Comb tooth lifting type automatic carrier

A car carrier and lifting technology, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve problems such as inability to work, high installation accuracy requirements, and high failure rate in use, so as to reduce the probability of failure and install Reduced precision requirements, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

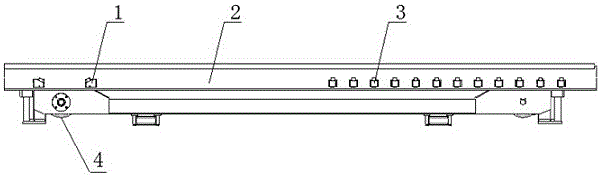

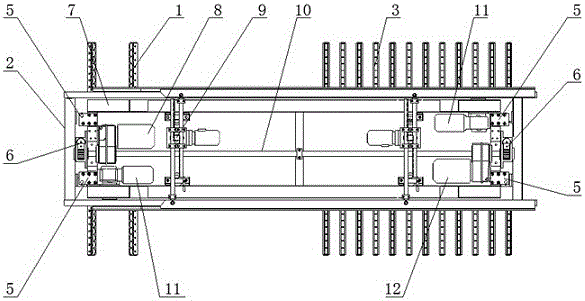

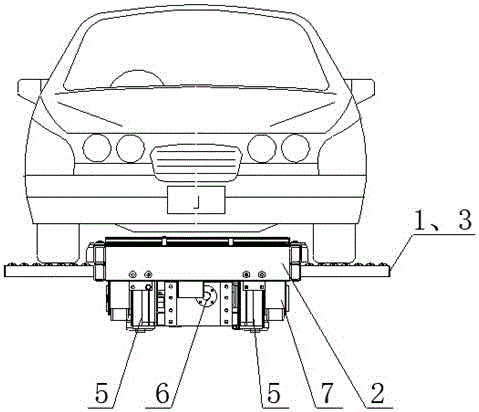

[0057] see Figure 1 to Figure 10 , as shown in the figure, the comb-tooth lifting type car carrier includes a car body 7 and a lifting frame 2, and the lifting frame 2 is provided with front comb teeth 1, rear comb teeth 3 and wheel centering devices 9 for carrying automobile wheels. 7 is provided with guide wheels and the walking wheel train 4 driven by walking motor 11, and the vehicle body 7 is connected with lifting frame 2 by a lifting device. The lifting device includes 2 lifters 6 and 2 lifting drive motors installed on the two ends of the vehicle body 7 respectively. The lifting drive motors are double-axis extension motors. One shaft extension of the front lift drive motor 8 and the other shaft extension of the rear lift drive motor 12 are connected through the synchronous shaft 10,

[0058] The lifter 6 includes a base body 601, a lifting guide shaft 604, a pair of meshing gears 602 and a rack 603, and a copper sleeve 605 embedded in the base body 601; the base bod...

Embodiment 2

[0062] The comb-tooth lifting vehicle carrier includes a body 7 and a lifting frame 2. The lifting frame 2 is provided with front combs 1, rear combs 3 and wheel centering devices 9 for carrying automobile wheels, and the body 7 is provided with guide wheels. With the traveling wheel train 4 driven by the traveling motor 11, the vehicle body 7 is connected with the lifting frame 2 through a lifting device. The lifting device includes 2 lifters 6 and 1 lifting drive motor installed on the two ends of the vehicle body 7 respectively. The drive motor is connected.

[0063] The lifter 6 includes a base body 601, a lifting guide shaft 604, a pair of meshing gears 602 and a rack 603; the base body 601 is connected to the vehicle body 7, and the top of the lifting guide shaft 604 is connected to the lifting frame 2 by bolts. Can slide along the guide hole 605 in the seat body 601, the gear 602 is connected with the shaft end of the synchronous shaft, and is rotatably connected to th...

Embodiment 3

[0065] The comb-tooth lifting vehicle carrier includes a body 7 and a lifting frame 2. The lifting frame 2 is provided with front combs 1, rear combs 3 and wheel centering devices 9 for carrying automobile wheels, and the body 7 is provided with guide wheels. With the traveling wheel train 4 driven by the traveling motor 11, the vehicle body 7 is connected with the lifting frame 2 through a lifting device. The lifting device includes 2 lifters 6 and 2 lifting drive motors installed on the two ends of the vehicle body 7 respectively, and the 2 lifters are connected with the lift drive motors respectively.

[0066] The lifter 6 includes a base body 601, a lifting guide shaft 604, a pair of meshing gears 602 and a rack 603; the base body 601 is connected to the vehicle body 7, and the top of the lifting guide shaft 604 is connected to the lifting frame 2 by bolts. Can slide along the guide hole 605 in the seat body 601, the gear 602 is connected with the shaft end of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com