Circuit board conveying structure and electroplating equipment

A technology of electroplating equipment and circuit boards, which is applied in the direction of conveyors, conveyor objects, lighting and heating equipment, etc., can solve problems such as circuit board surface wrinkles, achieve uniform thickness of electroplating layer, and prevent wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

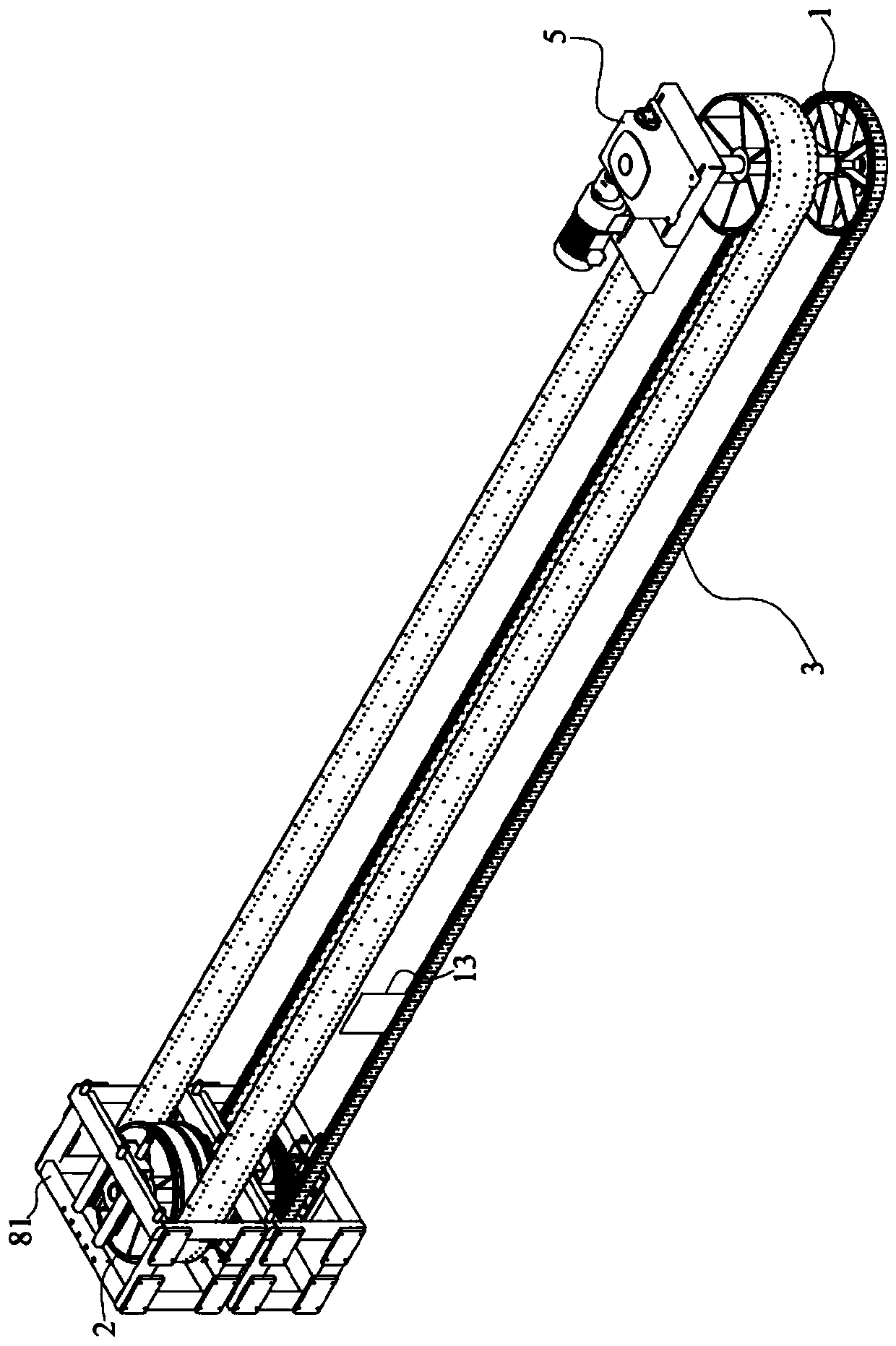

[0060] Such as Figure 1 to Figure 4 A specific implementation of the conveying structure of the circuit board shown includes:

[0061] The first transmission mechanism.

[0062] The second transmission mechanism is arranged parallel to each other in the vertical direction with the first transmission mechanism.

[0063] At least one clamp is arranged on the first transmission mechanism for clamping the upper end of the circuit board 13 and can move synchronously with the first transmission mechanism driven by the first transmission mechanism.

[0064] At least one material clip 4 is arranged on the second transmission mechanism and below the corresponding clamps, and is used to clamp the lower end of the circuit board 13, and can be driven by the second transmission mechanism with the The second transmission mechanism moves synchronously, and the running speed of the clamp is the same as that of the material clip 4 .

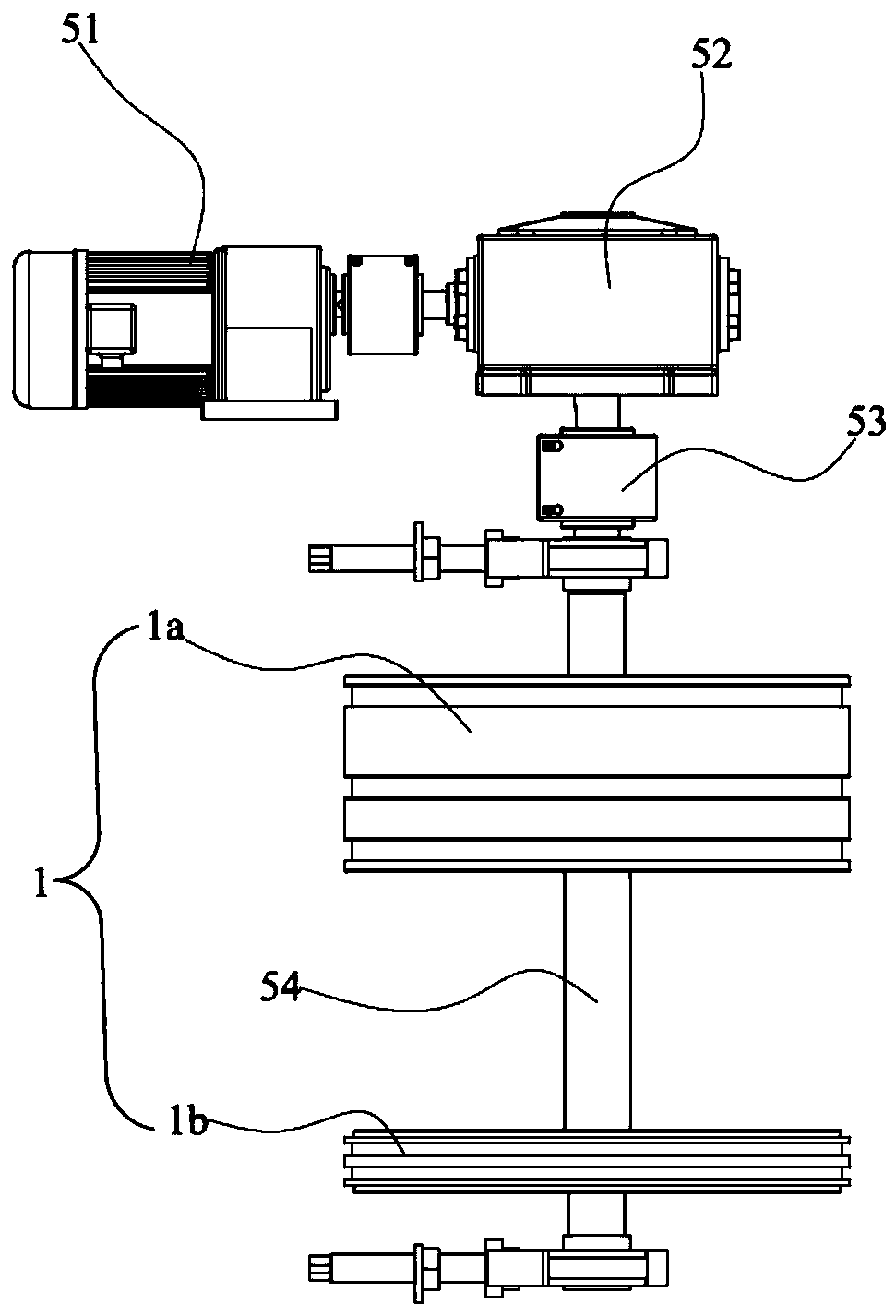

[0065] The driving mechanism 5 is connected with the fi...

Embodiment 2

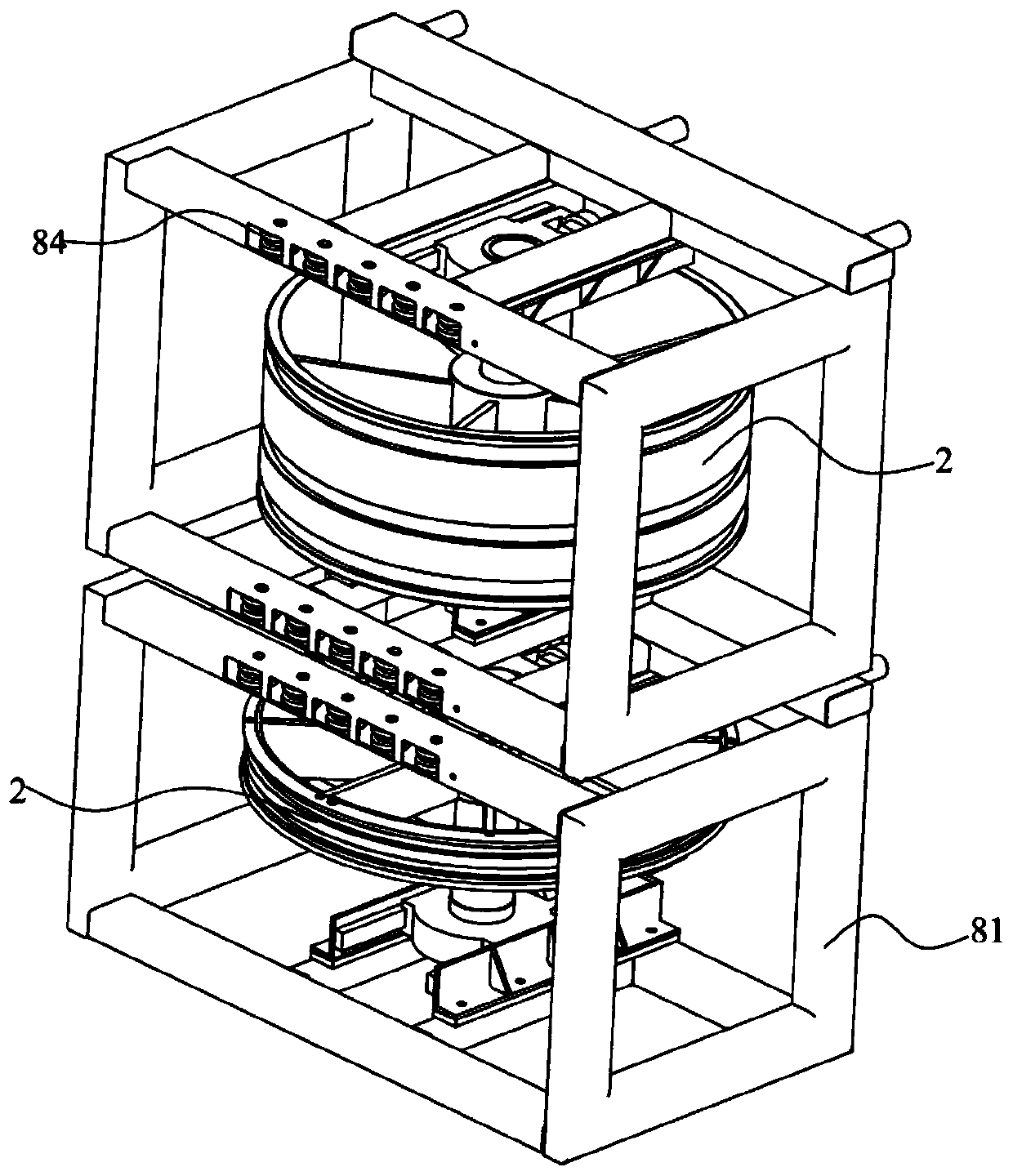

[0078] Such as Figure 1 to Figure 7 A specific implementation of the shown electroplating equipment includes:

[0079] The feeding device 6 is used for loading the circuit board 13 to be electroplated.

[0080] The unloading device 7 is used for unloading the electroplated circuit board 13 .

[0081] An electroplating tank, located between the feeding device 6 and the unloading device 7, is used to form an electroplating layer on the circuit board 13 to be electroplated when the circuit board 13 to be electroplated passes through. as well as

[0082] The conveying structure of the circuit board 13 described in the first embodiment is used to drive the circuit board 13 to be electroplated from the feeding device 6 to the unloading device 7 through the electroplating tank.

[0083] In the above-mentioned electroplating equipment, the circuit board 13 is loaded on the conveying structure of the circuit board 13 through the action of the feeding device 6, and then the plating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com