Material conveying device for segmented construction of superstructure

A conveying device and segmented construction technology, applied to ships and other directions, can solve the problems of time-consuming and laborious, affecting on-site construction progress, affecting shipbuilding efficiency, etc., and achieve the effect of preventing overturning, saving manpower transportation, and facilitating stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

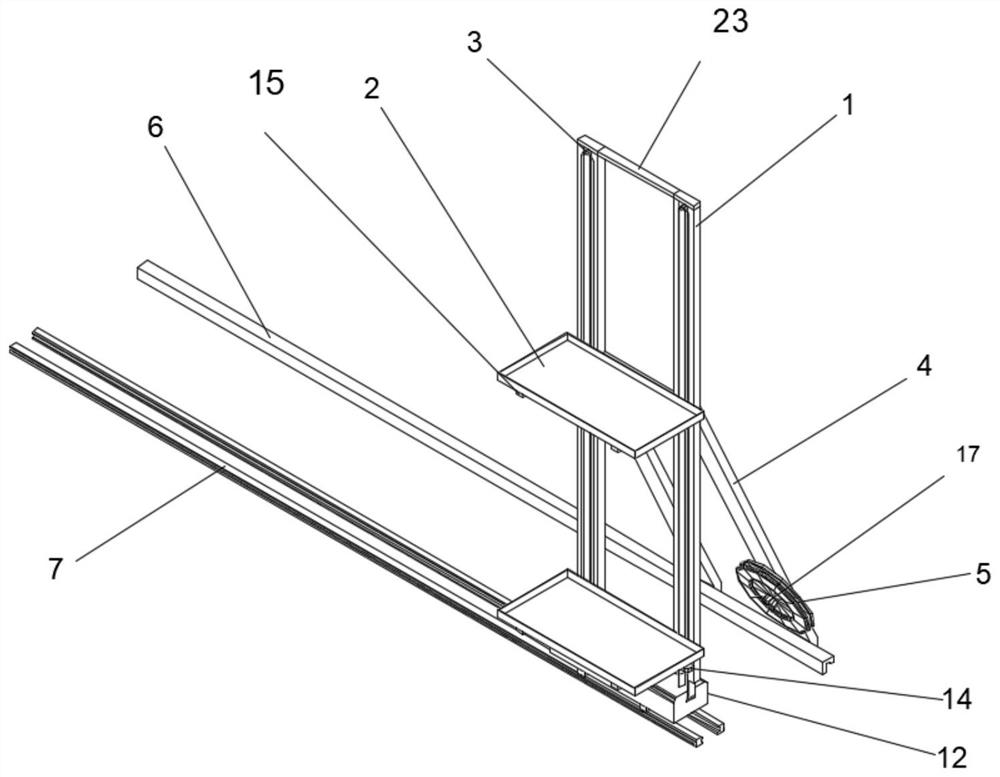

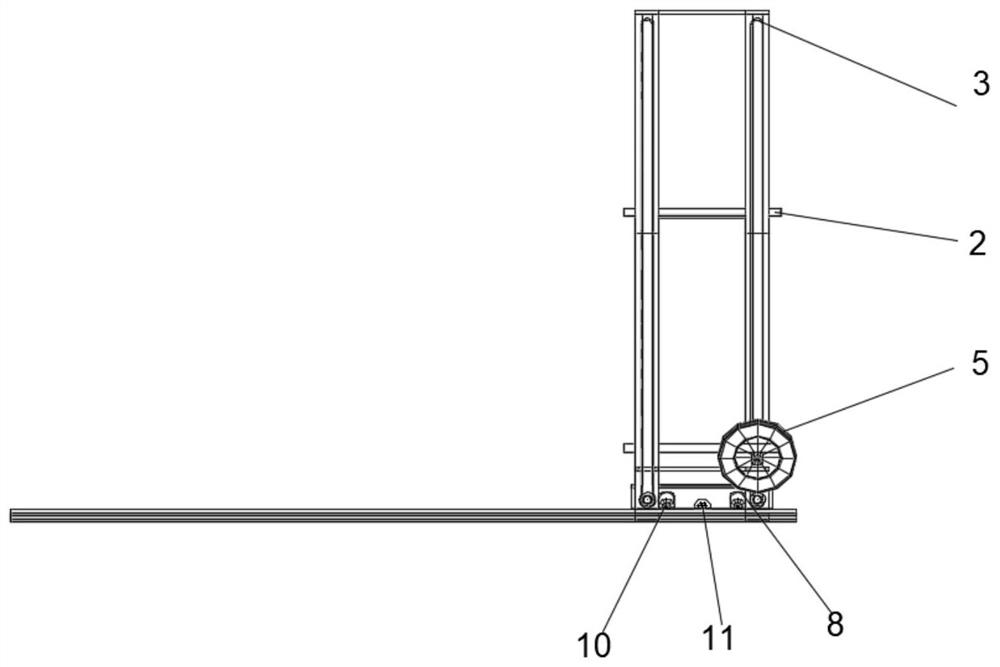

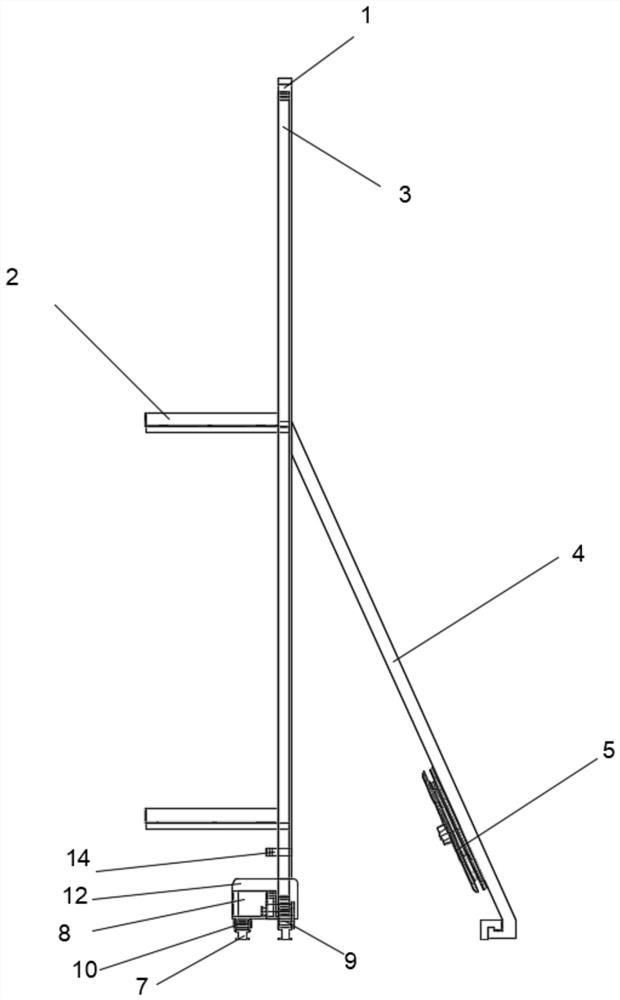

[0023] In the process of ship construction, material transportation and transshipment are required during segmental construction, and some auxiliary resources such as truck cranes and forklifts need to be used. When resources are tight, the process is time-consuming and laborious, which greatly affects the construction progress on site and affects the entire shipbuilding efficiency. , see Figure 1 to Figure 5 , a material conveying device for sub-construction of the upper building, including: two pallet lifting rails 1, a protective shell 12, a lifting structure, a moving structure and a supporting structure, and the two pallet lifting rails 1 are respectively installed on the sides of the protective shell 12 On the upper surface, the lifting structure is installed on the front of the pallet lifting rail 1 for material lifting; the mobile structure is installed on the bottom of the pallet lifting rail 1 for sliding; the supporting structure is installed on the back of the pall...

Embodiment 2

[0031] Most of the common material conveying devices are transported and lifted in a single way. However, when there are too many sections, the efficiency is reduced and they cannot be constructed at the same time. Refer to Figures 1 to 3 , the walking track 7 and the locking track 6 can be extended according to requirements, and the device can be increased according to the number of segments, and the working efficiency is improved at the same time, and the practicability of the device is improved.

[0032] The rotation directions and rotation speeds of the two tray lifting motors 8 and the two driving wheel motors 13 are consistent, so that the device can run stably.

[0033]Working principle: The construction personnel transport the materials to the vicinity of the section through the flatbed truck, and then use the forklift to transport the materials on the corresponding pallets to the material pallet 2. According to the type and model of the materials, they are placed on d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com