Ball mill used for producing graphite powder

A ball mill and graphite powder technology, applied in grain processing and other directions, can solve the problems of difficulty in controlling the diameter of the pulverized particles, shortening the service life of the ball mill, and inability to preheat and pulverize materials, and achieve a simplified process, increase the pulverization speed, and improve the pulverization quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

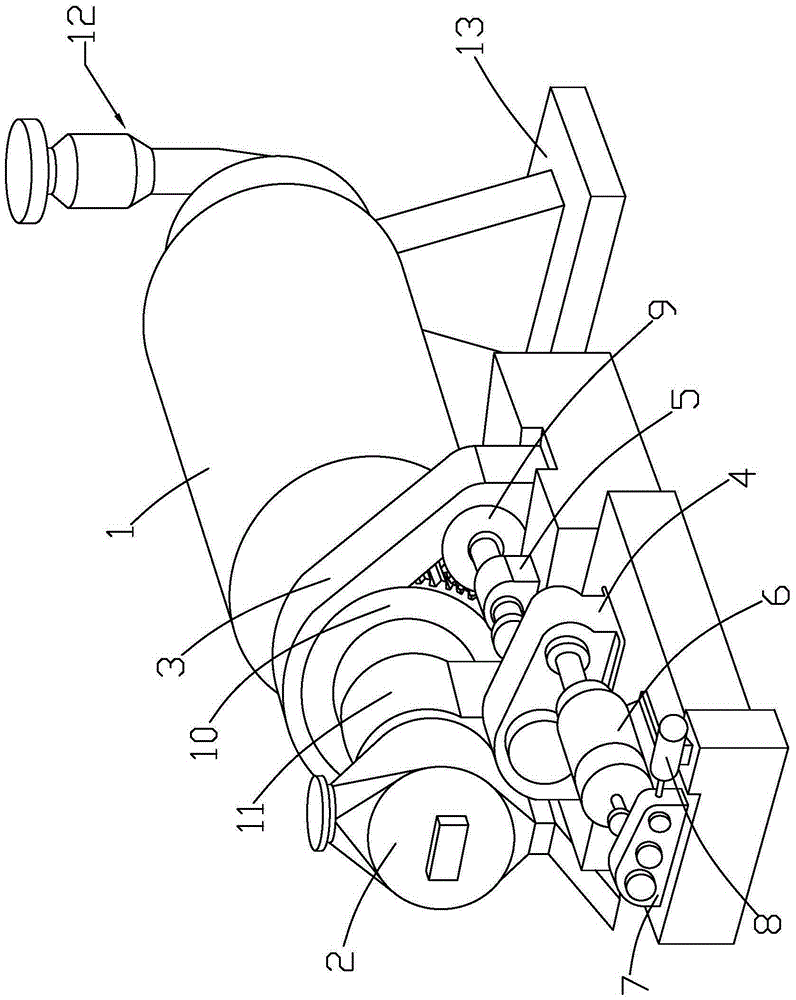

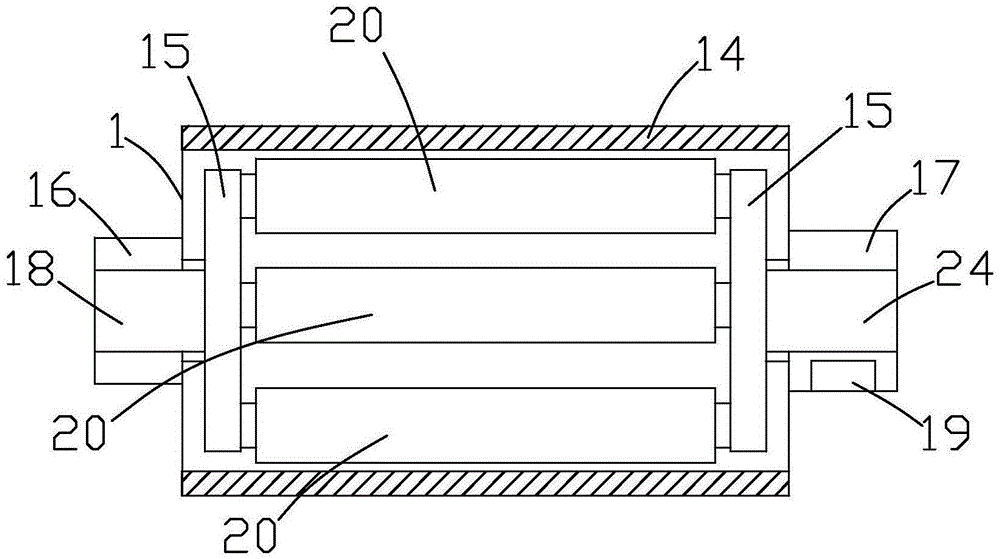

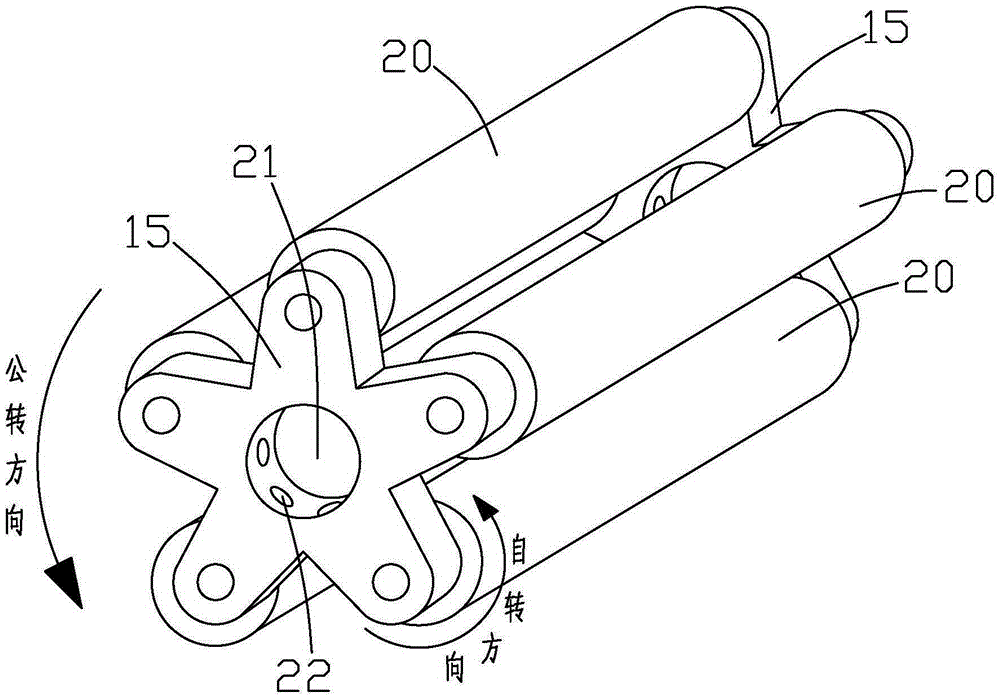

[0030] Such as Figure 1 to Figure 6Shown, be a kind of ball mill for producing graphite powder of the present invention, ball mill comprises drum 1, power drive unit, feeder 12 and unloading device 2, feeder 12 is positioned at the right side of drum 1, the left side of drum 1 There is a gear box 3 on the side, and the unloading device 2 is located on the left side of the gear box 3. The gear box 3 and the unloading device 2 are connected by a sealing sleeve 11. The power drive device is connected to the gear box 3. The power drive device includes a main motor 6. The main reducer 4, the auxiliary motor 8 and the auxiliary reducer 7, the right side of the main motor 6 is connected to the main reducer 4, the main reducer 4 is connected to the first transmission gear 9, the connection between the main reducer 4 and the first transmission gear 9 A bearing seat 5 is arranged between them, the left side of the main motor 6 is connected to the auxiliary reducer 7, and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com