Wall-breaking and pulverizing machine for Chinese herbal medicines

A pulverizer and Chinese herbal medicine technology, applied in grain processing and other directions, can solve the problems of reducing the service life of propeller blades, increasing the wear of grinding rods and protrusions, and reducing the particle size of medicines, so as to shorten the pulverization time, improve the pulverization efficiency, and reduce the wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

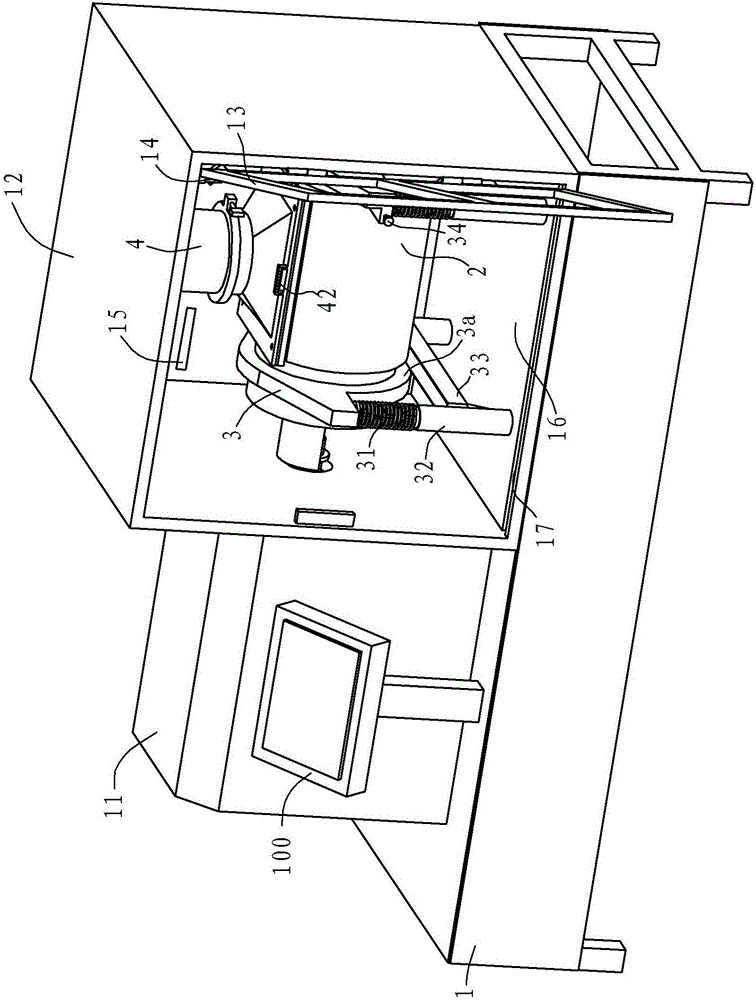

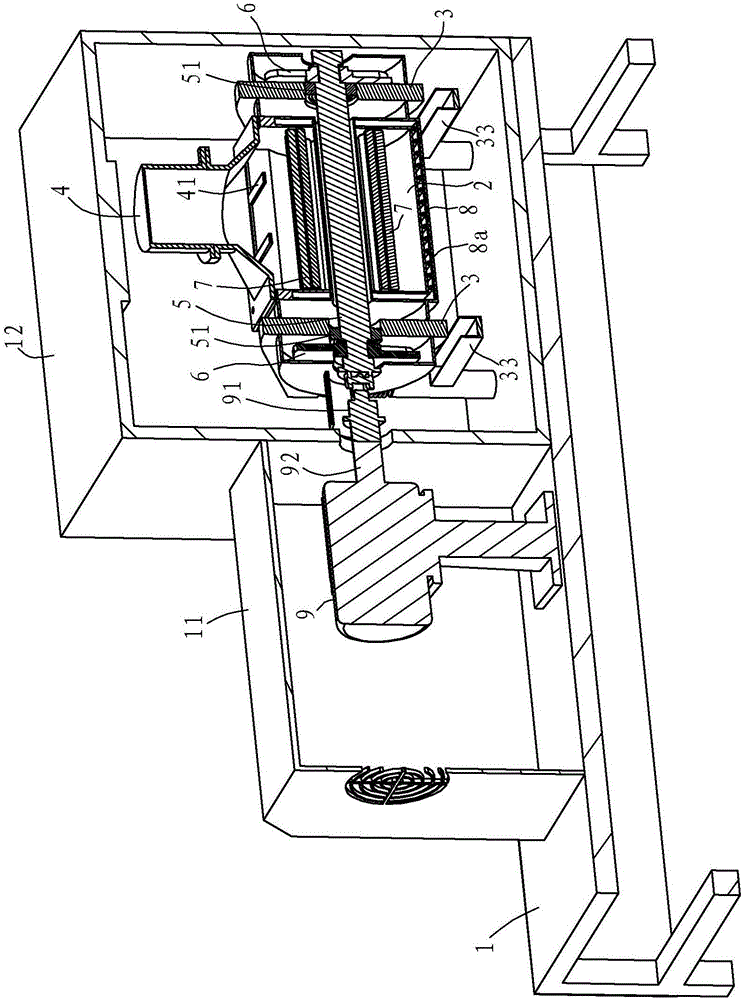

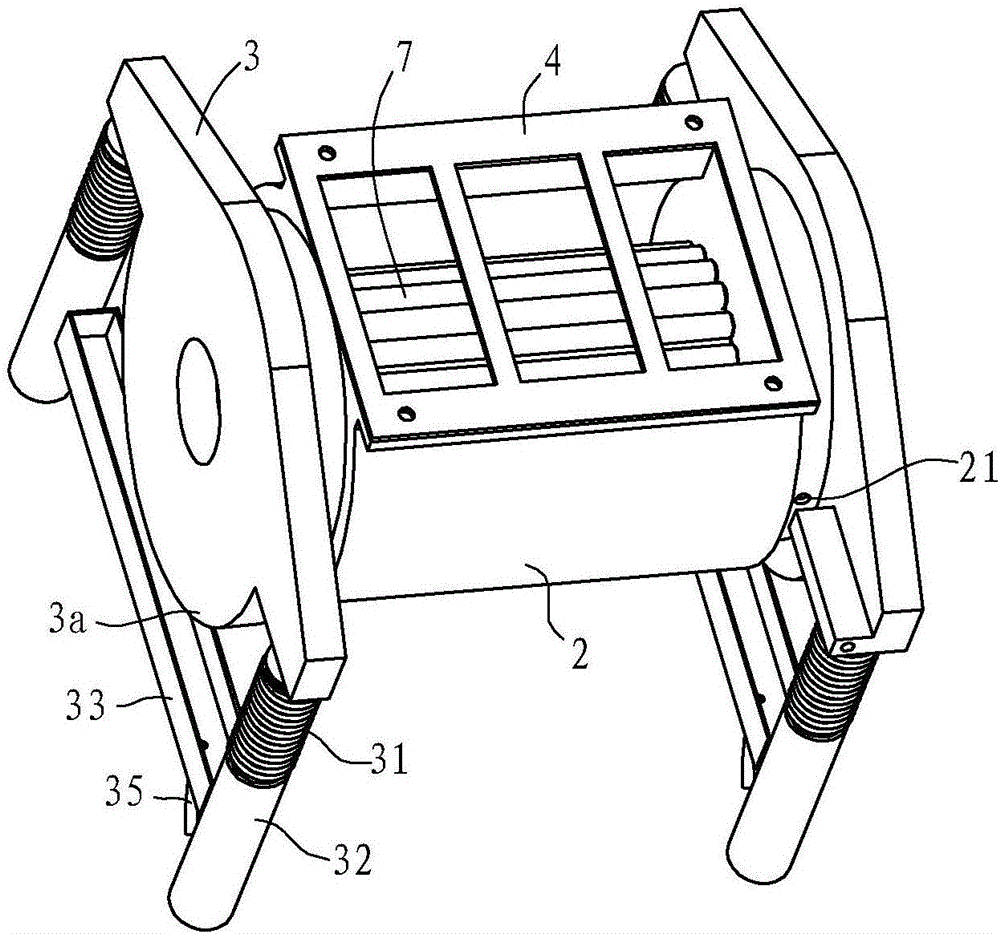

[0041] Example 1, such as figure 1 , figure 2 , image 3 and Image 6 As shown, the Chinese herbal medicine wall-breaking pulverizer in the present embodiment comprises a support 1, a motor 9, a grinding cylinder 2, a grinding rod 7, and a refrigeration unit 101 (see Image 6 As shown), the excitation part 3, the ultraviolet lamp 15, the vibration spring 31, the rotating shaft 5, the eccentric block 6 and the controller 100.

[0042] Frame 1 is provided with soundproof box 12, and this soundproof box 12 has a door 13 that can open and close, is provided with ultraviolet lamp tube 15 in soundproof box 12; A soundproof cover 11 is provided.

[0043] The grinding cylinder 2 is located in the soundproof box 12, the outer circumference of the grinding cylinder 2 is wound with a cooling coil 8, the outside of the cooling coil 8 is wrapped with an insulating layer 8a, the inner wall of the grinding cylinder 2 is smooth, and the middle of the grinding cylinder 2 has an axial holl...

Embodiment 2

[0055] Example 2, such as Figure 7 As shown, the middle part of the outer wall of the grinding cylinder 2 in this embodiment is gradually inclined to both sides, and both sides of the lower end of the grinding cylinder 2 are in contact with the flange 3 a of the vibrating member 3 . In this way, the condensed water on the outer wall of the grinding cylinder 2 will accumulate from the flanges 3 a of the vibrating elements 3 on both sides, and drip into the water collection tank 33 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com