Patents

Literature

83results about How to "Easy to ship out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

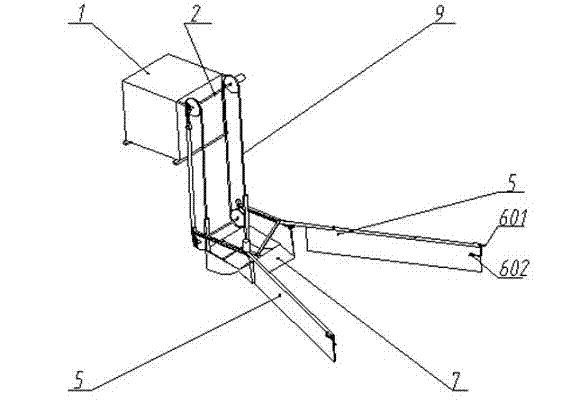

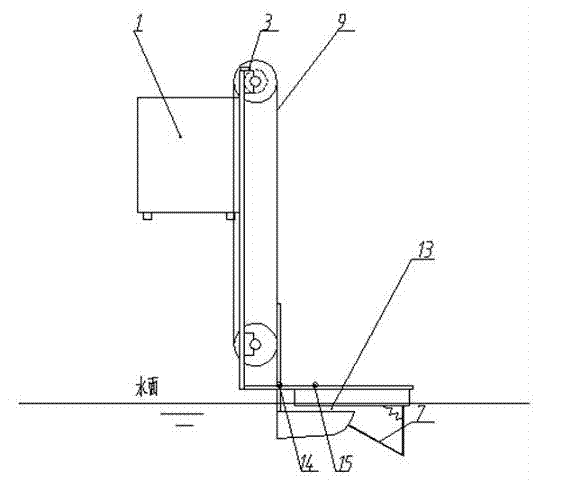

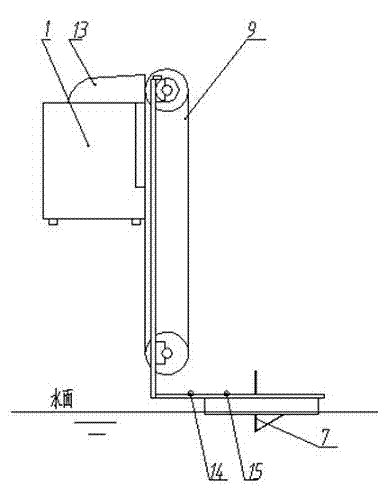

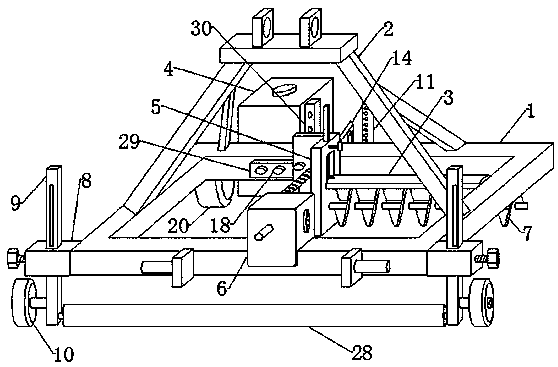

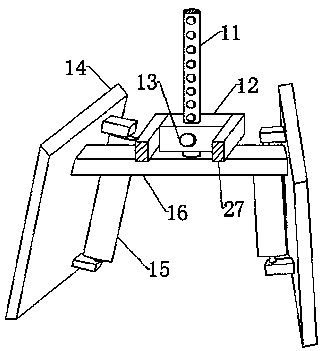

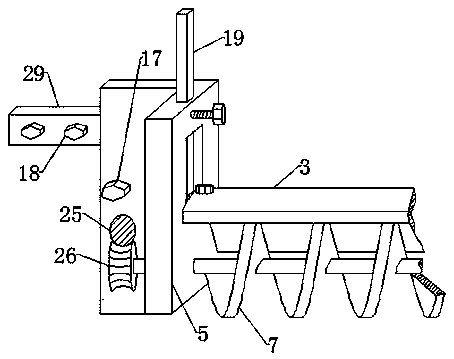

Automatic clearing ship for rubbish on water

InactiveCN102963505ASimple structureReduce operating costsWater cleaningWaterborne vesselsElectric machineryCollection system

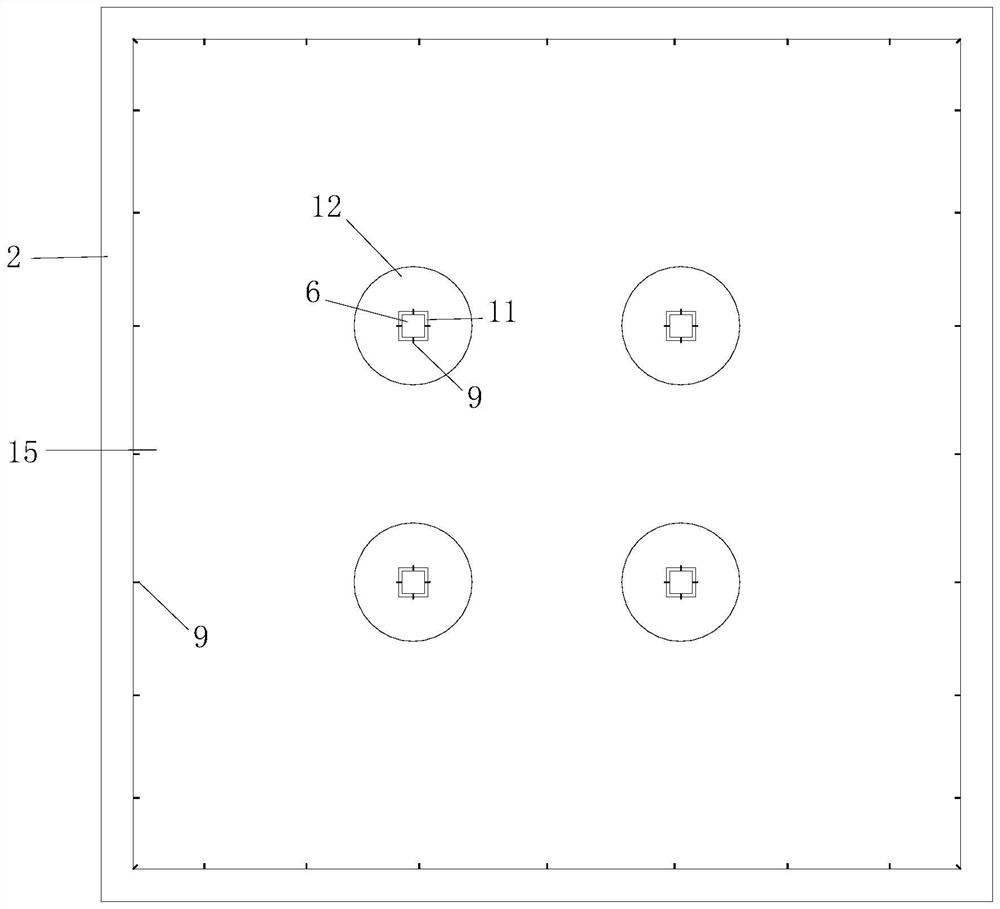

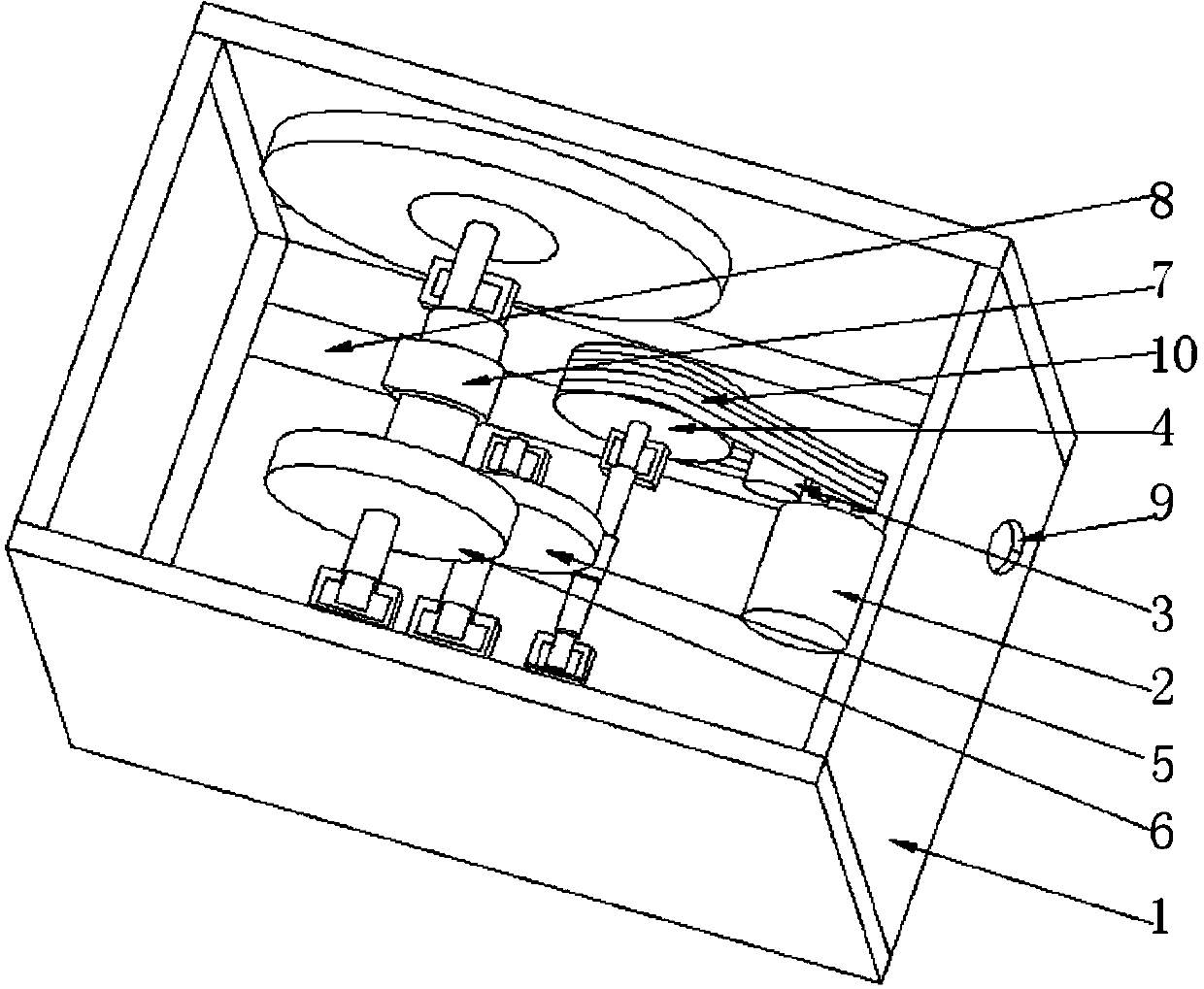

The invention discloses an automatic clearing ship for rubbish on water and belongs to the technical field of cleaning the rubbish on the water. The ship comprises a ship body, a rubbish collection system and a rubbish transport system, wherein the rubbish collection system comprises a rubbish storage bin, a chain shaft, guide arms, an arresting barrier, chains and a collection basket; the rubbish transport system comprises a guide rail transmission stand and a lifting stand; the guide rail transmission stand consists of transverse guide rails and longitudinal guide rails by crossing; and the lifting stand comprises a hook, a sleeve, diagonal rods, a base, a vertical rod, a cross rod, a motor and a screw rod. The ship body is simple in structure, so that the structure of the complete ship is simplified on the basis of function addition, the operation cost and manufacturing cost are lowered greatly, the energy consumption is reduced correspondingly, the popularization and use of the clearing ship are facilitated, and the automatic clearing of the rubbish on the water can be achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

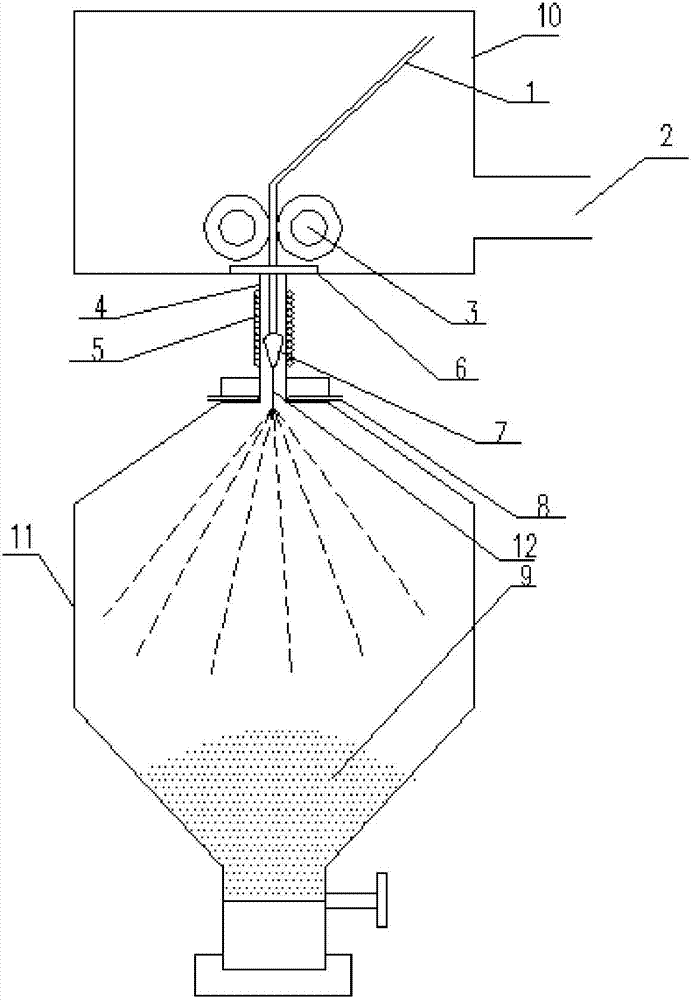

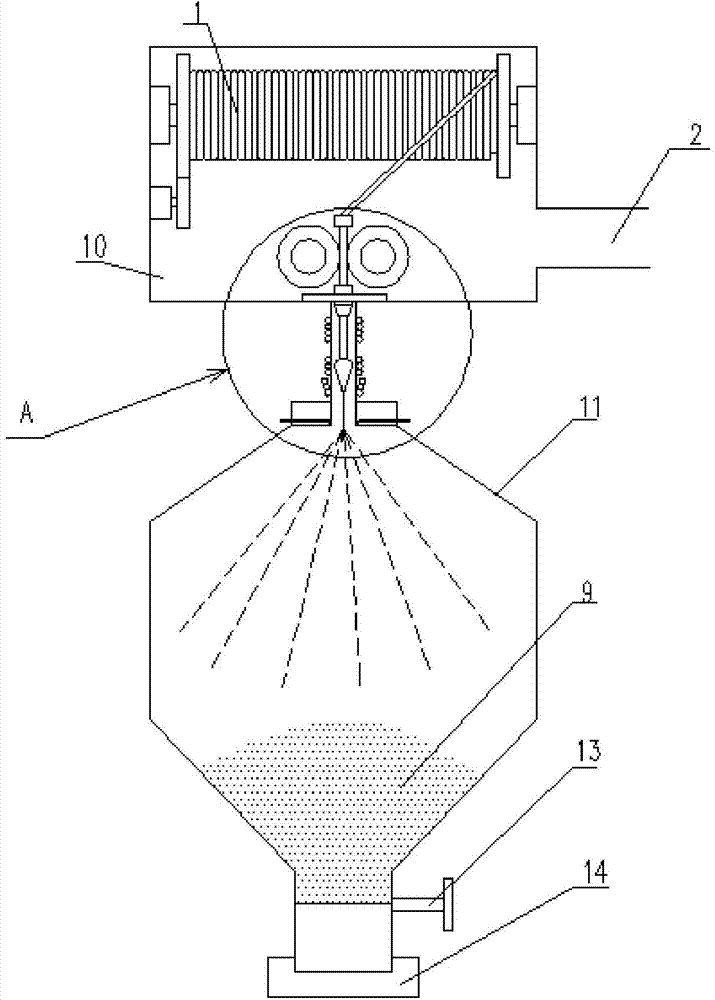

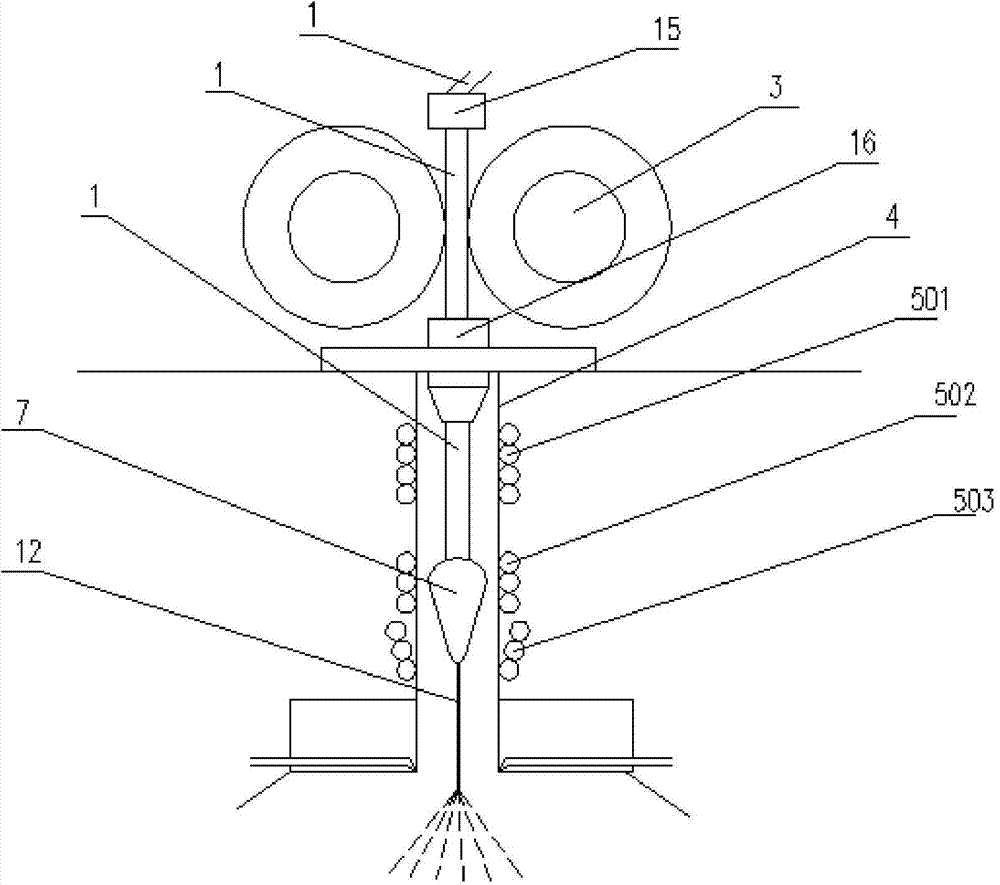

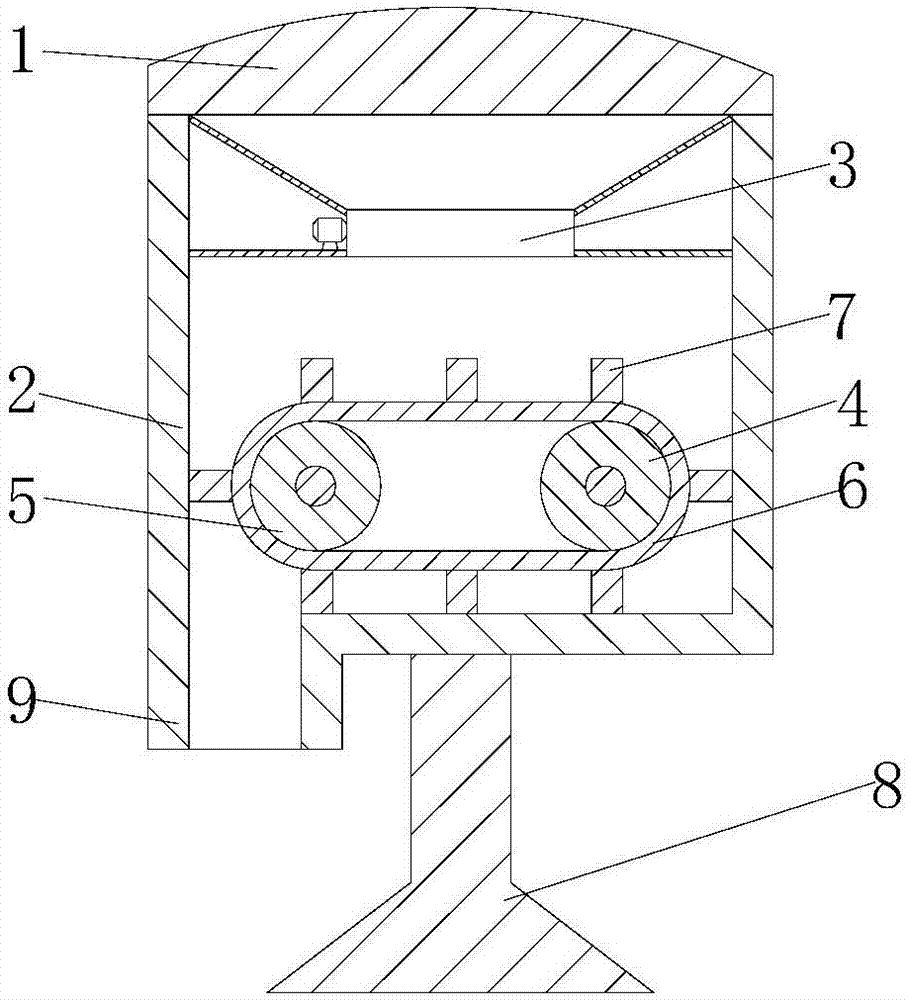

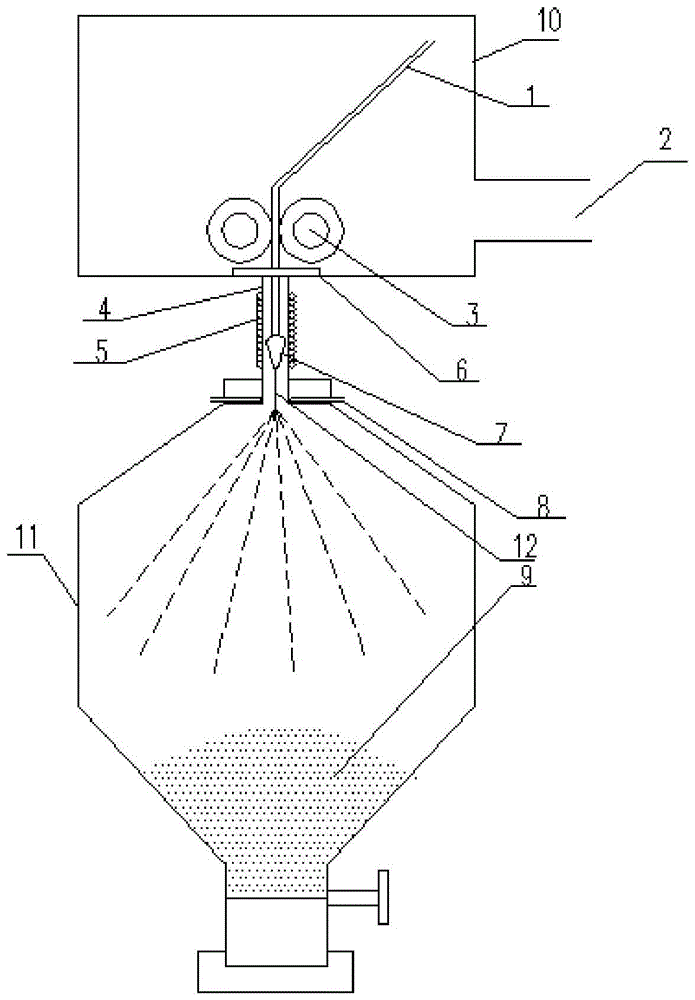

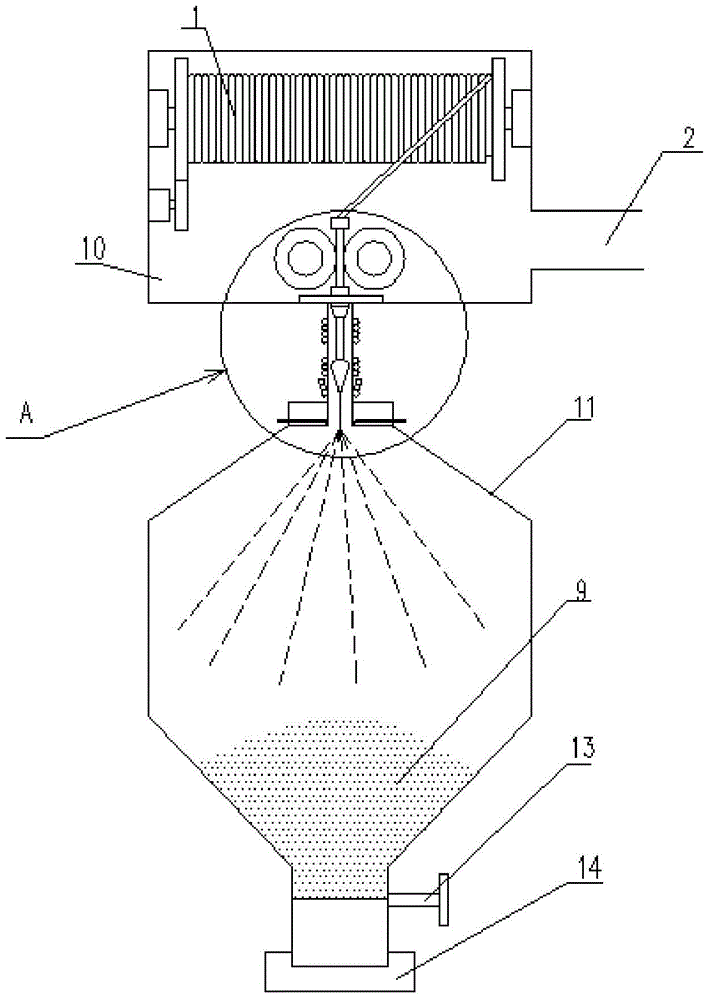

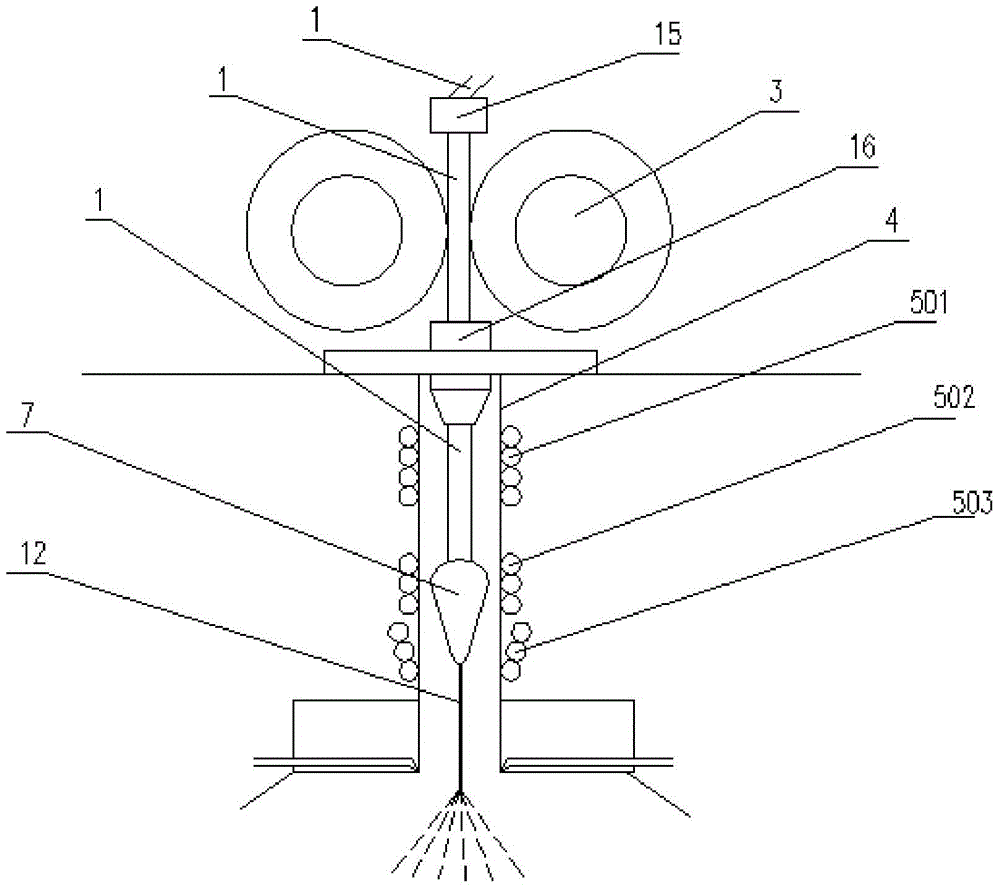

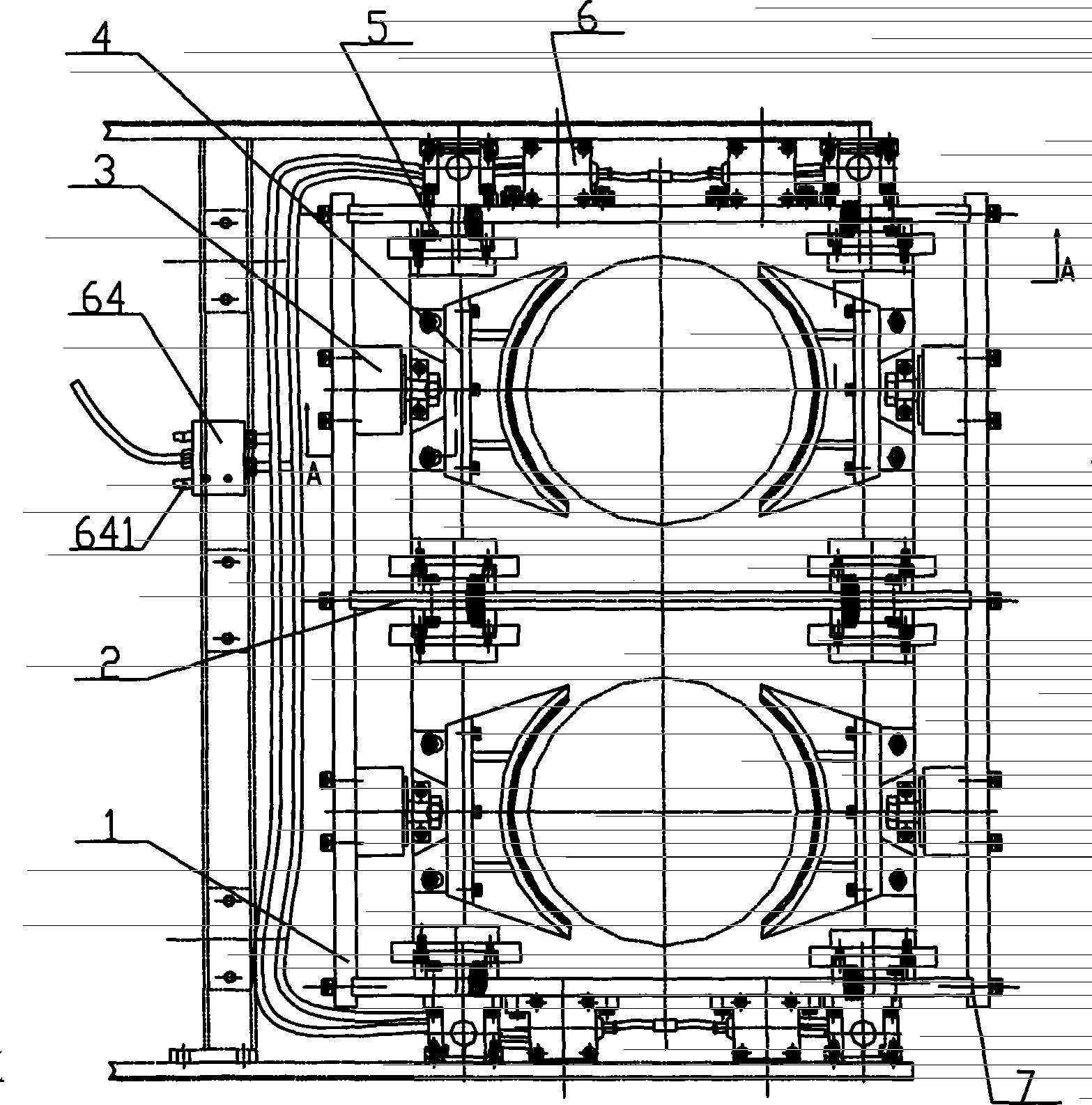

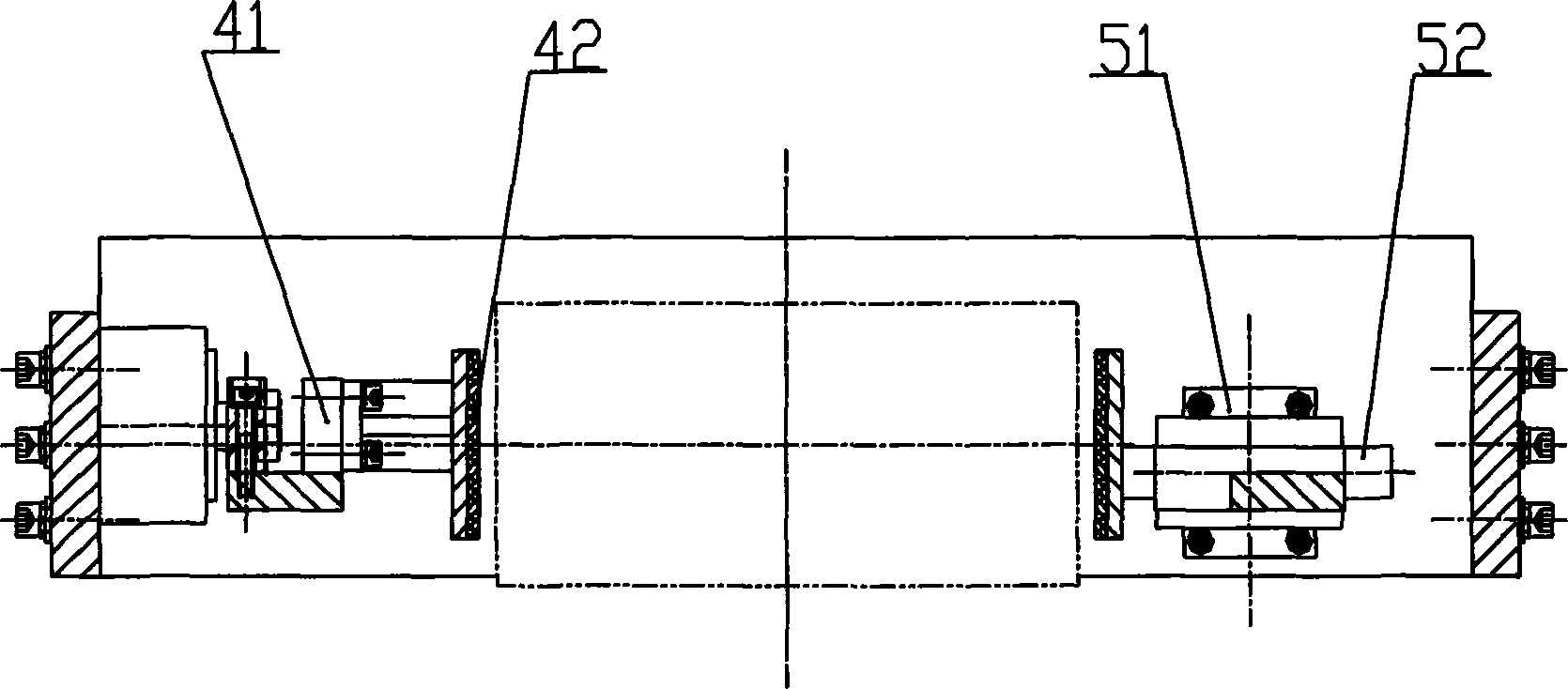

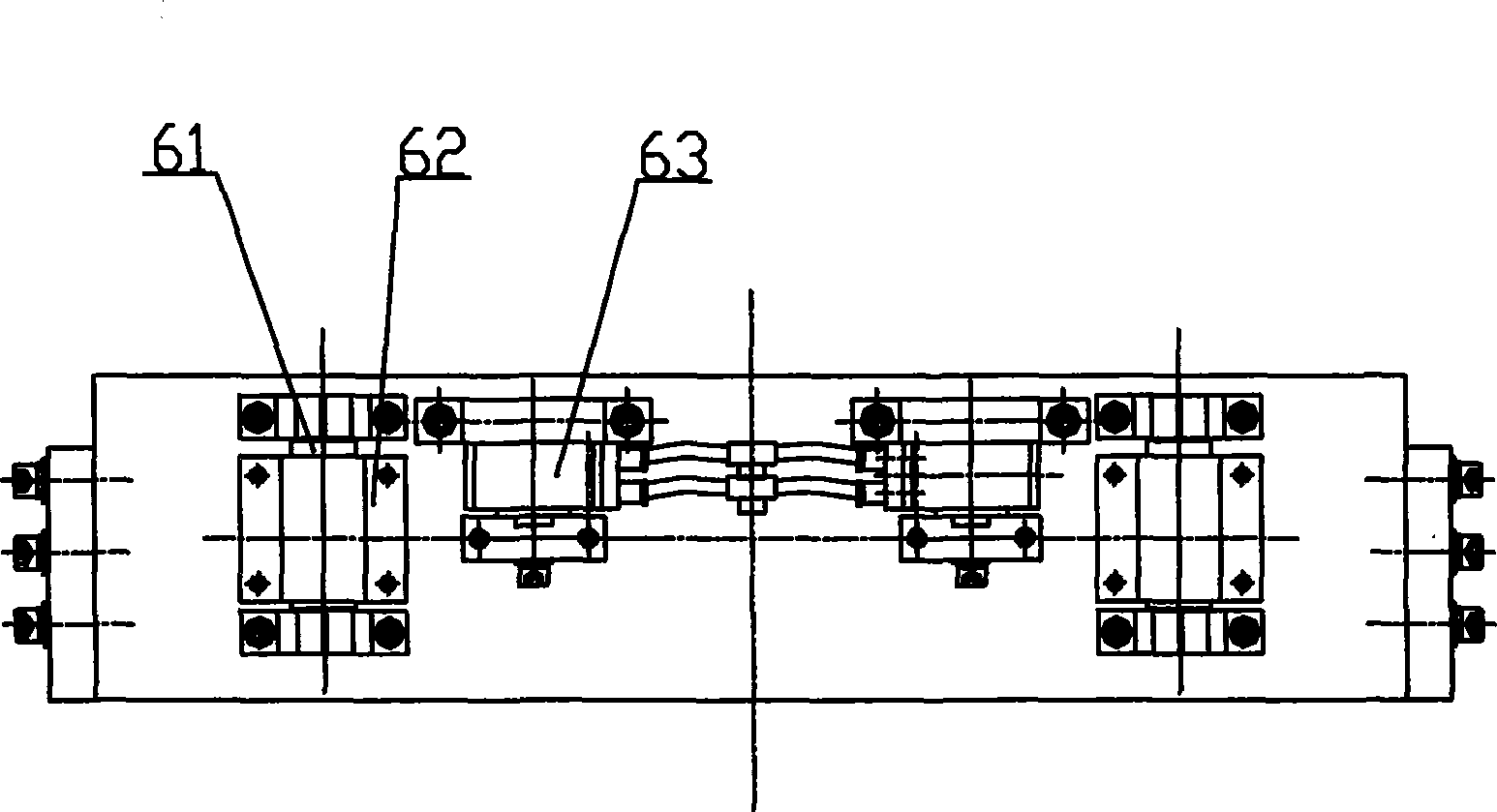

Method and device for metal powder preparation based on controllable magnetic levitation melting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

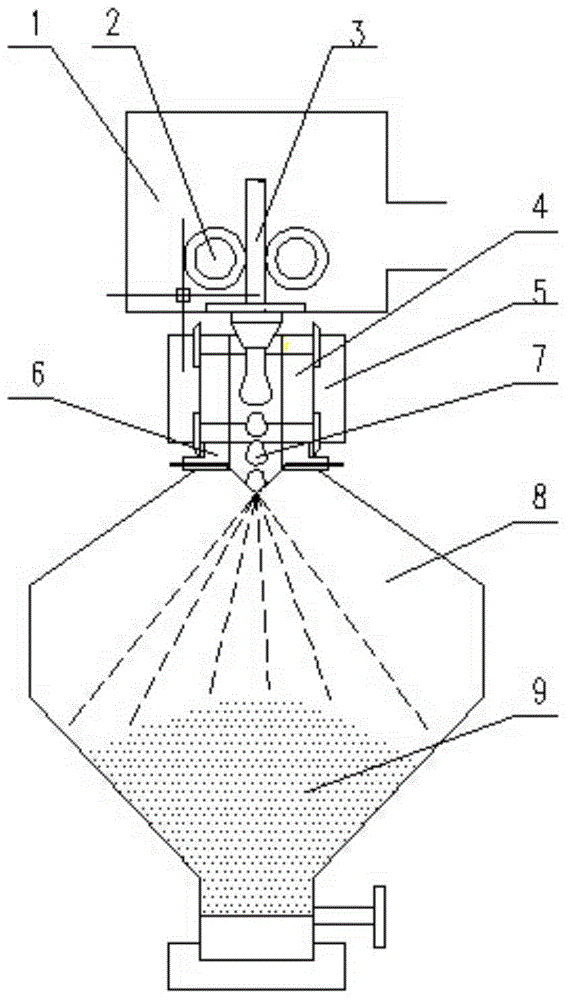

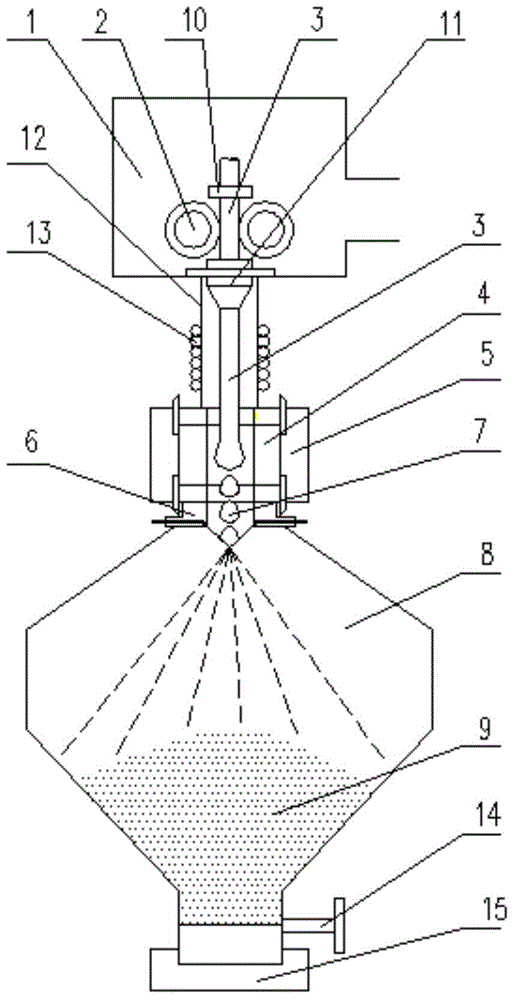

Metal powder preparation method and device based on DC (Direct Current) resistance heating non-contact smelting

The invention relates to a metal powder preparation method and device based on DC (Direct Current) resistance heating non-contact smelting. The metal powder preparation method comprises the following steps: enabling one end of a metal rod to pass through an electrified graphite area at a uniform speed; heating to melt the metal rod in the electrified graphite area; continuously forming metal liquid drops from molten metal under the action of the gravity; continuously dripping the metal liquid drops to a gas atomization area; impinging and scattering the metal liquid drops by high-pressure and high-speed inertial gas in the gas atomization area, and cooling to form metal powder. The metal powder preparation device comprises a vacuum cavity, a pair of idler wheels and a graphite pipe, wherein the two idler wheels are parallel in the axial direction, the rotation directions of the idler wheels are opposite, and a gap between rotating surfaces of the two idler wheels is matched with the diameter of the metal rod; the gap between the rotating surfaces of the two idler wheels is communicated with a metal rod outlet; one end of the graphite pipe is connected with the metal rod outlet, and the other end of the graphite pipe is sequentially connected with a gas atomization nozzle and a powder collector. According to the metal powder preparation method and device, the flow velocity of molten metal liquid can be stably controlled, and the industrial production demands can be met.

Owner:CHINA JIUYUAN HI TECH EQUIP

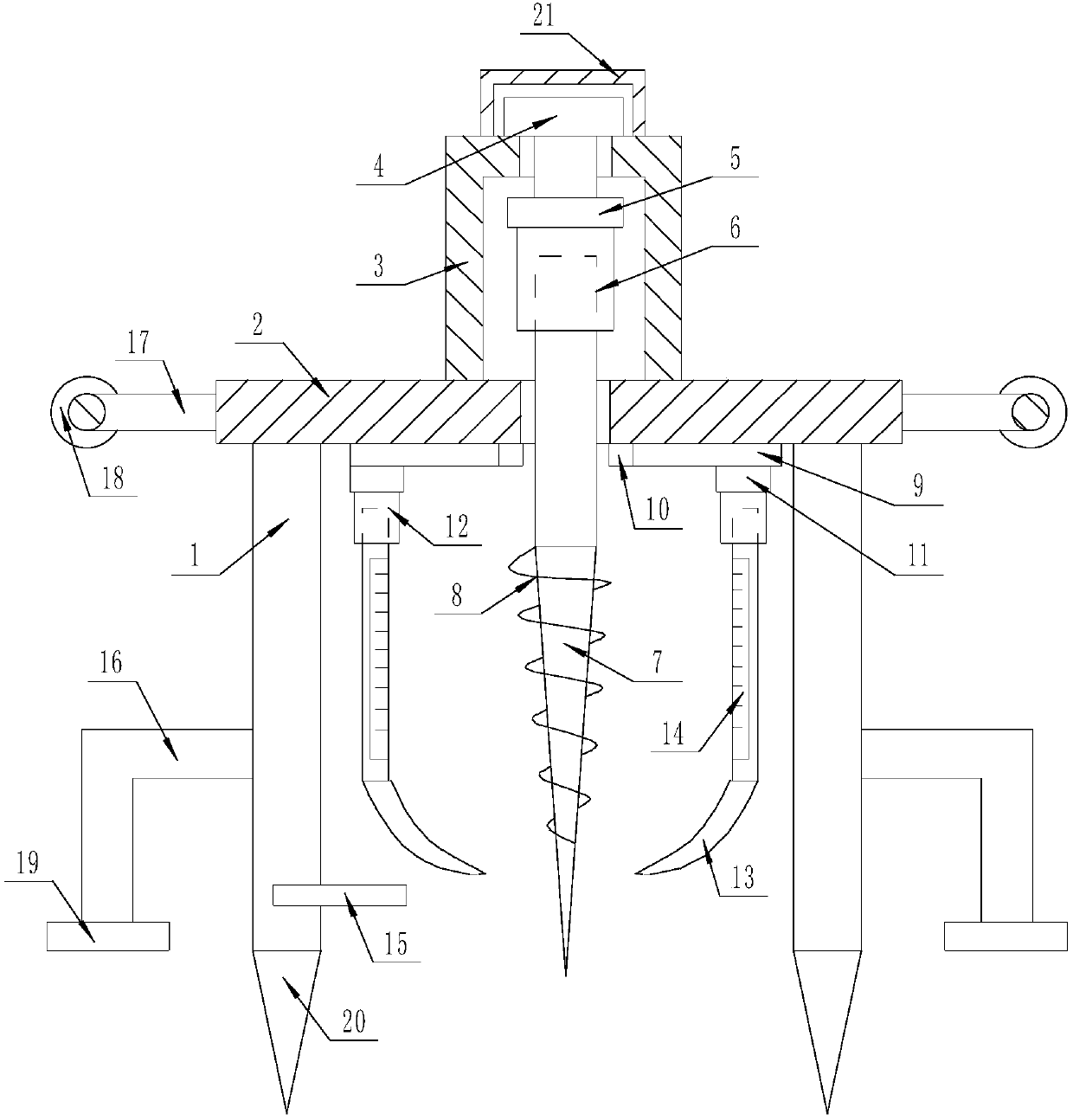

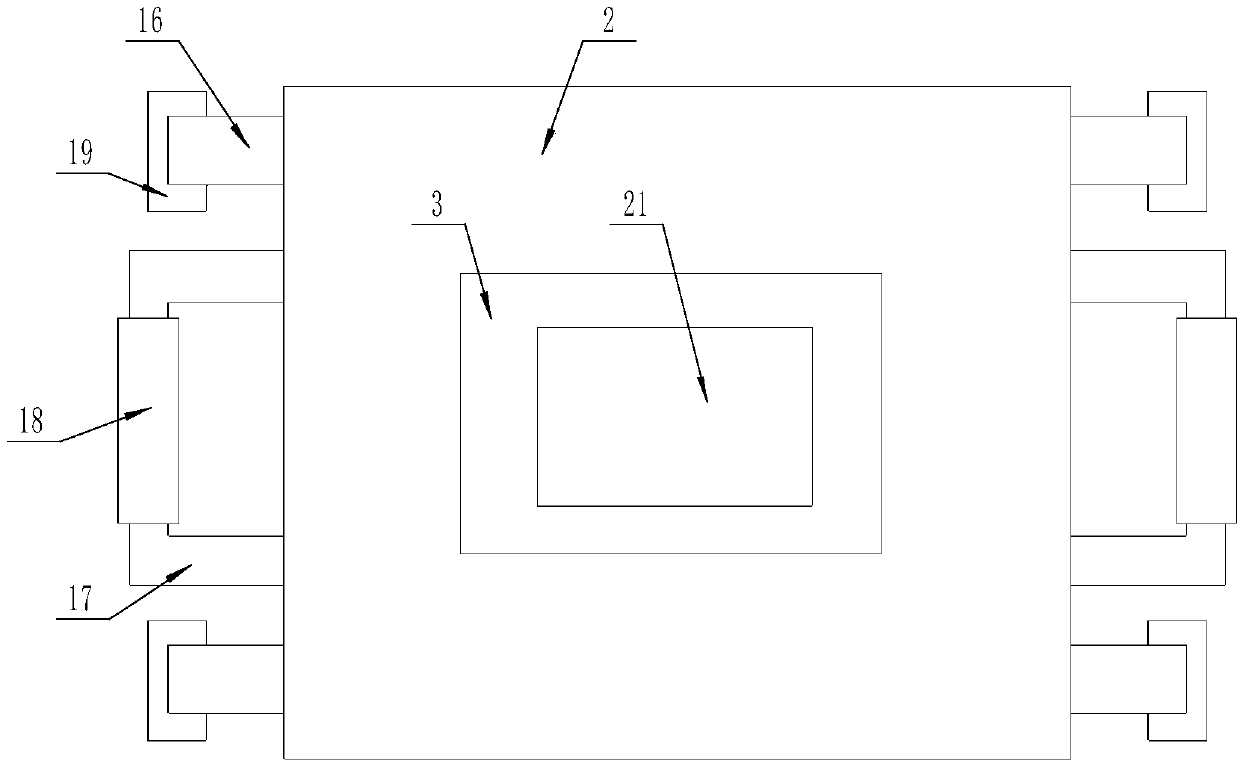

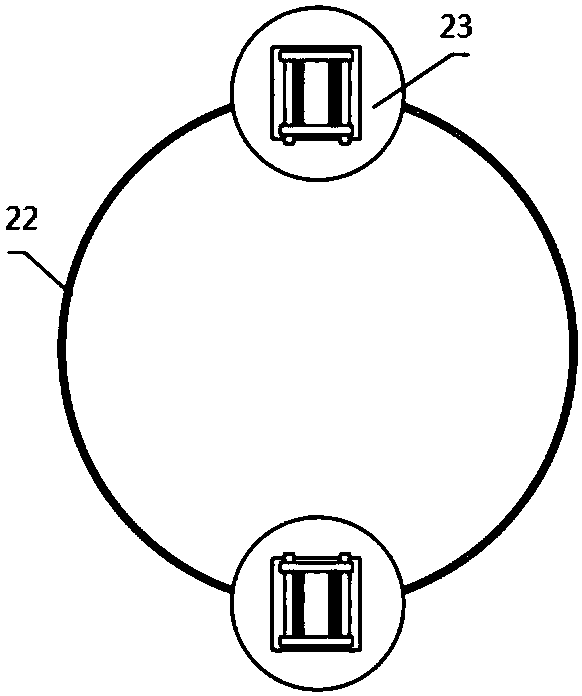

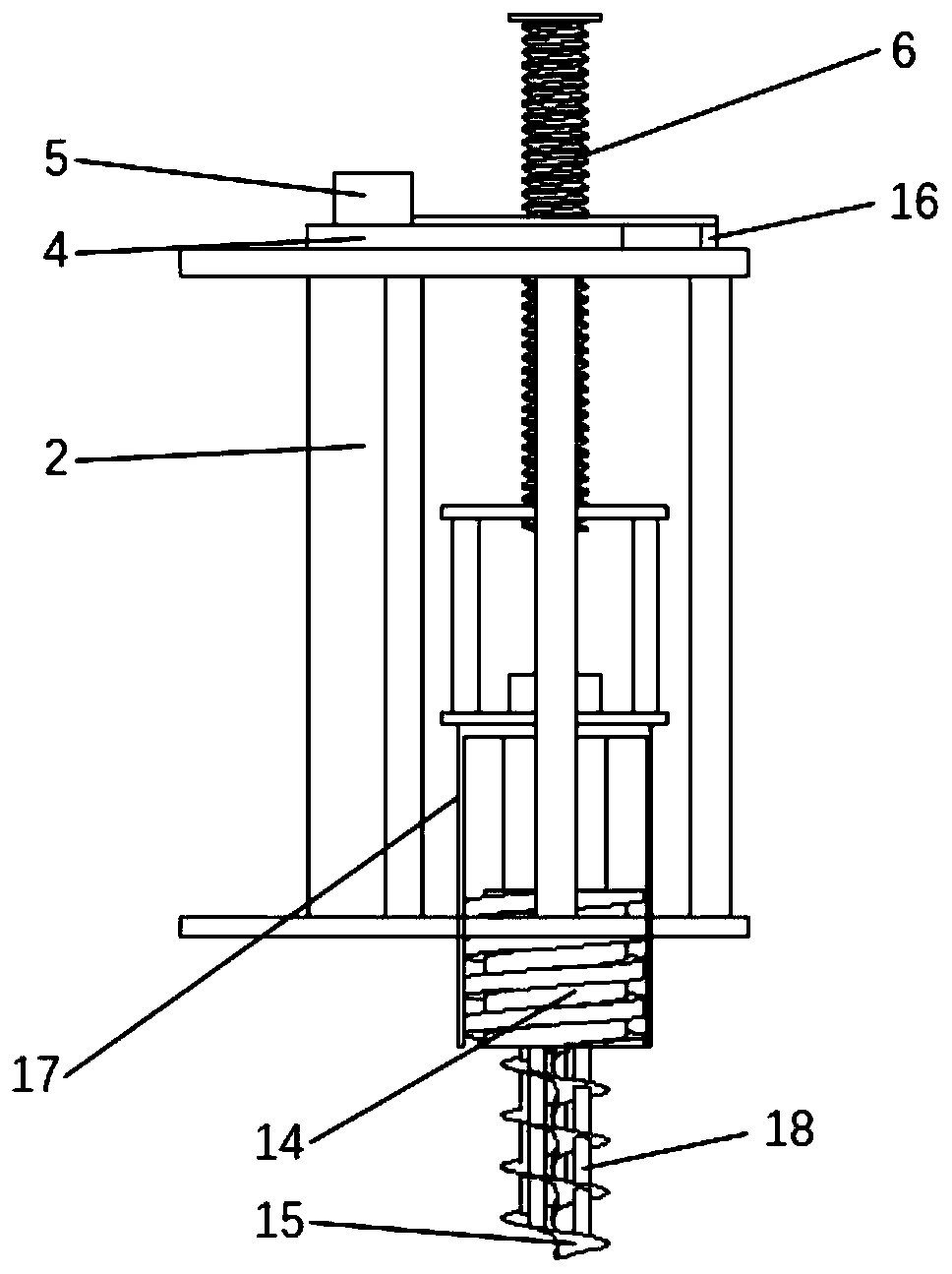

Municipal construction digging equipment

ActiveCN107852896AEasy to watchEasy to measurePlantingFurrow making/coveringHelical bladeArchitectural engineering

The invention discloses municipal construction digging equipment. The equipment comprises two pairs of support legs, a rectangular mounting plate is fixedly connected to the upper surfaces of the twopairs of the support legs, a circular opening is machined in the upper surface of the rectangular mounting plate, a door-shaped support frame is fixedly connected to the upper surface of the rectangular mounting plate, a mounting opening is machined in the upper surface of a beam of the door-shaped support frame, a driving motor with a rotating end facing downwards is installed in the mounting opening in an embedded mode, a circular connecting plate is fixedly connected to the rotating end of the driving motor, a hydraulic telescopic rod which stretches out of the circular opening and is provided with a telescopic end facing downwards is fixedly connected to the lower surface of the circular connecting plate, a conical drill pipe is fixedly connected to the telescopic end of the hydraulictelescopic rod, and helical blades are fixedly connected to the side surface of the conical drill pipe. The municipal construction digging equipment has the advantages of being simple in structure andhigh in practicability.

Owner:中泰建诚(北京)建设工程有限公司

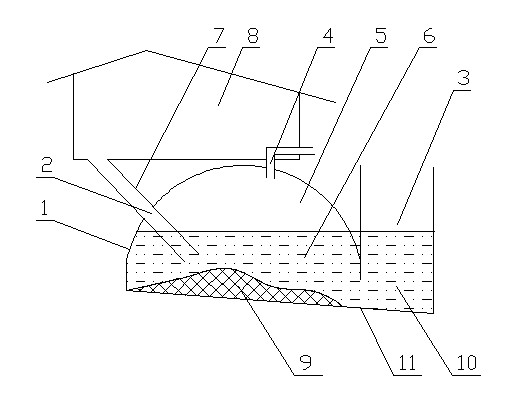

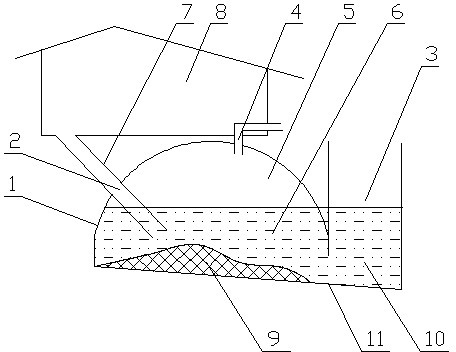

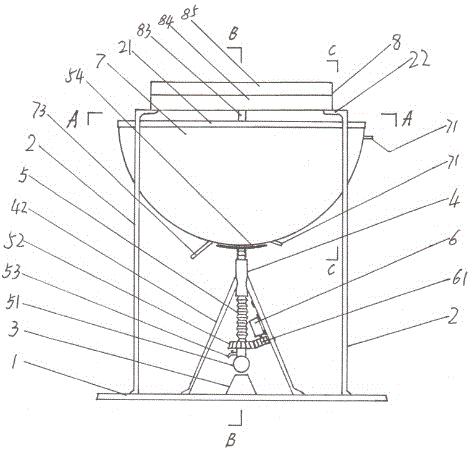

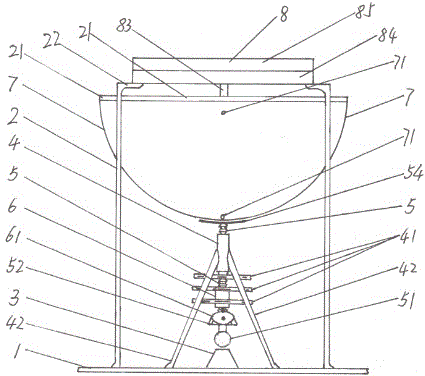

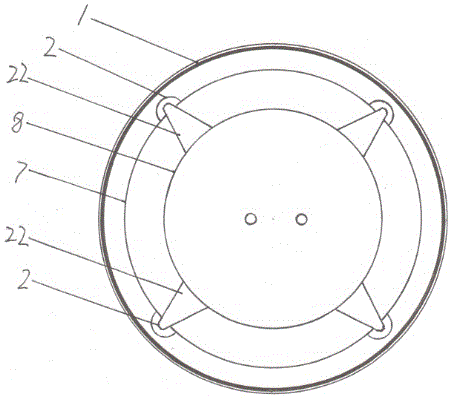

Methane tank capable of facilitating slag removal

InactiveCN102212464AEasy to ship outPlay a stirring roleGas production bioreactorsWaste based fuelPoisoning riskSlag

The invention discloses a methane tank capable of facilitating slag removal. The methane tank comprises a methane tank body, wherein a feed port, a discharge port and a methane outlet are formed on the methane tank body; a gas storage chamber is arranged on the upper part in the methane tank body; a fermenting chamber is arranged on the lower part in the methane tank body; the bottom surface of the methane tank body is inclined; the feed port corresponds to the higher part of the inclined surface; and the discharge port corresponds to the lower part of the inclined surface. The bottom surface of the methane tank body is set to be the inclined surface, so when removing methane slag, a user only needs to draw out one part of methane liquid and return the methane liquid from the feed port (a feed pipe) to impact the bottom surface of the methane tank body to push the methane slag into the discharge port (a water pressure room) along with the inclined surface, and then can take out the methane slag conveniently from the discharge port (the water pressure room), so the user does not need to enter the fermenting chamber to remove the slag under a poisoning risk, and time and labor are saved; and in addition, the tank is stirred by the impact of the methane liquid, so that methane bacteria completely contact with fermenting materials newly entering the tank and yield of the methane is increased.

Owner:金海

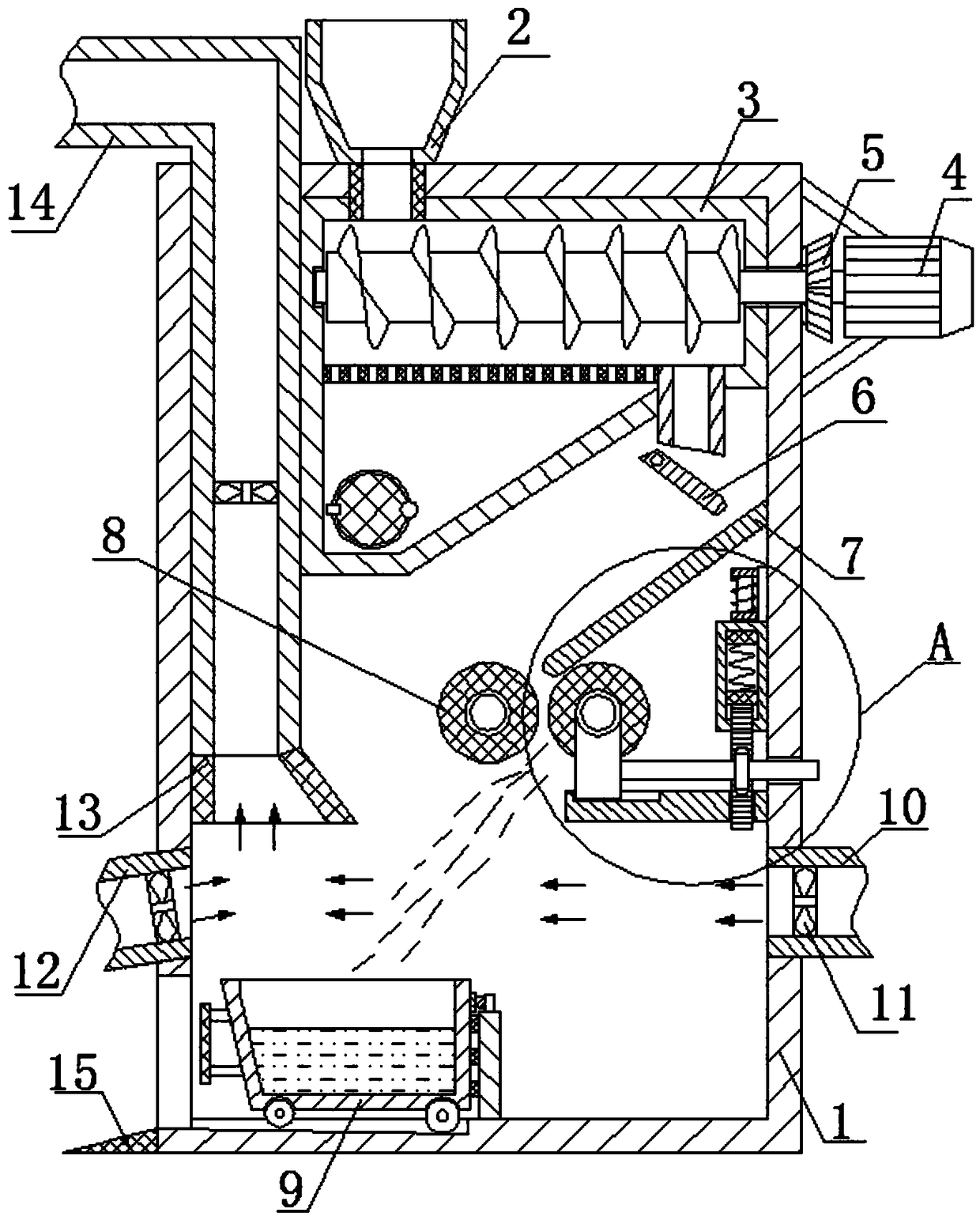

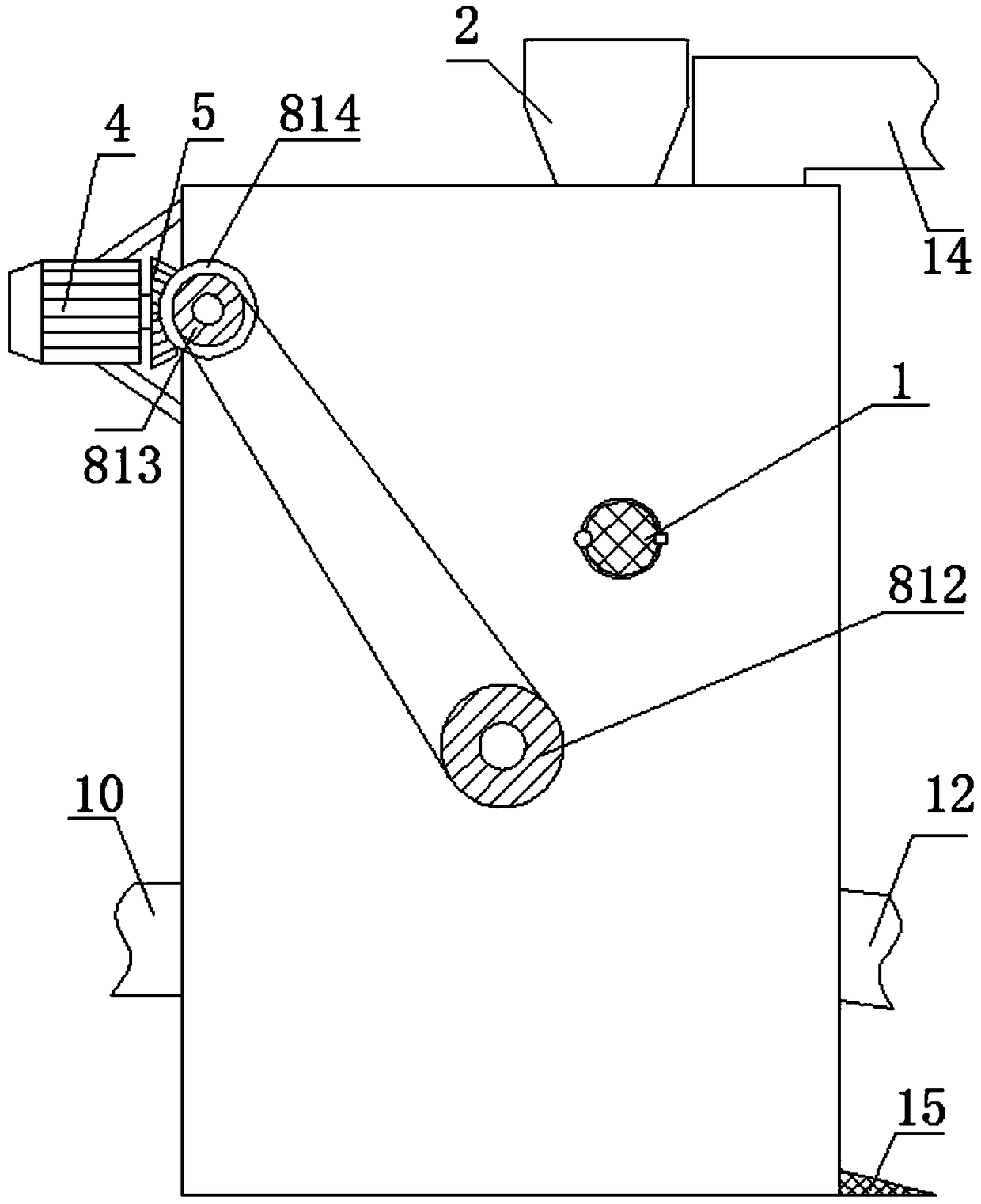

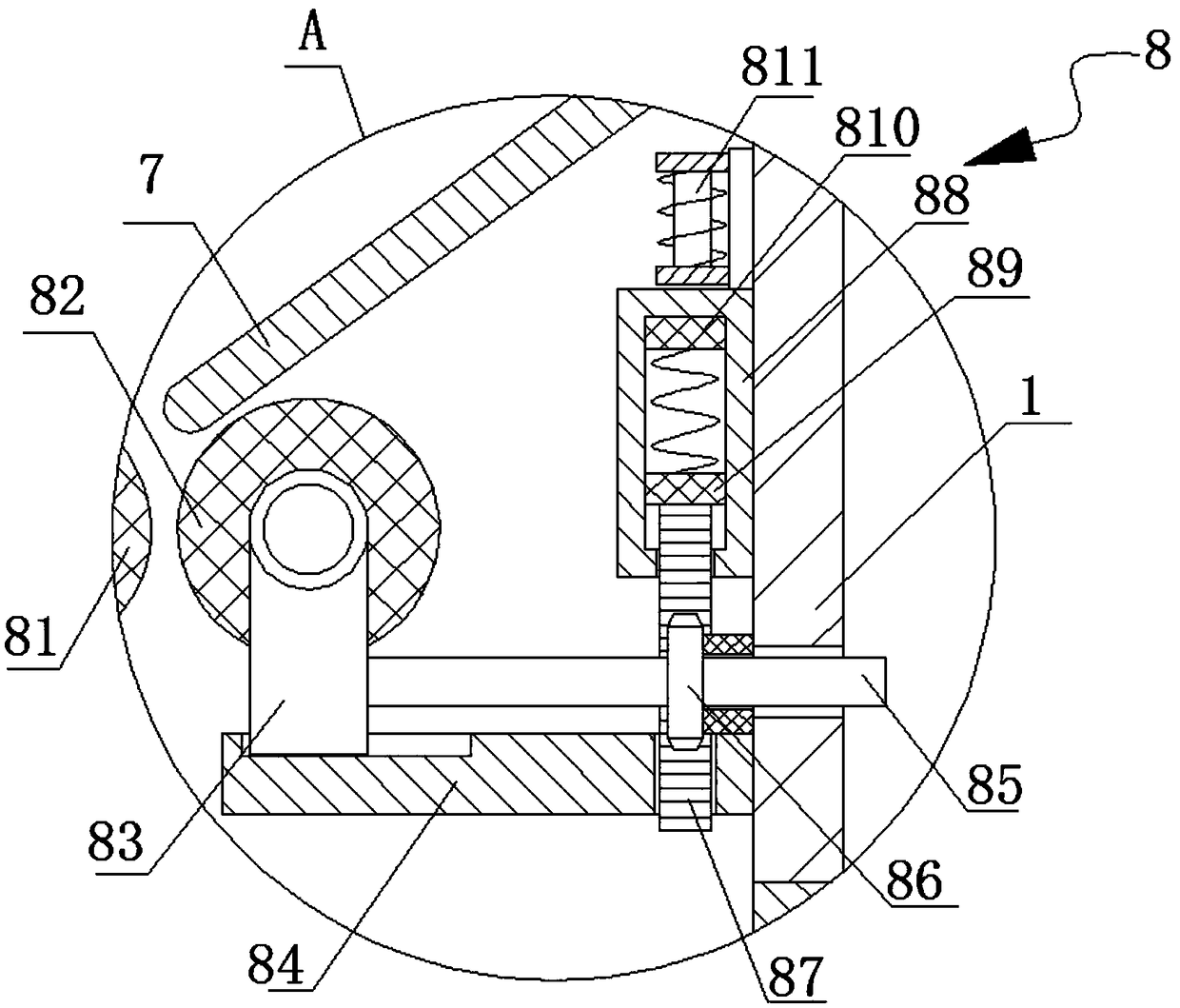

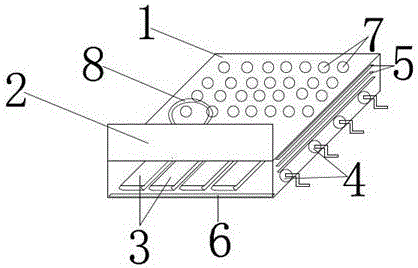

Automatic purification husking device for rice processing

InactiveCN108855305AImprove the rice yieldEffective tearing and peelingGrain huskingGrain polishingEngineeringUltimate tensile strength

The invention provides an automatic purification husking device for rice processing. The automatic purification husking device comprises a device shell and a feeding hopper. The feeding hopper is connected to the upper end of the device shell in an inserted and penetrating mode, and the lower end of the feeding hopper reaches an inner cavity of the device shell and is connected to the upper end ofa cleaning device in a penetrating mode. The upper end of the cleaning device is fixedly connected to the inner top wall of the device shell, and a motor is welded to the upper end of the outer sidewall of one side of the device shell through a first bracket. The automatic purification husking device overcomes the deficiencies of the prior art, has reasonable design and a compact structure, effectively purifies dried-up seed and grass seed in rice, improves the milled rice rate of the rice and can timely and effectively transport the processed brown rice; and the labor intensity of rice processing personnel is reduced, and the quality of the brown rice is improved.

Owner:怀宁县谷丰米业有限公司

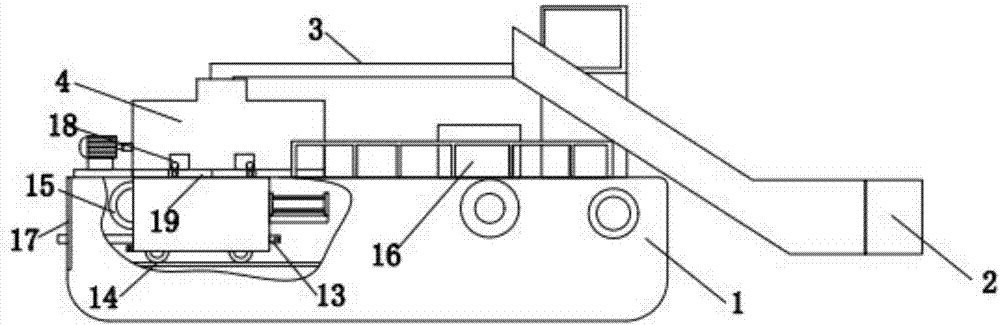

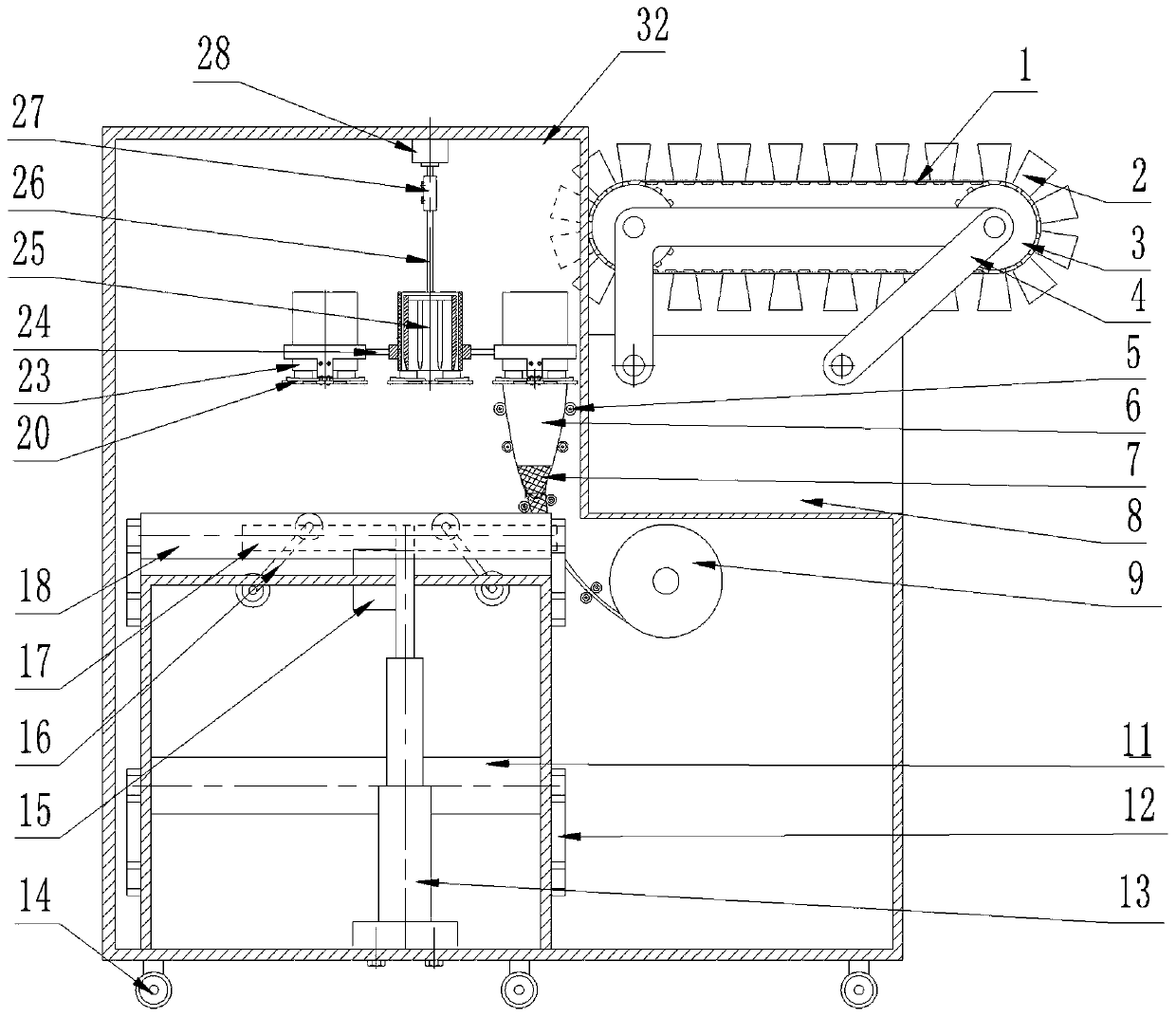

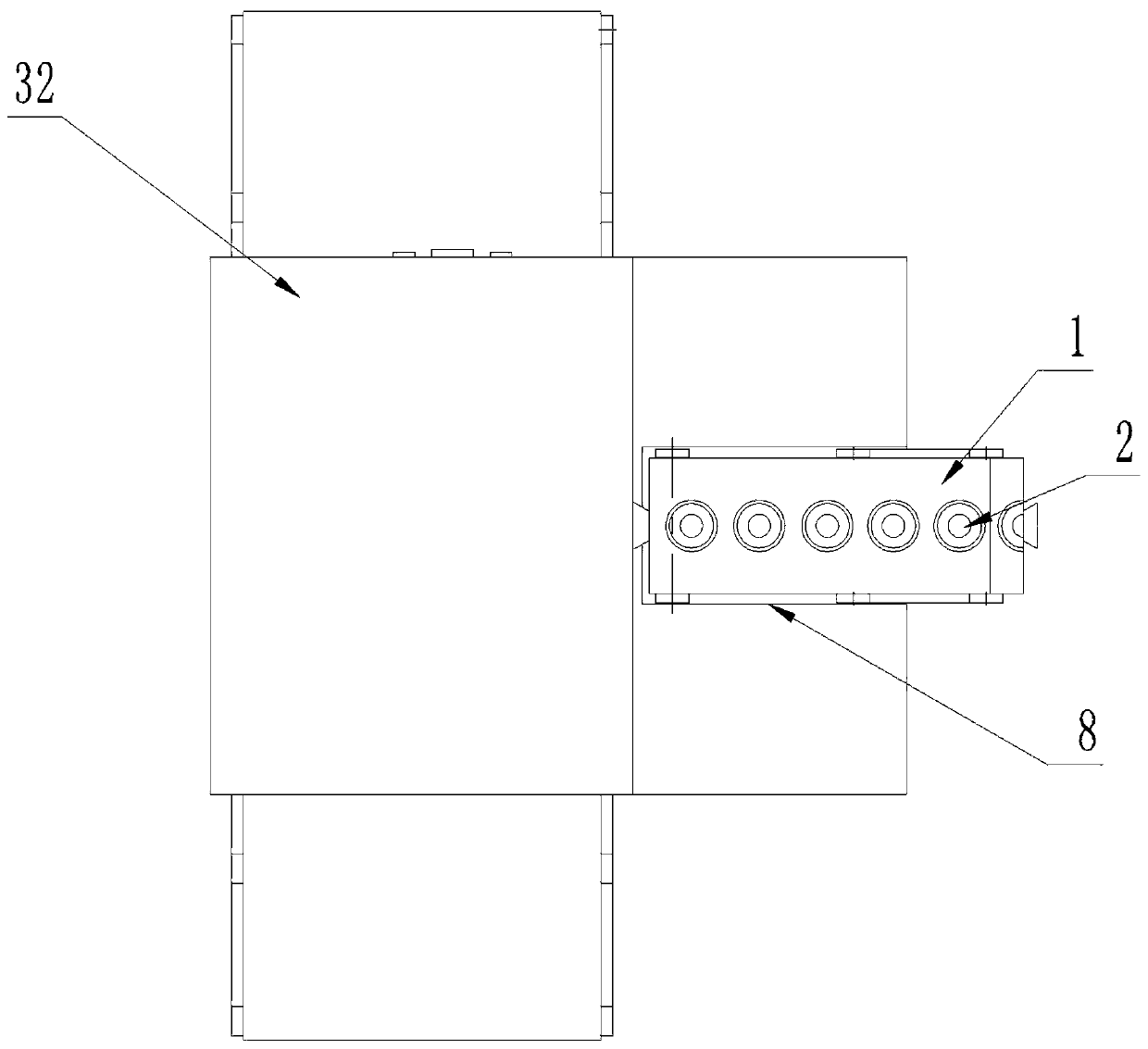

Ship for dragging water hyacinths

InactiveCN107878694AEasy to ship outReduce the burden onWaterborne vesselsHarvestersMarine engineeringComminution

The invention relates to a water hyacinth salvage ship, which comprises a hull; a salvage mechanism is arranged at the front end of the hull; a conveyor belt, a garbage box and a crushing and dehydrating mechanism are also arranged on the hull; the crushing and dehydrating mechanism is located at the rear end of the hull; The front end of the conveyor belt is connected with the salvage mechanism, and the rear end of the conveyor belt is located above the crushing and dehydrating mechanism; the garbage bin is located below the conveyor belt; a water hyacinth salvage ship according to the present invention can not only salvage the water hyacinths on board, but also The water hyacinth can be crushed and dehydrated by the crushing and dehydrating mechanism on the ship to reduce the burden on the hull. The movable dehydration box can transport the processed water hyacinth out of the cabin conveniently and quickly.

Owner:昆山朗捷通物联信息有限公司

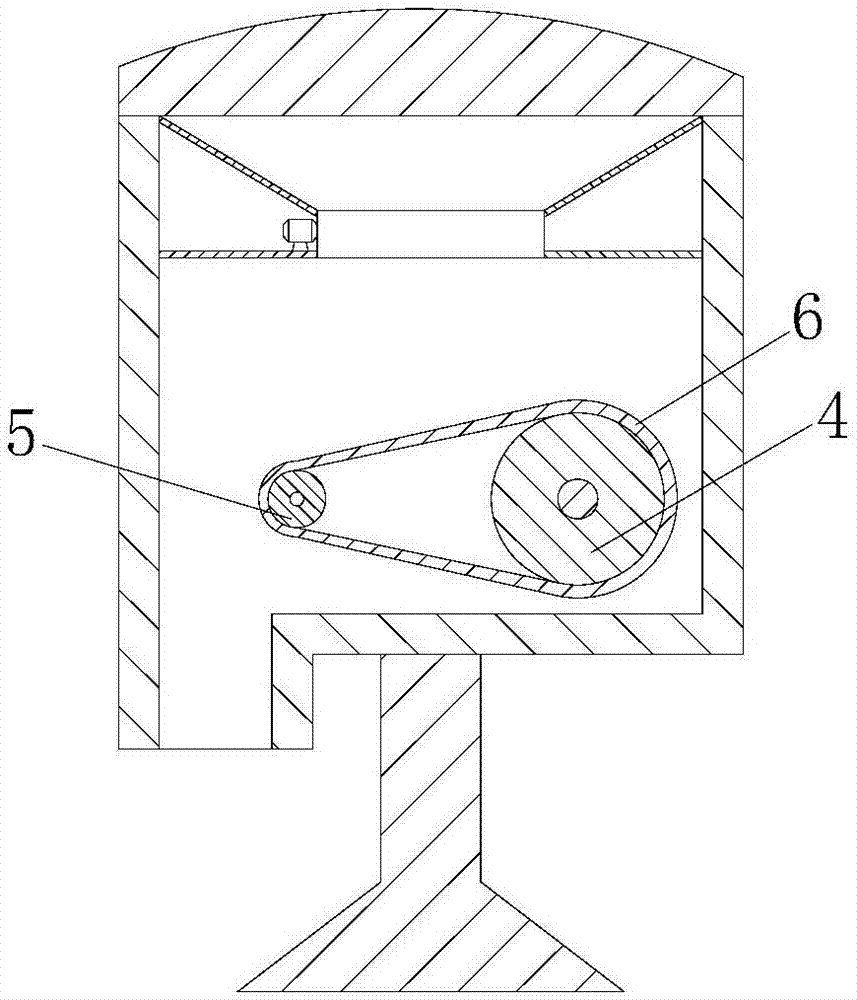

Dustbin

InactiveCN107054939AComprehensive collectionReduce volumeRefuse receptaclesElectric machineryEngineering

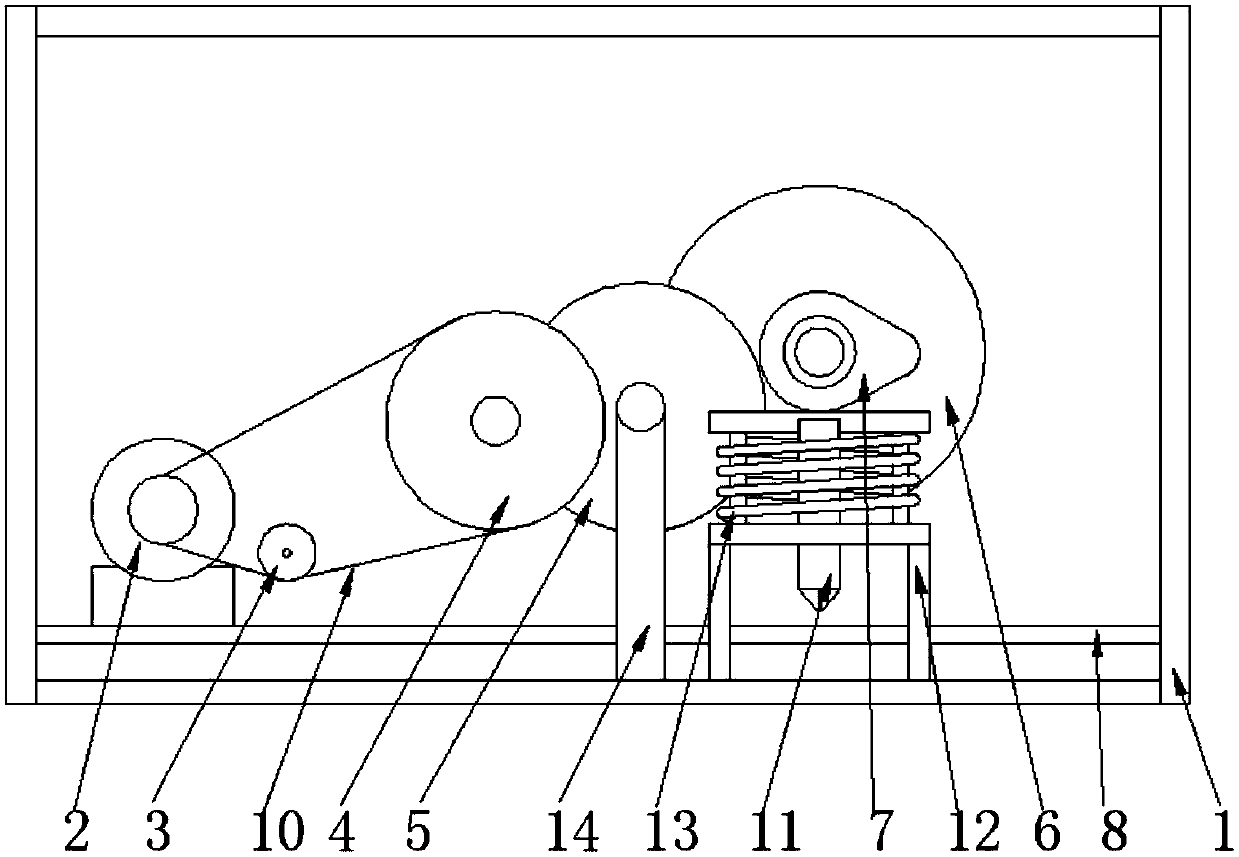

The invention discloses a dustbin and belongs to the field of living goods. The dustbin comprises a dustbin shell provided with a rubbish placing opening provided with a dustbin cover. A rubbish smashing device is arranged below the rubbish placing opening. A conveying device is arranged below the rubbish smashing device and comprises a conveying motor, a driving belt pulley, a driven belt pulley and a belt. The driving belt pulley is fixedly installed on an output shaft of the conveying motor. The driving belt pulley and the driven belt pulley are in transmission connection through the belt. A discharge gap is reserved between the tail end of a conveying belt and the dustbin shell. The bottom of the dustbin shell is provided with a discharge outlet corresponding to the discharge gap. A base is further arranged at the lower end of the dustbin shell. The dustbin provided by the invention has a rubbish smashing function and an automatic rubbish conveying function.

Owner:蒋丽红

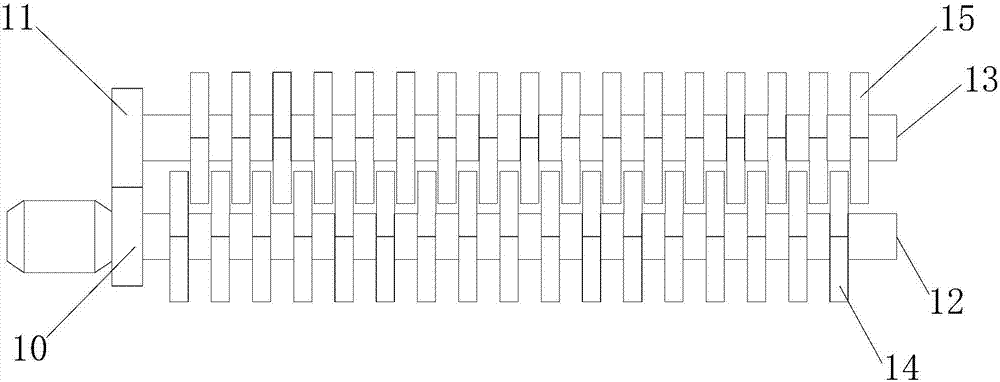

Device for manufacturing bubble bag

InactiveCN103009676AIncrease productivityChange widthPaper-makingBox making operationsEngineeringElectrical and Electronics engineering

The invention discloses a device for manufacturing a bubble bag, which comprises a film discharging device, a transverse edge sealing device, an air supply device, a longitudinal edge sealing device and a cutting device which are sequentially connected. The film discharging device can output an upper film and a lower film which correspond to each other; the transverse edge sealing device comprises a plurality of transverse devices and first liftable heating blocks; the air supply device can inflate the bubble bag; the longitudinal edge sealing device comprises at least one longitudinal device and one second liftable heating block; and the cutting device comprises at least one longitudinal device and a liftable cutter. The device is characterized in that the number of the first heating blocks for transverse edge sealing can be regulated. When a plurality of heating blocks simultaneously work, a plurality sections of longitudinal positions of the upper film and the lower film can be simultaneously subjected to transverse edge sealing; and by regulating the number of the first heating blocks which participate in working, the distance between two adjacent sections of transverse sealed edges can be changed, so that the width of the bubble bag can be changed to regulate the size of the bubble bag. The device is suitable for producing the bubble bags with different sizes and specifications.

Owner:SUZHOU SKY IND

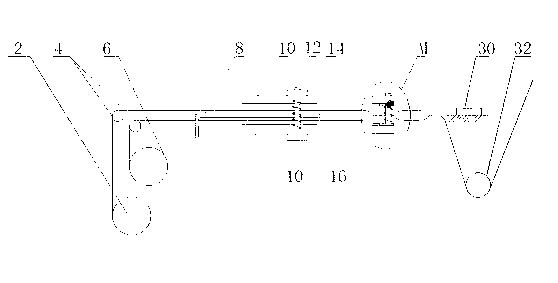

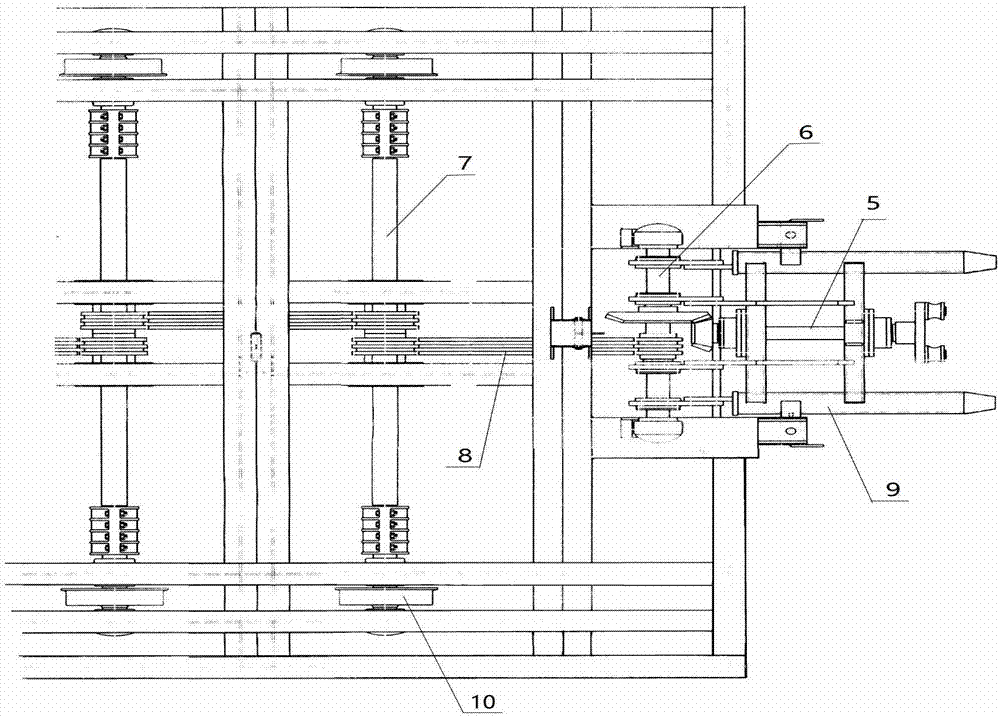

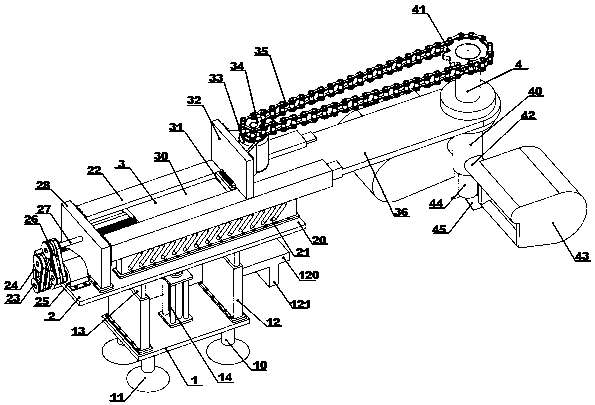

Vacuum oil injection system for transformer or capacitor

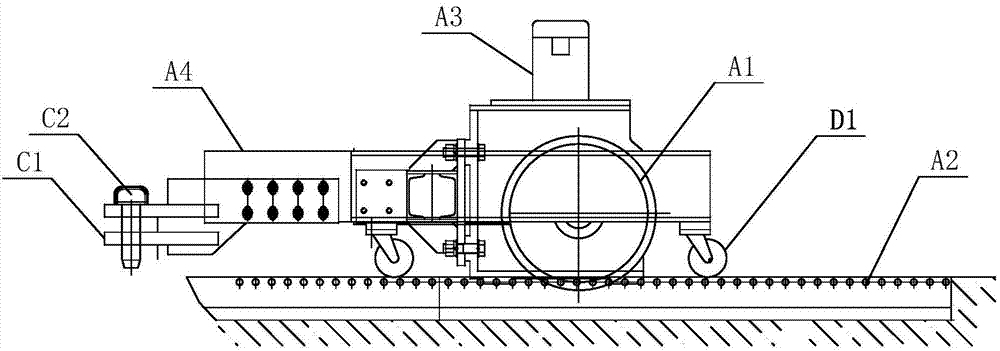

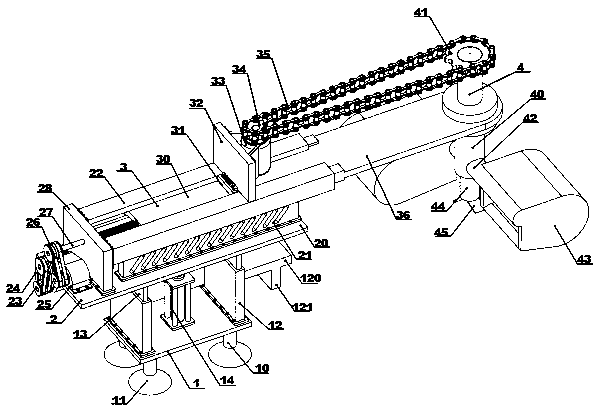

ActiveCN106992060ALarge towing weightExtended service lifeTransformers/inductances coolingLiquid transferring devicesThrough transmissionSprocket

The invention relates to a vacuum oil injection system for a transformer or a capacitor. The vacuum oil injection system comprises a towing vehicle and a vacuum oil injection device. The vacuum oil injection device comprises an oil-level controller, an oil storage tank, a buffering tank and a vacuum tank; the oil storage tank supplements oil into the buffering tank, and relying on the liquid level difference, the buffering tank automatically injects oil into the transformer or the capacitor; the oil-level controller controls the oil storage tank to stop to supplement oil when the oil level in the buffering tank is located on the upper set liquid level, and controls the oil storage tank to start to supplement oil when the oil level in the buffering tank is located on the lower set liquid level, an oil injection soaking pipe communicated with the vacuum tank is installed on an oil injection opening of the transformer or the capacitor, and the maximum liquid level permitted in the oil injection soaking pipe is slightly higher than the upper set liquid level; the towing vehicle comprises a vehicle head and a vehicle body detachably connected with the vehicle head, and the vehicle head is engaged with chain rails installed outside the vacuum tank through transmission chain wheels for achieving reciprocating motion of the towing vehicle. By means of the vacuum oil injection system for the transformer or the capacitor, automatic oil supplementing and automatic oil injection of the transformer or the capacitor are achieved, and the towing vehicle is high in transmission efficiency and long in service life.

Owner:HEFEI GENERAL MACHINERY RES INST

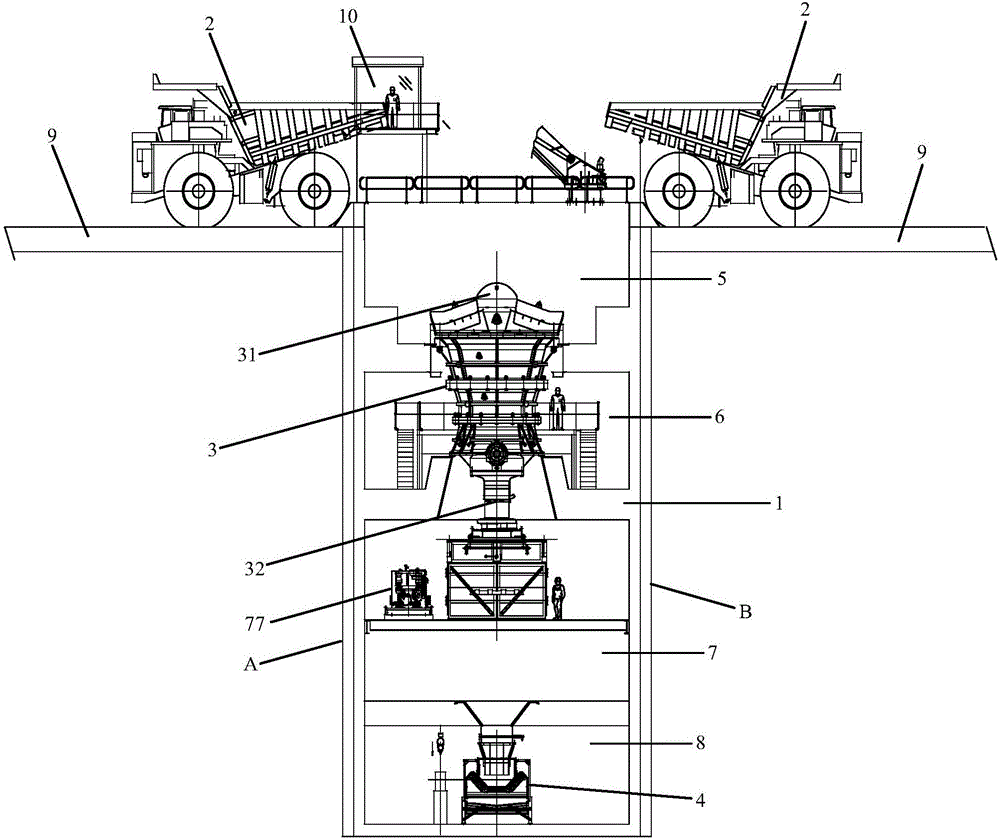

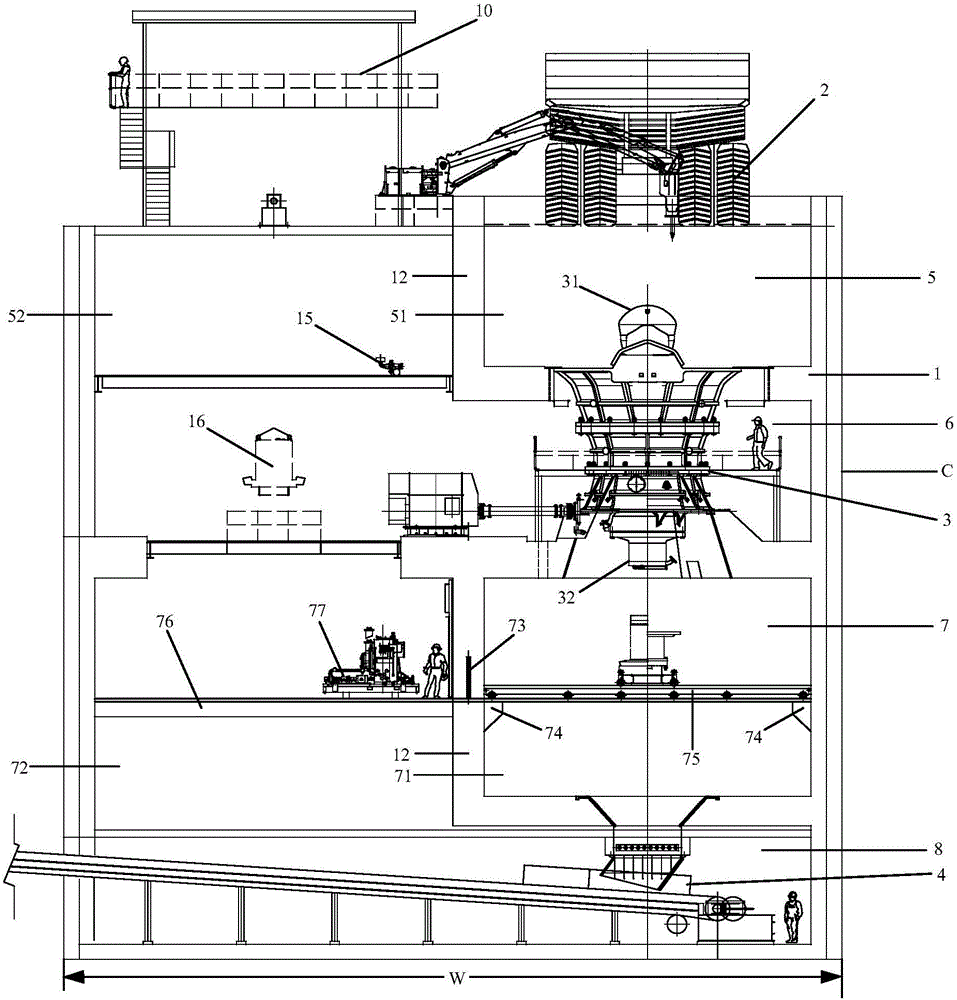

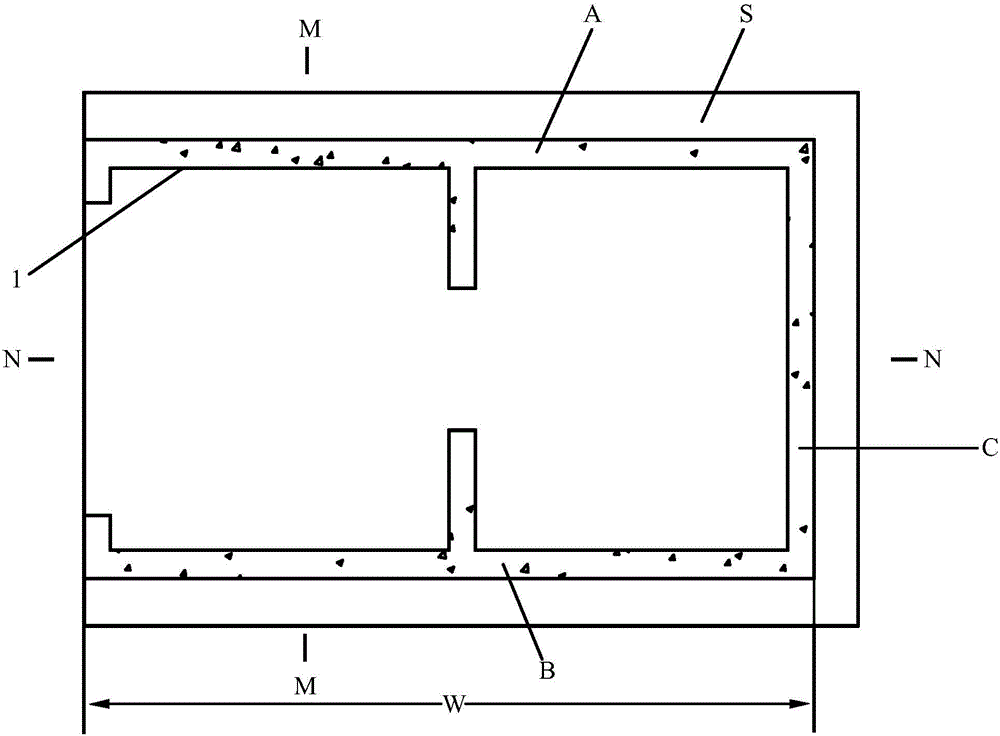

Semi-fixed crushing station and arrangement method

An embodiment of the invention provides a semi-fixed crushing station and an arrangement method, and belongs to the technical field of ore crushing of open pit mines. The semi-fixed crushing station comprises a crushing station foundation, a truck, a crusher and a discharge belt, wherein the crushing station foundation comprises three side surfaces and a bottom surface; the three side surfaces and the bottom surface are arranged in an open pit slope; the crushing station foundation is divided into four layers from top to bottom; the four layers successively comprise an upper stock bin, a crusher bin, a lower stock bin and a belt bin; an unloading platform is arranged on the top surface of the open pit slope; the truck is positioned on the unloading platform; the crusher is positioned in the crusher bin; a feeding opening of the crusher communicates with the upper stock bin; a discharge opening of the crusher communicates with the lower stock bin; the discharge belt is positioned in the belt bin; and the belt bin communicates with the lower stock bin through a through hole. The crushing station foundation only comprises the three side surfaces and the bottom surface, so that equipment such as the crusher is convenient to repair and maintain; and because trenches are dug in the open pit slope, excavation difficulty is reduced, and manufacturing costs of supports are reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

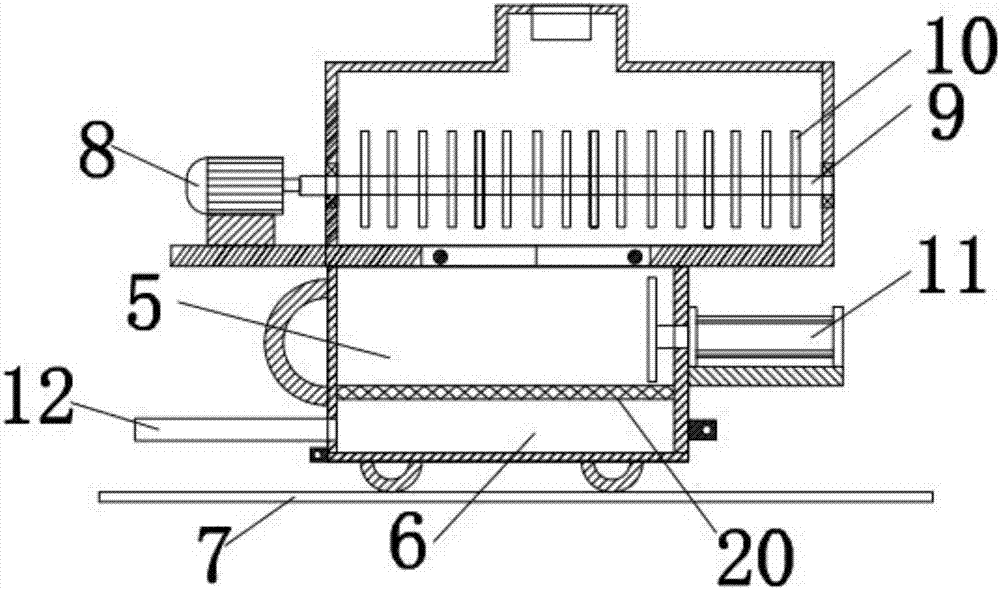

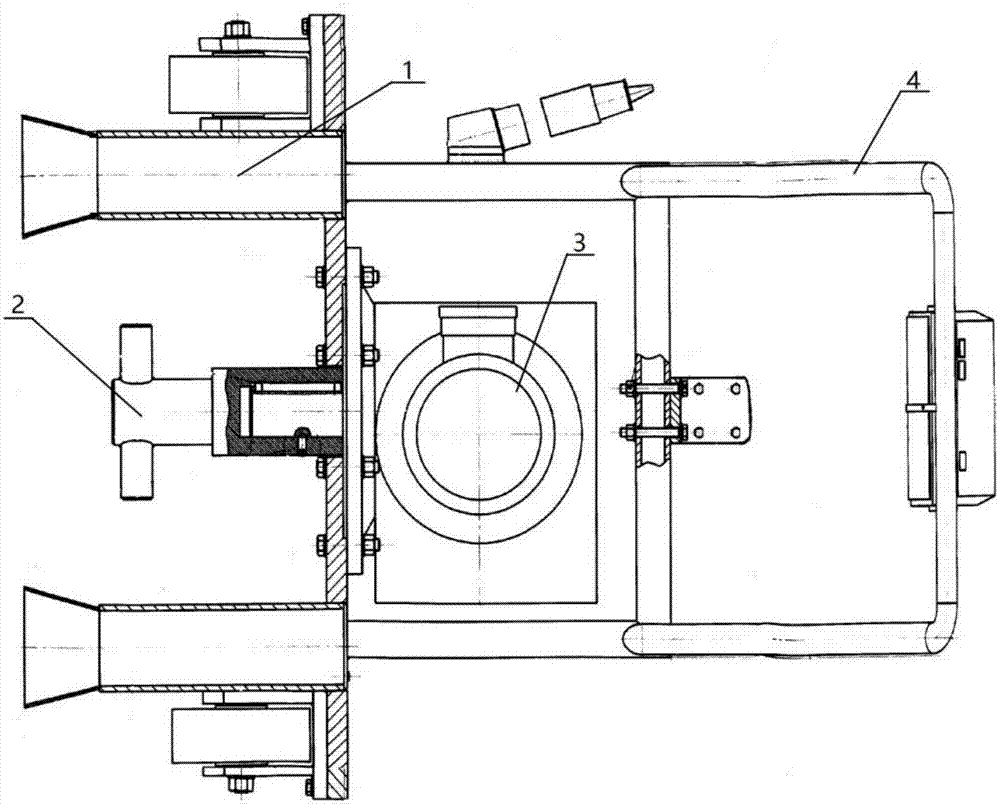

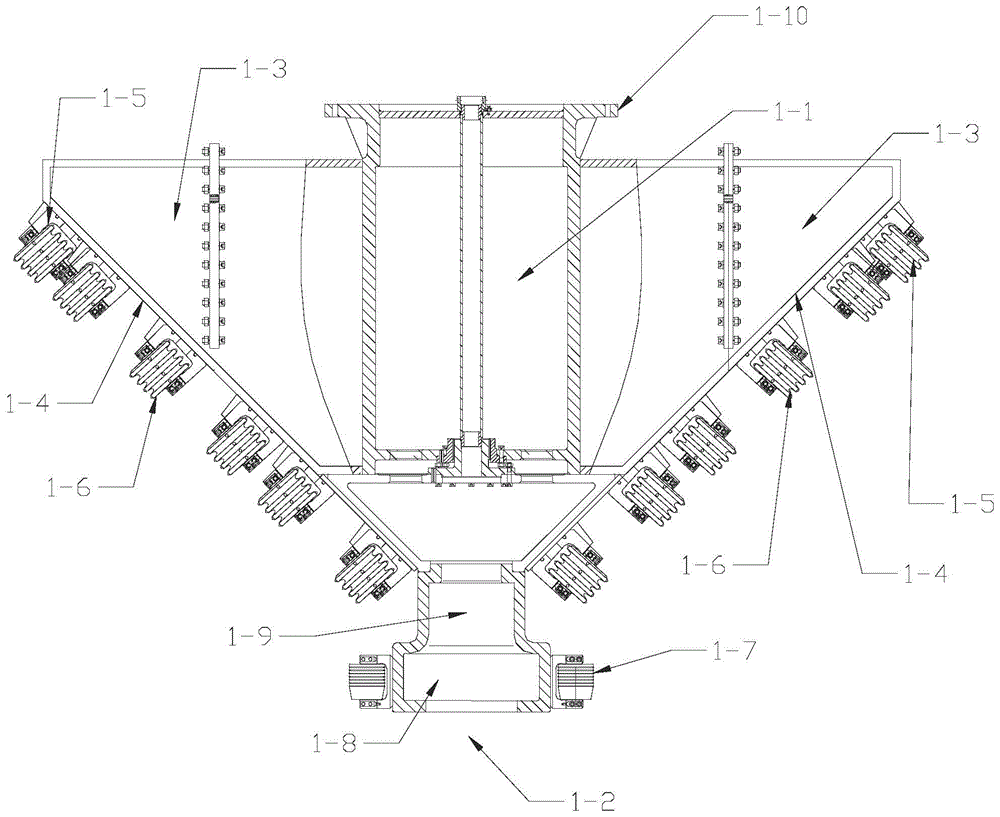

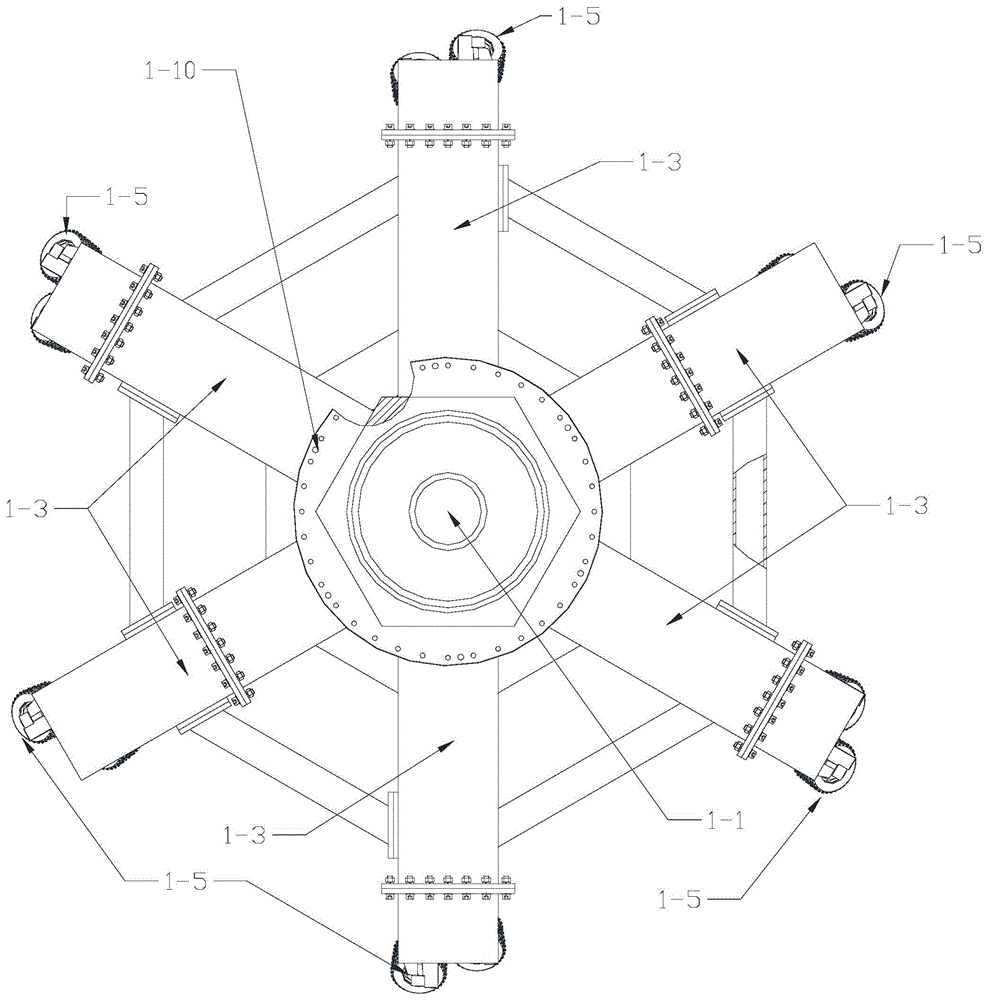

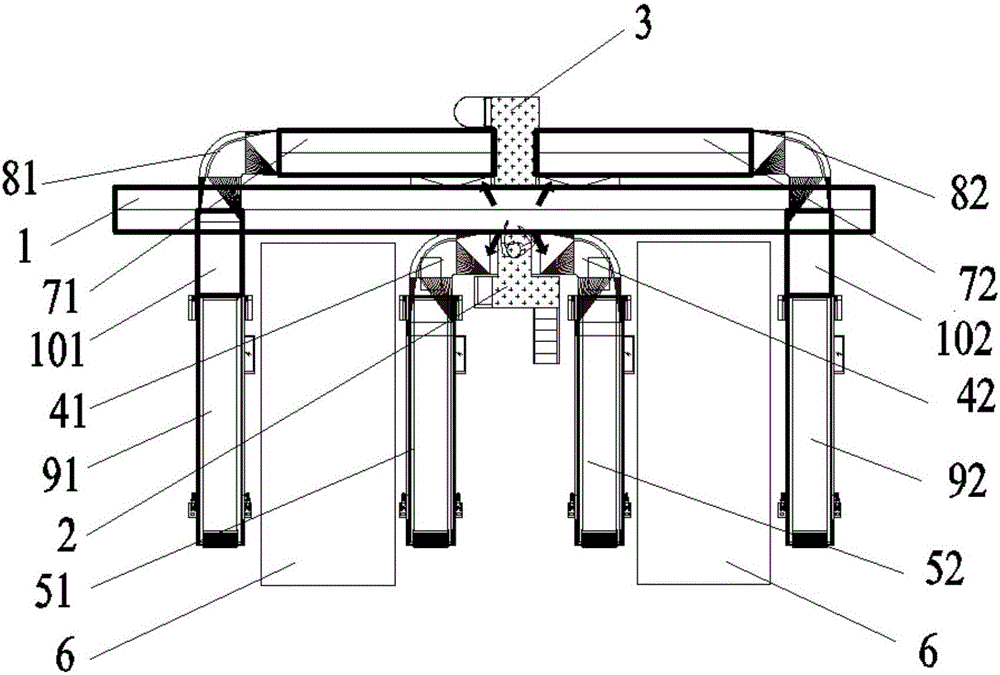

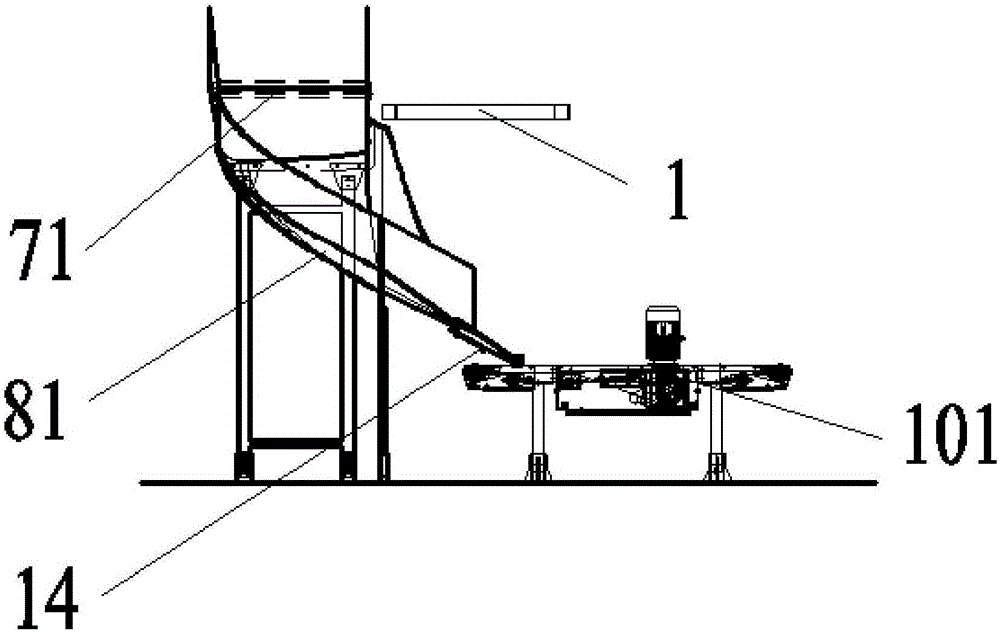

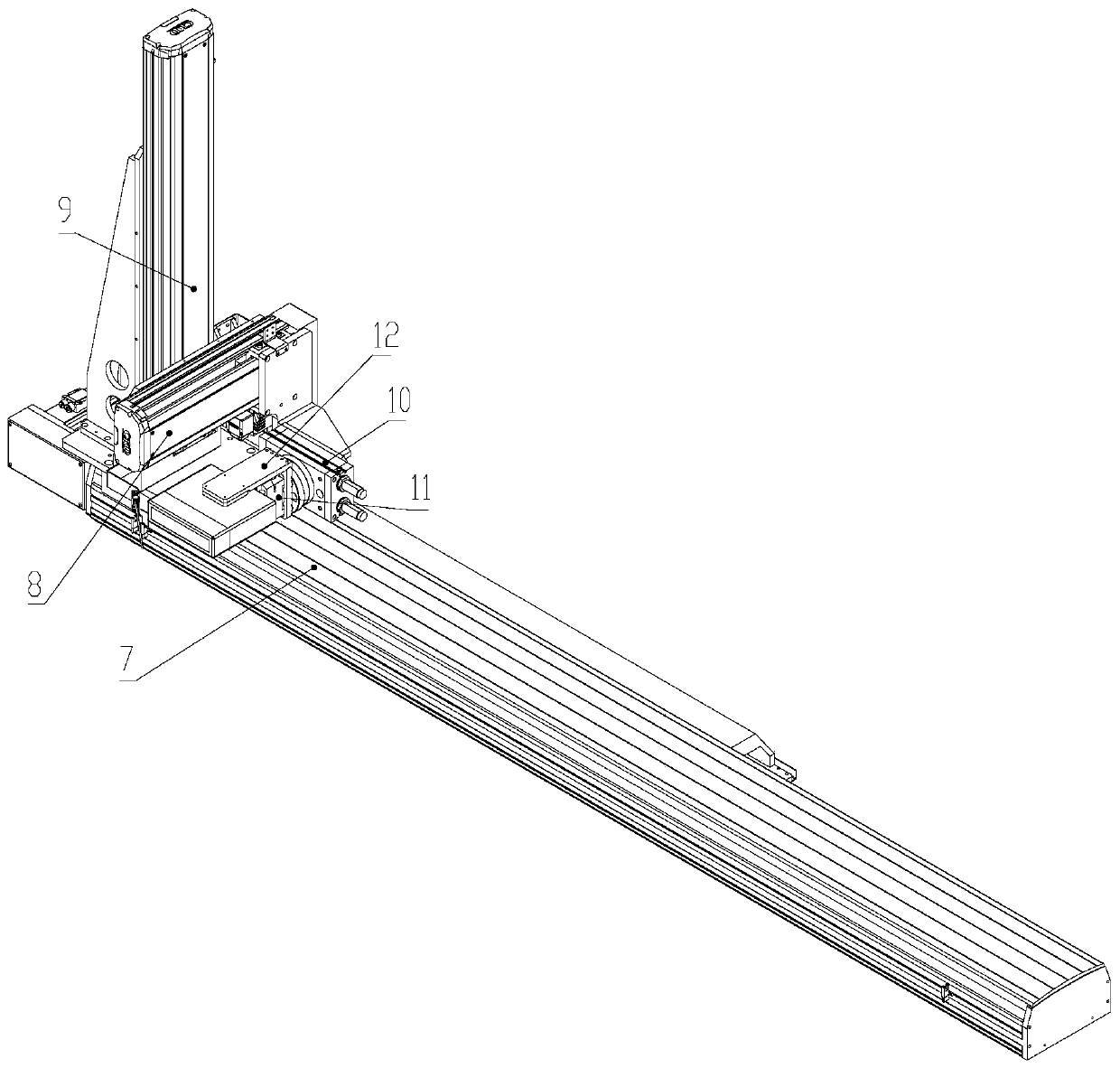

Stirring slag scraping machine used for molten aluminum mixing furnace

The invention discloses a stirring slag scraping machine used for a molten aluminum mixing furnace. The stirring slag scraping machine used for the molten aluminum mixing furnace comprises a base, a movable platform, a forward stretching mechanism and a stirring slag scraping mechanism; the movable platform is arranged on the base; the forward stretching mechanism is arranged on the movable platform; and the stirring slag scraping mechanism is arranged at one end of the forward stretching mechanism. The stirring slag scraping machine used for the molten aluminum mixing furnace is simple in structure, the slag scraping efficiency of the slag scraping machine is greatly improved, and shaking of the slag scraping machine in the slag scraping process is reduced to the maximum extent; and by means of stirring, dispersed slag in the molten aluminum mixing furnace is precipitated out, and high practicability is achieved.

Owner:阿坝铝厂

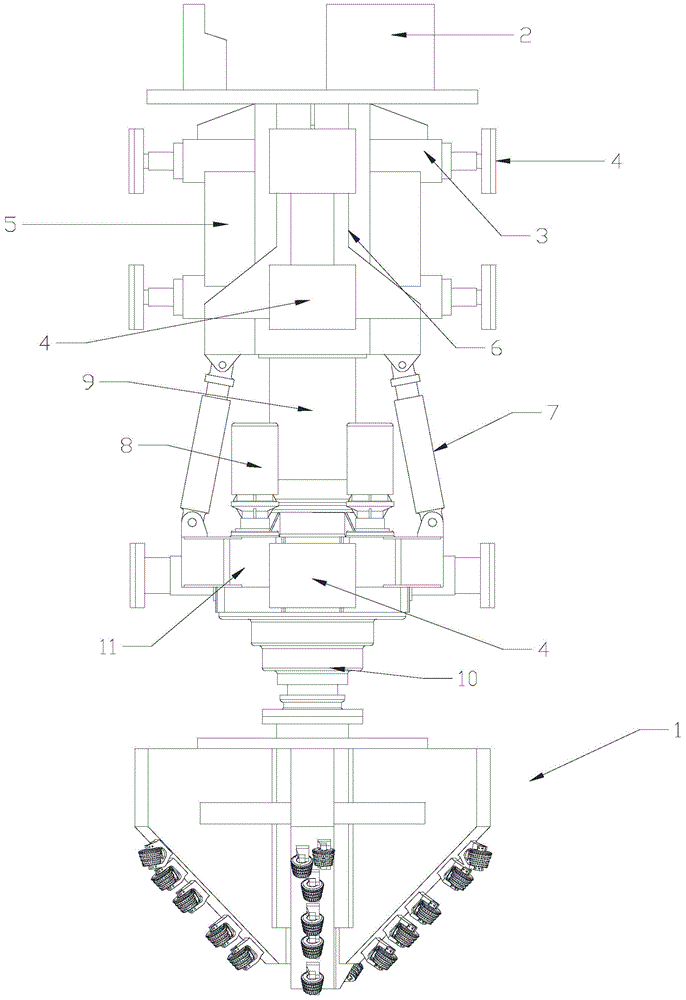

Roadheader suitable for vertical shaft drilling in presence of pilot shaft

The invention discloses a roadheader suitable for vertical shaft drilling in presence of a pilot shaft. The roadheader comprises a main body rack, a rock breaking drill bit, a drive system, a support system and a control system, wherein the drive system comprises a rotation drive sub-system and a pushing drive sub-system; the rock breaking drill bit, the rotation drive sub-system, the pushing drive sub-system, the support system and the control system are mounted on the main body rack respectively; the rotation drive sub-system is in transmission connection with the rock breaking drill bit; the rock breaking drill bit comprises a cutter head and a guide device. The roadheader can be used for drilling vertical shafts with designed diameters sequentially in the presence of the pilot shaft, and when the roadheader is used for vertical shaft drilling, correction equipment is not required under the condition that the borehole deflection degree of the pilot shaft is guaranteed.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

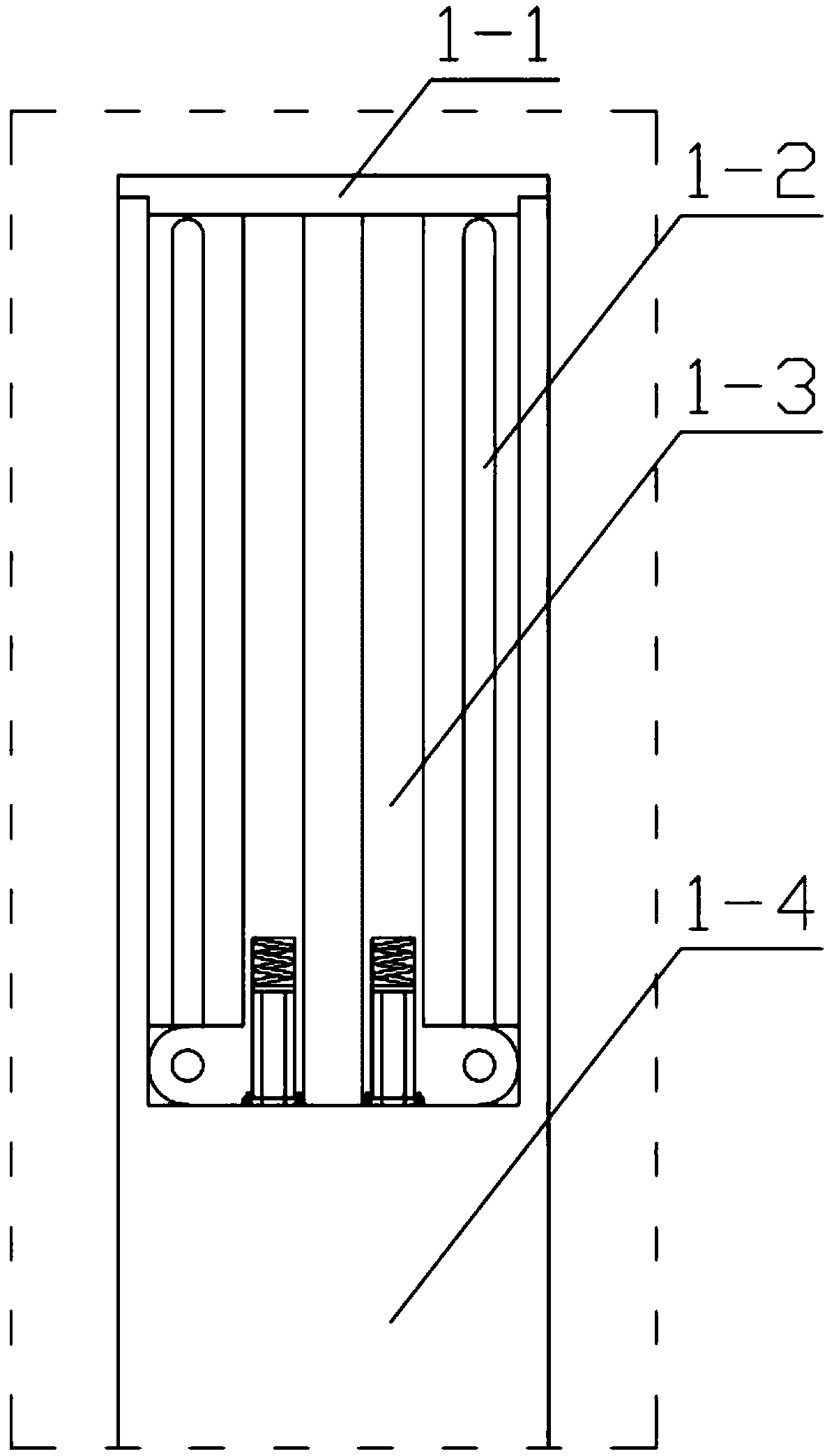

Novel multifunctional cable take-up and pay-off device convenient and fast to use

The invention relates to a communication related device, in particular to a novel multifunctional cable take-up and pay-off device convenient and fast to use. The device comprises bobbin central shaftmechanism, a bobbin tray mechanism, a buffer roller mechanism, a bottom layer device disc mechanism and a device adjusting mechanism. The device can freely carry out take-up and pay-off operation oncables, use is convenient and fast, the device can store a bobbin quite conveniently, and the cables can be conveyed out conveniently. The device is provided with a bobbin fixing mechanism, and a winding shaft is prevented from being disengaged from a rail during cable take-up and pay-off operation. The device is provided with a moving mechanism, and cable conveying is facilitated. The bobbin central shaft mechanism and the bobbin tray mechanism are connected by welding, the bobbin tray mechanism is in contact connection with the buffer roller mechanism, the bobbin central shaft mechanism andthe bottom layer device disc mechanism are connected by welding, the buffer roller mechanism and the bottom layer device disc mechanism are connected through a fastening screw, and the bottom layer device disc mechanism is connected with the device adjusting mechanism.

Owner:浙江天成认证有限公司

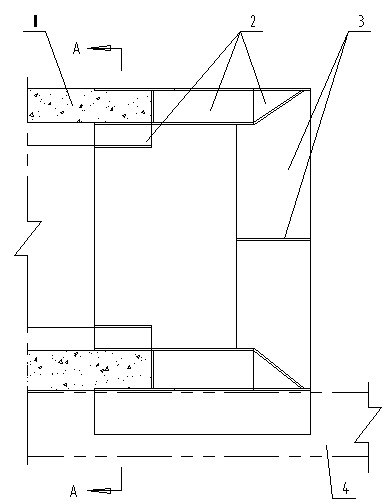

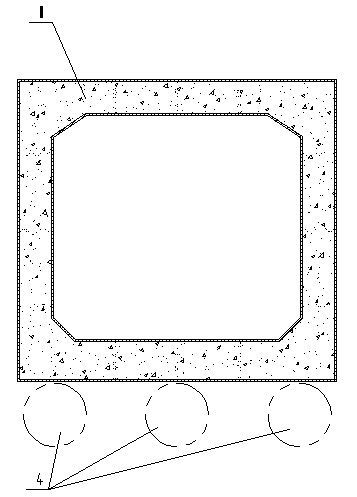

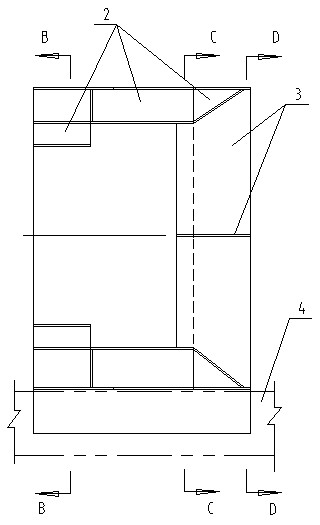

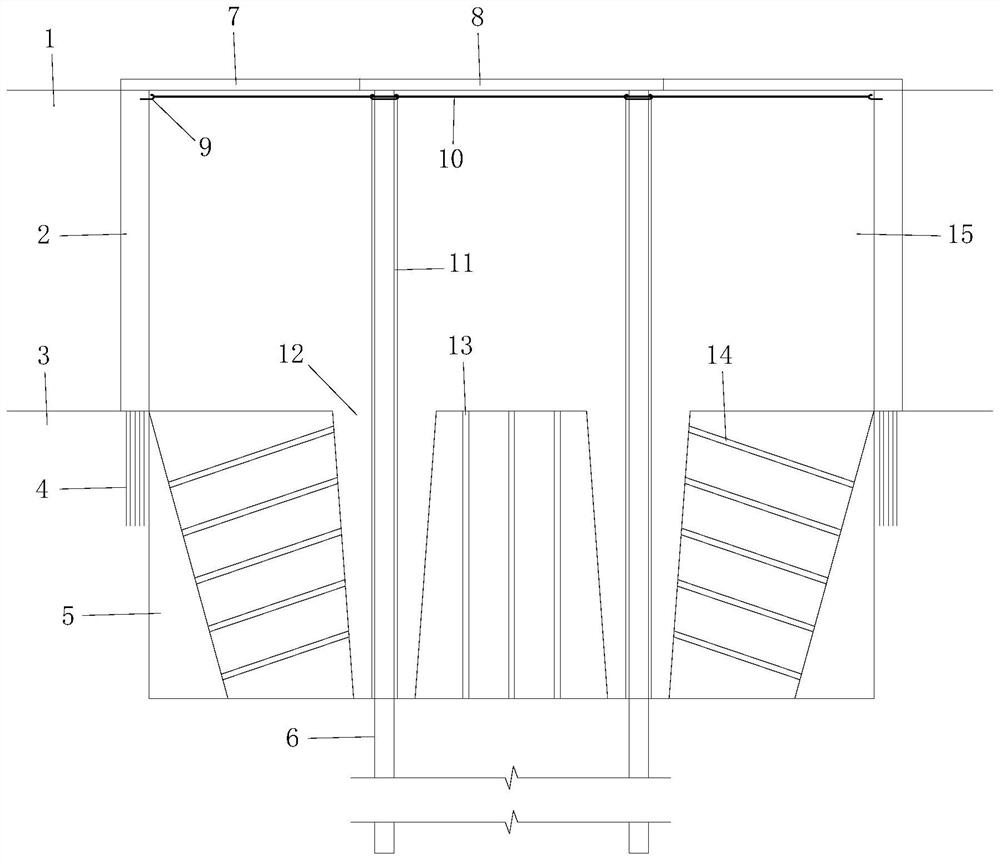

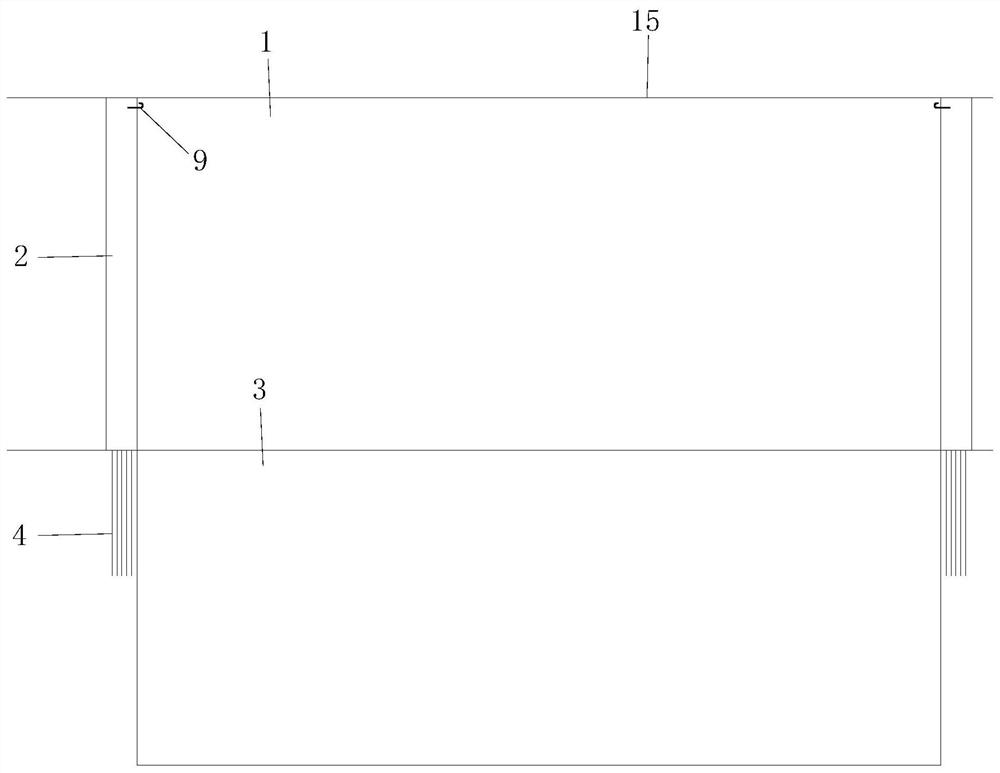

Guide shield for pushing rectangular concrete frame bridge

InactiveCN102154985AMeet the requirements of normal operationEasy to ship outGround-workBridge erection/assemblyWhole bodyClassical mechanics

The invention relates to a guide shield for pushing a rectangular concrete frame bridge, which is characterized in that the front end of a prefabricated rectangular concrete frame bridge is provided with a rectangular metal frame structure, the rear end of the rectangular metal frame structure and the front end of the rectangular concrete frame bridge have the same section dimension, and are mutually engaged into a whole body, four surfaces of the rectangular metal frame structure has a box-shaped structure, an inner cavity of the rectangular metal frame structure is hollow, the periphery of the front end of the rectangular metal frame structure has a wedge-shaped structure, two side plates of the rectangular metal frame structure extend downwards to be in sliding contaction with the outer wall of a bottom plate guide steel tube for pushing the rectangular concrete frame bridge, and grating steel plates which are crisscrossed are uniformly distributed in the hollow inner cavity of the front of the rectangular metal frame structure, and divide the hollow inner cavity of the front of the rectangular metal frame structure into two-hole, four-hole, six-hole or nine-hole grating units. When the rectangular concrete frame bridge of a railway or a highway subgrade is pushed by the guide shield disclosed by the invention, I-steel, temporary beams and other reinforcement measures or speed limit running are free, so that the defects of the occurrence of landslides or the offset of pushing can be prevented.

Owner:李家稳

Multipurpose mechanical equipment suitable for field orchard management

The invention relates to the technical field of agricultural machinery, and discloses multipurpose mechanical equipment suitable for field orchard management. The multipurpose mechanical equipment comprises a rectangular frame, a spindle box and a support frame, wherein the spindle box and the support frame are fixed at the upper end of the rectangular frame; the inner wall of the rear side of therectangular frame is rotatably connected with a worm through a first rolling bearing, and a fixing plate is arranged on the rod wall of the worm; one side of the fixing plate is rotationally connected with the rod wall of the worm through a second rolling bearing; a soil baffle is fixedly connected to the front side of the fixing plate; a rotating shaft is rotationally connected to the right sideof the soil baffle through a first sealing bearing; and a spiral blade is fixedly connected to the shaft wall of the rotating shaft. According to the multipurpose mechanical equipment suitable for field orchard management, ditch digging, field soil ridging, deep ploughing and fertilizing, weeding among ridges and other operations can be achieved in the field fruit orchards, operation is easy, thelabor intensity of managers is relieved, and meanwhile the cost for purchasing mechanical equipment is reduced.

Owner:杨海丽

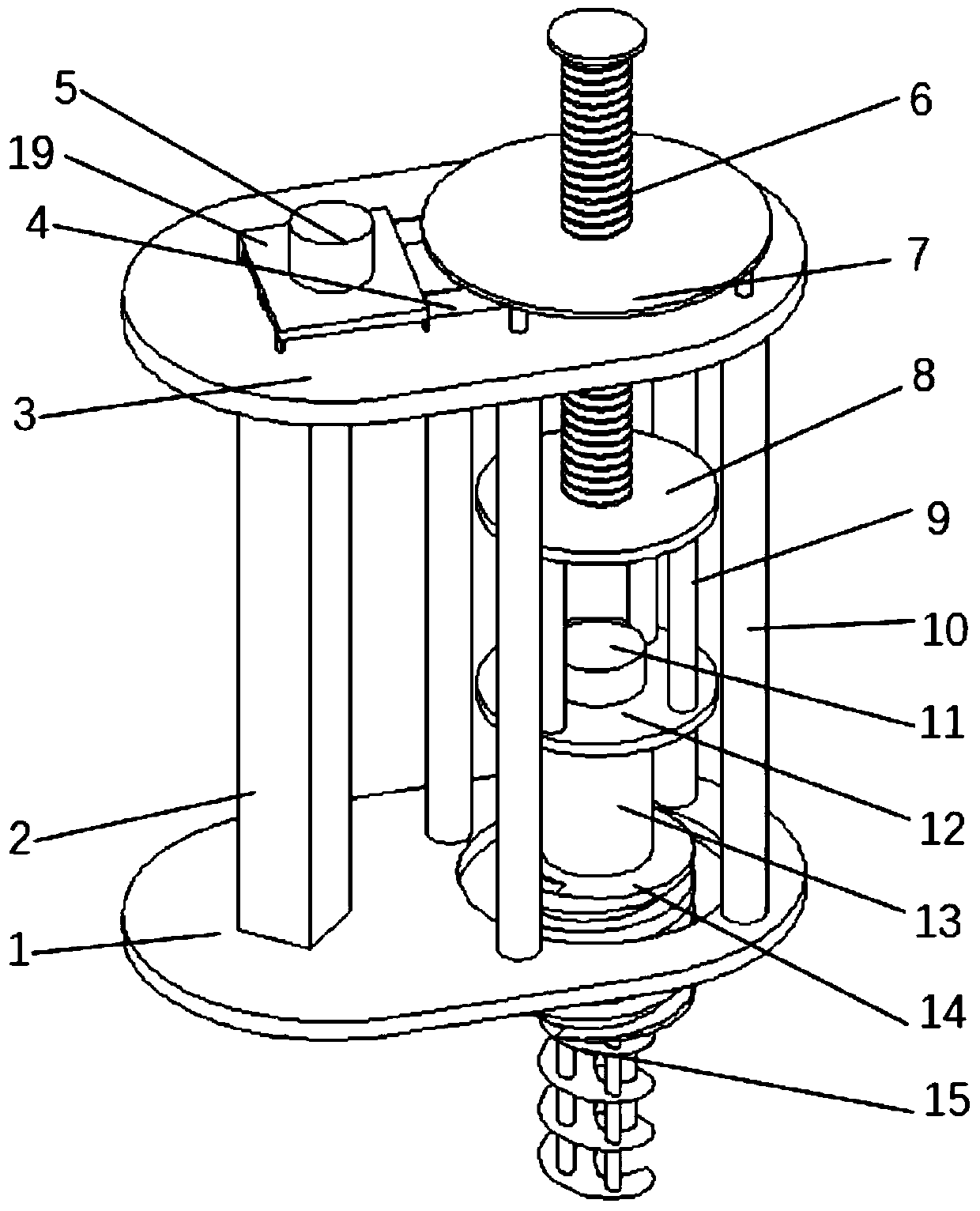

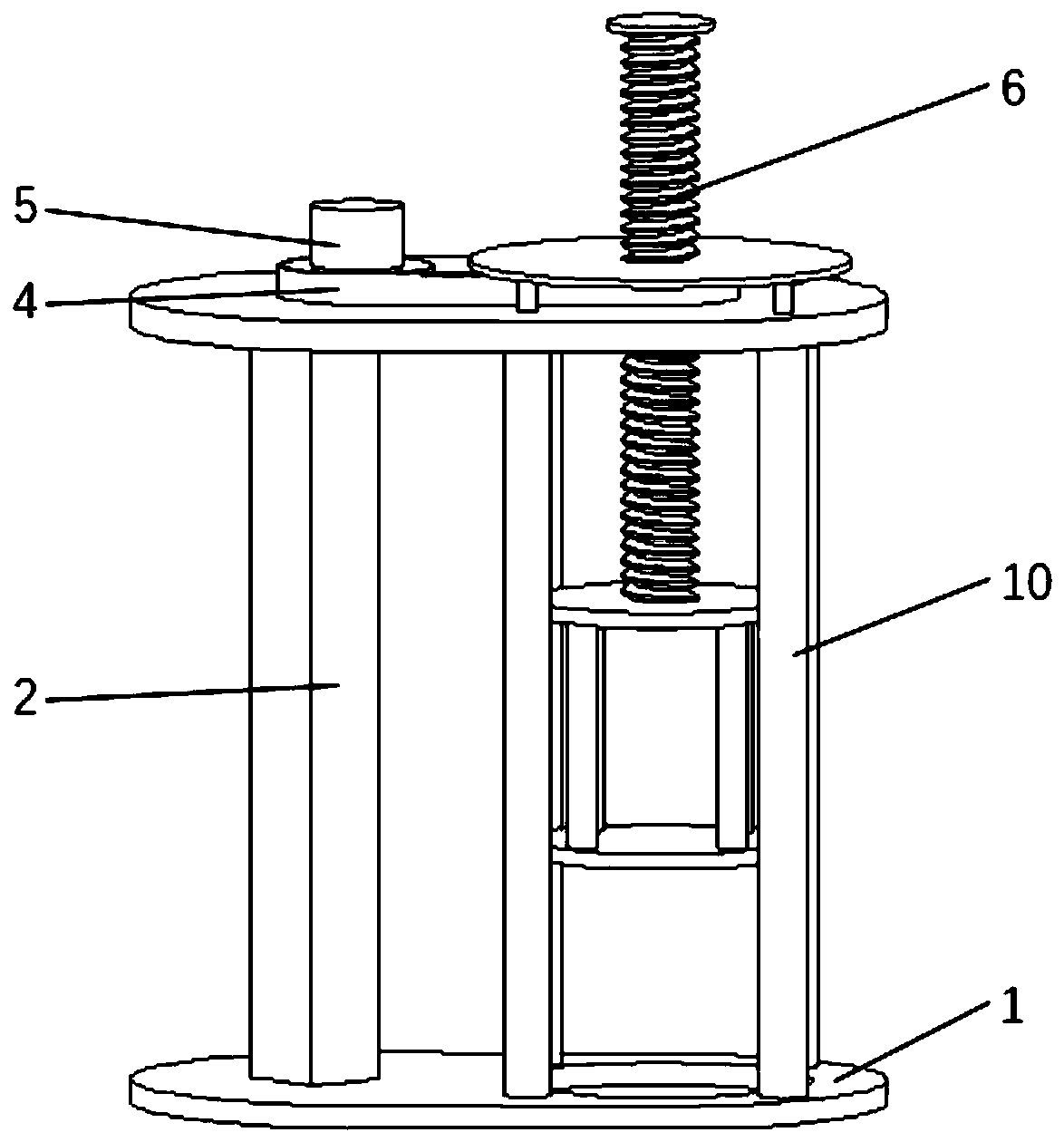

Soil sampling device for petroleum exploration

PendingCN111397950ASampling helpsReduce labor costsWithdrawing sample devicesSoil scienceSpiral blade

The invention provides a soil sampling device for petroleum exploration, and belongs to the technical field of petroleum exploration. The soil sampling device comprises a bracket with circular throughholes at the top and the bottom, and a feeding device and a sampling device which are arranged in the circular through holes. The feeding device comprises a screw rod, a connecting plate fixedly arranged at the bottom end of the screw rod and a first driving device for driving the screw rod to drive the connecting plate to move up and down, and the first driving device is erected at the top of the bracket; the sampling device is connected with the feeding device through a plurality of first supporting columns and comprises a motor plate fixedly connected with the lower ends of the first supporting columns and an inverted cylinder with an opening in one end; the bottom of the cylinder is fixedly connected with the bottom of the motor plate; a rotating shaft, a spiral column fixedly connected with the lower end of the rotating shaft and a second driving device for driving the rotating shaft to rotate are rotationally arranged in the cylinder; spiral blades are fixedly connected to the lower end of the spiral column; a spiral groove body is formed in the cylindrical surface of the spiral column. The device can obtain soil samples with different depths and replaces manual work and isconvenient to sample.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Blasting excavation system for land rock foundation pit and construction method applying same

ActiveCN111851510AEasy to ship outPrevent flying outExcavationsBulkheads/pilesReinforced concreteRock slope

The invention provides a blasting excavation system for a land rock foundation pit and a construction method applying the same. An even wall is arranged on the rock stratum around the foundation pit,the upper ends of anchor bars are integrally connected with reinforcing bars of the even wall, the lower ends of the anchor bars are vertically embedded in the rock stratum, engineering piles are arranged in pile pits of the foundation pit, the pile pits are formed in the rock stratum of the central zone of the foundation pit, anti-collision rubber layers are arranged on and wrap the exposed portions of the engineering piles, embedded drag hooks are arranged on the upper ends of the even wall and the engineering piles, a protection net is fixed to the embedded drag hooks and arranged on a foundation pit opening, a construction platform is arranged on the top ends of the engineering piles, one end of a construction trestle is arranged on the construction platform, the other end of the construction trestle is arranged on the top end of the even wall, vertical blast holes are formed in the central area of the rock stratum of the foundation pit, and inclined blast holes are formed in the area, close to the edge rock stratum, of the foundation pit. The after-digging rock slope reserved through final blasting is dug by adopting a cutter in combination with static blasting to form a natural rock retaining structure, and the lossless connection between the system and the reinforced concrete even wall of the upper portion is guaranteed.

Owner:四川港航建设工程有限公司

Electric power cable shearing device

The invention discloses an electric power cable shearing device which is mainly formed by a motor, a driven wheel, a small flywheel, a large flywheel, a cam, a cutter and a cutter support. The motor is connected with the driven wheel through a transmission belt, a gear is arranged on a shaft where the driven wheel is located, the small flywheel is meshed with the gear on the driven wheel shaft, a gear is arranged on a shaft where the small flywheel is located, the large flywheel is meshed with the gear on the small flywheel shaft, the cam is located on a shaft where the large flywheel is located, the upper end of the cutter is connected with the upper portion of the cutter support, the cutter support is located below the cam, and a spring is arranged on the cutter support. By means of the electric power cable shearing device, the cam is driven by the motor to rotate to eject the cutter to regularly shear a cable, physical power consumption is not needed, and the electric power cable shearing device is simple in structure and convenient to carry.

Owner:STATE GRID CORP OF CHINA +1

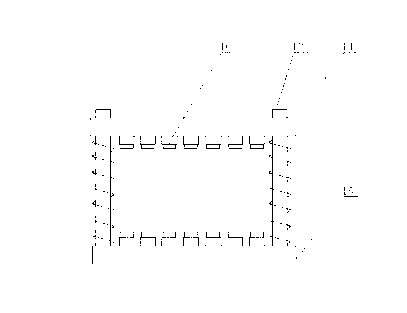

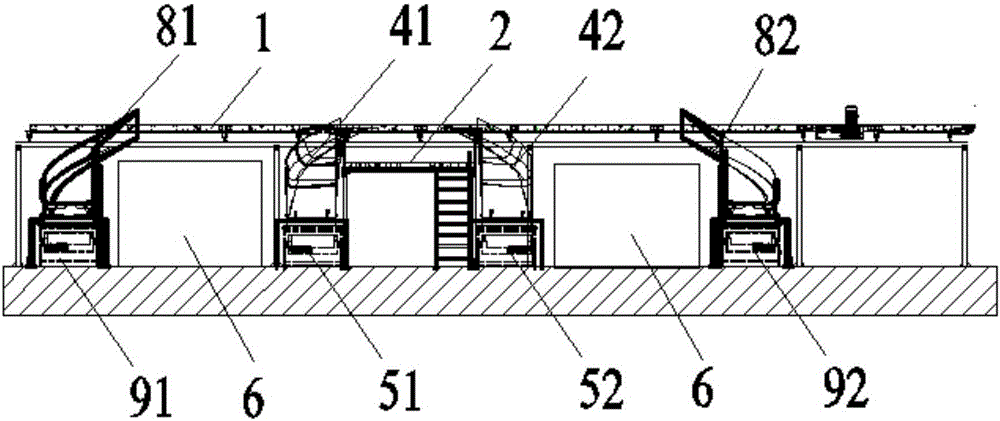

Sorting system

The invention provides a sorting system. The system comprises a main express item conveying device, a main operation platform and an auxiliary operation platform. The main operation platform is arranged on one side of the main express item conveying device. The auxiliary operation platform is arranged on the other side of the main express item conveying device. The two sides of the main operation platform are each provided with a main sorting slide groove or main sorting barrel. An express item slide-out end of each main sorting slide groove or main sorting barrel is provided with a main loading and conveying device. The two sides of the auxiliary operation platform are each provided with a first express item conveying device, wherein the first express item conveying devices extend to the two sides of the auxiliary operation platform from the auxiliary operation platform. The end, away from the auxiliary operation platform, of each first express item conveying device is provided with an auxiliary sorting slide groove or an auxiliary sorting barrel. An express item slide-out end of each auxiliary sorting slide groove or auxiliary sorting barrel is provided with an auxiliary loading and conveying device. The sorting system has the beneficial effects that the number of sorting flow directions is large and damaged pieces or large pieces can be conveniently conveyed out.

Owner:SF EXPRESS

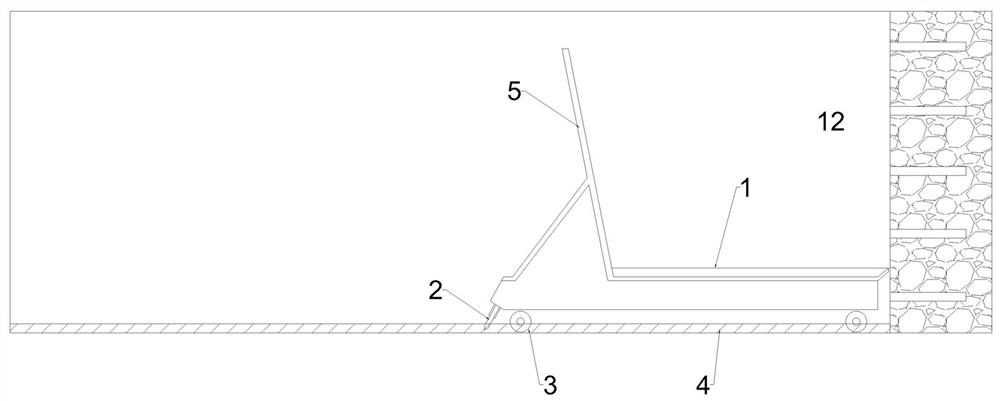

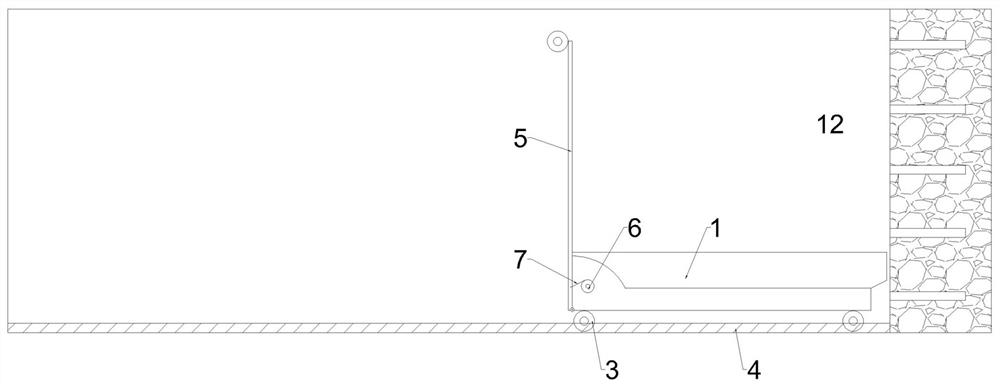

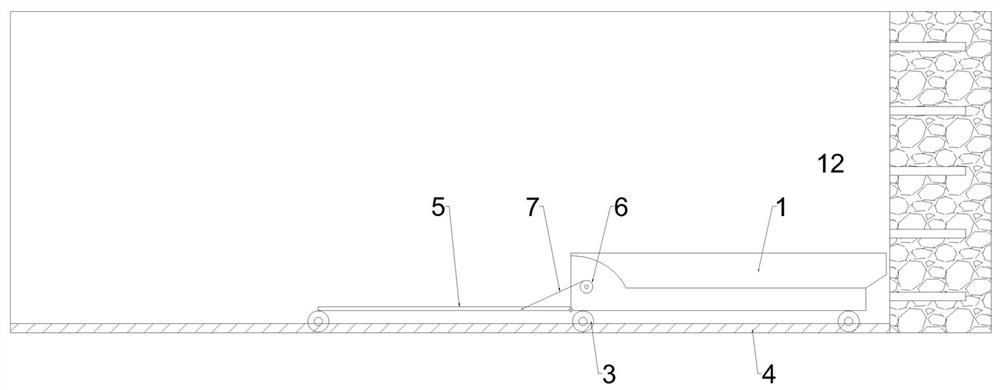

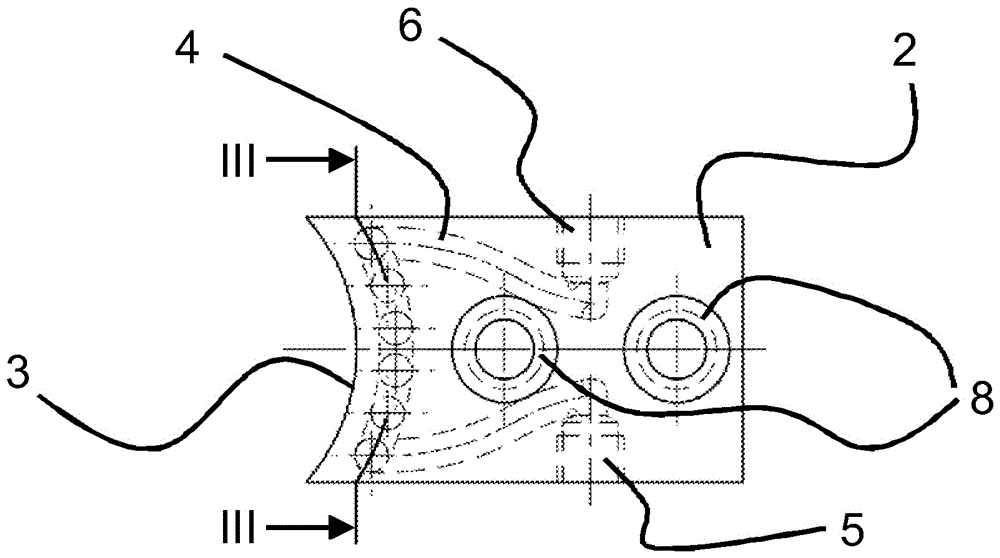

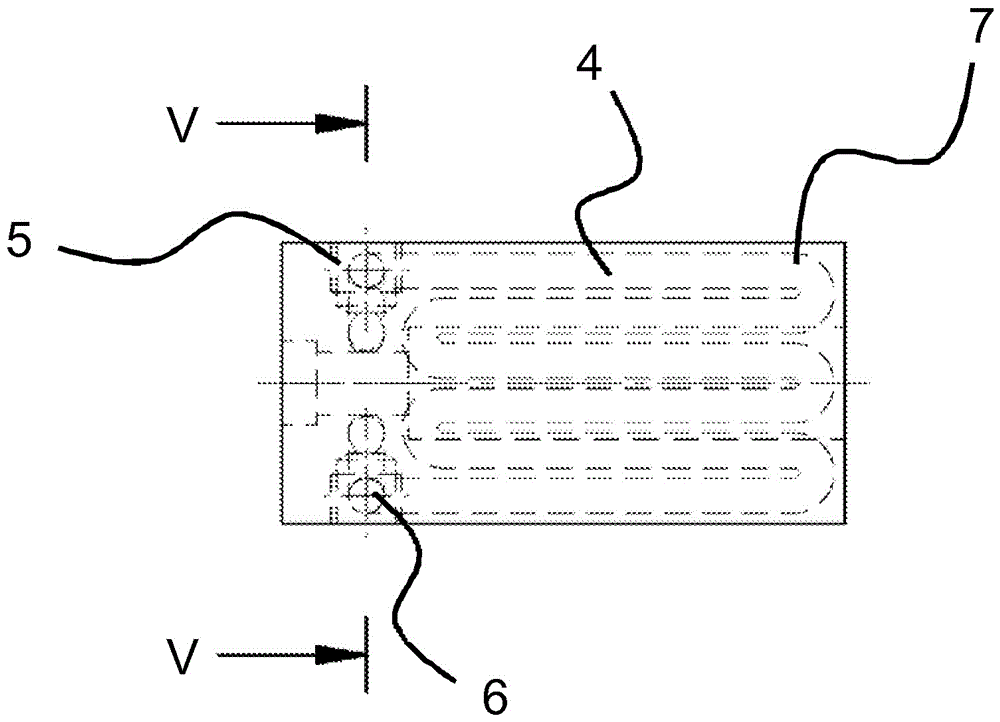

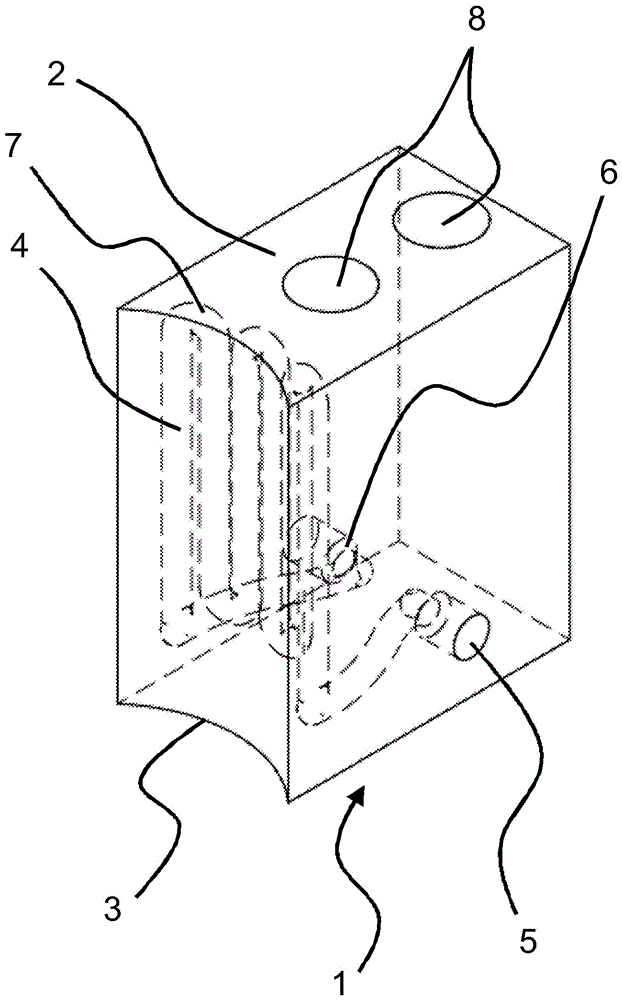

Stone conveying mechanism in tunnel drilling and blasting engineering

ActiveCN111792298AImprove loading efficiencyImprove transportation efficiencyDust removalFire preventionEnvironmental geologyStructural engineering

The invention discloses a stone conveying mechanism in tunnel drilling and blasting engineering. The stone conveying mechanism comprises a transport vehicle which comprises a vehicle hopper and wheels. A telescopic inclined supporting rod is arranged at the rear end of the vehicle hopper and provided with a spiral telescopic driving mechanism, a motor is arranged below the vehicle hopper and drives the wheels, the spiral telescopic driving mechanism and the motor are provided with a wireless receiving device, and the wireless receiving device is provided with a remote controller so as to control the transport vehicle to move and conduct inclined supporting. Nowadays, the tunnel blasting technology is greatly developed, and stones on a blasting surface can fall down in a relatively mild manner after cracks are formed. The stone conveying mechanism can be tightly attached to the blasting surface; after blasting, most of stones falling forwards fall into the vehicle hopper, and through awireless control mode, the transport vehicle can retreat from a tunnel backwards along a track, so that workers are prevented from entering places with a large amount of dust and fume for operation after blasting, and the stones formed by blasting can be quickly and voluntarily loaded.

Owner:WENZHOU UNIVERSITY +1

Clamping plate and method for manufacturing a clamping plate

InactiveCN106493512ARemove heatEfficient dischargeAdditive manufacturing apparatusPositioning apparatusEngineeringAbutment

The invention provides a clamping plate and a method for manufacturing the clamping plate. The clamping plate for clamping or holding a workpiece is described. The clamping plate includes a base body (2) and a clamping contour (3), which is provided for abutment against a workpiece and can be cooled by a cooling device. The cooling device is implemented by at least one coolant duct, which is provided for receiving a coolant and which is formed in the base body by a generative production (e.g., additive manufacturing) process. The formation of the base body is free of auxiliary bores. Furthermore, a method for manufacturing a clamping plate is described.

Owner:ROHM CO LTD

A stirring slag removal machine for aluminum liquid mixing furnace

ActiveCN108277363BAvoid jitterImprove efficiencyStirring devicesCasting cleaning apparatusSlagMaterials science

Owner:阿坝铝厂

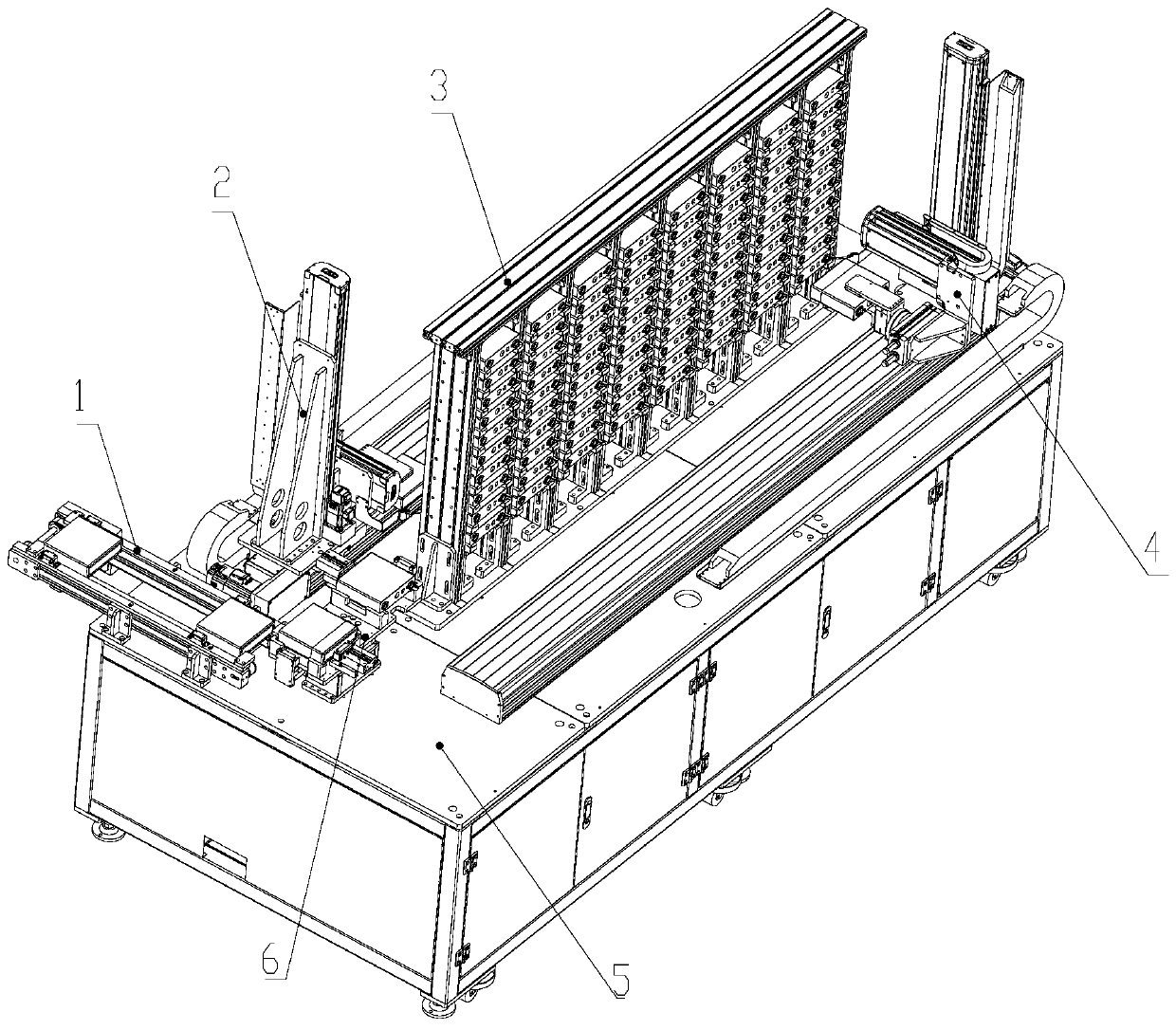

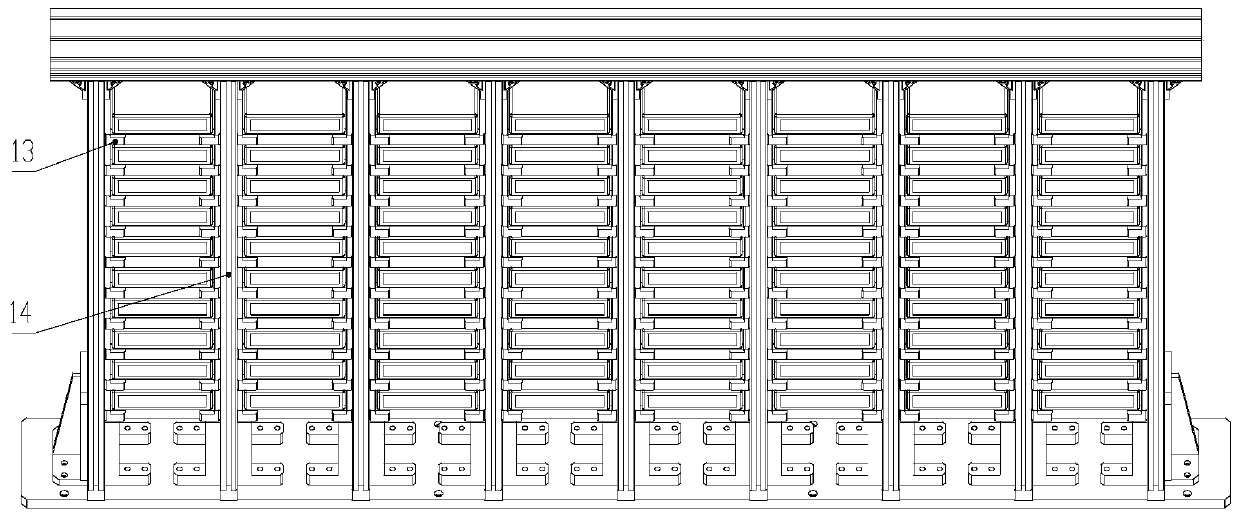

Lithium battery cell matching device

PendingCN109830735AAvoid collisionReduce manpower consumptionFinal product manufactureSecondary cells manufactureEngineeringManufacturing line

A lithium battery cell matching device comprises a work bench. The work bench is provided with a cache frame used for placing a cell. The two sides of the cache frame are provided with a warehousing material taking mechanism for transporting the cell and an ex-warehouse material taking mechanism. One side of the warehousing material taking mechanism is provided with a conversion bench. One side ofthe conversion bench is provided with an abnormal output line. In the invention, a unique novel structure is adopted, warehousing and ex-warehouse are performed through adopting two sets of mechanisms; warehousing and ex-warehouse work can be performed simultaneously and is not interfered; and the abnormal output line is added so that the cells which are not needed temporarily after a cache library is full can be conveniently transported to the outside world, and an abnormal situation can be effectively processed. The ex-warehouse material taking mechanism and the warehousing material takingmechanism are equipped with sensors for detecting whether there is the cell. During the processes of emptying and material taking, a position where the material is released is not discharged again toprevent collision. In the invention, the device is high automatic, manual intervention is not needed under a normal production condition, and manpower consumption of a production line is effectively reduced.

Owner:苏州德星云智能装备有限公司

Logistics turnover box

InactiveCN106628544AReduce labor intensityImprove convenienceLarge containersDischarging meansLogistics managementDrive shaft

Owner:CHENGDU TIAN HANG ZHI HONG IP MANAGEMENT CO LTD

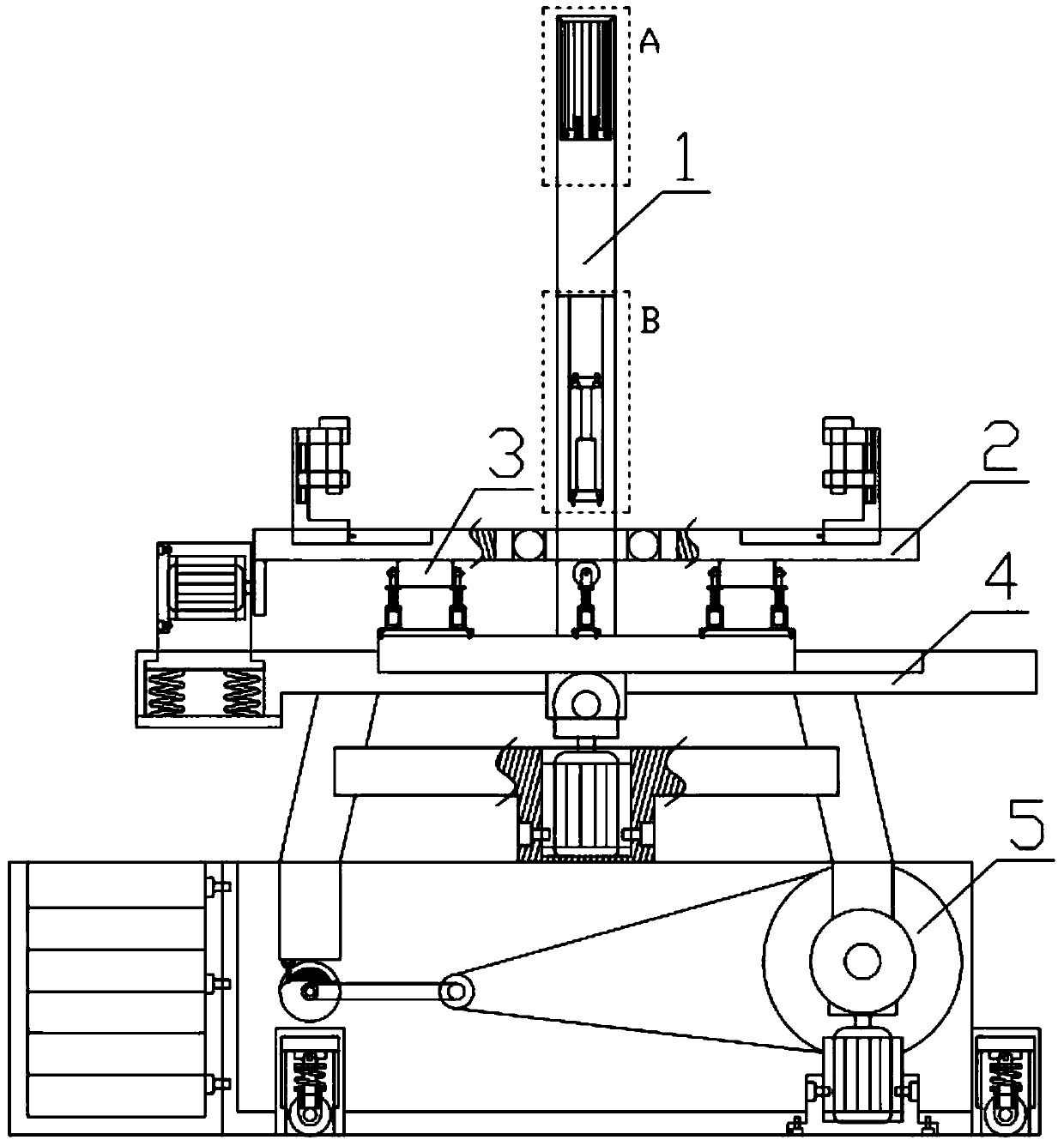

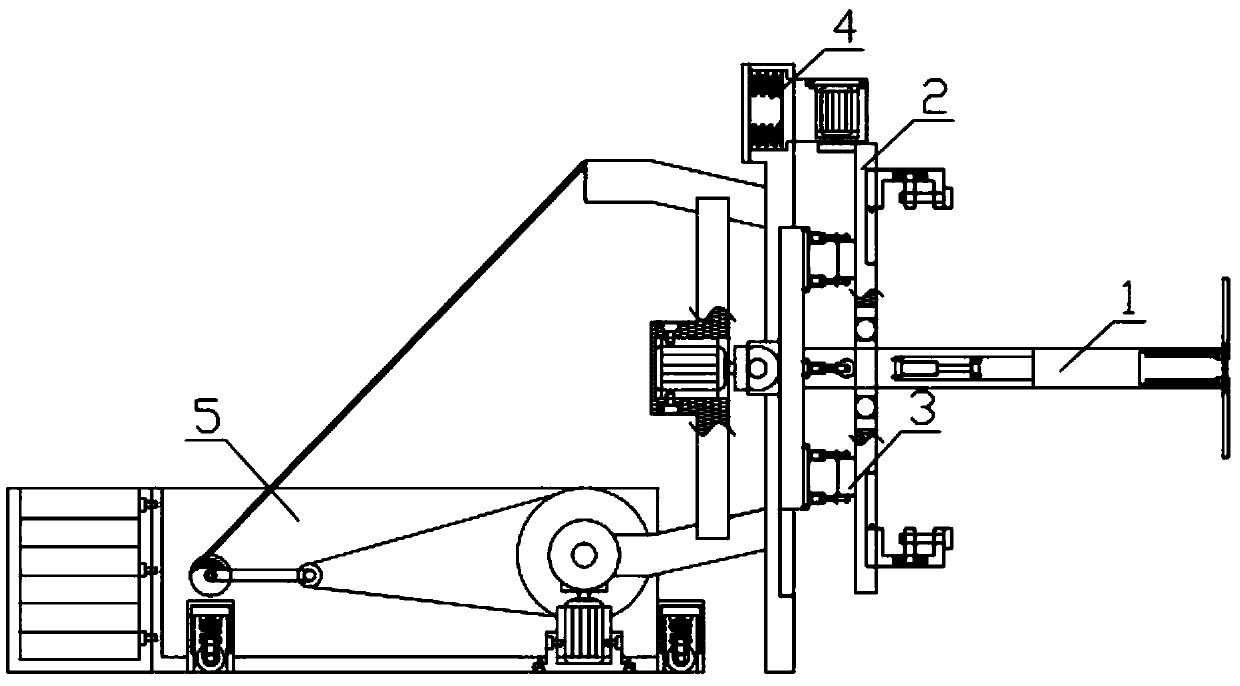

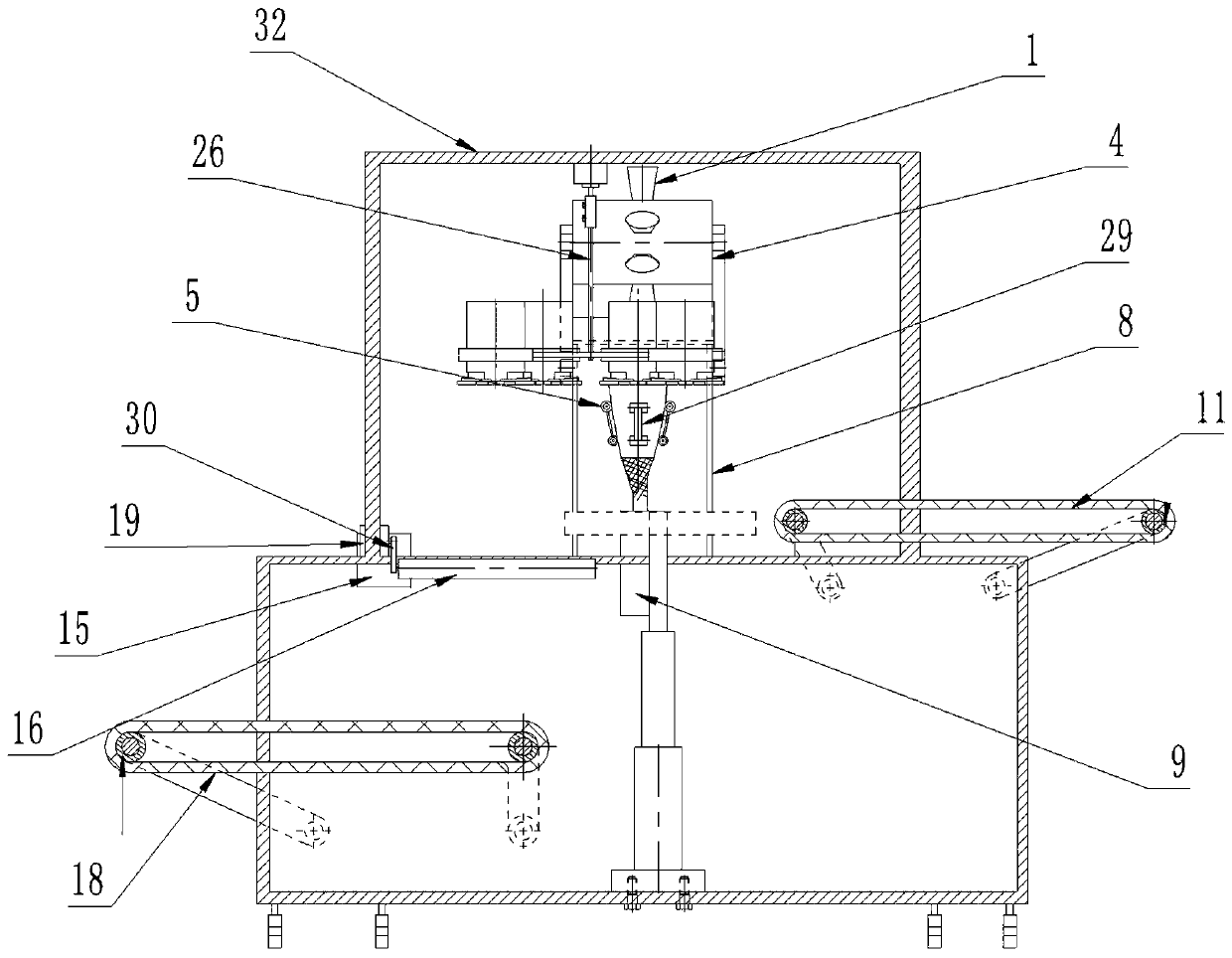

Automatic continuous apple packaging machine

InactiveCN110342011AImprove packaging efficiencyLow costWrapper twisting/gatheringPackaging fruits/vegetablesCartonEngineering

The invention relates to the technical field of packaging equipment, and discloses an automatic continuous apple packaging machine. The automatic continuous apple packaging machine comprises a rack, and a conveying device is arranged on the upper side of the rack; the rack is provided with a six-base rotating frame, six stations of the six-base rotating frame are each provided with a packaging sleeve in a penetrating manner, a six-rod foam sleeve opener is arranged in each packaging sleeve, and a foam net shear is arranged on the lower side of each packaging sleeve; a net sleeve opening mechanism is arranged under the six-base rotating frame, a packaging box pallet used for driving a conveying mechanism is arranged under the six-base rotating frame, and a lifting mechanism is arranged on the lower side of the packaging box pallet; and the side, in the direction of being perpendicular to the conveying direction of the conveying device, of the packaging box pallet is provided with a feeding conveying mechanism used for conveying cartons, the other side, in the direction of being perpendicular to the conveying direction of the conveying device, of the packaging box pallet is providedwith a delivering conveying mechanism used for conveying the cartons, and an encapsulating mechanism used for pressing and sealing the cartons is arranged above the delivering conveying mechanism. Theautomatic continuous apple packaging machine has the advantages of being high in packaging efficiency and low in manufacturing cost.

Owner:LANZHOU CITY UNIV

Electromechanical oil extraction device capable of increasing oil extraction rate

InactiveCN104403784AEasy to sellNovel and reasonable structureFatty-oils/fats productionEdible oils/fatsEngineeringMechanization

The invention discloses an electromechanical oil extraction device capable of increasing the oil extraction rate. The electromechanical oil extraction device comprises a support frame, a circular-truncated-cone-shaped oscillator, a guide cylinder, a transmission rack bar, a variable-frequency motor, a hemispherical flexible container and a stone mill, wherein the circular-truncated-cone-shaped oscillator, the guide cylinder, the hemispherical flexible container and the stone mill are connected with the support frame by bolts; the transmission rack bar is in bell-and-spigot joint with the guide cylinder; the lower end of the transmission rack bar is in collision contact with the circular-truncated-cone-shaped oscillator through an oscillating ball; the upper section of the transmission rack bar is inserted into the hemispherical flexible container through the center of the bottom surface of the hemispherical flexible container; the variable-frequency motor is connected with the guide cylinder through bolts and is meshed with the transmission rack bar through a gear. The electromechanical oil extraction device is reasonable and novel in structure, multifunctional, high in mechanization degree, capable of simulating the conventional oil extraction process of people, high in oil extraction speed, high in oil extraction rate, and high in practicability, and the extracted oil is full-bodied and pure in flavor.

Owner:盛文领

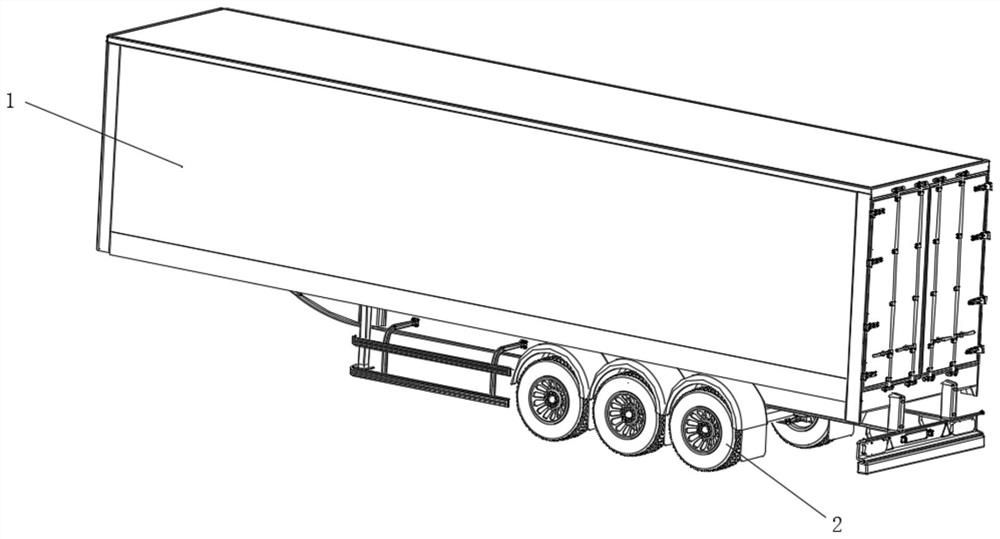

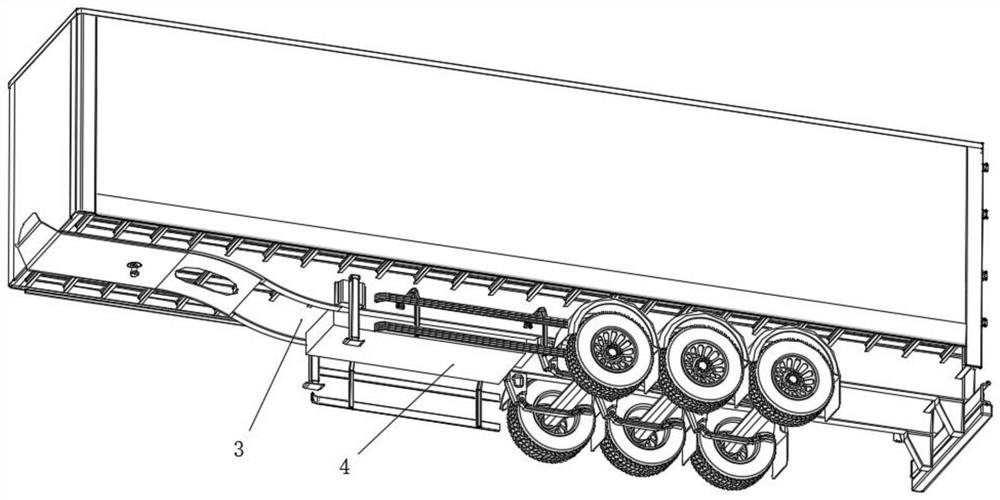

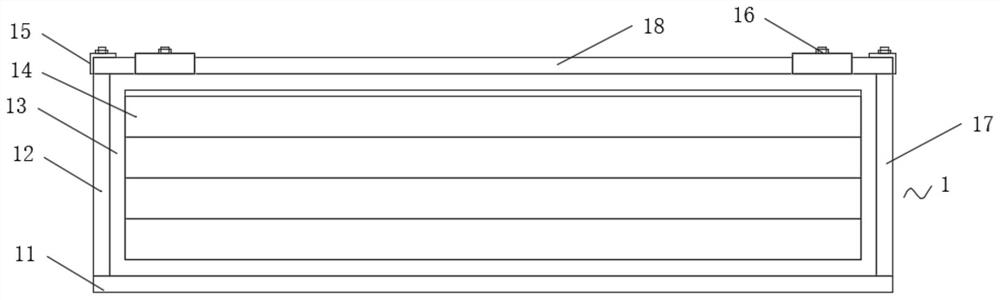

Method for transporting semitrailer carriage special for full-load logistics

PendingCN114771671AFix instabilityEasy to ship outLoading-carrying vehicle superstructuresHydraulic cylinderLogistics management

The invention discloses a method for transporting a semitrailer carriage special for full-load type logistics, and relates to the technical field of vehicle manufacturing. A cross beam mounting base body is fixed to the bottom of a weighing cross beam, two hydraulic cylinders are rotationally arranged at the two ends of the cross beam mounting base body, the moving ends of the two hydraulic cylinders are rotationally arranged at the two ends of a mounting panel respectively, the length of the two mounting panels is extended when the mounting panels are started, and the mounting panels move downwards as a whole; a buffer plate is fixedly arranged on the surface of the bottom of the cross beam mounting base body, and buffer springs are fixedly arranged at the two ends of the bottom of the buffer plate and used for buffering the mounting panel; the problems that due to the fact that the height of the gravity center position easily leads to instability of vehicle running and due to the fact that the brake degrees of a semi-trailer carriage and a traction carriage are inconsistent due to the weight of goods, the carriage drifts easily, and potential safety hazards are increased are solved.

Owner:ANHUI LONGJIA TRAFFIC EQUIP

Metal powder preparation method and device based on controllable magnetic levitation smelting technology

The invention provides a method and device for metal powder preparation based on a controllable magnetic levitation melting technology. The method includes the following steps: one end of a metal wire passes through an electromagnetic field at a constant speed; the metal wire is warmed and melted in the electromagnetic field and forms metal droplets continuously; the metal droplets drop into a gas atomization area continuously; and the metal droplets are impacted, scattered and cooled by high-pressure and high-speed inert gas in the gas atomization area to form the metal powder. The device includes a vacuum cavity, a pair of rollers arranged in the vacuum cavity and a quartz glass tube with two open ends. The axial directions of the two rolls are parallel, the rotation directions of the two rollers are opposite, and a gap between rotation surfaces of the two rollers is matched with the diameter of the metal wire. One end of the quartz glass tube is connected with an outlet of the metal wire, and the other end of the quartz glass tube is connected with a gas atomization nozzle and a powder collector successively. A coil is wound around the quartz glass tube. The method and device for metal powder preparation based on the controllable magnetic levitation melting technology can stably control the flow rate of melting metal liquid and can satisfy industrial production requirements.

Owner:CHINA JIUYUAN HI TECH EQUIP

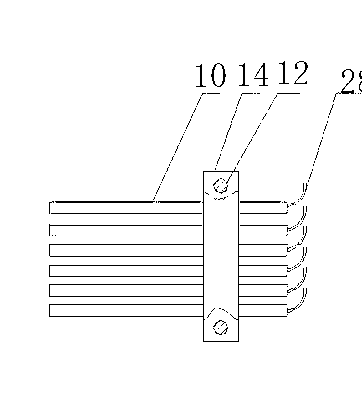

Briquette clamp for cylindrical briquettes

InactiveCN101954750BRealize the clamping functionReduce breakageManipulatorPressesMolding machineHydroforming

The invention relates to an auxiliary device of a briquetting hydraulic molding machine for metallurgical direct reduced iron, in particular to a briquette clamp for cylindrical briquettes, which comprises two positioning plates and a plurality of supporting plates, wherein the plurality of supporting plates are verticality and fixedly installed and combined with the two positioning plates according to a certain space into a briquette clamping frame; the briquette clamp is characterized by also comprising a driving device, a guiding device, claws and an elevating mechanism, wherein the claws are relatively distributed in pairs and respectively connected with the briquette clamping frame through the driving device and the guiding device; the elevating mechanism is installed on the support plates outside the briquette clamping frame; each claw comprises a clamping surface and a clamping bracket; and the clamping surface is provided with a circular surface adaptive to the exterior shape of the cylindrical briquette. By the clamping of the claws and the elevating and falling of the elevating mechanism, the function of clamping the cylindrical briquettes is realized, so that a briquette moving car can deliver the briquettes out from a forming machine, and the invention has simple structure and convenient operation, reduces breakage of the cylindrical briquettes in handling, improves the quality of products, dispenses with manual handling, and improves the production efficiency.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com