Equipment for extracting high-gelation-degree pectin from shaddock peel

A technology of grapefruit peel and high glue, applied in metal processing and other directions, to ensure the cutting quality, stable moving path, and prevent deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

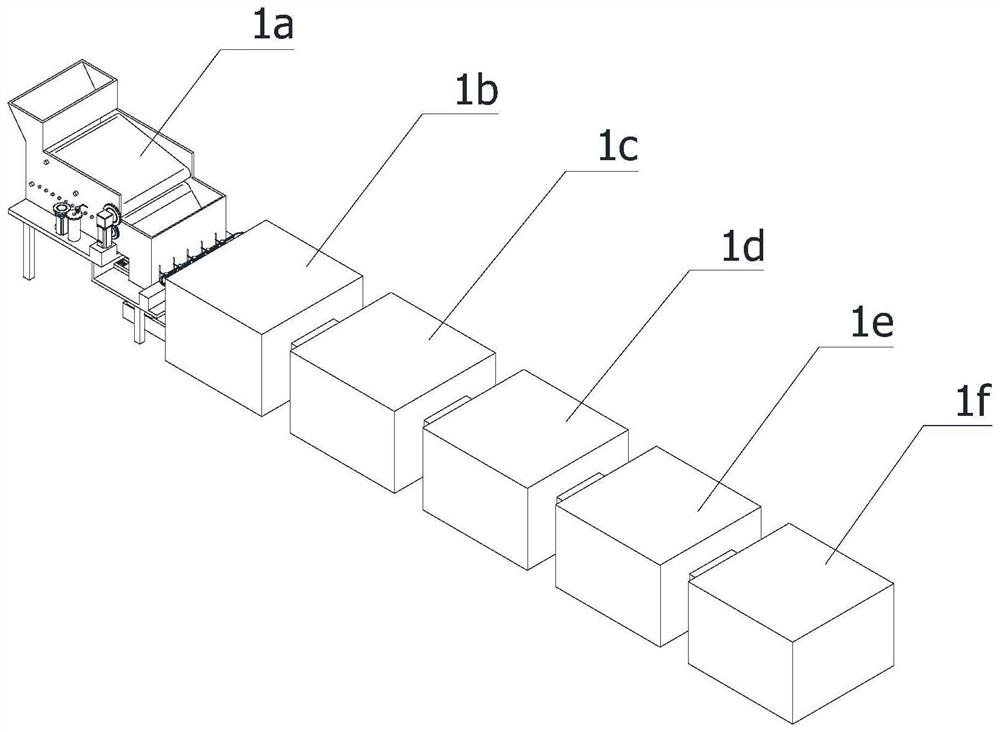

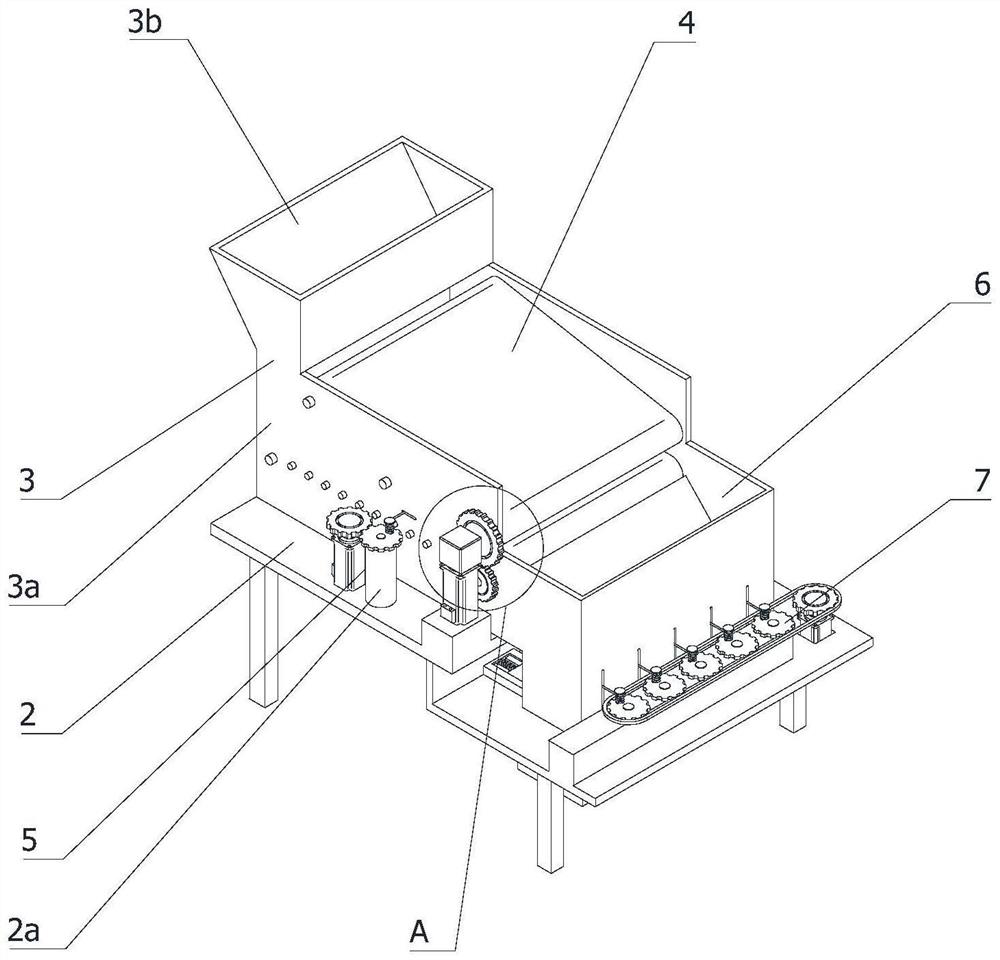

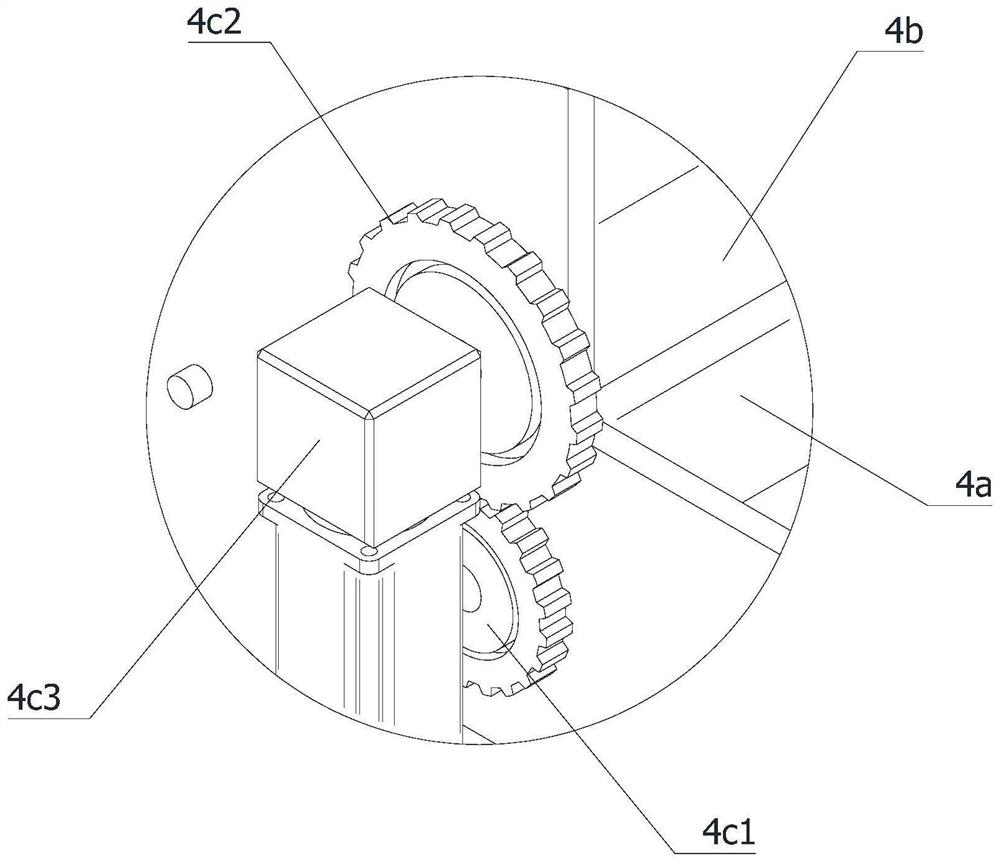

[0051] like Figure 1 to Figure 7 Shown: a kind of equipment for extracting pectin with high gelling degree from pomelo peel, including grapefruit peel cutting device 1a, the discharge end of grapefruit peel cutting device 1a is connected to the feeding end of cleaning device 1b, and cleaning device 1b is connected to drying The device 1c, the drying device 1c is connected to the crushing device 1d, the crushing device 1d is connected to the mixing and filtering device 1e, the mixing and filtering device 1e is connected to the pectin precipitation device 1f, the grapefruit peel cutting device 1a includes a base 2, and a shell is fixedly installed on the base 2 3. The housing 3 is formed by splicing ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com