 and the holder positioning substrate 2, and the connection between the box body 1 and the rotating shaft 5 A rotating shaft rotation drive member 11 is arranged between them, and a positioning substrate knocking mechanism 12 is arranged on the side of the rotating shaft 5 .

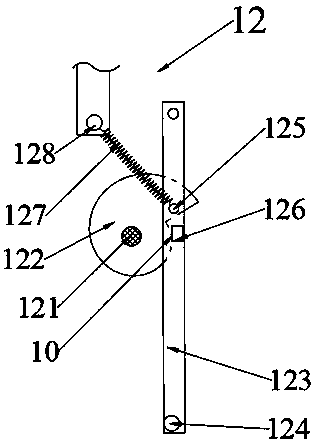

[0061] The positioning substrate knocking mechanism 12 includes a drive shaft 121, a special-shaped cam 122 fixedly pierced on the drive shaft 121, a swing arm 123 positioned a...

Embodiment 1

[0067] During embodiment 1 work, concrete steps are:

[0068] S1: Fix the holder with the sample fixedly connected to the holder positioning substrate 2;

[0069] S2: drive the rotating shaft to rotate the driving part 11 to adjust the inclination of the sample, and spray test water to the surface of the sample through the funnel 3 and the nozzle 4;

[0070] S3: drive the rotating shaft to rotate the driving member 11 to the level of the sample surface downward, drive the positioning substrate knocking mechanism 12 to knock the clamper positioning substrate 2;

[0071] S4: Drive the rotary drive member 7 to rotate the clamper positioning substrate 2 by 180° in the horizontal plane, and drive the positioning substrate knocking mechanism 12 to strike the clamper positioning substrate 2 again.

Embodiment 2

[0073] Such as Figure 5-7 As shown, embodiment 2 is based on embodiment 1, the difference is that the drive shaft 121 in the positioning substrate knocking mechanism 12 is the rotating shaft 5, the minimum distance between the involute and the center of the rotating shaft is the knocking contact point 10, and the knocking contact point 10 and the plane where the center of the rotating shaft 5 is parallel to the rotary pallet 8 and the holder positioning base plate 2 .

[0074] The return elastic member 127 is a compression spring, and the compression spring and the special-shaped cam 122 are located on both sides of the swing arm 123; the box body 1 is hingedly provided with a second elastic member positioning seat 129, and the pressing spring is arranged on the first elastic member positioning seat 125 and the second elastic positioning seat 129.

[0075] Special-shaped cams 122 are respectively pierced at both ends of the rotating shaft 5 , swing arms 123 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com