Spring polishing device

A technology of equipment and grinding discs, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems affecting the beauty of springs, the accuracy of installation, and the injury of operators, so as to achieve fast switching, prevent damage, and good social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further description will be given below in conjunction with the accompanying drawings

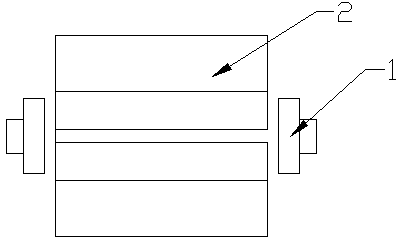

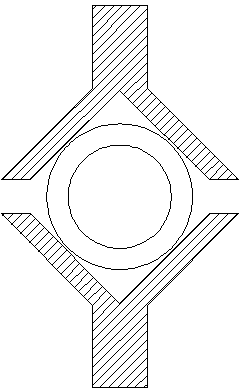

[0012] Such as Figure 1~2 , a kind of spring grinding equipment, described spring grinding equipment comprises horizontal grinding bracket 2, two side grinding discs 1, frame, telescoping mechanism, rotating motor, gear box, and described horizontal grinding bracket 2 is two symmetrically arranged A strip-shaped metal block with a Y-shaped cross-section. A spring clamping space with a rhombus-shaped cross-section is formed between the two metal blocks. Sanding plates are arranged on the opposite surfaces of the two strip-shaped metal blocks. The transverse The grinding bracket 2 moves one or two strip metal blocks through the telescopic mechanism to clamp or loosen the spring. The motor is arranged on the frame, and the two lateral grinding discs 1 are symmetrically arranged on the horizontal grinding bracket 2. The grinding surfaces of the two lateral grinding discs 1 are perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com