Automatic pocket creasing mechanism

An automatic and bag-folding technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and papermaking, etc., can solve the problems of low work efficiency and achieve the effects of easy operation, quality assurance and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with embodiments.

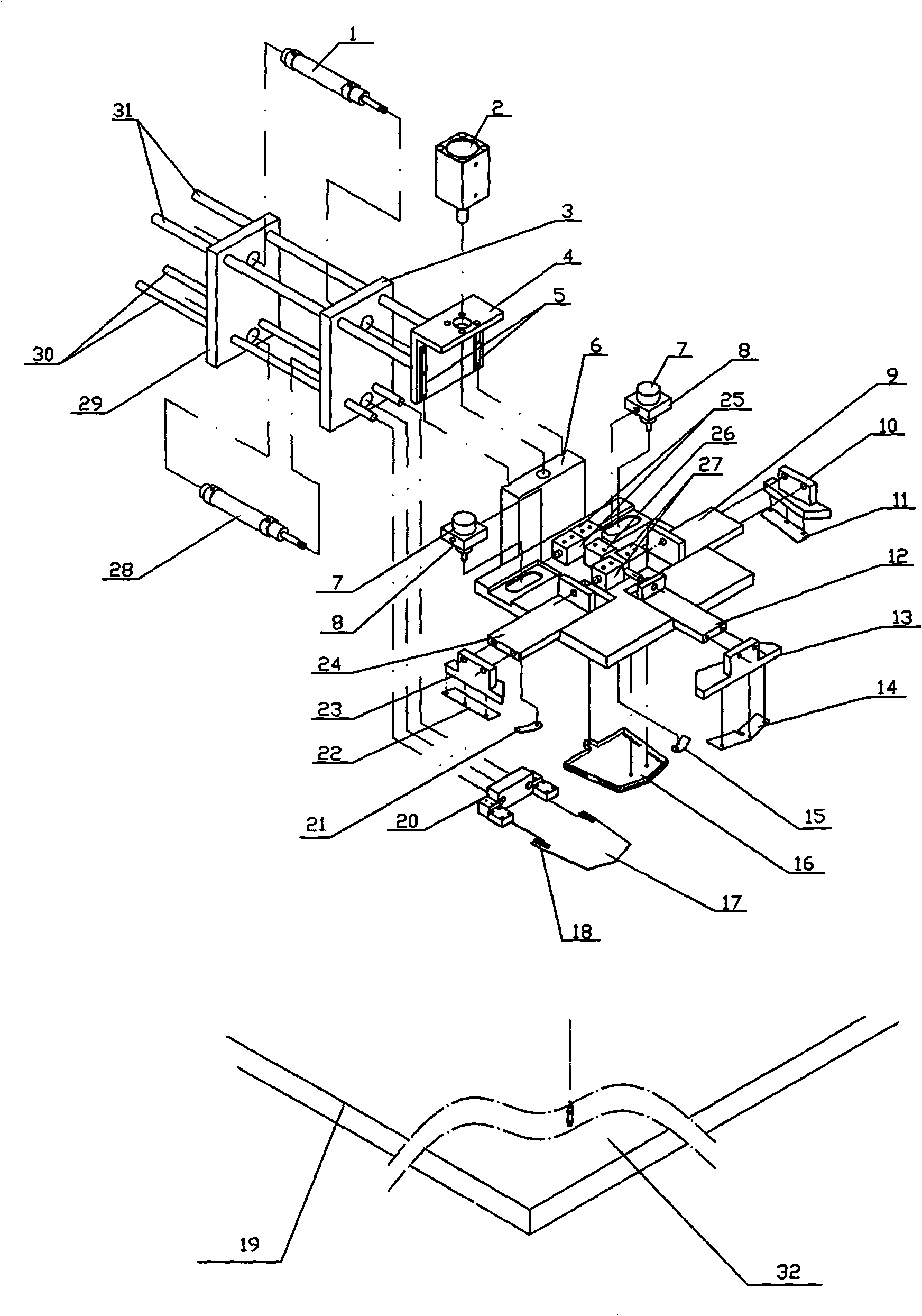

[0027] Automatic bag folding mechanism, including two parts: primary forming component and side folding forming component:

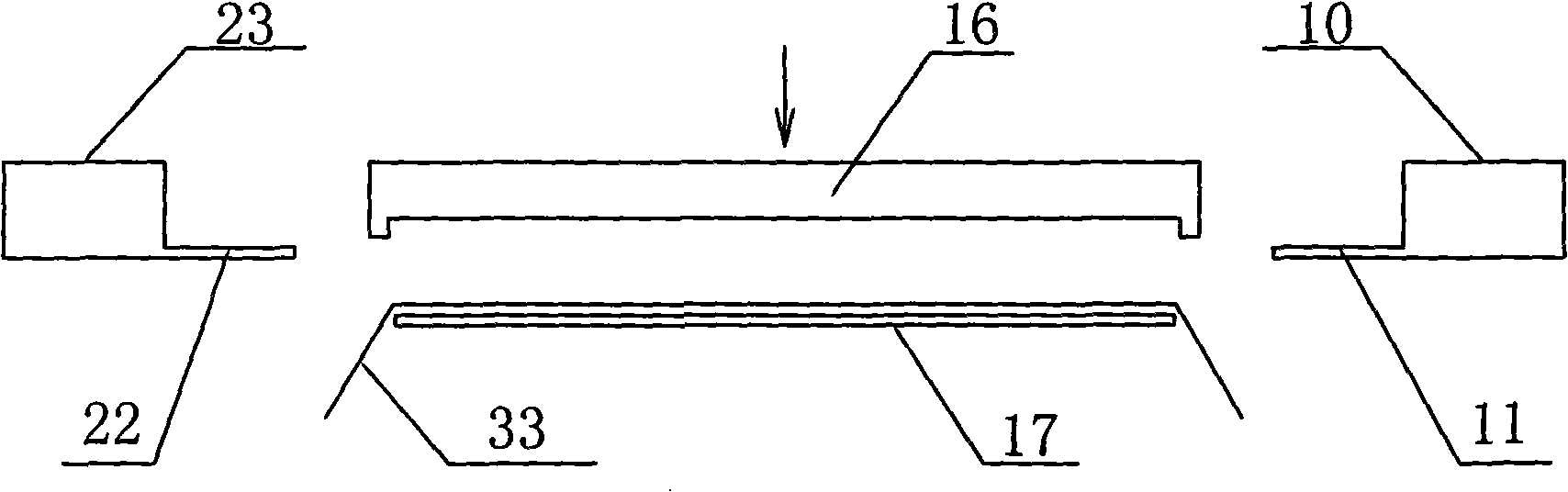

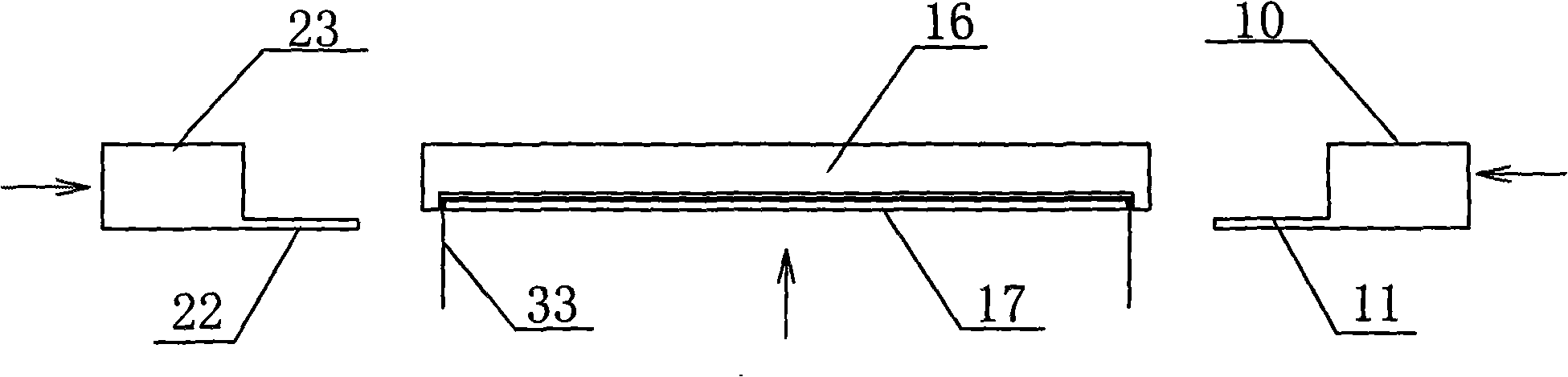

[0028] 1. Preliminary forming components: including the bottom folding bag template 17, the top folding bag template 16 and the top folding bag action component. The bottom folding bag template 17 can be movably embedded in the top folding bag template 16, and the top folding bag template 16 It is fixedly connected with the upper folding bag template action component, and the lower folding bag template 17 is fixedly connected with the lower folding bag template action component.

[0029] The above-mentioned upper-folding bag template action component and lower-folding bag template action component include forward and backward horizontal movement components, and the upper-folding bag template action component also includes up and down movement components:

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com