Gear signal processing output signal digital differential control booster system

A technology of output signal and signal processing, which is applied in the field of front wheel and rear wheel differential distribution assist bicycle power supply controller system, which can solve the problem of no electronic differential module and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

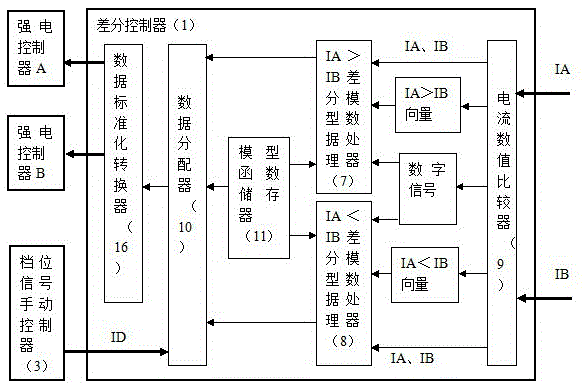

[0057] Embodiment 1. Digital differential control booster system for gear signal processing output signal

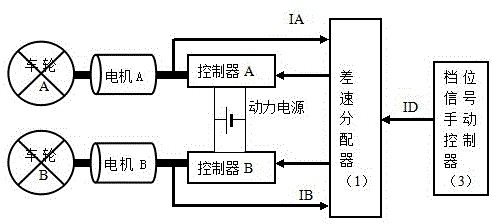

[0058] like figure 1 , 2 , including the two wheels of the electric assist bicycle: wheel A and wheel B, and the motor A driving the wheel A and the motor B driving the wheel B, including the gear signal manual controller 3 of the electric assist bicycle, and also including the differential controller 1 ,

[0059] The differential controller 1 and the motor A are connected by the controller A, and the controller A uses the control signal given by the differential controller 1 to control the power supply to supply power to the wheel A;

[0060] The differential controller 1 and the motor B are connected by the controller B, and the controller B uses the control signal given by the differential controller 1 to control the power supply to supply power to the wheels B.

[0061] Take the feedback control signal current IA between the motor A and the controller A and input ...

Embodiment 2

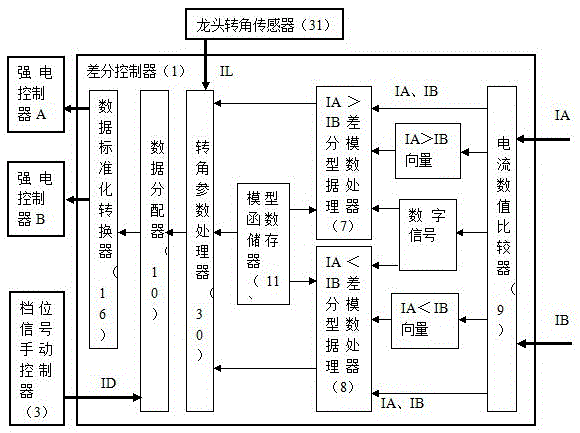

[0086] Embodiment 2. Digital differential control booster system with gear signal processing output signal of rotation angle parameter processor

[0087] like image 3 , 4 , as the whole structure of embodiment 1, and IA>IB differential model data processor 7 and IA<IB differential model data processor 8 are connected with data distributor 10 through corner parameter processor 30, and corner parameter processor 30 is also connected with faucet The angle sensor 31 is connected.

[0088] A pressure sensor is arranged on the human seat cushion of the power-assisted bicycle, or on the elastic part connected with the cushion, and the pressure sensor is connected with the data distributor 10 in the differential controller 1, and the pressure signal of the pressure sensor is respectively sent to two data distributors in the data distributor 10. The control digital signals are processed in the same proportion to increase or the same proportion to decrease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com