Patents

Literature

63results about How to "Same rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

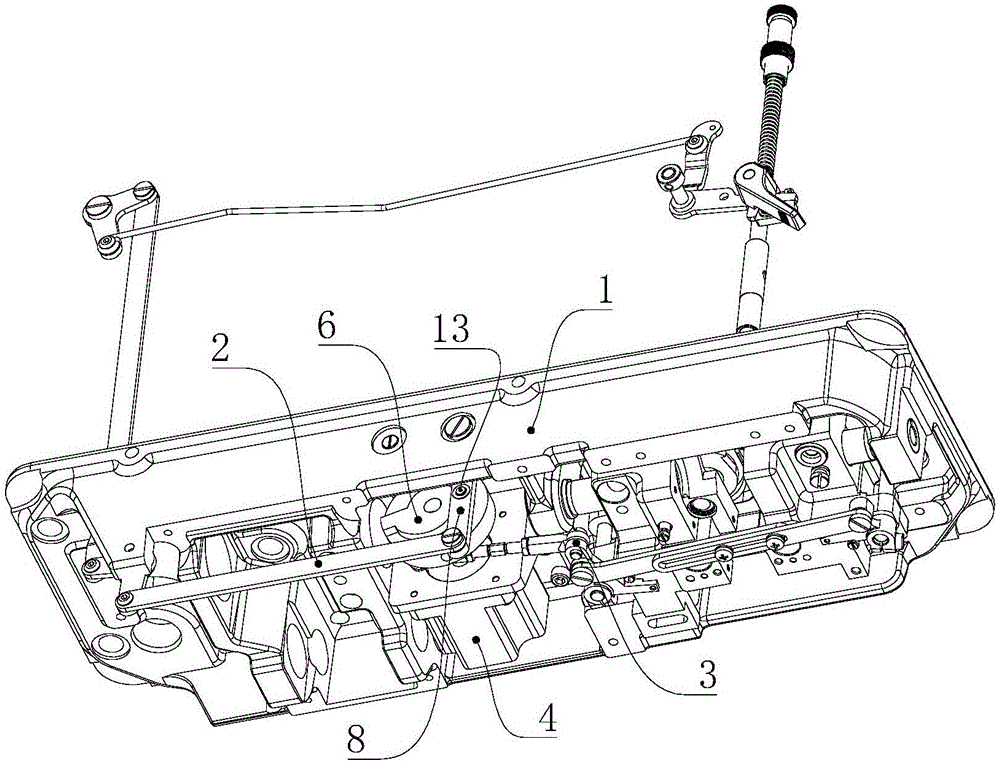

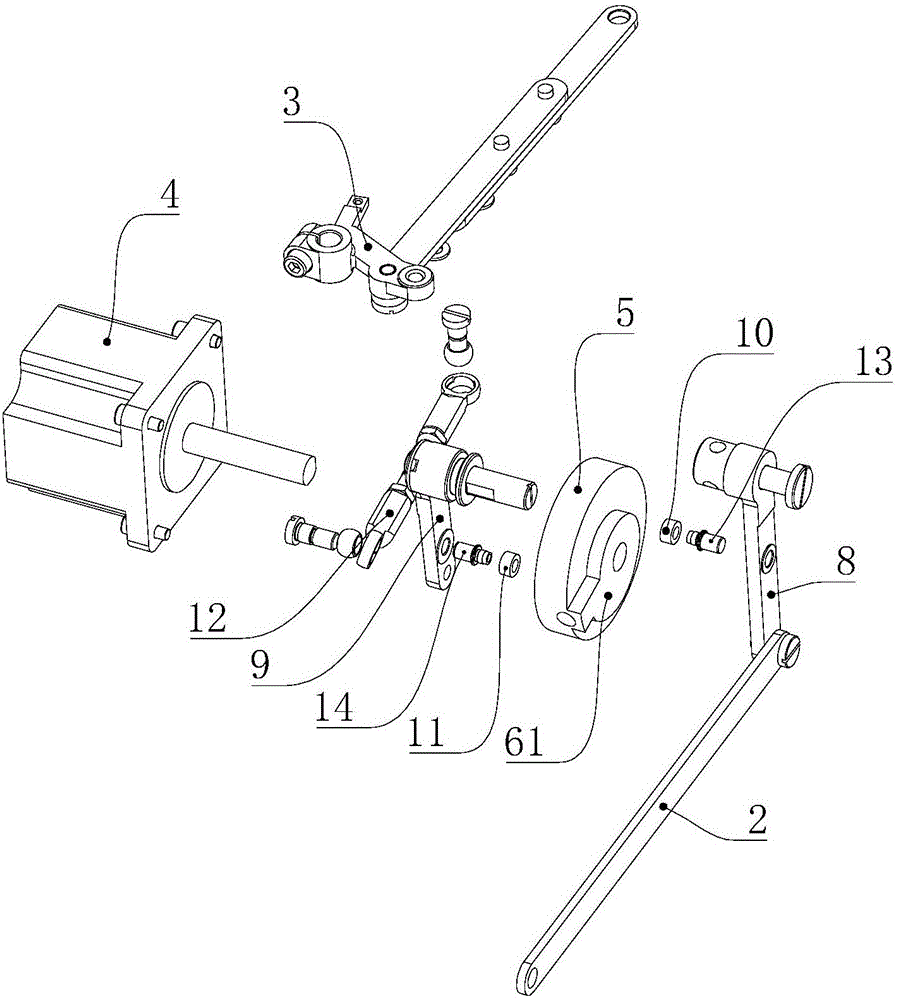

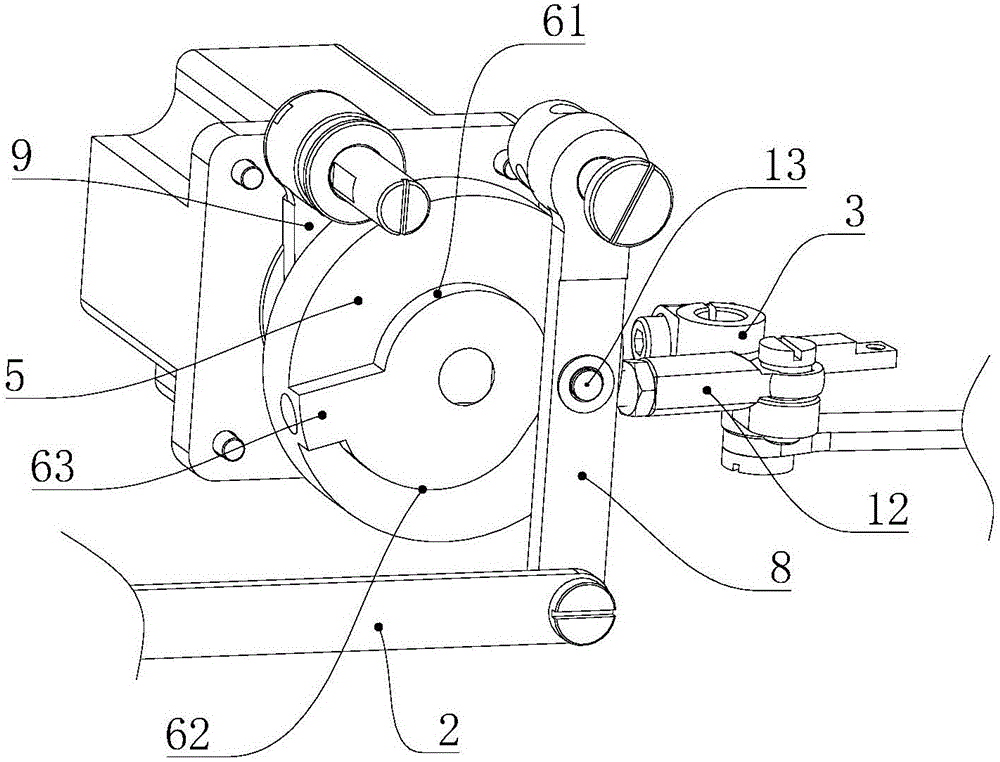

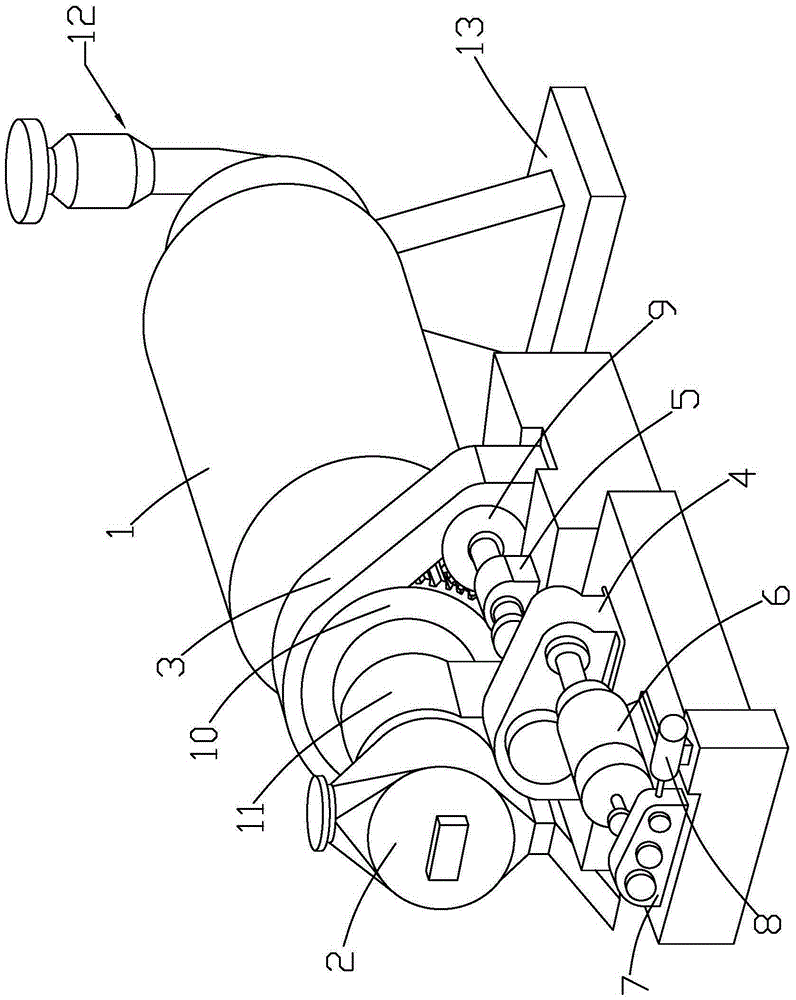

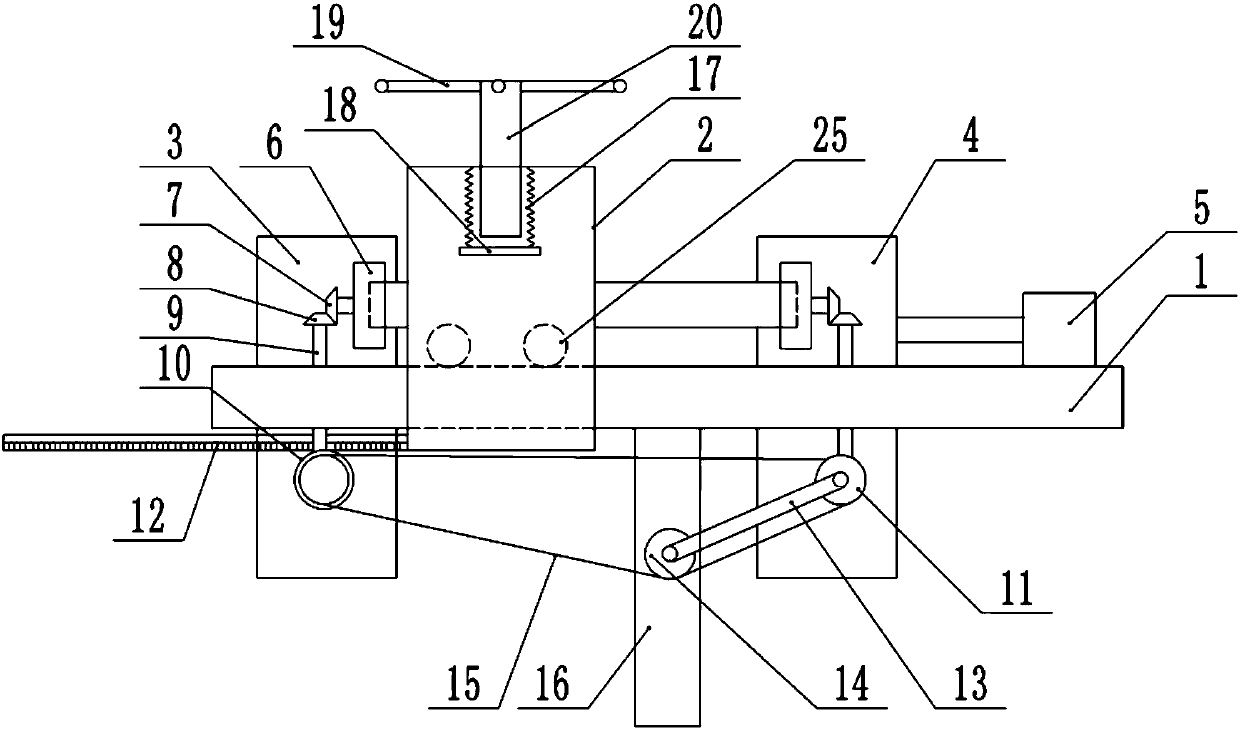

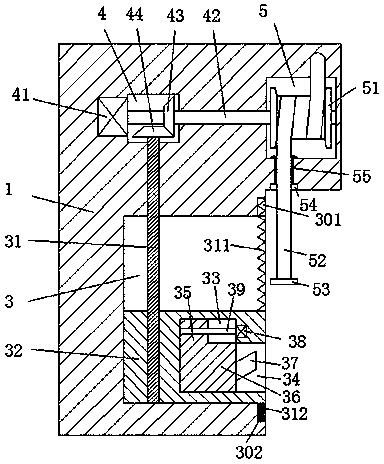

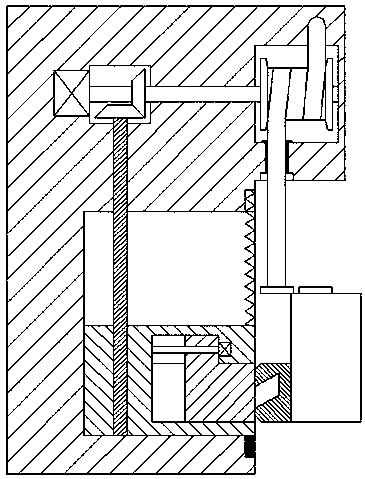

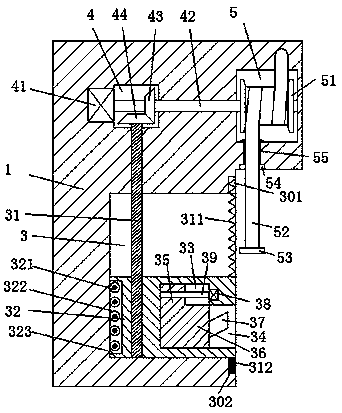

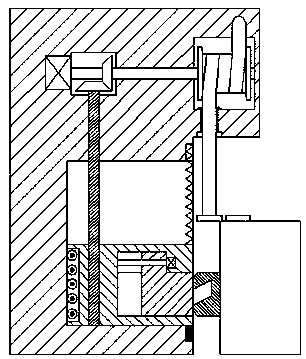

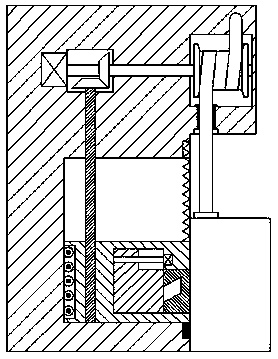

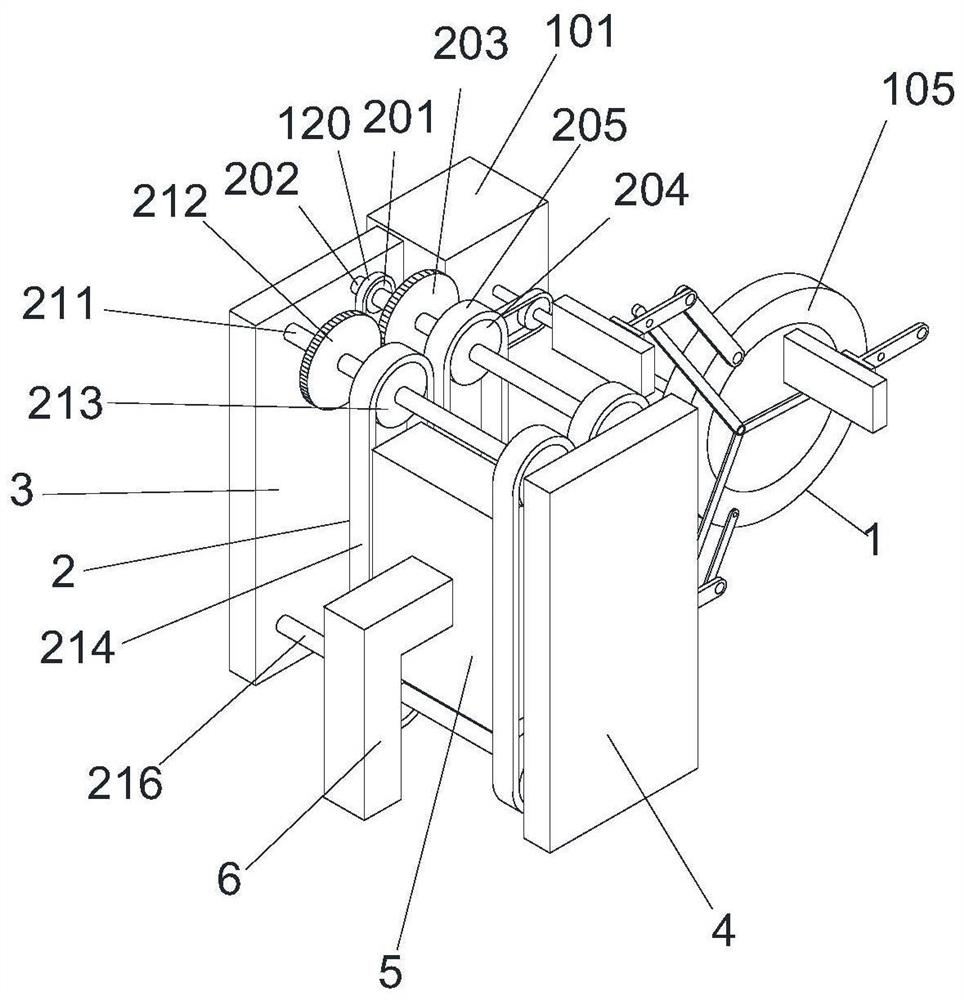

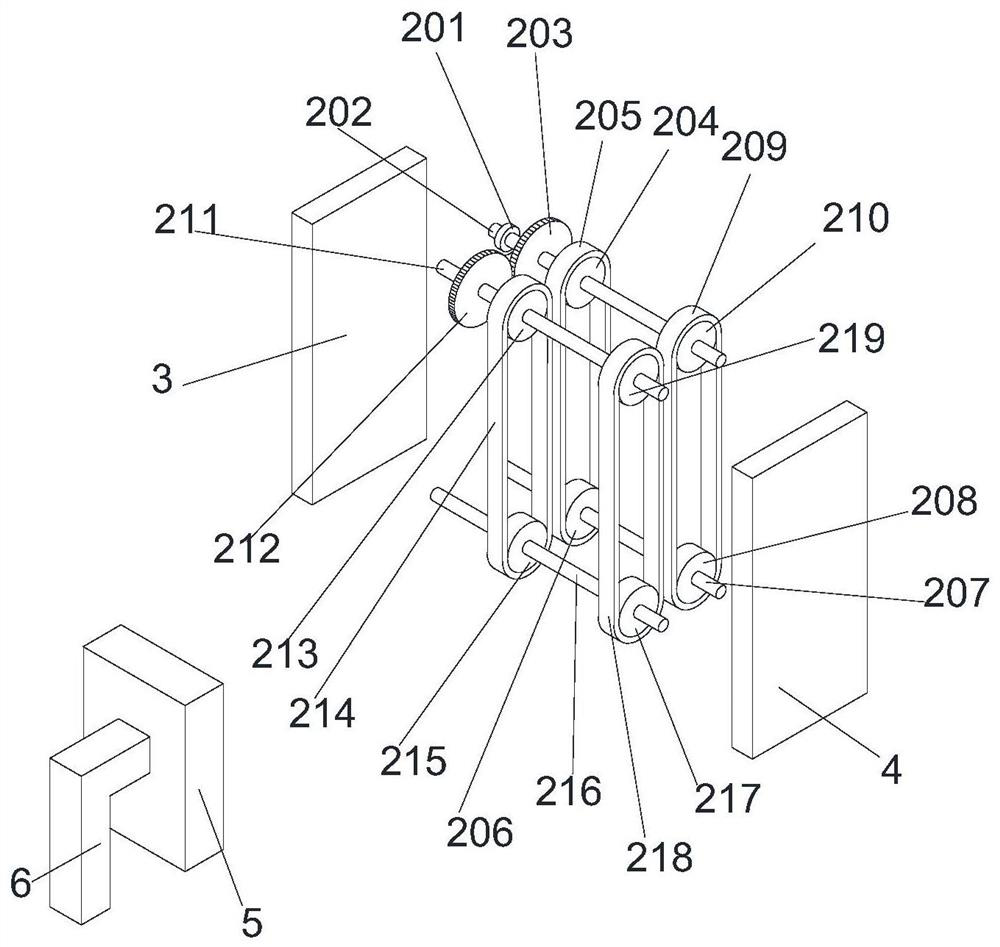

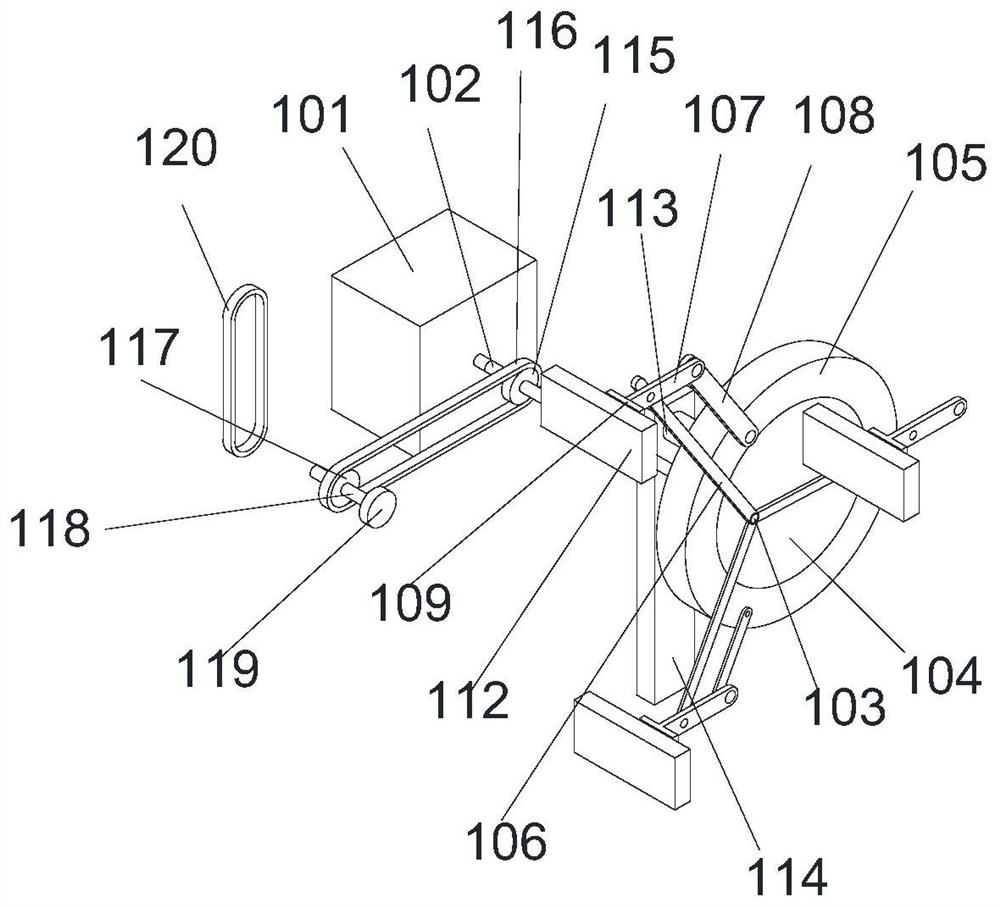

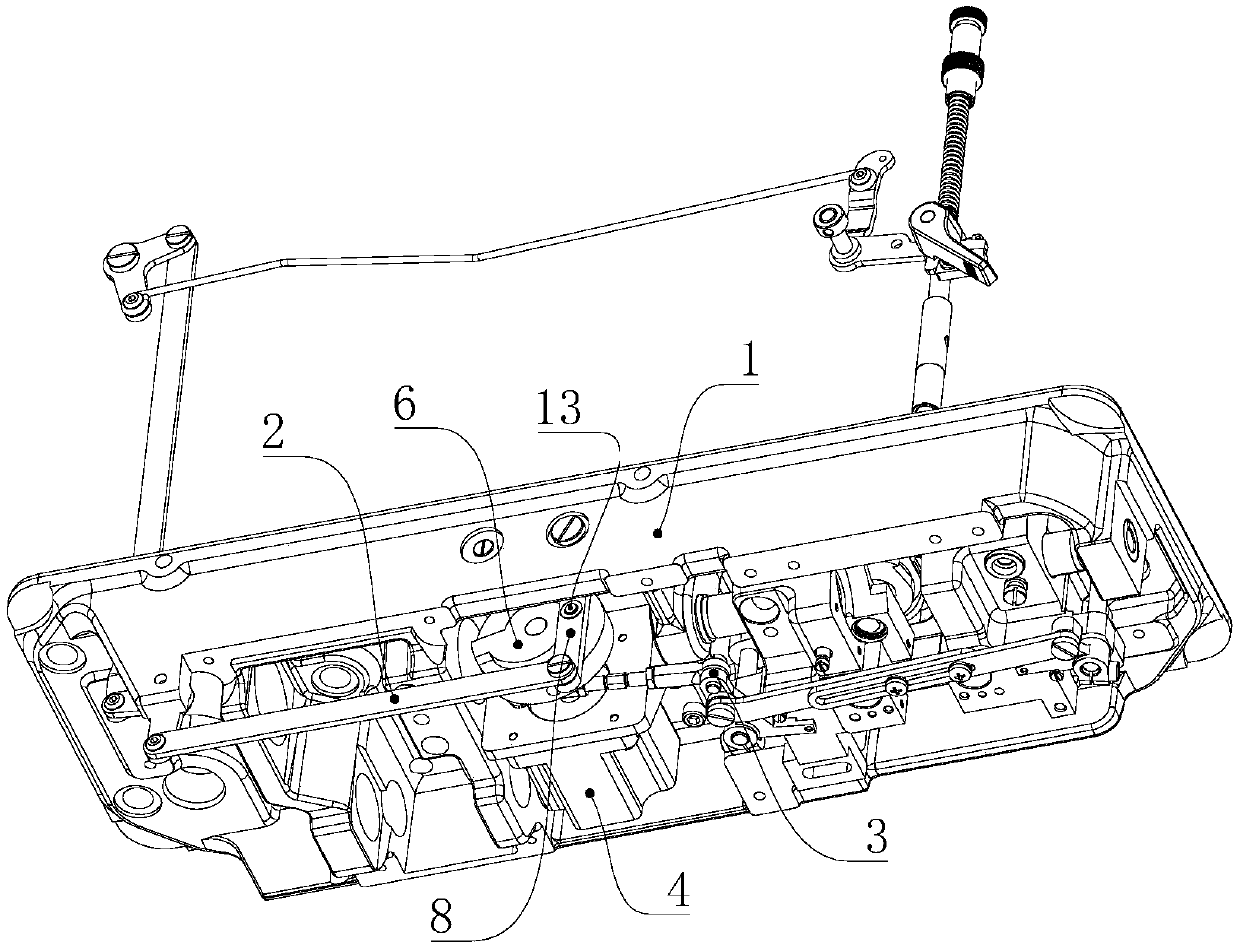

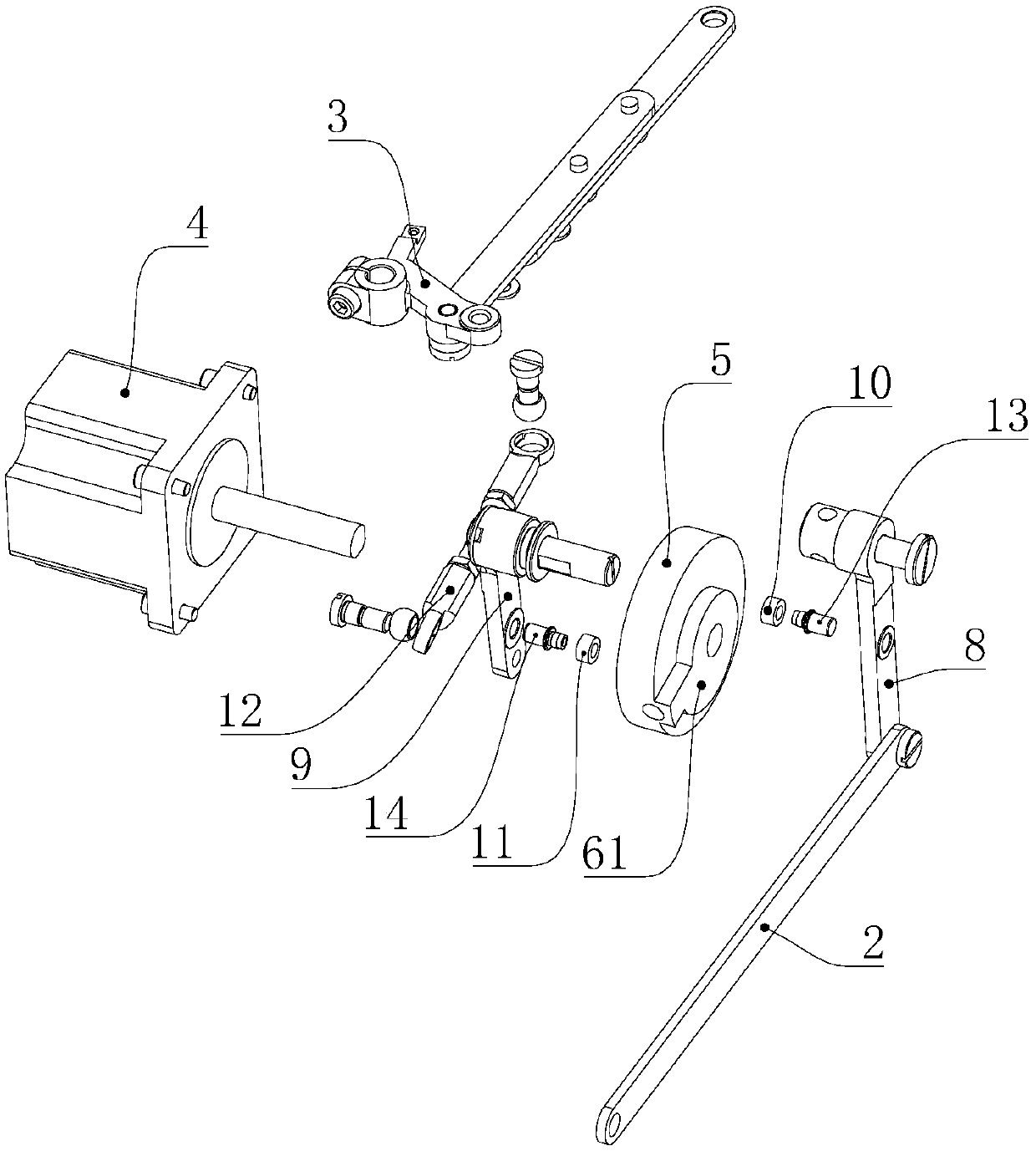

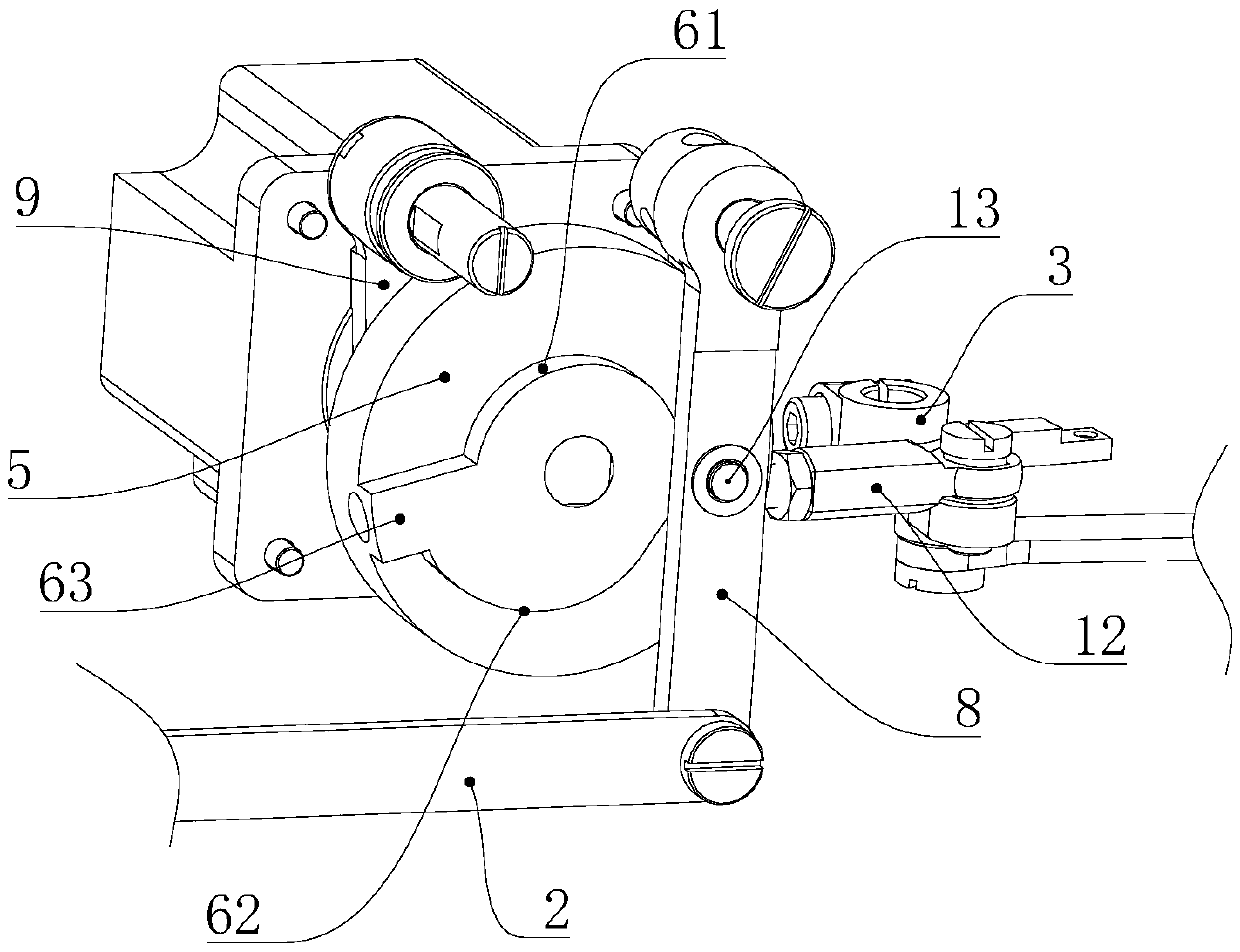

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN106012323ACompact structureSame rotation speedNeedle severing devicesPressersMotor driveEngineering

The invention belongs to the technical field of sewing machines, and particularly discloses a driving device for automatic thread trimming and automatic presser foot lifting. The driving device is simple in structure and capable of guaranteeing stable operation of a sewing machine. The driving device comprises a presser foot lifting transmission rod, a thread trimming transmission rod, a stepping motor, a cam body arranged on the stepping motor, a pressure foot lifting connecting rod and a thread trimming connecting rod. The cam body is provided with a pressure foot lifting driving cam surface and a thread trimming driving cam surface, both of which comprise a base circle surface and a lift curved surface. The other end of the pressure foot lifting connecting rod is hinged to one end of the pressure foot lifting transmission rod, and the pressure foot lifting connecting rod is provided with a first driven pin. The thread trimming transmission rod is hinged to the other end of the thread trimming connecting rod, and the thread trimming connecting rod is provided with a second driven pin. When the stepping motor drives the cam body to rotate clockwise by a certain angle, one driven pin enters the lift curved surfaces from the base circle surfaces, and the other driven pin slides on the base circle surfaces; when the stepping motor drives the cam body to rotate anticlockwise, one driven pin slides on the base circle surfaces, and the other driven pin enters the lift curved surfaces from the base circle surfaces.

Owner:ZHEJIANG DUMA SEWING MACHINE

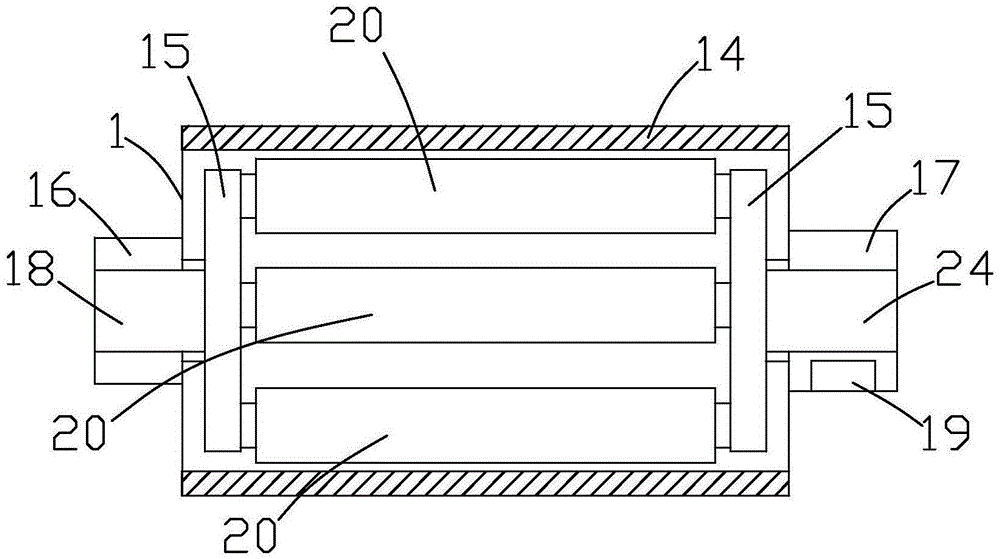

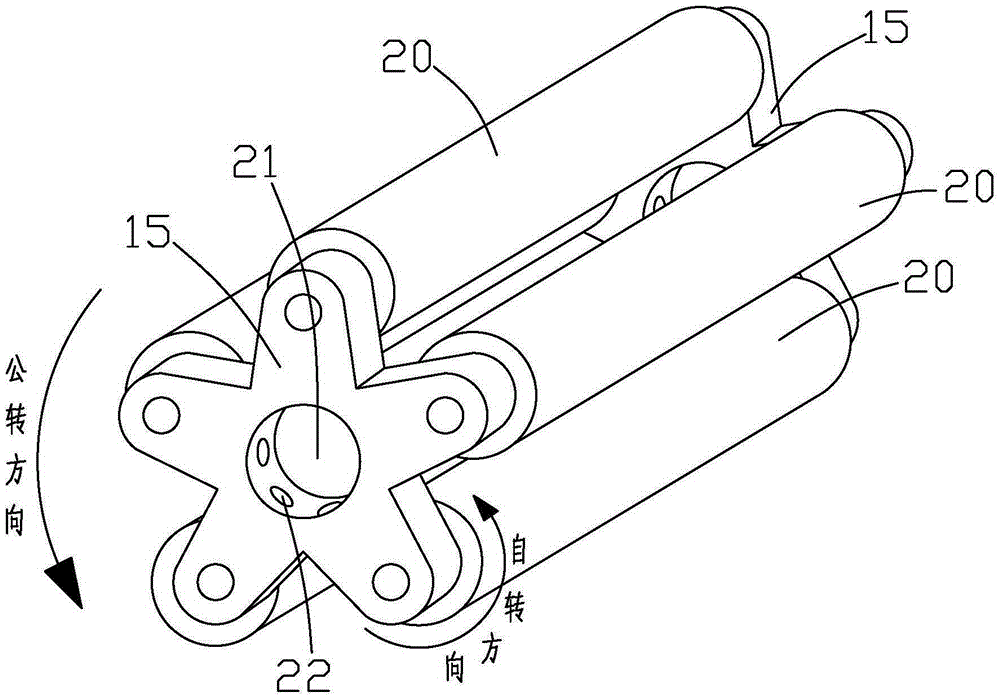

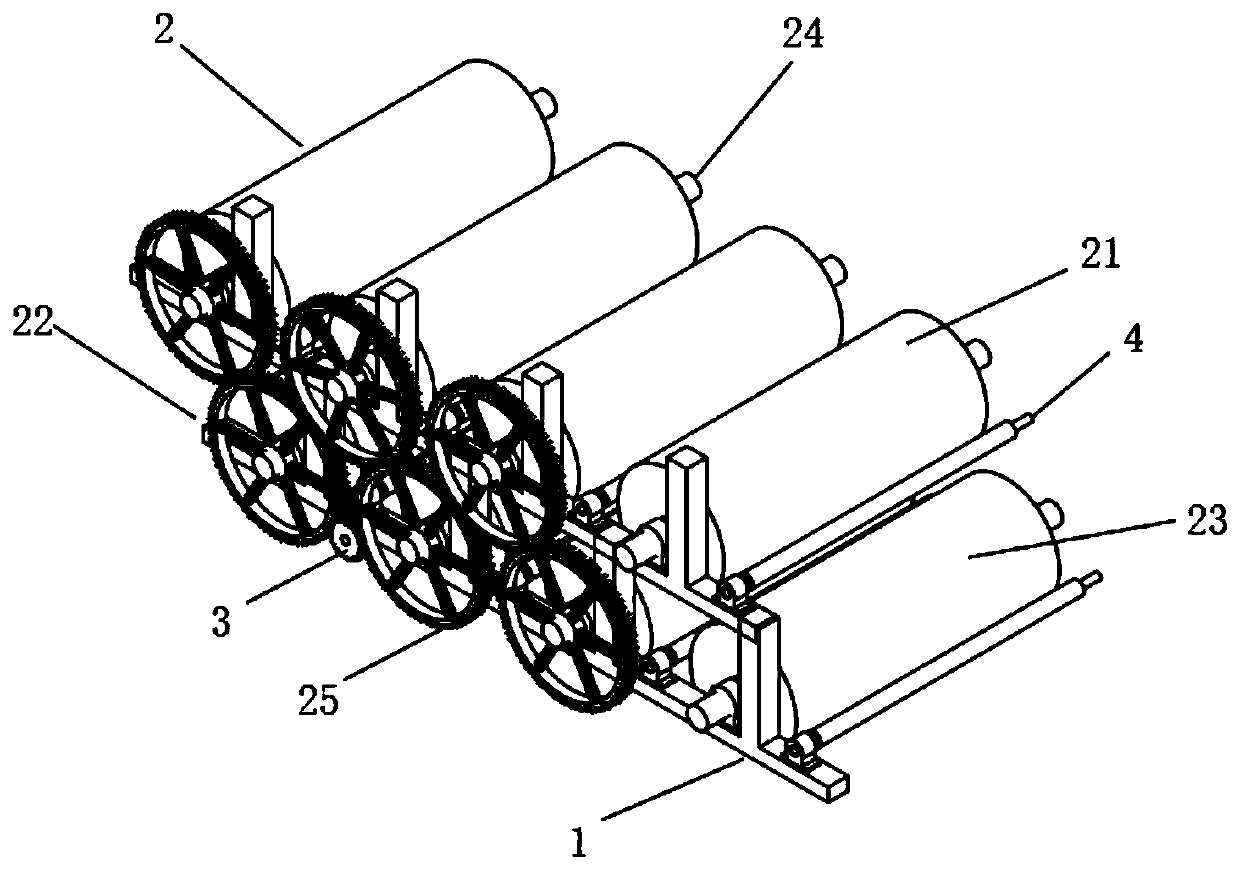

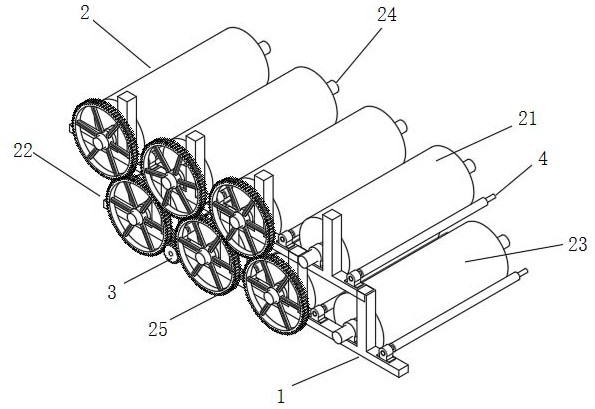

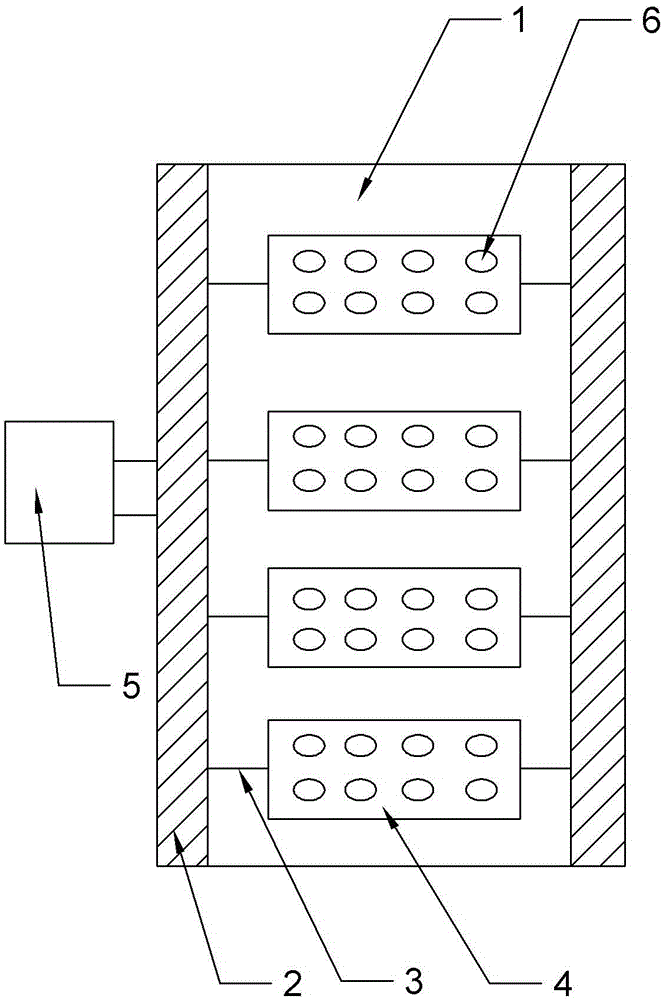

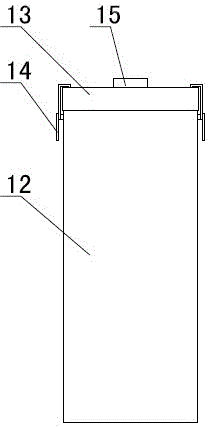

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

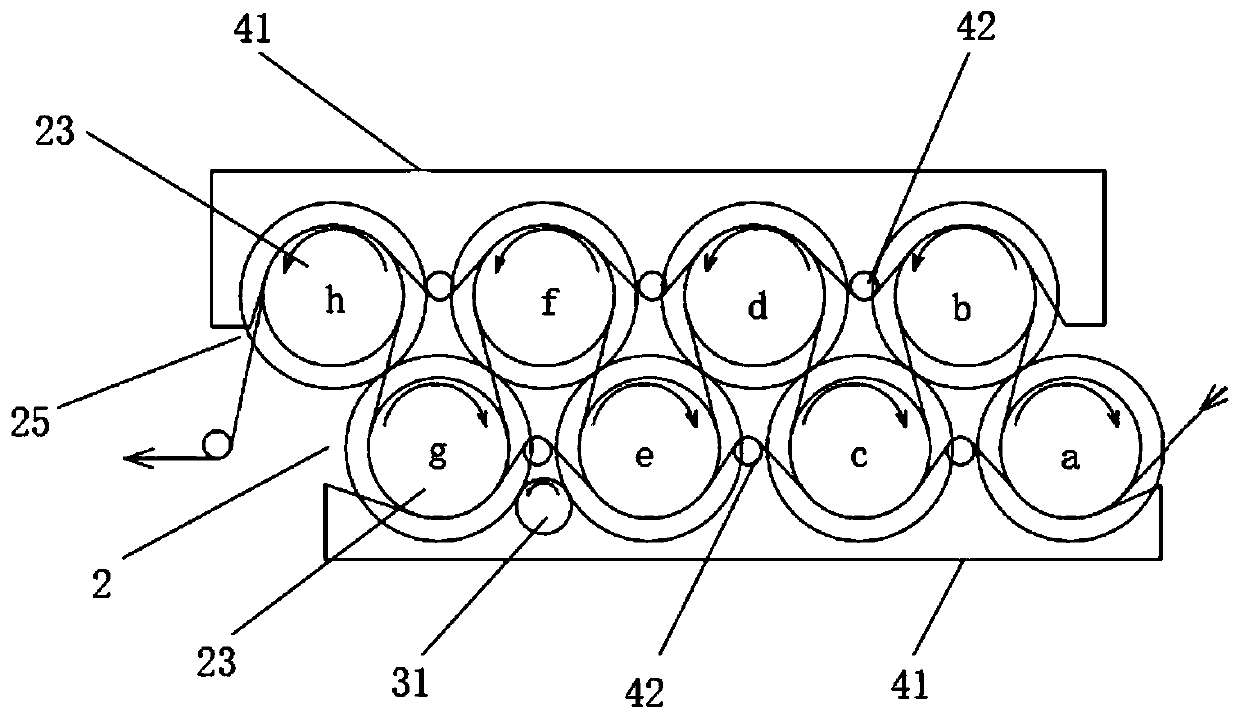

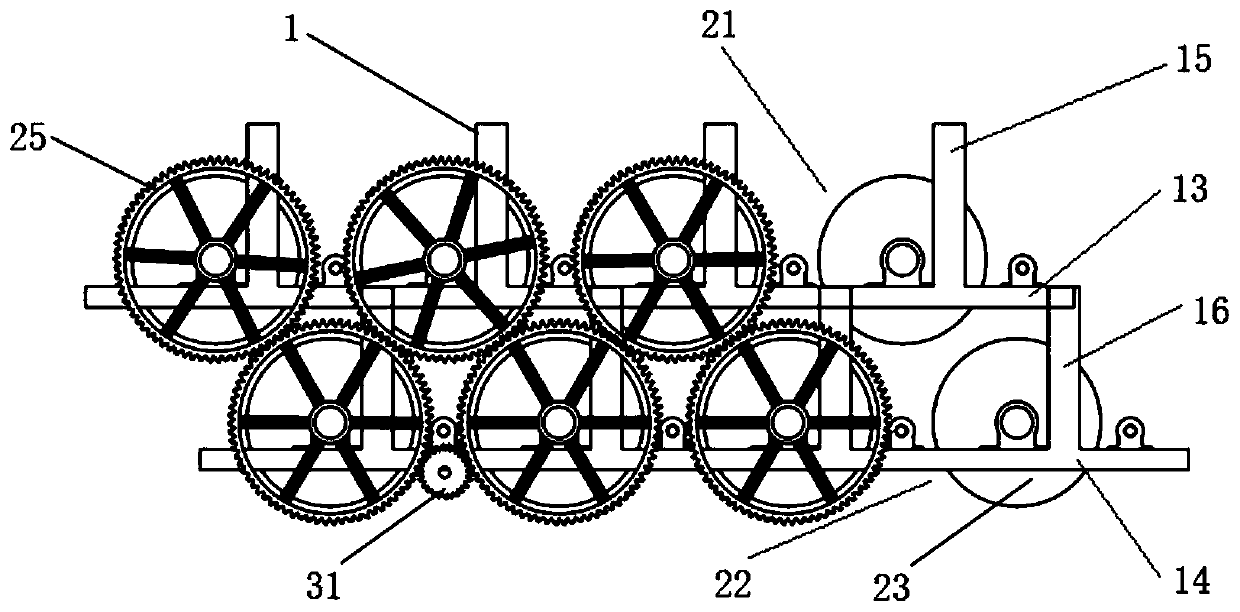

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

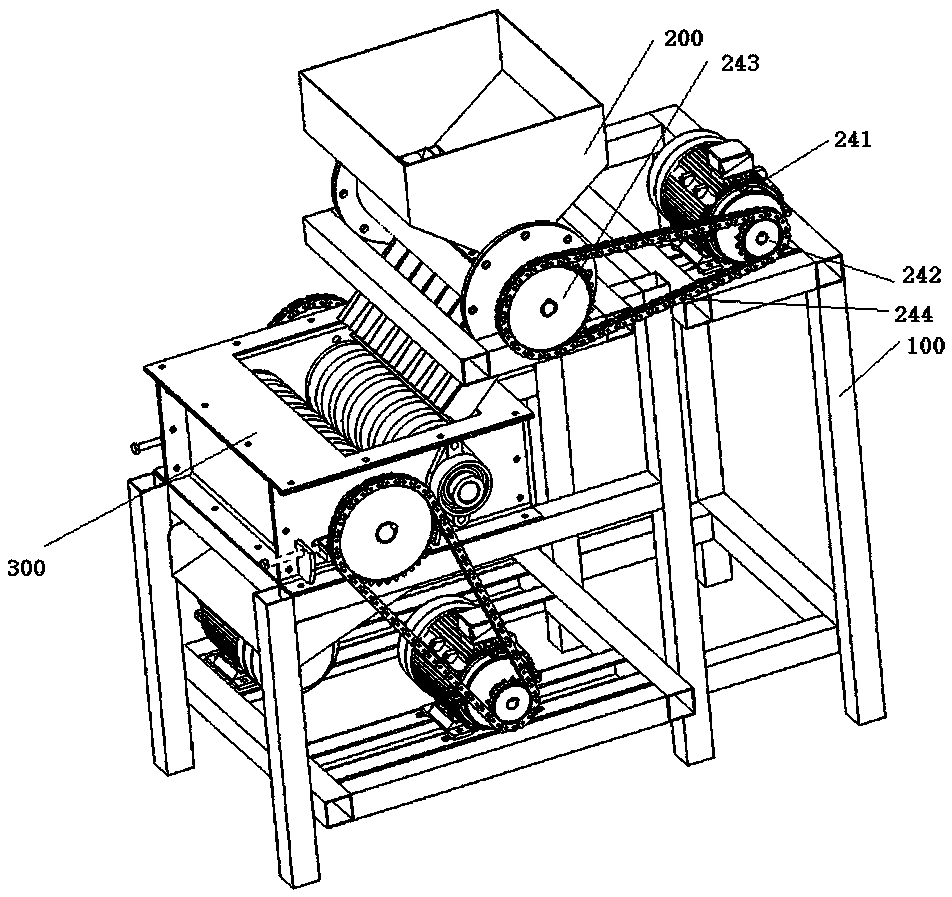

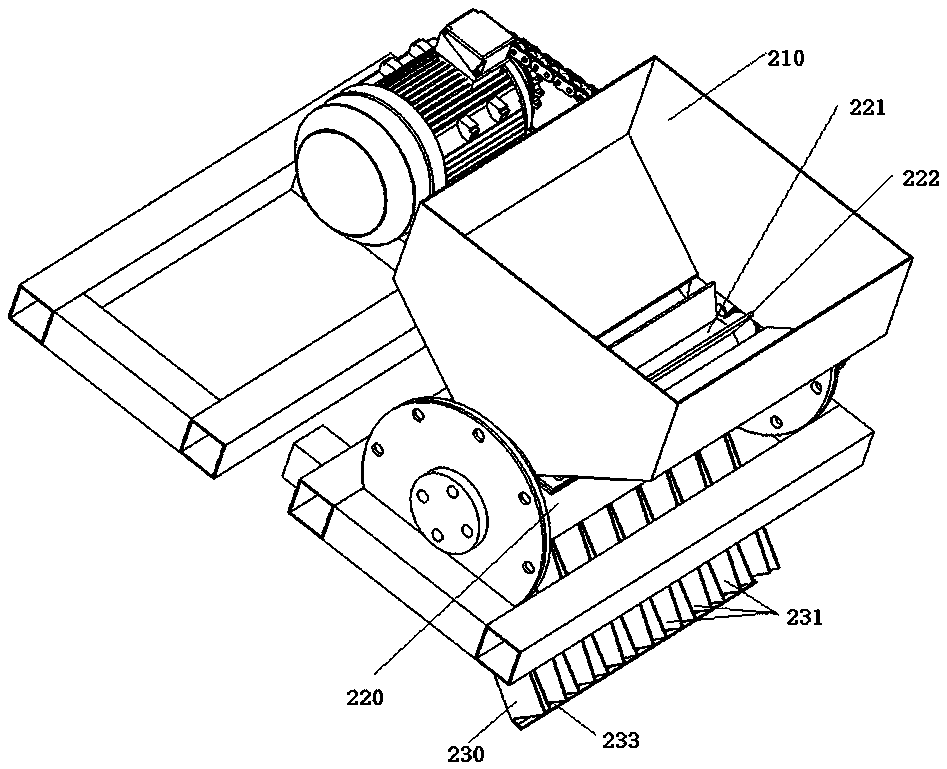

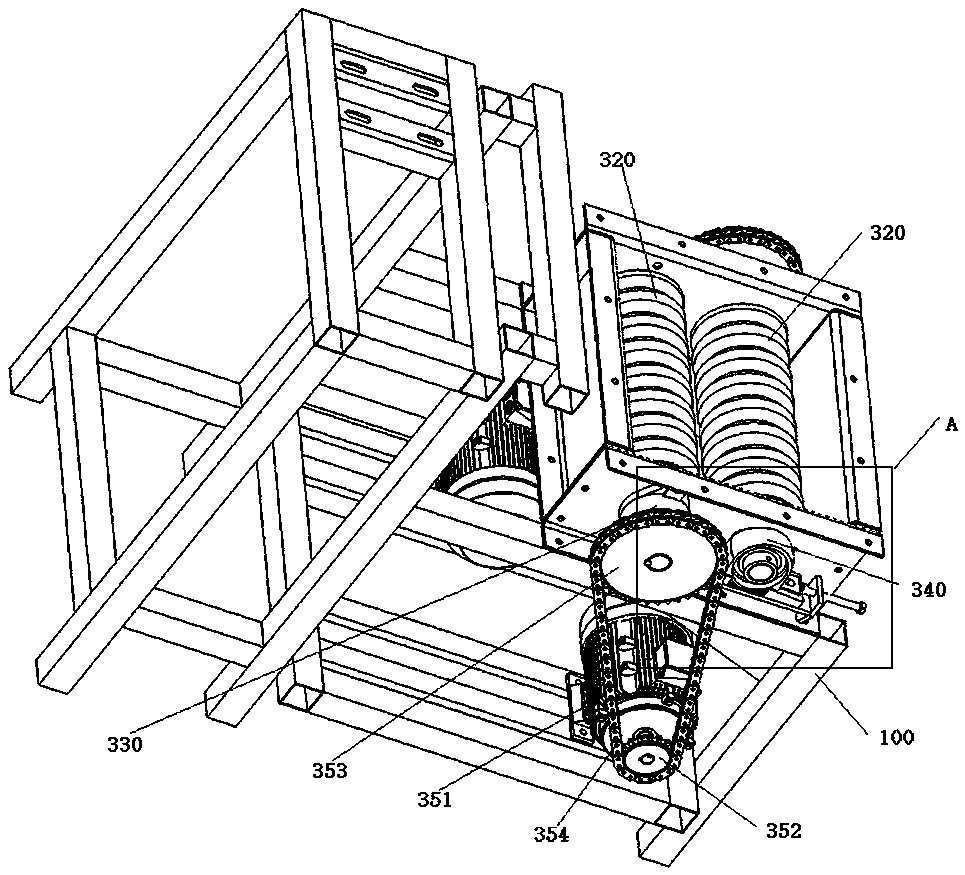

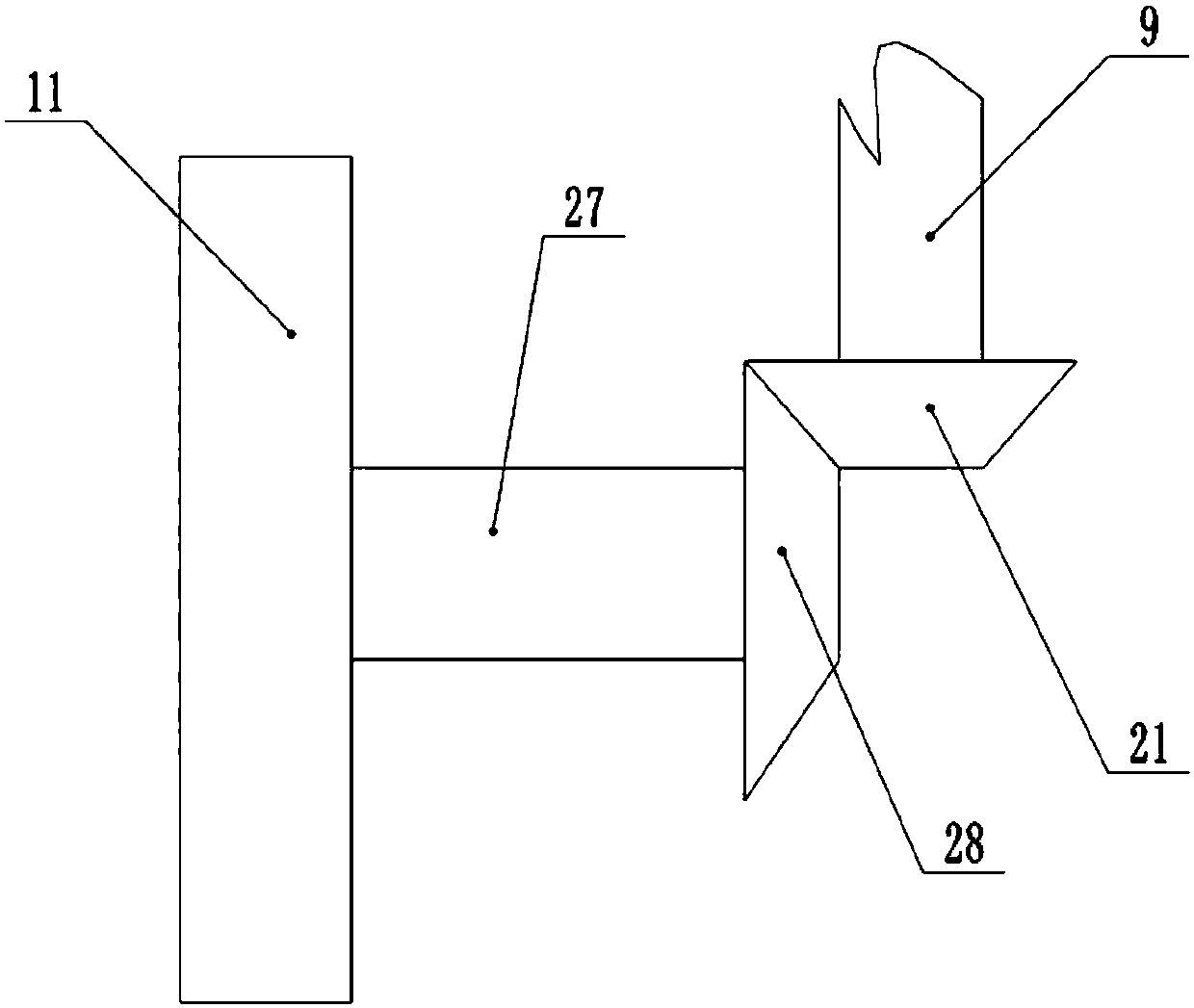

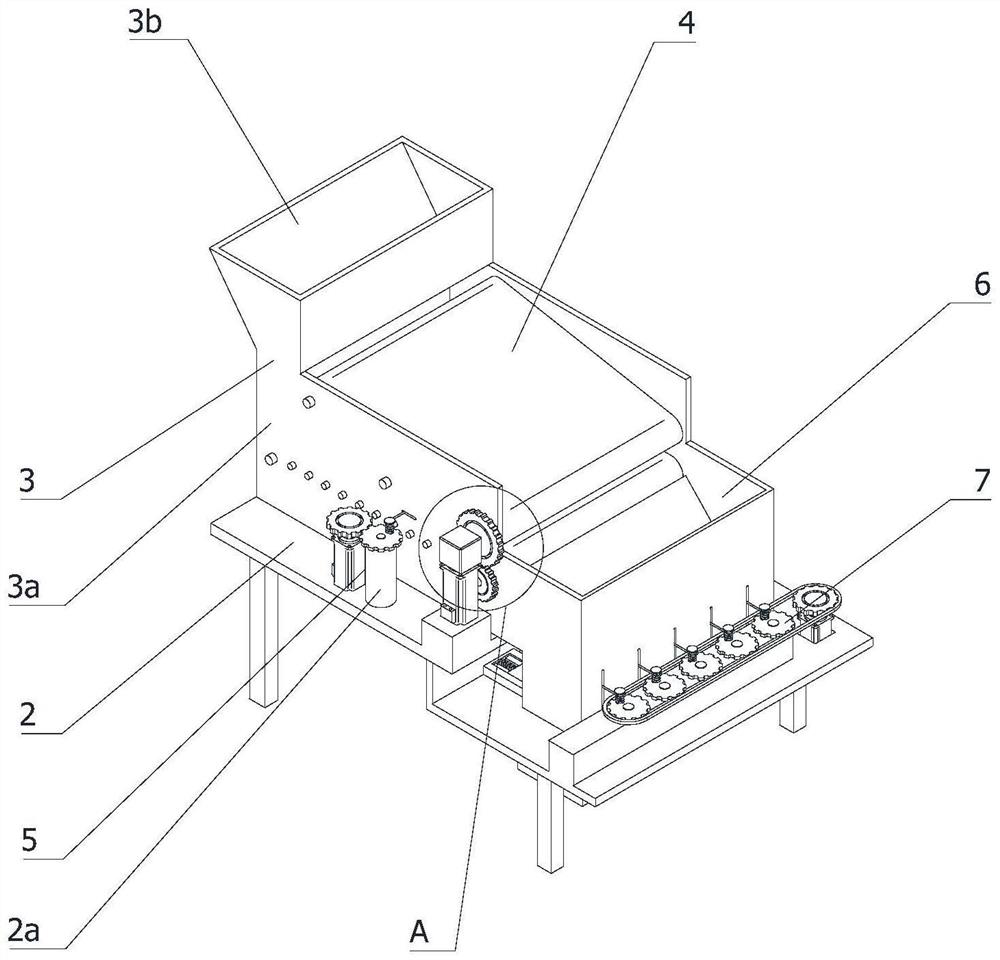

Hull breaking machine based on pretreated walnuts

The invention discloses a hull breaking machine based on pretreated walnuts, and relates to the field of walnut deep processing equipment. The hull breaking machine comprises a rack, an impeller feeding device and an opposite roller extrusion device; the impeller feeding device conducts feeding through an impeller to enable the walnuts to fall into the opposite roller extrusion device orderly, sothat the feeding efficiency is ensured; rollers of the opposite roller extrusion device are structurally optimized, V-shaped annular grooves in the rollers of the opposite roller extrusion device areformed alternately with roller sections to avoid mutual interference of the walnuts and improve the hull breaking efficiency, meanwhile one of the rollers is fixedly arranged, and the other roller isadjustable so as to adapt to hull breaking of the walnuts with different sizes and increase the kernel exposure rate; the impeller feeding device and the opposite roller extrusion device are both driven in a chain transmission mode, the driving speed of the impeller feeding device and the driving speed of the opposite roller extrusion device are matched to enable the materials to be smooth, the work continuity of the hull breaking machine is ensured, and the efficiency is improved; the outer surfaces of the rollers are wrapped with a PVC belt, jumping of the walnuts during falling is reduced,the extrusion efficiency is improved, meanwhile the adaptability of the walnuts in an extrusion work area is improved through the PVC belt, and the high kernel exposure rate is achieved.

Owner:SHIHEZI UNIVERSITY

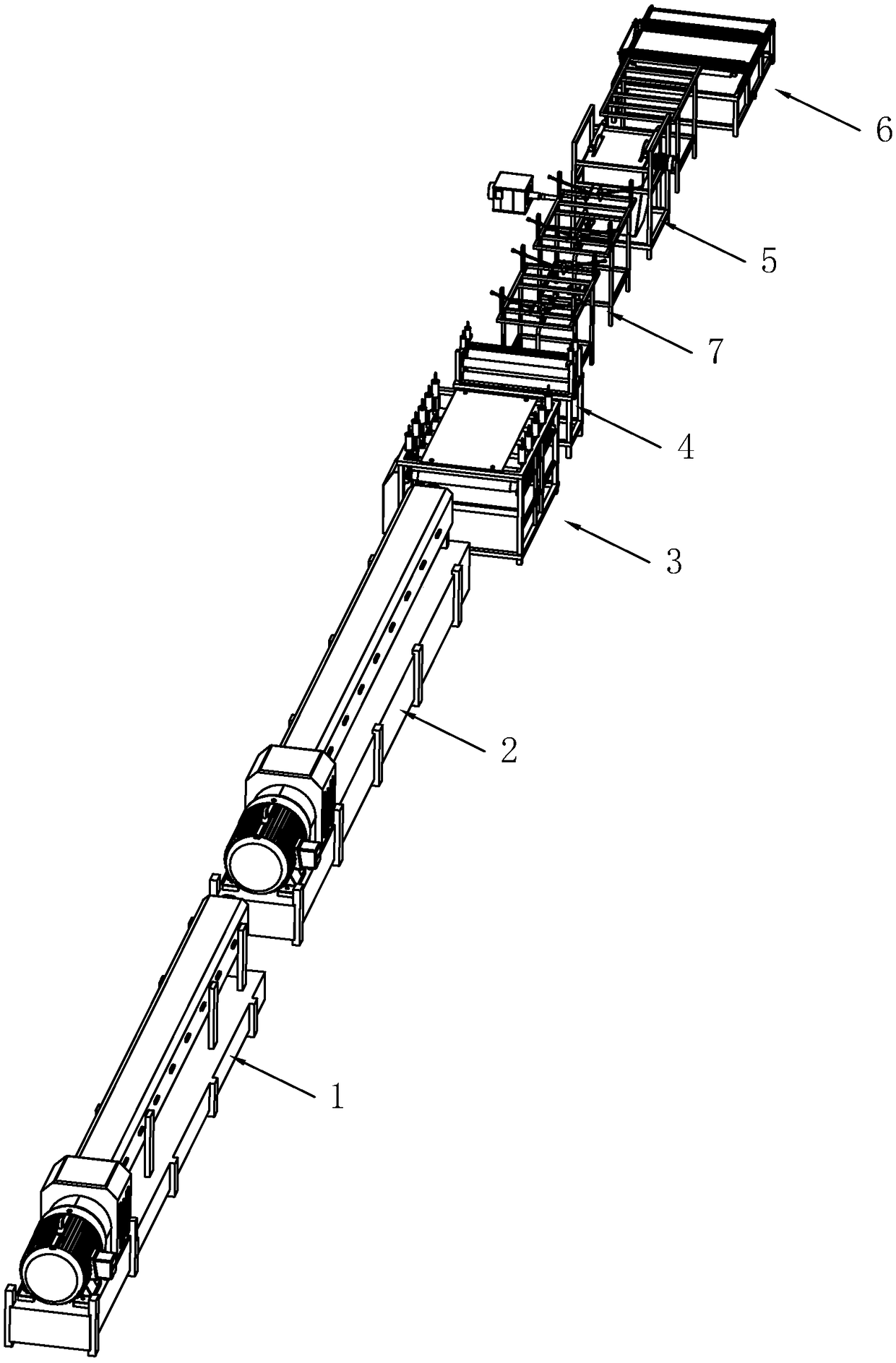

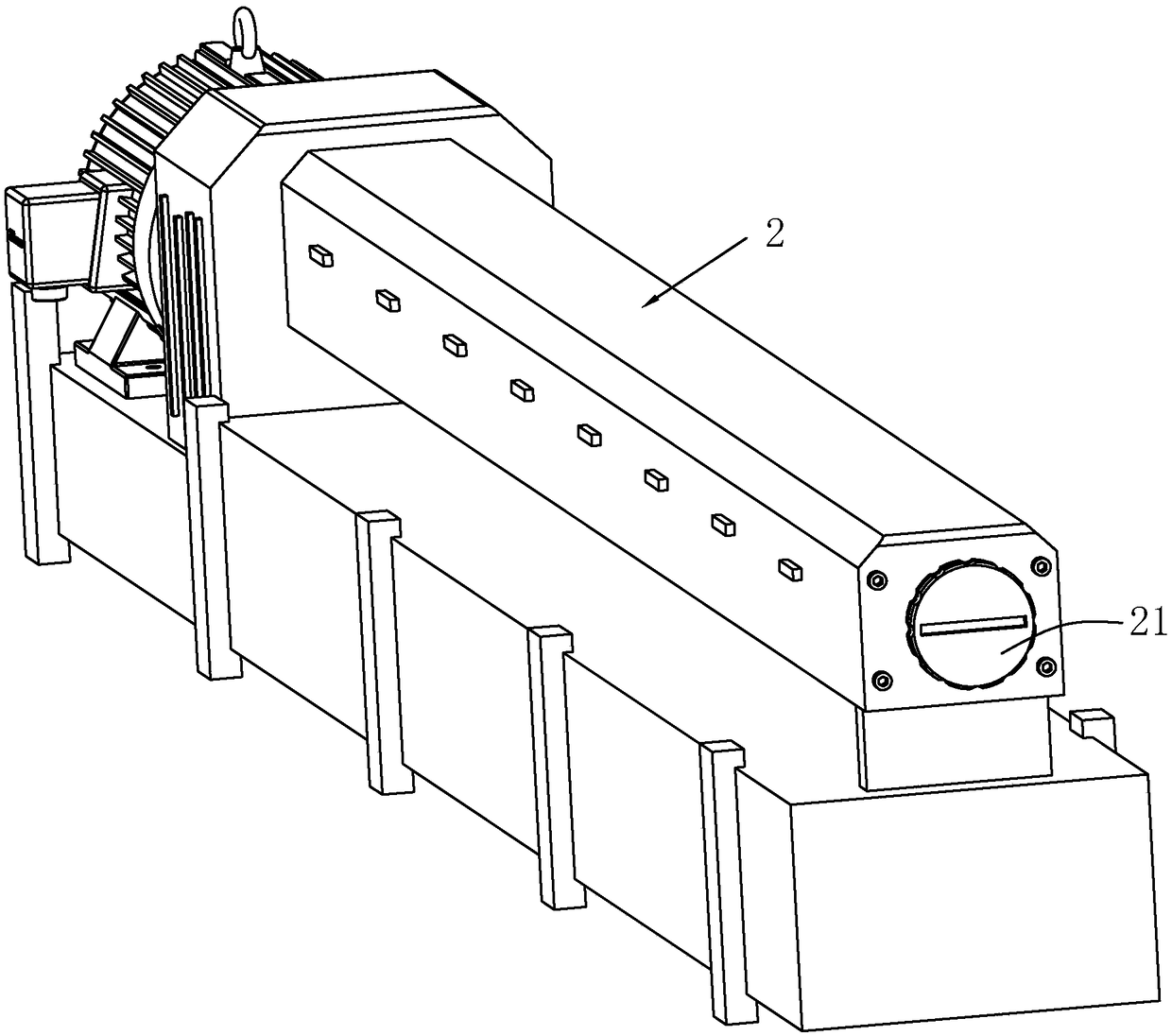

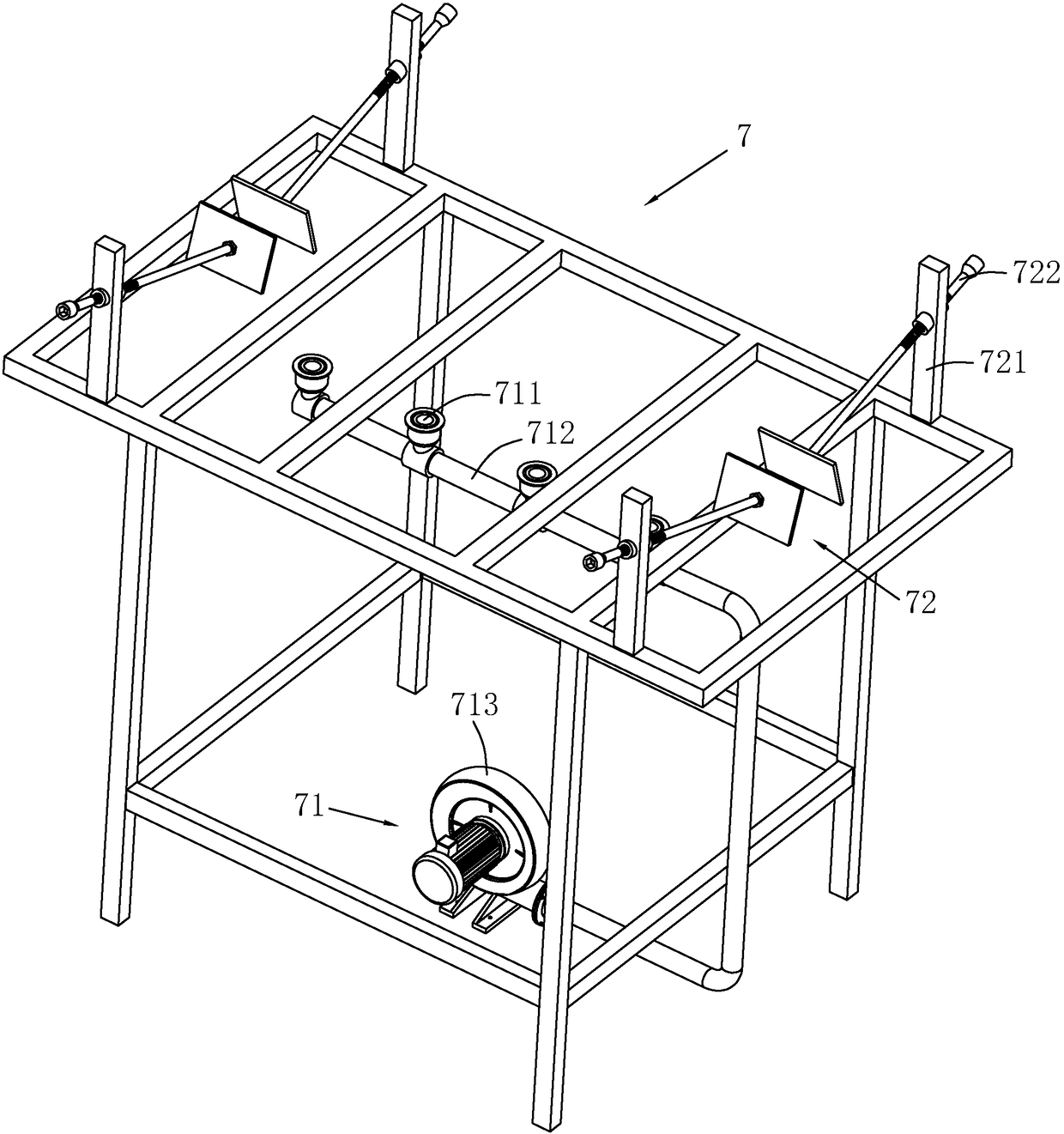

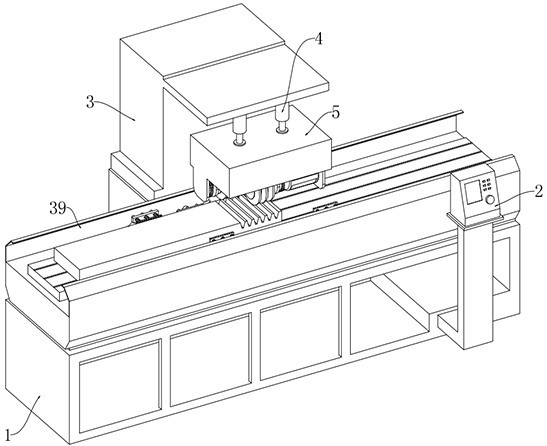

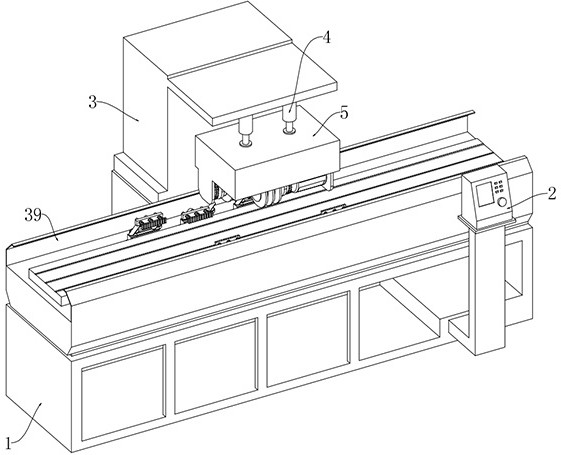

Foam plate extrusion production line

ActiveCN108582726AIncrease productivityImprove cutting efficiencyMetal working apparatusProduction lineConveyor belt

The invention relates to a foam plate extrusion production line. The foam plate extrusion production line comprises a double-cutting saw, and the double-cutting saw comprises a machine frame. A conveyor belt and a cutting device are arranged on the machine frame. The cutting device comprises connecting rods arranged on the both sides, in the transmission direction, of the machine frame. Rotating shafts are rotatably arranged in the connecting rods on both sides in a crossing mode. Fixed rods are arranged on the position, in the circumferential direction, of the rotating shafts. Telescopic rodsare arranged on the end portions, away from the rotating shafts, of the fixed rods in a sleeving mode. First cutters are arranged on the end portions, away from the fixed rods, of the telescopic rods. First springs are arranged between the fixed rods and the first cutters. The first springs are located in the telescopic rods. Sliding grooves are formed in the connecting rods. The sliding groovescomprise first horizontal sections, arc-shaped sections and second horizontal sections. Sliding blocks sliding in the sliding grooves are arranged on the first cutters, and the sliding blocks slide inthe sliding grooves and drives the first cutters to resist the elastic force of the first springs to move towards the foam plate to complete the cutting, so that the production efficiency is improved.

Owner:南京昊翔机械制造有限公司

Shaft part marking device

The invention relates to a shaft part marking device. The shaft part marking device comprises a workbench and a marking head, wherein a marking frame is arranged on the workbench in a sliding mode; the top of the marking frame is in threaded connection with a screw; the marking head is positioned on the marking frame; a spring is connected between the marking frame and the marking head; a fixed plate and a movable plate are arranged at the two sides of the marking frame; a triangular chuck, a first chain wheel and a transverse shaft are arranged on each of the fixed plate and the movable plate; each transverse shaft is fixedly connected on the corresponding first chain wheel; a bevel gear is connected between each transverse shaft and the corresponding triangular chuck; a chain is engagedbetween two first chain wheels; a straight gear is connected on the first chain wheel at the left side; a rack which is engaged with the straight gear is connected on the marking frame; the bottom ofthe workbench is connected with a vertical slide rail; a second chain wheel engaged with the chain is connected on the slide rail in a sliding mode; and a connecting rod is rotatably connected betweenthe second chain wheel and the first chain wheel on the movable plate. The scheme realizes axial movement of the marking head along shaft parts, and the shaft parts also can automatically rotate in aradial direction.

Owner:重庆市合川区云天机械制造有限公司

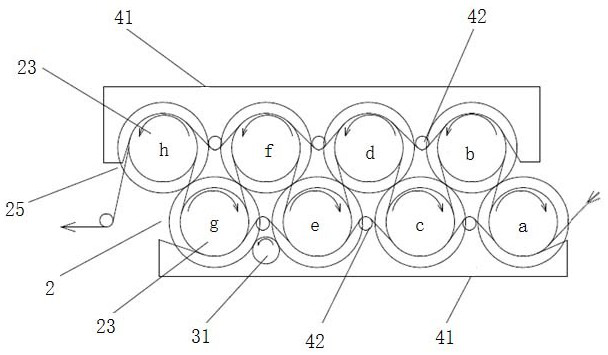

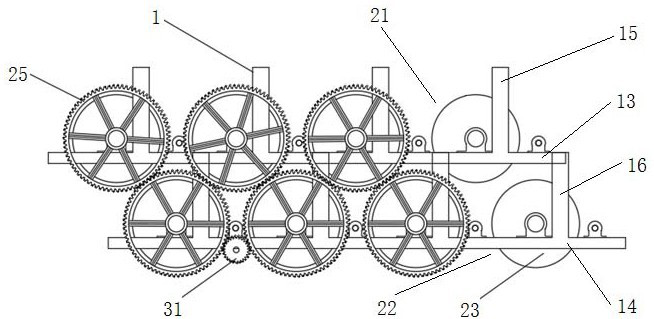

Papermaking drying cylinder mechanism

ActiveCN111501394AExtended run lengthImprove drying effectDryer sectionPaper sheetElectric machinery

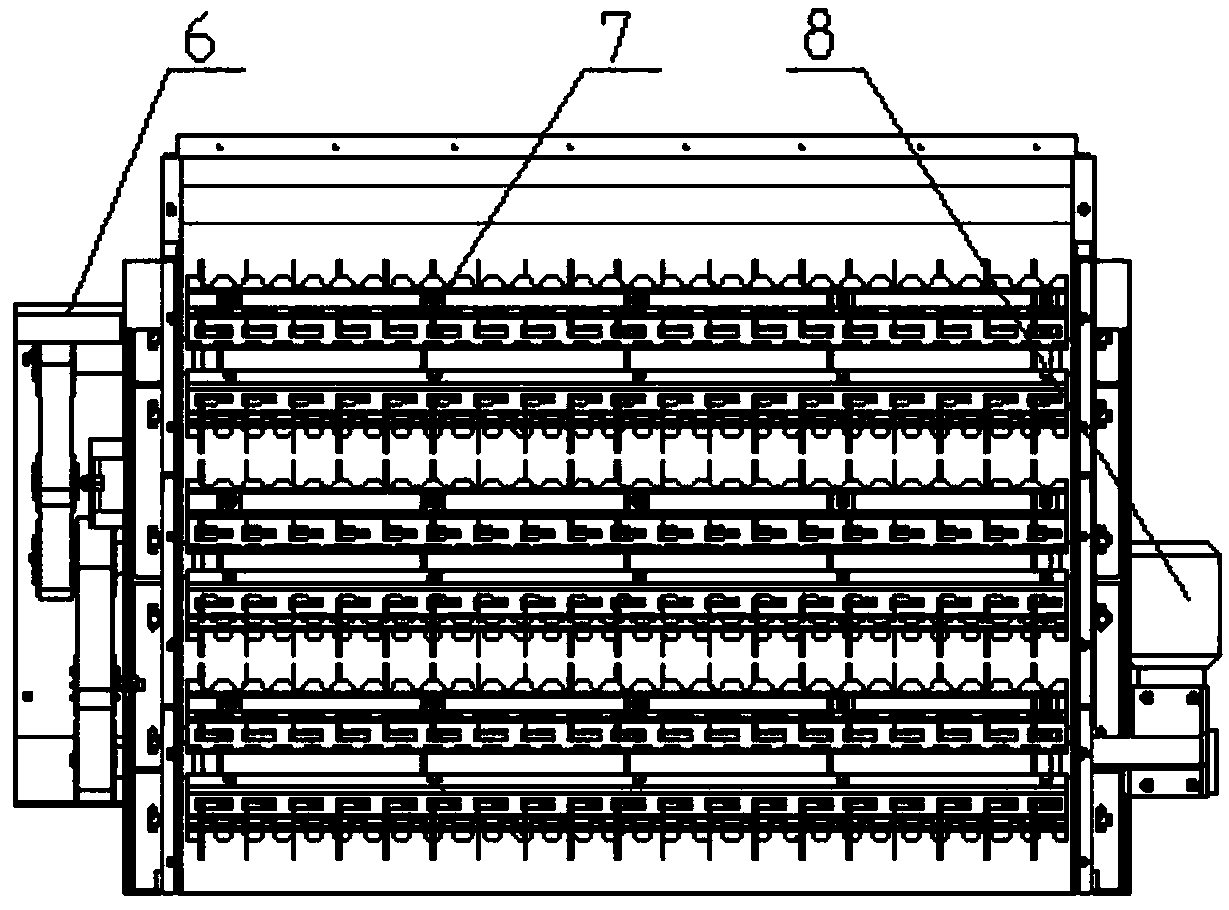

The invention relates to the technical field of papermaking, and specifically relates to a papermaking drying cylinder mechanism that comprises a machine frame; a plurality of drying cylinder assemblies installed on the machine frame; a driving assembly is in transmission connection with any drying cylinder assembly, a bearing assembly is installed on the periphery of the whole drying cylinder assembly, and a brake assembly is installed on the driving assembly, wherein the drying cylinder assemblies comprise the upper drying cylinder assembly and the lower drying cylinder assembly which are arranged in an up-down staggered mode. The upper drying cylinder assembly and the lower drying cylinder assembly each comprise a drying cylinder body, a center shaft axially penetrating through the drying cylinder body and a transmission gear installed at the front end of the center shaft. The driving assembly comprises a motor, a driving shaft fixedly connected with the output end of the motor anda driving gear fixedly connected with the other end of the driving shaft, and the driving gear is in meshing transmission with any transmission gear; the driving shaft is sleeved by the brake assembly. According to the papermaking drying cylinder mechanism, a paper web can be dried and conveyed stably, the tension of paper can be better adjusted, and the production quality of the paper is improved.

Owner:DONGGUAN JINTIAN PAPER CO LTD

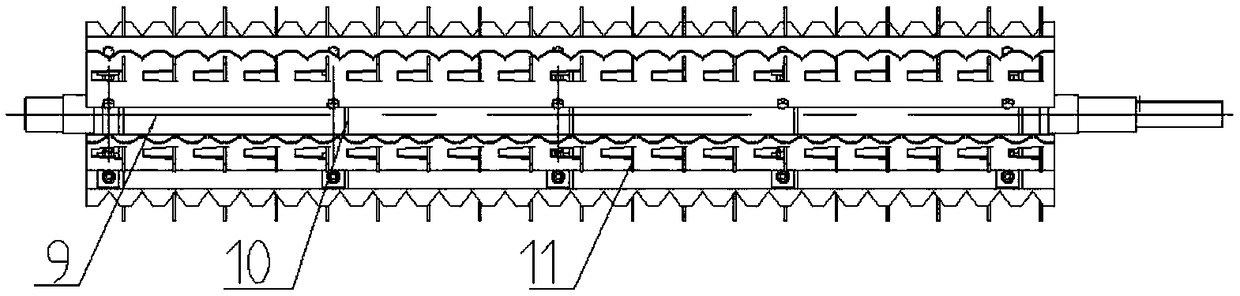

Material stirring device of quantitative feeder for straw organic fertilizer

ActiveCN109230391ASmall running resistanceImprove delivery efficiencyThrowing machinesConveyorsAcute angleOrganic fertilizer

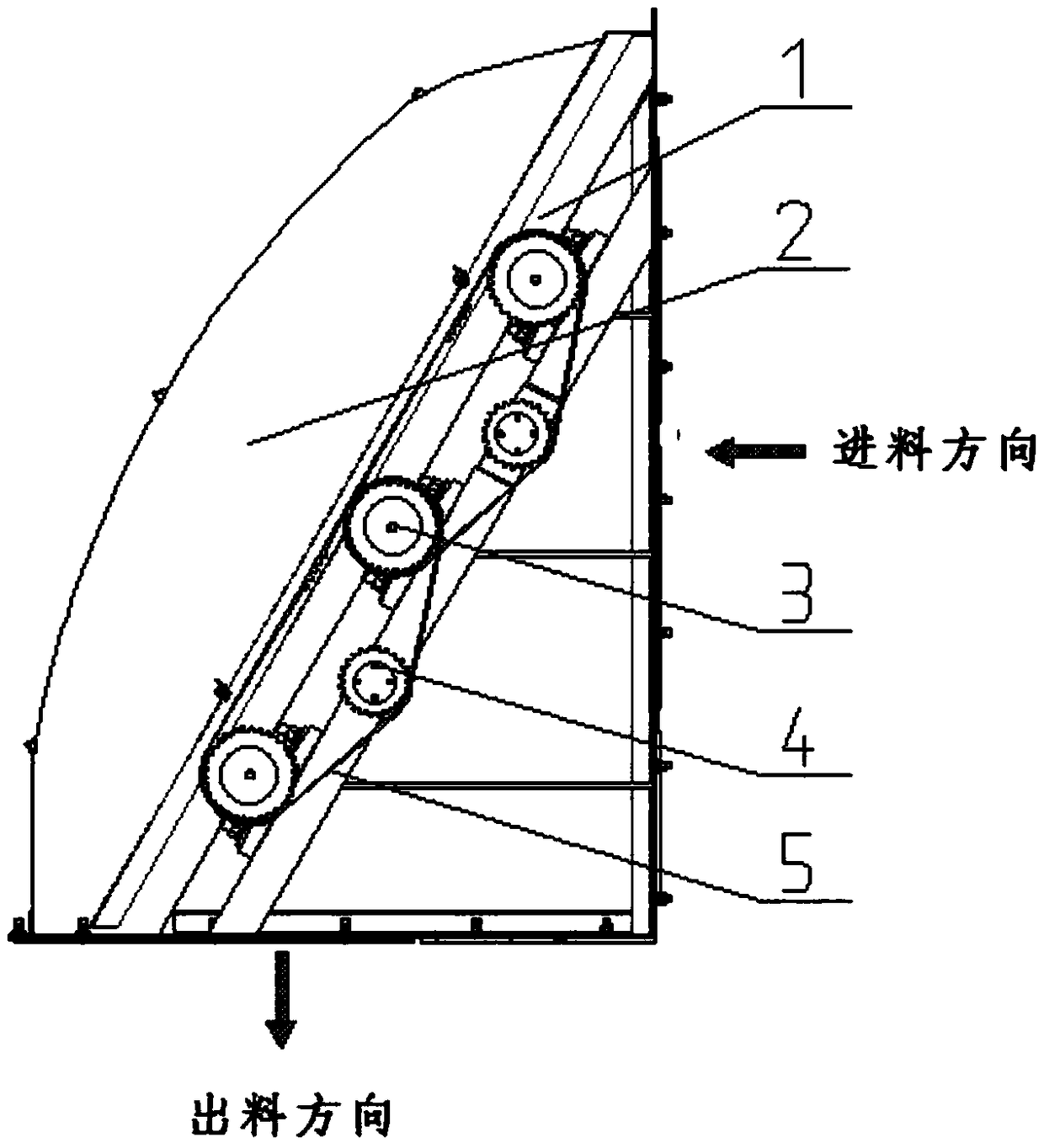

The invention discloses a material stirring device of a quantitative feeder for straw organic fertilizer production. The material stirring device comprises at least one material stirring roller. The material stirring roller comprise a roller body and at least a material stirring plate uniformly arranged in a circumferential direction of the roller body, wherein the roller body can rotate when being driven by a driving device, the material stirring plate is arranged in an axial direction of the roller body and is mounted on the roller body via a connecting device, comb teeth and stirring teethare arranged on the material stirring plate, and the comb teeth are arranged in a row along an axial line of the roller body while the stirring teeth are arranged in a different row along the axial line of the roller body. Axial lines of a plurality of material stirring rollers are mounted on one machine rack and on the same plane, the plane and a material feeding direction form a certain acute angle, a linear arrangement structure is formed, a bottom part of the machine rack is a material outlet direction, and the material outlet direction and the material feeding direction form an angle of 90 degrees.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

A new energy-saving wall lamp device

InactiveCN107143789BEasy to insertEasy to installLighting support devicesLight fasteningsStructural engineering

Owner:重庆市桑麻环保技术研究院有限公司

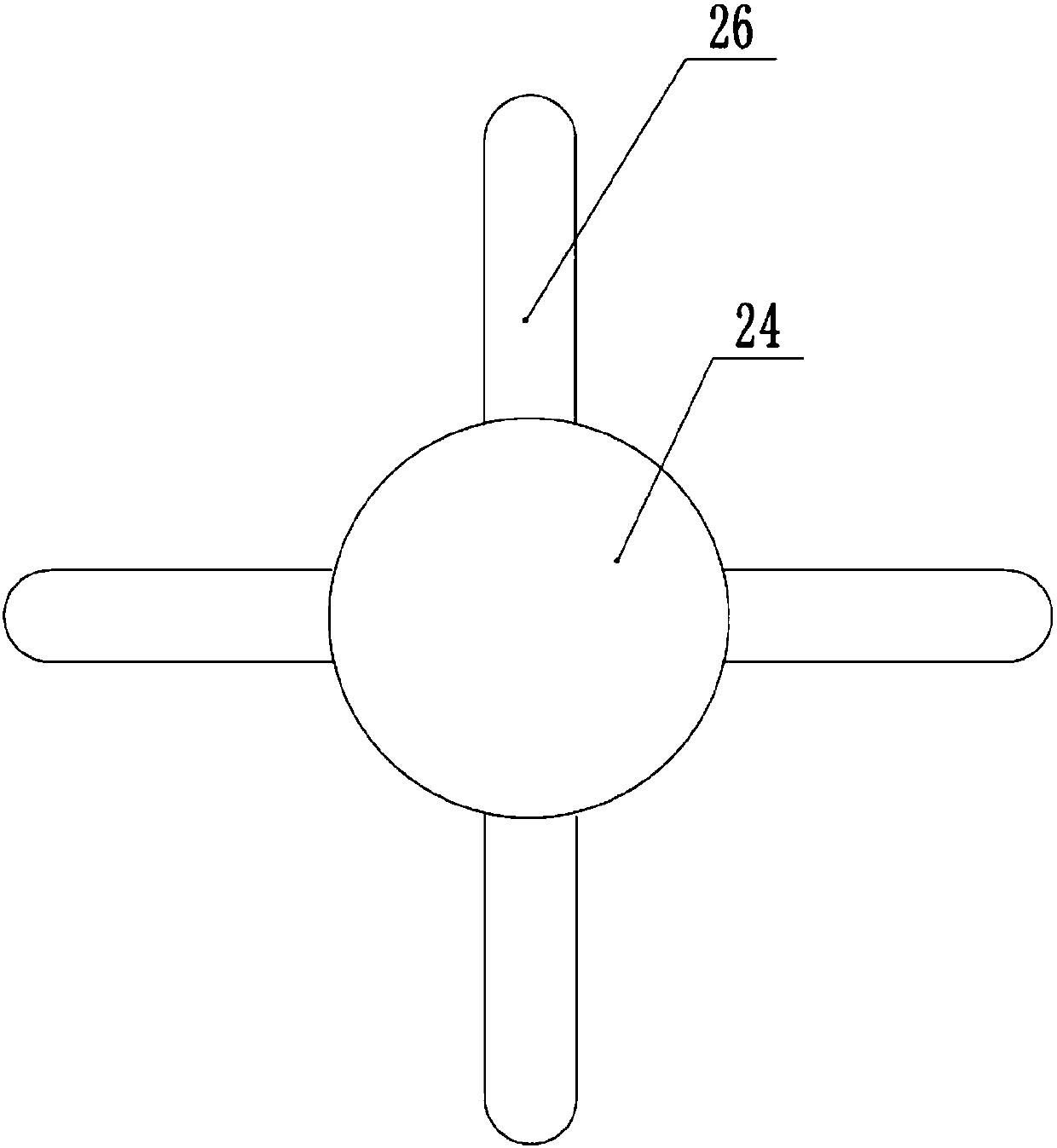

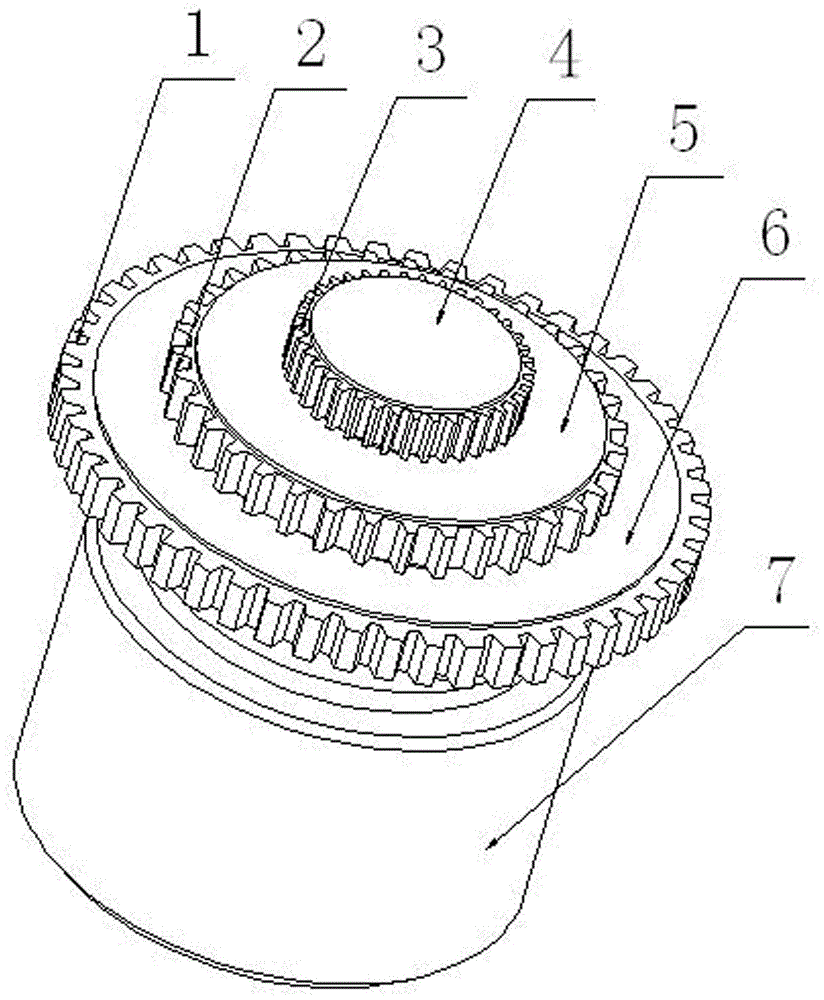

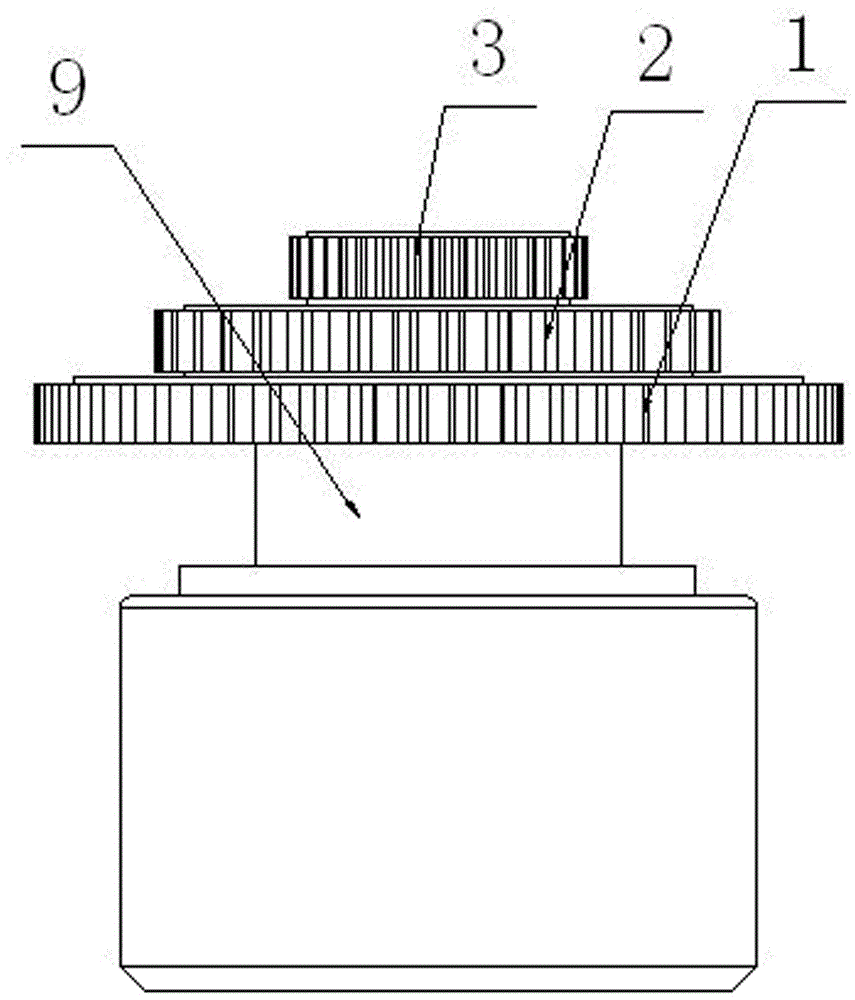

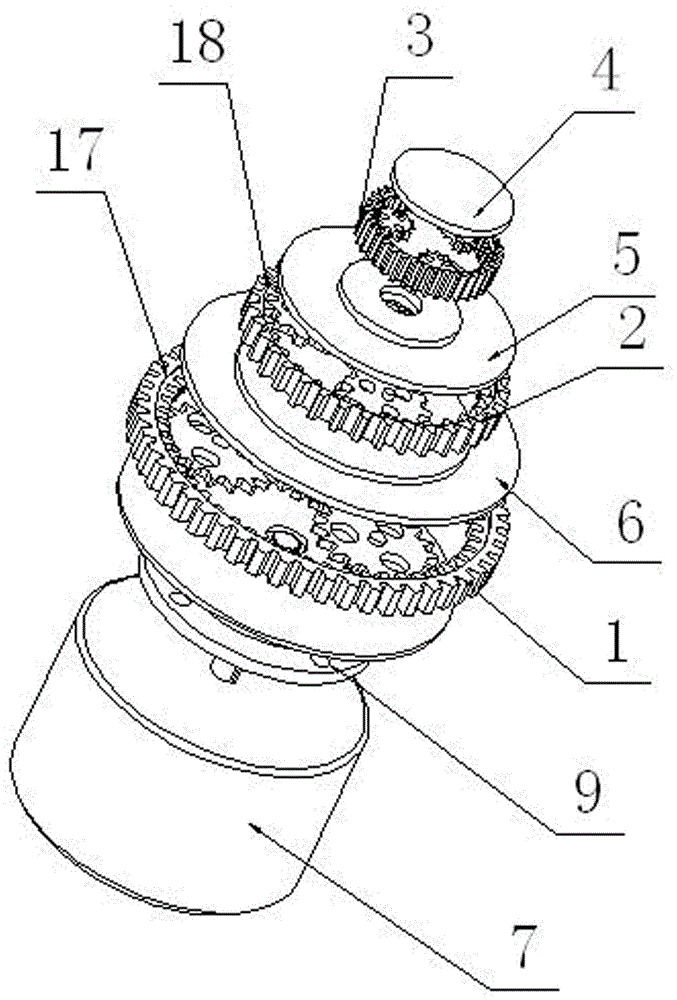

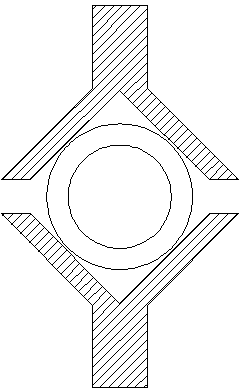

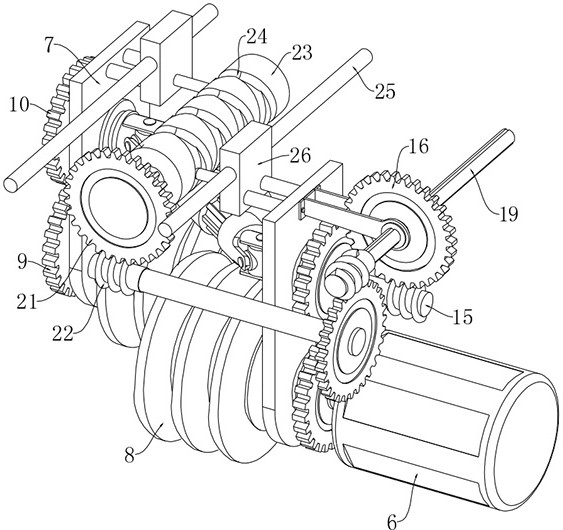

Speed change gear of automatic skin cleaning bath instrument

ActiveCN105782360ASame rotation speedConsistent rotation speedBathroom accessoriesToothed gearingsSkin cleanMechanical engineering

The invention discloses a speed change gear of an automatic skin cleaning bath instrument, and relates to a bath head. The speed change gear comprises a first same-speed ring, a second same-speed ring and a third same-speed ring; the first same-speed ring includes an outer tooth A, an inner tooth, three small gears, a ring gear A, pin shafts and two glands C; the outer tooth A is arranged on the outer side of the gear ring A; the inner tooth is arranged on the inner side of the gear ring A, and is engaged with the small gears; the pin shafts are respectively arranged in the center positions of the three small gears; the two glands C are respectively positioned on the upper and lower two surfaces of the gear ring A; the second same-speed ring includes a gear ring B, an outer tooth B, an inner tooth, three small gears, pin shafts and two glands B; the outer tooth B is arranged on the outer side of the gear ring B; the inner tooth is arranged on the inner side of the gear ring B; as the outer tooth A, the outer tooth B and an outer tooth C rotate with the same speed, an inner ring, a middle ring and an outer ring of the bath head also rotate with the same speed; and when the three rings of the bath head rotate with the same speed, the bath effect is greatly improved, and more convenience is brought to users.

Owner:陈景刚

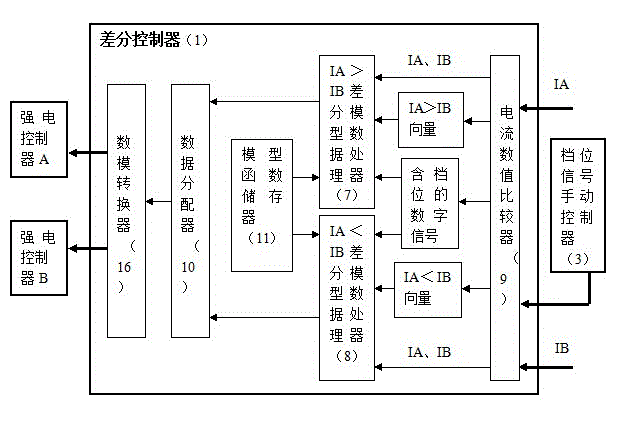

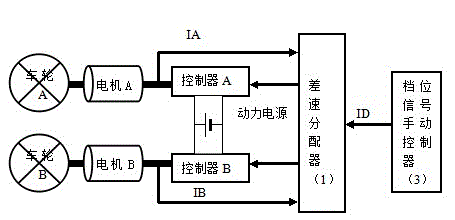

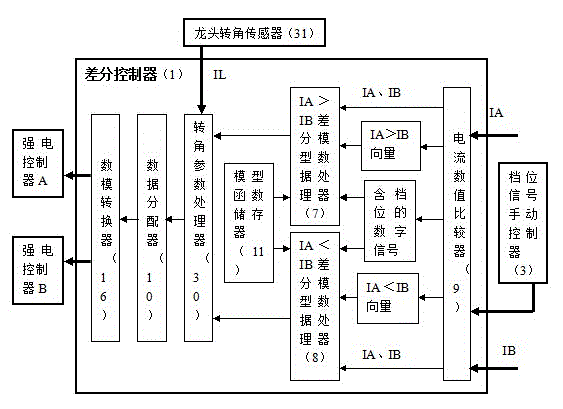

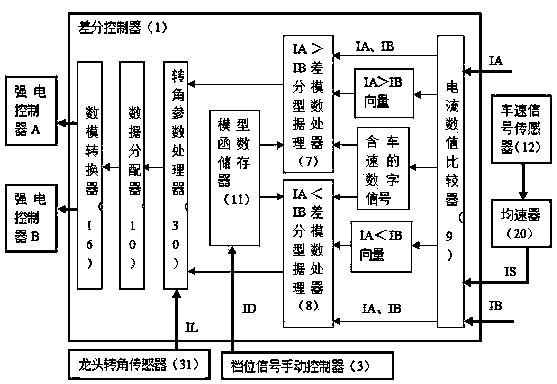

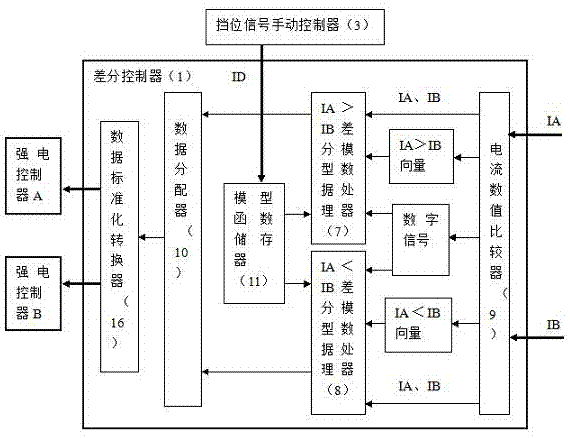

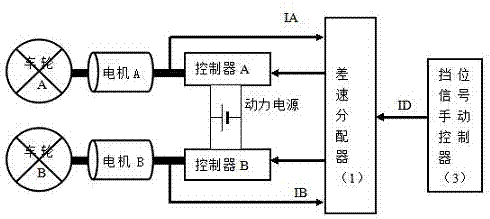

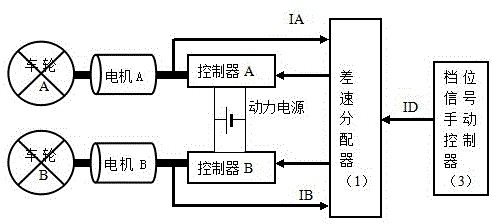

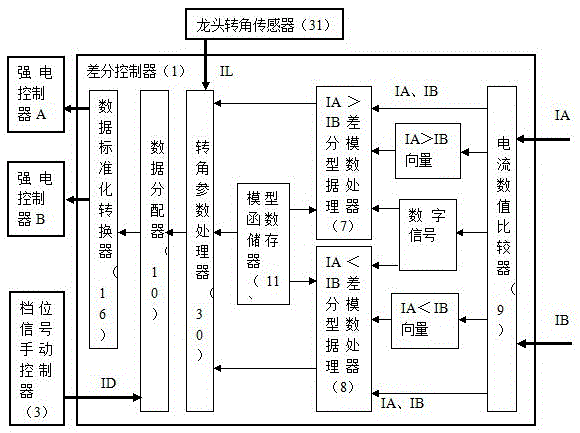

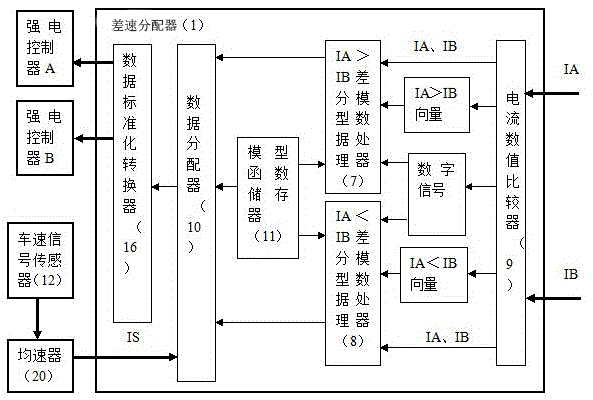

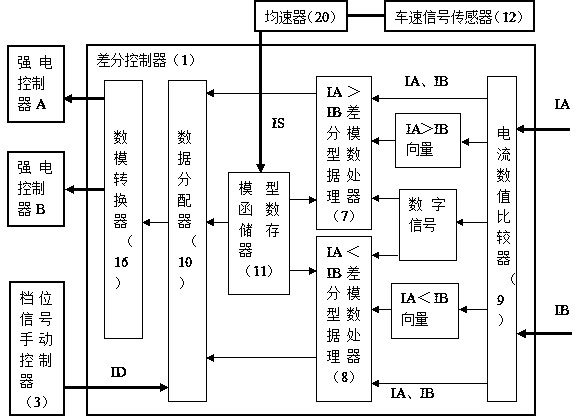

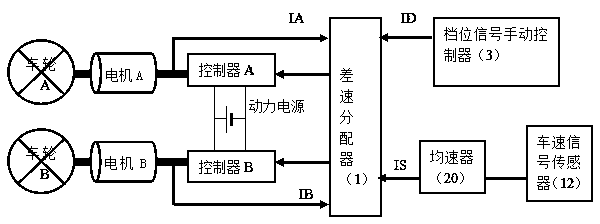

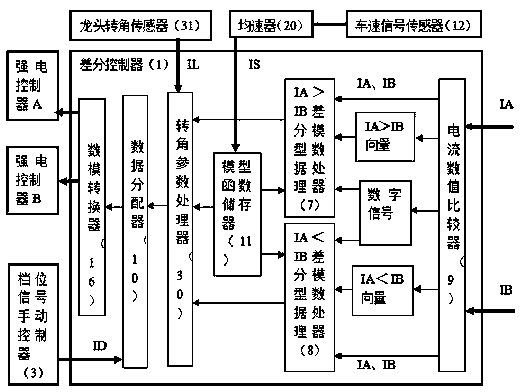

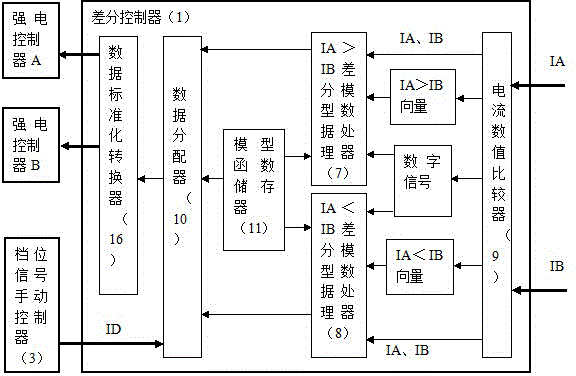

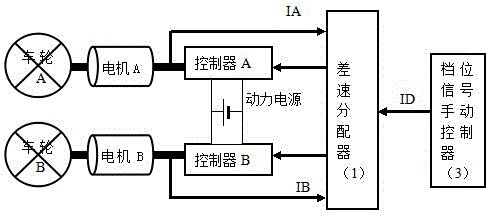

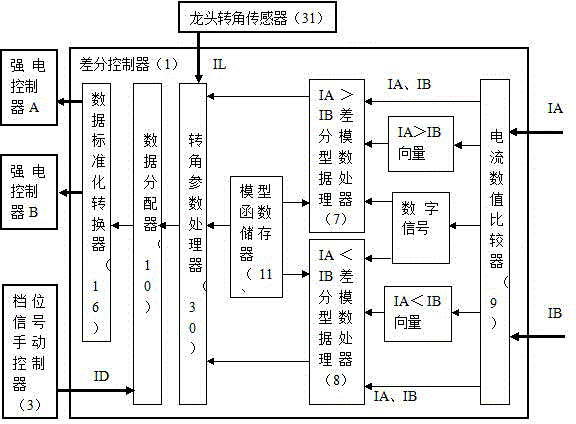

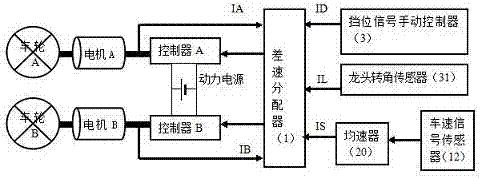

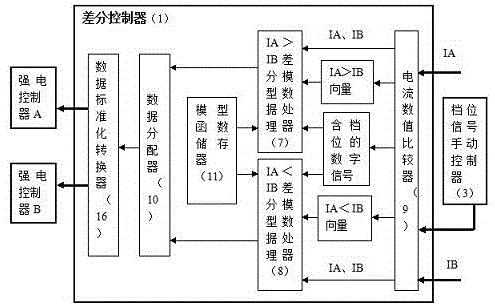

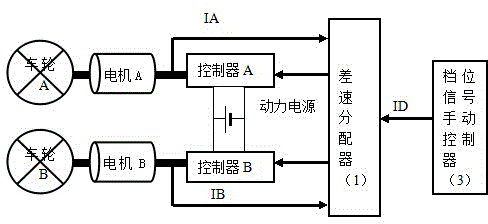

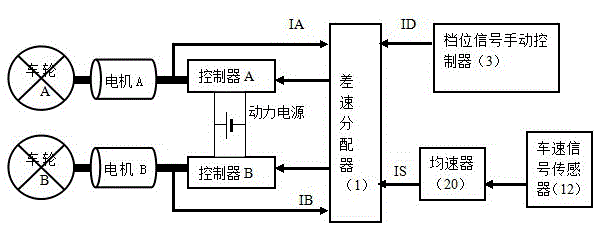

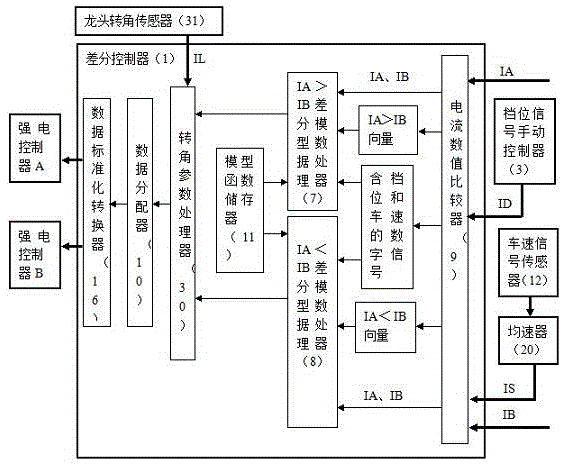

Voltage differential control moped system for gear signal feeding comparator

InactiveCN104139826ASame rotation speedNo waste of electricityRider propulsionCycle actuatorsElectricityElectric machine

The invention discloses a voltage differential control moped system for a gear signal feeding comparator and belongs to a power supply controller system for differentially supplying assistance power for a power-assisted bicycle with parameters distributed to a front wheel and a rear wheel. The voltage differential control moped system for the gear signal feeding comparator comprises two wheels and two motors of an electric power-assisted bicycle, a manual gear signal controller and a differential controller, wherein the differential controller comprises three modules which are sequentially connected with one another; a first module is used for comparing values of a gear signal ID taken as an original input signal for controlling in the manual gear signal controller, feedback control signal current IA and feedback control signal IB; a second module is used for carrying out model function treatment on data of the first module by using a set model function; a third module is used for distributing the model function treatment to a controller A and a controller B which are taken as controlled electric appliances. The voltage differential control moped system for the gear signal feeding comparator has the advantages that the two motors of the front and rear wheels of the power-assisted bicycle are differentially controlled and powered; the differential control content is the predetermined model function treatment.

Owner:陈金花

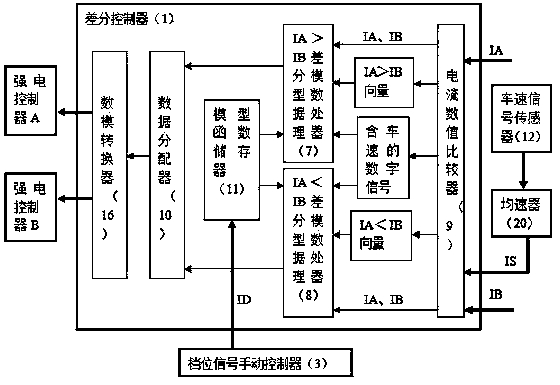

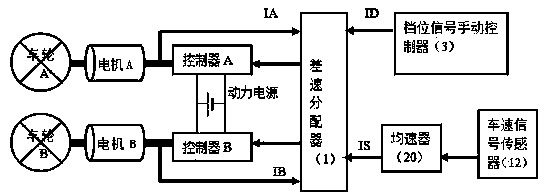

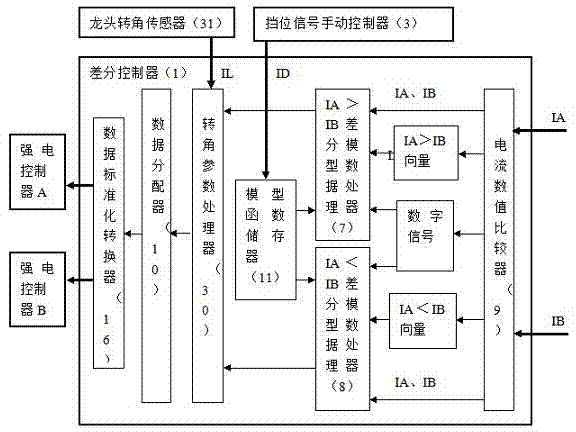

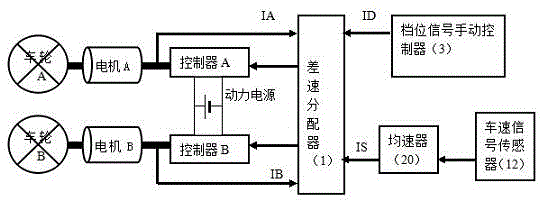

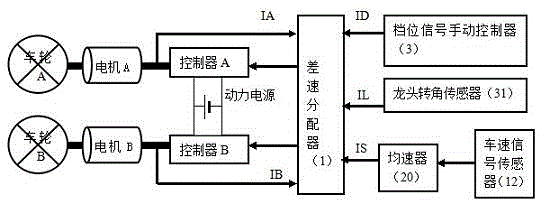

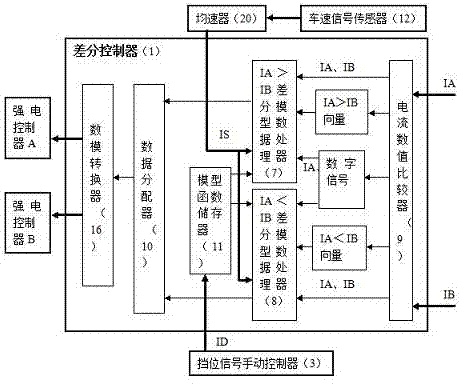

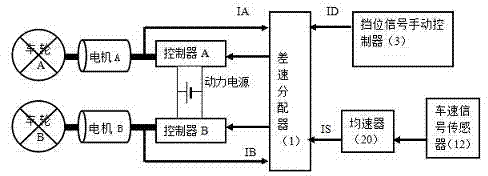

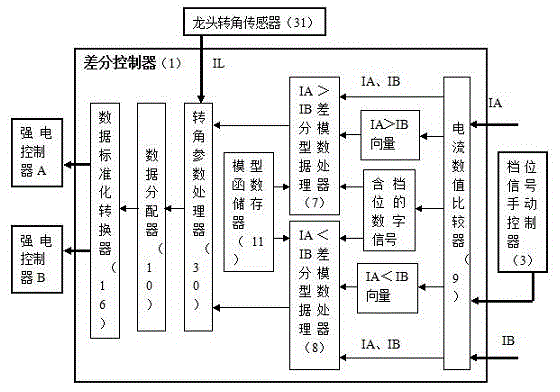

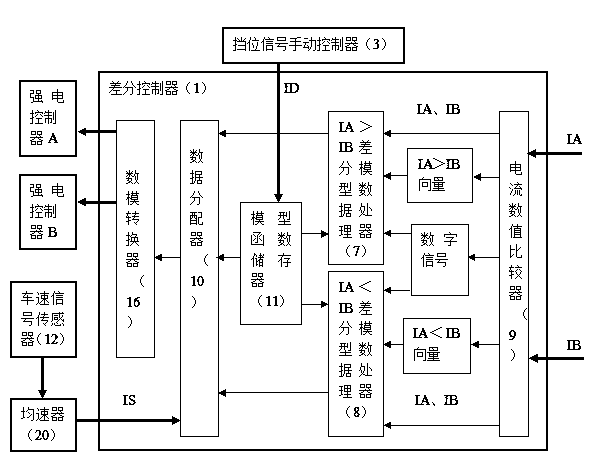

Voltage differential assisted bicycle system with requirement of inputting gear signal and speed signal into differential distributor

InactiveCN104129468ASame rotation speedNo waste of electricityRider propulsionCycle actuatorsElectricityPower flow

The invention provides a voltage differential assisted bicycle system with the requirement of inputting a gear signal and a speed signal into a differential distributor, and belongs to an assisted bicycle power supply controller system for distributing the differential of a front wheel and a back wheel which are used for supplying assisted power in a differentiation manner. The system comprises two wheels and two motors of the assisted bicycle, manual gear signal controllers, and a differential distributor, wherein the differential distributor comprises three modules which are successively connected; the first module is used for comparing the values of an average speed signal IS of the bicycle and feedback control signal currents IA and IB; the second module is used for processing the data through a model function by utilizing a gear signal ID to select a model function; and the third module is used for obtaining the control data which comprise the four elements, such as the feedback control signal currents IA and IB, the gear signal ID, and the average speed signal IS of the bicycle through the controllers A and B. The system has the advantages that the front wheel, the back wheel and the two motors of the assisted bicycle are supplied with the power in a differentiation control manner, and the differentiation control is performed by previously processing set model function.

Owner:CHENGDU KUANHE TECH +3

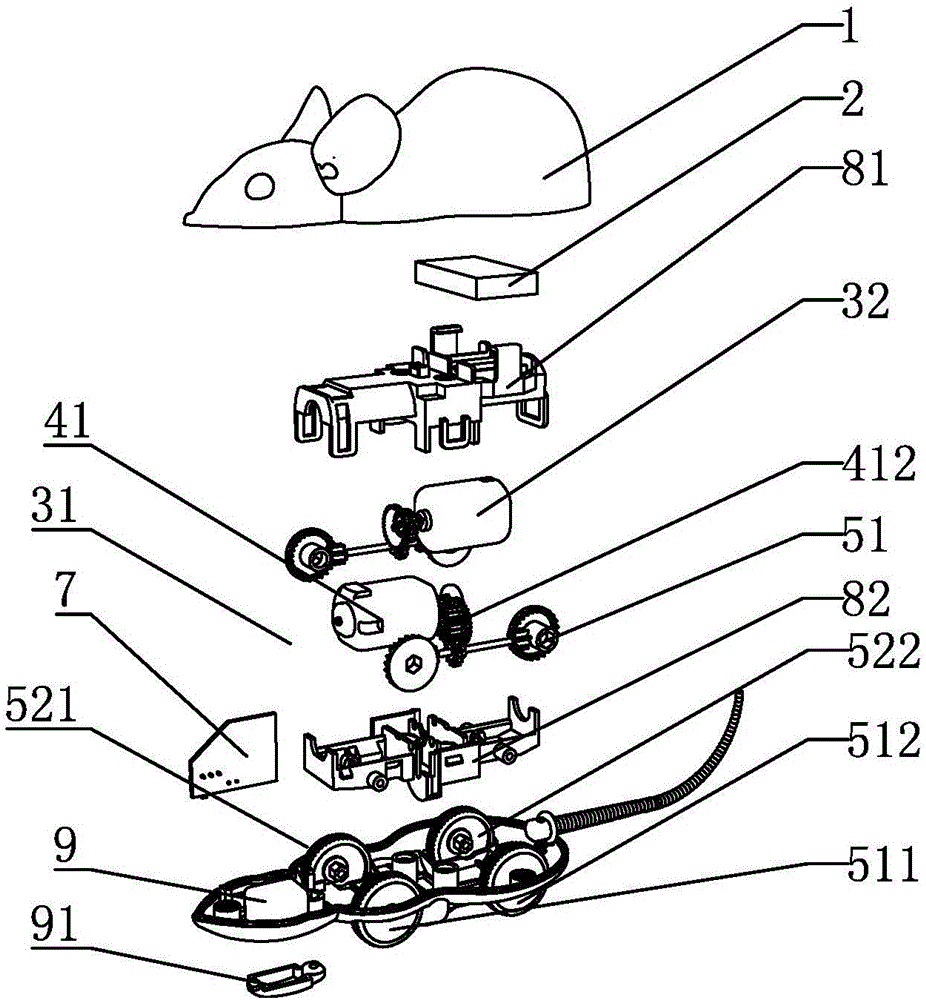

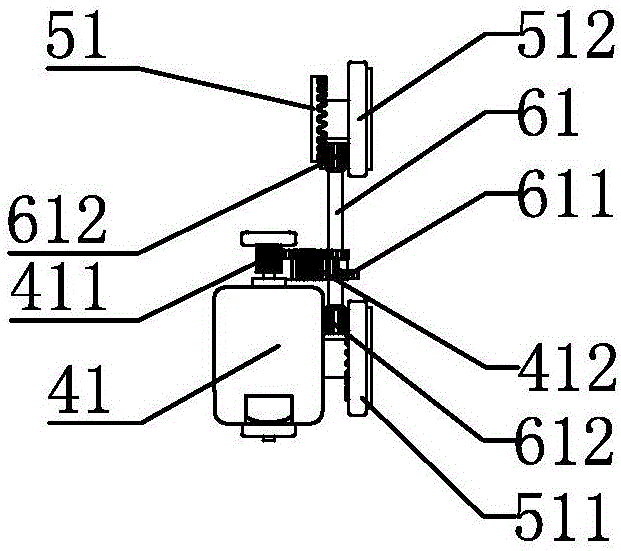

Electric pet toy and method for controlling same

InactiveCN106719056AMove forward flexiblyFlexible retreatTaming and training devicesElectric machineRemote control

The invention discloses a pet toy, and particularly relates to an electric pet toy and a method for controlling the same. The electric pet toy comprises a shell, and is characterized in that two independent driving devices are further arranged in the shell, each driving device comprises a bi-directional motor and rolling wheels, the bi-directional motors are in transmission connection with the rolling wheels by machinery, parts of the rolling wheels extend to be positioned on the outer side of the bottom of the shell and are in contact with the ground, the two bi-directional motors are respectively connected with a control unit, the control unit is provided with signal receivers, and the signal receivers are in signal connection with remote control ends. The electric pet toy and the method have the advantages that the two driving devices are independently arranged, and accordingly the electric pet toy can be flexibly driven to advance, retreat or turn.

Owner:HANGZHOU TIANYUAN PET PROD

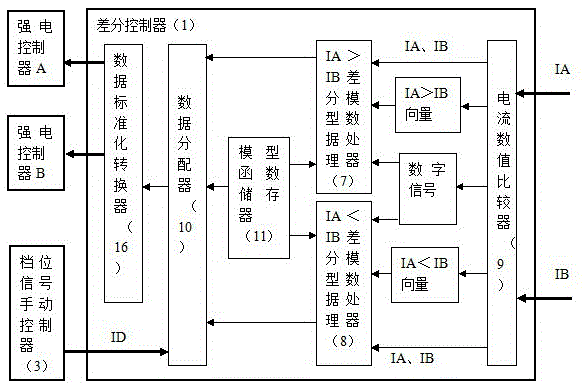

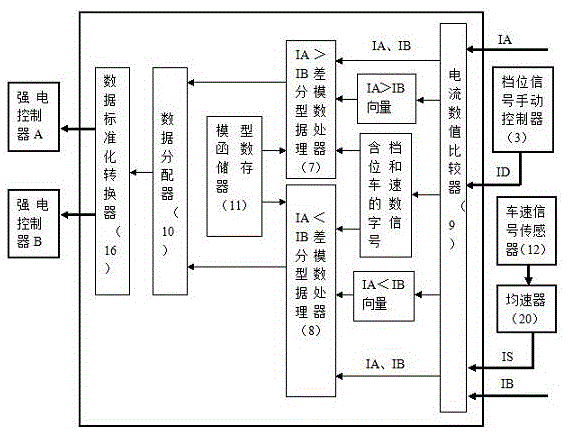

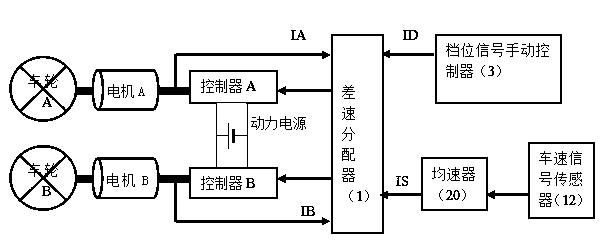

Digital differential control aided bicycle system with gear signal adding model processors

ActiveCN104742759ASame rotation speedNo waste of electricitySpeed controllerRider propulsionElectricityControl signal

The invention provides a digital differential control aided bicycle system with gear signal adding model processors and belongs to an aided bicycle power supply controller system differentiated in aiding power supply and providing differential aiding power distribution for a front wheel and a rear wheel. The digital differential control aided bicycle system comprises two wheels and two motors of an electric aided bicycle and a manual gear signal controller and further comprises a differential controller, wherein the differential controller comprises three modules connected in sequence. The first module is used for conducting numeric comparison processing on original input signal feedback control signal currents IA and IB for control. The second module is used for using a gear signal of the manual gear signal controller and selecting a model function set in a model function memory to conduct model function processing on data of the first module. The third module is used for allocating model function processing data to a controller A and a controller B of a controlled electric appliance. The digital differential control aided bicycle system has the advantages that differentiated power supply control is conducted on the two motors of the front wheel and the rear wheel of the aided bicycle, and a differentiated control content is the model function processing set in advance.

Owner:江苏海丰交通设备科技有限公司

Gear signal processing output signal digital differential control booster system

ActiveCN104149650BSame rotation speedRotation speed is not wastedSpeed controllerRider propulsionDigital signal processingControl signal

The digital differential control booster system of the present invention, which processes the output signal of the gear signal, belongs to the power supply controller system of the front wheel and the rear wheel with differential distribution of the differential power supply for the booster bicycle. It includes two wheels and two motors of the electric power-assisted bicycle, a manual controller for the gear position signal, and a differential controller. The differential controller includes three modules connected in sequence; the first module feedbacks and controls the original input signal used for control The signal current IA and IB are numerically compared and processed; the second module uses the set model function to perform model function processing on the data of the first module; the third module inputs the gear signal ID of the gear signal manual controller to the differential controller The data distributor, so that the control data obtained by the controllers A and B not only have the feedback control signal, but also have the elements of the gear signal ID. Advantages: Differentially control and supply power to the two motors of the front and rear wheels of the power-assisted bicycle. The content of the differential control is the pre-set model function processing.

Owner:江苏鸿迅机车有限公司

Differential voltage control of the moped system with gear and speed signals input successively

InactiveCN104149651BSame rotation speedNo waste of electricitySpeed controllerElectric machinesElectricityControl power

The invention discloses a voltage differential control moped system with a gear signal and a speed signal input successively, and belongs to front wheel and rear wheel difference distributing assisting bicycle power supply controller systems for differentially supplying assisting power. The system comprises two wheels and two motors of an electric assisting bicycle and a gear signal manual controller, and further comprises a differential distributor, and the differential distributor comprises three modules connected in sequence. The first module carries out numeric comparison processing on a gear signal ID, a feedback control signal current IA and a feedback control signal current IB. The second module carries out model function processing on the data of the first module. The third module inputs a bicycle uniform speed signal IS into a data distributor (10), control data are processed with speed signal elements added, and a controller A and a controller B obtain the gear signal ID, the feedback control signal current IA, the feedback control signal current IB and the bicycle uniform speed signal IS. The system has the advantages that differential control power supply is respectively carried out on the two motors of the front wheel and the rear wheel of the assisting bicycle, and the content of differential control is preset model function processing.

Owner:管小利

A papermaking dryer mechanism

Owner:DONGGUAN JINTIAN PAPER CO LTD

Improved electric meter box device

InactiveCN107894522AEasy to insertEasy to lockTime integral measurementEngineeringMechanical engineering

Owner:四川软测技术检测中心有限公司

Spring polishing device

InactiveCN103419104ARealize clampingTo achieve clamping, grinding in twoEdge grinding machinesSocial benefitsPolishing

The invention discloses a spring polishing device. With the adoption of the spring polishing device, the clamping of the spring is realized through two Y-shaped metal blocks; when two polishing plates are rotated backward, the condition that the two sides of the spring are horizontally polished can be realized; when the polishing plates are rotated in the same direction, the condition that the surface of the spring is polished can be realized; meanwhile, with the adoption of the spring polishing device, through a speed changing box, the rapid switching of polishing plate rotating directions is realized, the same rotating speed of the two polishing plates is guaranteed, and the spring is prevented from being damaged due to different rotating speeds; and the spring polishing device has good social benefits.

Owner:SUZHOU SHENGNENG MACHINERY

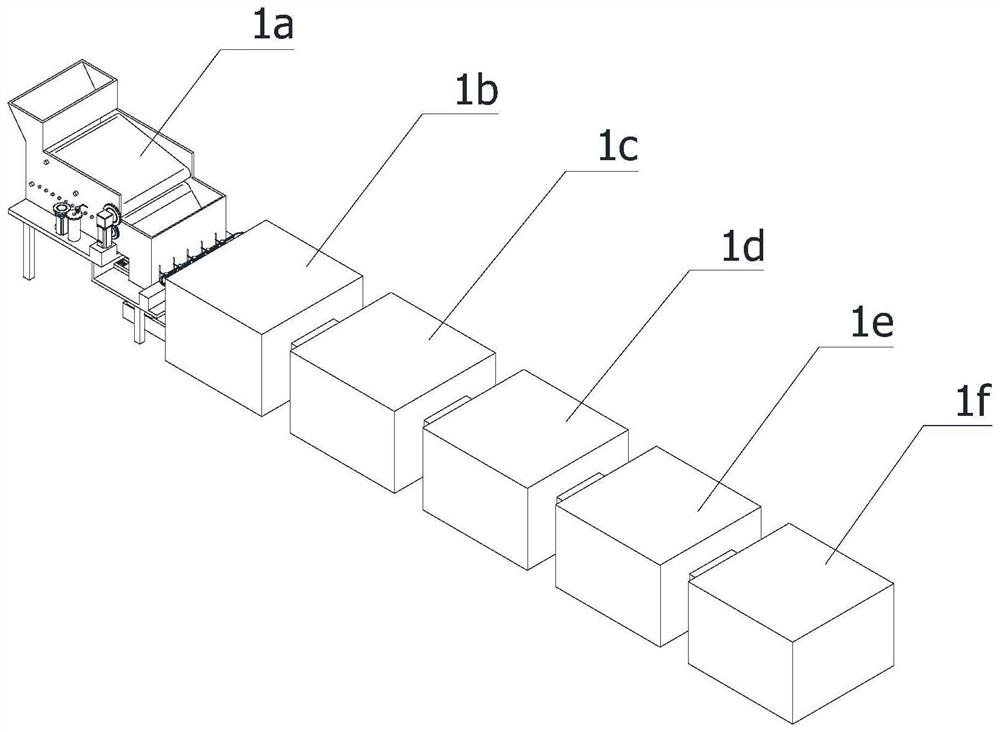

Equipment for extracting high-gelation-degree pectin from shaddock peel

PendingCN114102740AImprove cleaning efficiencyImprove drying efficiencyMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of biological extraction, and particularly relates to equipment for extracting high-gelation-degree pectin from shaddock peel, the equipment comprises a shaddock peel cutting device, a cleaning device, a drying device, a smashing device, a mixing and filtering device and a pectin precipitation device, the working ends of the shaddock peel cutting device, the cleaning device, the drying device, the smashing device, the mixing and filtering device and the pectin precipitation device are sequentially connected, the feeding channel is in a narrowing shape through a first conveying belt and a second conveying belt, at least one first cutting assembly used for cutting shaddock peels in the feeding channel is arranged in the feeding channel, and a plurality of second cutting assemblies which are horizontally distributed at equal intervals are arranged at the position of the discharging channel. And a working shaft of the second cutting assembly is arranged in the direction perpendicular to the working shaft of the first cutting assembly. According to the technical scheme, the technical problems of how to automatically cut a large number of pomelo peels so as to quickly obtain small pomelo peels, reduce the cleaning and crushing difficulty and improve the pectin preparation efficiency are solved.

Owner:JIAYING UNIV

Carton board printing device

ActiveCN111716880AReduce distanceImprove work efficiencyRotary pressesPrinting press partsCartonElectric machinery

The invention discloses a carton board printing device, and relates to the technical field of printing equipment. The carton board printing device comprises a printing driving device, a carton board moving device and a baffle; the printing driving device comprises a motor, wherein a connecting shaft I is fixedly connected to the front side face of a rotating shaft of the motor, and a printing device body is arranged on the front side of the printing driving device; and the printing device body comprises a fixing disc, a connecting shaft II is rotationally connected to the front side face and the rear side face of the fixing disc in a penetrating mode, and the rear side face of the connecting shaft II is fixedly connected with the front side face of the connecting shaft I. The problem thatthe efficiency is low due to prolonged overall working time caused by the fact that pause is needed during printing every time due to the fact that a carton board continues to move after being separated from a printing plate after the situation that the printing plate is attached to the surface of the carton board to print patterns and stays for a period of time to ensure even ink printing due tothe fact that the carton board needs to stop moving when the carton board is conveyed to one side of the printing plate during printing carried out by an existing carton board printing device is solved.

Owner:山东黑马印刷包装有限公司

Voltage difference moped system with gear signals and speed signals input into processor

InactiveCN104192024ACalculation variable reductionFast operationSpeed controllerRider propulsionElectricityPower flow

The invention relates to a voltage difference moped system with gear signals and speed signals input into a processor and belongs to power supply controller systems of mopeds with assisting power supplied in a differentiation mode and with front wheels and rear wheels distributed in a difference mode. The voltage difference moped system comprises two wheels and two motors of an electric moped, and a gear signal manual controller and further comprises a differential distributor, wherein the differential distributor comprises three modules connected in sequence, the first module is used for conducting numeric comparison processing on feedback currents IA and IB, the second module is used for conducting model function processing on data of the first module through a moped mean speed signal IS selecting model function, and the third module is used for inputting the gear signals ID into a data distributor (10) of the differential distributor (1), so that control data obtained by a controller A and control data obtained by a controller B have elements of the feedback currents IA and IB and also have elements of the gear signals ID. The voltage difference moped system with the gear signals and the speed signals input into the processor has the advantages that differentiation control power supply is conducted on the two motors of the front wheel and the rear wheel of the moped, and the content of differentiation control includes preset model function processing.

Owner:RUGAO FUKAI METAL PROD CO LTD

Digital differential-control type power system capable of outputting signal after processing gear signal

ActiveCN104149650ASame rotation speedRotation speed is not wastedSpeed controllerRider propulsionElectricityControl signal

The invention discloses a digital differential-control type power system capable of outputting a signal after processing a gear signal and belongs to differential power supplying type bicycle power supply controller systems for distributing power to a front wheel and a rear wheel in a differential mode. The digital differential-control type power system capable of outputting a signal after processing a gear signal comprises two wheels of an electricity-assisted bicycle, two motors of the electricity-assisted bicycle, a manual gear signal controller and a difference controller, wherein the difference controller comprises three modules which are connected in sequence, the first module is used for comparing the values of original input signals, including the feedback control signal current IA and the feedback control signal current IB, used for control, the second module is used for conducting model function processing on data of the first module according to a set model function, and the third module is used for inputting the gear signal ID of the manual gear signal controller into a data distributor of the difference controller, so that control data obtained by a controller A and a controller B can contain feedback control signals and elements of the gear signal ID. The digital differential-control type power system capable of outputting a signal after processing a gear signal has the advantages that power is supplied to the two motors of the front wheel and the rear wheel of the electricity-assisted bicycle in a differential-control mode, and differential control refers to the model function processing which is set in advance.

Owner:江苏鸿迅机车有限公司

Voltage difference moped system requiring gear positions and speed signals to be added into processor

InactiveCN104743046ASame rotation speedNo waste of electricityRider propulsionCycle actuatorsElectricityControl power

The invention discloses a voltage difference moped system requiring gear positions and speed signals to be added into a processor, and belongs to a front wheel and rear wheel difference distribution moped power supply controller system supplying power differently. The voltage difference moped system comprises two wheels and two motors of an electric moped, a gear position signal manual controller and a differential speed distributor, wherein the differential speed distributor comprises three modules sequentially connected; according to the first module, numeric comparison processing is carried out on feedback control signal currents IA and IB; according to the second module, model function processing is carried out on data of the first module and car average speed signals IS of a speed average device; according to the third module, the control data have the elements of the feedback control signal currents IA and IB and the four elements of gear position signals ID, the car average speed signals IS and the like. The voltage difference moped system requiring gear positions and speed signals to be added into the processor has the advantages that differential control power supply is carried out on the two motors of the front and rear wheel of the moped, and the content of differential control is preset model function processing.

Owner:CHENGDU KUANHE TECH +3

Conveying device for blank steel plates

InactiveCN105416975AIncrease frictionReduce in quantityConveyorsRollersSheet steelElectric machinery

The invention relates to the field of steel ring machining, in particular to a conveying device for blank steel plates. The conveying device comprises a machine frame and a working platform fixedly arranged on the machine frame. Vertical baffles are arranged on the two sides of the working platform respectively and are connected through rotating shafts. The rotating shafts are sleeved with rollers and are arranged at equal intervals. A motor is arranged below the machine frame and connected with the rotating shafts. The conveying device is characterized in that a plurality of protrusions are evenly arranged on the rollers. By means of the conveying device, the friction force between the rollers and steel plates can be increased, and therefore the number of the rollers is decreased, and cost is reduced.

Owner:CHONGQING CHUANGLONG IND

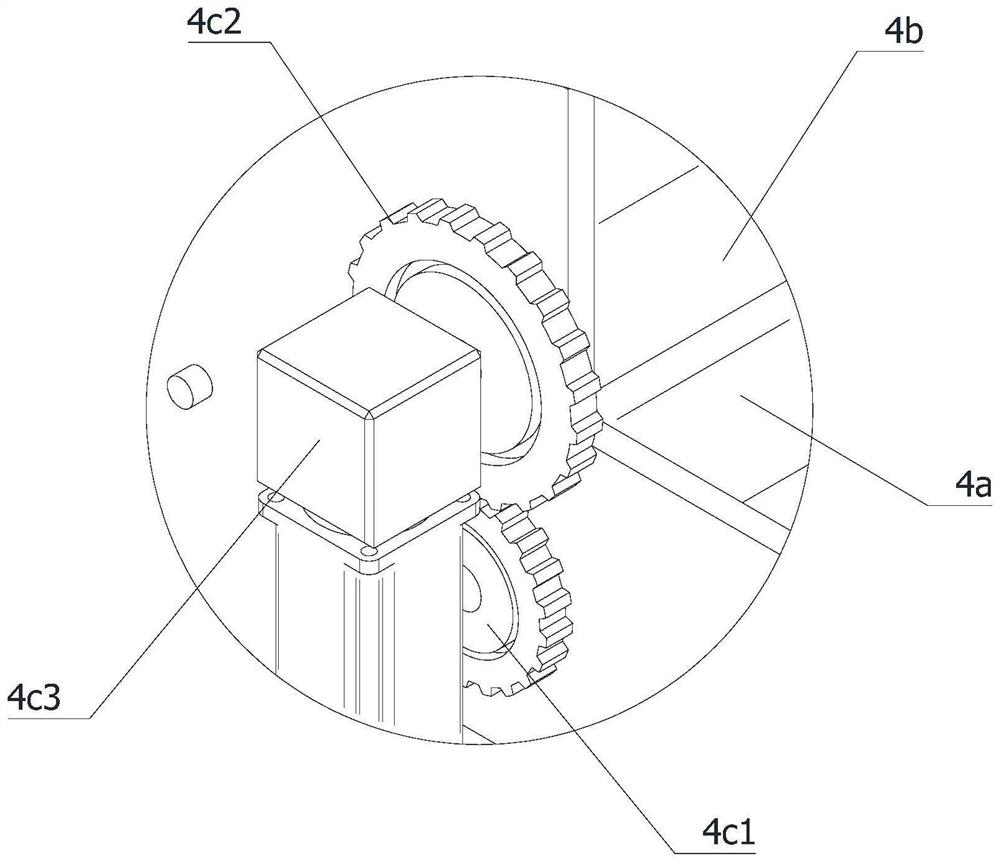

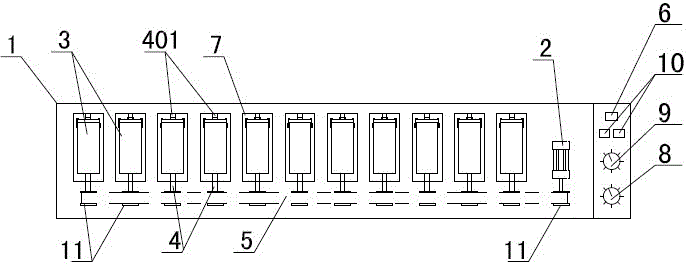

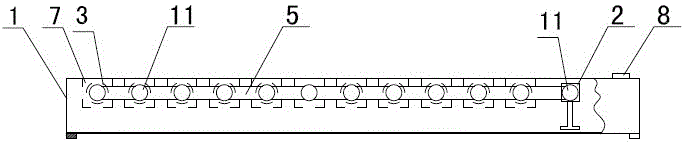

Mixer for x-ray fluorescence spectrometer

InactiveCN104707514BImprove mixing efficiencyImprove accuracyRotating receptacle mixersTransportation and packagingTest sampleX-ray

A mixing machine for an X-ray fluorescence spectrometer belongs to the technical field of mixing equipment for a fluorescence spectrometer. It includes a body (1), and a motor (2) is installed on the body (1). It is characterized in that: a plurality of mixing barrels (3) are installed on the body (1), and each mixing barrel (3) passes through The rotating shaft (4) is connected with the body (1), one end of the rotating shaft (4) is flexibly connected with the mixing tank (3), and the other end of the rotating shaft (4) is connected with the rotating shaft of the motor (2) through a chain (5). The mixing material for the X-ray fluorescence spectrometer of the invention can simultaneously mix a plurality of test samples, and the mixing speed is fast, and the mixing degree of the samples is uniform.

Owner:许宏民

Digital differential control aided-bicycle system of gear signal addition comparator

InactiveCN104787218ASame rotation speedNo waste of electricityRider propulsionElectricityControl power

The invention discloses a digital differential control aided-bicycle system of a gear signal addition comparator and belongs to a differential distribution aided-bicycle power supply controller system of a front wheel and a rear wheel of differentiation supply aided electricity. The digital differential control aided-bicycle system of the gear signal addition comparator comprises two wheels and two motors of an electric aided-bicycle, a gear signal manual controller and a differential controller, wherein the differential controller comprises three sequentially connected modules; the first module performs numeric comparison processing on a gear signal ID, a feedback control signal current IA and a feedback control signal current IB of the gear signal manual controller used for controlling original input signals; the second module uses a set model function to perform model function processing on the data of the first module; the third module processes and distributes the model function processing to a controller A and a controller B. The digital differential control aided-bicycle system of the gear signal addition comparator has the advantages that differentiation control power supply is performed on the two motors of the front wheel and the rear wheel of the electric aided-bicycle, and the content of the differentiation control is the preset model function processing.

Owner:CHENGDU KUANHE TECH +3

A mechanical rack processing and manufacturing equipment

ActiveCN114425640BSame rotation speedIncrease the number of teethGear-cutting machinesGear teethMilling cutterUniversal joint

The invention discloses a processing and manufacturing equipment for a mechanical rack, which comprises a frame and a case. The side of the frame is provided with a controller, and the top side of the case is provided with a side plate above the frame. The bottom of the plate is provided with a telescopic piece, and the bottom of the telescopic piece is provided with a cover body, and the inside of the cover body is provided with two milling cutters and a driving part for driving the milling cutters to rotate. In the present invention, the movement of the two milling cutters is controlled by setting the driving part to realize the synchronous reverse movement of the two milling cutters. Compared with the traditional processing method, the number of teeth that can be processed by the milling cutter is increased within one processing time. , thereby increasing the processing amount per unit time and improving the processing efficiency. At the same time, the driving part transmits the power of the milling cutter rotation through the gear and the universal joint to keep the rotation speed of the two milling cutters the same. By setting a drive motor, The device structure is simplified, the device structure is compacted, and the cost of the device is reduced.

Owner:电子科技大学成都学院

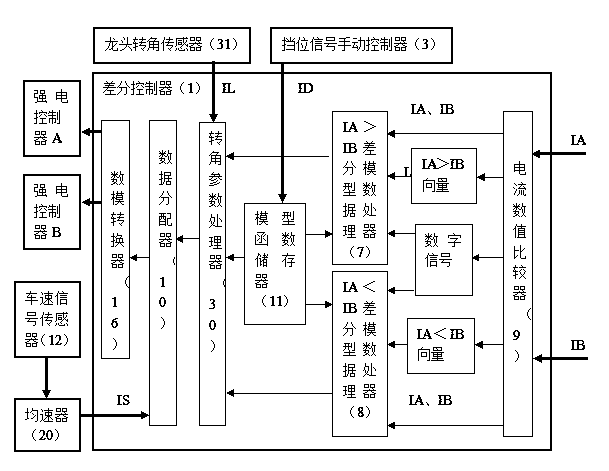

A digital differential moped system with both gear and speed signals added to a comparator

ActiveCN104175906BSame rotation speedNo waste of electricitySpeed controllerRider propulsionElectricityDifferential function

In the present invention, the digital differential power-assisted bicycle system in which both the gear position and the speed signal are added to the comparator belongs to the power supply controller system of the front wheel and the rear wheel with differential distribution of power-assisted power supply. It includes two wheels and two motors of the electric power-assisted bicycle, a manual controller for the gear signal, and a differential controller. The differential controller includes three modules connected in sequence; the first module controls the gear position of the manual controller for the gear signal. The signal ID, the vehicle average speed signal IS of the speed equalizer, the feedback control signal current IA and IB are numerically compared and processed; the second module uses the set model function to perform model function processing on the data of the first module; the third module controls The data not only includes elements of gear position signal ID, feedback control signal current IA and IB, but also four elements of vehicle average speed signal IS. Advantages: Differentially control and supply power to the two motors of the front and rear wheels of the power-assisted bicycle. The content of the differential control is the pre-set model function processing.

Owner:江苏禾立拓智能科技有限公司

Voltage differential moped system needing gear signal and speed signal to be input to differentiator successively

InactiveCN104129469ASame rotation speedNo waste of electricityRider propulsionCycle actuatorsElectric machineryElectricity

The invention discloses a voltage differential moped system needing a gear signal and a speed signal to be input to a differentiator successively, and belongs to a front wheel and rear wheel difference distribution motor bicycle power supply controller system with aided electricity supplied in a differentiation mode. The voltage differential moped system comprises two wheels of an electrically powered bicycle, two motors of the bicycle, a gear signal hand controller and a differential distributor. The differential distributor comprises three modules which are connected in sequence. The first module is used for conducting numeric comparison processing on a feedback current IA and a feedback current IB; the second module is used for conducting model function processing on the data of the first module by selecting a model function through the gear signal ID; the third module is used for inputting a vehicle mean speed signal IS to a data distributor 10, so that the control data acquired by a controller A and a controller B have the elements of the feedback current IA, the feedback current IB and the vehicle mean speed signal IS. The voltage differential moped system has the advantages that the two motors of the front wheel and the rear wheel of the motor bicycle are subjected to differentiation control power supply, and the differentiation control content is to process the preset model function.

Owner:CHENGDU KUANHE TECH +3

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN109680415ACompact structureSame rotation speedNeedle severing devicesSewing-machine control devicesEngineeringCam

Owner:ZHEJIANG DUMA SEWING MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com