Test tube clamping mechanism of test tube bar code pasting machine

A technology for pasting machines and test tubes, which is applied in the field of test tube clamping mechanism of test tube barcode pasting machines, which can solve the problems of high labor cost, slow placement of test tubes, and influence on the test process, and achieve the effect of saving time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In conjunction with the accompanying drawings, the present invention will be described in further detail.

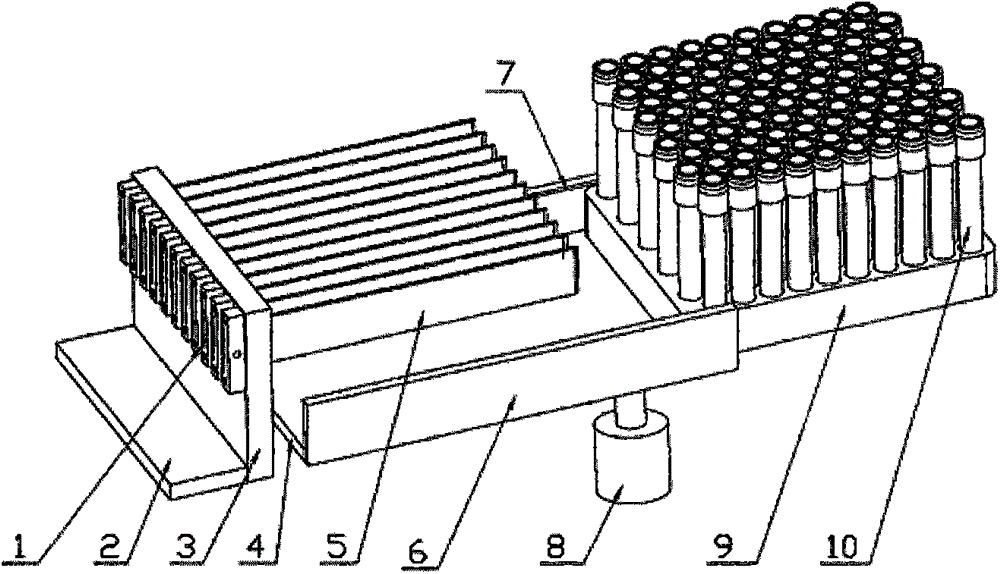

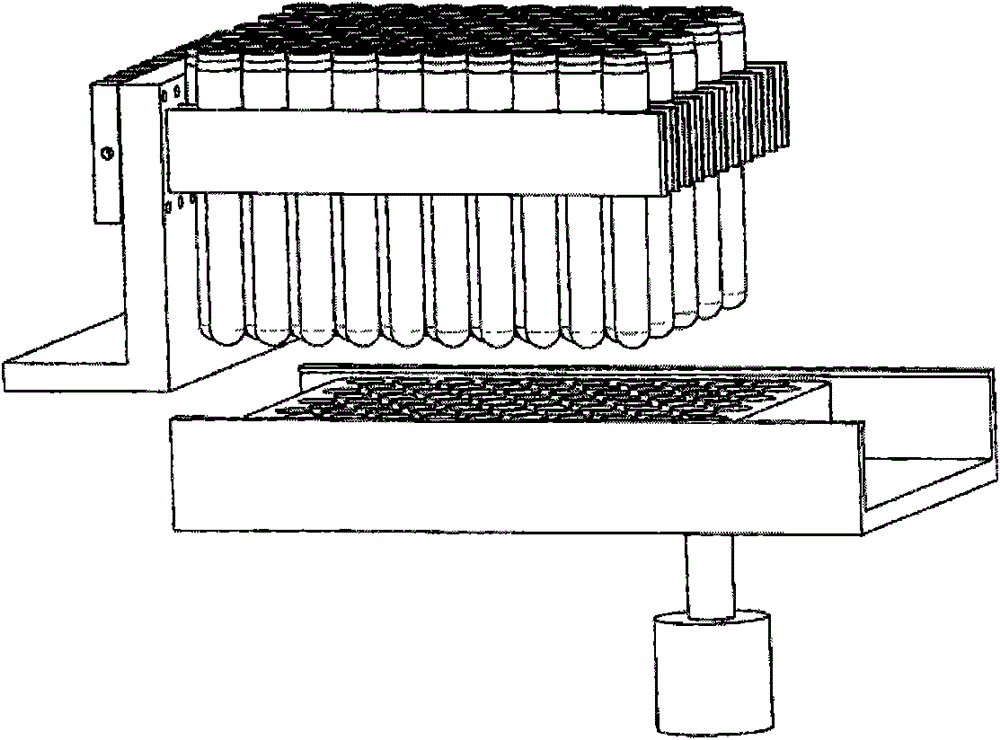

[0014] As shown in the figure, a test tube clamping mechanism of a test tube barcode pasting machine includes an insert spacing adjustment mechanism (1), a horizontal mounting plate or slider (2), a vertical mounting plate (3), and a supporting plate (4) ), insert (5), left splint (6), right splint (7), lifting mechanism (8), test tube foam seat (9), test tube (10).

[0015] The insertion pieces (5) are connected with the insertion piece spacing adjustment mechanism (1), and are installed on the vertical mounting plate (2) together to form parallel and equidistant test tube racks. The test tube rack is connected with the horizontal mounting plate or the slider (2) to play a role of fixing or moving.

[0016] The left splint (6) and the right splint (7) are respectively installed on the left and right sides of the test tube placement pallet (4), and their installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com