Patents

Literature

61results about How to "Consistent rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

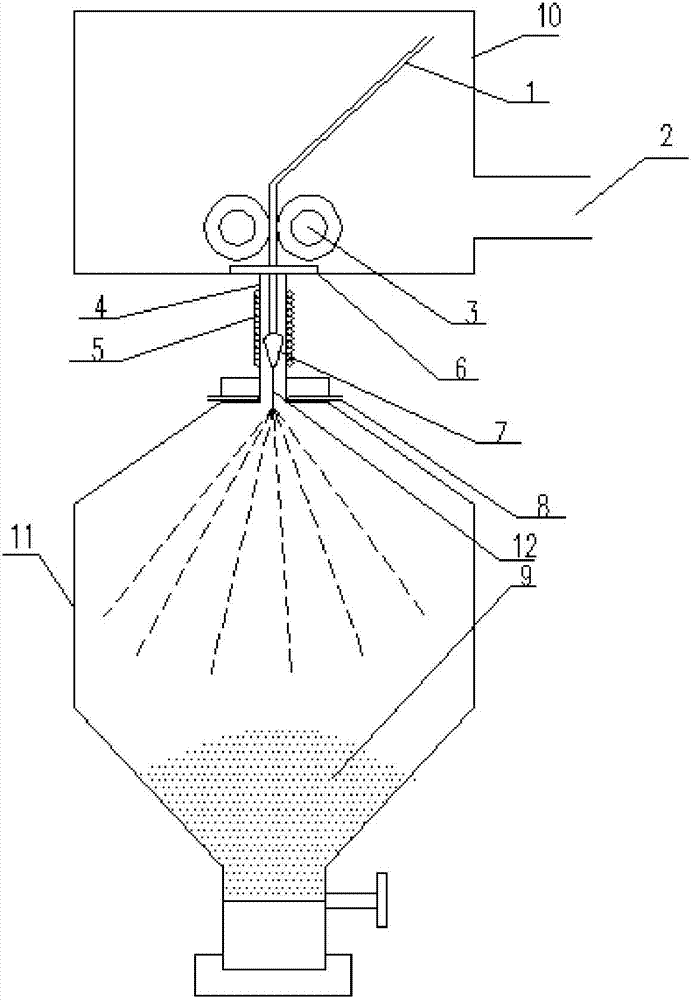

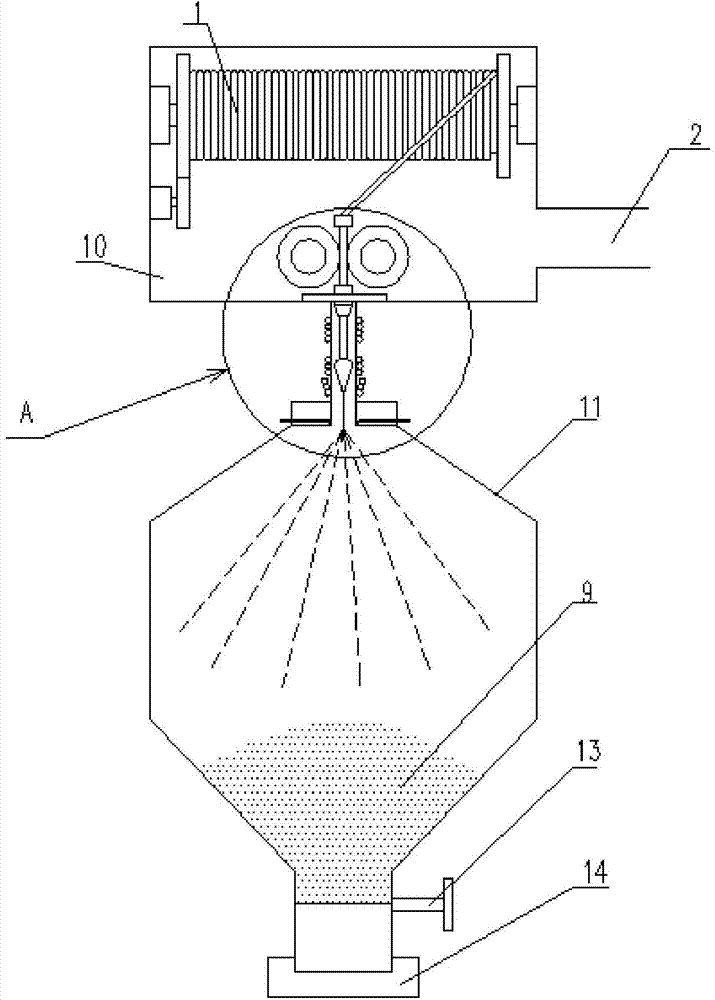

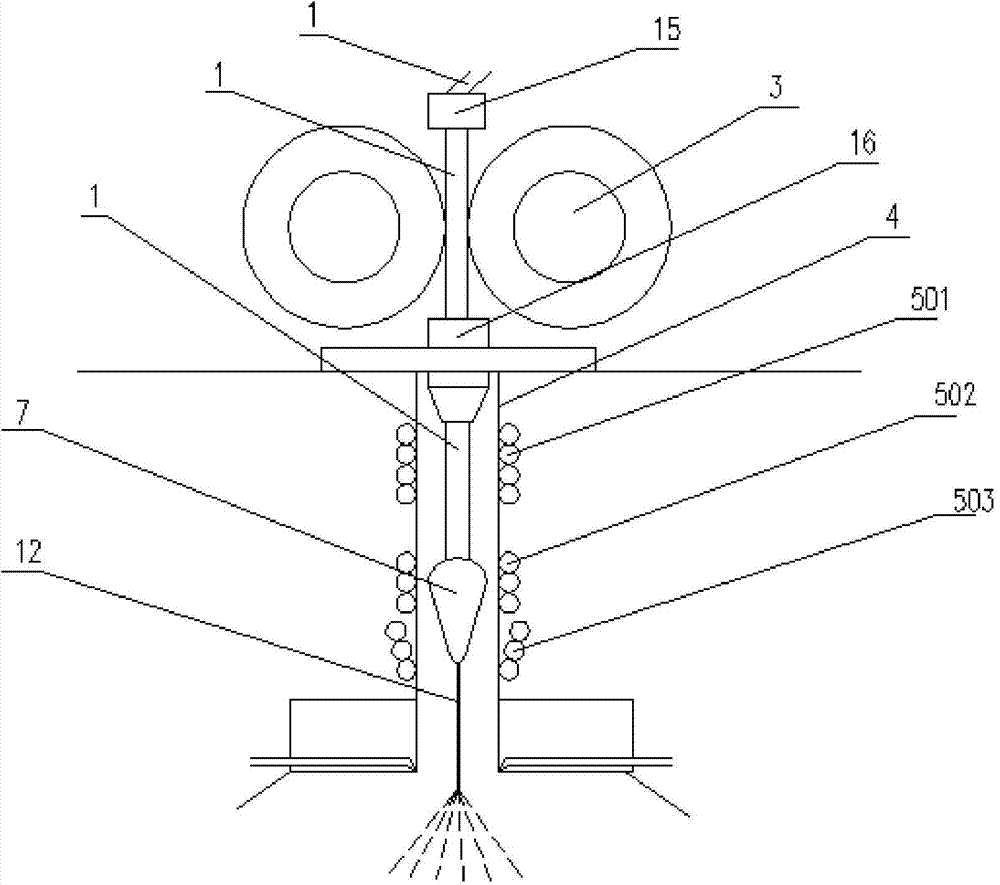

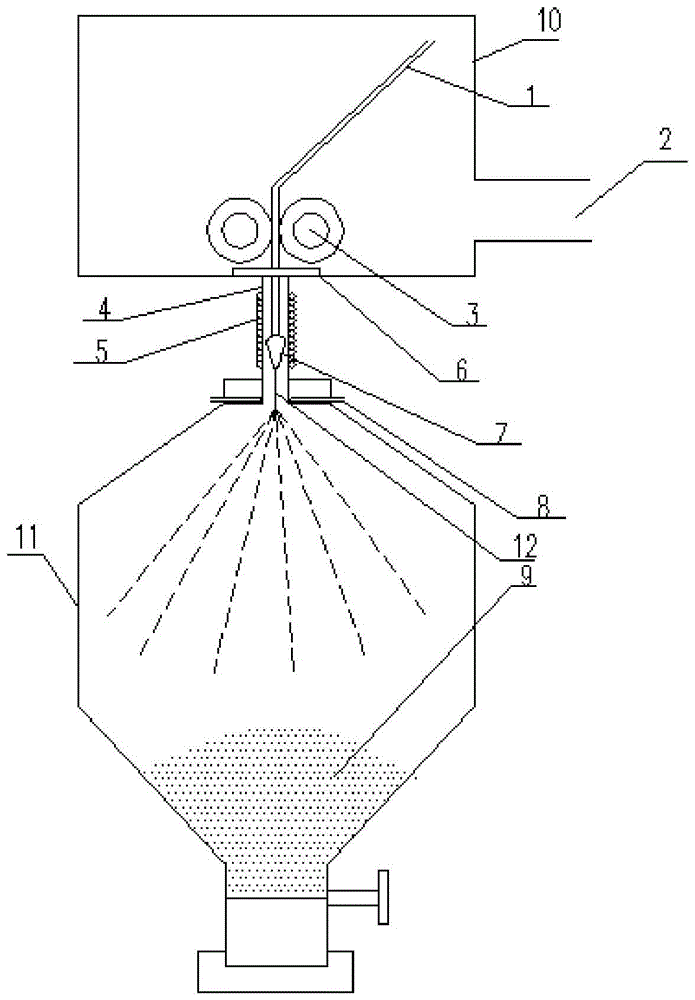

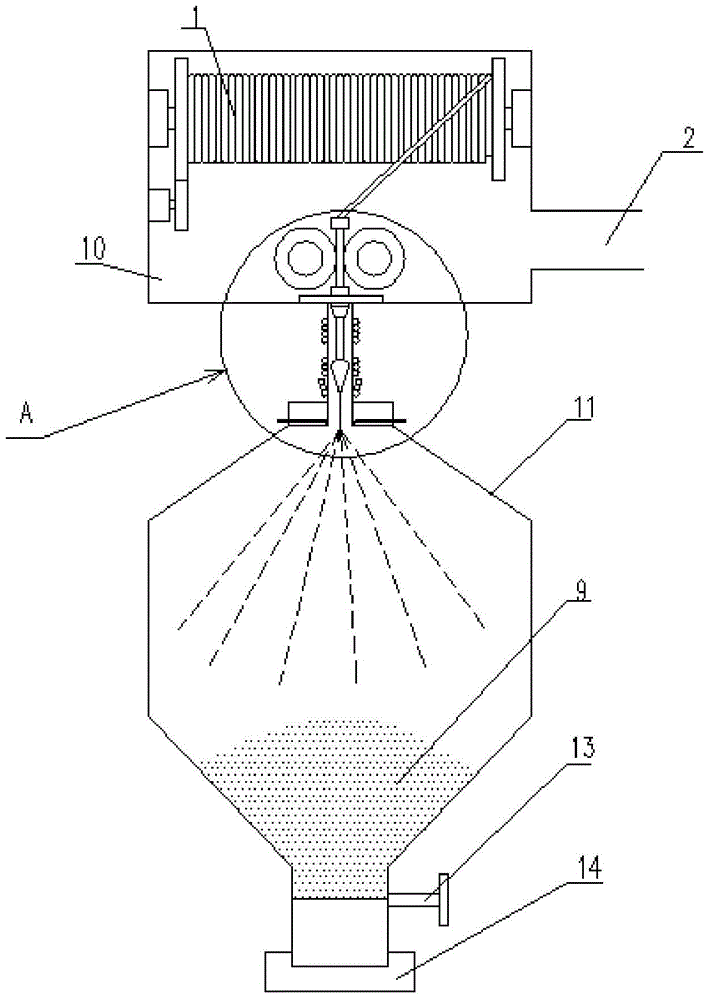

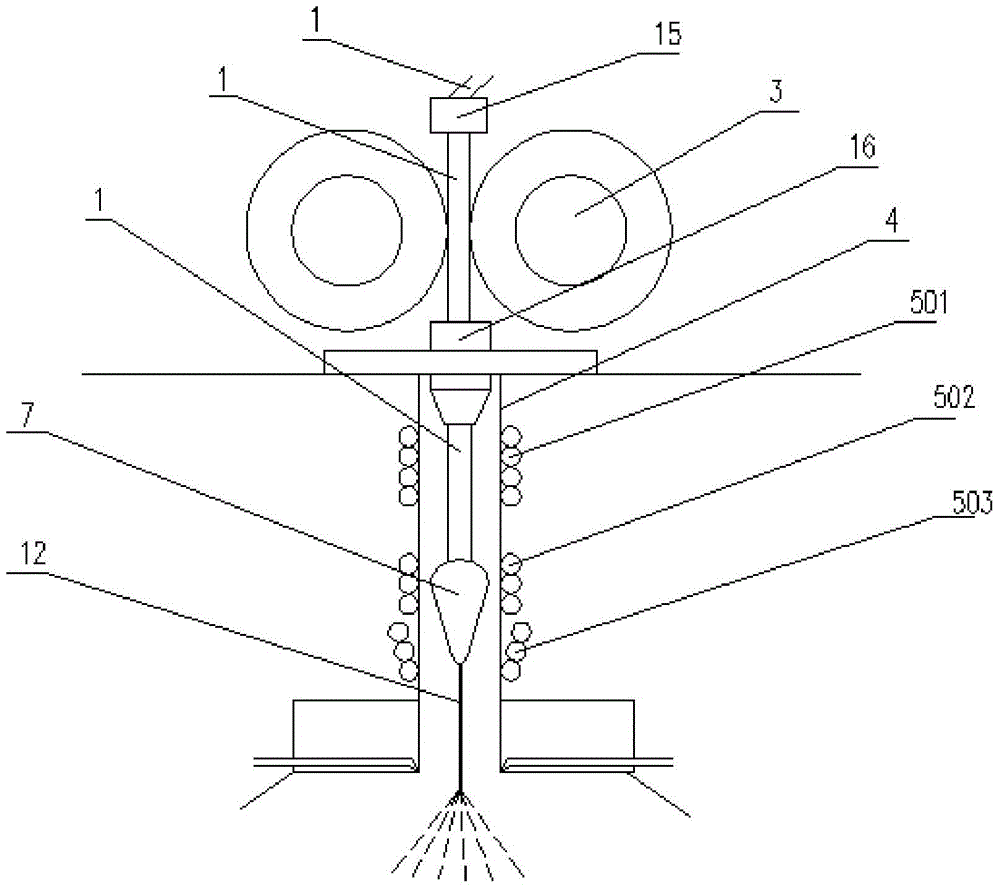

Method and device for metal powder preparation based on controllable magnetic levitation melting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

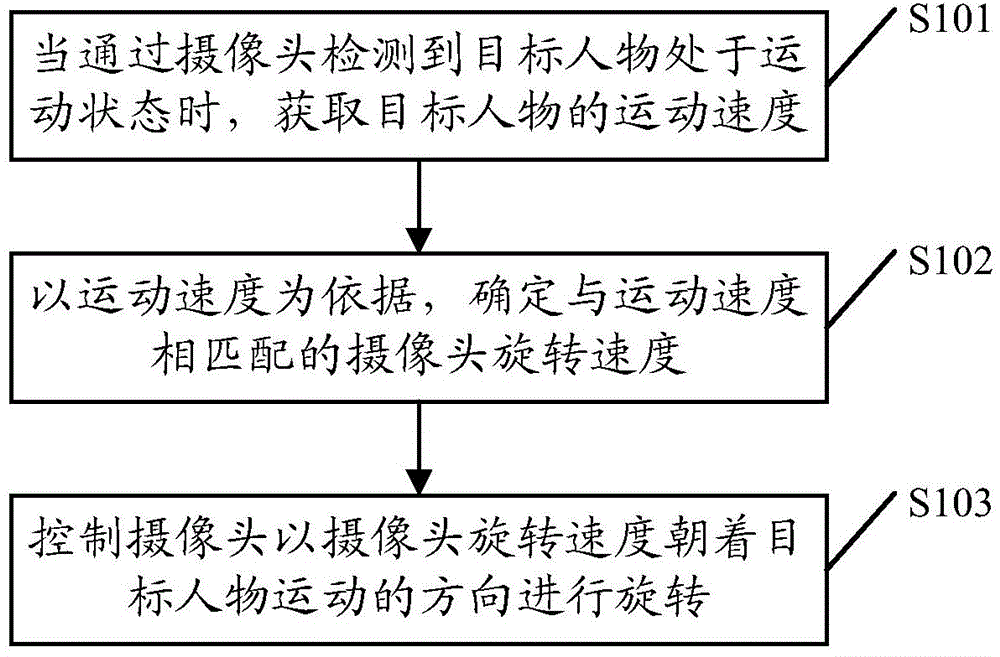

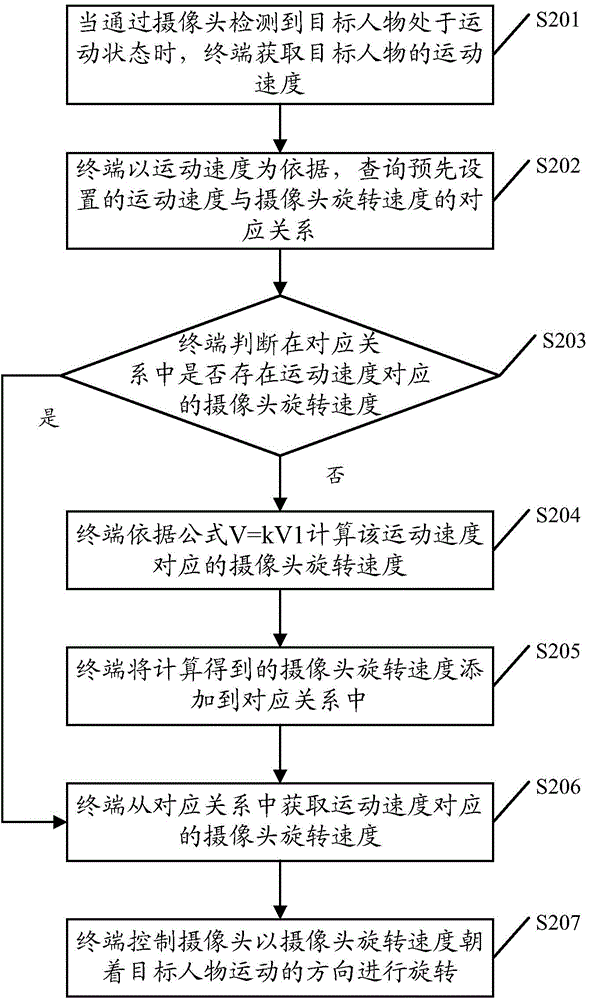

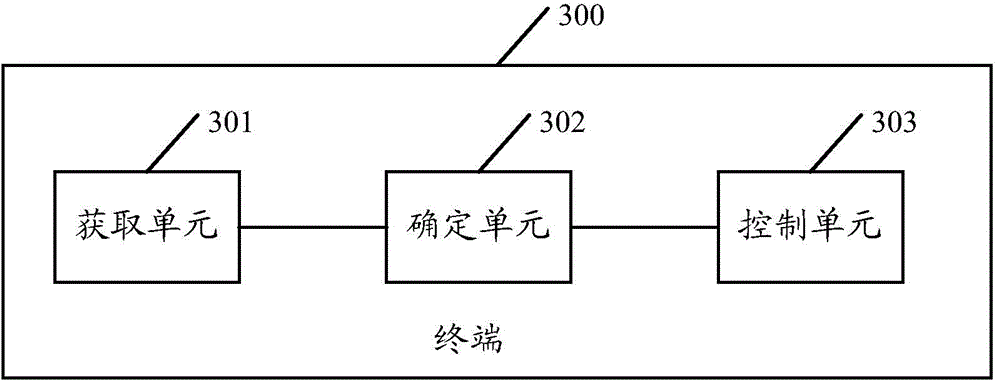

Rotary camera control method and terminal

ActiveCN104902169AImprove the shooting effectConsistent rotation speedTelevision system detailsColor television detailsCamera controlRotation velocity

The embodiment of the invention discloses a rotary camera control method and a terminal. The method comprises the following steps: acquiring a movement velocity of a target person when detecting that the target person is in a movement status through the camera; determining the rotary velocity of the camera matched with the movement velocity on the basis of the movement velocity; controlling the camera to rotate in the movement direction of the target person at the rotary velocity of the camera. A shooting effect of a movement target can be improved through the adoption of the method disclosed by the embodiment of the invention.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

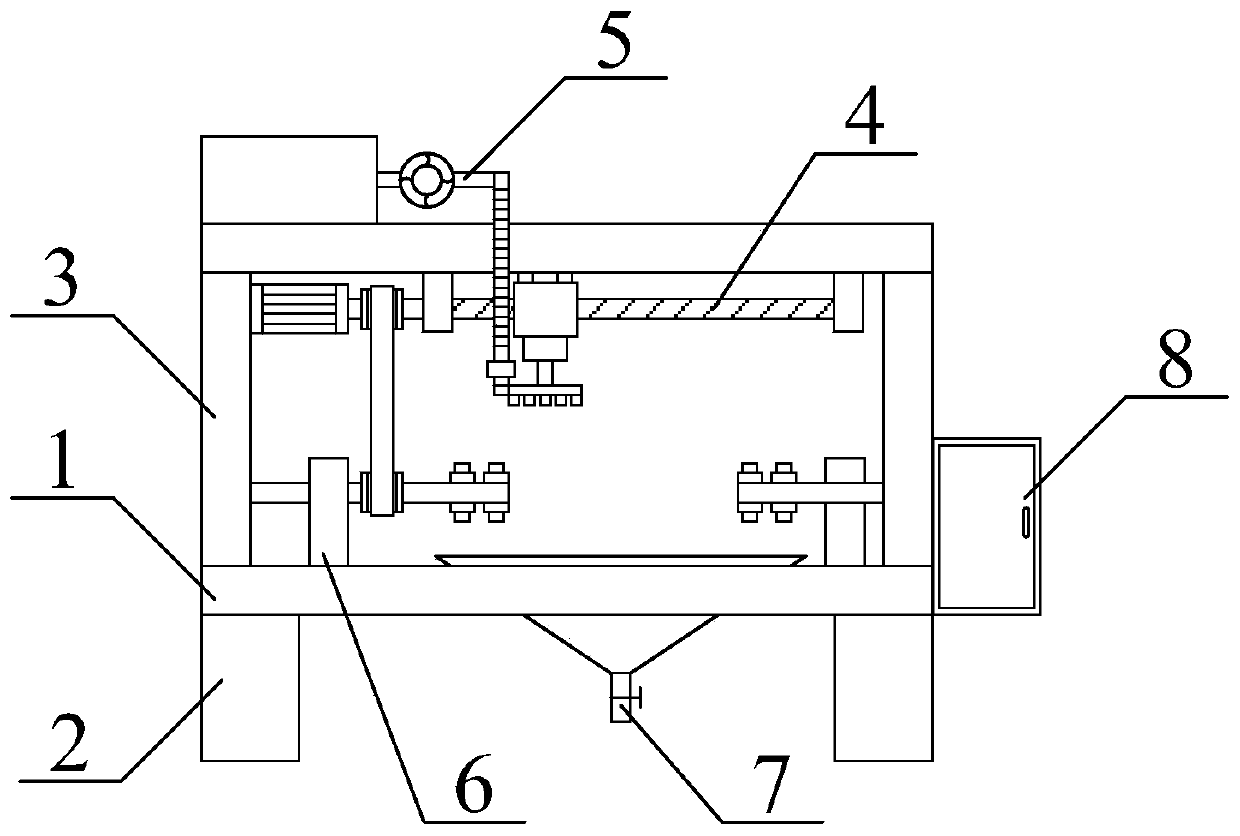

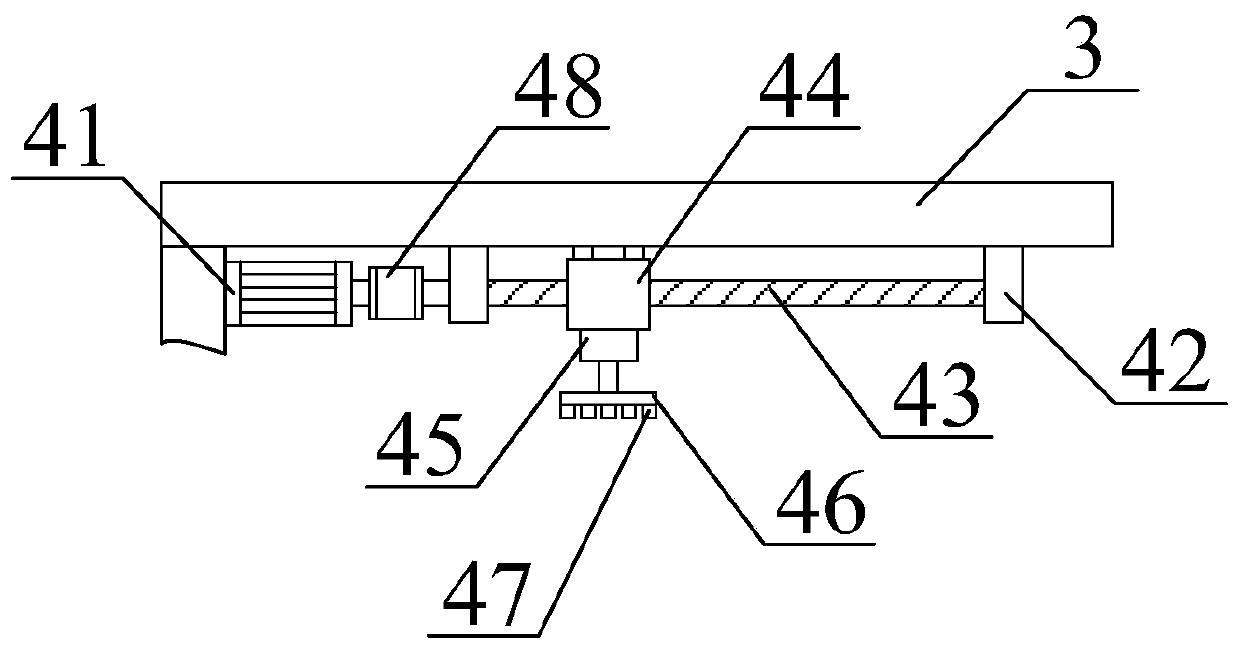

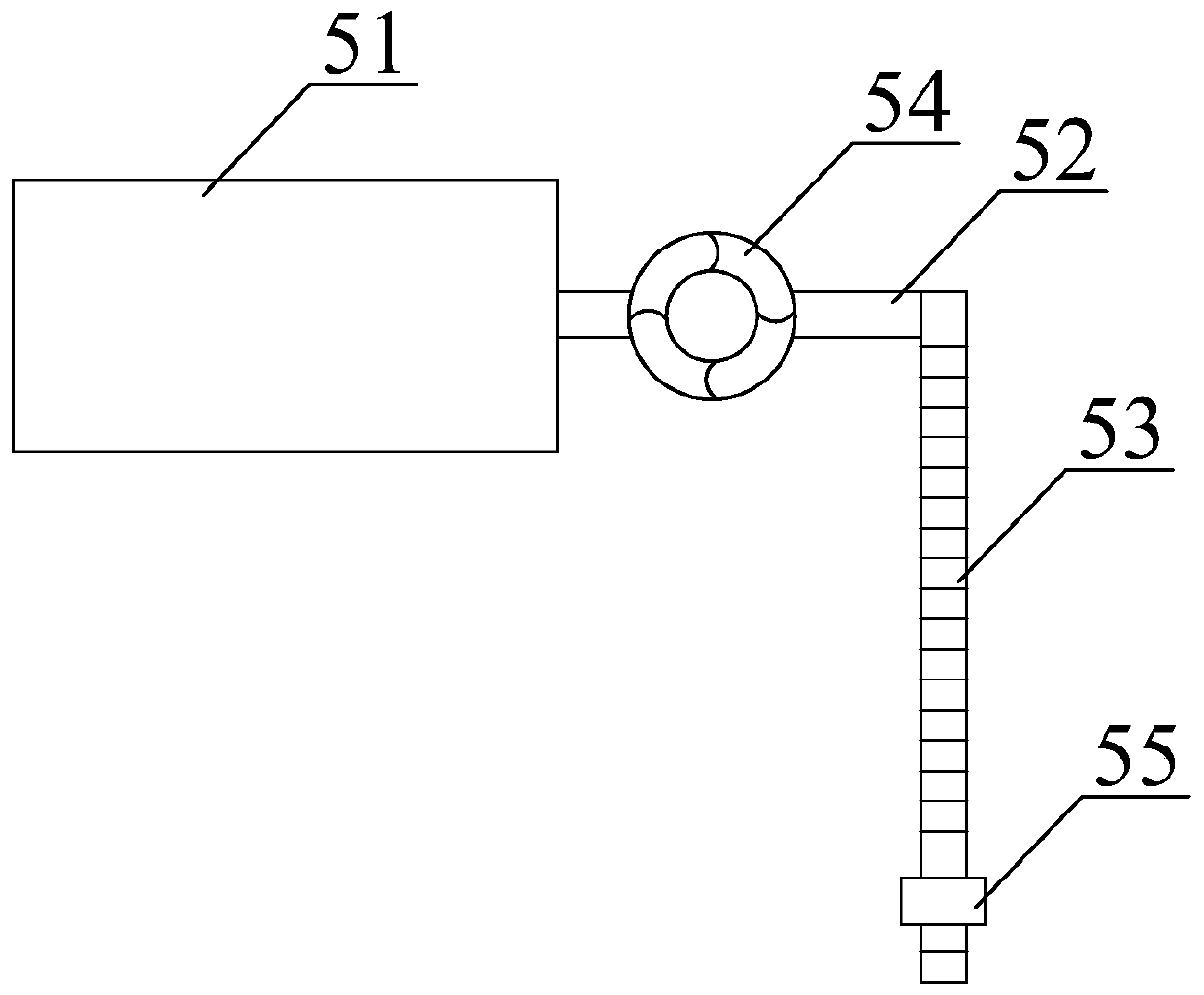

Spraying device for steel pipe surface

InactiveCN111299005AImprove spray qualityImprove consistencyLiquid spraying apparatusElectric machineElectric control

The invention discloses a spraying device for a steel pipe surface. The spraying device comprises a workbench, a support foot, a bracket, a spraying assembly, a feeding assembly, a support assembly, awaste box and an electric control cabinet. By setting the support assembly, one end of the steel pipe is sleeved on a second electric pushing rod, the other end of the steel pipe is sleeved on a third electric pushing rod, the second electric pushing rod and the third electric pushing rod are powered to run and extend to support the steel pipe, the support is carried out by an inner support method, and during the spraying process, the outer surface of the steel pipe can be sprayed without dead angles to improve the spraying quality of the steel pipe; by setting the spraying assembly, a mobilemotor is powered to run so that a nut seat is moved to one end of the steel pipe, the first electric pushing rod is powered to run so that a nozzle stretches above the steel pipe, a driving pulley drives a driven pulley to rotate, so that the movement speed of the nut seat is consistent with the rotational linear speed of a first rotary rod, the consistent spraying speed and the rotating speed ofthe steel pipe are ensured, and the consistency of the steel pipe spraying quality is improved.

Owner:严白双

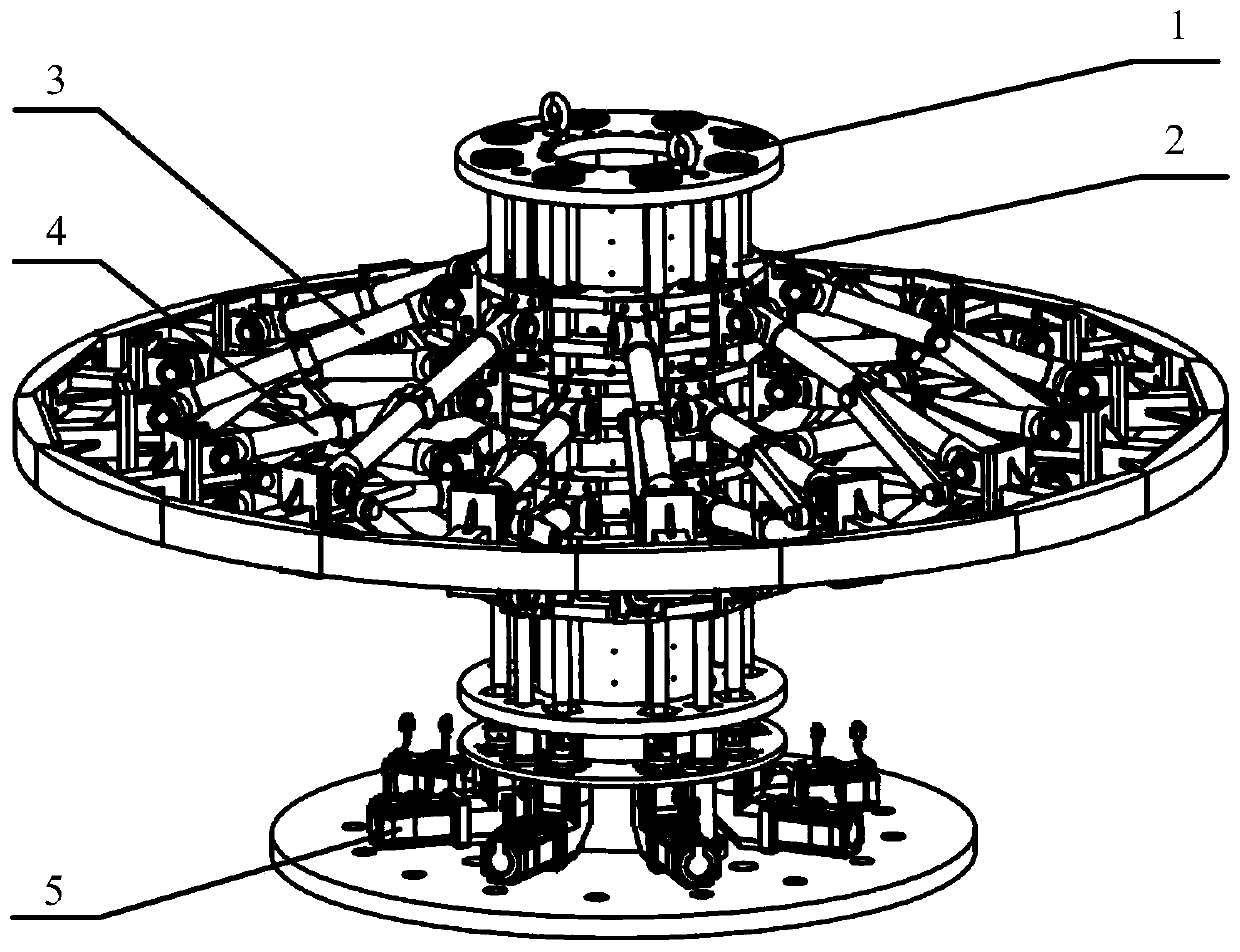

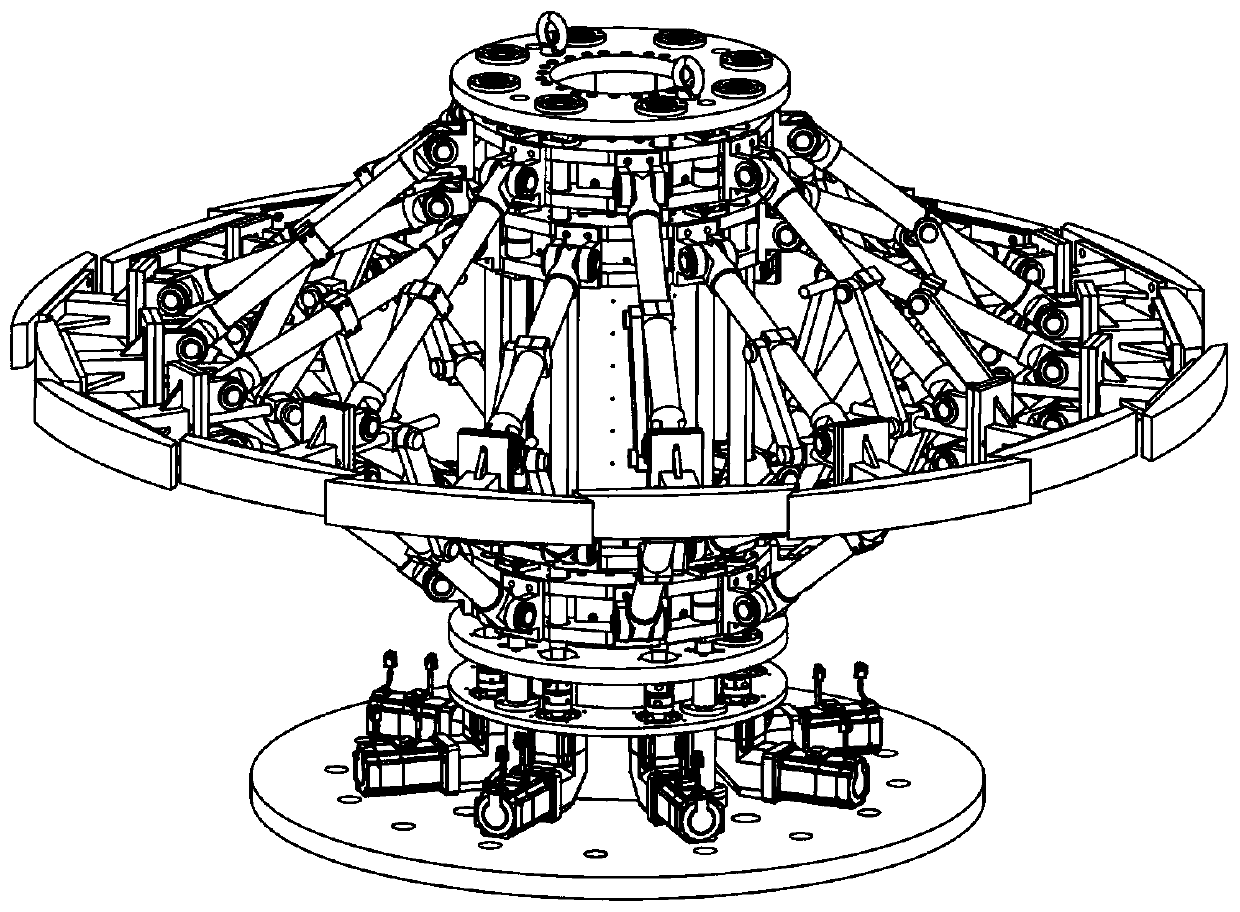

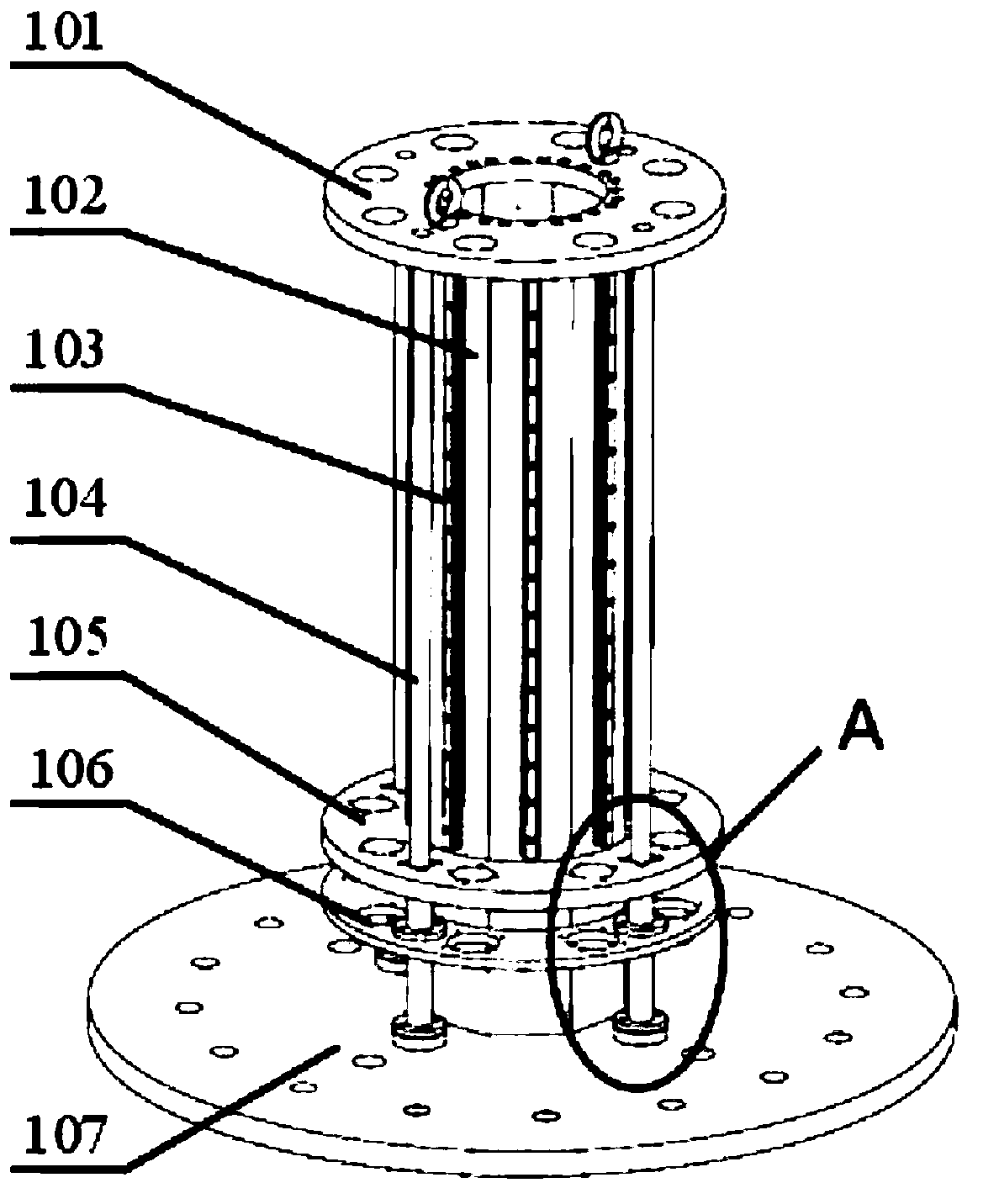

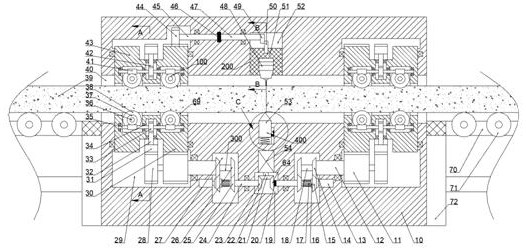

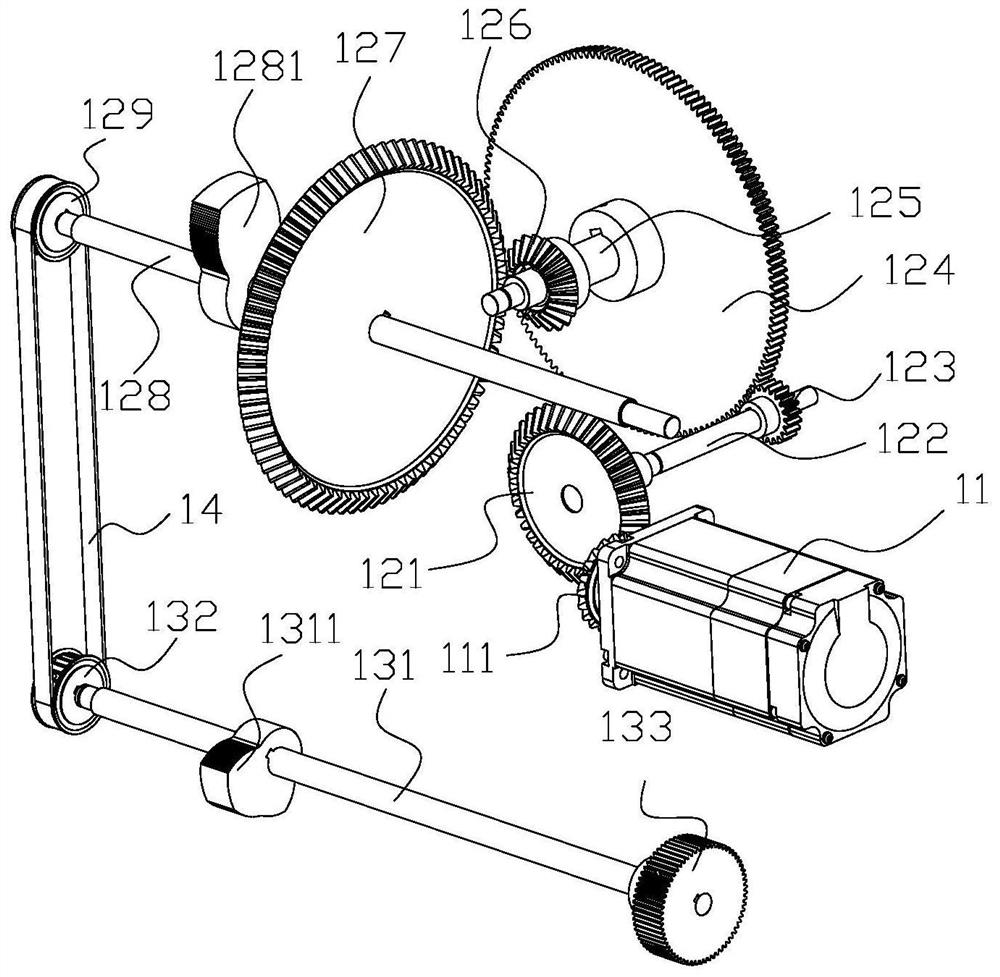

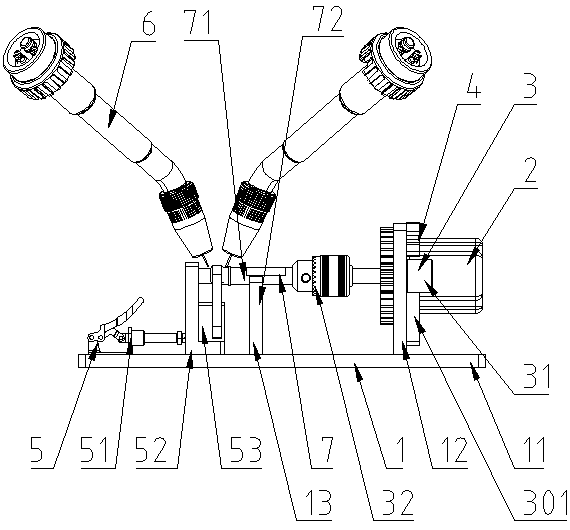

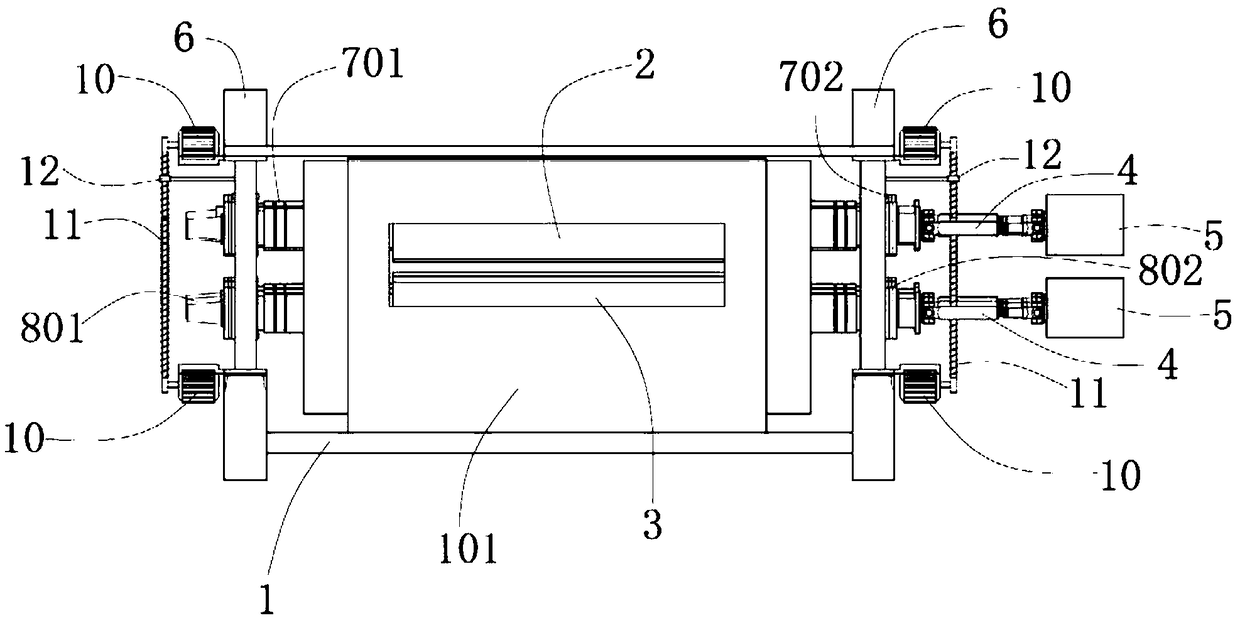

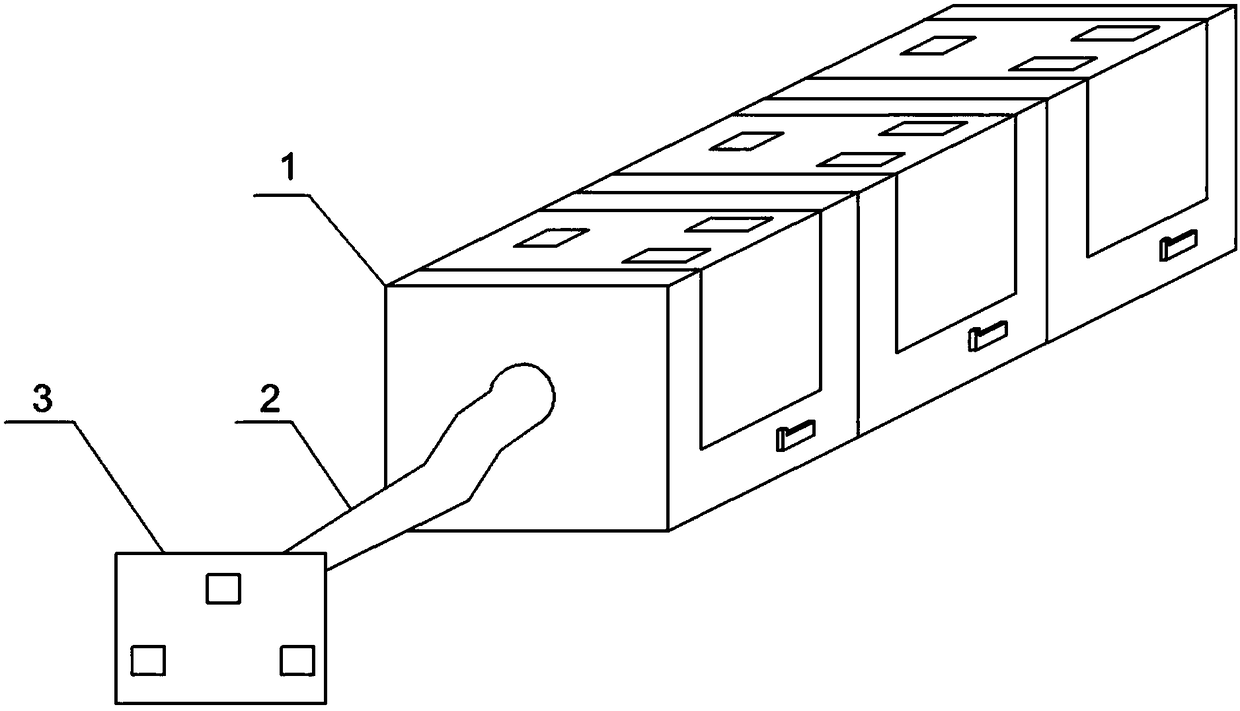

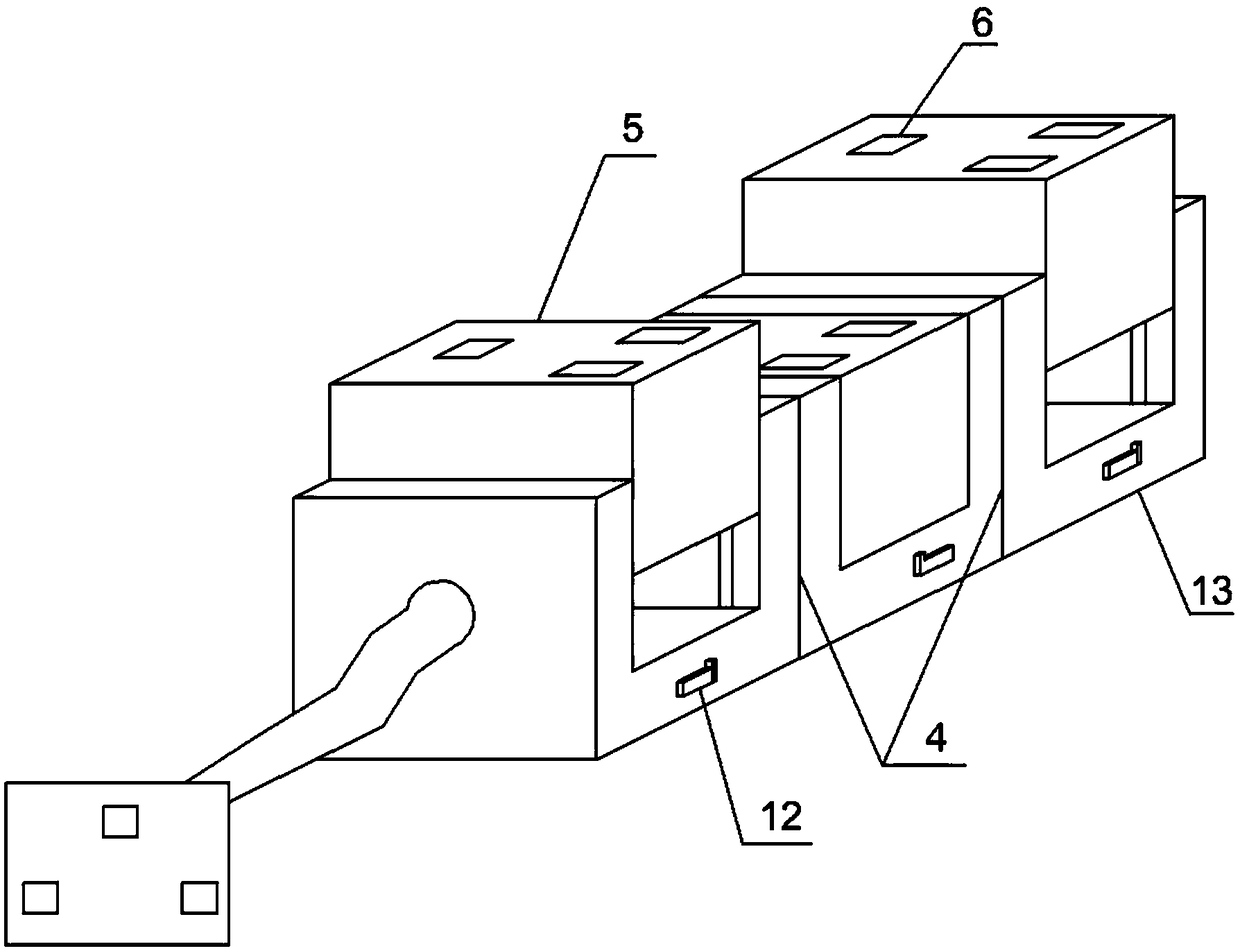

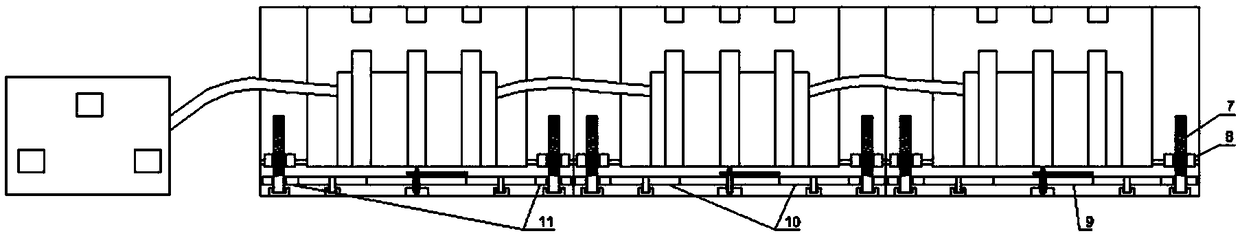

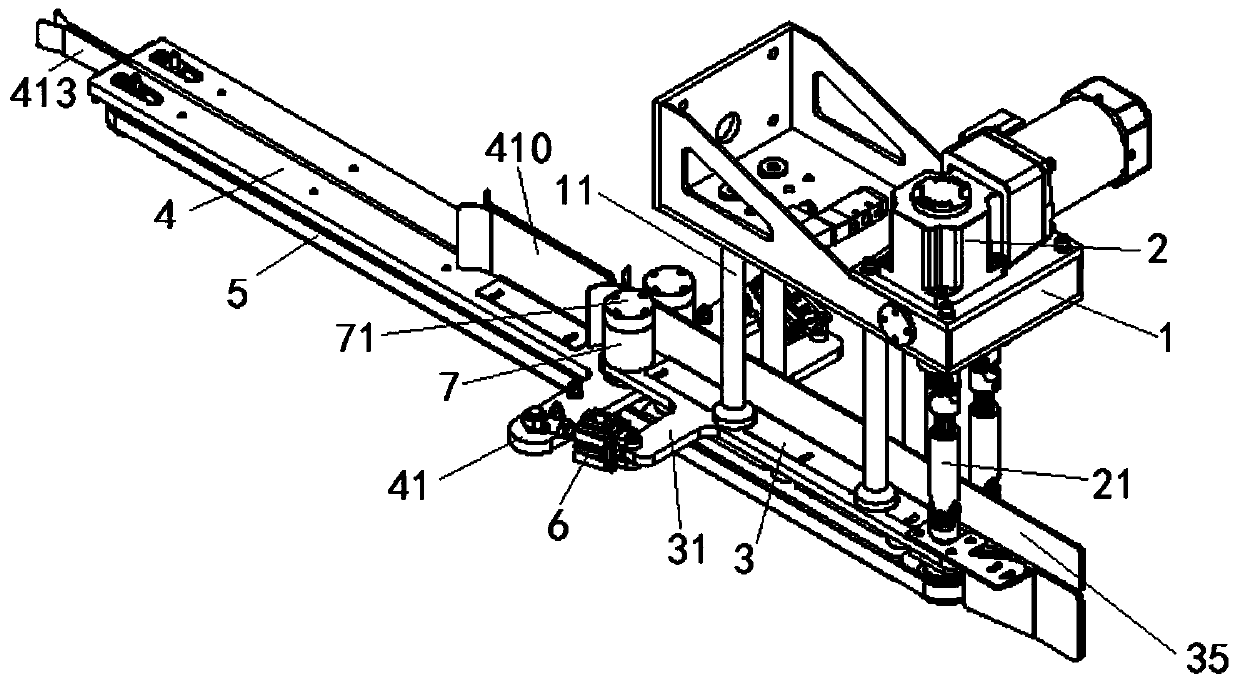

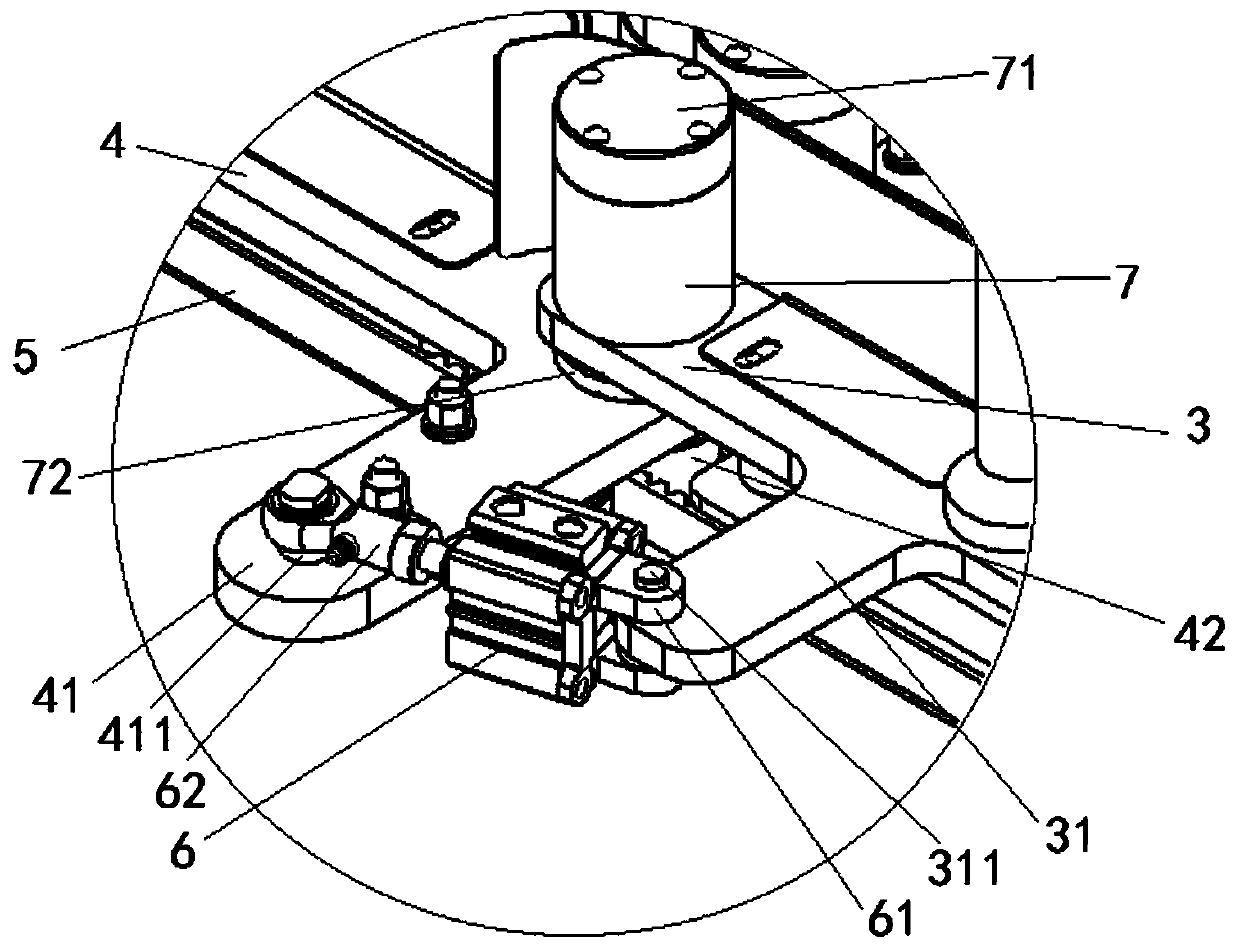

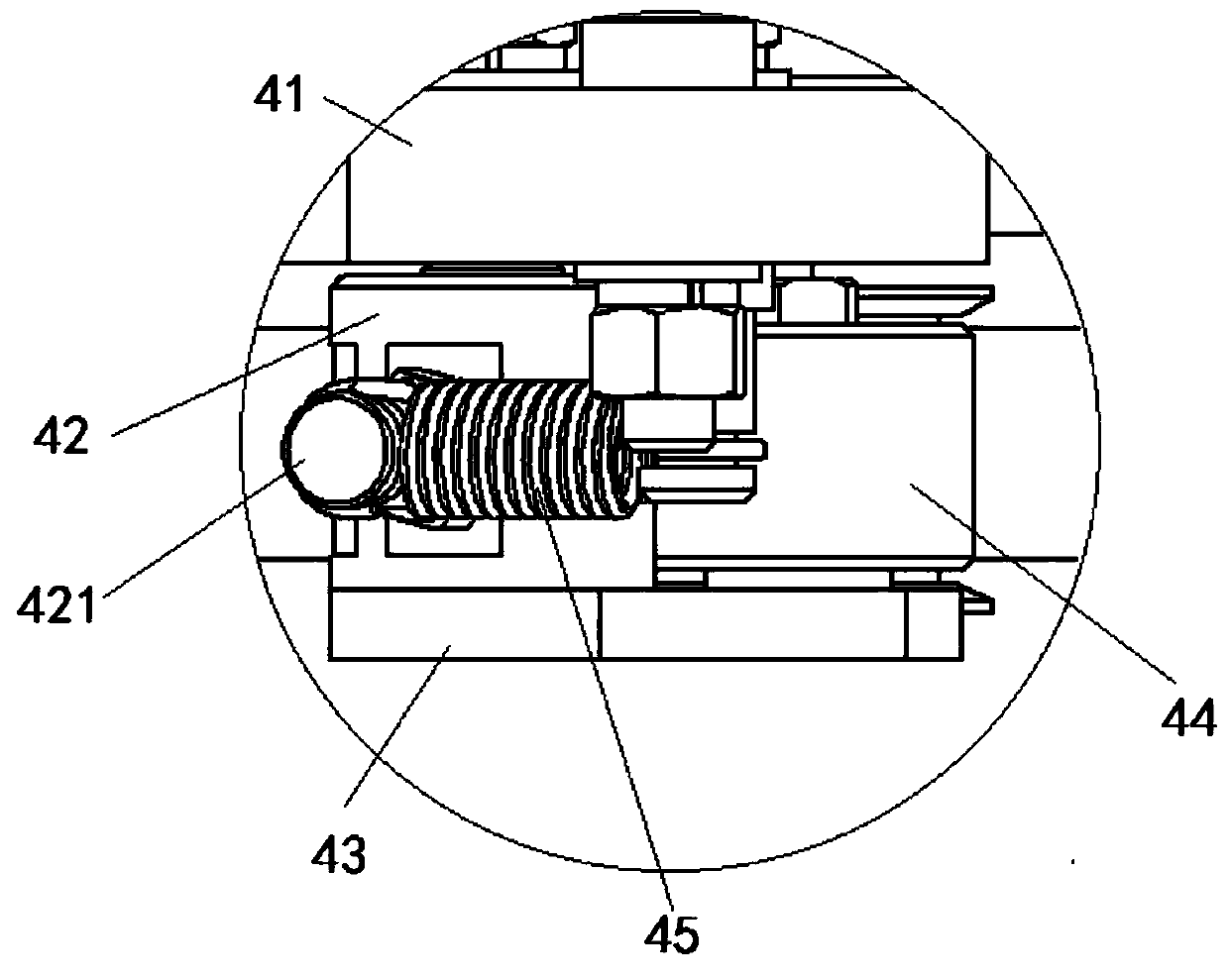

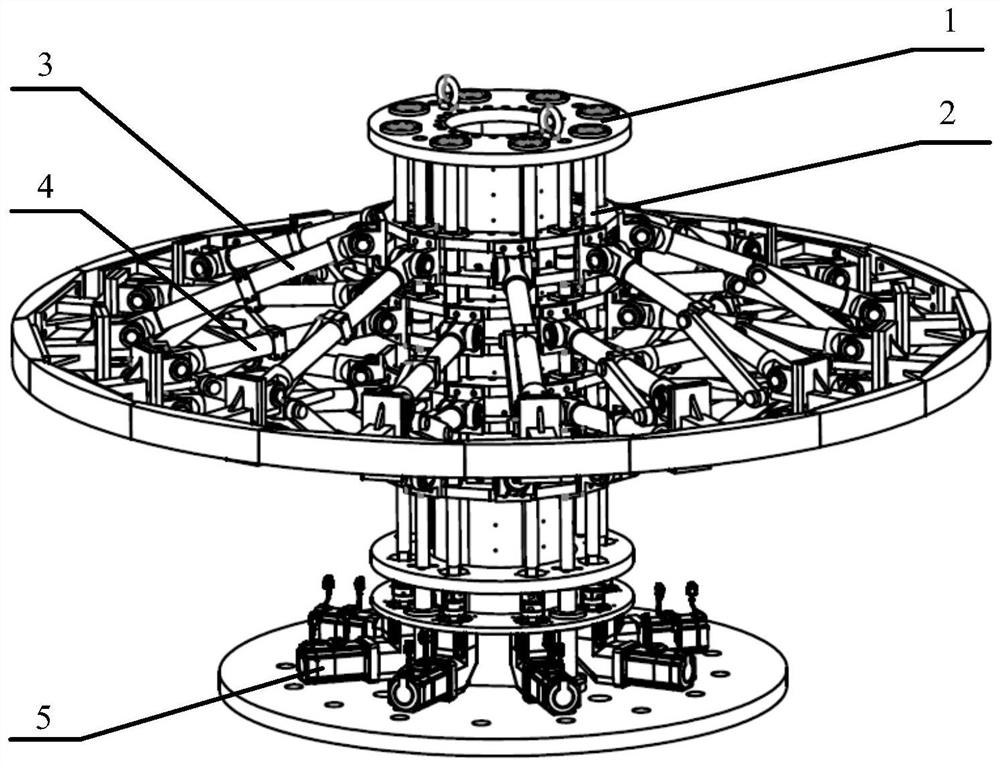

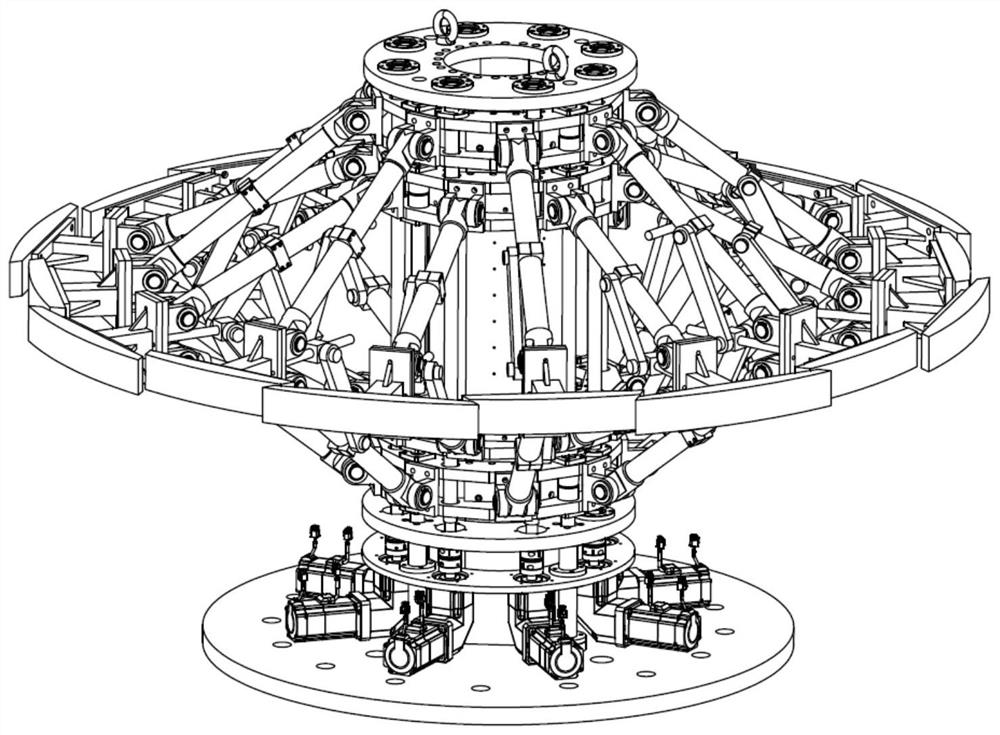

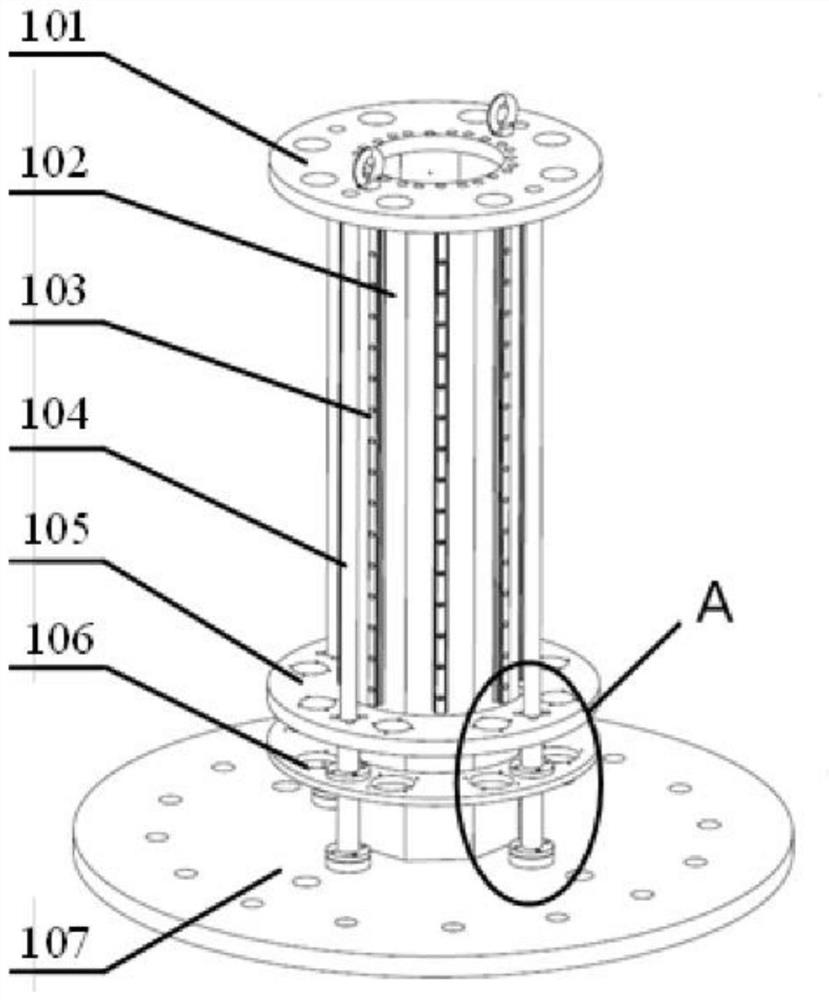

Inner support clamping device for inner support of annular open component and using method thereof

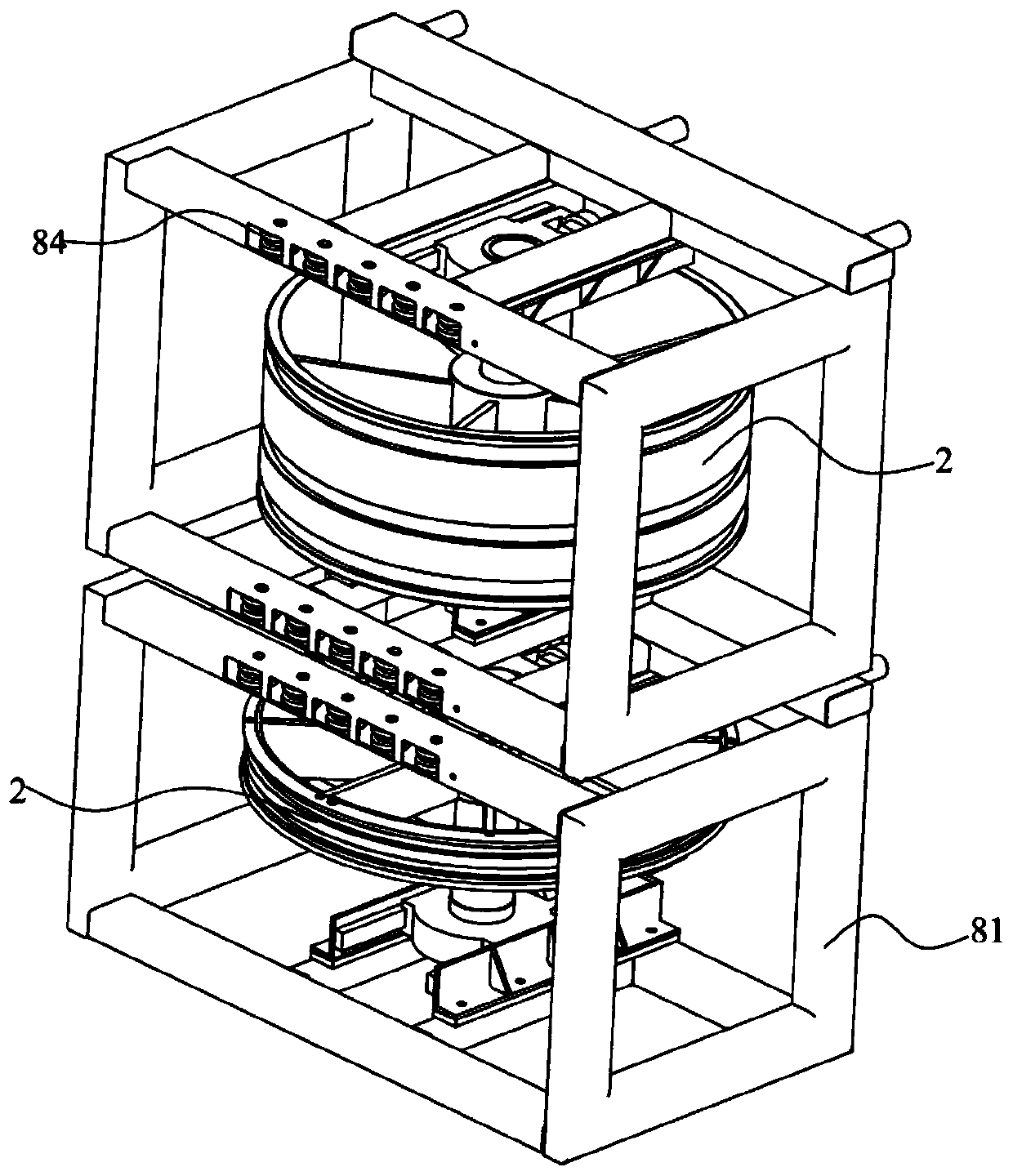

ActiveCN109848634AUniform outriggerImprove manufacturing precisionWelding/cutting auxillary devicesAuxillary welding devicesSoftware engineeringFlange

The invention discloses an inner support clamping device for an inner support of an annular open component and a using method thereof. According to the technical scheme, the inner support clamping device for the inner support of the annular open component is characterized by comprising a fixing rack, bottom flanges of the fixing rack are connected to an external mechanism or a ground, the fixing rack is provided with a central driving platform, a convex radial supporting mechanism, a concave radial supporting mechanism and a servo driving mechanism. According to the inner support clamping device for the inner support of the annular open component and the using method thereof, supporting rigidity of the inner support mechanism of the component is greatly improved, the precision of the tailend is guaranteed, moreover, the influence of gravity can be omitted, and the inner support clamping device can be used for vertical supporting mechanisms and can also be used for horizontal supporting mechanisms.

Owner:SHANGHAI JIAO TONG UNIV

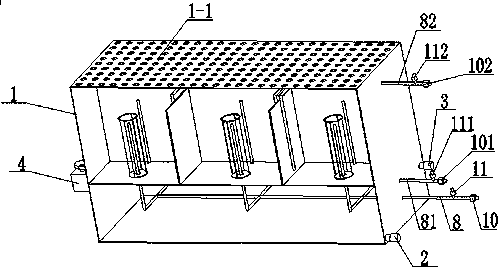

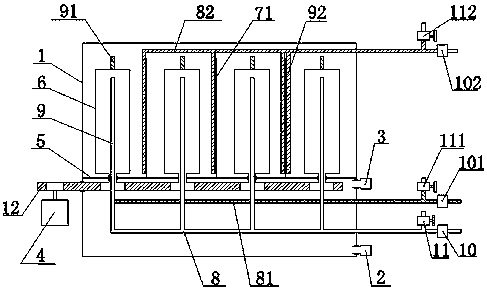

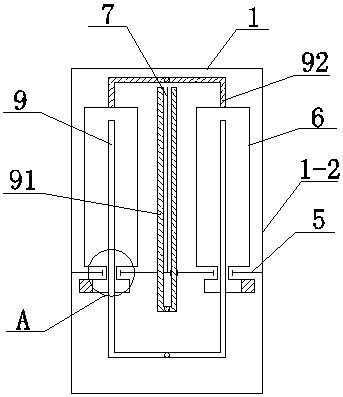

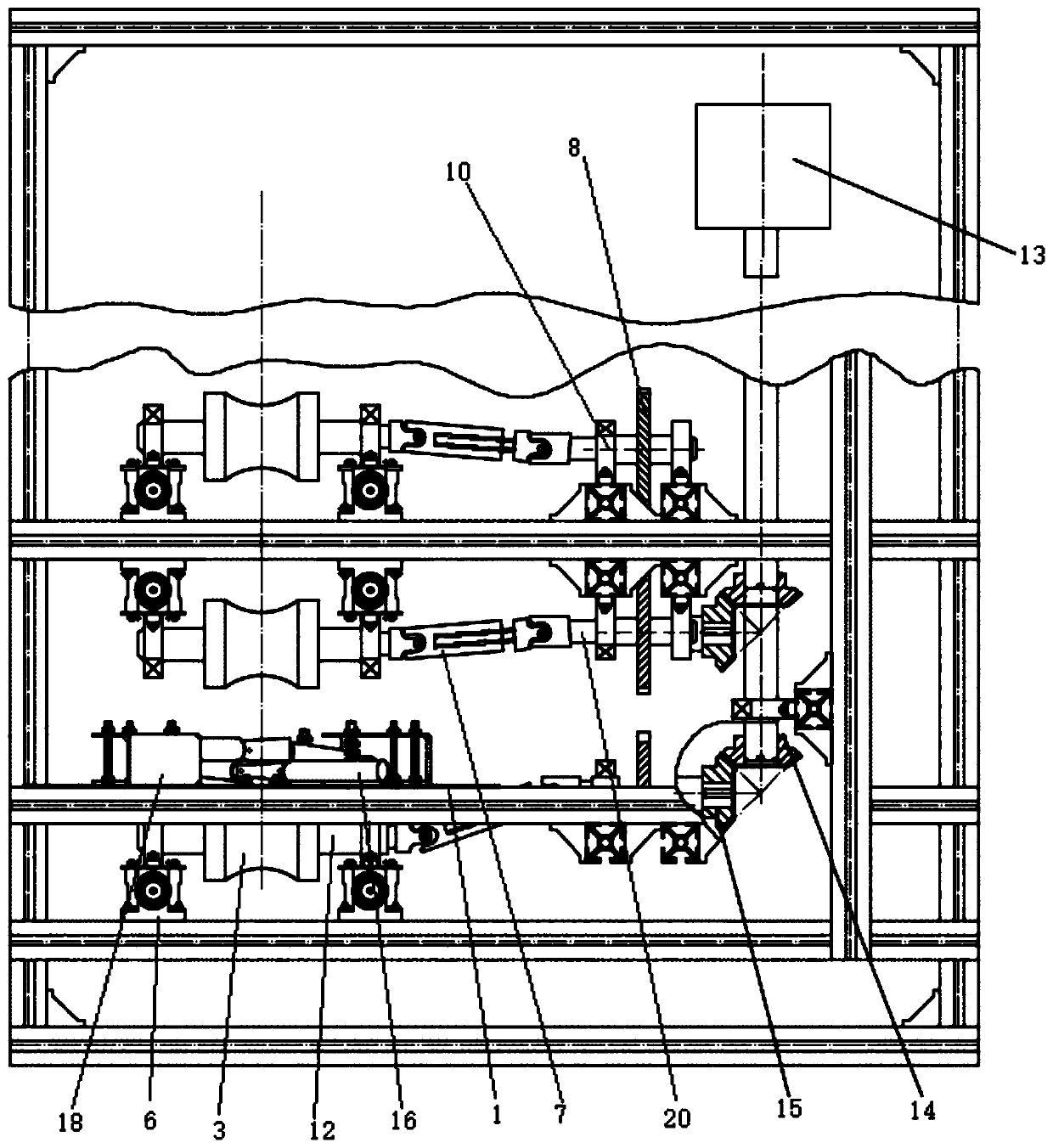

Double-row double-spraying cleaning device for high-temperature-resistant filter bag

ActiveCN108188121ARealize internal and external cleaningClean upHollow article cleaningFilter regenerationWater leakageSewage

The invention discloses a double-row double-spraying cleaning device for a high-temperature-resistant filter bag. The cleaning device comprises a box body, a power system, an inner bag cleaning subsystem, a front-position outer bag cleaning subsystem, a side-position outer bag cleaning subsystem, a sewage pump and a vacuum pump, wherein a water leakage plate is horizontally arranged inside the boxbody, two rows of filter bag supports and cleaning partition plates are arranged on the water leakage plate, and the front row of filter bag supports and the rear row of filter bag supports are arranged symmetrically with the plane of the cleaning partition plates as an axis; the power system comprises a motor and a tooth-shaped conveyor belt; the inner bag cleaning subsystem comprises an inner bag water supply pipe, inner spraying pipes, an inner bag cleaning pressure regulator and an inner bag washing liquid adding device; the front-position outer bag cleaning subsystem comprises a front-position outer bag water supply pipe, front-position outer spraying pipes, a front-position outer bag cleaning pressure regulator and a front-position outer bag washing liquid adding device; and the side-position outer bag cleaning subsystem comprises a side-position outer bag water supply pipe, side-position outer spraying pipes, a side-position outer bag cleaning pressure regulator and a side-position outer bag washing liquid adding device. According to the double-row double-spraying cleaning device for the high-temperature-resistant filter bag, the structure is simple, a surface structure ofthe filter bag cannot be damaged, cleaning efficiency is high, and the quality is good.

Owner:WUHAN TEXTILE UNIV

Automatic building steel pipe welding machine

InactiveCN112621044AFast welding speedConsistent rotation speedWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention relates to the technical field of building steel pipes, in particular to an automatic building steel pipe welding machine. The welding machine comprises a machine body, wherein a working cavity penetrating from left to right is formed in the machine body; power cavities are outwards formed in the working cavity in a left-right symmetrical communicating manner; a moving body which internally penetrates from left to right and extends from left to right is rotatably arranged in each power cavity; a translation gear cavity with an outward opening is formed in each moving body; a rotating gear ring is fixedly arranged at the position, close to the symmetry center, of the translation gear cavity in each moving body; and sliding gear cavities are formed in the sides, close to the symmetry center, of the power cavities in the machine body in a left-right symmetrical manner. According to the automatic building steel pipe welding machine provided by the invention, manual operation is not needed, automatic feeding and discharging welding can be completed as long as steel pipes needing to be welded are placed on the welding machine, the steel pipe welding speed is increased, the labor force is released, the rotating speeds of two steel pipe sections are consistent, and the welding quality can be guaranteed.

Owner:深圳市天雄星实业有限公司

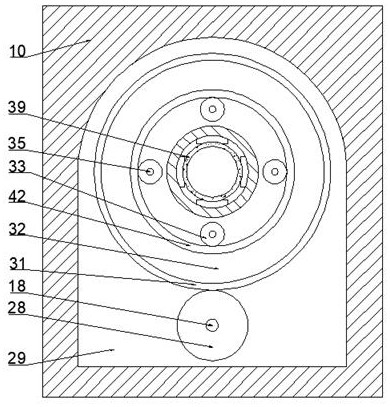

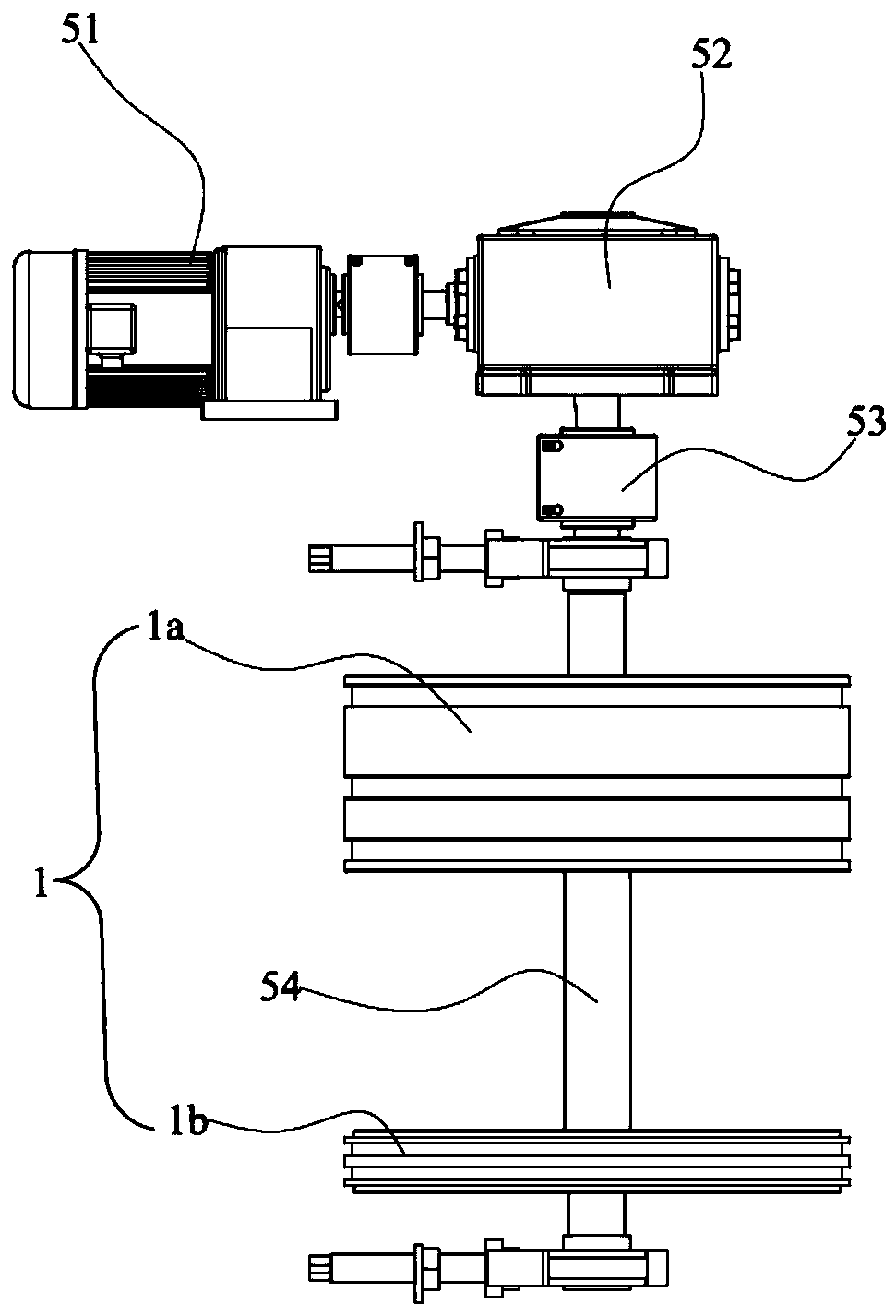

Traditional Chinese medicine tablet stamping mechanism and method

InactiveCN112238644AConsistent rotation speedGuaranteed uniformityPharmaceutical product form changePress ramElectric machineryDrive motor

The invention belongs to the technical field of traditional Chinese medicine pharmaceutical production, and relates to a traditional Chinese medicine tablet stamping mechanism and method. The mechanism comprises a driving device and a stamping device; the driving device comprises a driving motor, an upper driving module and a lower driving module; the driving motor is connected with the upper driving module and used for driving the upper driving module to rotate, and the upper driving module and the lower driving module are connected through a conveying belt; the stamping device comprises a downward pressing module at the upper part and a jacking module at the lower part; and the upper driving module is matched with the downward pressing module, and the lower driving module is matched withthe jacking module, so that traditional Chinese medicine tablets are stamped and formed by pressing the downward pressing module and the jacking module towards the middle. The mechanism has the advantages that the traditional Chinese medicine tablets are directly stamped and formed through cooperation of downward pressing and jacking, and the stamping quality of the stamped traditional Chinese medicine tablets is improved.

Owner:魏乃淳

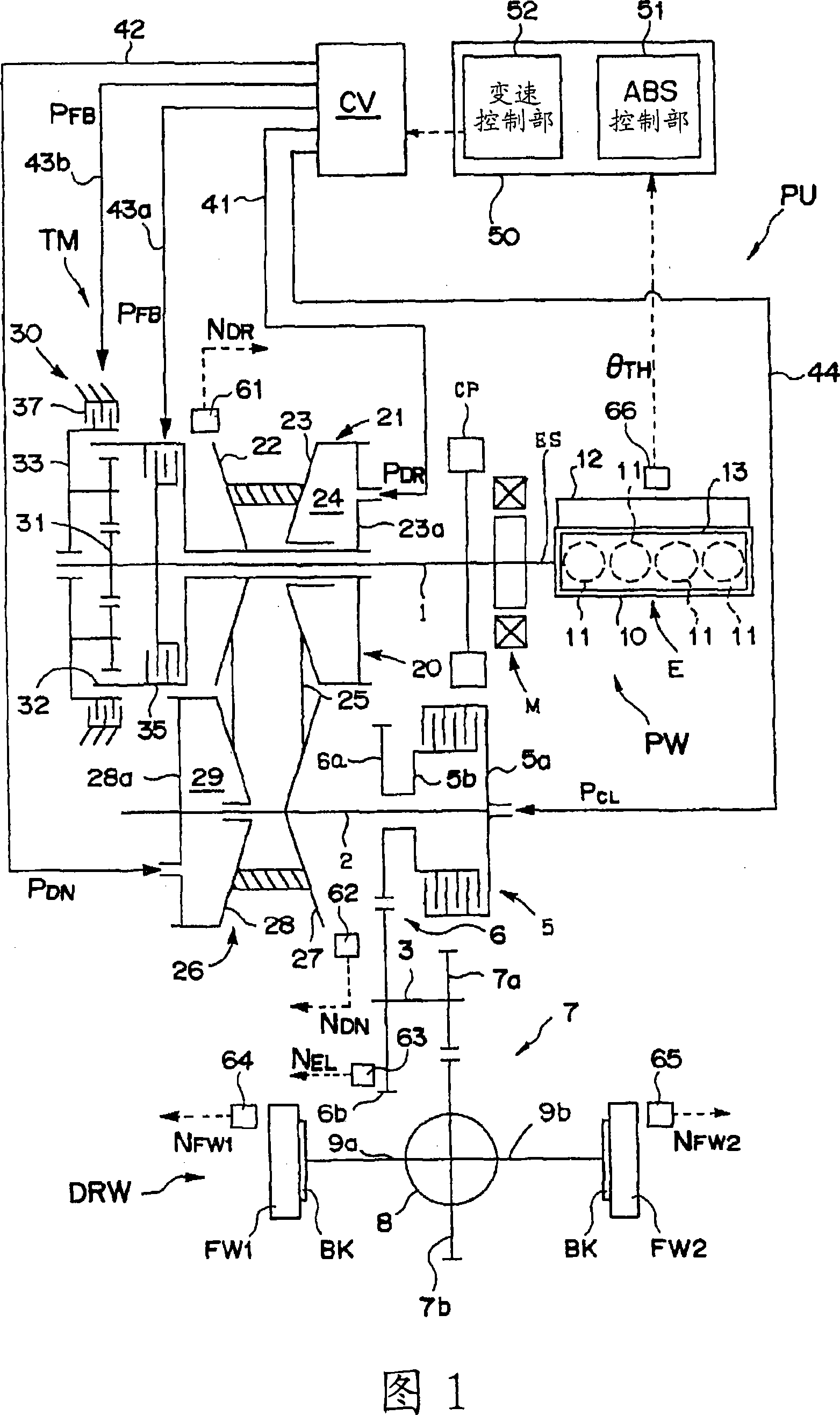

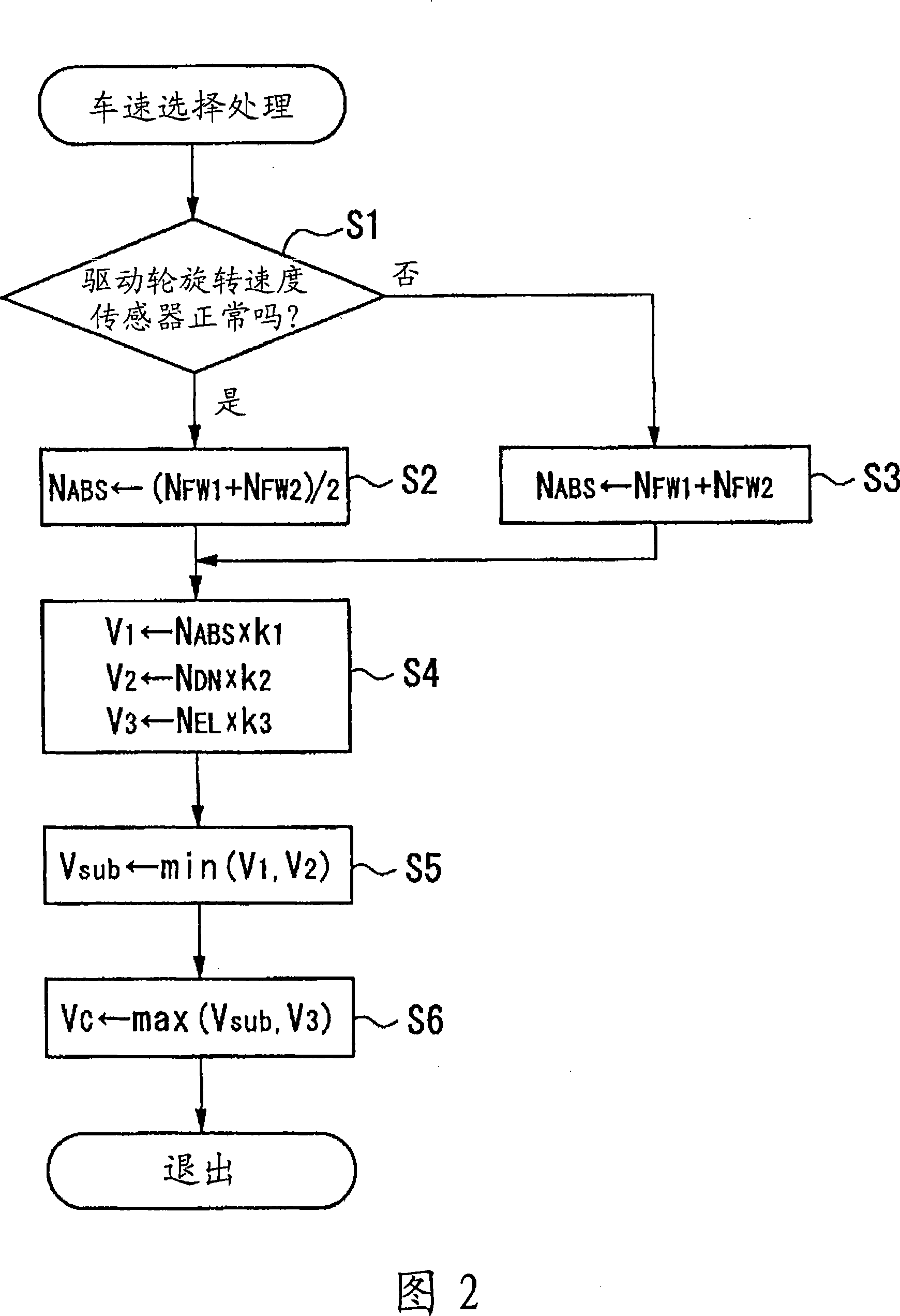

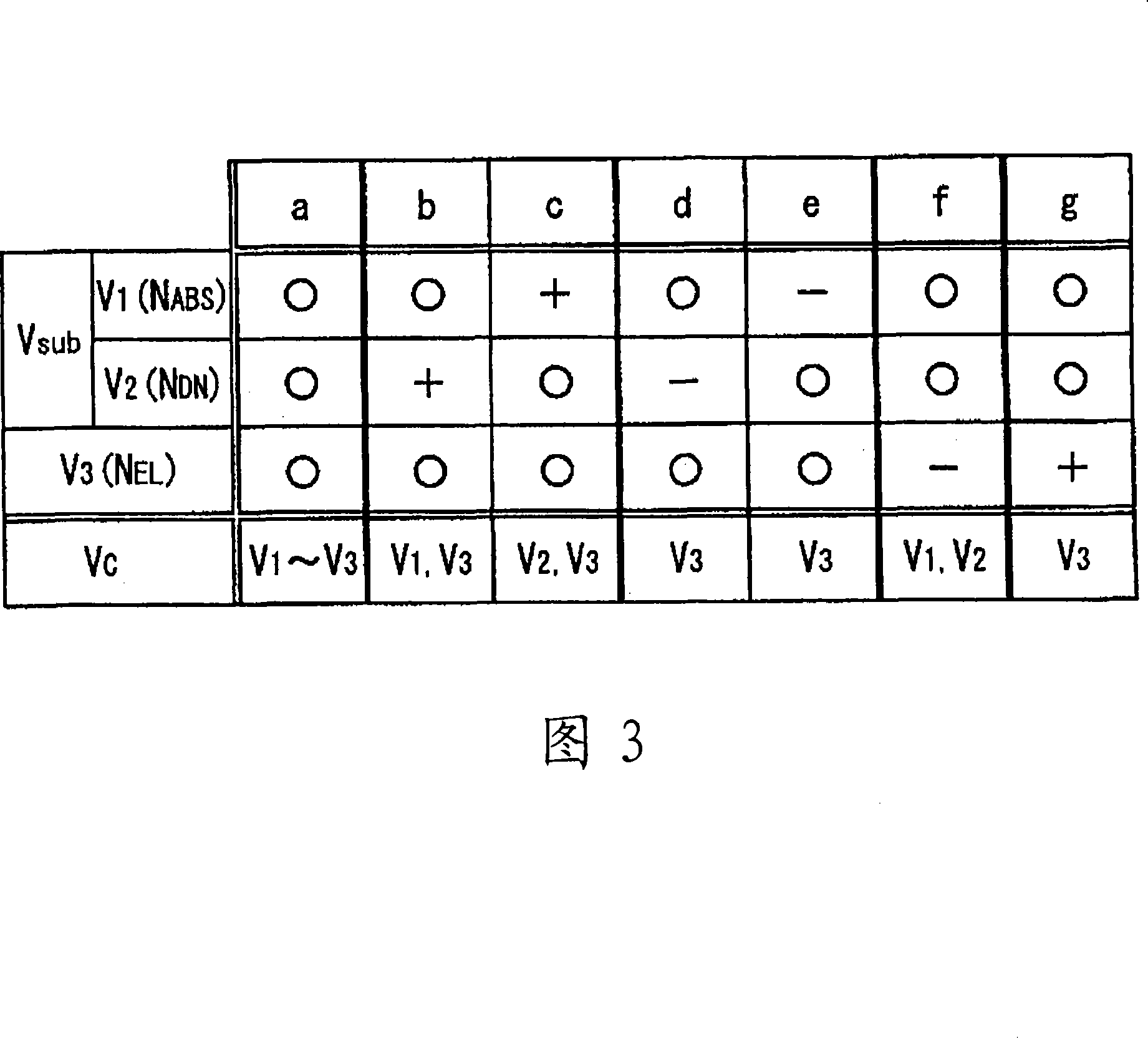

Vehicle stepless transmission

ActiveCN101149108AConsistent rotation speedPreventing Variable Speed Control SituationsGearingGearing controlChange controlClutch

A speed change control device carries out speed change control of a stepless speed change mechanism in accordance with the vehicle speed. The speed change control device includes: first vehicle speed selection means for comparing a first vehicle speed obtained from the rotation speed of an output member (26) of the stepless speed change mechanism and a second vehicle speed obtained from the rotation speed of the wheels and for selecting the lower of the first and second vehicle speeds as the substitute vehicle speed; and second vehicle speed selection means for comparing the third vehicle speed obtained from the output side rotation speed of a clutch mechanism and the substitute vehicle speed, and for selecting the higher of the third vehicle speed and the substitute vehicle speed as the control vehicle speed. The control vehicle speed is used as the vehicle speed V for carrying out speed change control.

Owner:HONDA MOTOR CO LTD

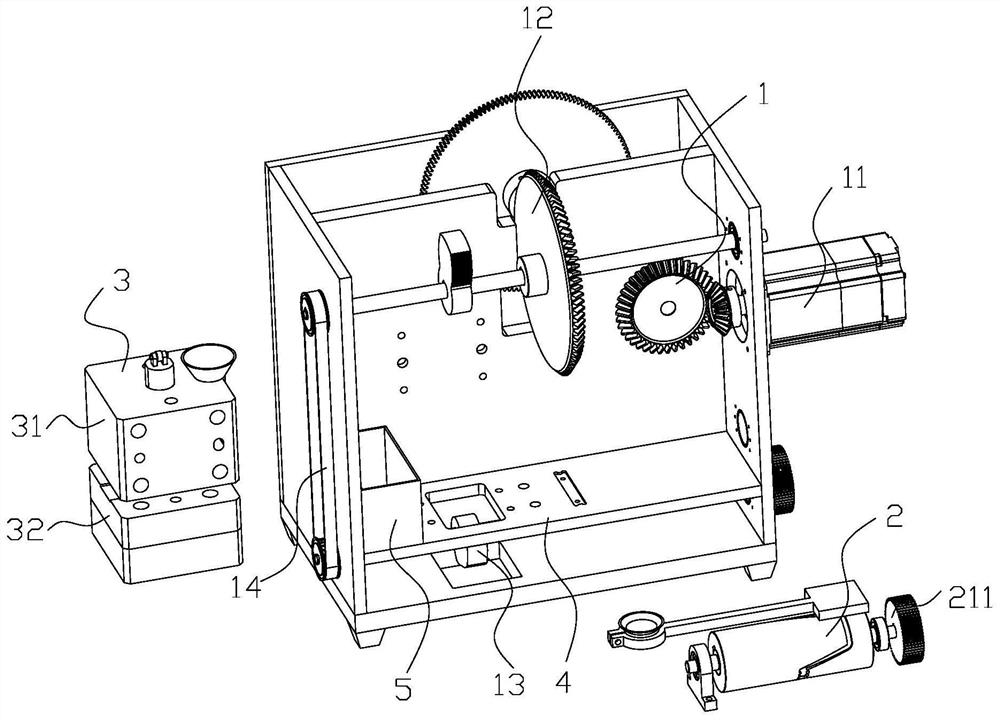

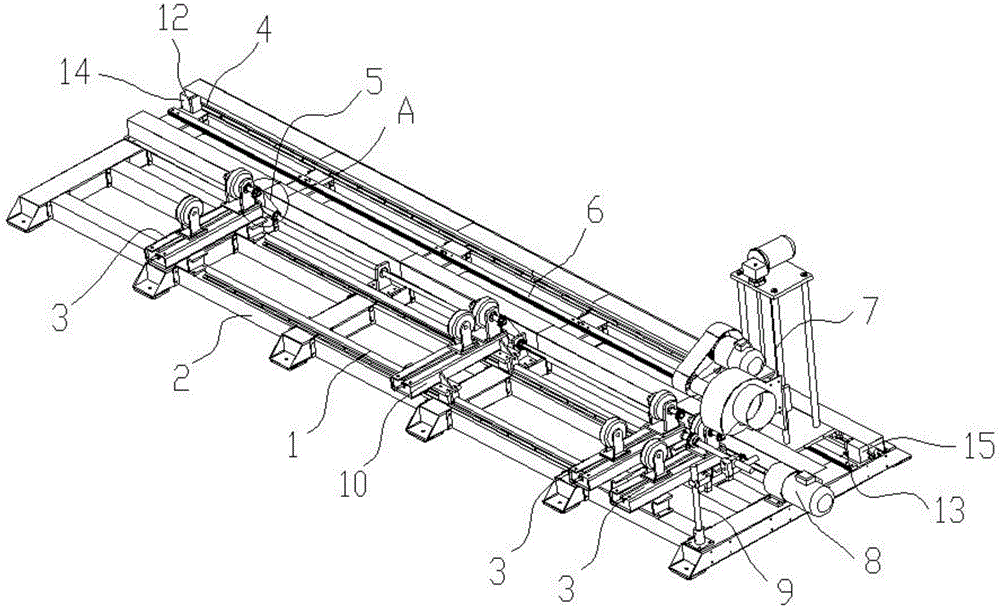

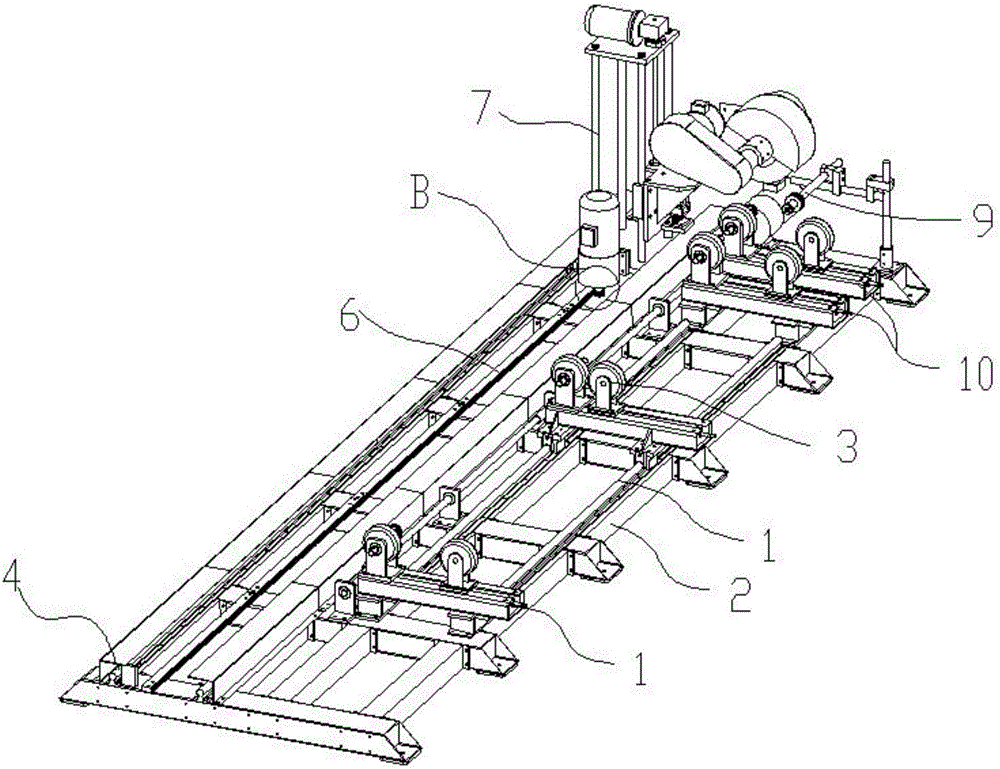

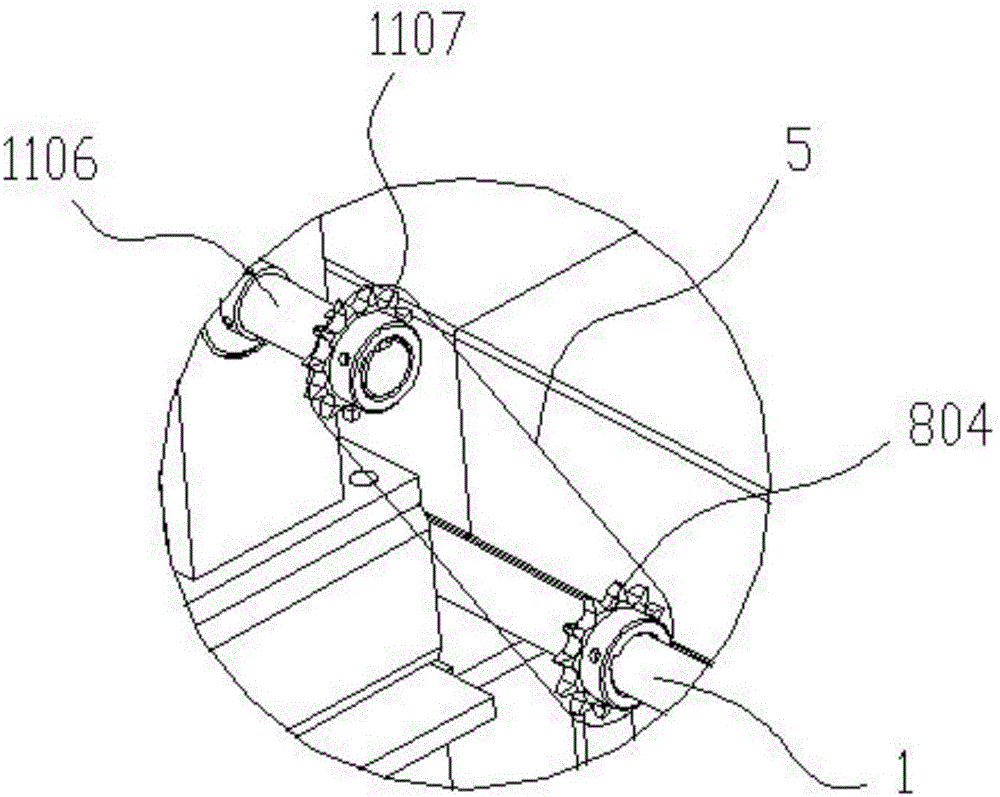

Precise and adjustable round tube automatic polishing machine

ActiveCN106002586ASolve cumbersome functionsImprove processing efficiencyGrinding carriagesPolishing machinesAgricultural engineering

The present invention discloses a precise and adjustable round tube automatic polishing machine, and belongs to the field of workpiece polishing technology. The precise and adjustable round tube automatic polishing machine comprises a first group of crosswise double rails, a pedestal, fixed roller mechanisms, a second group of crosswise double rails, chains, a rack, a grinding head assembly, a transmission assembly, a limiting assembly, mobile roller mechanisms, roller mechanisms, a first baffle plate, a second baffle plate, a first travel switch and a second travel switch. The precise and adjustable round tube automatic polishing machine provided by the invention can be adjusted properly according to diameters and lengths of different round tubes, is excellent in polishing efficiency and consistency, and can automatically absorb dust, protective measures of motors are also enhanced, and thus the service life of equipment is raised.

Owner:岳阳高澜节能装备制造有限公司

Linked cam welding tool

InactiveCN108942046AConsistent rotation speedAvoid inconsistent qualityWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceCam

The invention discloses a linked cam welding tool which comprises a welding platform. The welding platform comprises a base plate, a fixed plate and a bearing plate, the fixed plate is fixedly provided with a motor and a rotary positioning clamp which are in transmission through gear engagement, a positioning rod is fixedly arranged on the outer circle face of the right side of the rotary positioning clamp, a travel switch is arranged on the fixed plate through bolt connection and is triggered by the positioning rod, the included angle at the trigger position of the travel switch is 135 degrees, a compression device is fixedly arranged on the left side of the welding platform, a welding gun is arranged on the exterior of the welding platform through a welding gun clamping mechanism, and alinked cam is arranged on the rotary positioning clamp. In the using process, the rotary positioning clamp is used for fixing the linked cam, the bearing plate and the compression device are used forconducting assistant positioning, and the welding position accuracy is guaranteed when the linked cam is welded. The linked cam welding tool has the advantages that positioning is accurate, the welding quality is high, and manual work is saved.

Owner:河南共创知识产权代理有限公司

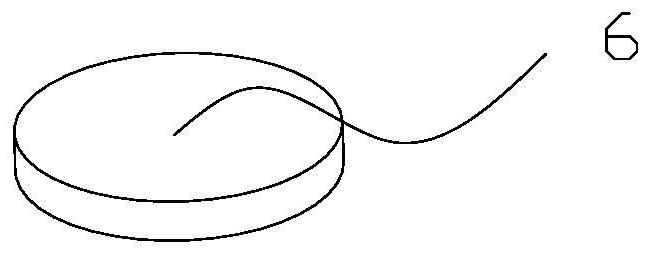

A kind of polysulfone nanofiber separator for lithium battery and preparation method thereof

The invention relates to a polysulfone nano-fiber diaphragm for a lithium battery and a preparation method of the polysulfone nano-fiber diaphragm, and belongs to the technical field of lithium battery diaphragms. The polysulfone nano-fiber diaphragm for the lithium battery is prepared by the steps of dissolving one or more polysulfones with any proportion in a polar organic solvent and then performing electrostatic spinning. The polysulfone nano-fiber diaphragm is characterized in that the thickness is 10-50Mum, the diameter is 100-300nm, the elongation at break is 15-25%, the thermal decomposition temperature is 250-350 DEG C, the porosity is 20-90%, the mechanical tensile strength is 15-20MPa, and the electric breakdown strength is 1*107-1.5*107v / m. The polysulfone nano-fiber diaphragm for the lithium battery has the advantages of resisting to tearing, thermal contraction, high temperature and high-voltage large-current overcharge (electricity), and also has good homogeneity and high porosity.

Owner:DONGFANG ELECTRIC CORP LTD

Circuit board conveying structure and electroplating equipment

PendingCN109941751AAvoid wrinklesUniform thicknessElectrolysis componentsConveyorsEngineeringOperating speed

The invention provides a circuit board conveying structure. The circuit board conveying structure comprises a first transmission mechanism, a second transmission mechanism, at least one clamp, at least one material clamp and a driving mechanism, wherein the first transmission mechanism and the second transmission mechanism are arranged in parallel in the vertical direction; the at least one clampis arranged on the first transmission mechanism, is used for clamping the upper end of a circuit board and can be driven by the first transmission mechanism to move synchronously with the first transmission mechanism; the at least one material clamp is arranged on the second transmission mechanism and under the corresponding clamps, is used for clamping the lower end of the circuit board, and canbe driven by the second transmission mechanism to move synchronously with the second transmission mechanism, and the operating speed of the clamps are the same as that of the material clamps; and thedriving mechanism is connected with the first transmission mechanism and the second transmission mechanism and drives the first transmission mechanism and the second transmission mechanism to move synchronously. By means of the circuit board conveying structure, the lower end of the circuit board does not lag behind the upper end of the circuit board, and the board surface of the circuit board isprevented from being wrinkled in the conveying process.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

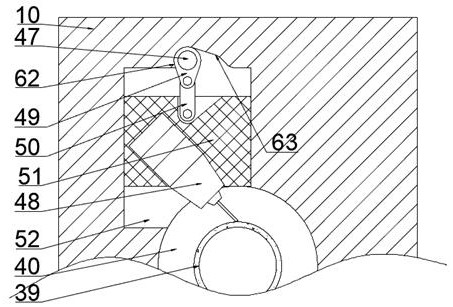

Traditional Chinese medicine tablet transferring mechanism and method

InactiveCN112238647AConsistent rotation speedGuaranteed uniformitySievingScreeningProcess engineeringTransfer mechanism

The invention belongs to the technical field of traditional Chinese medicine pharmaceutical production, and relates to a traditional Chinese medicine tablet transferring mechanism and method. The mechanism comprises a driving device and a traditional Chinese medicine tablet transferring device; the traditional Chinese medicine tablet transferring device comprises a transferring rotating shaft, a transferring cam, a transferring clamping rod and a traditional Chinese medicine tablet vibrating screen; the right end of the transferring rotating shaft penetrates through a rack and is connected with a transferring driven gear; the transferring driven gear is matched with a lower driving module; the transferring cam sleeves the transferring rotating shaft; a transferring motion rail is arrangedon the transferring cam; the transferring clamping rod is horizontally arranged, a vibrating screen limiting sleeve is arranged at the left end of the transferring clamping rod, and the traditional Chinese medicine tablet vibrating screen is located in the vibrating screen limiting sleeve; a rail matching rod is arranged at the bottom of the right end of the transferring clamping rod; the bottom of the rail matching rod is located on the transferring motion rail; and the rail matching rod moves on the transferring motion rail to enable the transferring clamping rod to horizontally transfer. The mechanism has the advantages that the traditional Chinese medicine tablet transferring efficiency and precision are improved, and the phenomenon that traditional Chinese medicine tablets are not transferred in place is prevented.

Owner:魏乃淳

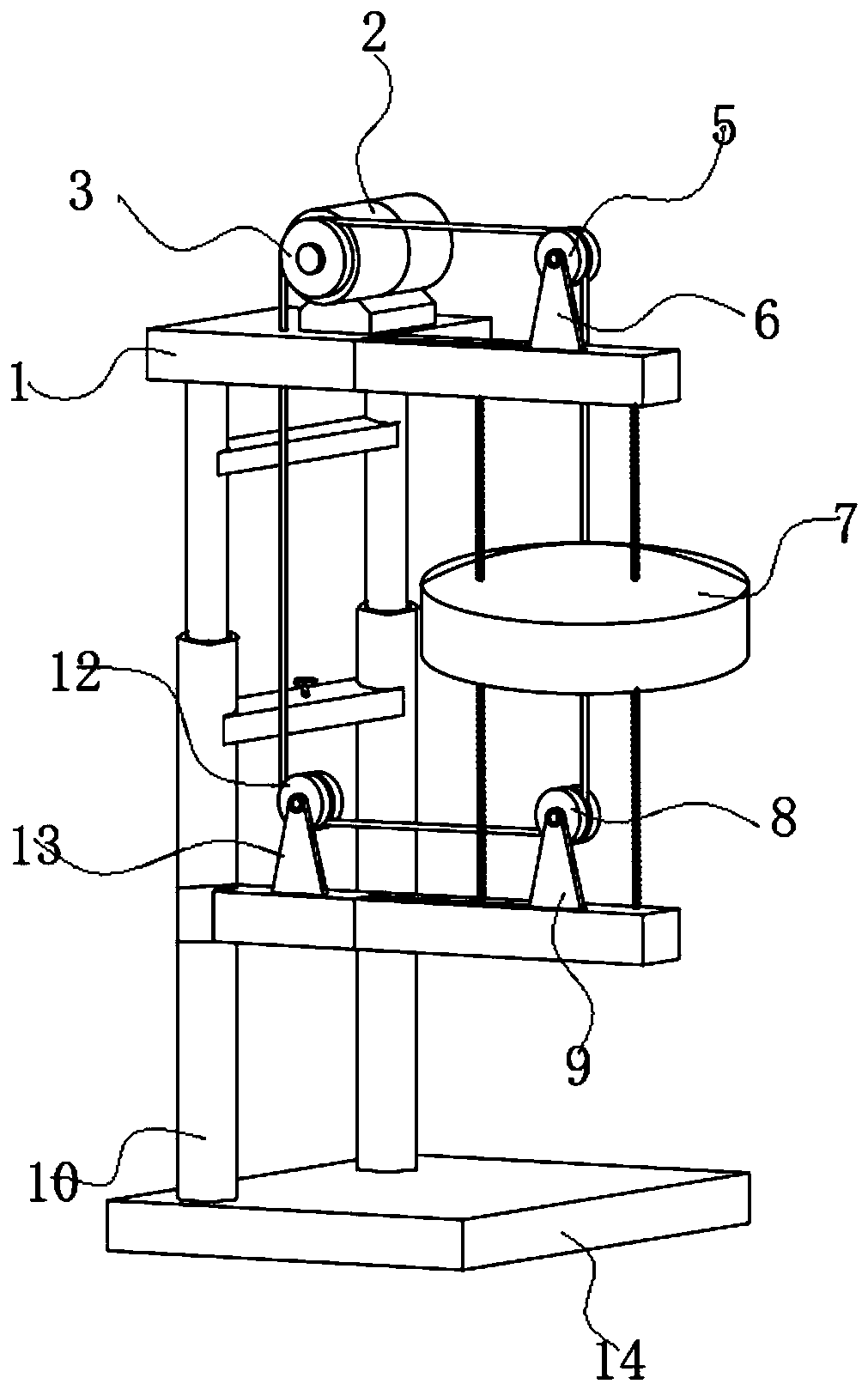

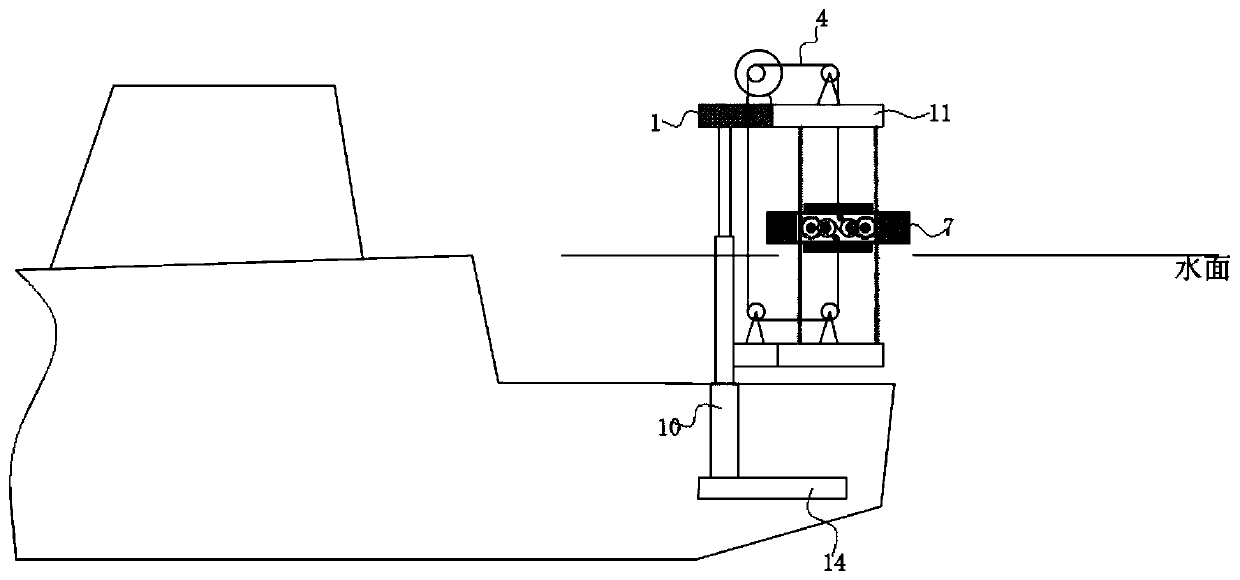

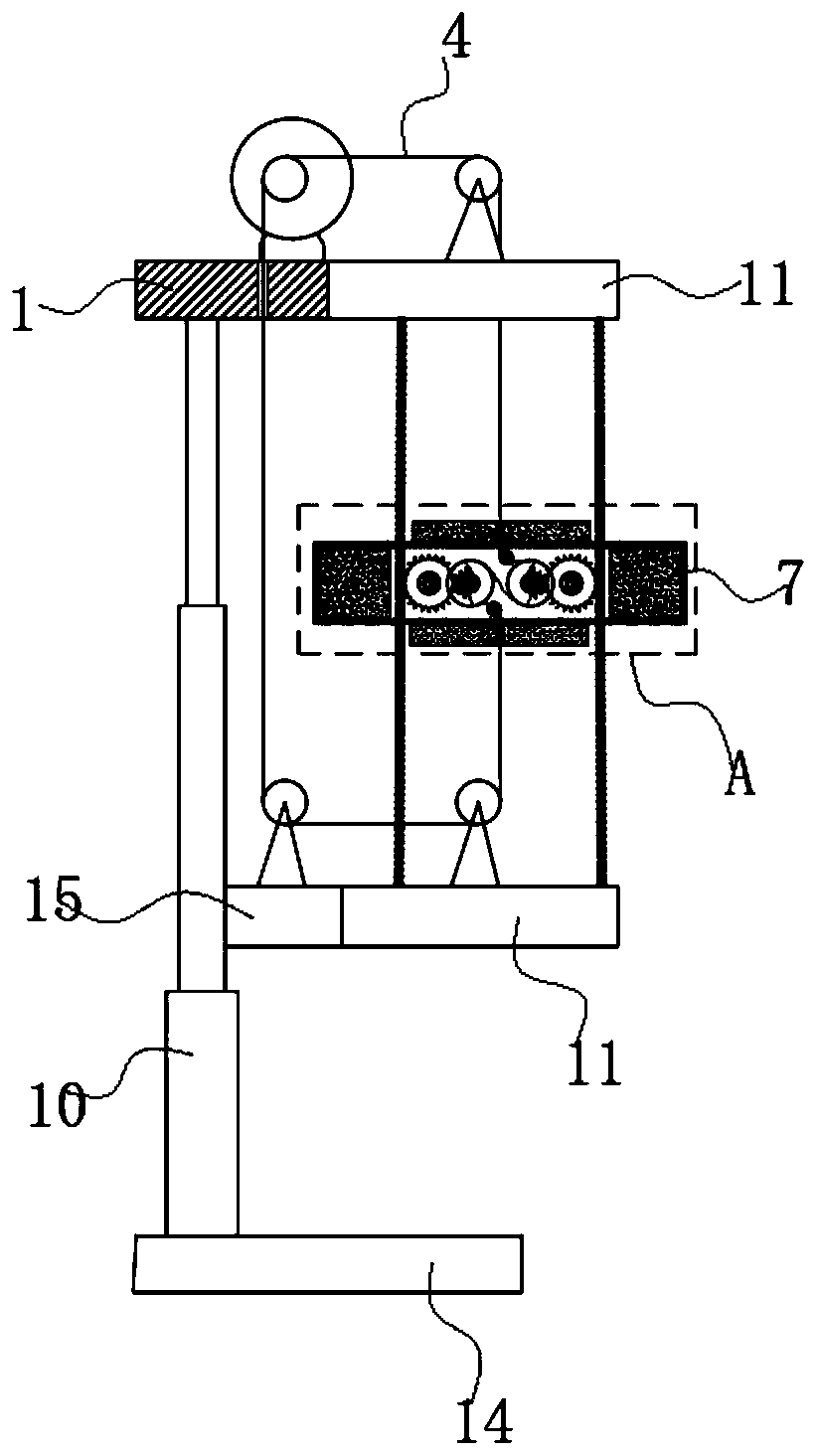

Ship wave energy electricity generating equipment

ActiveCN111336055AImprove stabilityConsistent rotation speedMachines/enginesEngine componentsShip wavesMarine engineering

The invention discloses ship wave energy electricity generating equipment. The ship wave energy electricity generating equipment comprises a top seat, an electric generator, a float assembly and a height regulator. The top seat is fixed to the end of the adjusting end of the height regulator, the height regulator is fixed to a base, and the base is arranged in a ship; and the electric generator isfixed to the upper surface of the top seat, the electric generator is driven by a belt pulley fixed to the input end of the electric generator to rotate to generate electricity, the belt pulley is connected with the float assembly by using ropes, the float assembly is placed on the water surface and can swing up and down with water waves, and then the belt pulley is driven to rotate. In the shipwave energy electricity generating equipment, a transmission structure of a gear arranged in a float seat and a follower wheel can make up the defect of the small amplitude of heaving up and down by using greater heave impact force of the waves up and down, and the overall electric generation efficiency is improved.

Owner:YANCHENG INST OF IND TECH

Measuring method for bearing's integration parameters

InactiveCN106370135AConsistent rotation speedImprove detection efficiencyMeasurement devicesRotation velocityEngineering

The invention discloses a measuring method for bearing's integration parameters, which belongs to the technical field of bearing measurement. The method comprises the following steps: 1) measuring the assembled high value of a to-be-measured bearing; 2) setting the fastest rotation speed of the to-be-measured bearing; 3) measuring the end face jumping and the external diameter's swing value in the same period when the to-be-measured bearing reaches the set rotation speed; and 4) measuring the clearance value of the to-be-measured bearing. According to the invention, without manual rotation or overturn of the bearing, the bearing achieves the consistent rotation speed in every rotation, reaches the rotation speed simulating the real one and realizes the measurement of the clearance, the assembled high value, the end face jumping and the external diameter's swing value of the bearing. With high detection efficiency, accurate detection data can also be obtained.

Owner:DALIAN HUAKONG INDAL EQUIP

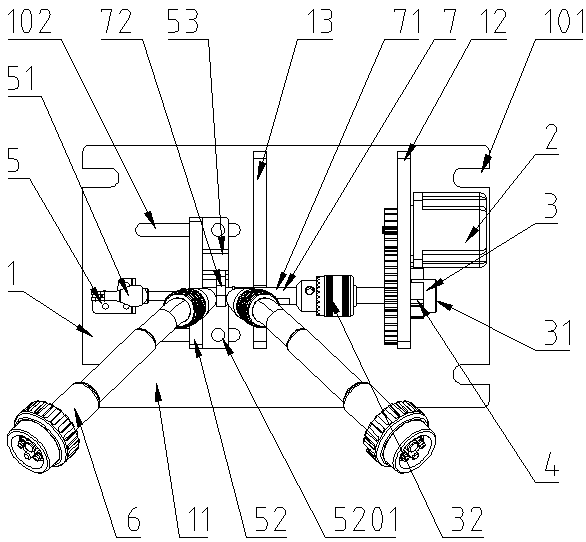

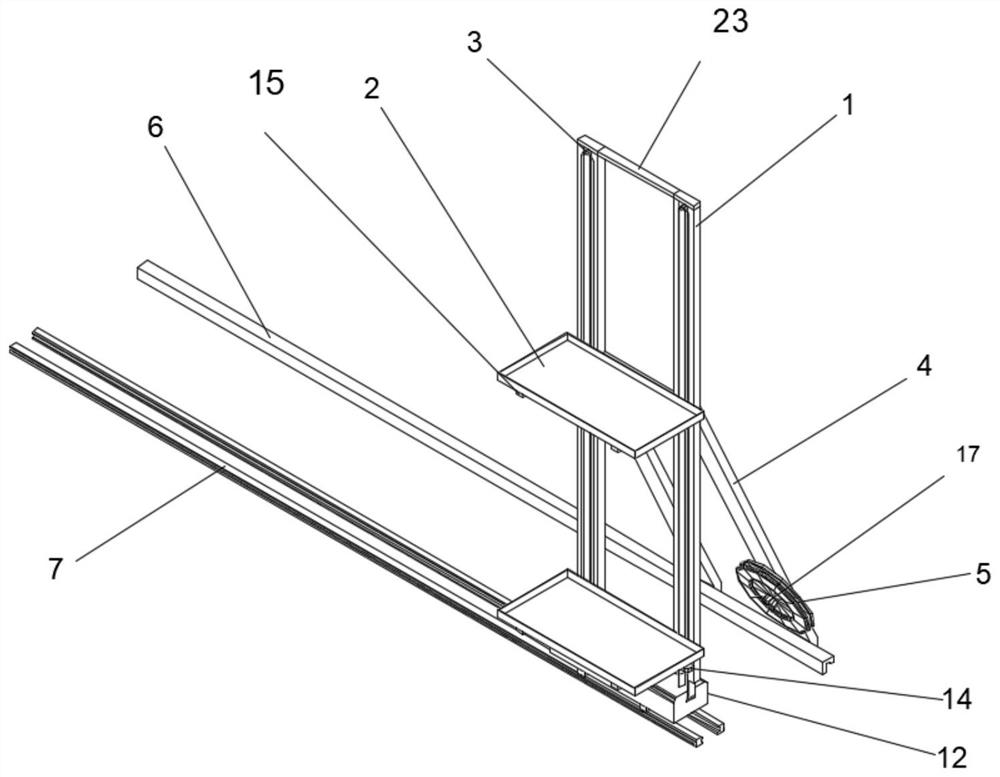

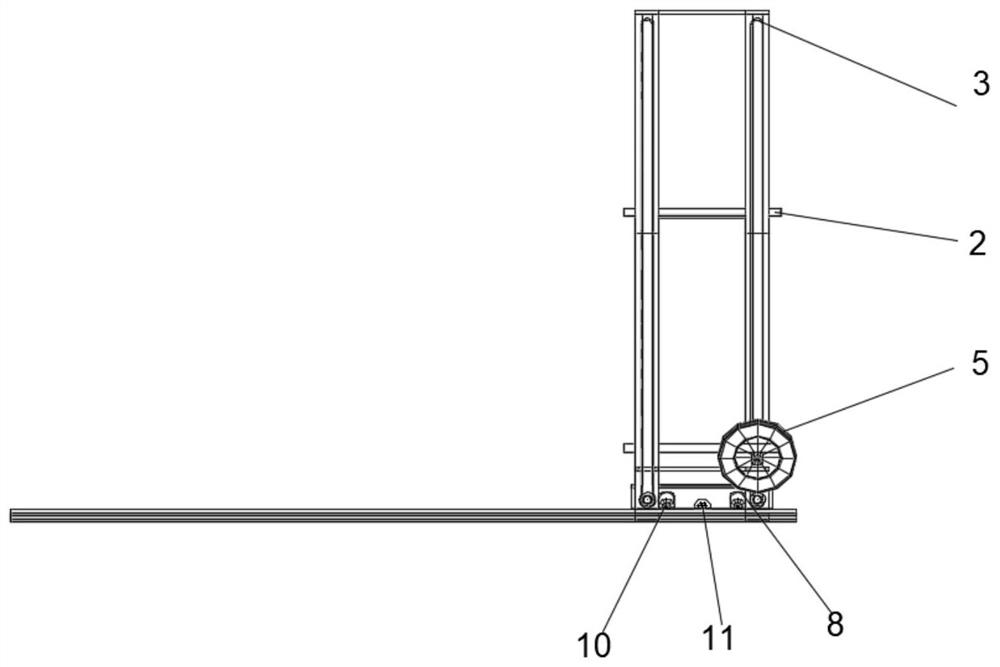

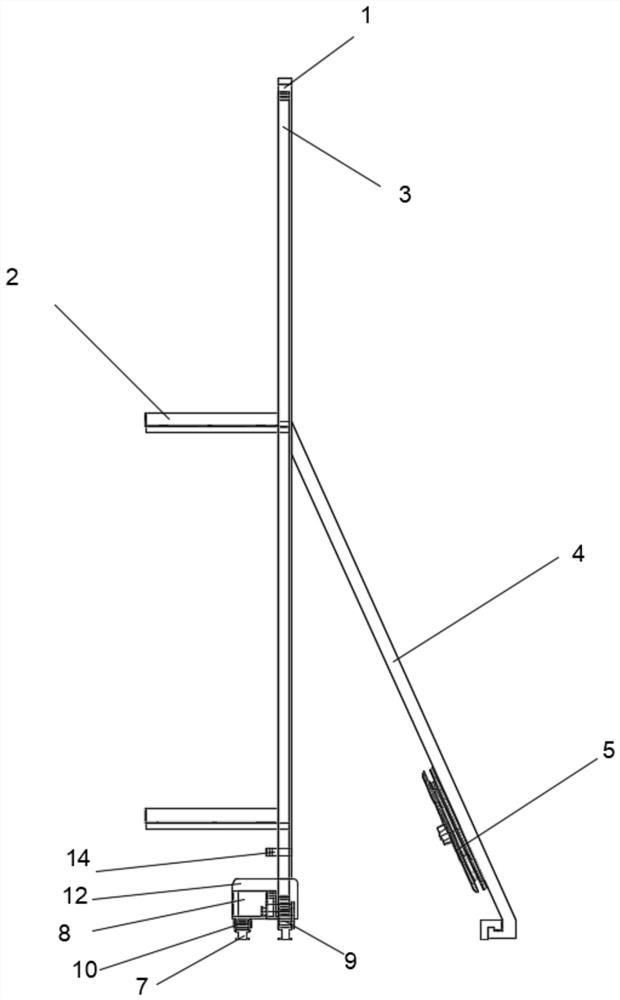

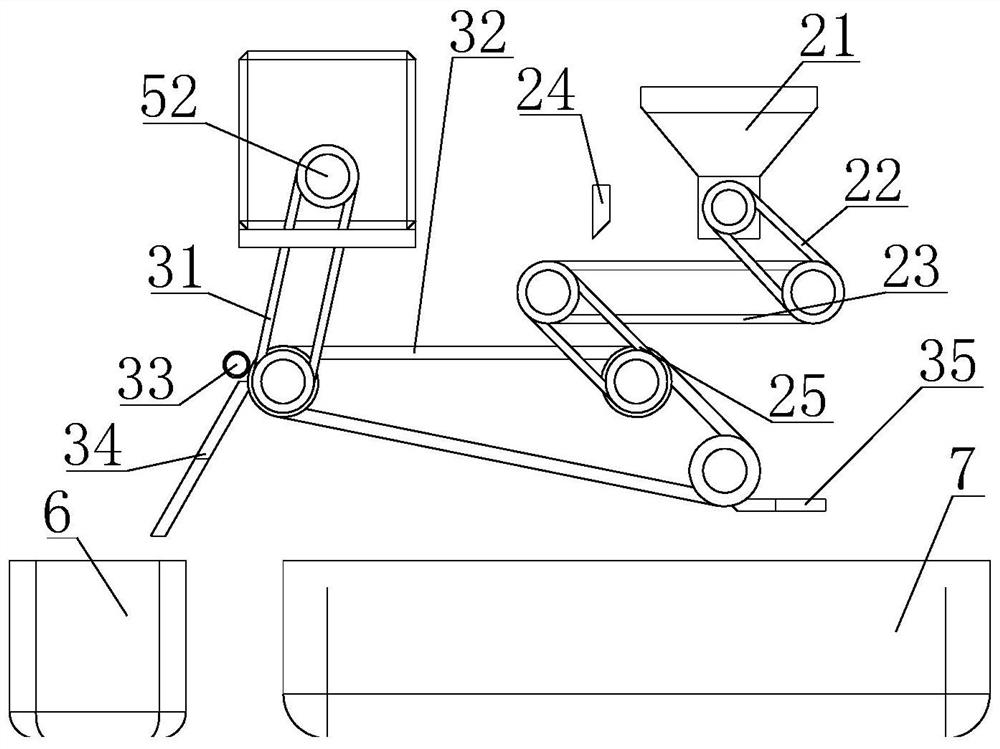

Material conveying device for segmented construction of superstructure

PendingCN113697062AAvoid overall overturningEasy to replaceWaterborne vesselsArchitectural engineeringUltimate tensile strength

The invention discloses a material conveying device for segmented construction of a superstructure. The material conveying device comprises two tray lifting rails and a protective shell, the two tray lifting rails are installed on the upper surface of the protective shell, and the material conveying device further comprises a lifting structure installed on the front portions of the tray lifting rails and used for lifting materials; a moving structure which is mounted at the bottom of the tray lifting track and is used for sliding; a back part which is mounted on the tray lifting track, and a supporting structure is mounted on the back of the tray lifting track and used for supporting, so that the working intensity of field constructors can be greatly reduced, the time for the field constructors to carry materials is saved, the consumption of auxiliary resources such as field truck cranes and forklifts is reduced, and the field segmented construction efficiency is improved.

Owner:上海外高桥造船海洋工程有限公司

Steel belt brush washer

PendingCN109262429AAvoid damageAvoid scratchesCleaning using toolsGrinding machinesElectric machineryDrive motor

The invention provides a steel belt brush washer. The steel belt brush washer comprises a rack, two wringing mechanisms and a brushing mechanism, and the brushing mechanism is arranged between the twowringing mechanisms. The rack is provided with an inlet end and an outlet end, one wringing mechanism is installed at the inlet end, and the other wringing mechanism is installed at the outlet end. The brushing mechanism comprises a first brush roller and a second brush roller; the first brush roller comprises a third installing end and a third transmission end, the second brush roller comprisesa fourth installing end and a fourth transmission end, and the third transmission end and the fourth transmission end extend out of the side wall of the rack and are connected with a driving motor, and the third installing end and the third transmission end are connected with a second air cylinder. Lifting mechanisms are installed on the two side walls of the rack; one lifting mechanism is close to the third transmission end and the fourth transmission end, and the other lifting mechanism is close to the third installing end and the fourth installing end. The steel belt brush washer can effectively avoid that steel belts are scratched, the product yield is improved, and the production cost is reduced.

Owner:SHANDONG HONGWANG INDUSTRY CO LTD

Lifting socket

ActiveCN108110487AEasy to plug in at the same timeAchieve electrical connectionCouplings bases/casesTransformerPower strip

The invention discloses a lifting socket comprising a power strip body, a power line and a plug body. The power strip body comprises a housing. The top of the housing is provided with three square openings arranged in a straight line. A pair of separating plates vertically arranged in parallel divide the interior of the housing into three cavities. Each opening is located above the corresponding cavity. The separating plates have through holes for the power line to pass through. Any cavity is provided therein with a power strip unit which includes: an electrical component box, a pair of lead screw and lead screw nut pairs, and a gear assembly. The lifting socket can adjust the height of the electrical component box, staggers the multiple groups of sockets, facilitates the simultaneous plugging of the transformer plugs of multiple electrical appliances, and has the advantages of simple structure and high promotion value.

Owner:广西南宁英凡达科技有限公司

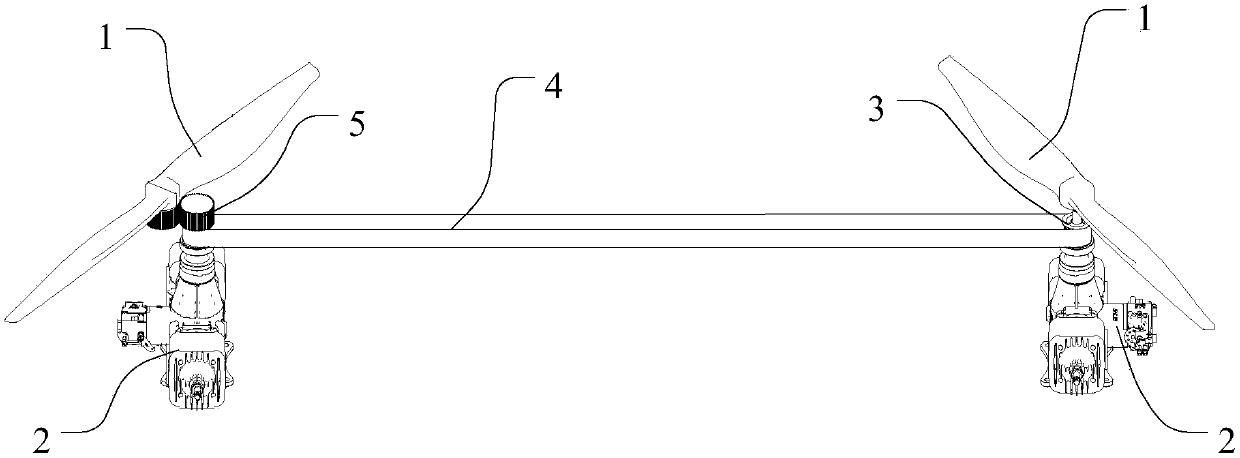

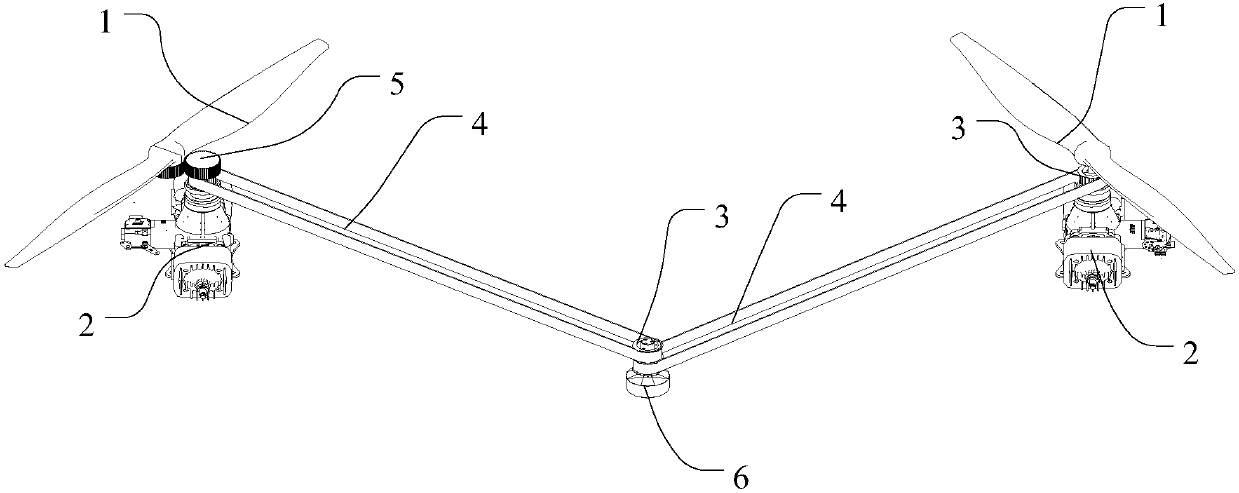

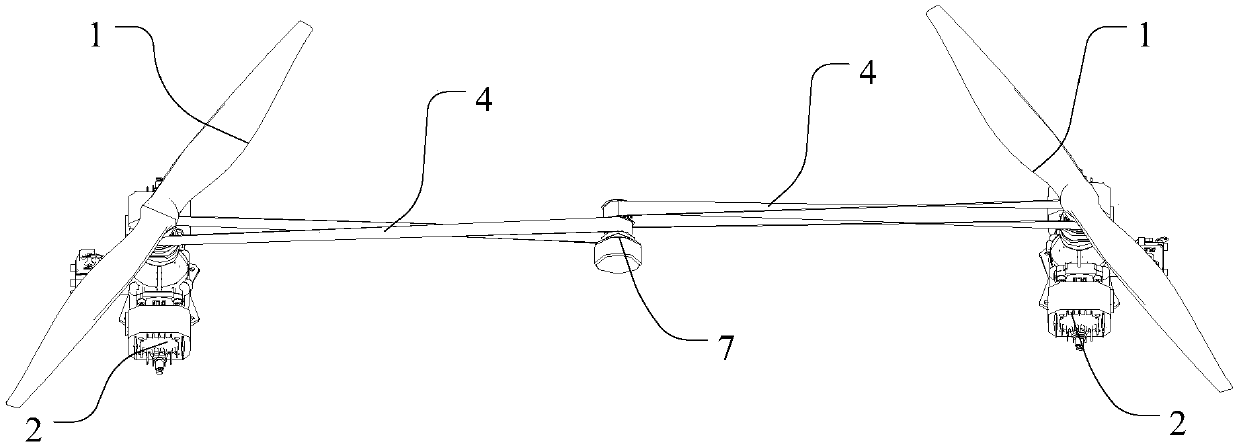

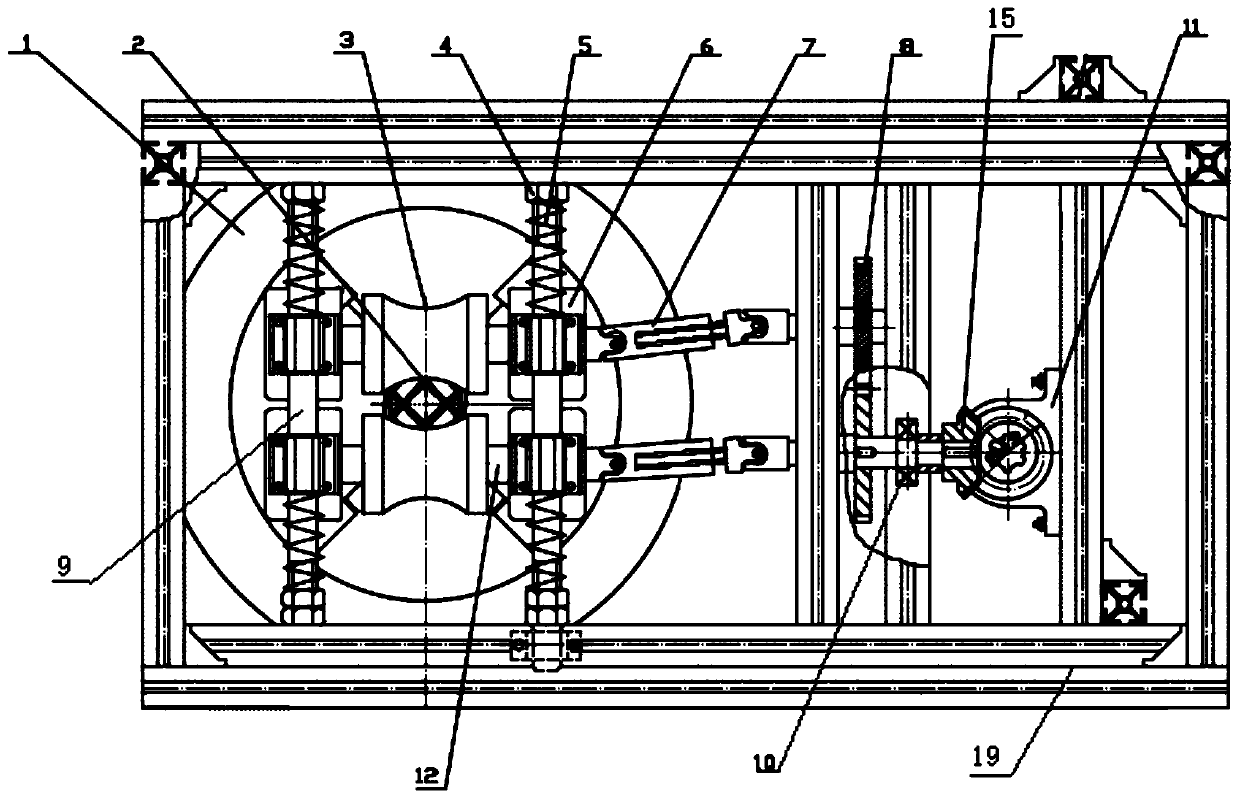

Synchronization mechanism of unmanned aerial vehicle power rotor wings and unmanned aerial vehicle

ActiveCN108045586AConsistent rotation speedHigh precisionDepending on number of power plantsDepending on number of propellersMotor driveRotary wing

Owner:SHENZHEN QIKER INTELLIGENT TECH CO LTD

Cassava peeler

PendingCN110870582ARealize automatic deliveryAchieve peelingVegetable peelingElectric machineryStructural engineering

The invention discloses a cassava peeler. The cassava peeler comprises a frame, a conveying device, cutters and a motor, the frame is a frame structure, the motor is arranged on the frame, the conveying device comprises four conveying arms, the conveying arm comprises rollers, the two rollers in each conveying set are coaxially connected to a roller shaft, the roller shaft penetrates through the rollers and extends out of the two ends of the rollers, the two ends of the roller shaft are provided with first bearing pedestals, the first bearing pedestal is connected to the frame through a firstelastic piece, the front end of the roller shaft is hinged with a motor output shaft, the cutter is located between the two conveying sets and comprises a cutter rest and a plurality of cutter handleshafts, the cutter rest is fixed in the frame, the tail ends of the cutter handle shafts are connected to the cutter rest through second elastic pieces, and the cutter is arranged at the front end ofeach cutter handle shaft. Automatic cassava peeling processing is achieved, the working efficiency is improved, the labor cost is reduced, and the current situation that cassava peeling is difficult to process is solved.

Owner:SHAANXI UNIV OF SCI & TECH

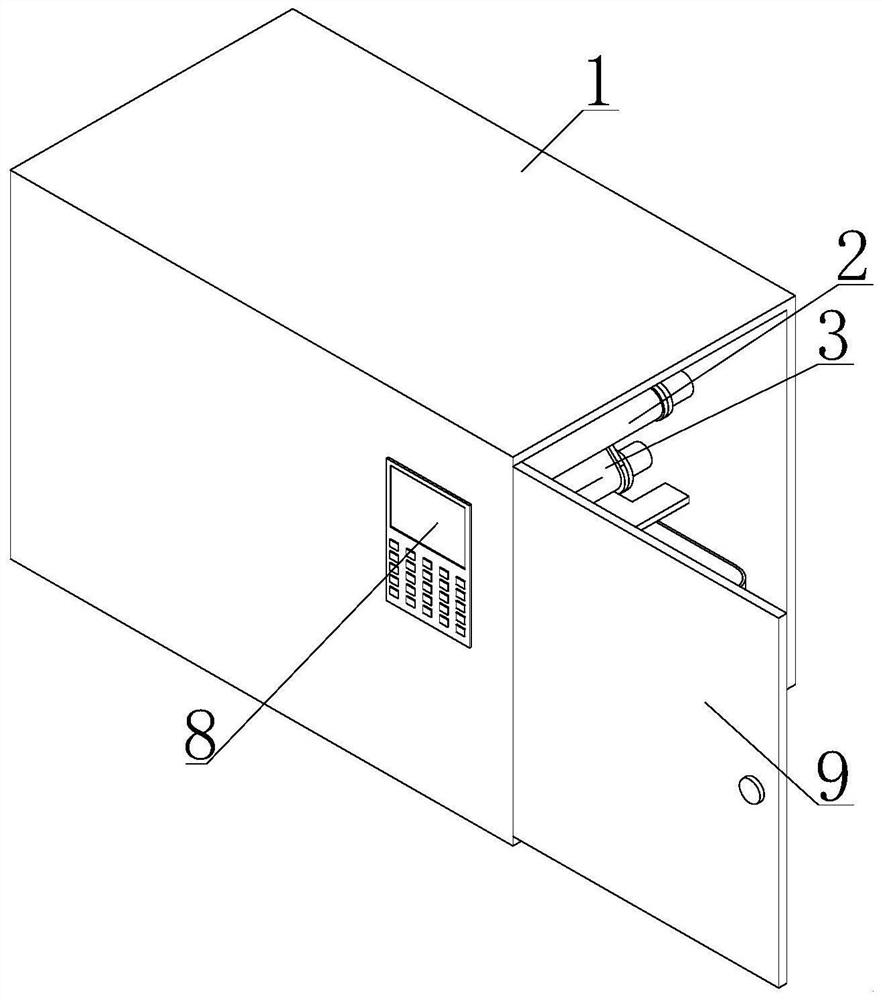

Silk quilt processing and forming device

InactiveCN112458547AHigh degree of automationImprove work efficiencySilk filament obtainingMechanical engineeringManual handling

The invention discloses a silk quilt processing and forming device, and relates to the technical field of silkworm cocoon processing. The silk quilt processing and forming device comprises a dust isolation box cover; a movable door is movably connected to the position, close to the right side, of the outer wall of the dust isolation box cover; a control panel is arranged at the position, close tothe front face, of the outer wall of the dust isolation box cover; the outer wall of the control panel is movably connected with the outer wall of the movable door through the arranged dust isolationbox cover; and a feeding device is fixedly connected to the position, close to the top end, of the inner wall of the dust isolation box cover. According to the silk quilt processing and forming device, silkworm cocoons do not need to be evenly added and laid manually, so that more time and labor are saved; while manual operation is reduced, the cocoon silk reeling efficiency is improved; while theidle time of the device is shortened, manual operation can be reduced; while the production efficiency is improved, the product quality is improved; and the device is relatively suitable for mass production in factories.

Owner:胡长凤

Bag mouth guide device preventing falling of bag mouth

Owner:合肥博创智能包装设备有限公司

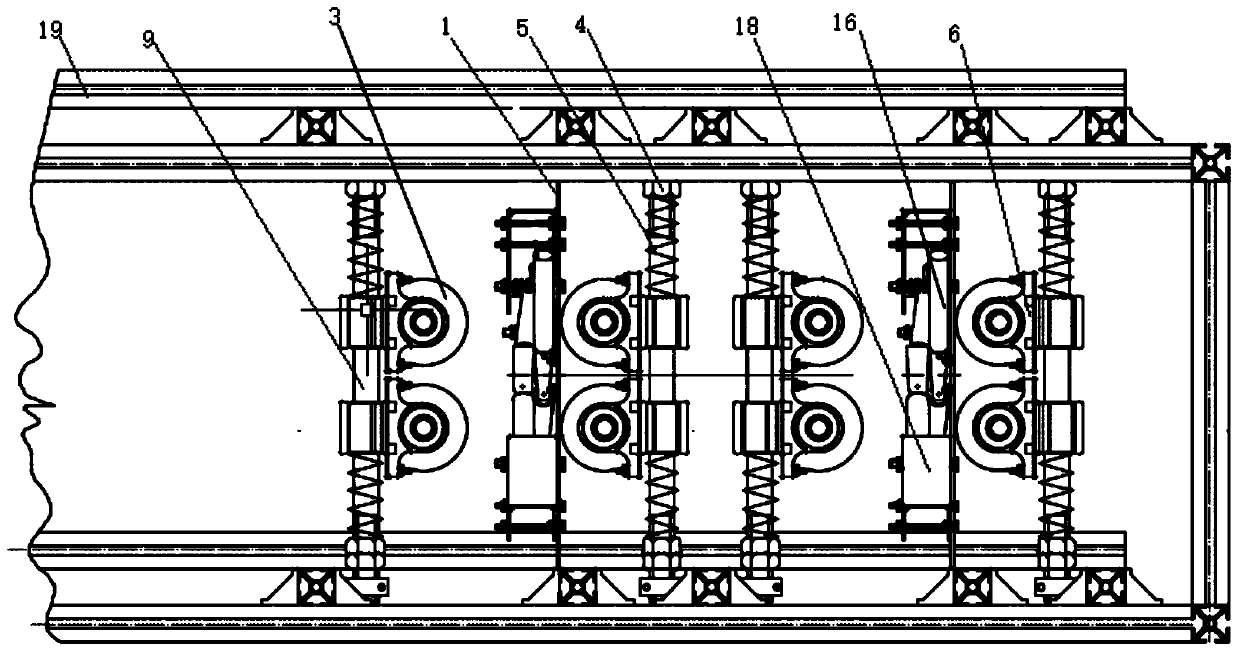

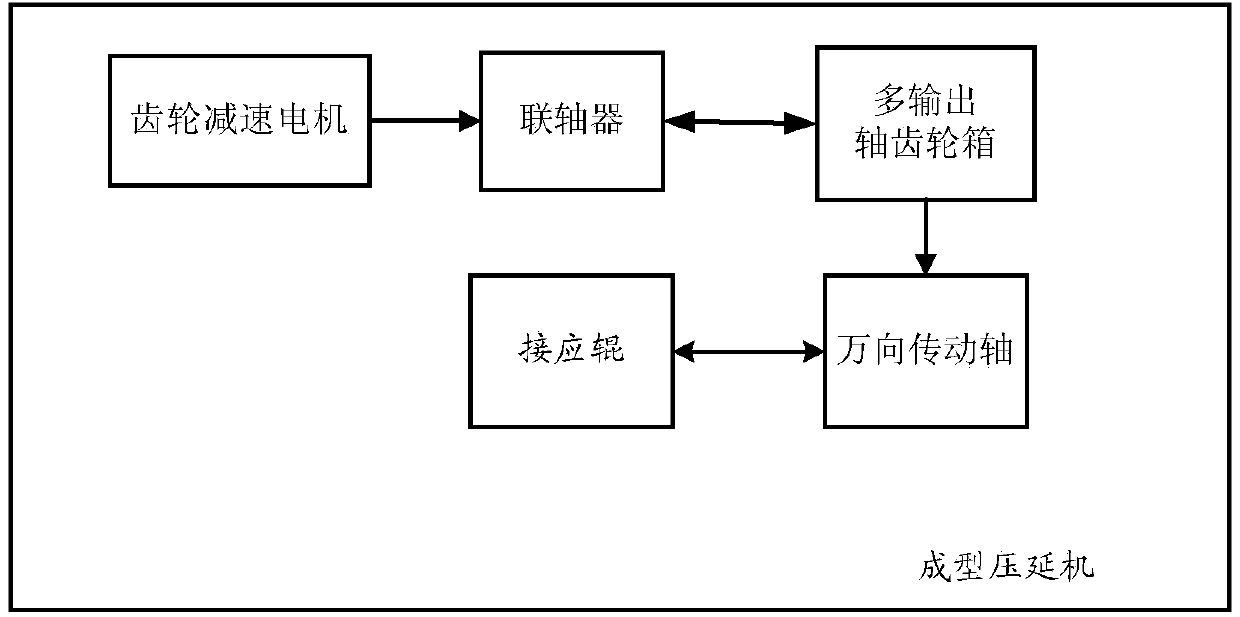

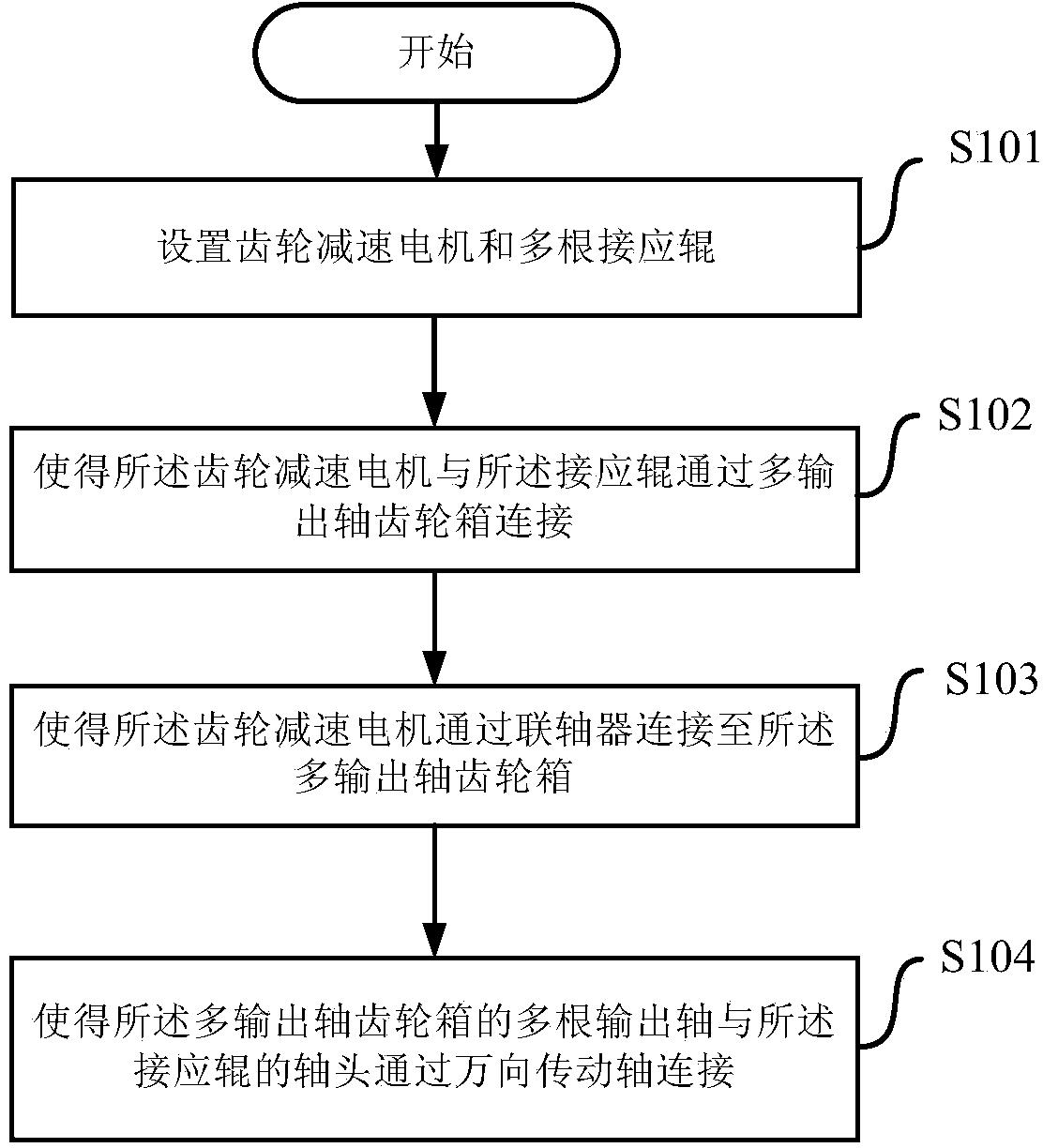

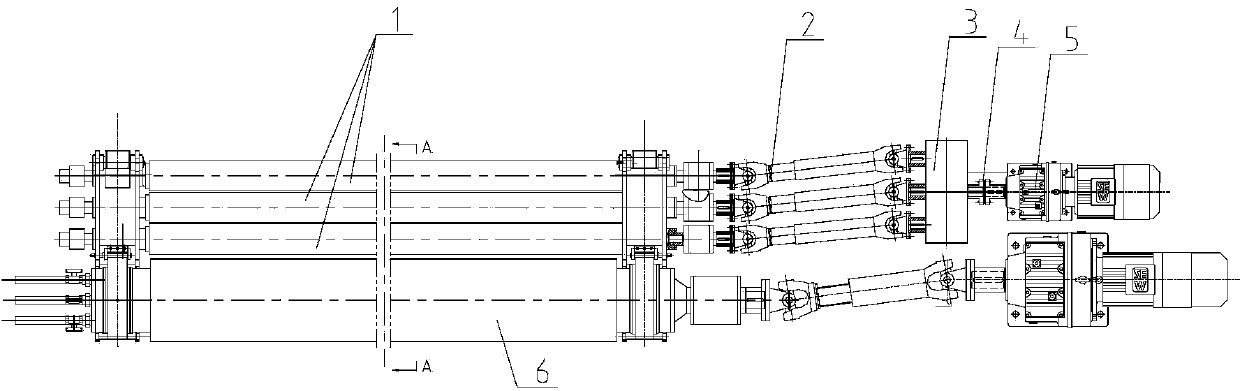

Plate glass forming calender and driving method for reinforcing rollers of plate glass forming calender

The invention discloses a plate glass forming calender. The calender comprises a gear reducing motor and a plurality of reinforcing rollers, wherein the gear reducing motor is connected with the reinforcing rollers through a multi-output-shaft gear box. According to the plate glass forming calender and a driving method for the reinforcing rollers of the plate glass forming calender, disclosed by the invention, the reducing motor is directly connected with the multi-output-shaft gear box, so that no speed difference exists between the reducing motor and the multi-output-shaft gear box; input shafts and output shafts of the multi-output-shaft gear box are driven by gears, so that the operating stability of the output shafts is ensured, and the input shafts and the output shafts are kept to be same in rotating direction and small in speed difference; the multi-output-shaft gear box is connected with the reinforcing rollers through universal driving shafts, so that the speeds of the reinforcing rollers are kept to be consistent with the speeds of the output shafts of the multi-output-shaft gear box.

Owner:CHINA TRIUMPH INT ENG

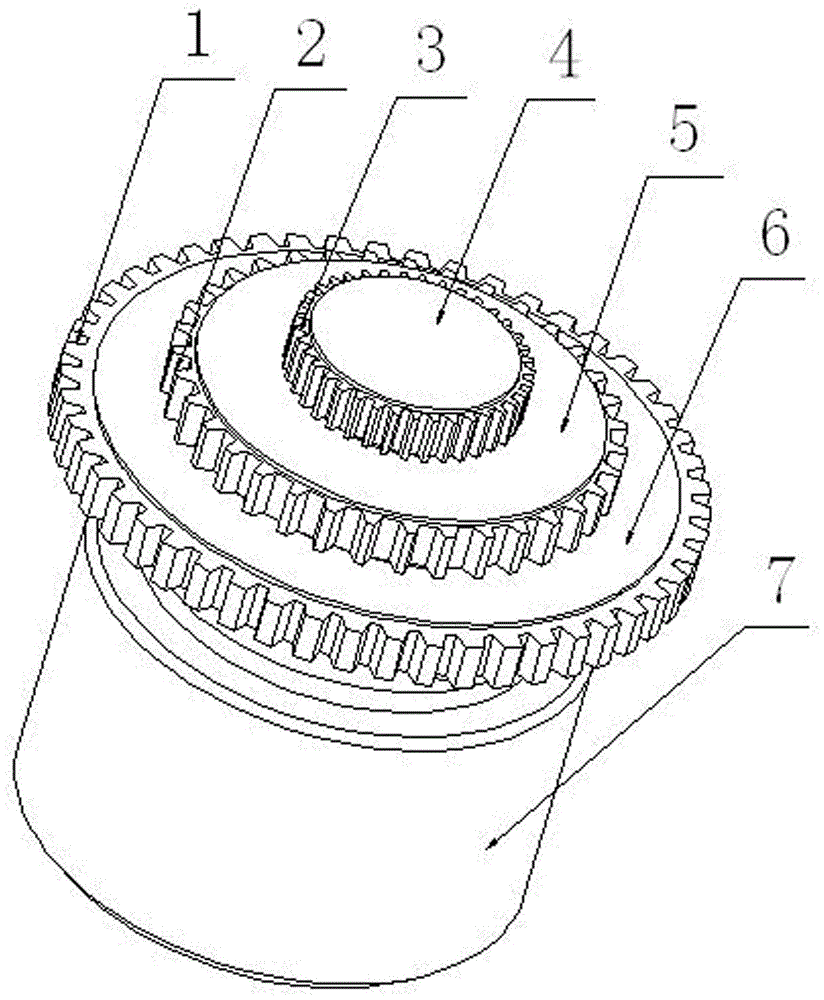

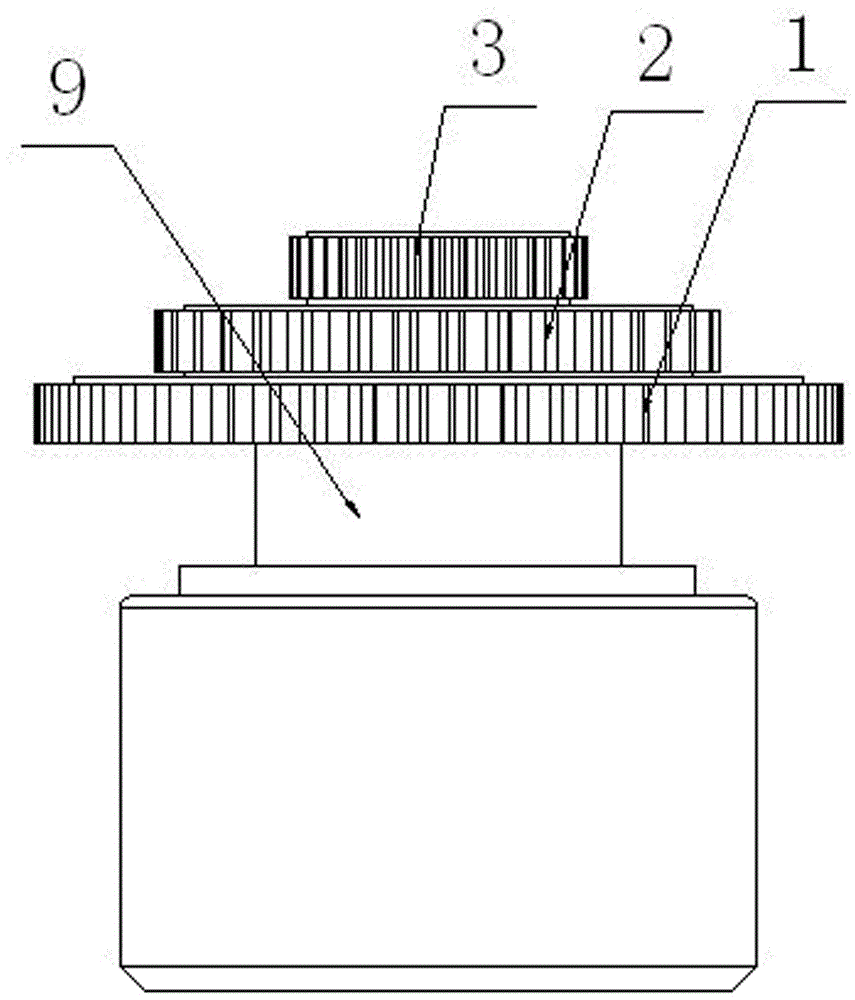

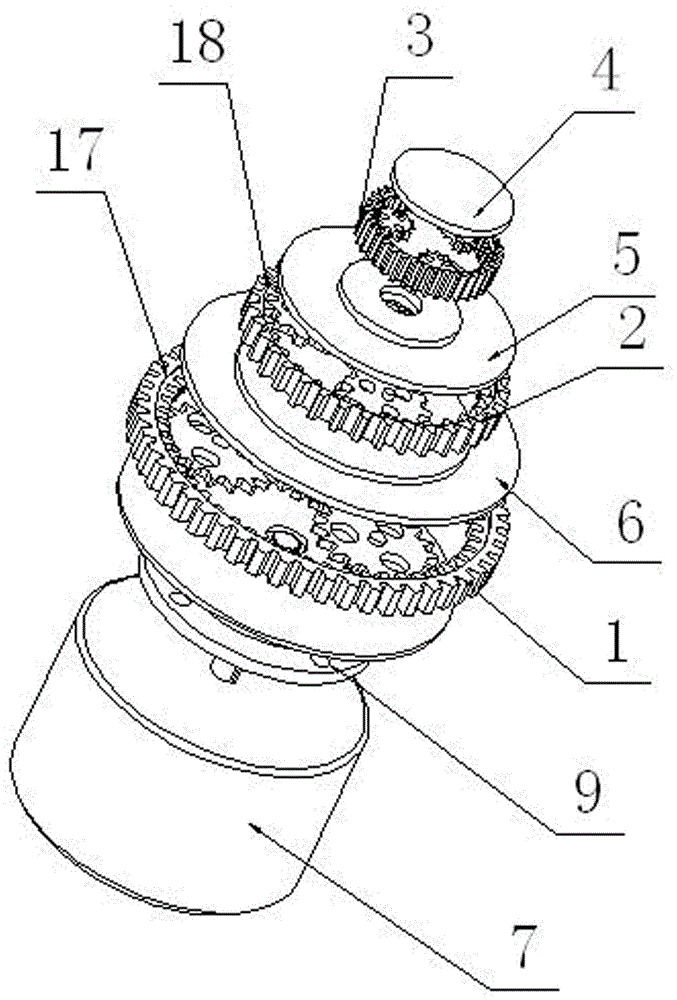

Speed change gear of automatic skin cleaning bath instrument

ActiveCN105782360ASame rotation speedConsistent rotation speedBathroom accessoriesToothed gearingsSkin cleanMechanical engineering

The invention discloses a speed change gear of an automatic skin cleaning bath instrument, and relates to a bath head. The speed change gear comprises a first same-speed ring, a second same-speed ring and a third same-speed ring; the first same-speed ring includes an outer tooth A, an inner tooth, three small gears, a ring gear A, pin shafts and two glands C; the outer tooth A is arranged on the outer side of the gear ring A; the inner tooth is arranged on the inner side of the gear ring A, and is engaged with the small gears; the pin shafts are respectively arranged in the center positions of the three small gears; the two glands C are respectively positioned on the upper and lower two surfaces of the gear ring A; the second same-speed ring includes a gear ring B, an outer tooth B, an inner tooth, three small gears, pin shafts and two glands B; the outer tooth B is arranged on the outer side of the gear ring B; the inner tooth is arranged on the inner side of the gear ring B; as the outer tooth A, the outer tooth B and an outer tooth C rotate with the same speed, an inner ring, a middle ring and an outer ring of the bath head also rotate with the same speed; and when the three rings of the bath head rotate with the same speed, the bath effect is greatly improved, and more convenience is brought to users.

Owner:陈景刚

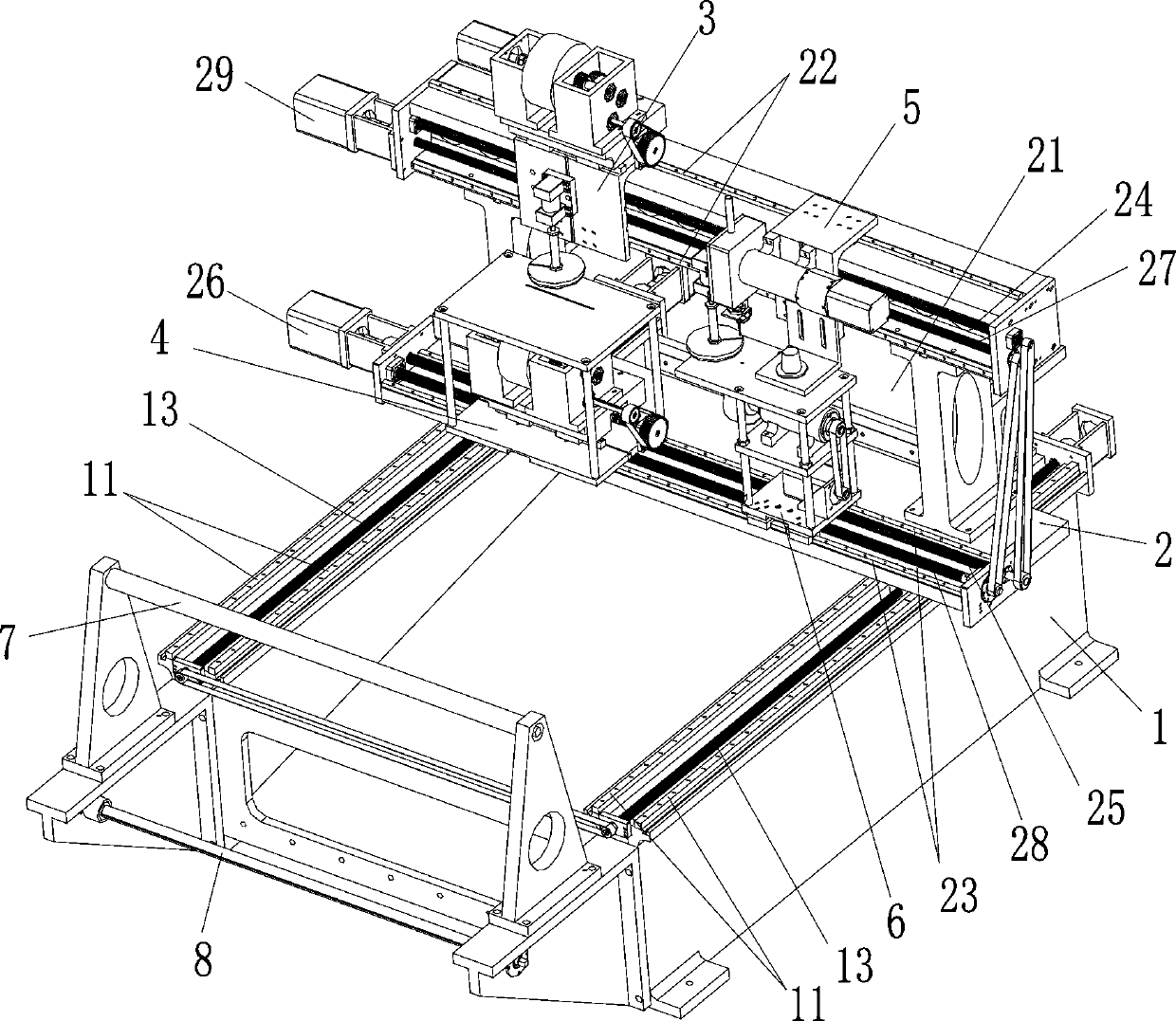

Gantry type sole stitching cutting numerical control machine tool

PendingCN111452115AEasy to cutSolve the defects of low efficiency and inconsistent qualityShoemaking devicesSevering textilesNumerical controlStructural engineering

The invention discloses a gantry type sole stitching cutting numerical control machine tool which comprises a rack, wherein a Y-axis controllable sliding rack is arranged on the rack, a first upper X-axis controllable sliding rack and a first lower X-axis controllable sliding rack are arranged on the Y-axis controllable sliding rack, a material distributing channel is arranged on the Y-axis controllable sliding rack, a first thread storage barrel driven by a first servo motor is arranged on the first upper X-axis controllable sliding rack, a second thread storage barrel driven by a second servo motor is arranged on the first lower X-axis controllable sliding rack, and a metal cutting wire is arranged between the first thread storage barrel and the second thread storage barrel. The gantry type sole stitching cutting numerical control machine tool matched with a control program can cut cloth into soles quickly and conveniently, is suitable for cutting multilayered thick cloth, is time-saving and labor-saving, cut the soles with high quality and efficiency, and overcomes the defect that conventional manual sole stitching is low in efficiency and non-uniform in quality.

Owner:绍兴市智凡机械科技有限公司

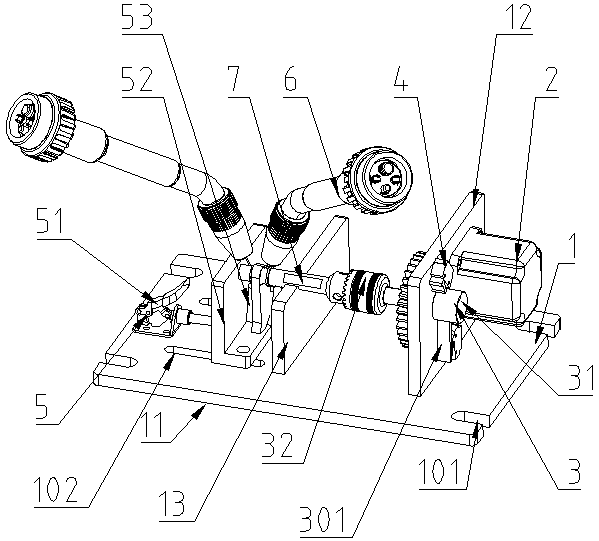

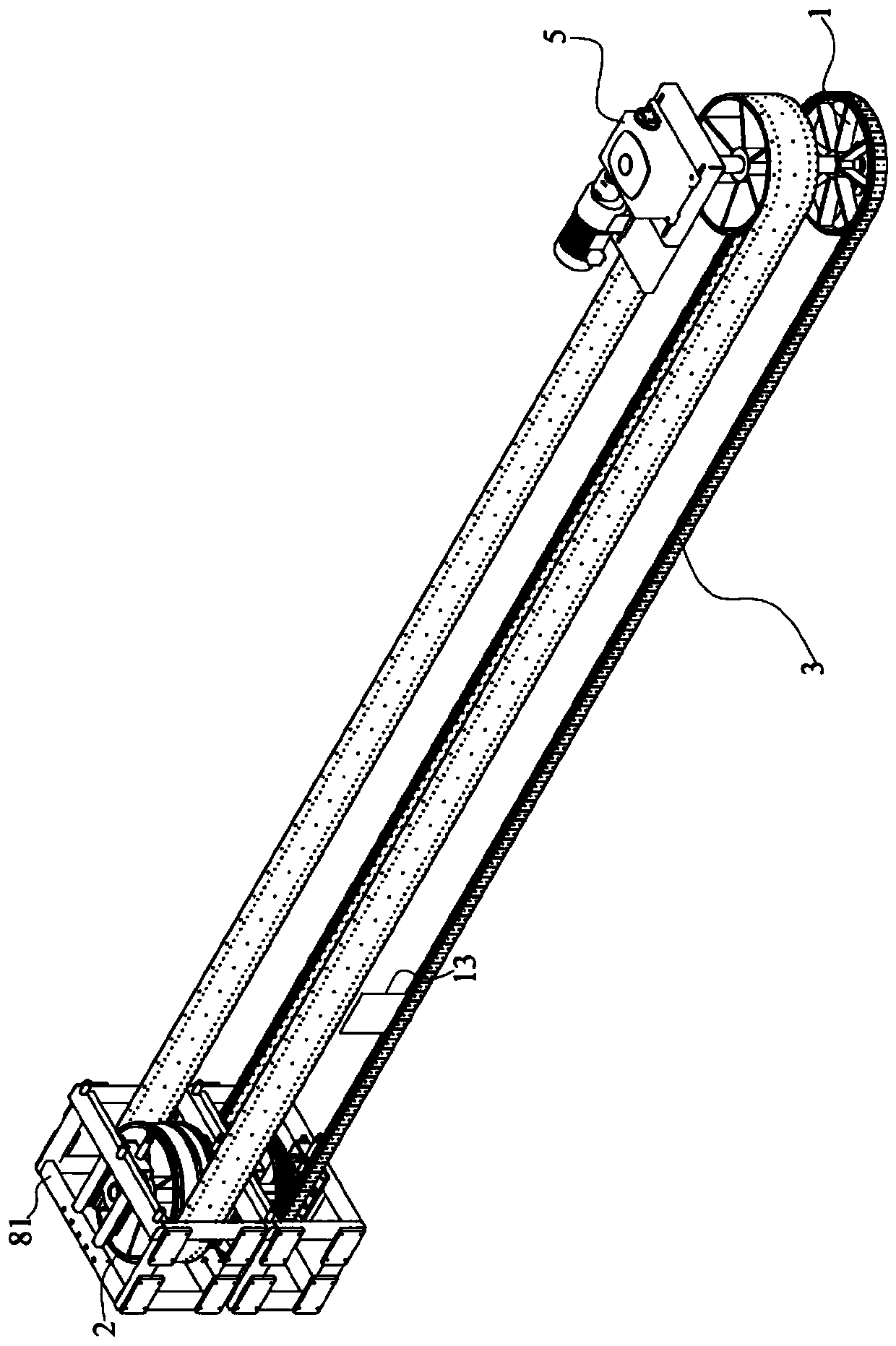

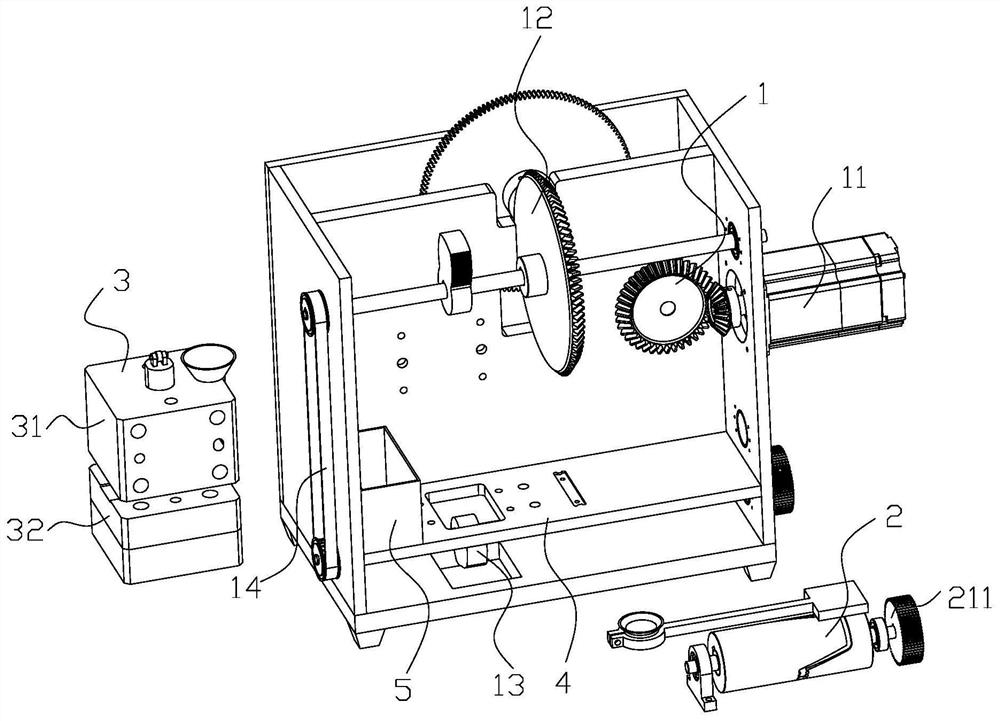

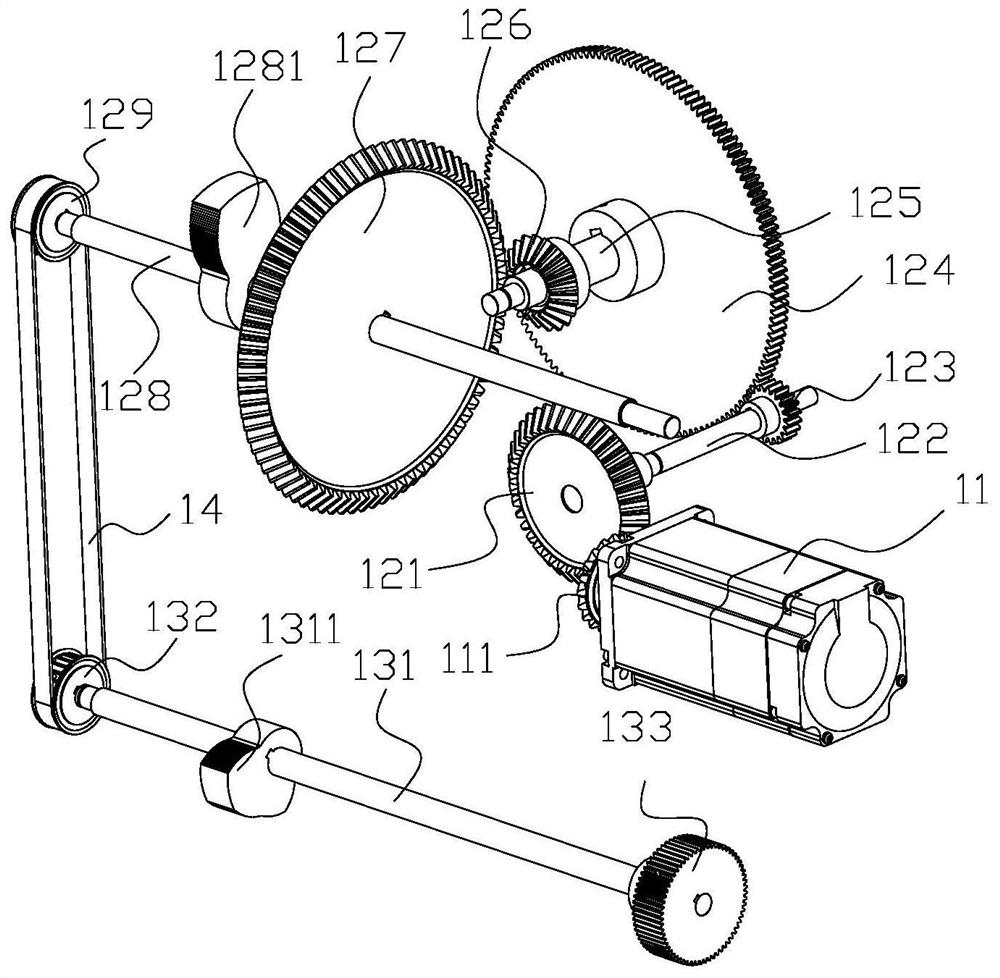

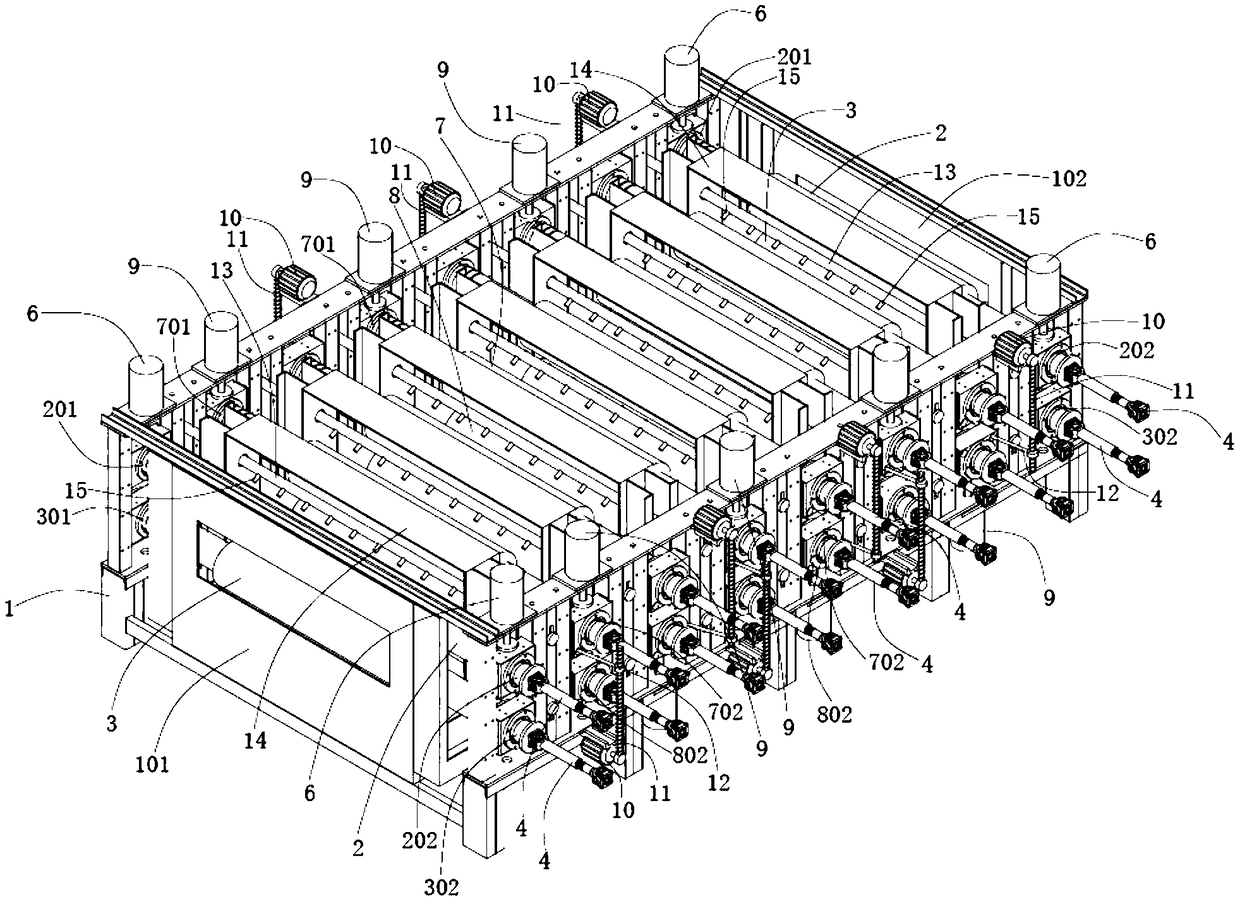

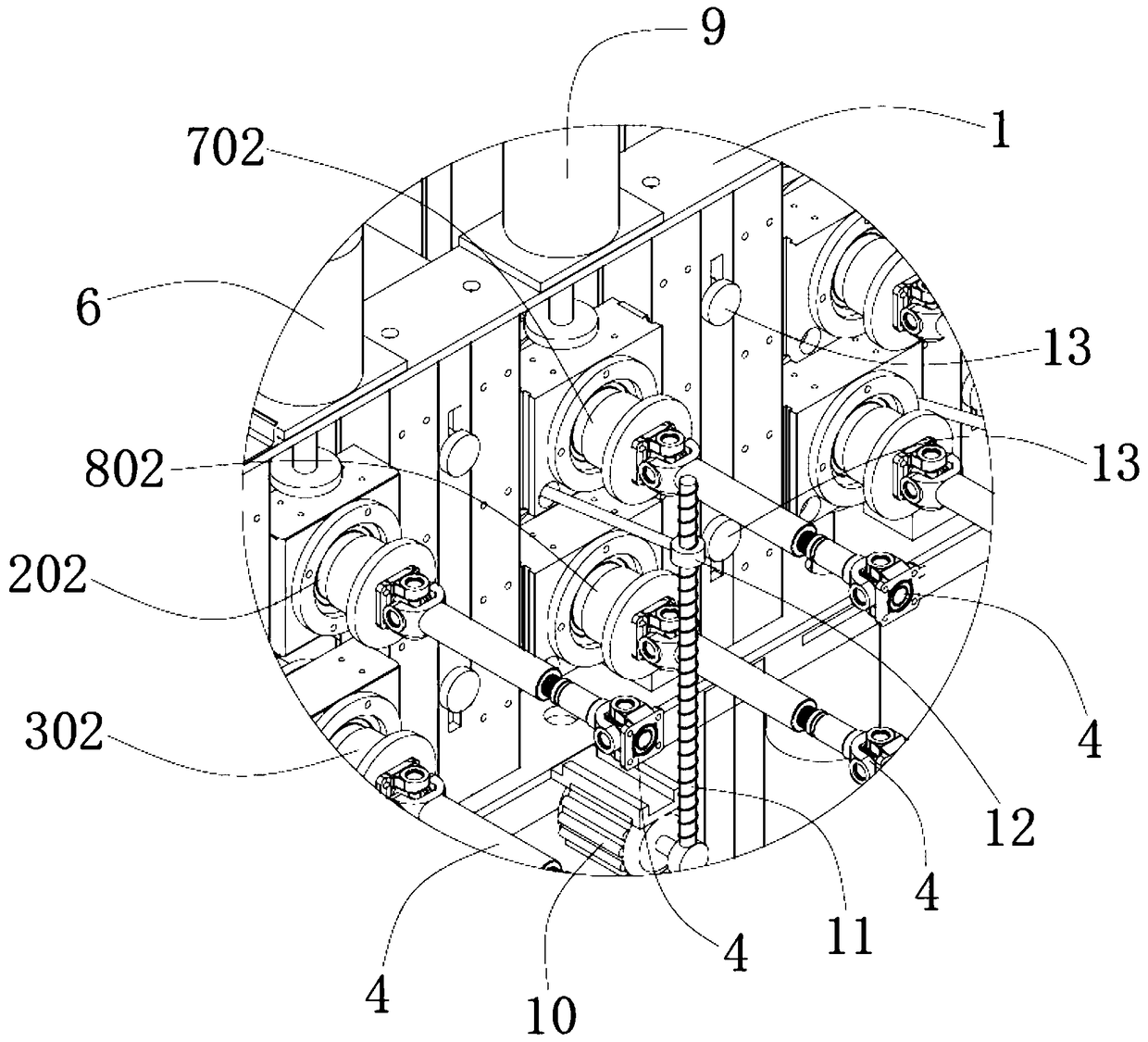

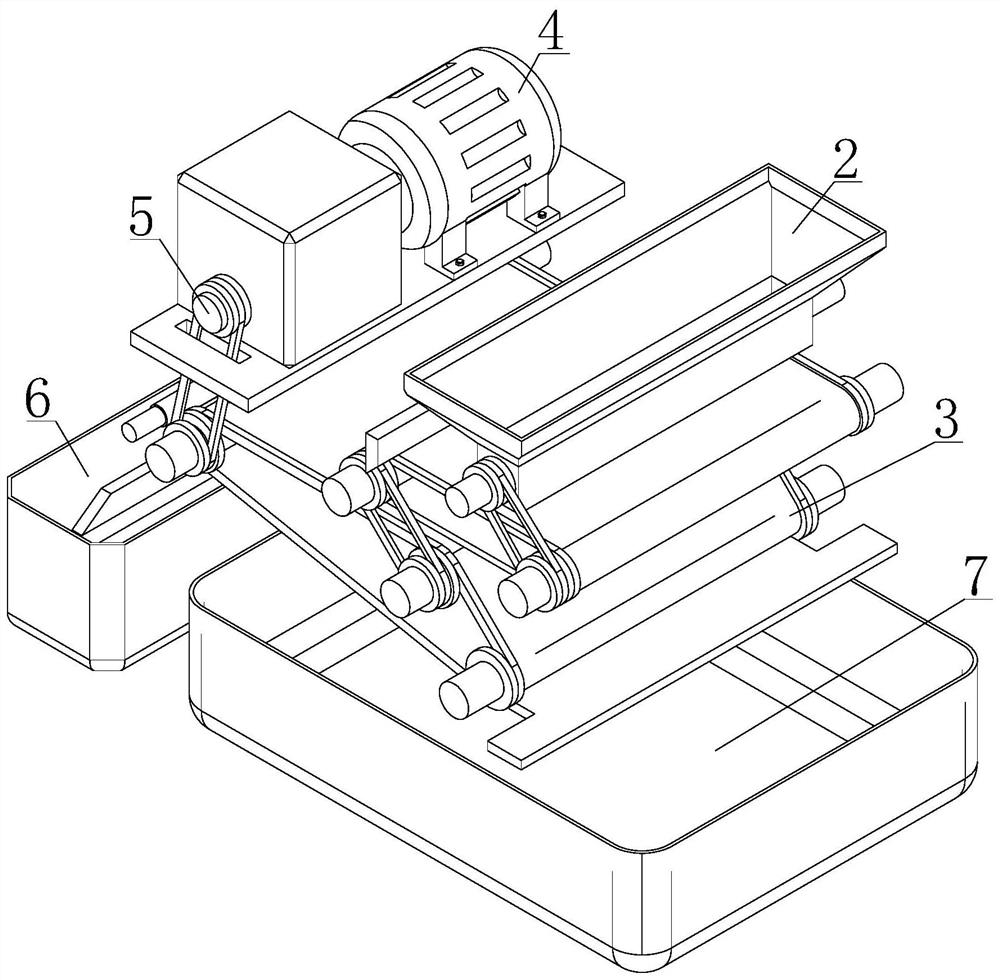

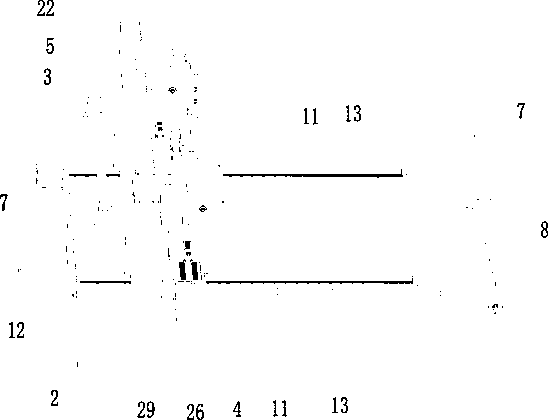

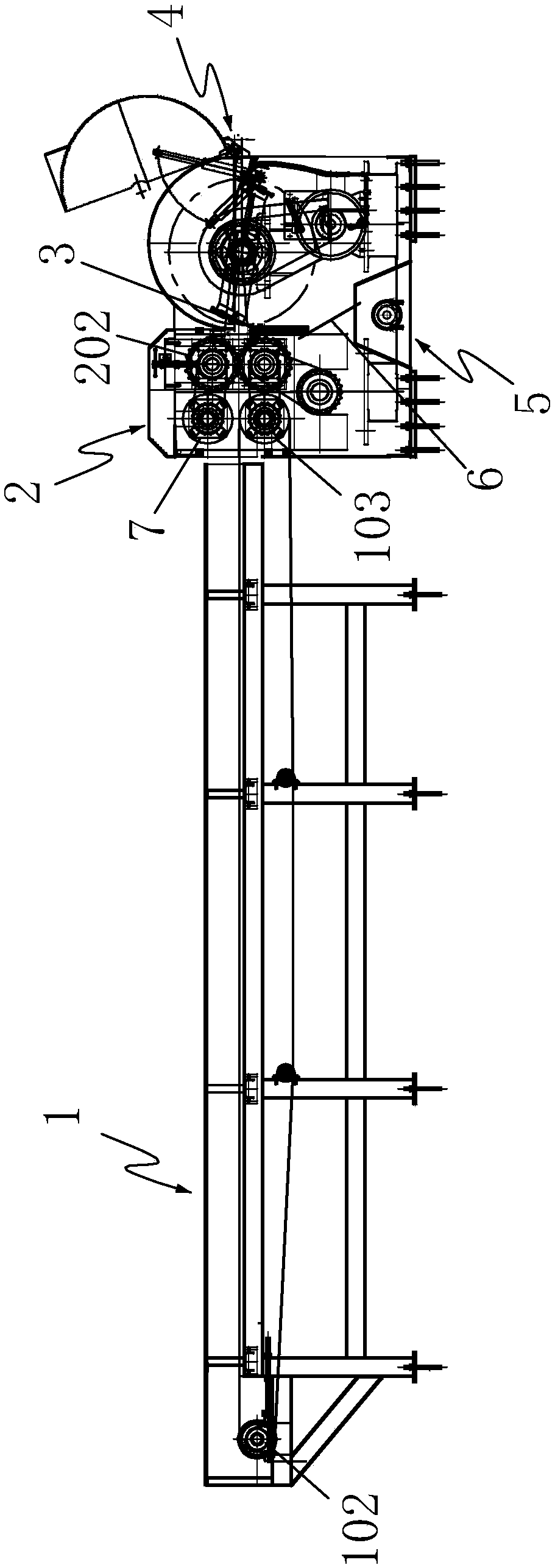

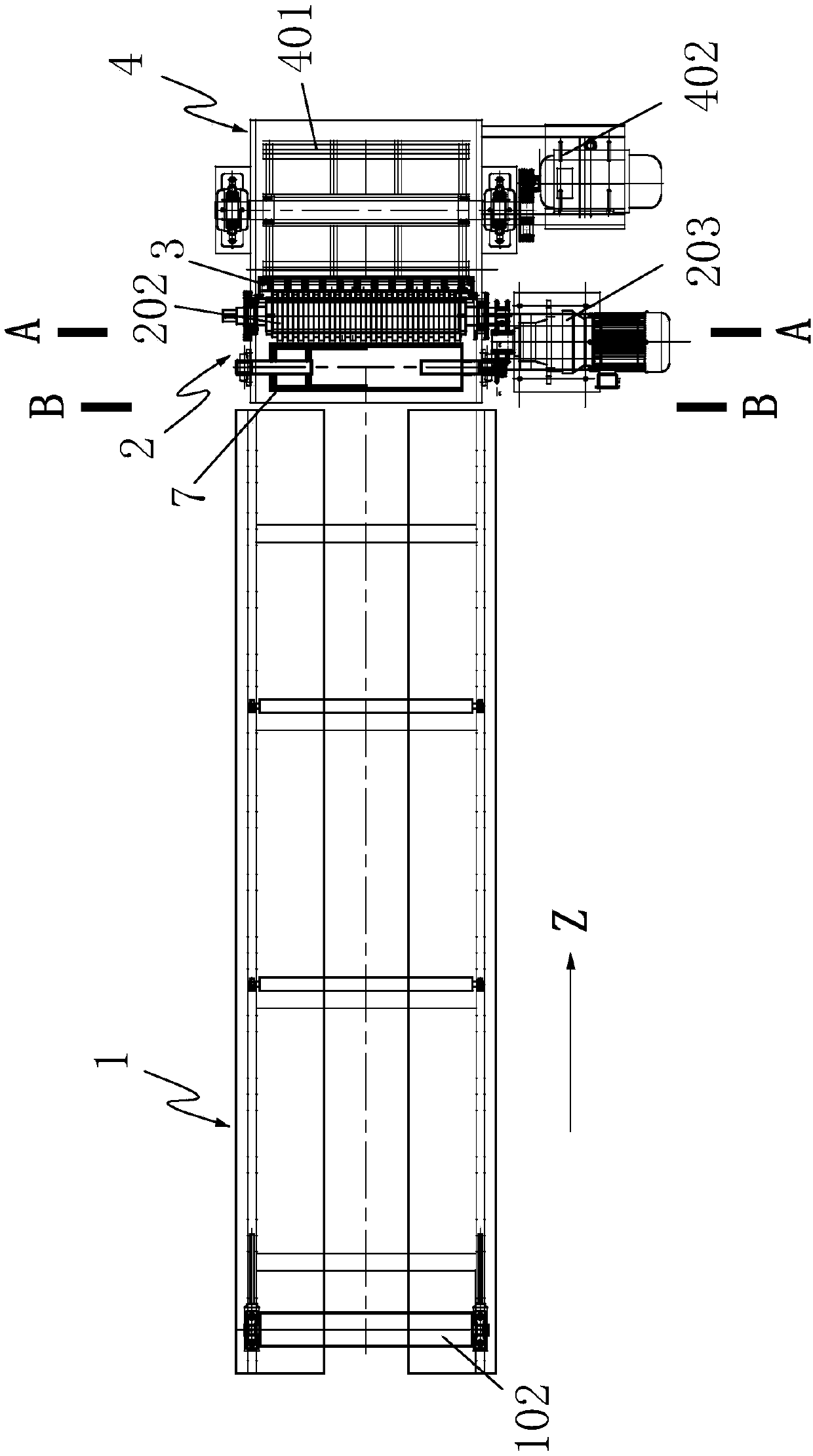

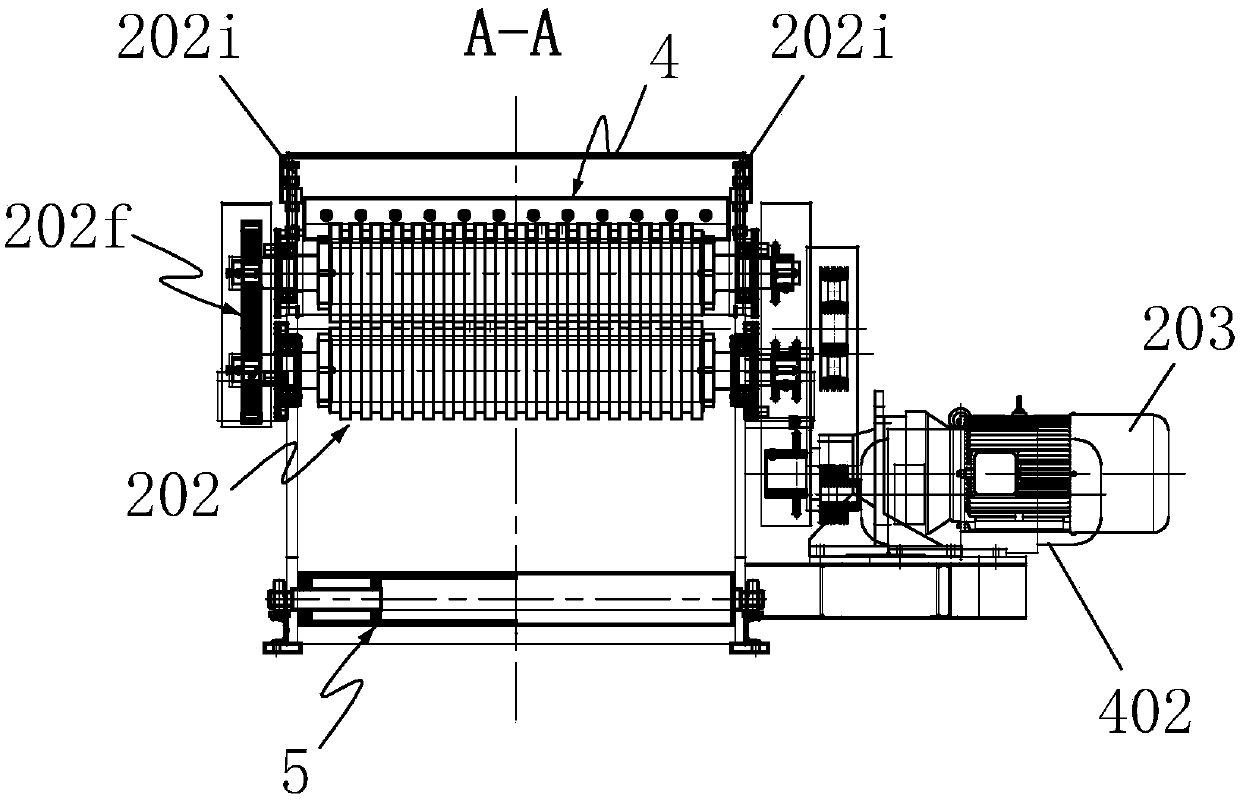

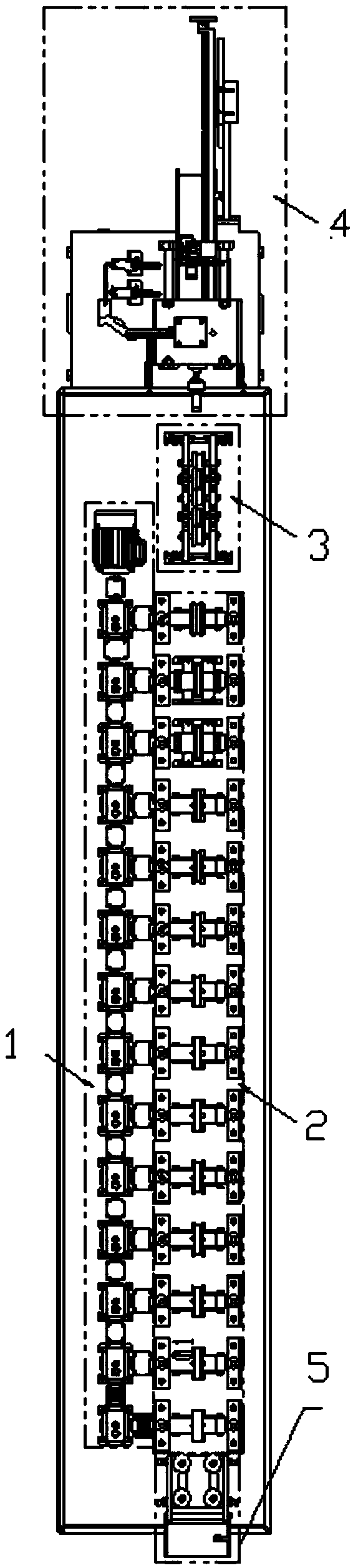

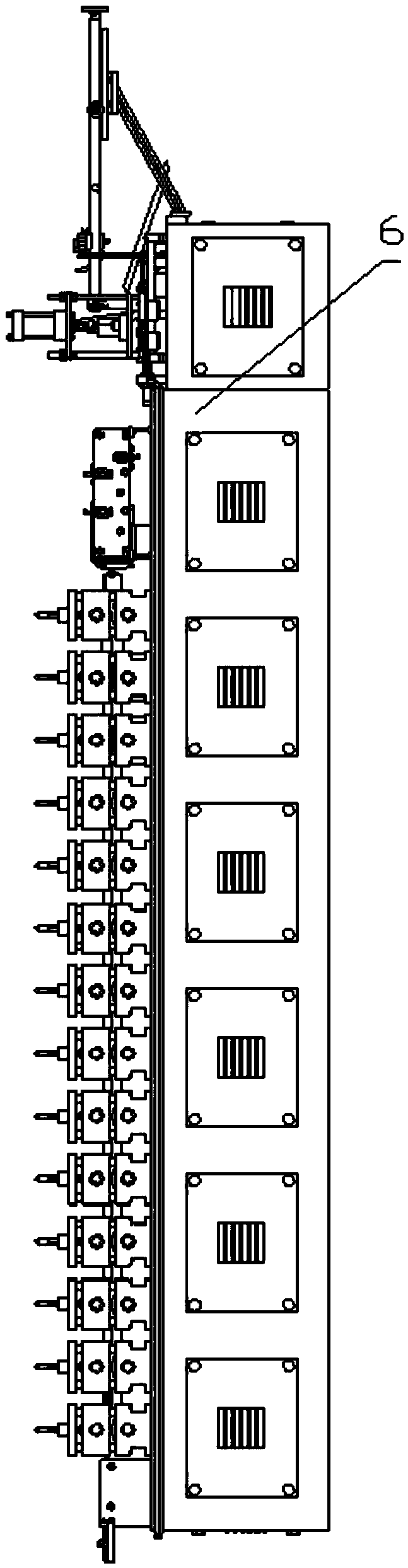

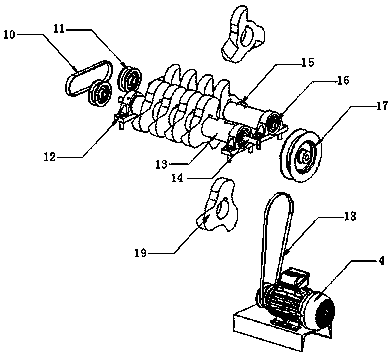

Knife-roll-type flaking machine for rotary cutting of board

PendingCN111469218AEasy to useEasy and rational use in OSB oriented strand board productionFlat surfacing machinesPlant fibreStructural engineering

The invention relates to a knife-roll-type flaking machine for rotary cutting of a board. The knife-roll-type flaking machine comprises a 1# conveying part (1), a vertical knife roll part (2), a stationary knife (3) and a horizontal knife roll part (4) which are connected in sequence. The 1# conveying part (1) conveys a plant fiber board-shaped material into the vertical knife roll part (2). The vertical knife roll part (2) comprises a vertical knife roll set (202), and the vertical knife roll set (202) vertically cuts the plant fiber board-shaped material into a strip-shaped material. The horizontal knife roll part (4) comprises a horizontal knife roll set (401). The horizontal knife roll set (401) horizontally cuts the strip-shaped material. By adopting the technical scheme, the plant fiber board-shaped material with the thickness of 0.5-1.0 millimeter can be processed to the specified dimension.

Owner:江苏保龙机电制造有限公司

Metal powder preparation method and device based on controllable magnetic levitation smelting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

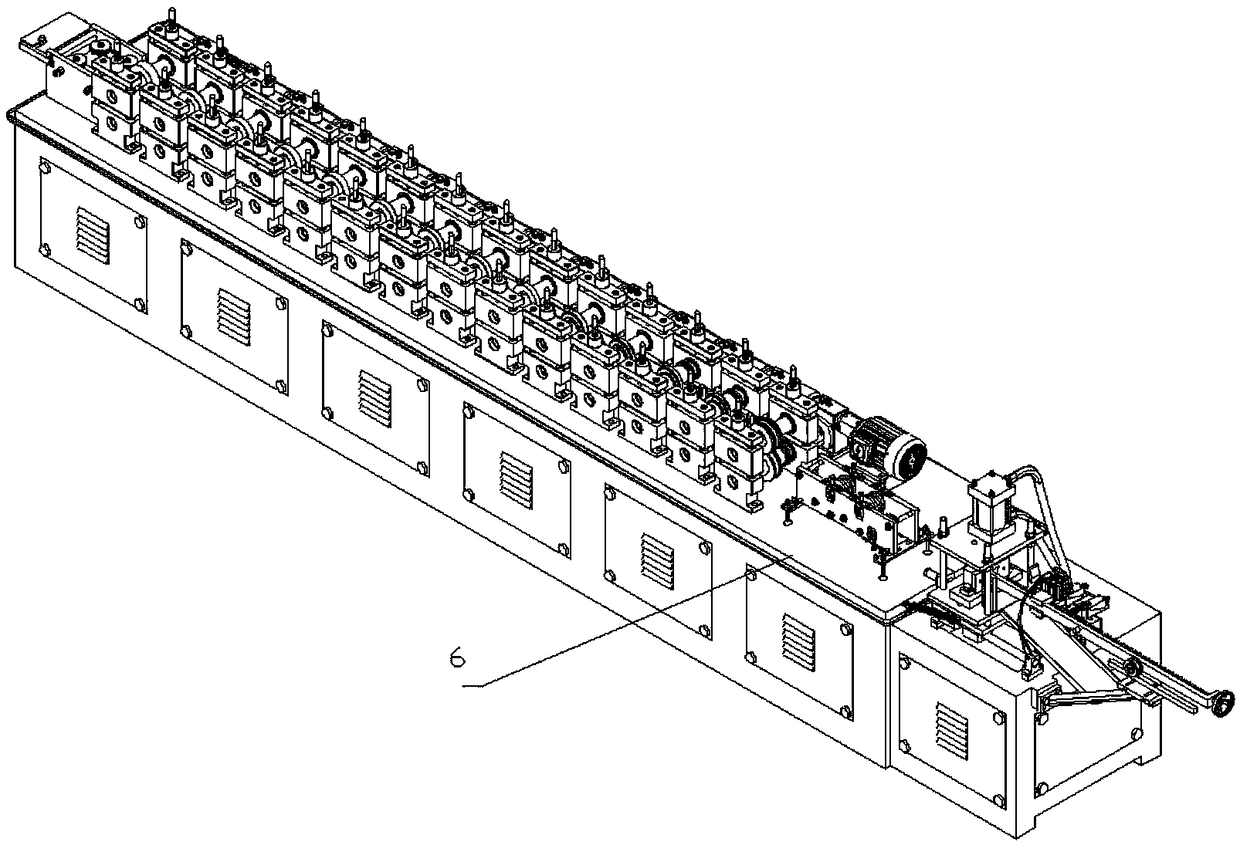

High-speed kerve cold forming machine

PendingCN109465301AConsistent rotation speedSmooth transmissionRollsRolling mill drivesLeveling mechanismGear wheel

The invention provides a high-speed kerve cold forming machine which comprises a power transmission mechanism, a cold press forming mechanism, a leveling mechanism, a cutoff mechanism and a cooling mechanism, wherein the power transmission mechanism adopts the turbine reducer-coupling transmission manner to drive an idler wheel to drive a workpiece for feeding. Compared with the prior art and geartransmission equipment, the rotational speeds, transmitted to all rolling wheel sets of the cold press forming mechanism, of the power transmission mechanism of the high-speed kerve cold forming machine are consistent, transmission is smooth and steady, and the phenomena of bending deformation caused by unstable rotation and gear print generated on the kerve caused by radial run-out of gear transmission are overcome. Compared with the prior art, the other advantage of the high-speed kerve cold forming machine is as follows: an additionally arranged buffer resetting device does not interrupt the the rolling force production process during the cutoff process, so that high speed production of the kerve is facilitated.

Owner:GUANGDONG AURICAN HARDWARE TECH CO LTD

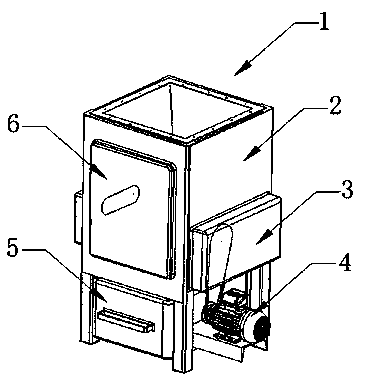

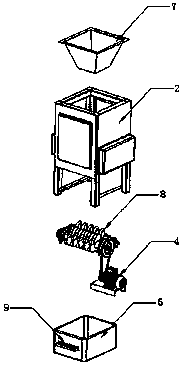

Crushing device for bean processing

The invention discloses a crushing device for bean processing. The crushing device for bean processing comprises a longitudinally-arranged case, wherein a collection box is arranged at the bottom of the case, an electric motor is arranged at the side edge of the collection box, a filter cone is arranged at the top of the case, a rotating device is installed in the case, and two symmetrically-distributed rotating shafts are installed in the rotating device; and the surfaces of the two rotating shafts are provided with a plurality of bulges uniformly distributed, each bulge is sleeved with an impeller, rotating rods are installed in the two rotating shafts, one side of each rotating rod is sleeved with a first rotating wheel, the two first rotating wheels are sleeved with a first belt, the other side of one rotating rod is sleeved with a second rotating wheel, and the second rotating wheel and the electric motor are sleeved with a second belt. In use, beans enter the rotating device through the filter cone to be crushed, and finally the beans are crushed and then dropped into the collection box.

Owner:陈沛

An inner support card device for inner support of an annular open member and its application method

ActiveCN109848634BImprove connection strengthConsistent rotation speedWelding/cutting auxillary devicesAuxillary welding devicesControl theoryFlange

The invention discloses an inner support clamping device for an inner support of an annular open component and a using method thereof. According to the technical scheme, the inner support clamping device for the inner support of the annular open component is characterized by comprising a fixing rack, bottom flanges of the fixing rack are connected to an external mechanism or a ground, the fixing rack is provided with a central driving platform, a convex radial supporting mechanism, a concave radial supporting mechanism and a servo driving mechanism. According to the inner support clamping device for the inner support of the annular open component and the using method thereof, supporting rigidity of the inner support mechanism of the component is greatly improved, the precision of the tailend is guaranteed, moreover, the influence of gravity can be omitted, and the inner support clamping device can be used for vertical supporting mechanisms and can also be used for horizontal supporting mechanisms.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com