Driving device for automatic thread trimming and automatic presser foot lifting

A driving device and presser foot lifting technology, which is applied in the field of sewing machines, can solve problems such as loud noises and shaking, affecting the stable operation of sewing machines, etc., and achieve the effects of reducing shaking and noise, reliable positioning, and reducing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

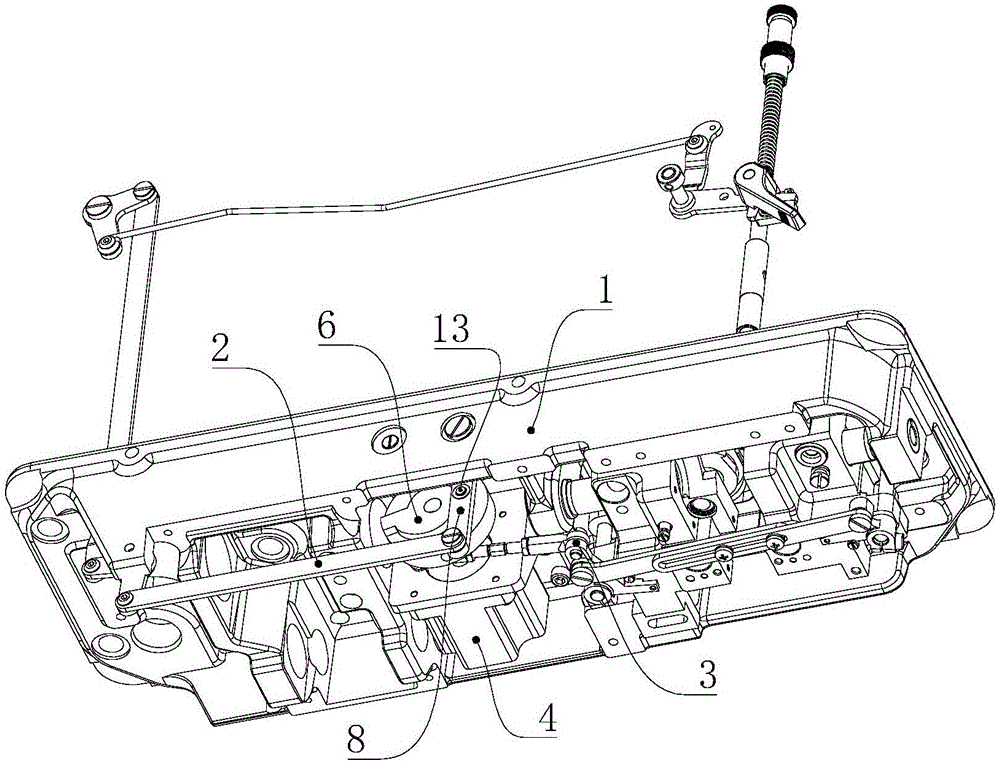

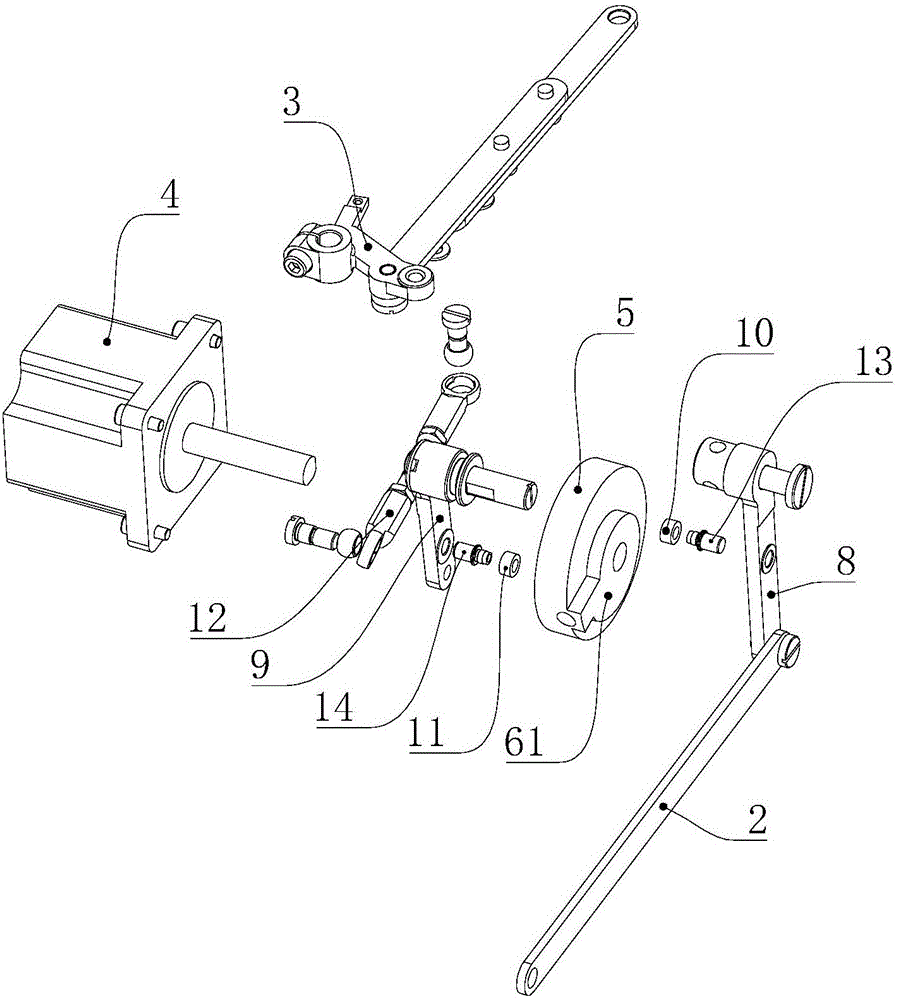

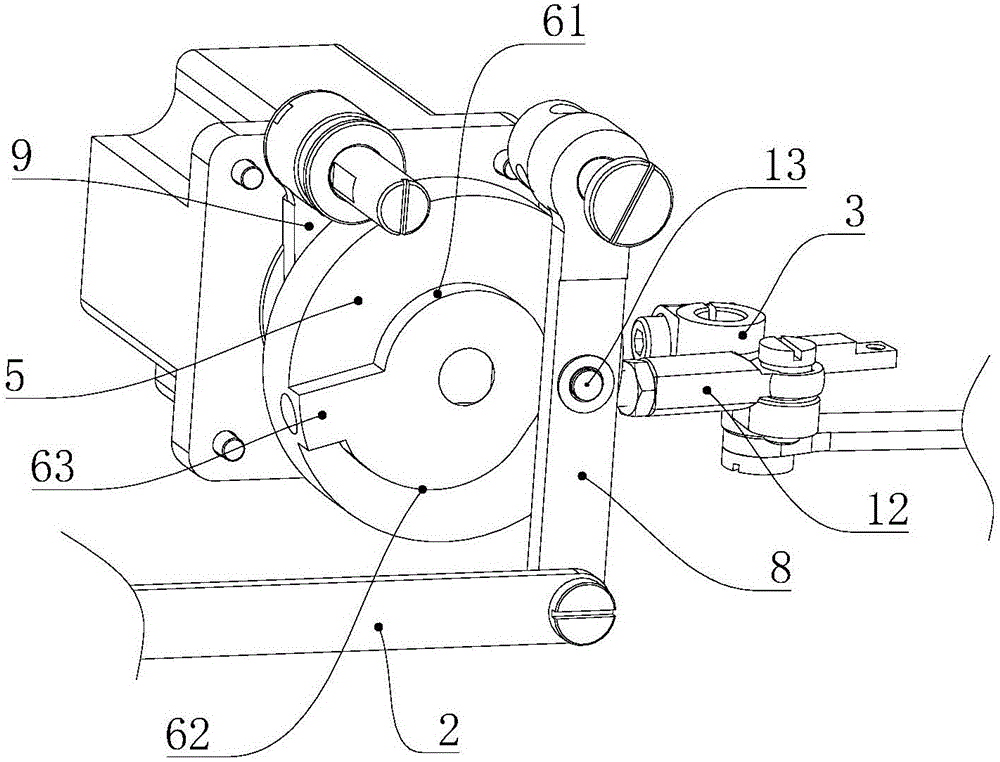

[0029] see Figure 1 to Figure 6 As shown, a driving device for automatic thread trimmer and automatic presser foot lifter includes a presser foot lifter drive rod 2, a thread trimmer drive rod 3, a stepper motor 4, a cam body 5, a presser foot lifter connecting rod 8 and a thread trimmer connection Rod 9, the cam body 5 is arranged on the output shaft of the stepping motor 4; the cam body 5 is provided with the presser foot driving cam surface 6 and the thread trimming driving cam surface; the presser foot connecting rod 8 One end is hinged on the sewing machine housing 1, the other end of the presser foot lifting connecting rod 8 is hinged on one end of the presser foot lifting transmission rod 2, the first driven pin 13 is also arranged on the presser foot connecting rod 8, the first driven pin The sub 13 slides along the presser foot driving ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com