Hydraulic hoisting machine for loading and unloading equipment and material in underground coal mine

A technology for loading and unloading equipment and hoisting machines, which is applied to cranes and other directions to achieve the effects of ensuring machine balance, avoiding lateral deviation and overturning, and avoiding gas explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

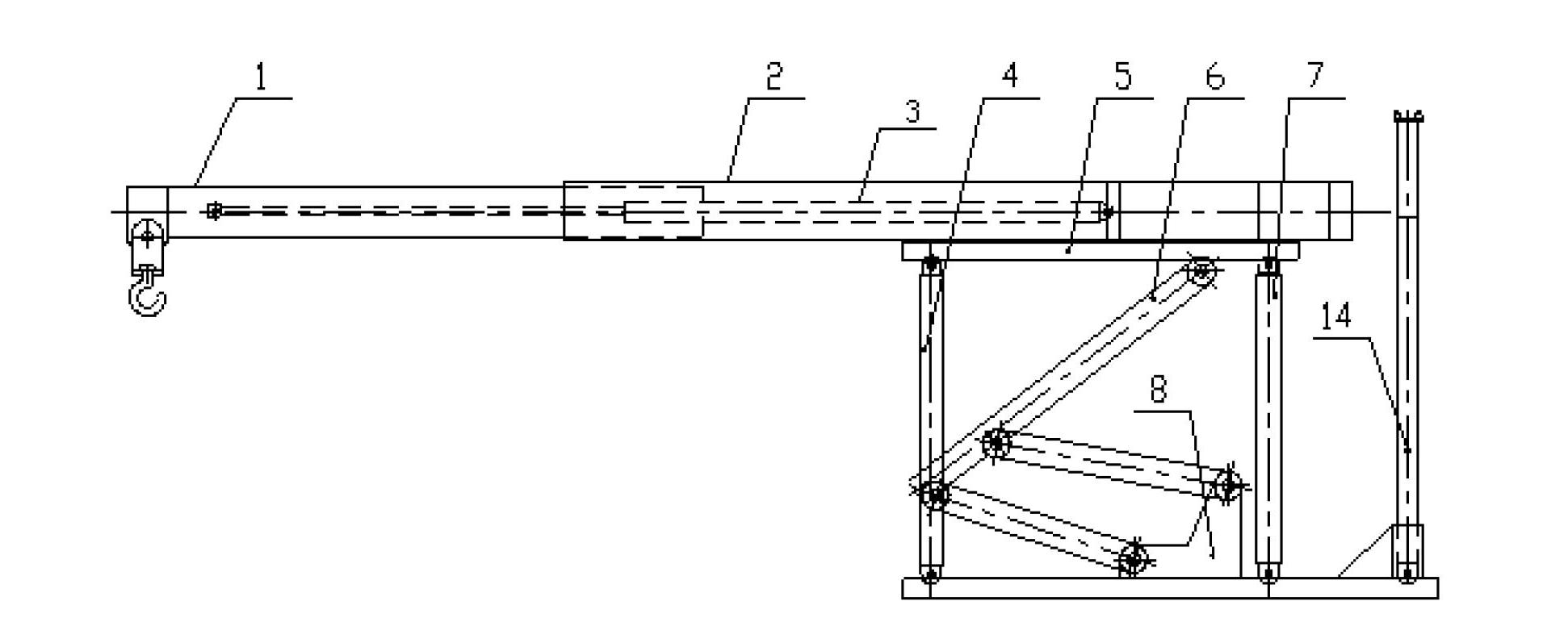

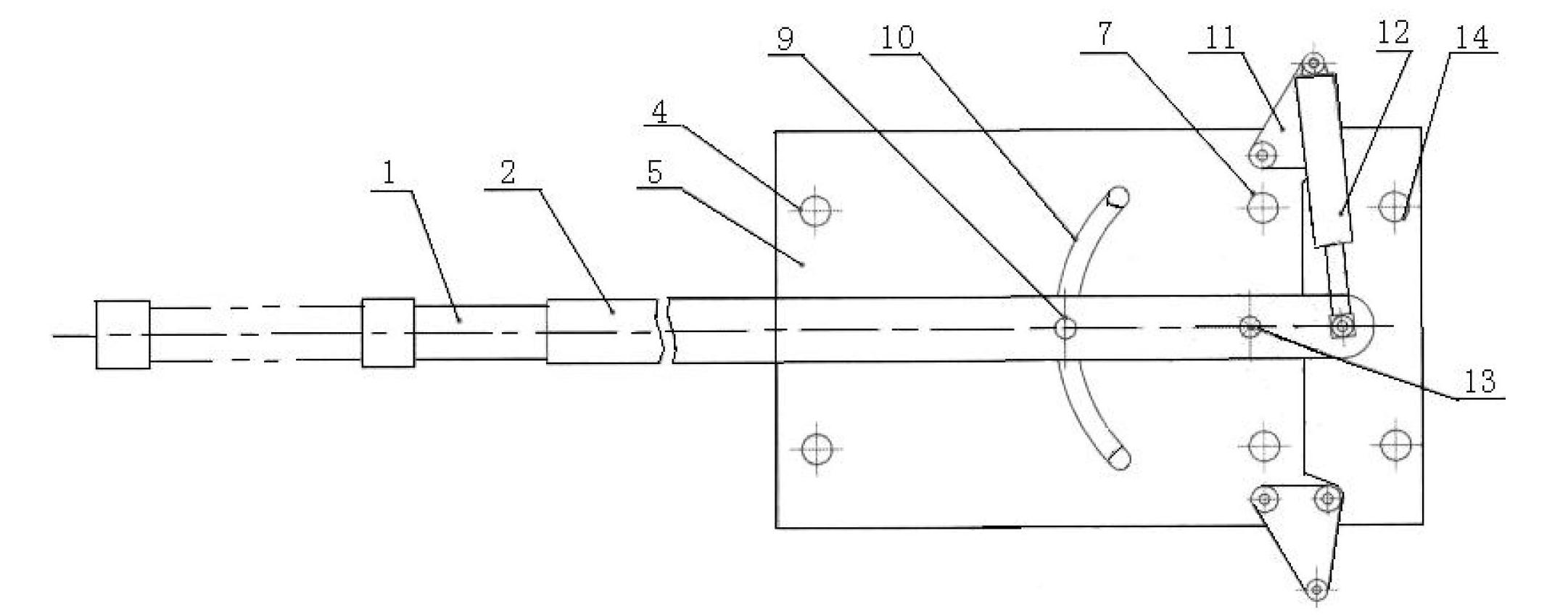

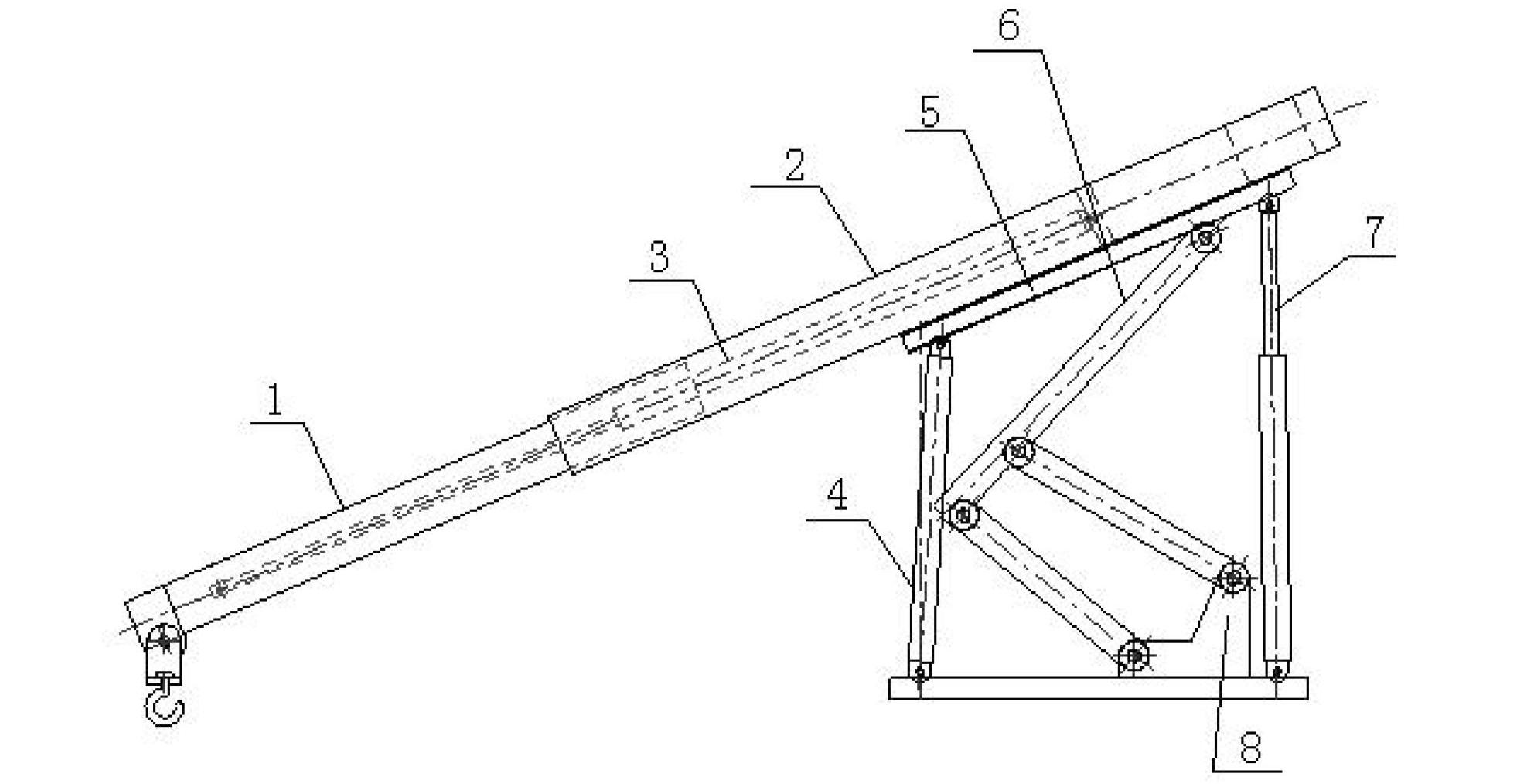

[0019] Such as figure 1 as shown, figure 1 It is a front view of a hydraulic hoist for coal mine underground loading and unloading equipment and materials proposed by the present invention. The hydraulic hoist for underground coal mine is composed of two parts: the boom and the hydraulic lifting frame. The boom includes a telescopic boom 1, a main boom 2 and a telescopic jack 3. The telescopic boom 1 is installed in the main boom 2 and forms a sliding pair with the main boom 2. One end of the telescopic jack 3 is hinged to the telescopic boom 1, and the other end is connected to the main boom. The boom 2 is hinged, and the expansion and contraction of the telescopic jack 3 can drive the telescopic arm 1 to expand and contract relative to the main boom 2. The hydraulic lifting frame is composed of a front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com