Patents

Literature

46results about How to "With correction function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

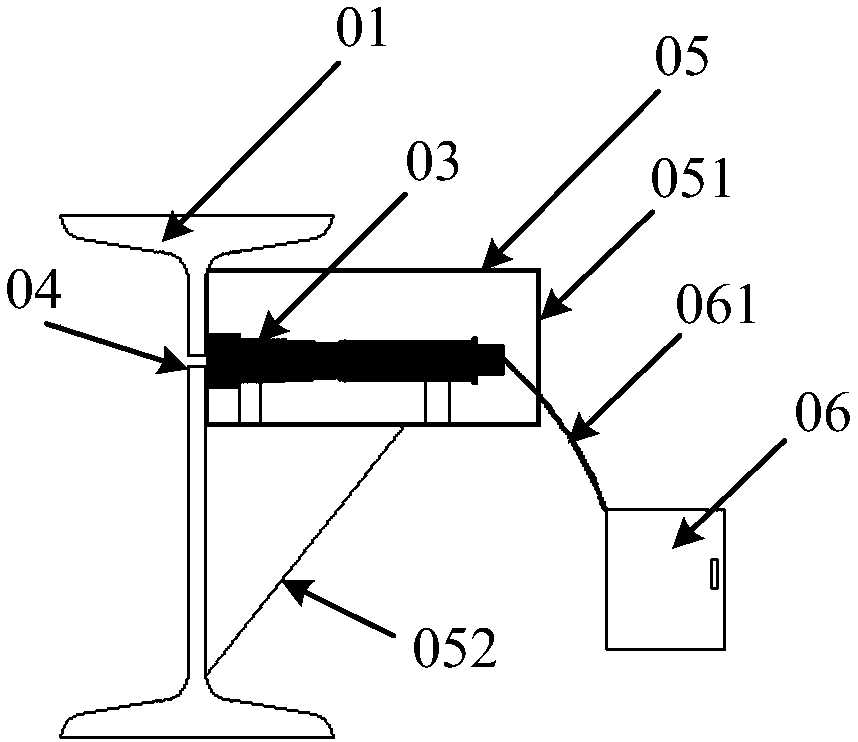

Method and device for measuring X-ray thickness

InactiveCN103206931AWith correction functionThe problem of inaccurate customer service measurementUsing wave/particle radiation meansSoft x rayUltrasound attenuation

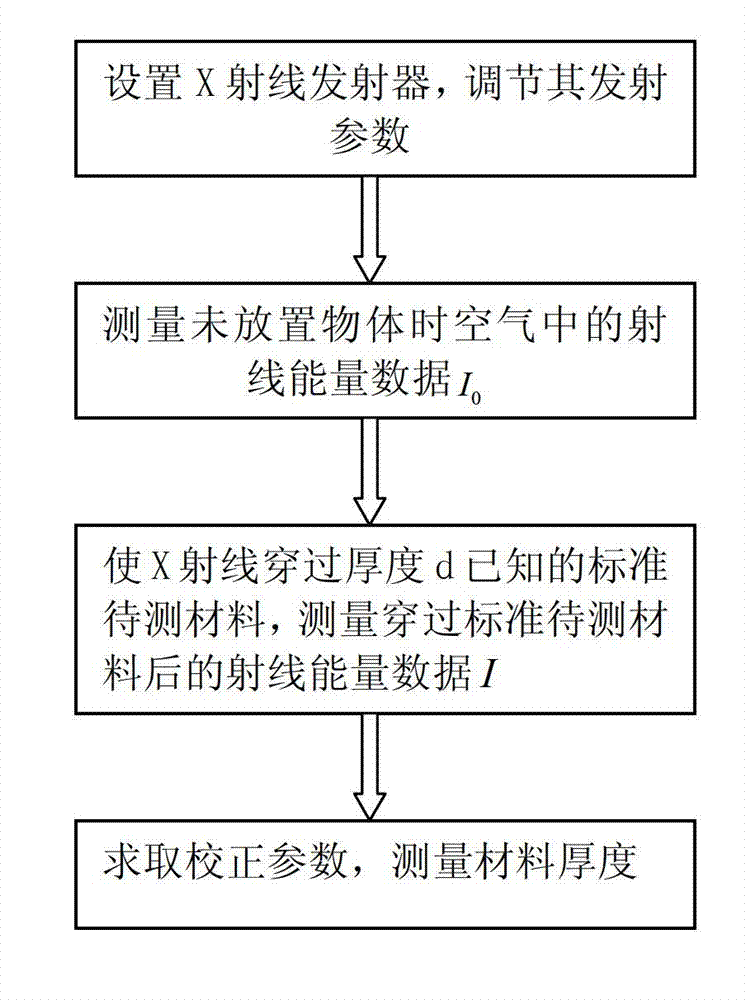

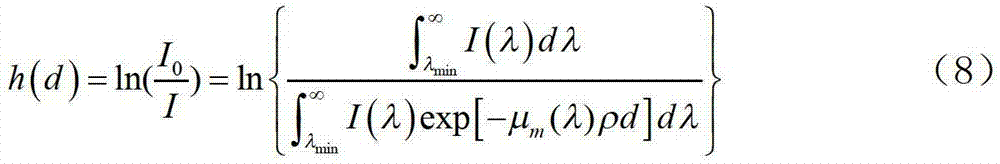

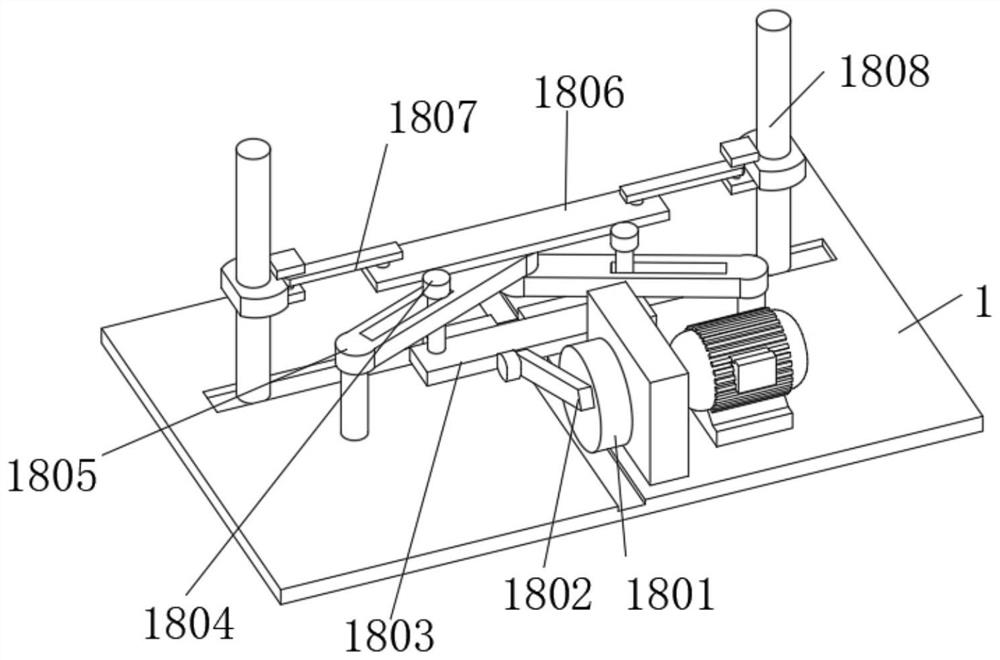

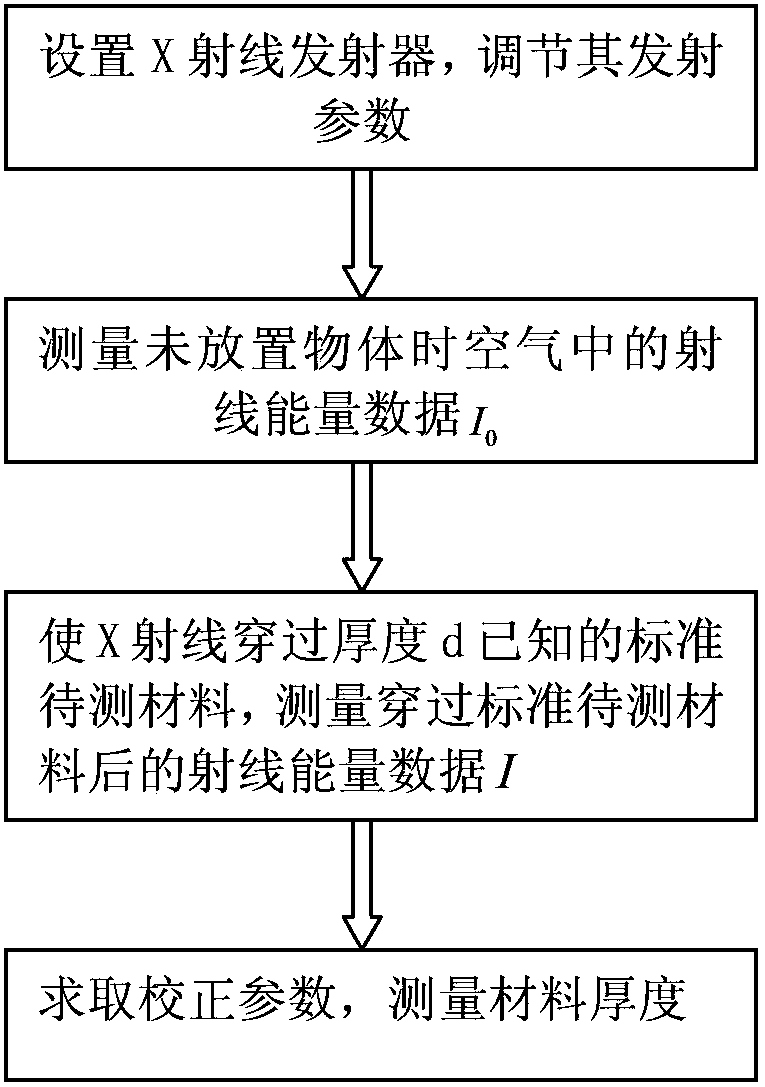

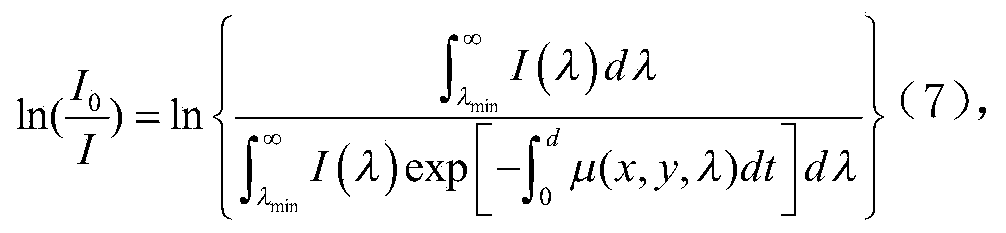

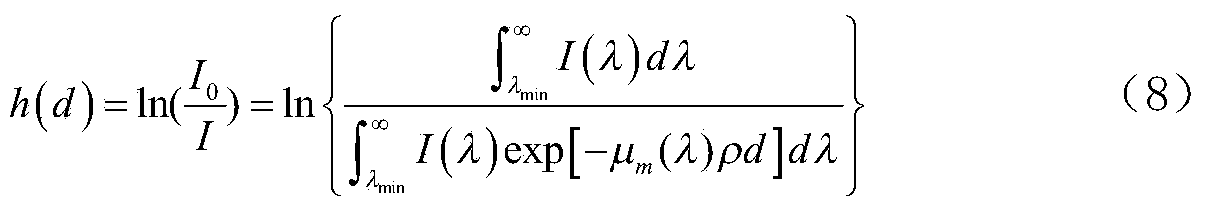

The invention discloses a method and device for measuring X-ray thickness and belongs to the field of ray measurement. The method for measuring the X-ray thickness comprises the steps of (1) arranging an X-ray emitter and adjusting emitting parameters; (2) starting up the X-ray emitter and measuring energy data I0 of rays in the air where an object is not placed; (3) starting up the X-ray emitter, enabling X-rays to penetrate through a standard to-be-measured material with known thickness d and measuring the ray energy data I after the rays penetrates through the to-be-measured material; and (4) calculating correction parameters by means of the following methods for obtaining corresponding attenuation coefficients mu according to a formula, performing least-squares curve fitting calibration to obtain the correction parameters A, alpha and beta according to a formula mu(d)=A(e-alphad+beta) and performing thickness measurement of the to-be-measured material according to a formula. By means of the method, the problem of mismeasurement caused by 'beam hardening' of the X-rays is solved. The method has a correction function. The method and device for measuring the X-ray thickness is simple and easy to operate, high in accuracy and strong in reliability.

Owner:CHONGQING UNIV

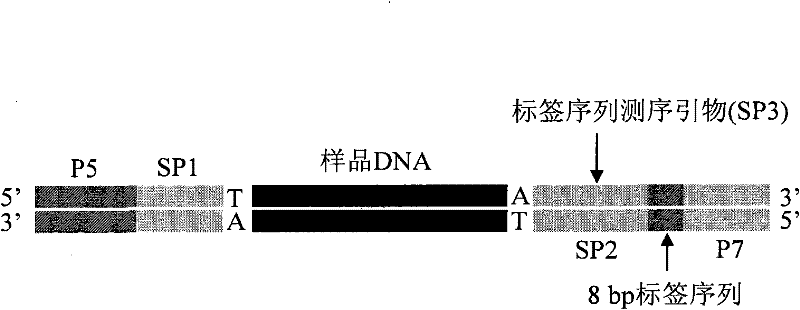

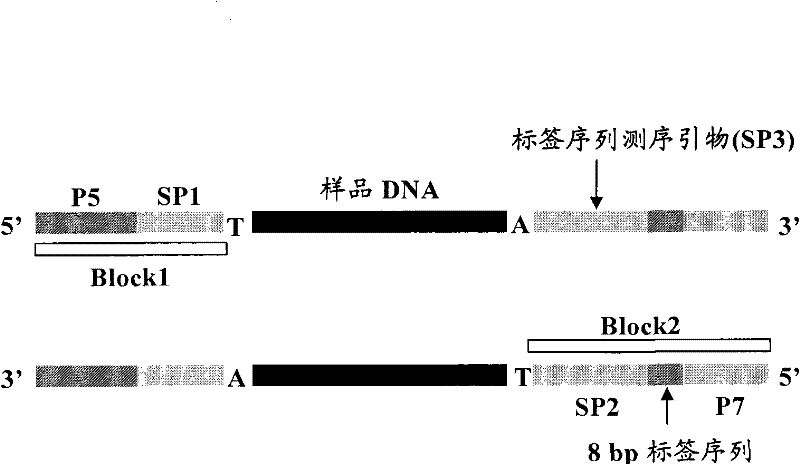

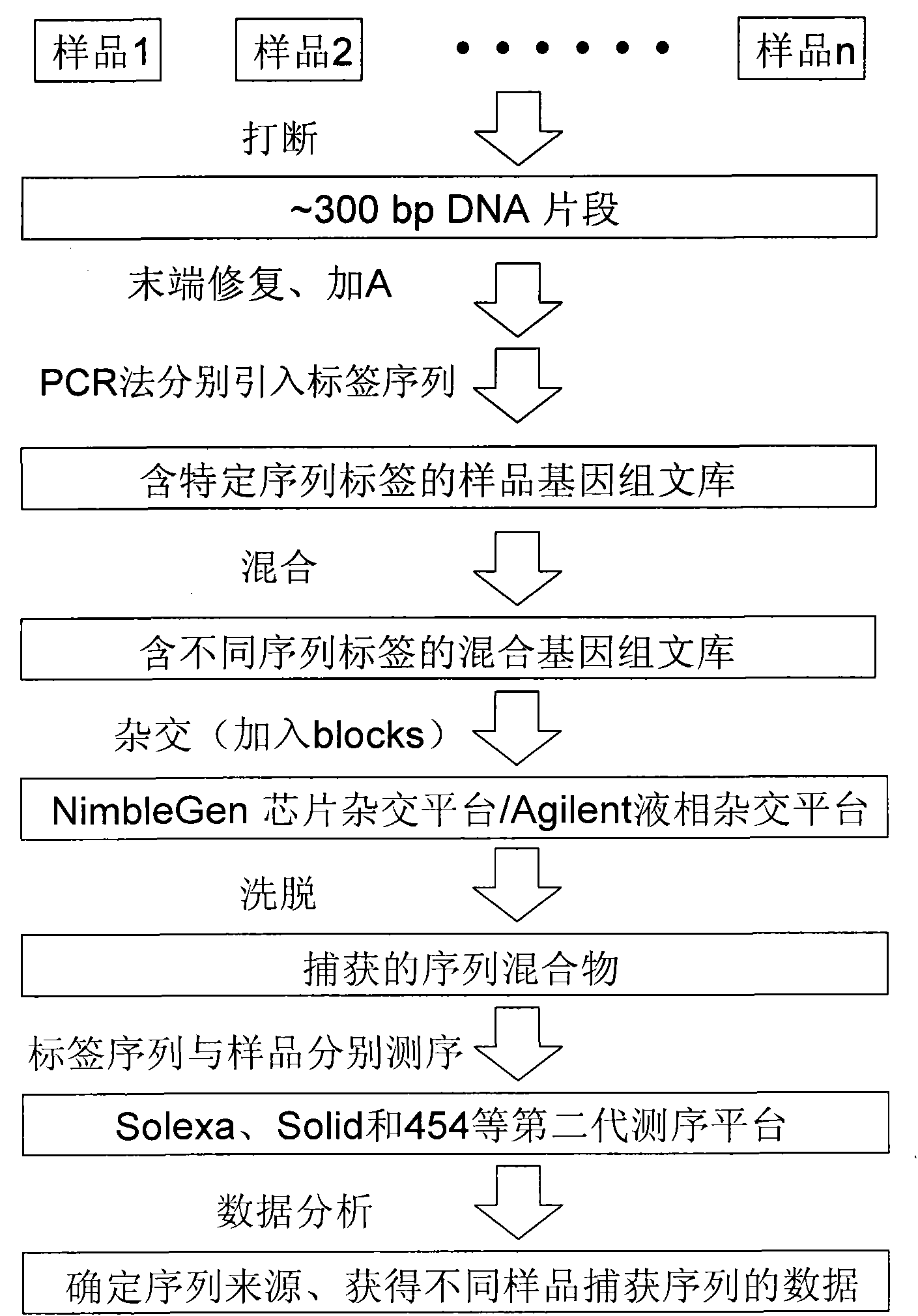

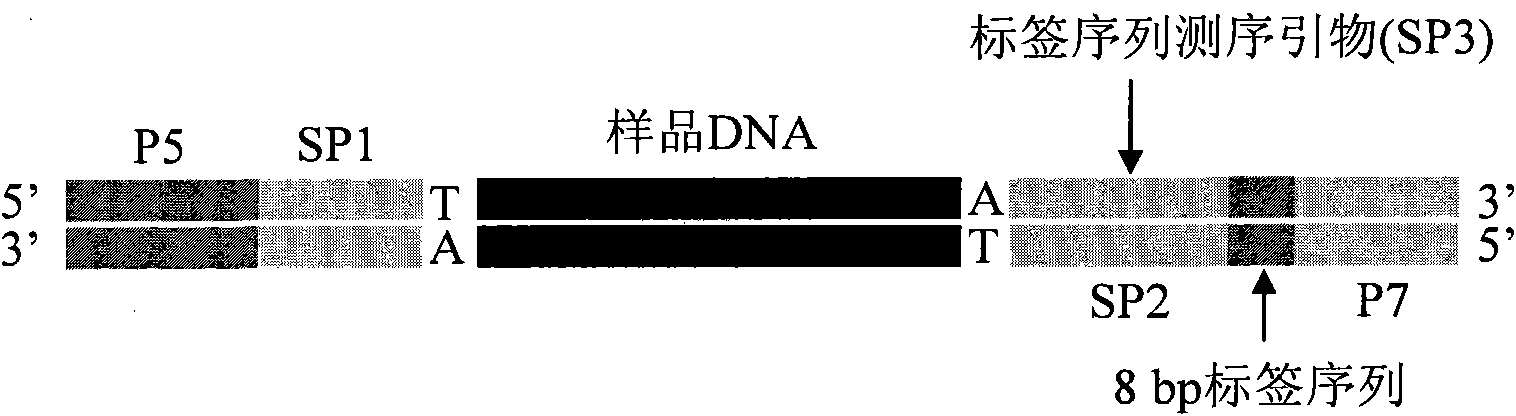

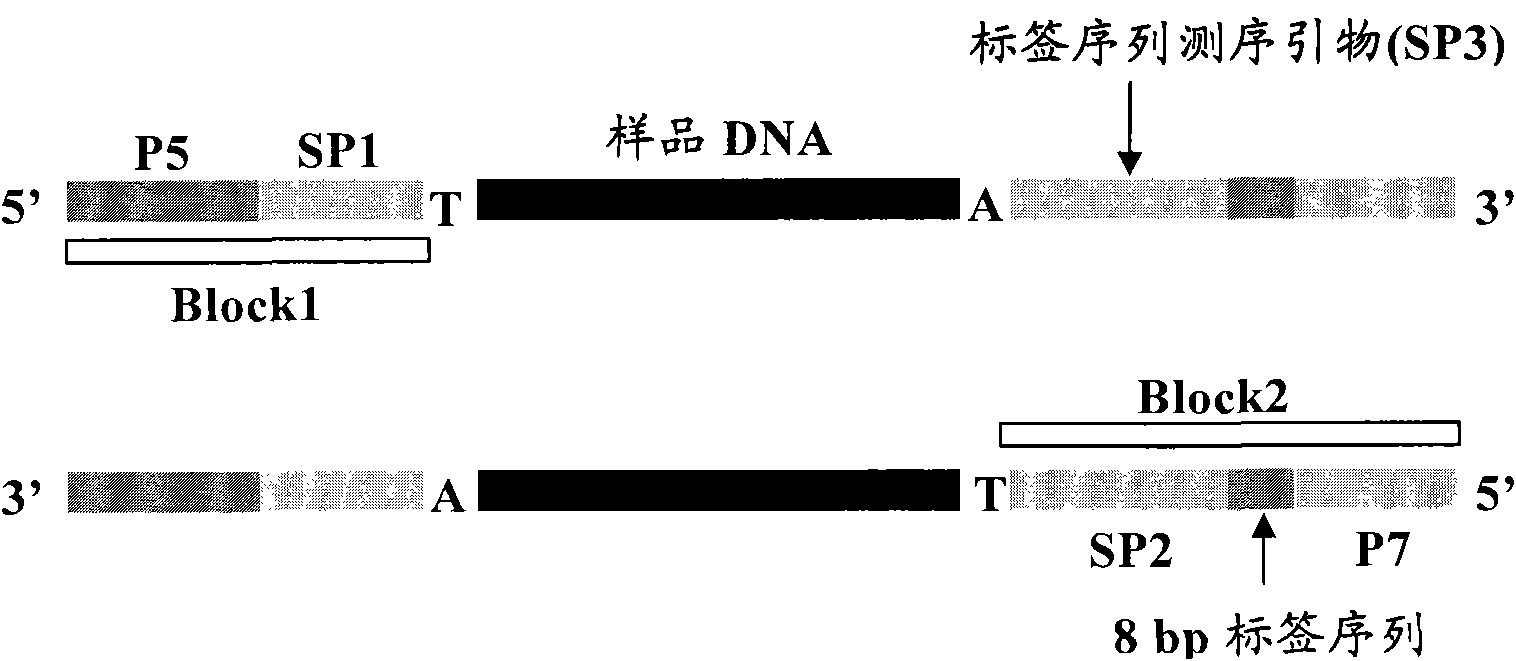

Method for building sequencing library by hybridization

ActiveCN102409047AImprove introduction efficiencyAvoid wastingMicrobiological testing/measurementLibrary creationPcr methodBioinformatics

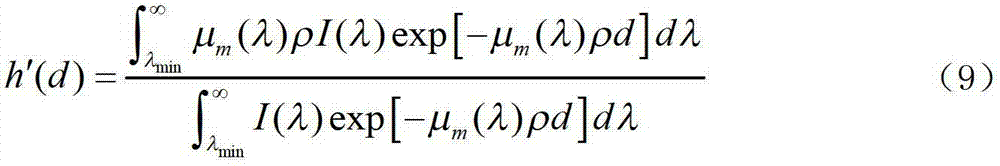

The invention provides indexes for DNA sequencing, especially for a sequence acquisition technology, and a method for introducing the indexes by adopting a PCR (polymerase chain reaction) method. The invention also provides adapter block sequences for blocking adapters and application of the adapter block sequences in a NimbleGen chip hybridization system, an Agilent liquid hybridization system and a NimbleGen EZ liquid hybridization system. The invention further provides a method for building a library and / or sequencing by using the indexes and / or adapter block sequence, and the library built by the method.

Owner:BGI TECH SOLUTIONS

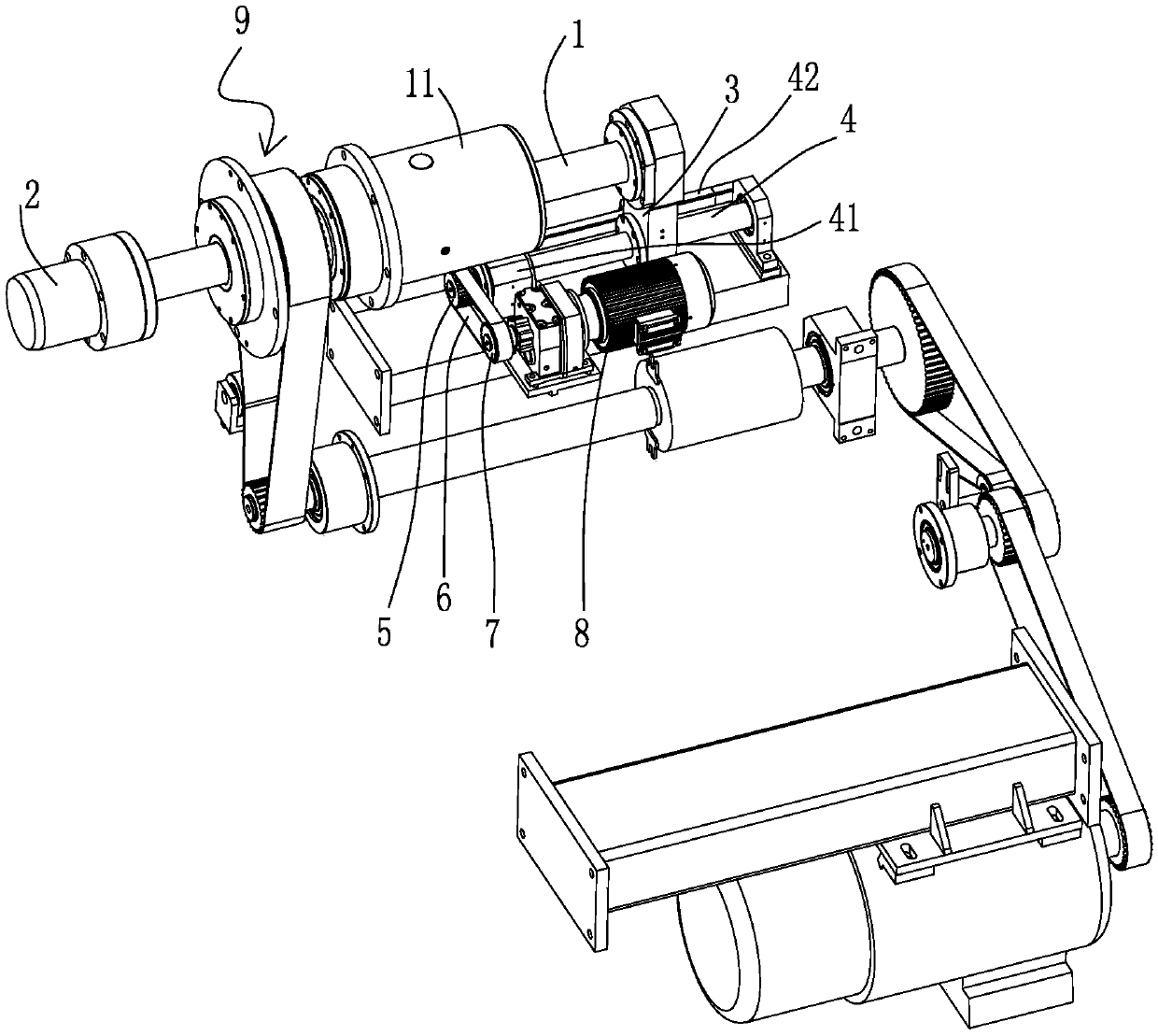

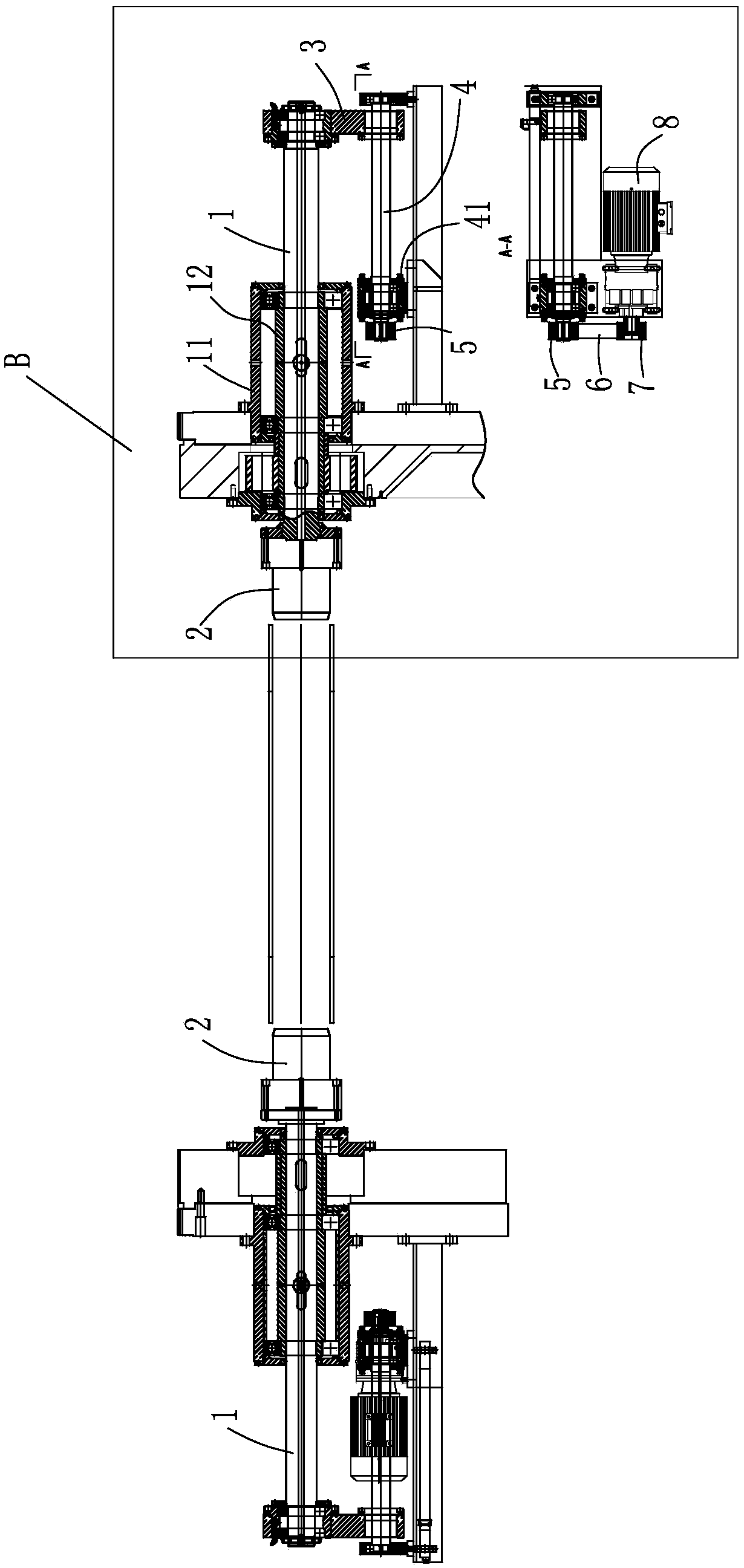

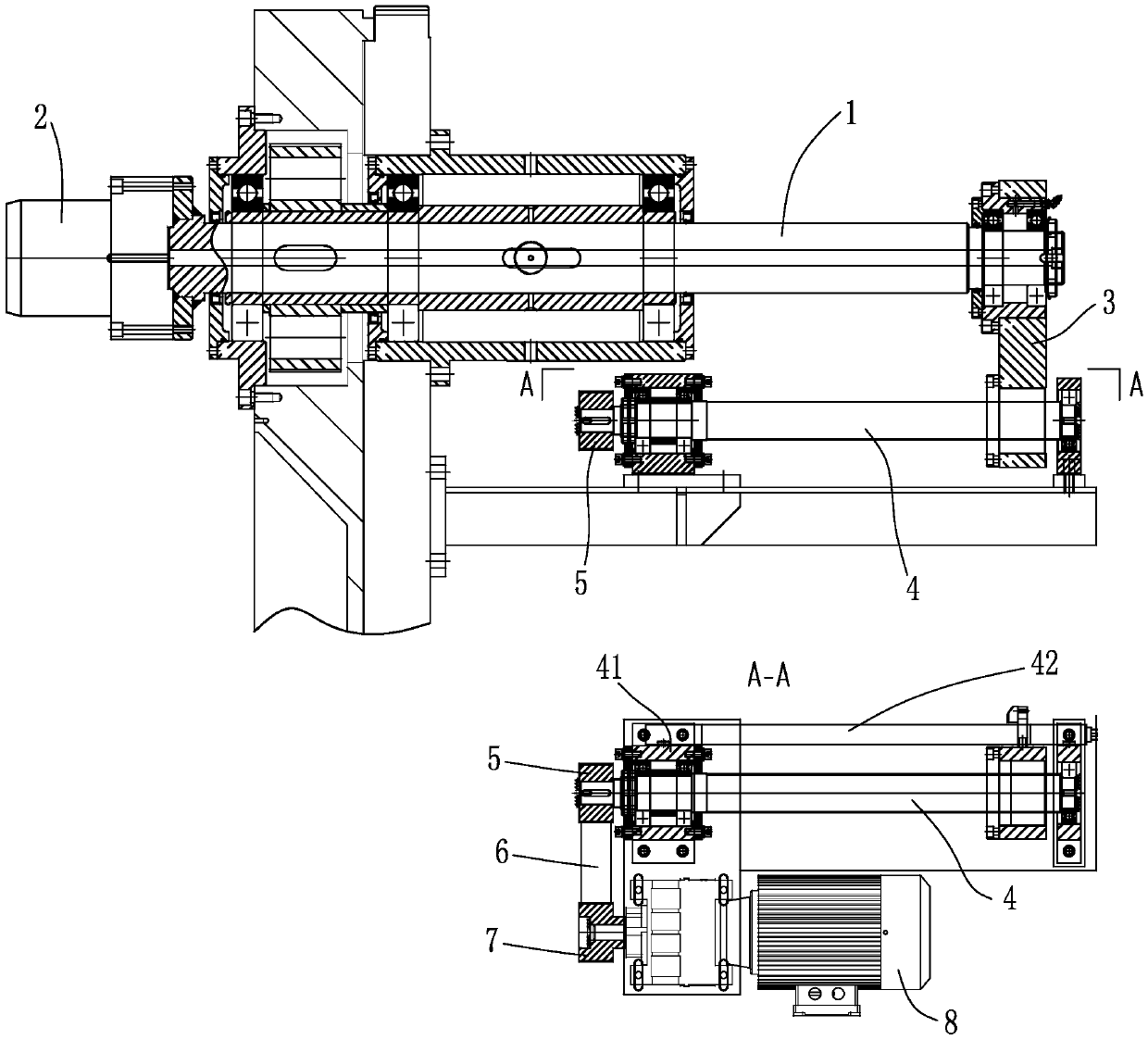

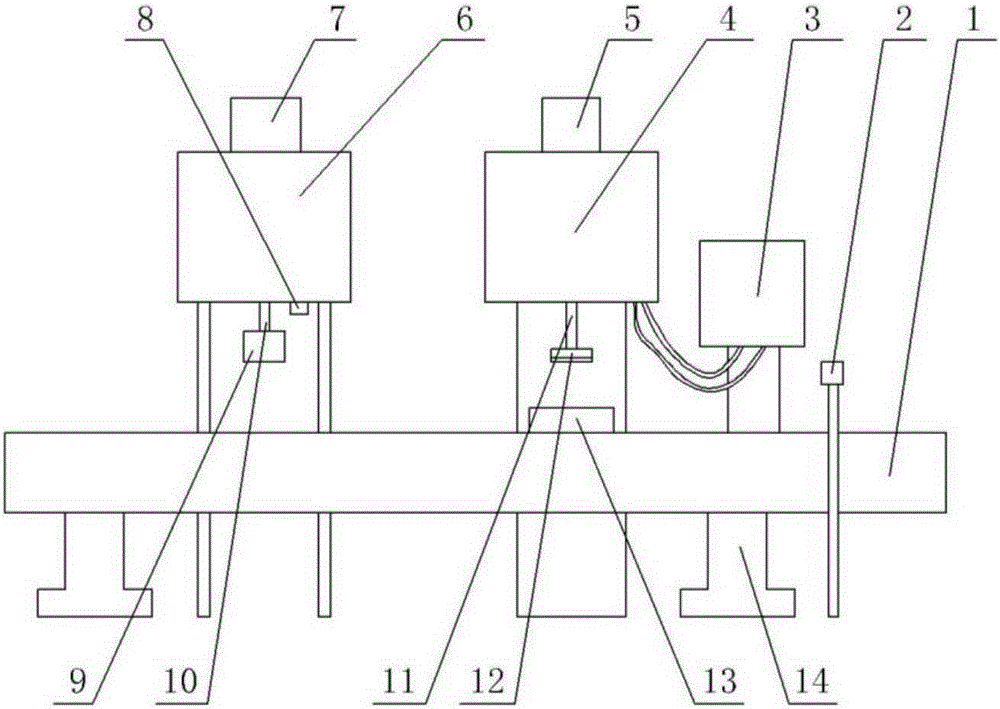

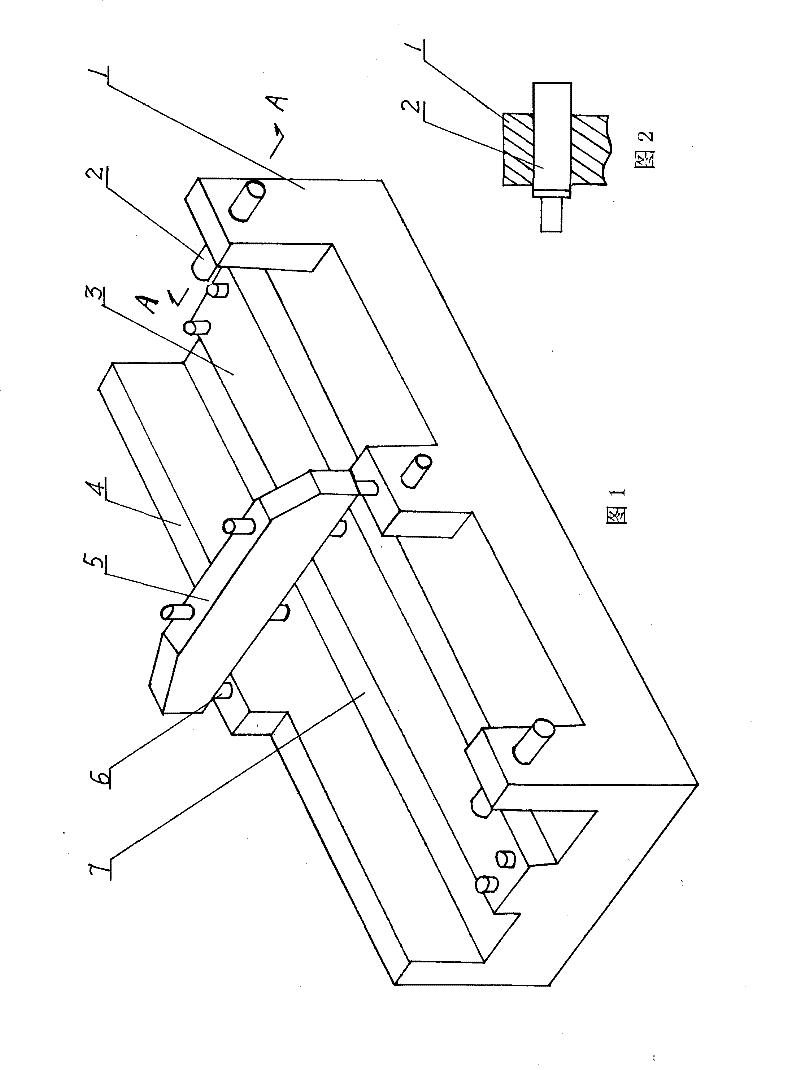

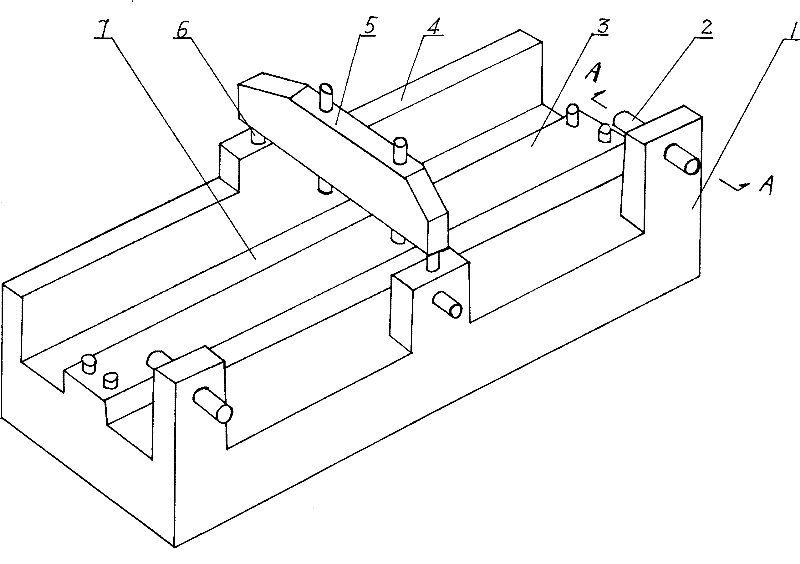

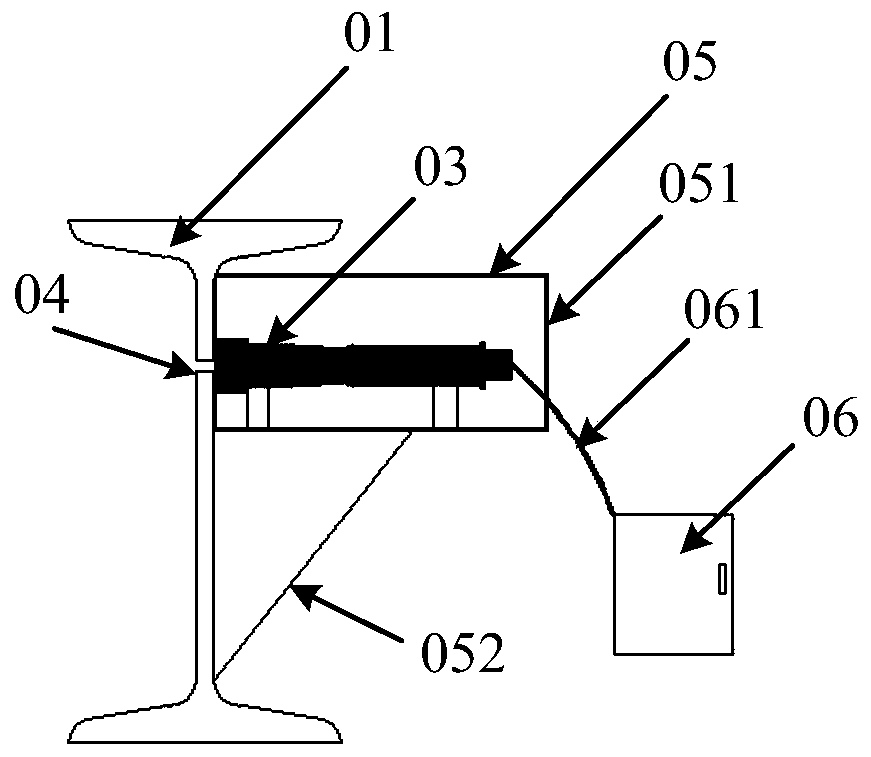

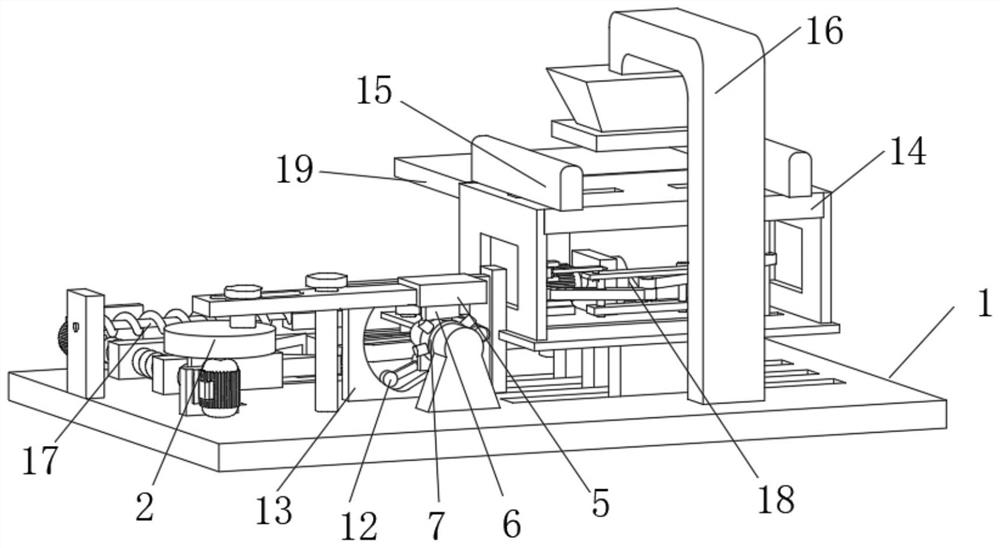

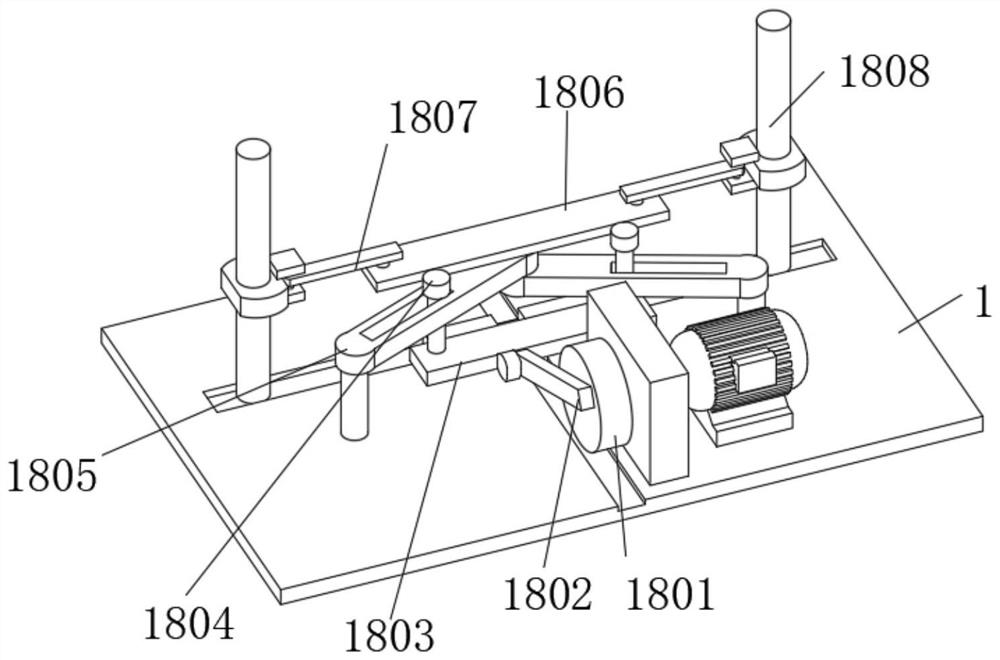

Winding and unwinding device for printing machine

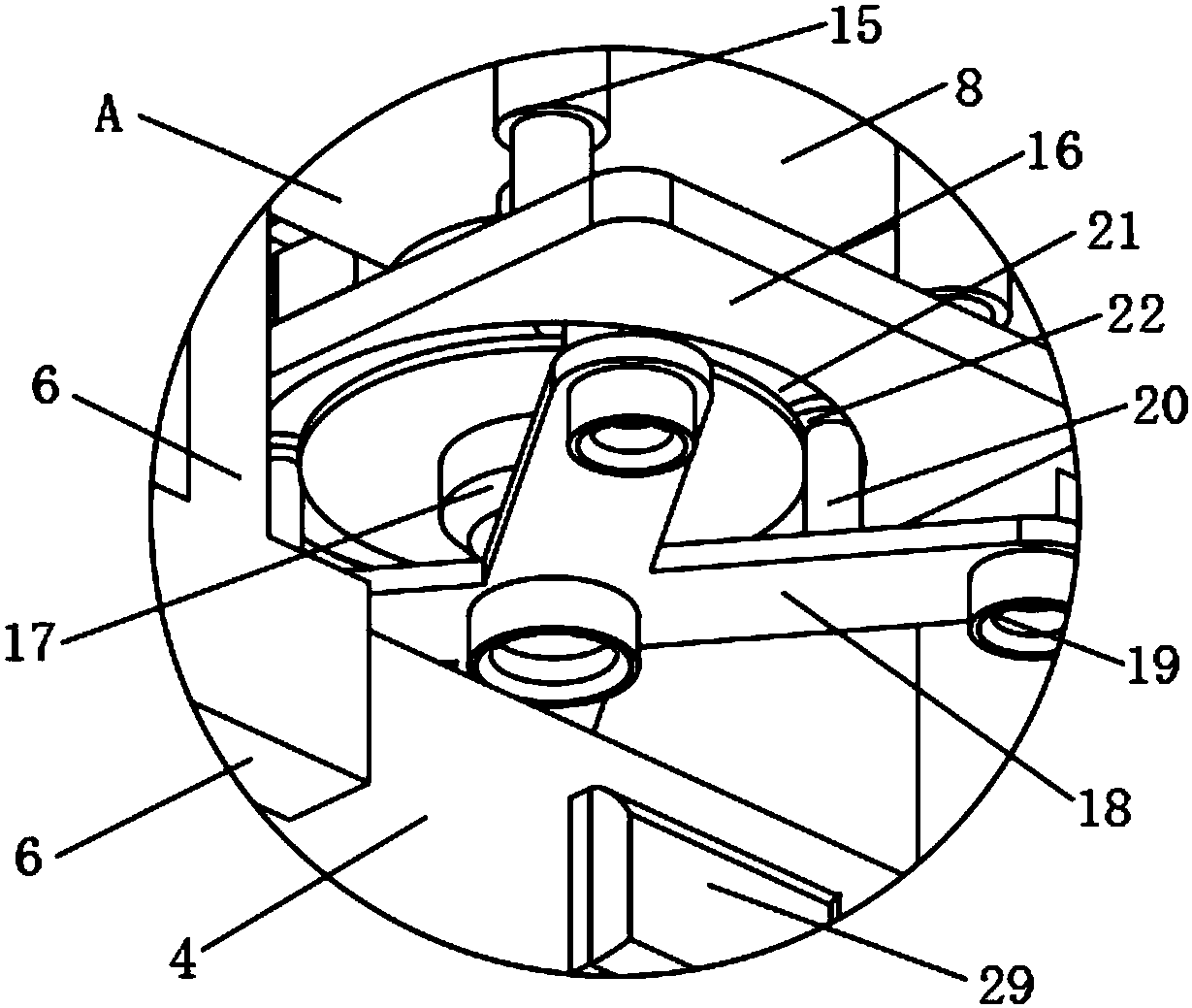

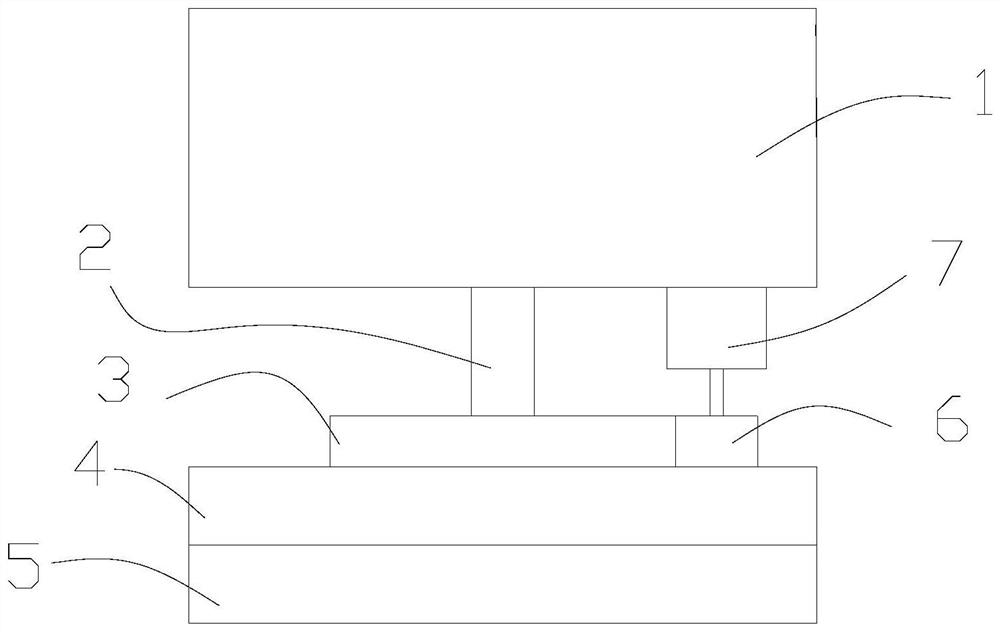

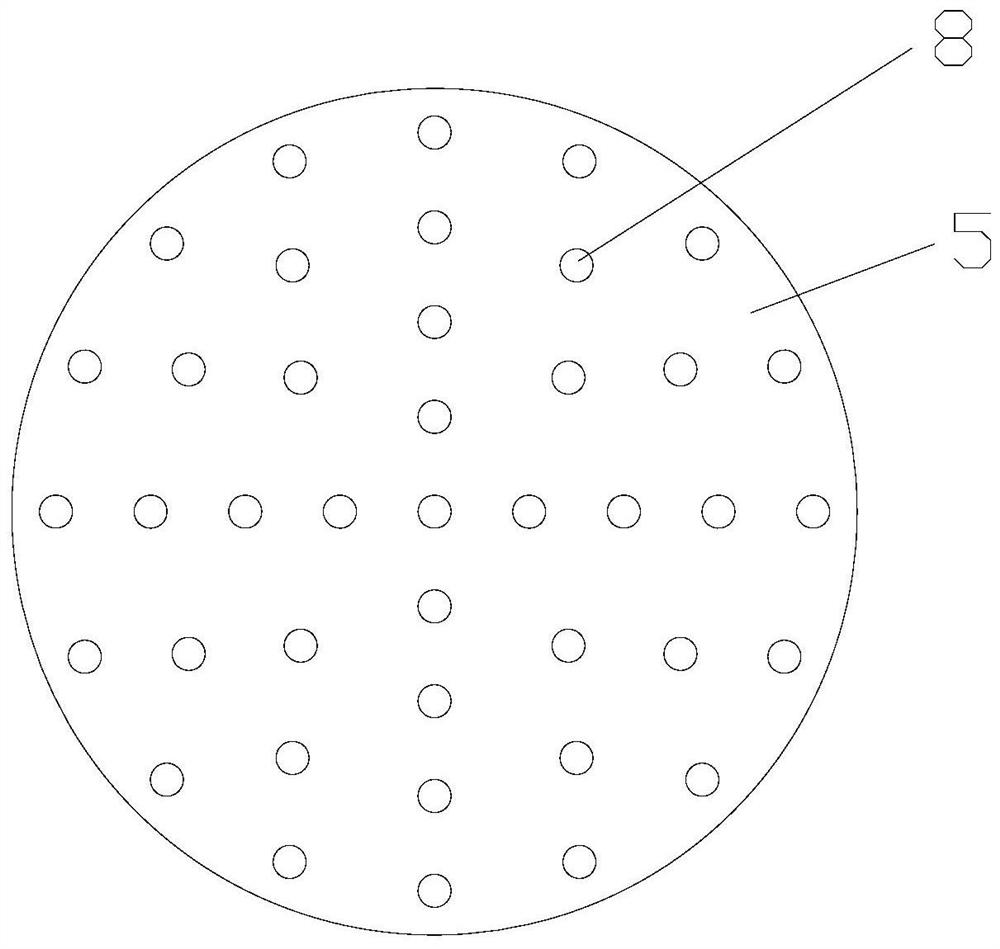

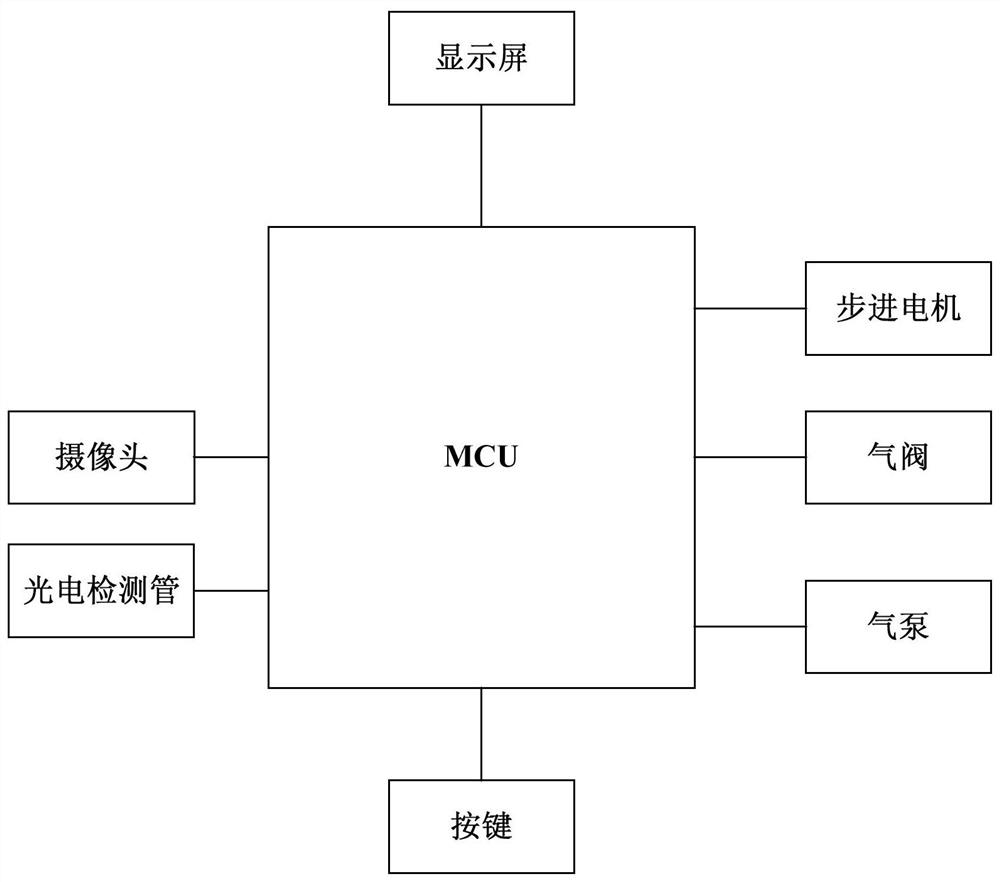

PendingCN109534104AEasy loading and unloadingIncrease productivityWebs handlingPneumatic pressurePrinting press

The invention relates to a winding and unwinding device for a printing machine. The winding and unwinding device for the printing machine is characterized in that the winding and unwinding device comprises a transmission shaft (1), an air pressure mechanical chuck (2) used for the winding and unwinding of the printing machine is arranged at one end of the transmission shaft (1), a screw nut base (3) used for driving the transmission shaft (1) to move in the axial direction is arranged at the other end of the transmission shaft (1), a ball screw (4) used for driving the screw nut base (3) to move is connected to the screw nut base(3), a screw rod synchronous wheel(5) used for driving the ball screw(4) to rotate is arranged at one end of the ball screw (4), a synchronous belt (6) is arrangedon the screw rod synchronous wheel (5), a motor synchronous wheel (7) is arranged on the synchronous belt (6), a speed reducing motor (8) is arranged on the motor synchronous wheel (7), and a rotating device (9) is arranged on the transmission shaft (1). The winding and unwinding device for the printing machine has the advantages of being easy in unloading and automatic in centering, shortening downtime, reducing labor intensity of employees, and improving the production efficiency, safety and reliability.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

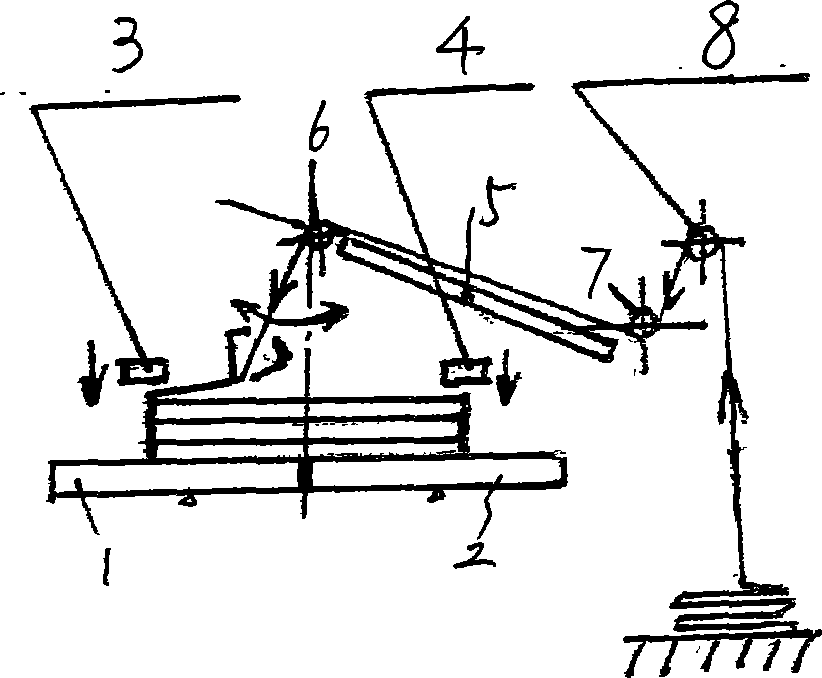

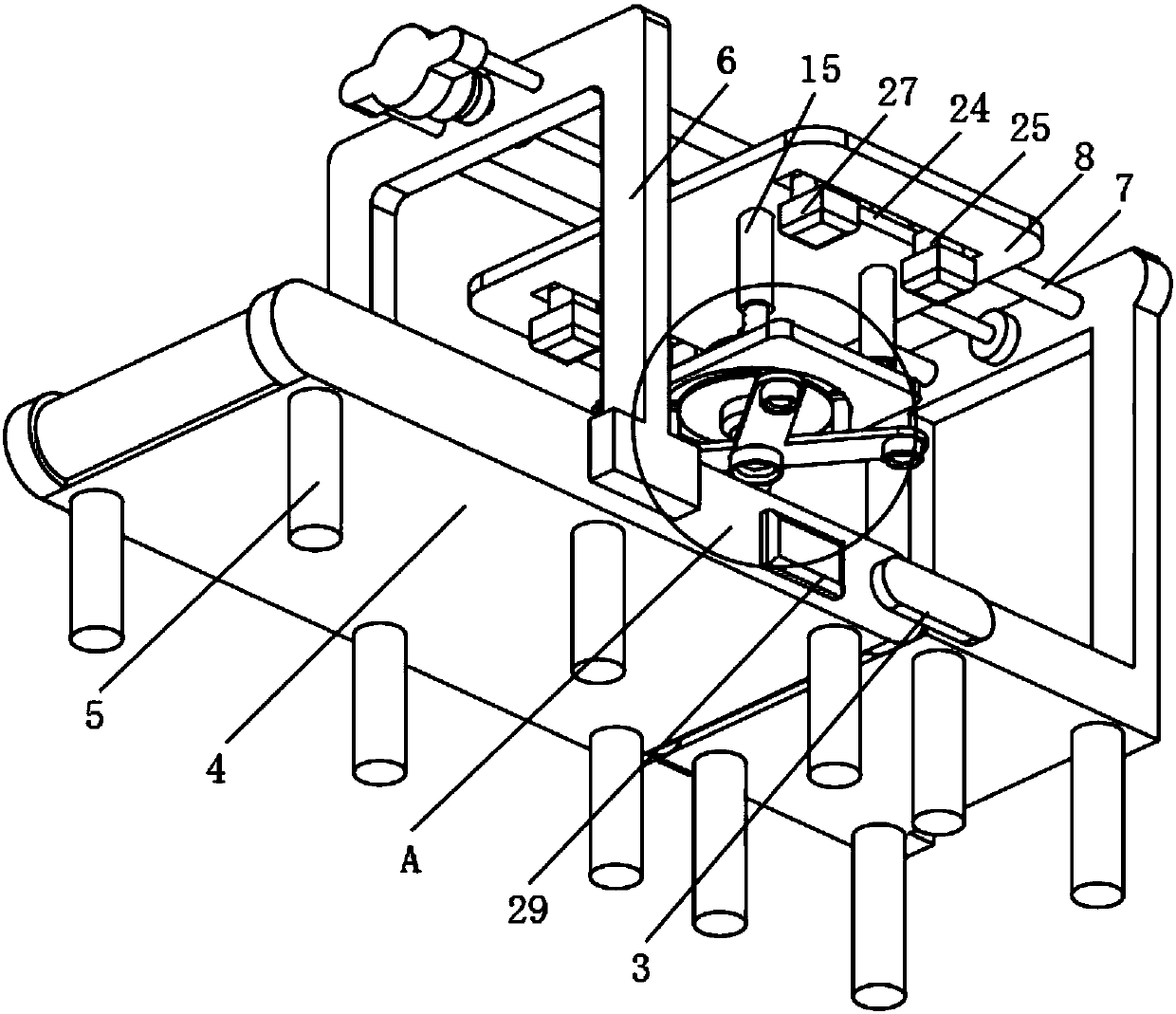

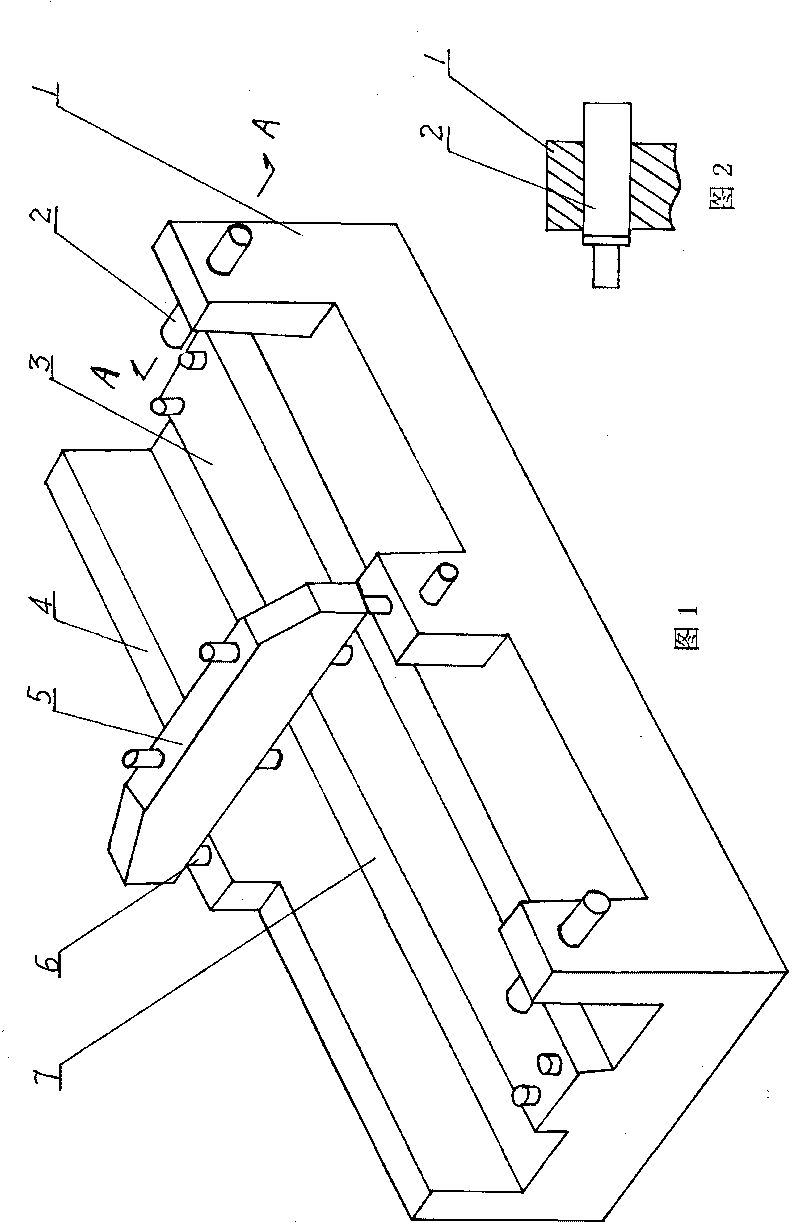

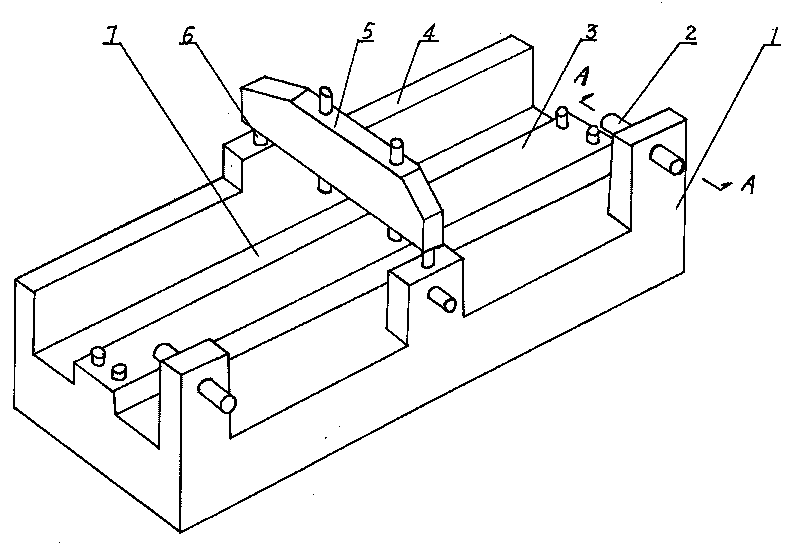

Full-automatic rectification system for cloth plaiting and laying

InactiveCN101391716AReasonable structureWith correction functionFolding thin materialsUnfolding thin materialsEngineeringTextile

The invention discloses a full-automatic correcting system used for plaiting and fabric-spreading, comprising a plaiting-machine supporting fabric bedplate, a pressing fabric plate, a guiding fabric plate, a front guiding fabric roller and a back guiding fabric roller. A supporting fabric roller used for correcting is arranged on the feeding direction of the feeding side of the back guiding fabric roller and the correcting function of the supporting fabric roller is realized through changing the parallelism of the supporting fabric roller and the guiding fabric roller and the eccentricity against the axes of the plaiting machine. The correcting system has reasonable structure and correcting function, the work effect is good, the structure is compact and the work is stable and harmonious.

Owner:瞿建新

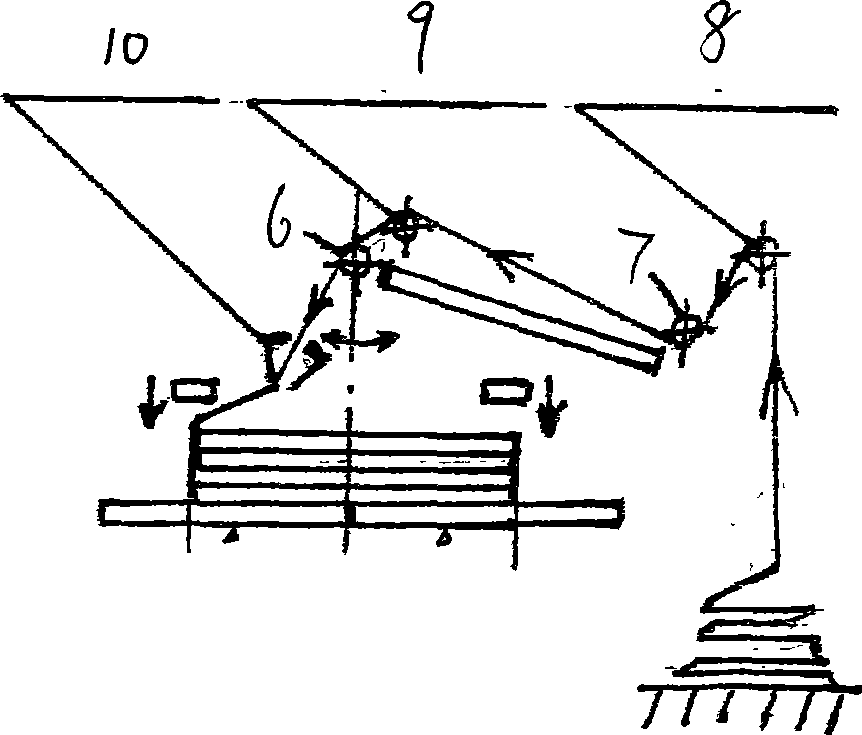

Pointwise scanning type micro-fluid metering device and method

ActiveCN101603889AAccurate and quantitative liquid extractionAvoid easy cloggingWithdrawing sample devicesProgramme control in sequence/logic controllersPeristaltic pumpEngineering

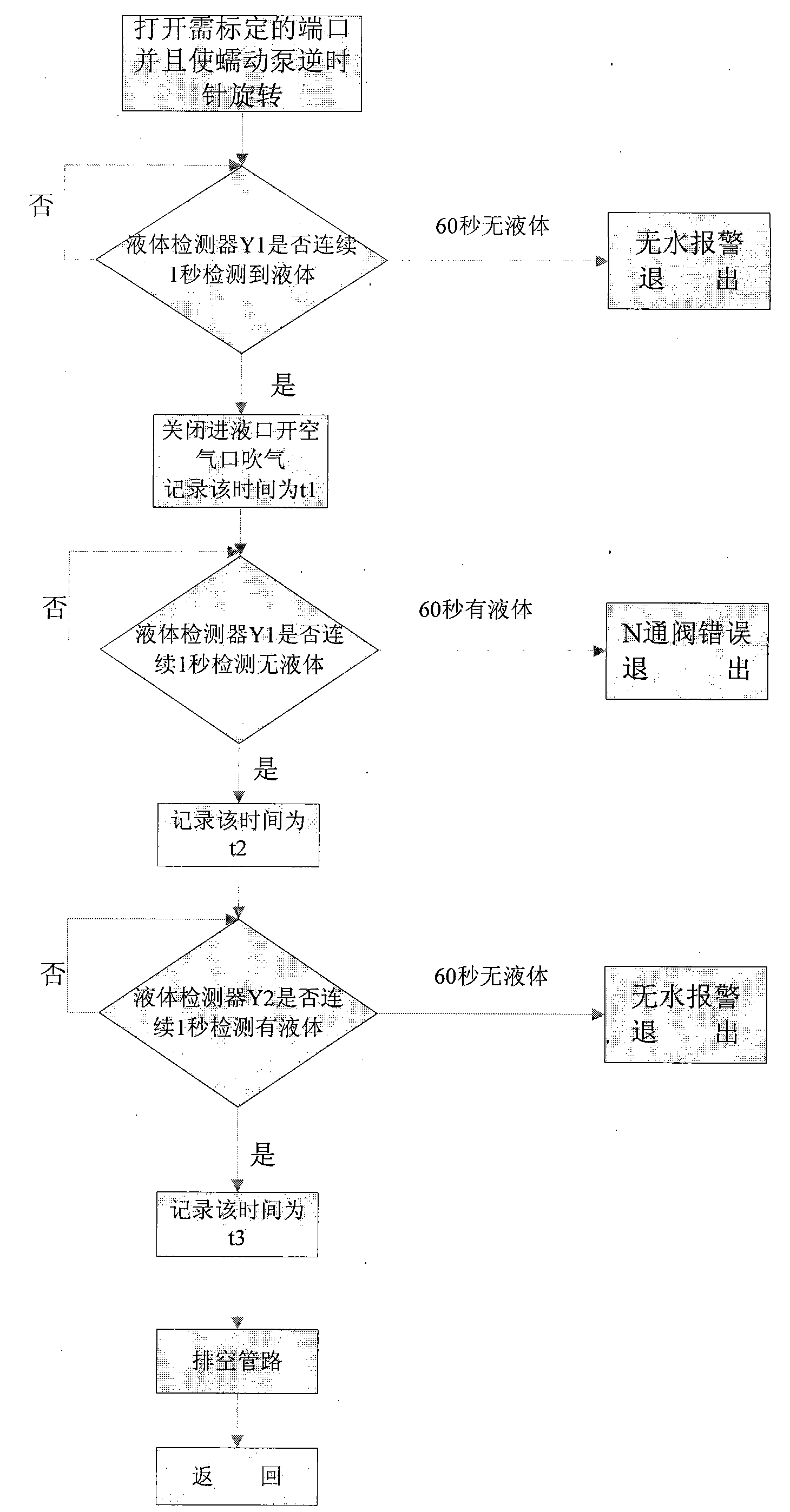

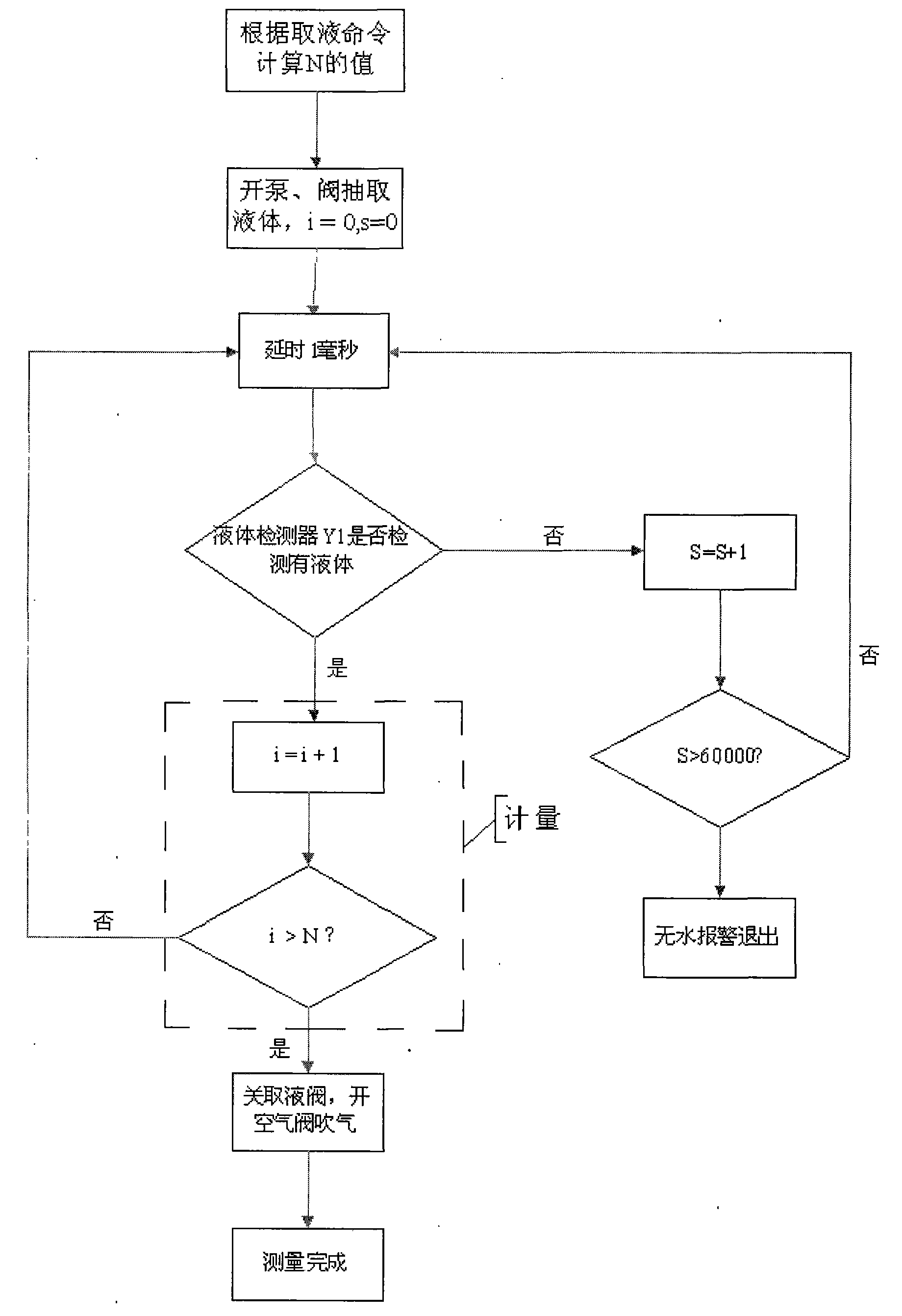

Disclosed is a pointwise scanning type micro-fluid metering device and a method thereof. The device comprises an N-way valve, a closed anti-corrosion fluororubber tube, a peristaltic pump, a fluid outlet, a control computing unit and two fluid detector Y1 and Y2, wherein for the N-way valve, 1-1 is an air port, 1-i are fluid inlets, and i is equal to 2 to N; the N-way valve is sequentially connected with the fluid detectors Y1 and Y2 through the closed anti-corrosion fluororubber tube the other end of which is connected with one end of the peristaltic pump with the other end connected with the fluid outlet; the control computing unit are respectively connected with the N-way valve, the fluid detectors Y1 and Y2 and the peristaltic pump.

Owner:YIWEN ENVIRONMENTAL SCI & TECH GUANGZHOU

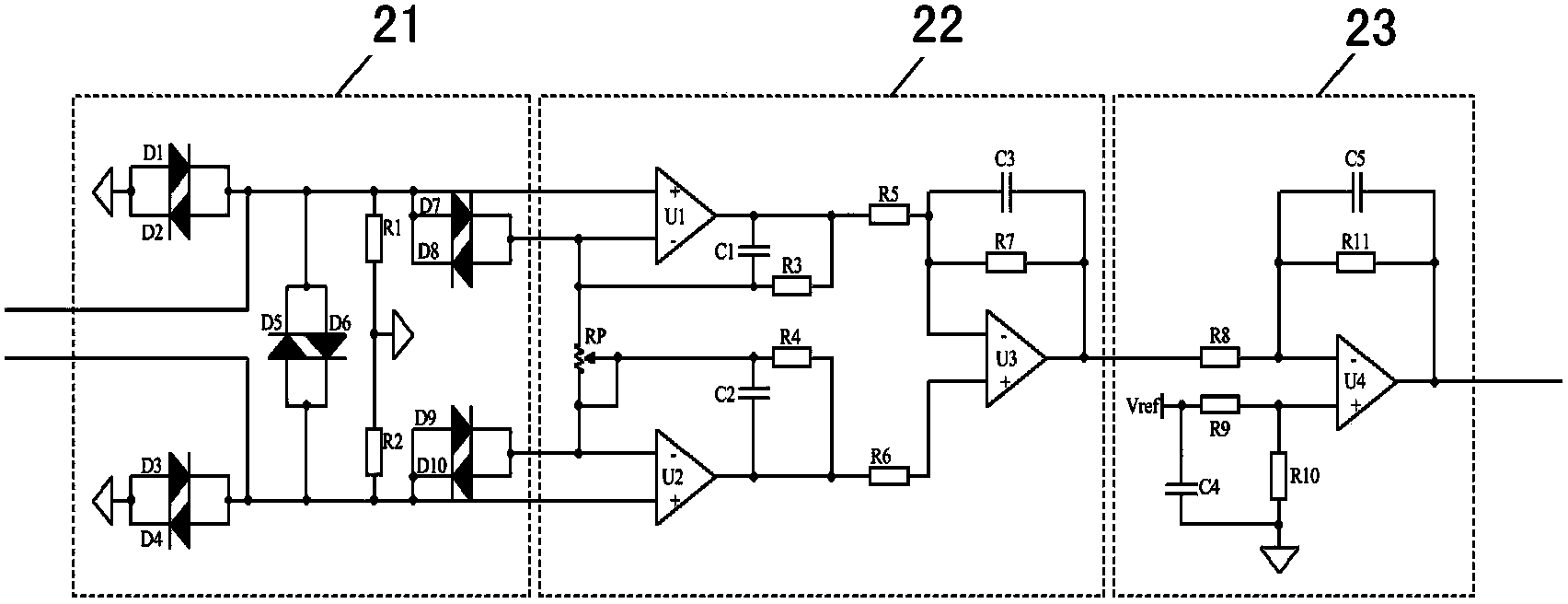

Zinc oxide arrester live detection device free of external connection with alternating-current power supply

InactiveCN103777064AEasy to testEasy to operateMeasurement using digital techniquesExternal connectionOxide

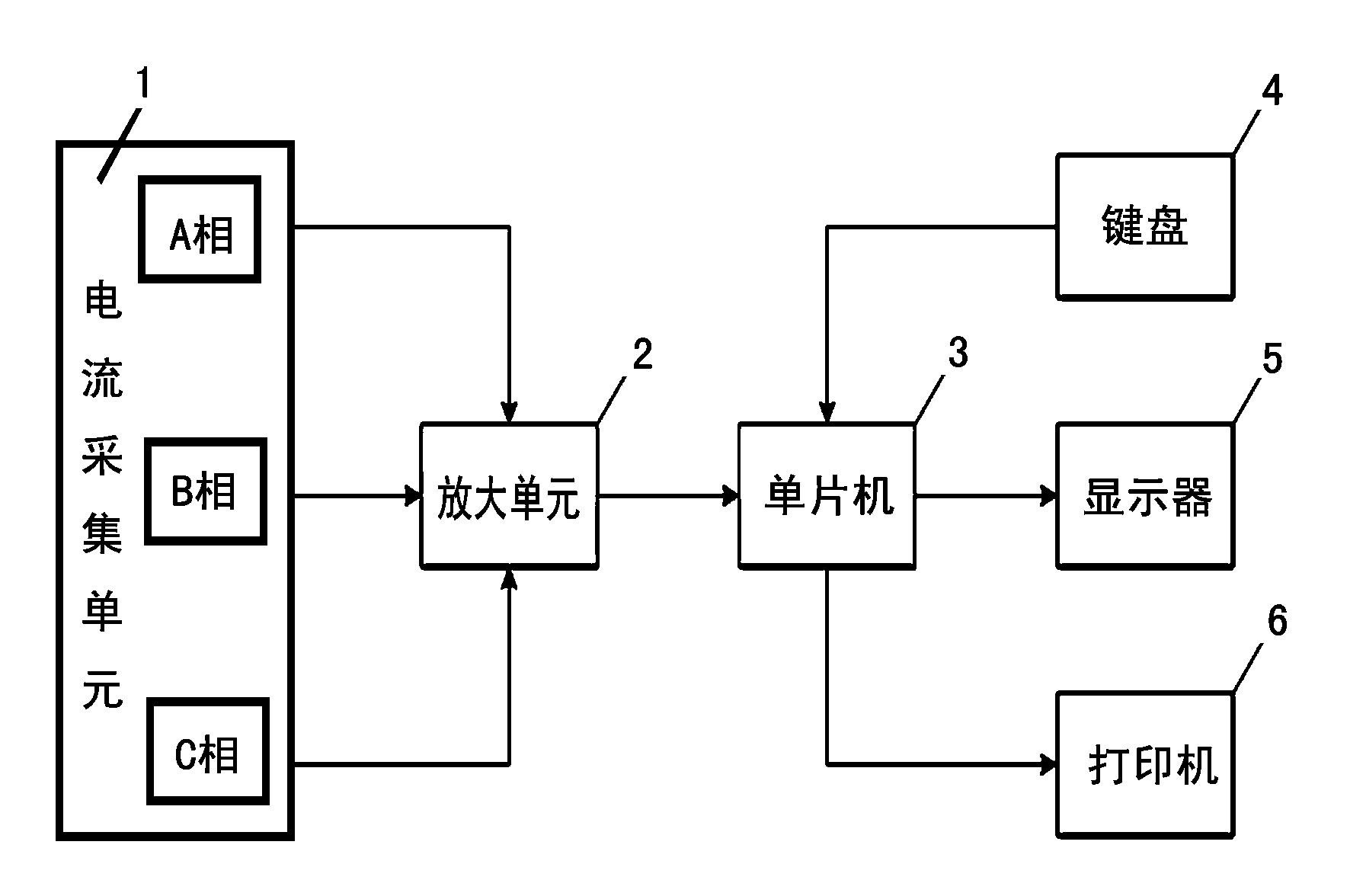

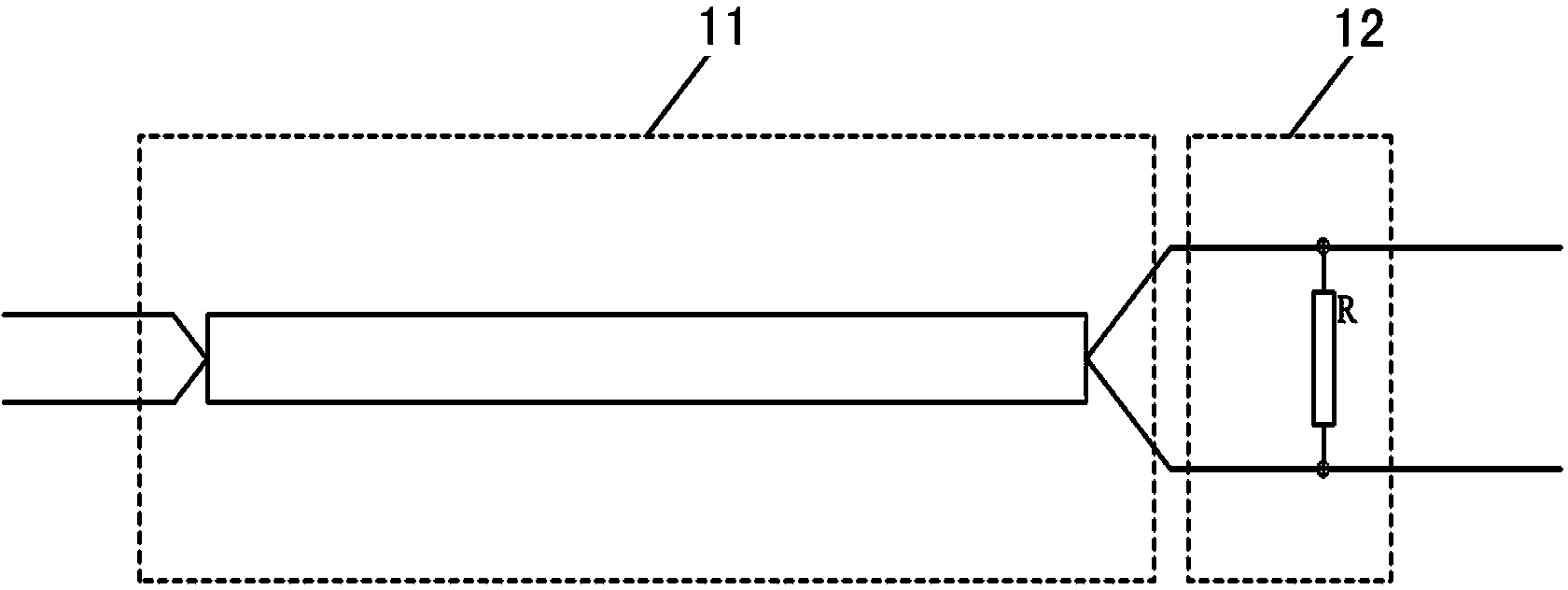

The invention belongs to the technical field of gapless zinc oxide arrester live detection in an electric system, in particular to a zinc oxide arrester live detection device free of external connection with an alternating-current power supply. The zinc oxide arrester live detection device free of external connection with the alternating-current power supply comprises a current collecting unit, an amplifying unit, a single-chip microcomputer, a keyboard, a displayer and a printer. The current collecting unit has the A-phase, the B-phase and the C-phase, wherein the A-phase, the B-phase and the C-phase of the current collecting unit are connected with the amplifying unit. The output end of the amplifying unit is connected with an A / D conversion channel of the single-chip microcomputer. A bus of the single-chip microcomputer is connected with the keyboard, the displayer and the printer in sequence. The zinc oxide arrester live detection device free of external connection with the alternating-current power supply can complete on-site detection of three-phase arresters at the same time in one-time measurement and has the remarkable advantages that testing operation is convenient, site interference is small, and data repeatability is good; the zinc oxide arrester live detection device free of external connection with the alternating-current power supply further has the remarkable advantages of being suitable for arrester live tests under different site conditions in a transformer substation and out of the transformer substation, capable of accurately judging the operation state of the arresters, high in measurement accuracy, wide in application range, convenient to use and low in maintenance cost.

Owner:STATE GRID CORP OF CHINA +1

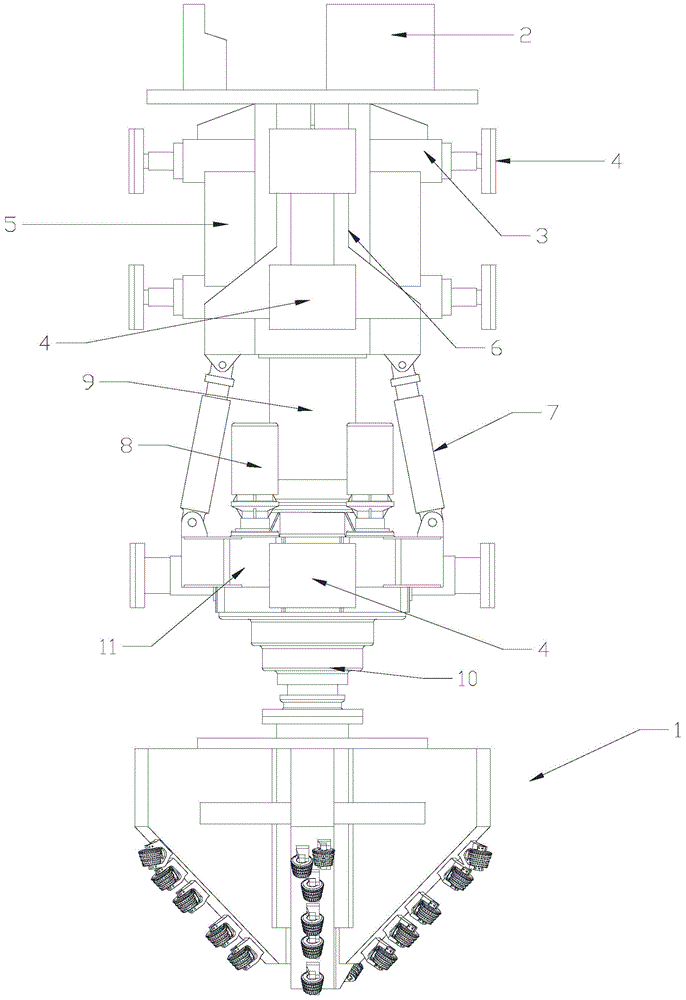

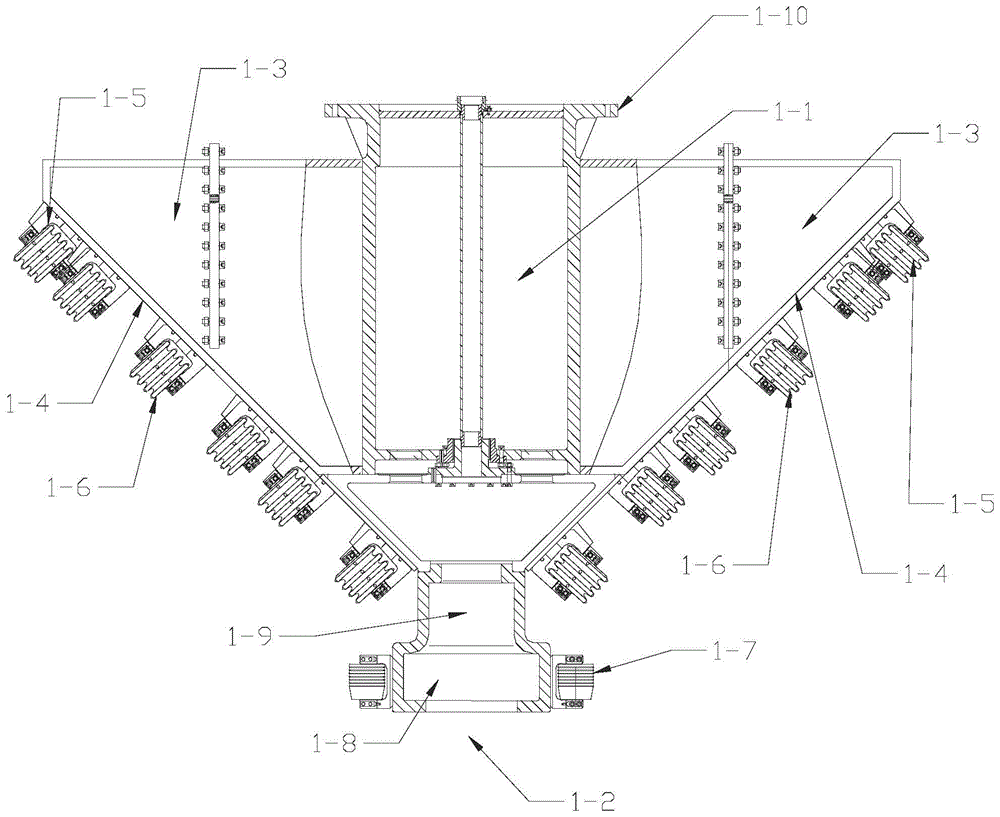

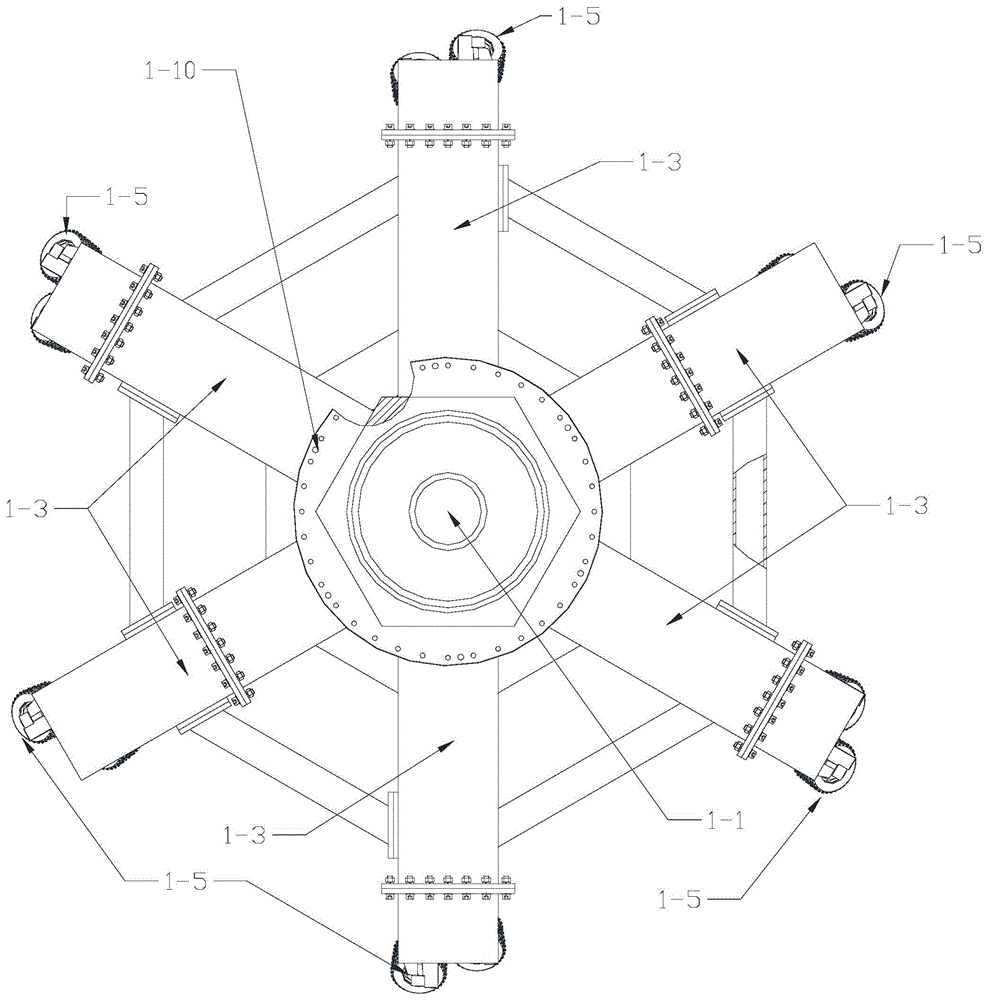

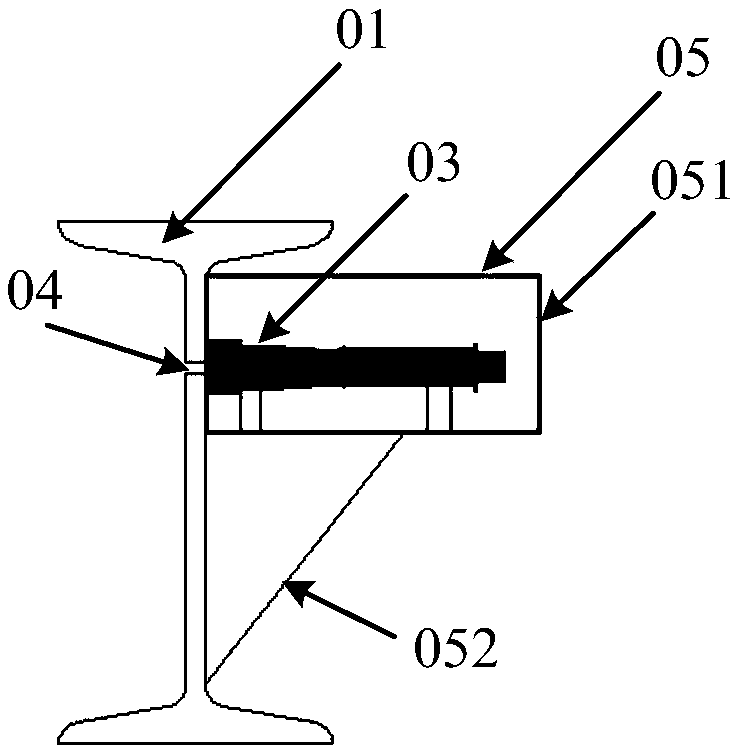

Roadheader suitable for vertical shaft drilling in presence of pilot shaft

The invention discloses a roadheader suitable for vertical shaft drilling in presence of a pilot shaft. The roadheader comprises a main body rack, a rock breaking drill bit, a drive system, a support system and a control system, wherein the drive system comprises a rotation drive sub-system and a pushing drive sub-system; the rock breaking drill bit, the rotation drive sub-system, the pushing drive sub-system, the support system and the control system are mounted on the main body rack respectively; the rotation drive sub-system is in transmission connection with the rock breaking drill bit; the rock breaking drill bit comprises a cutter head and a guide device. The roadheader can be used for drilling vertical shafts with designed diameters sequentially in the presence of the pilot shaft, and when the roadheader is used for vertical shaft drilling, correction equipment is not required under the condition that the borehole deflection degree of the pilot shaft is guaranteed.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

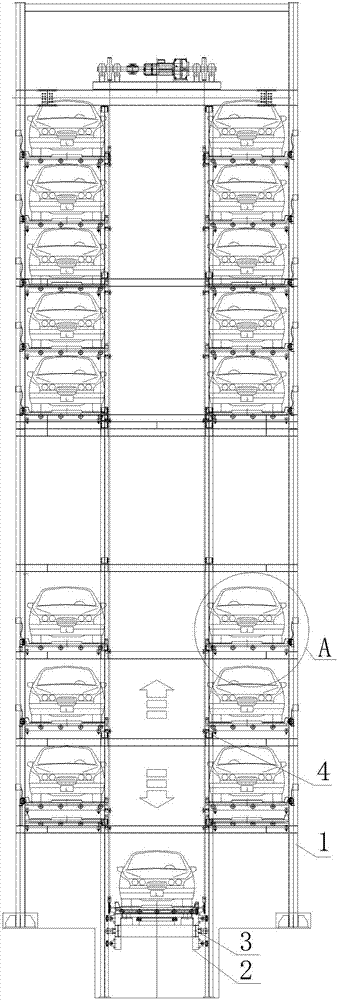

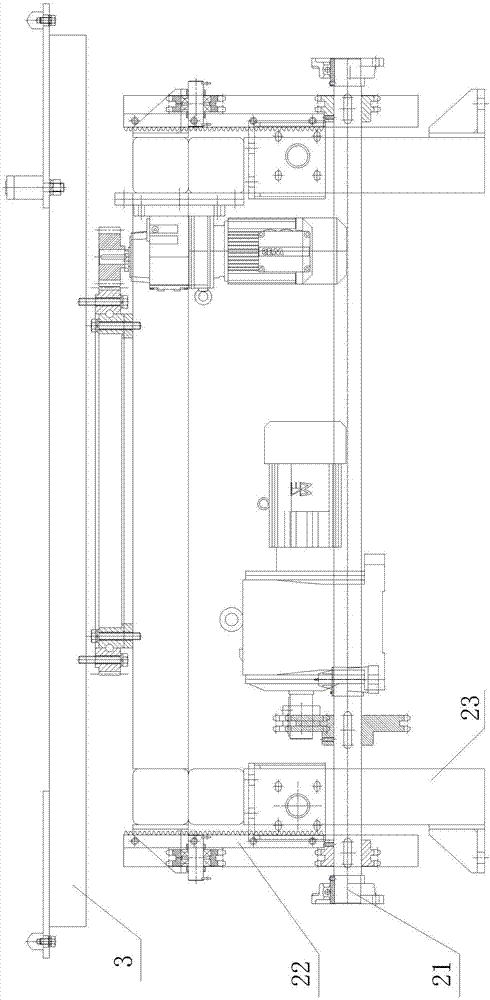

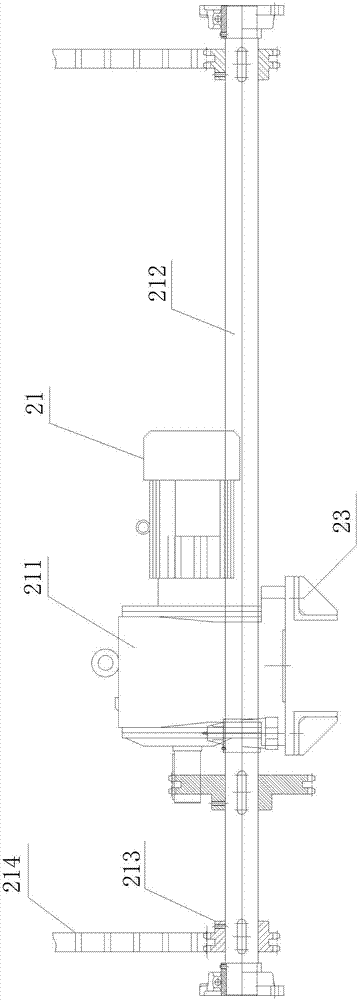

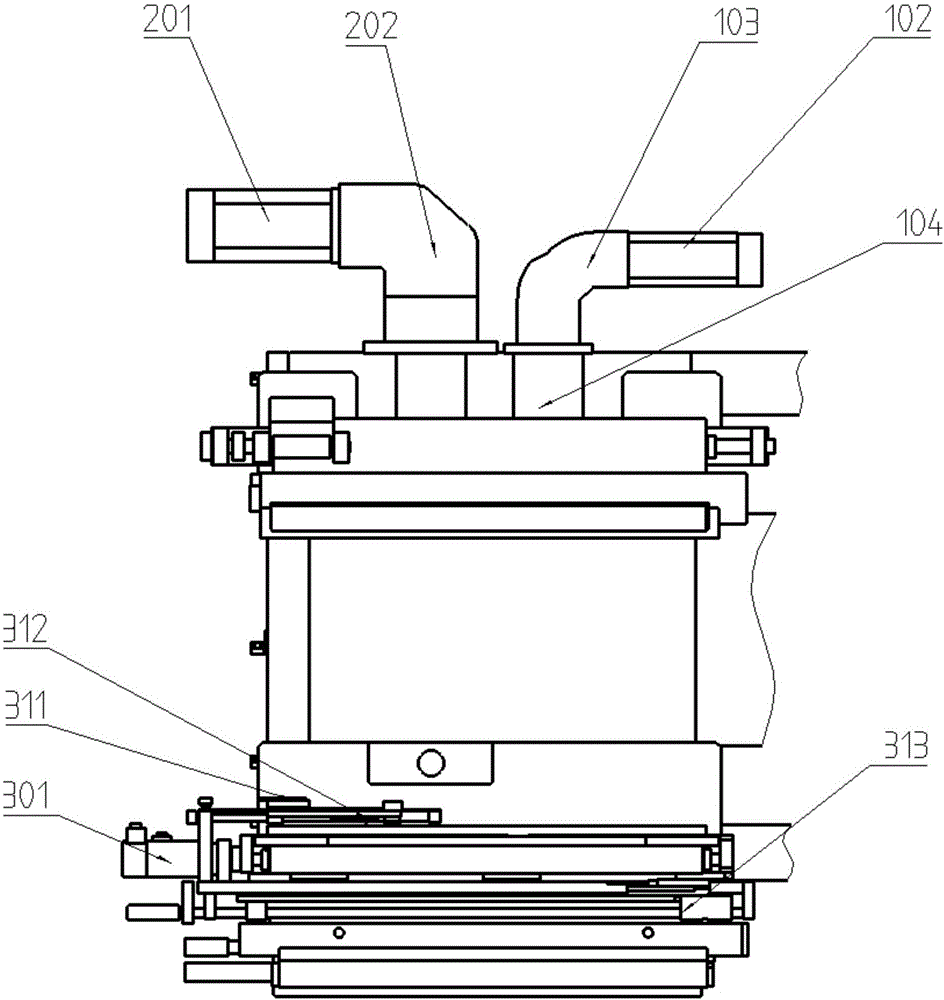

Tower-type parking garage with automatic charging function

ActiveCN107035189ASafe and secure storageWith correction functionVehicular energy storageParkingsTowerControl theory

The invention discloses a tower-type parking garage with an automatic charging function. The tower-type parking garage comprises a fixed support and a lifting carrying device. Multiple layers of garage positions are arranged on the fixed support. The lifting carrying device comprises a mounting support. The tower-type parking garage further comprises a positioning device. The positioning device comprises a vehicle carrying plate positioning device body and a garage position limiting device body. Due to the fact that the positioning device is provided with a positioning block with a bending corner, a positioning wheel can be also clamped in the bending corner of the positioning block if having a certain deviation, and the bending corner further takes the correction effect and can adjust the positioning wheel to the middle of the bending angle, so that vehicle carrying plates are corrected to the horizontal position. The positioning device is further provided with a bent limiting block, and in the same way, a limiting pushing wheel can also squeeze the limiting block to rotate to avoid entering of vehicles into garages if having a certain deviation, so that the positioning device is high in error-tolerant rate and further has a correction function, and it is guaranteed that the vehicles enter the garages stably and safely.

Owner:SHENZHEN YEEFUNG AUTOMATION TECH CO LTD

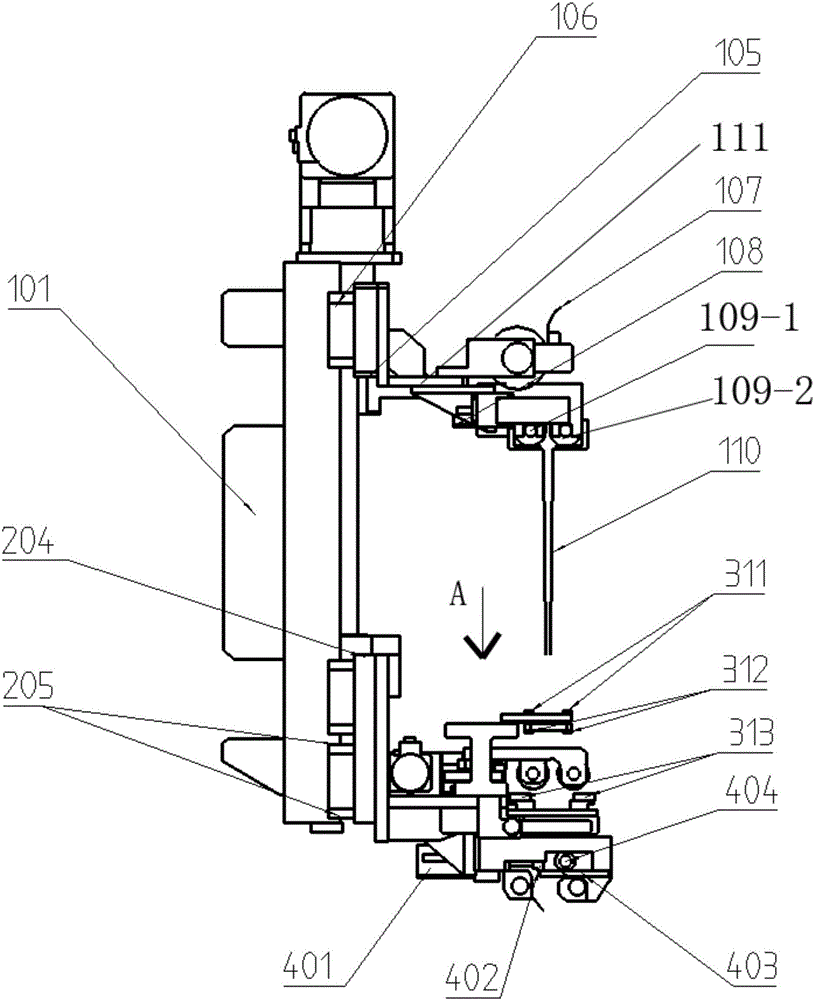

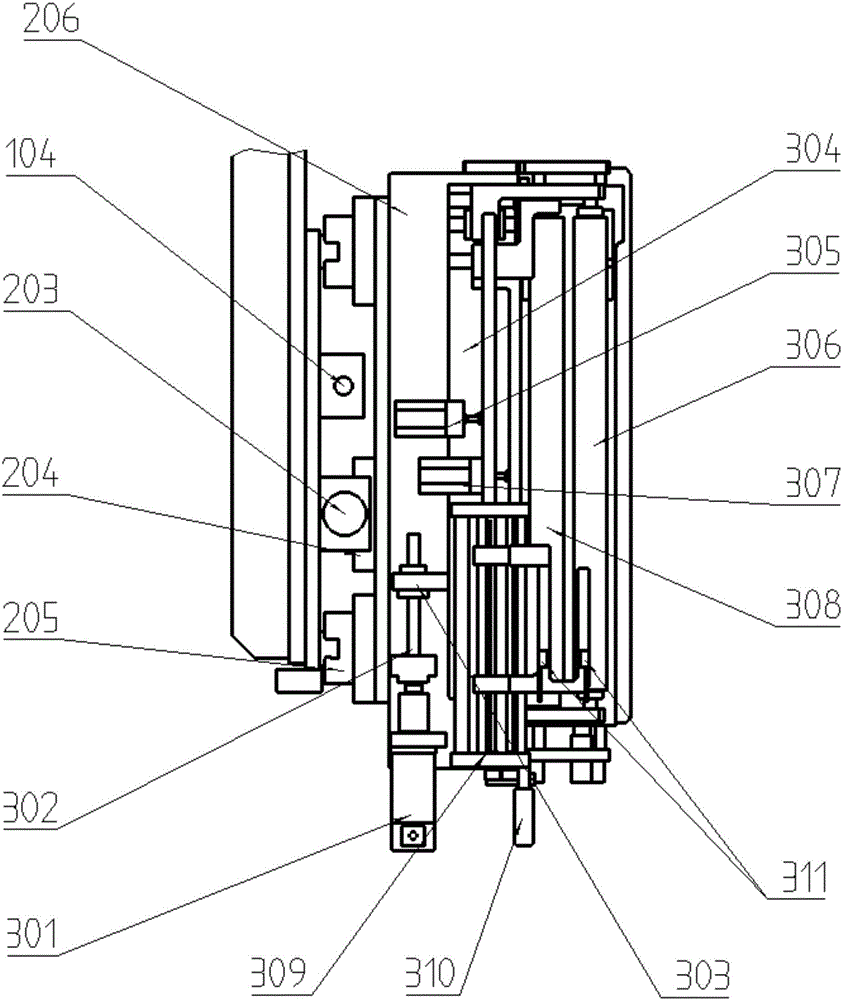

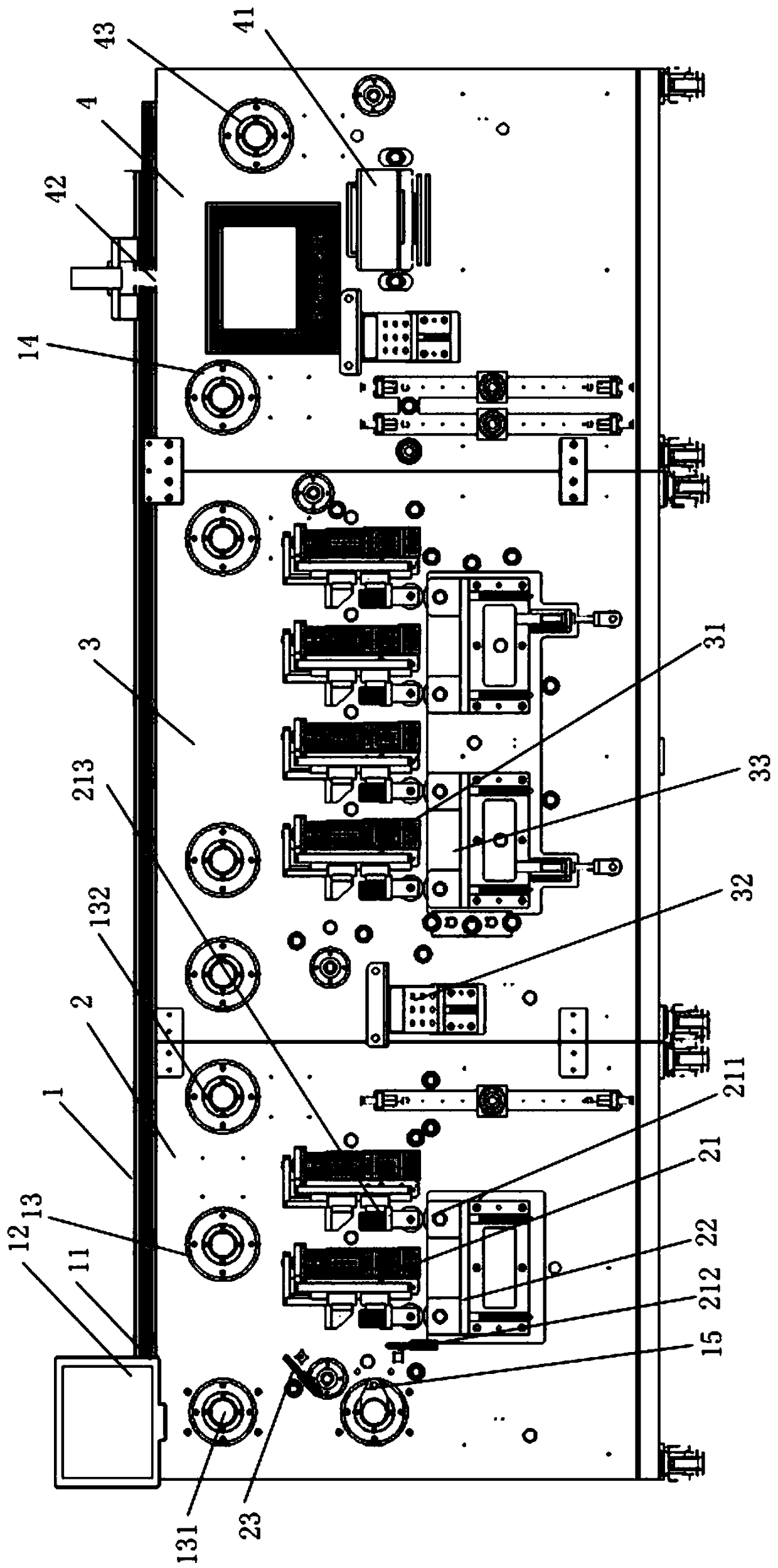

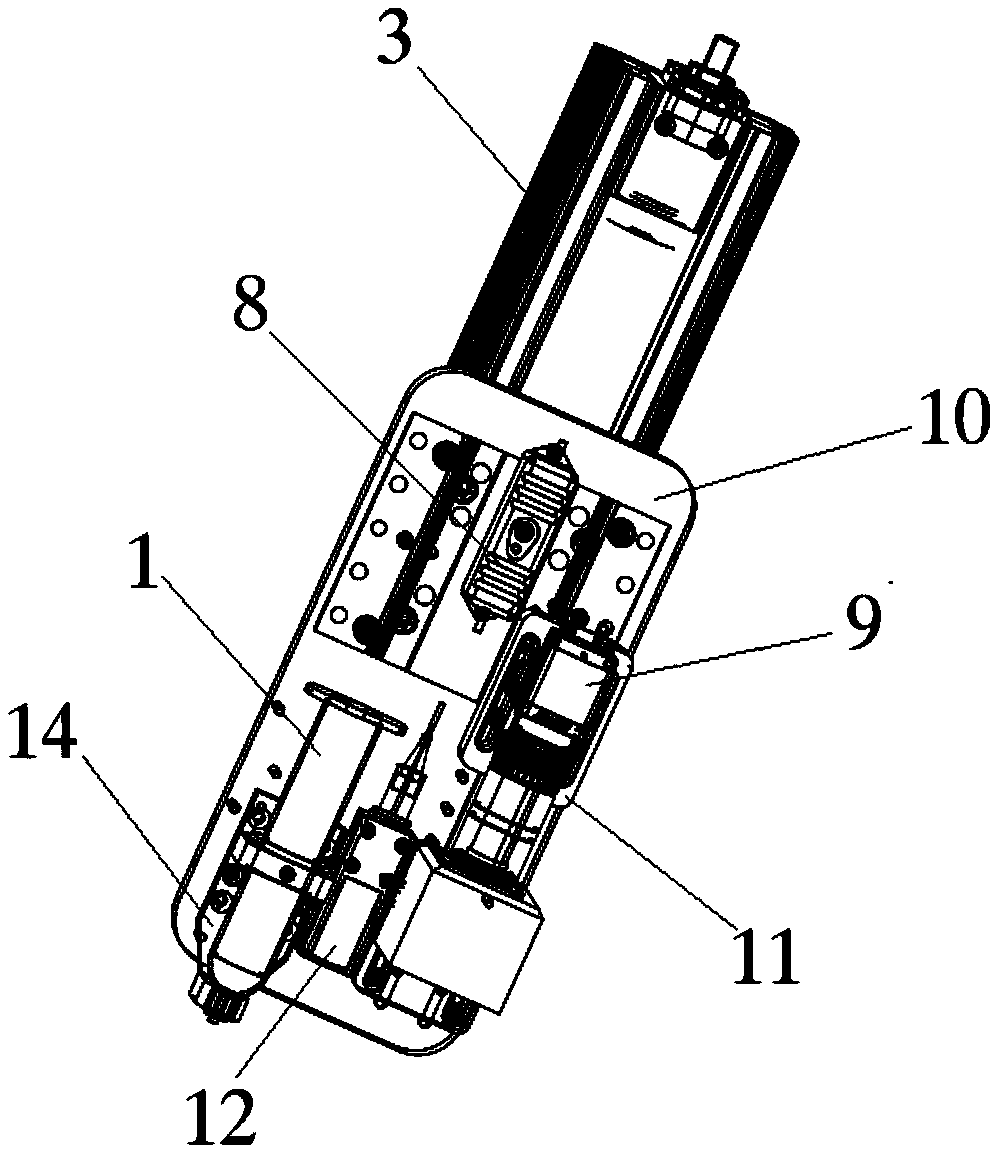

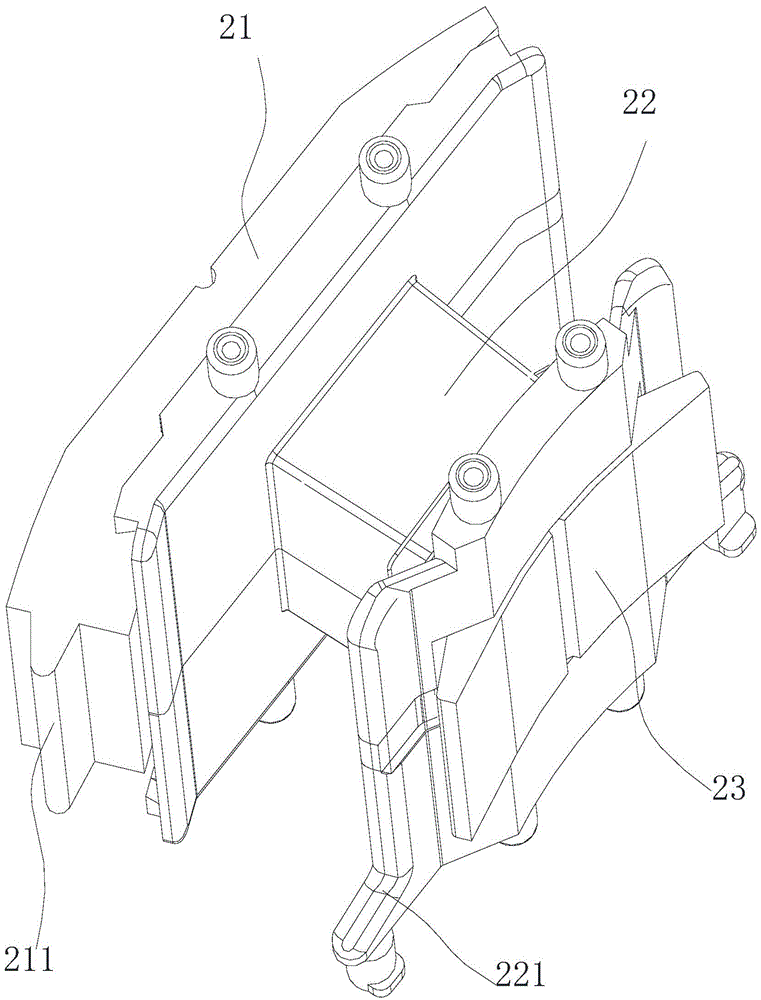

Pole piece fly-cutting mechanism and pole piece fly-cutting method

ActiveCN106410255AImprove cutting efficiencyWith correction functionAssembling battery machinesFinal product manufactureFeed driveEngineering

The invention relates to a pole piece fly-cutting mechanism and a pole piece fly-cutting method. The pole piece fly-cutting mechanism is characterized by comprising a feeding mechanism, a transmission mechanism and a cutter mechanism, the feeding mechanism comprises a first connecting block slidably arranged on a baseplate, the first connecting block is connected with a feeding driving device driving the first connecting block to move up and down and connected with a first connecting plate, a first clamping roller, a rack roller and a clamping driving device are mounted on the first connecting plate, and the first clamping roller and the rock roller are provided with clamping pieces; the transmission mechanism comprises a second connecting block slidably arranged on the baseplate, the second connecting block is connected with a transmission device driving the second connecting block to move up and down and connected with a second connecting plate, and the cutter mechanism is mounted on the second connecting plate. The pole piece fly-cutting method includes that fly-cutting is performed on pole pieces conveying speeds of the feeding mechanism and the cutter mechanism are maintained identical, and cell winding does not need to be stopped in the process of cutting off the pole pieces, so that working efficiency of cell winding is guaranteed.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

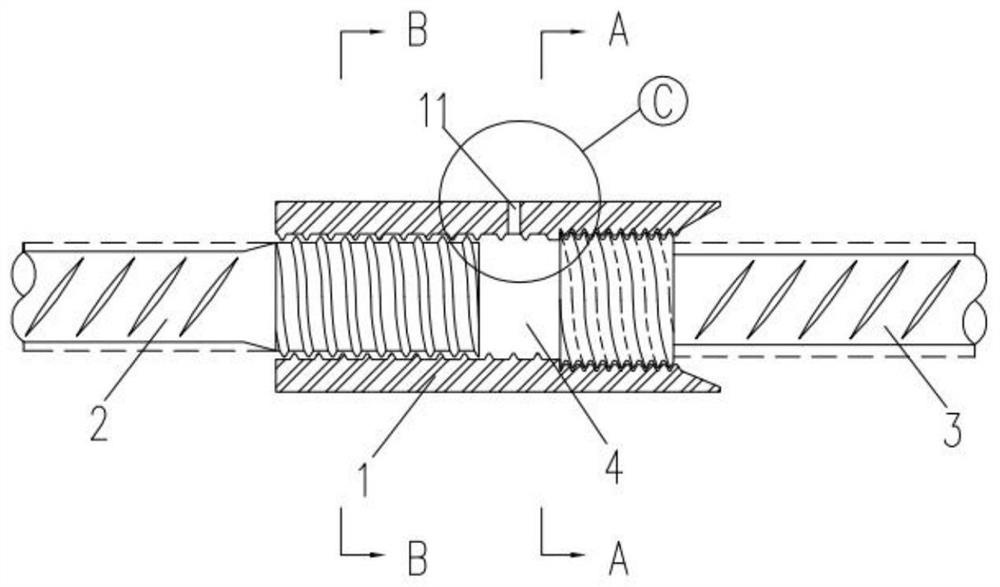

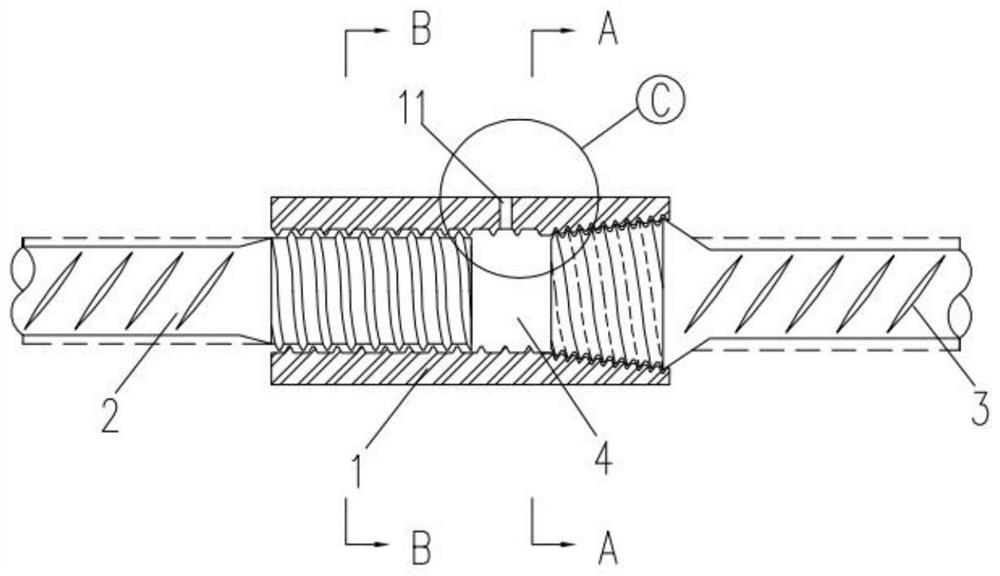

Half-thread glue injection type connecting sleeve design method, thread glue injection type steel bar connecting sleeve, and mounting method thereof

InactiveCN112761308AFirmly connectedWith correction functionBuilding reinforcementsAdhesiveEngineering

The invention discloses a half-thread glue injection type connecting sleeve design method, a half-thread glue injection type steel bar connecting sleeve, and a mounting method thereof. The half-thread glue injection type connecting sleeve is formed by combining a steel sleeve, two steel bars with threads at the ends, and an adhesive. One end of the inner surface of the steel sleeve and the outer surfaces of the ends of the corresponding reinforcing steel bars are machined into threads which are in weak engagement. After the steel sleeve is screwed with the two reinforcing steel bars, internal gaps between the steel sleeve and the reinforcing steel bars are filled with the adhesive, and the two reinforcing steel bars are connected into a whole after the adhesive is cured. Thread pitch of the weak occlusion threads is long, and thread teeth are narrow, so that the steel sleeve can connect two steel bars at any interval, and the other ends of the weak occlusion threads are in weak occlusion connection. After the gaps between the steel sleeve and the weakly-engaged reinforcing steel bars are filled with the adhesive, the strong connection between the two reinforcing steel bars by the connecting sleeve can be realized; and the required connecting strength index can be met by adjusting the length of a connecting thread section between the steel sleeve and the weakly-engaged steel bars.

Owner:TONGJI UNIV

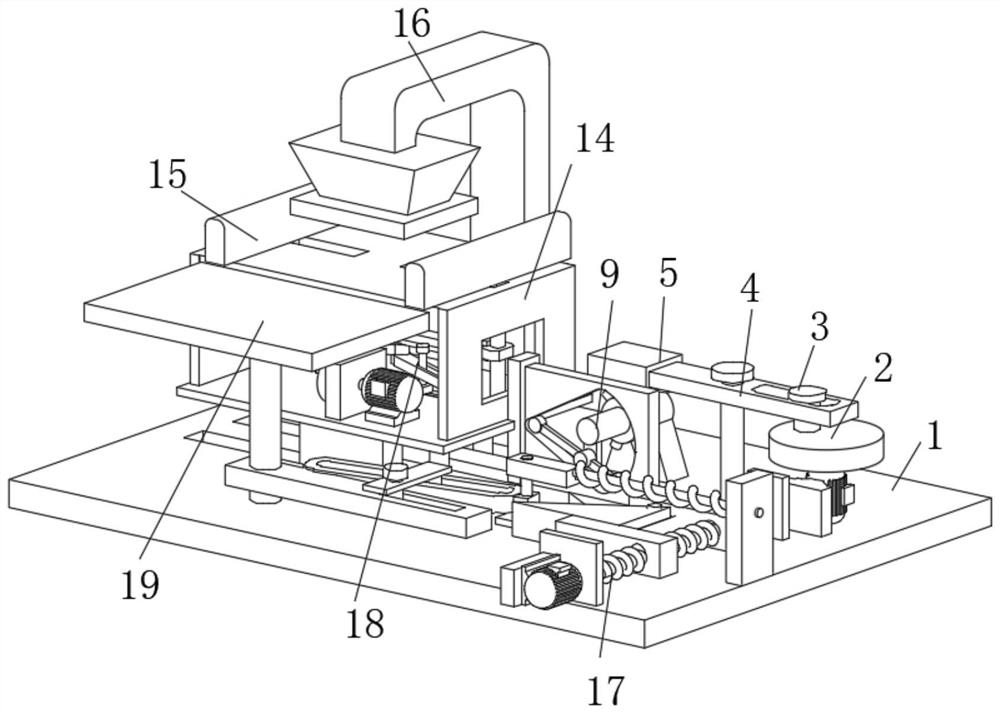

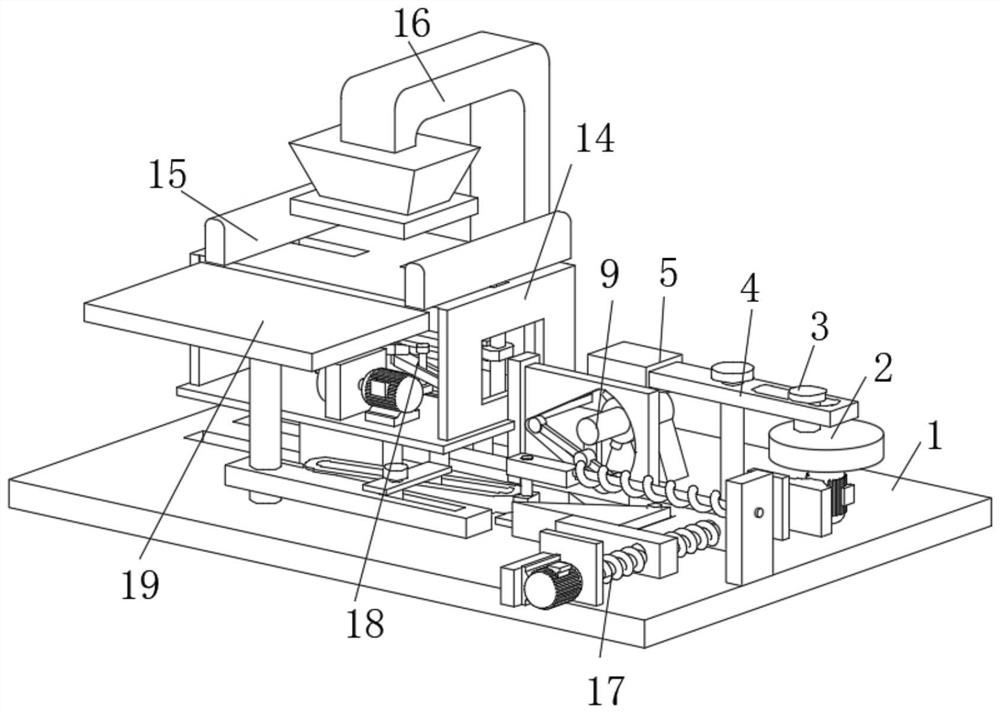

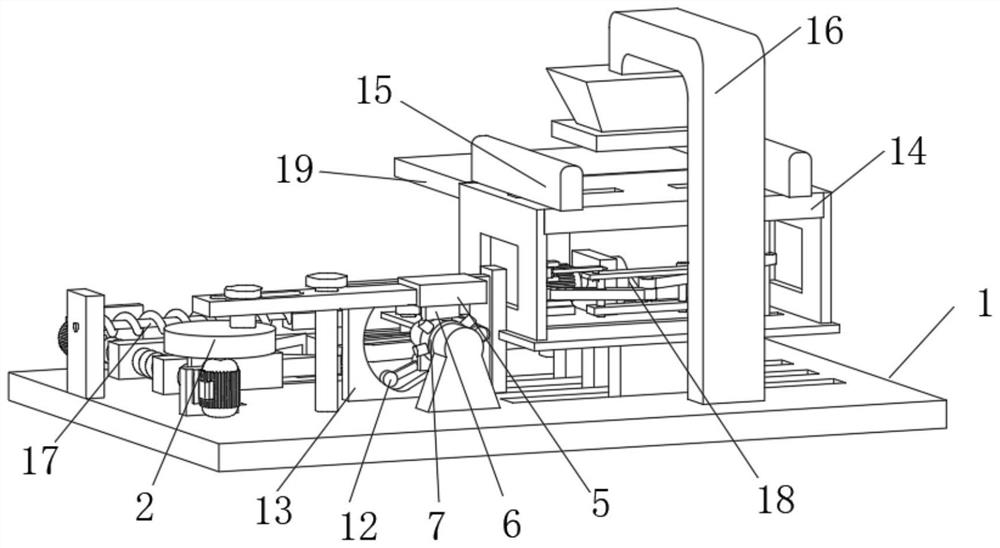

Magnetic crushing online automatic test all-in-one machine

PendingCN109141717AQuick operationImprove production qualityApparatus for force/torque/work measurementMaterial resistanceEngineeringFilm coating

The invention provides a magnetic crushing online automatic test all-in-one machine comprising an equipment body. The equipment body is composed of a film coating section, a magnetic crushing sectionand a test section in turn. The film coating section comprises a film coating mechanism, a tension mechanism, a film coating deviation correction mechanism driven by an automatic deviation correctionmotor, and a film coating servo motor for driving the film coating mechanism and the tension mechanism. The magnetic crushing section comprises a pressing mechanism, a pressure detection system, a tension mechanism and a magnetic crushing deviation correction mechanism driven by an automatic deviation correction motor. The test section comprises an Lcr inductance test mechanism. A feeding mechanism is arranged above the film coating section so as to facilitate the film coating operation. The film coating section, the magnetic crushing section and the test section are on the same horizontal line and arranged in order so as to facilitate overall direction control of the product. The automatic deviation correction device is arranged between the film coating section and the magnetic crushing section and between the magnetic crushing section and the test section so as to control product alignment.

Owner:三众机械设备(太仓)有限公司

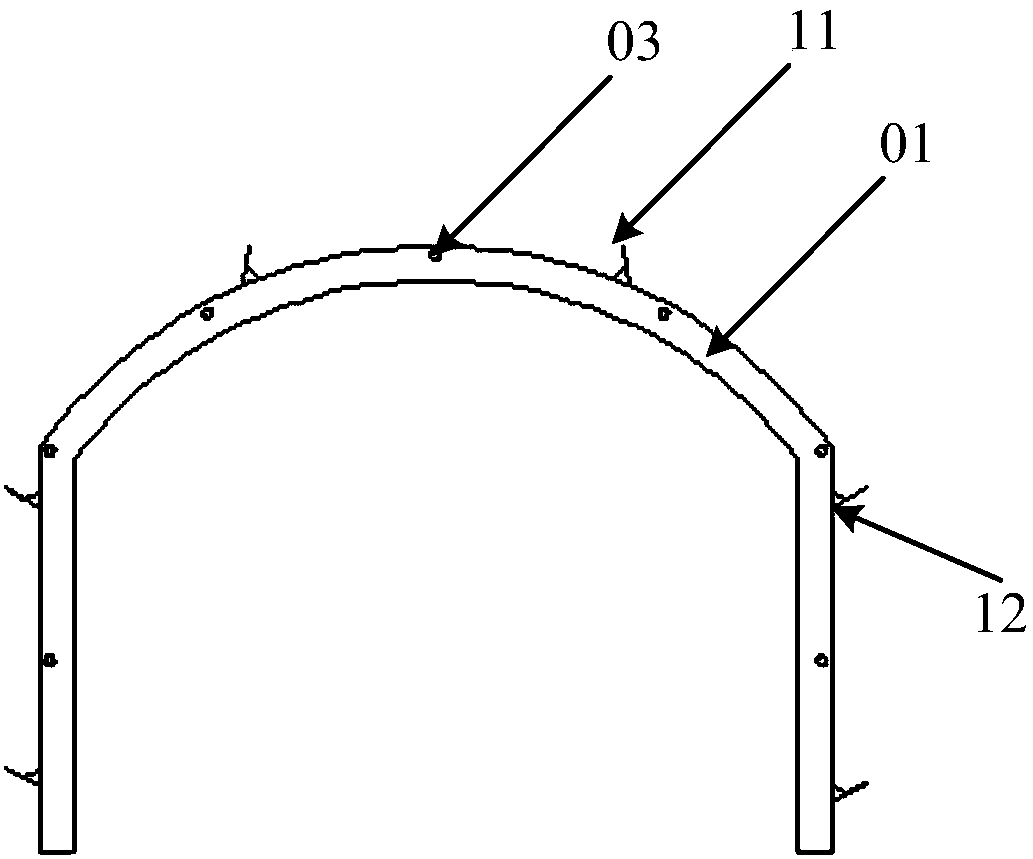

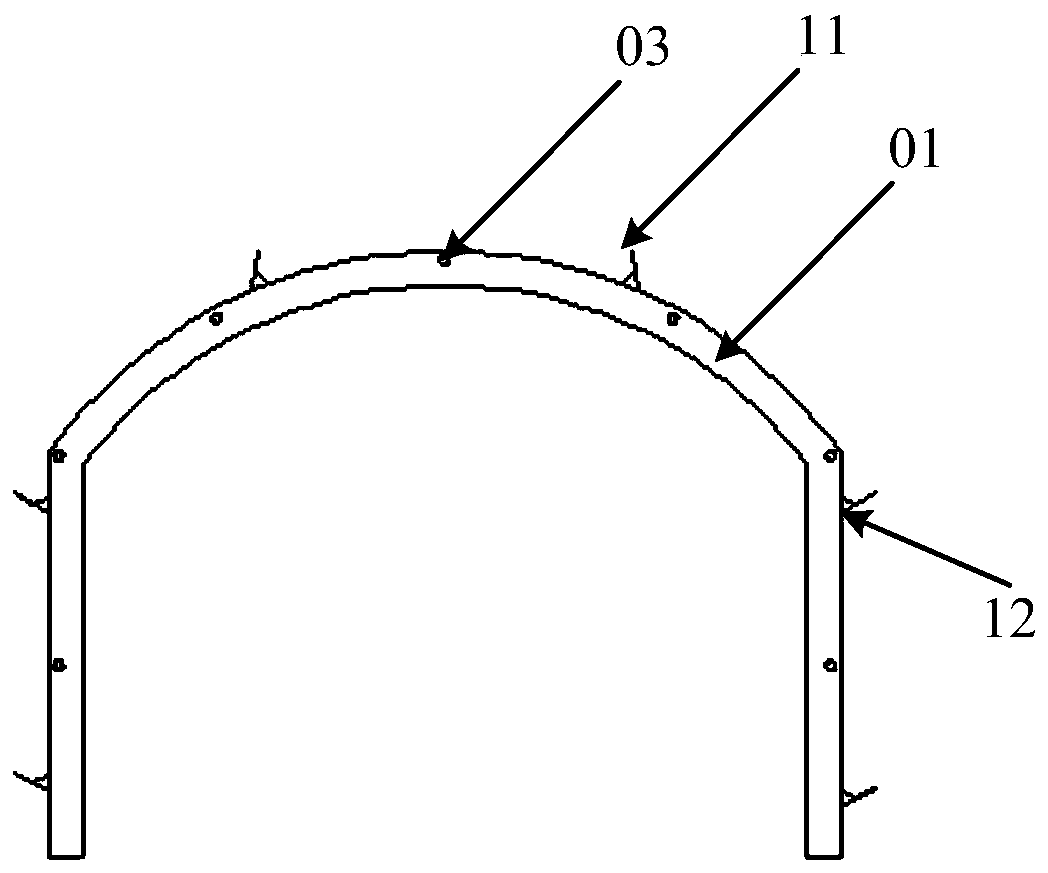

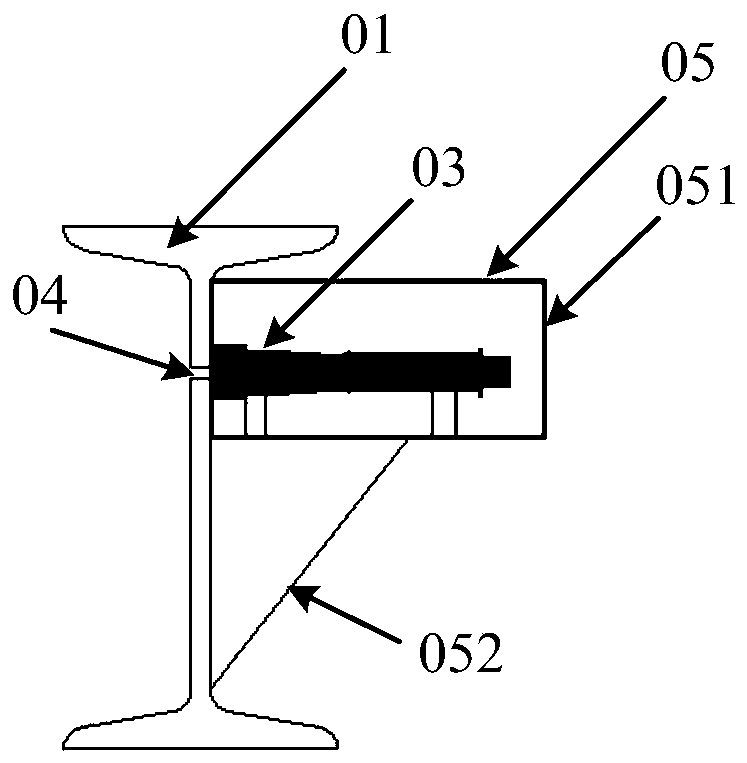

Pay-off device and method

ActiveCN107687842AEasy to makeEasy to operateReference line/planes/sectorsLaser transmitterOptoelectronics

The invention provides a pay-off device and method. The pay-off device comprises a first arching and a plurality of first laser transmitters, wherein the first arching has an outer contour which is the same as that of a target tunnel and is arranged at the outer side of an excavation section; the first laser transmitters are arranged on the first arching at intervals and are used for transmittingfirst laser to the excavation section to form a projection of the contour of the target tunnel. The pay-off device provided by the invention is simple to manufacture and measurement pay-off operationis convenient and has small working amount and high efficiency.

Owner:STATE GRID CORP OF CHINA +3

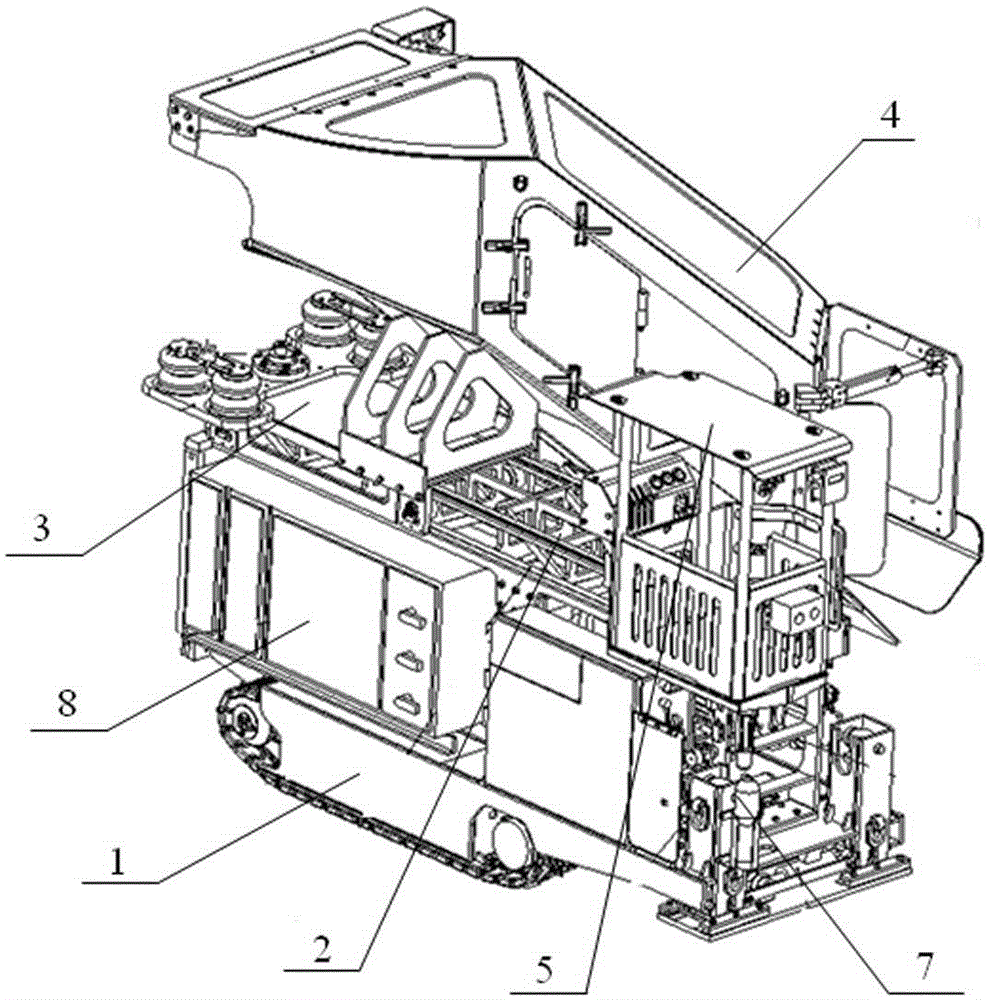

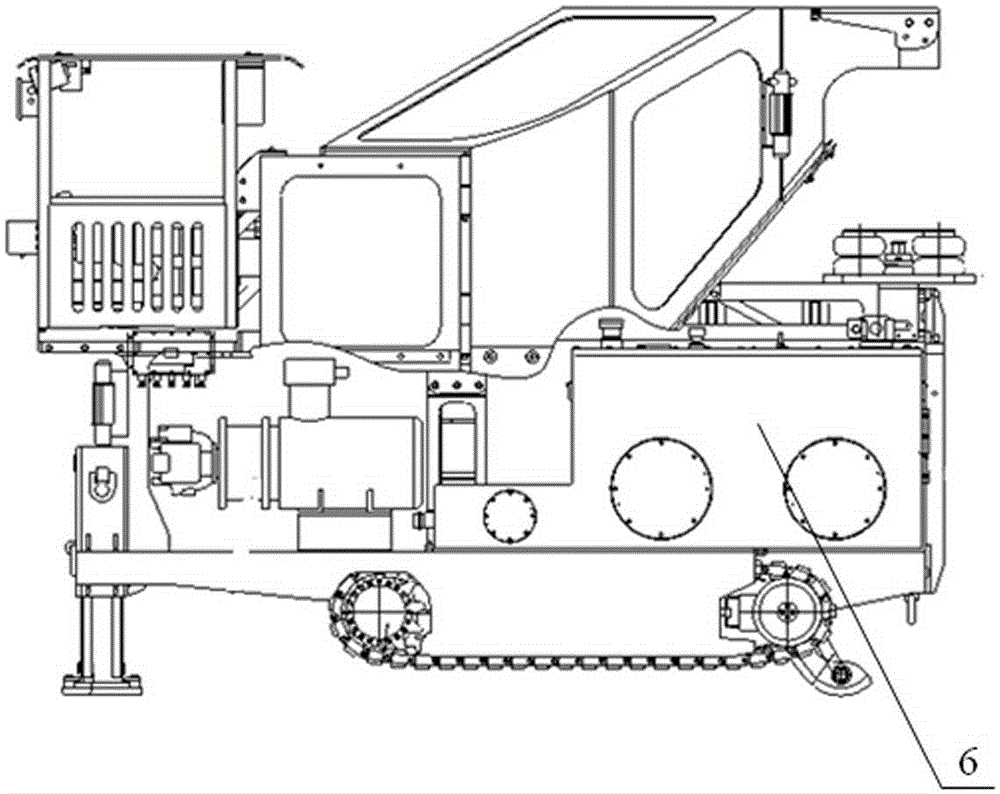

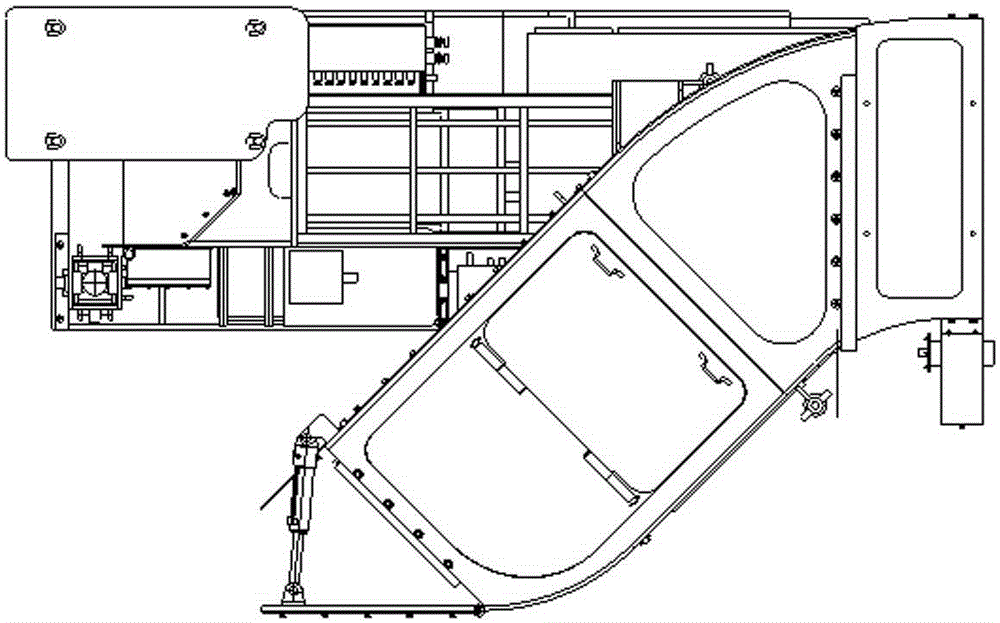

crawler self-moving tail

ActiveCN103758515BThe reprint path is reasonableImprove transport efficiencySlitting machinesTransport systemEngineering

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

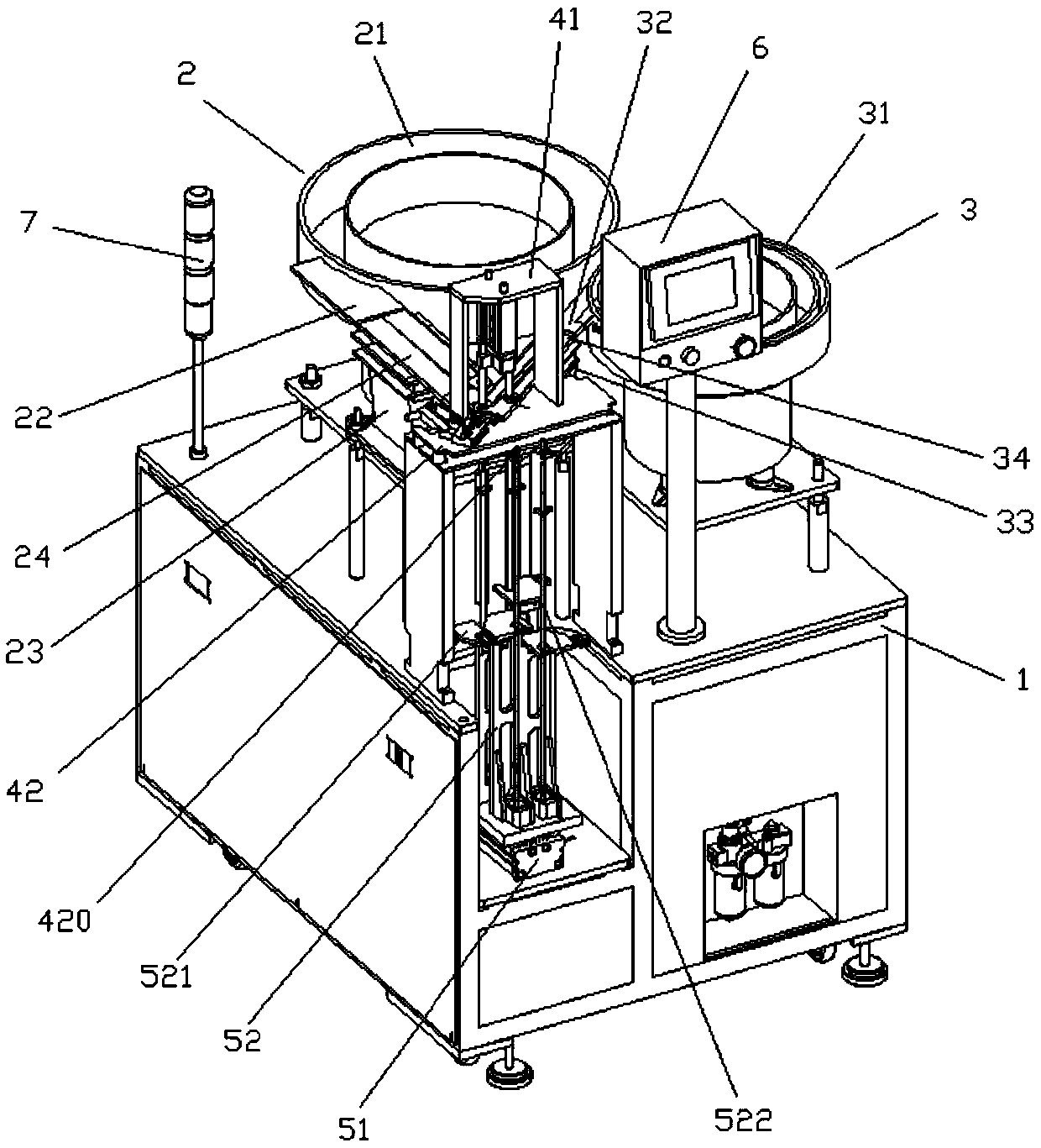

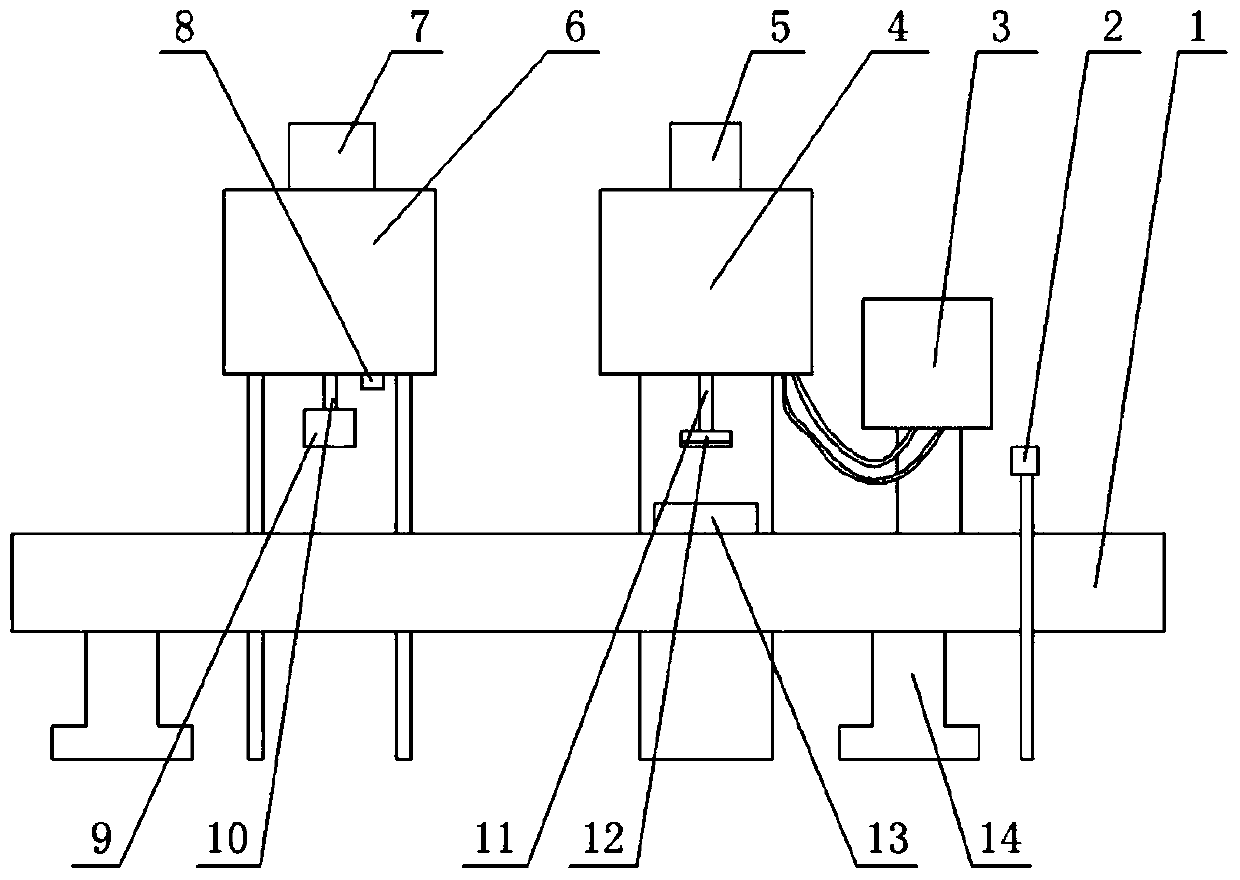

Automatic barcode pasting machine

ActiveCN105292650AWith correction functionEasy to operateManual label dispensersDisplay deviceBarcode

The invention provides an automatic barcode pasting machine and relates to the technical field of goods barcode pasting. The automatic barcode pasting machine comprises a machine frame, a conveying belt is arranged on the machine frame, and a laser thickness gauge is arranged at the right end of the conveying belt. A displayer is arranged at the left side of the laser thickness gauge. A barcode pasting machine body is arranged at the left side of the displayer. A barcode printer a is arranged on the upper portion of the barcode pasting machine body. A connecting rod a is arranged on the lower portion of the barcode pasting machine body. A barcode pasting block a is arranged on the lower portion of the connecting rod a. A barcode scanner is arranged at the left side of the barcode pasting machine body. A barcode printer b is arranged on the upper portion of the barcode scanner. A connecting rod b is arranged on the lower portion of the barcode scanner. A barcode pasting block b is arranged on the lower portion of the connecting rod b. A barcode scanning gun is arranged at the right side of the connecting rod b. The automatic barcode pasting machine is easy to operate, accurate in positioning and capable of achieving barcode pasting full automatically; the barcode pasting process is full automatic, and the leap change from manual operation to full automation is achieved; the barcode pasting efficiency is high, and the cost is reduced; the thickness of goods is measured firstly, and barcode pasting positioning is accurate; a correction function is achieved, and the barcode pasting error rate is low.

Owner:合肥佳田自动化工程科技有限公司

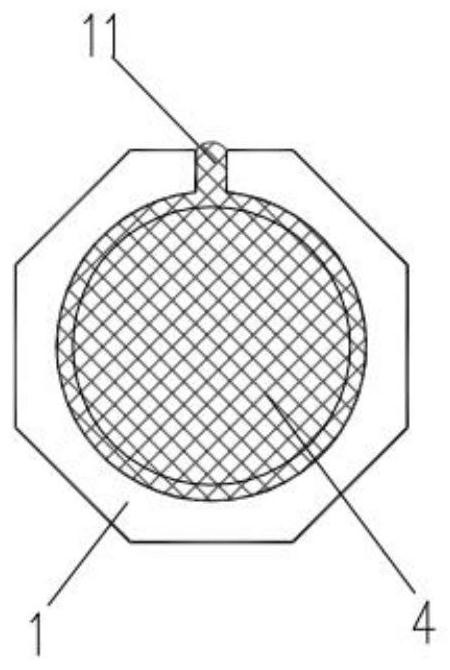

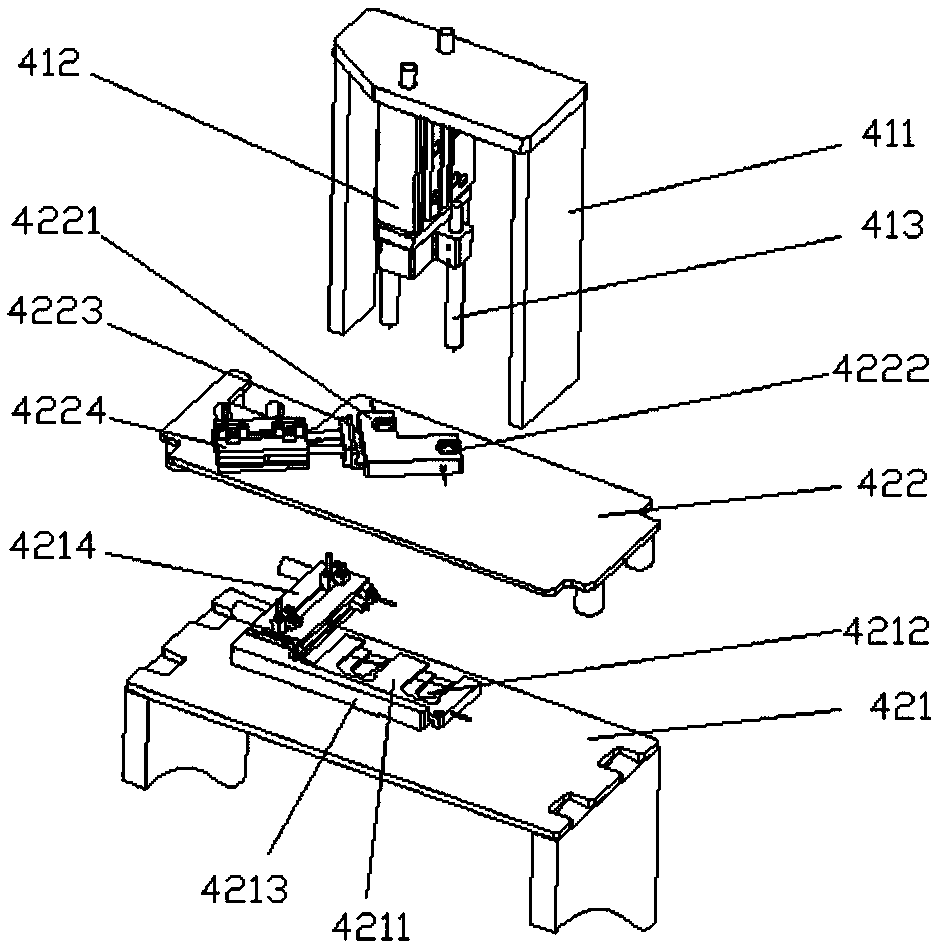

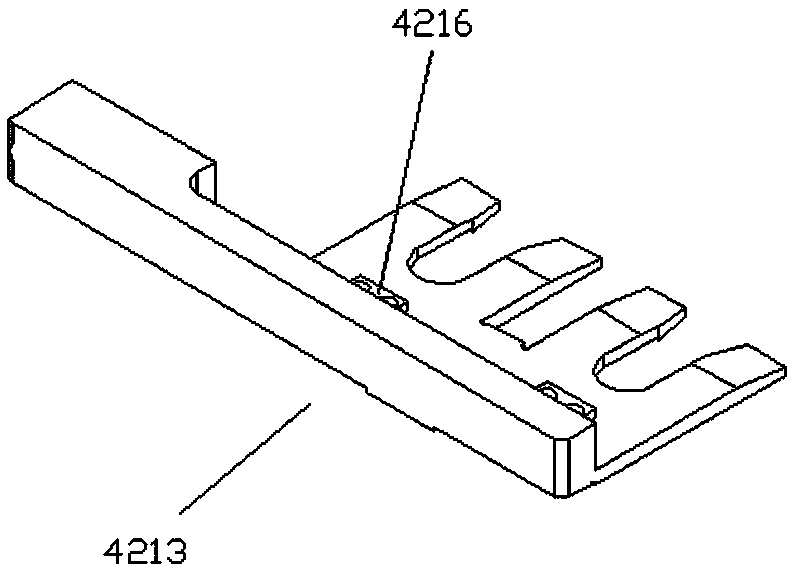

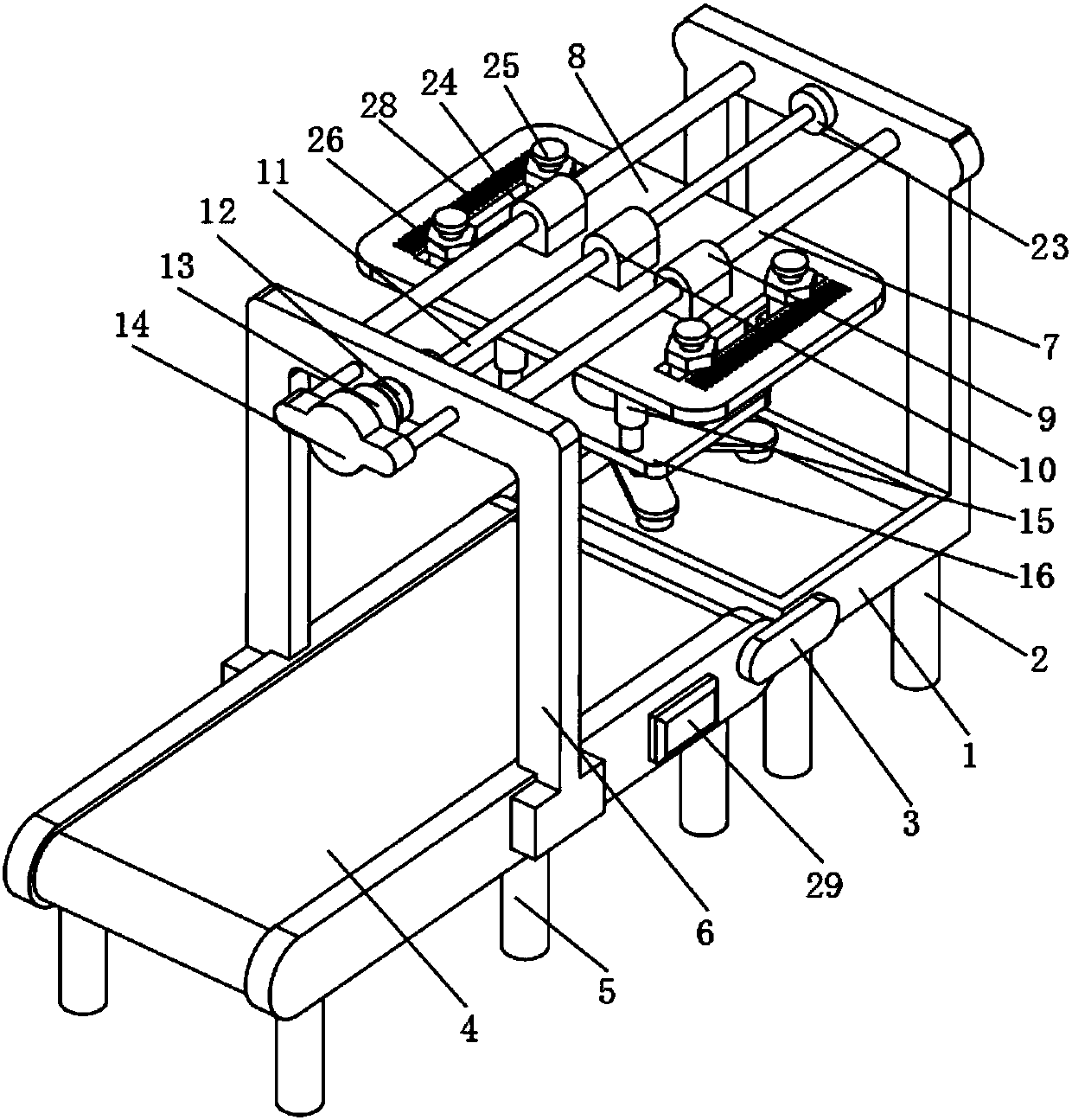

Big ring, small ring and blocking piece string equipment for correction tape automatic production

PendingCN109677870AHigh degree of automationImprove processing efficiencyPackagingConveyor partsBig RipEngineering

The invention discloses big ring, small ring and blocking piece string equipment for correction tape automatic production. A rack is provided with a first feeding mechanism, a second feeding mechanism, a pressing mechanism and a discharging mechanism. The pressing mechanism comprises a guiding part and a pressing part, the pressing part comprises a first support, the first support is provided witha blocking piece receiving base, the blocking piece receiving base is provided with a first discharging hole, the first discharging hole is connected with the first feeding mechanism, the first support is provided with a second support, the second support is provided with a small ring receiving base, the small ring receiving base is provided with a second discharging hole, and the second discharging hole is connected with the second feeding mechanism. The discharging mechanism is arranged below the first support and provided with string rods capable of receiving materials rotatablely and receiving small rings and blocking pieces adjusted by the guiding part. The equipment can realize automatic feeding, automatic pressing and automatic discharging of the small rings and the blocking piecesand has a high automation degree; meanwhile the processing efficiency can be improved because of the design of two conveying channels; and a guiding column has a deviation rectification function so that precise discharging can be achieved.

Owner:科思通自动化设备(苏州)有限公司

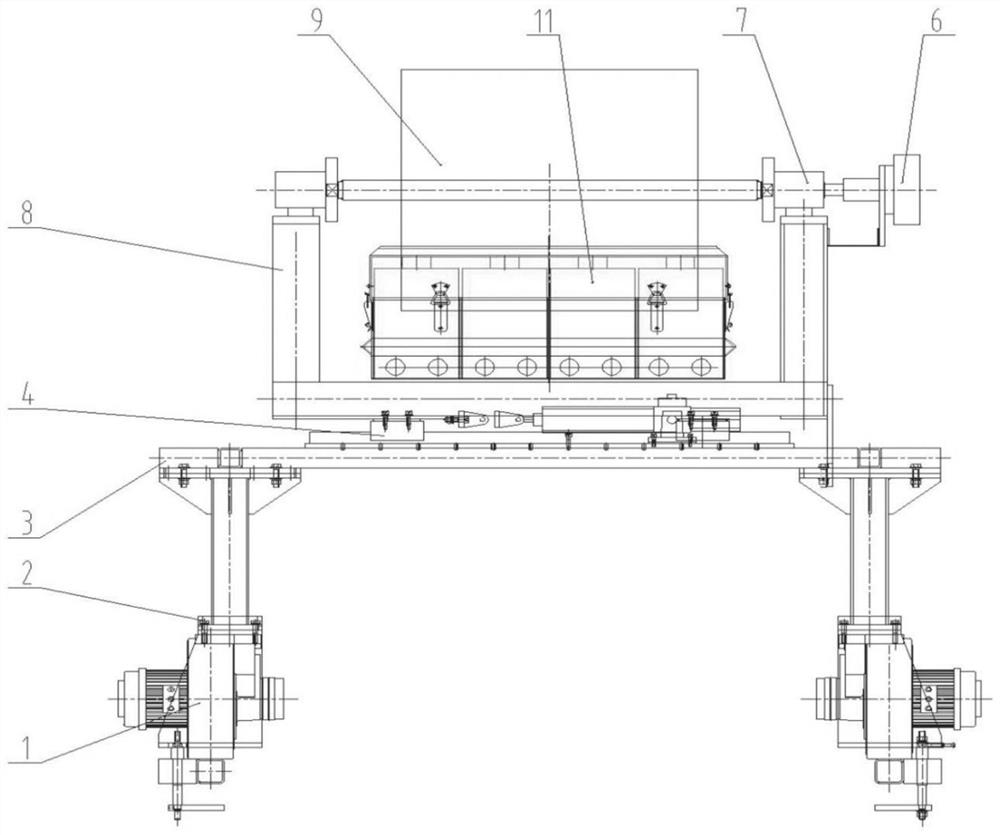

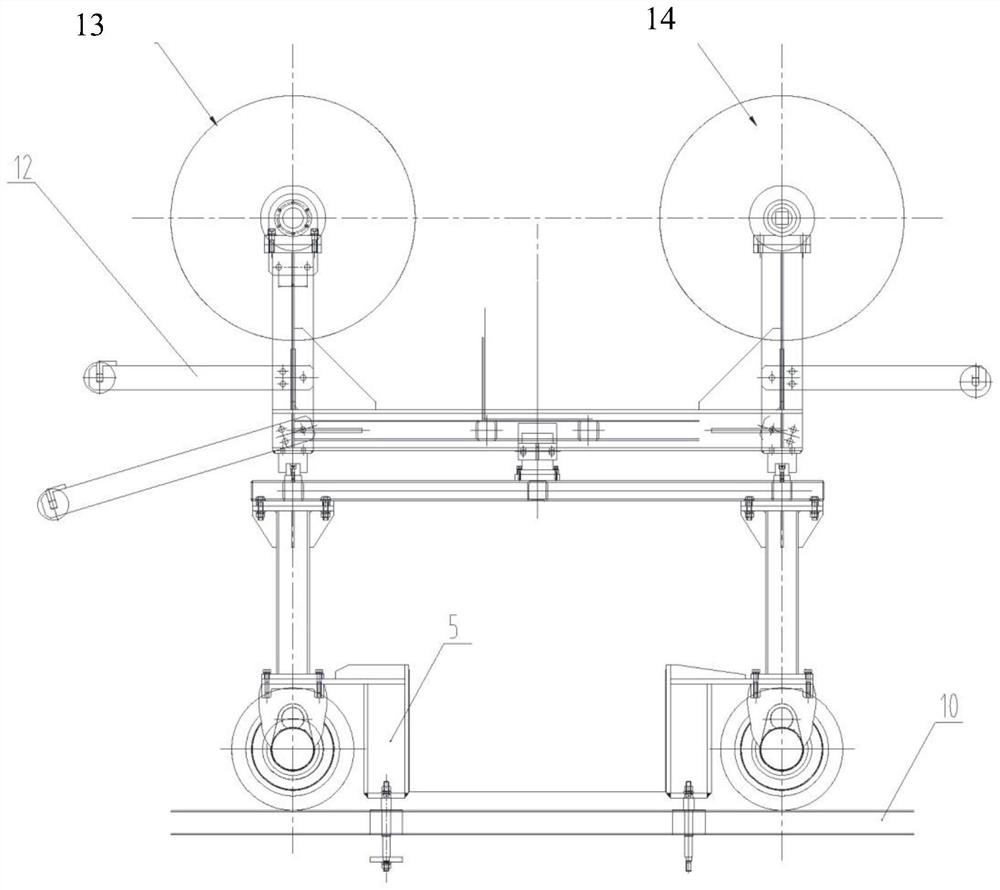

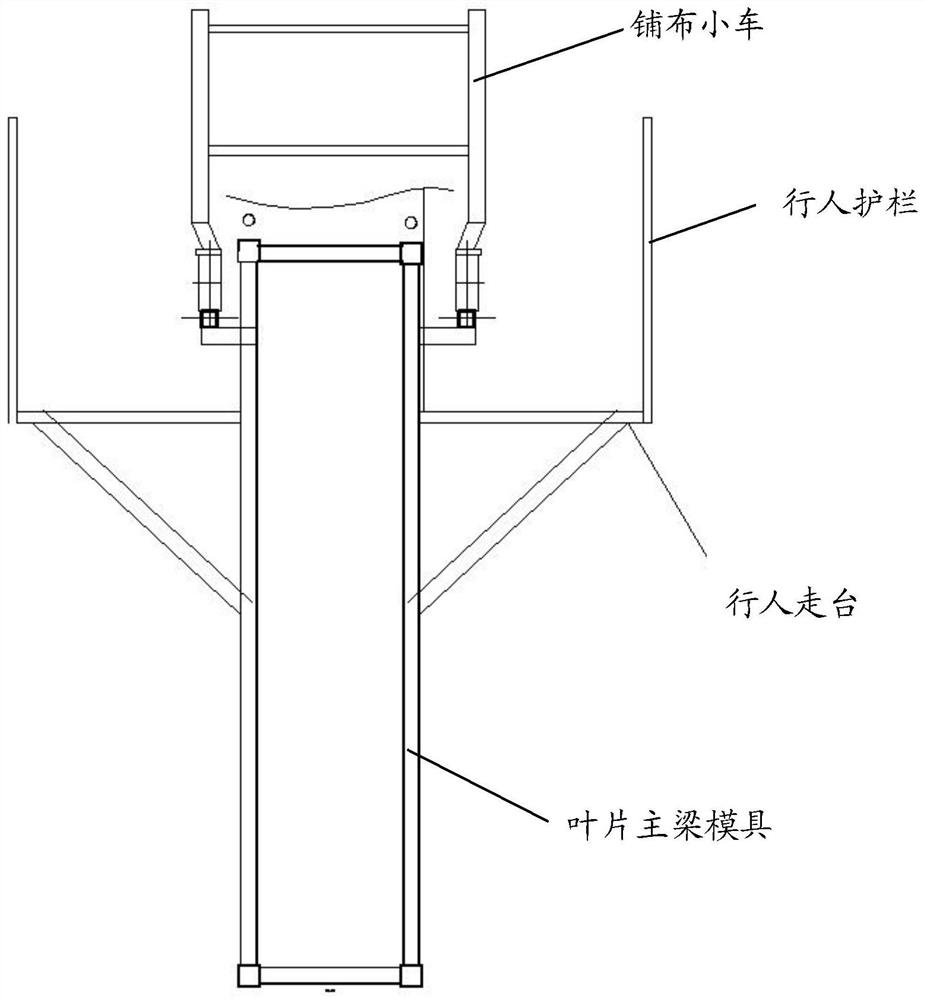

Automatic cloth paving equipment for wind power blade girder

The invention discloses automatic cloth paving equipment for a wind power blade girder. The automatic cloth paving equipment comprises: a track; a cloth paving trolley which reciprocates on a preset track; a first cloth paving assembly and a second cloth paving assembly which are arranged on the cloth paving trolley and used for driving a first cloth roll and a second cloth roll on the two sides to rotate relatively; and a control system which is connected with the first cloth paving assembly and the second cloth paving assembly and used for controlling the first cloth paving assembly and the second cloth paving assembly to perform relative layer paving so as to realize relative layer paving of a blade girder mold. The automatic cloth paving equipment has a cloth deviation rectifying function; four wheels and a variable-speed transmission device are adopted, so that the gradeability is excellent; two cloth winding shafts are adopted, so that reciprocating uninterrupted cloth paving can be realized, the efficiency is high, the tension of the cloth can be controlled, various safety protection measures are provided, and the problem of traditional, heavy and tedious labor activities of manually unfolding, paving and edge aligning fiber cloth in the production process is solved, automatic production is achieved, labor force is liberated, labor is saved, and efficiency is improved.

Owner:国能联合动力技术(保定)有限公司

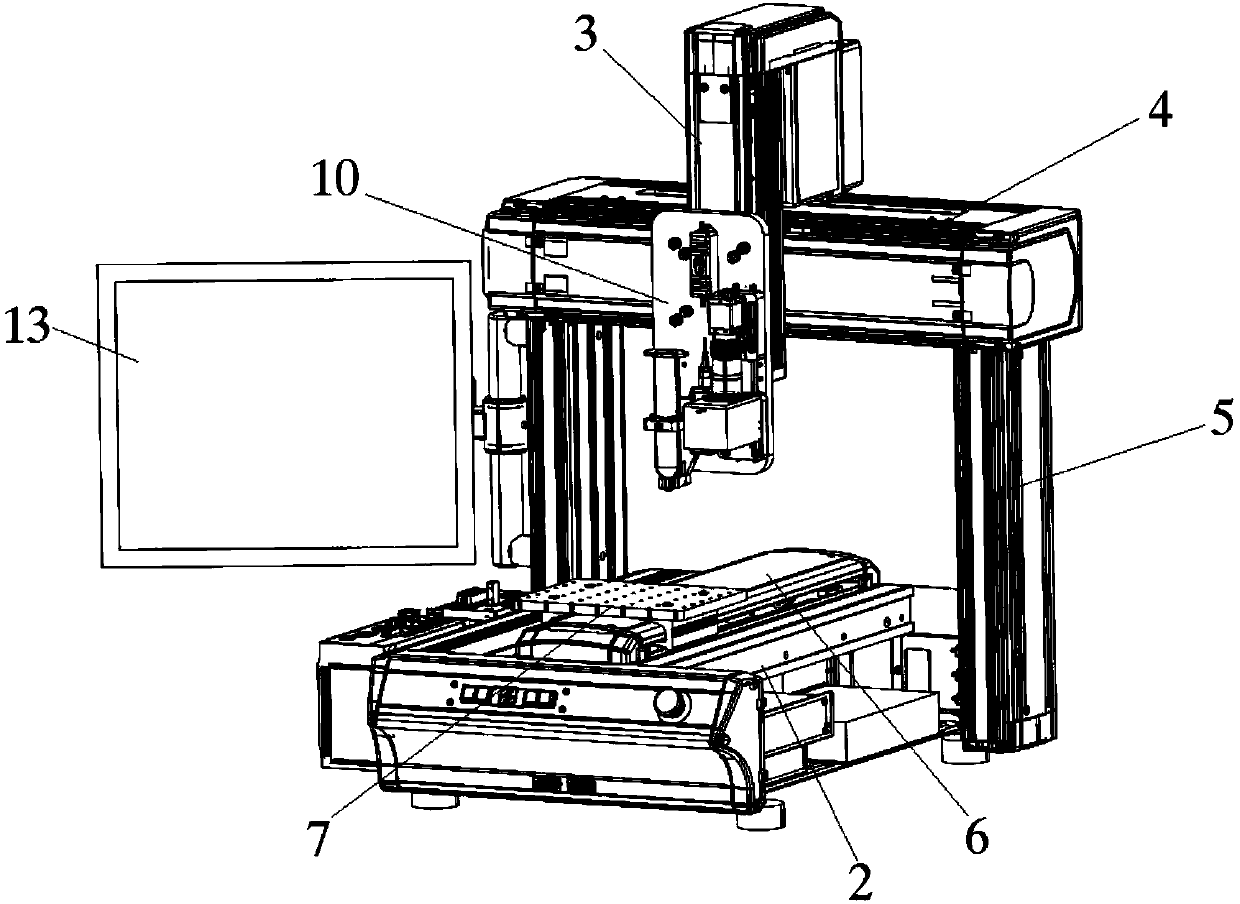

A desktop type glue dispensing robot

PendingCN107774517AImprove dispensing accuracyGuaranteed dispensing accuracyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A desktop type glue dispensing robot is disclosed. The robot includes a glue dispensing mechanism and a movement mechanism. The glue dispensing mechanism is fixed to a first movable arm, and can slideup and down along the first movable arm. The first movable arm is perpendicularly disposed on a second movable arm, and can slide left and right along the second movable arm. Two ends of the second movable arm are perpendicularly fixed between two vertical pillars. The two vertical pillars are fixed to two sides of a glue dispensing desktop respectively. The third movable arm is provided with a slide block in a slide manner, and the slide block can slide along the third movable arm backward and forward. The glue dispensing mechanism includes a glue dispensing valve. CCD detection and height measurement by laser ensure high-precision glue dispensing, requirements on product positions are low, and a glue dispensing position can be automatically recognized.

Owner:SUZHOU TERUITE ROBOT CO LTD

An automatic labeling machine

ActiveCN105292650BWith correction functionEasy to operateManual label dispensersBarcodeDisplay device

The invention provides an automatic code labeling machine, which relates to the technical field of code labeling of goods, comprising a frame, a conveyor belt is provided on the frame, a laser thickness gauge is provided at the right end of the conveyor belt, and a display is provided on the left side of the laser thickness gauge. There is a labeling machine on the left side, a barcode printer a on the upper part of the labeling machine, a connecting rod a on the lower part of the connecting rod a, a labeling block a on the lower part of the connecting rod a, and a code scanning machine on the left side of the labeling machine. The upper part of the code scanning machine is provided with a barcode printer b, the lower part of the code scanning machine is provided with a connecting rod b, the lower part of the connecting rod b is provided with a code sticking block b, and the right side of the connecting rod b is provided with a code scanning gun. The present invention is easy to operate, accurate in positioning and fully automatic for labeling. The process of labeling is fully automated, which realizes a leap from manual operation to full automation; the labeling efficiency is high and the cost is saved; the thickness of the goods is measured first, and the labeling and positioning are accurate; Correction function, low labeling error rate.

Owner:合肥佳田自动化工程科技有限公司

Paper conveyor with paper deviation rectifying function

PendingCN107673097AWith correction functionEasy to correctRegistering devicesArticle feedersCouplingEngineering

The invention discloses a paper feeding machine with the function of correcting the deviation of paper. The front surface and the rear surface of the frame and the conveyor belt conveyor are fixedly connected by connecting plates, the lower surface of the conveyor belt conveyor is provided with a pillar, the front surface of the conveyor belt conveyor is provided with a PLC controller, and the upper side of the conveyor belt conveyor is provided with a The support frame, and the lower right end and the lower left end of the support frame are fixedly connected to the placement frame and the conveyor belt conveyor respectively. A screw is provided in the middle of the upper surface of the support frame, and the left end of the screw is fixedly connected to the output shaft of the servo motor through a coupling. , The paper feeder with paper deviation correction function can be adjusted, can absorb and transport paper of different sizes, and can correct the deviation of the absorbed paper, saving manpower, reducing the workload of operators, simple operation and convenient use.

Owner:张峰

Pneumatic clamp with rotary suction cup

PendingCN112897055ARealize the rotation correction functionImprove reliabilityControl devices for conveyorsGear wheelElectric machinery

Owner:XINHUA HUNAN MEDICAL TECH CO LTD

Calibration and detection equipment of vehicle main girder

InactiveCN101734234BImprove efficiencyShorten the timeMeasurement devicesVehicle servicing/repairingMarine engineering

Owner:傅景宽

A device and method for unwinding

ActiveCN107687842BEasy to makeEasy to operateReference line/planes/sectorsLaser transmitterStructural engineering

The invention provides a pay-off device and method. The pay-off device comprises a first arching and a plurality of first laser transmitters, wherein the first arching has an outer contour which is the same as that of a target tunnel and is arranged at the outer side of an excavation section; the first laser transmitters are arranged on the first arching at intervals and are used for transmittingfirst laser to the excavation section to form a projection of the contour of the target tunnel. The pay-off device provided by the invention is simple to manufacture and measurement pay-off operationis convenient and has small working amount and high efficiency.

Owner:STATE GRID CORP OF CHINA +3

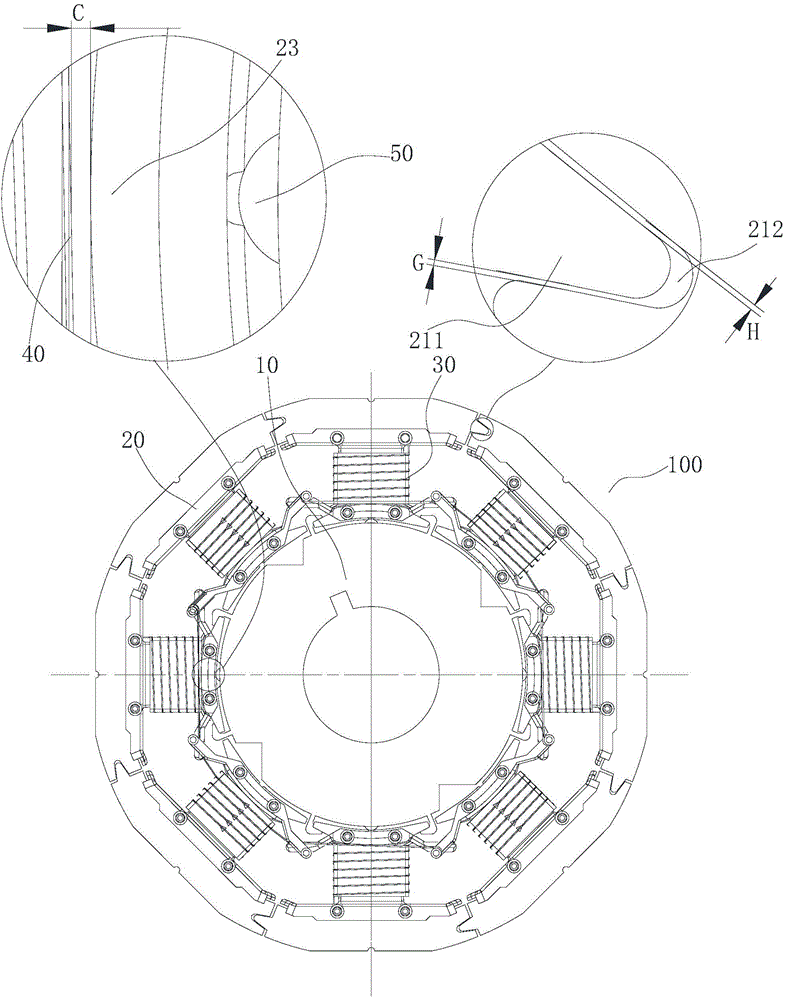

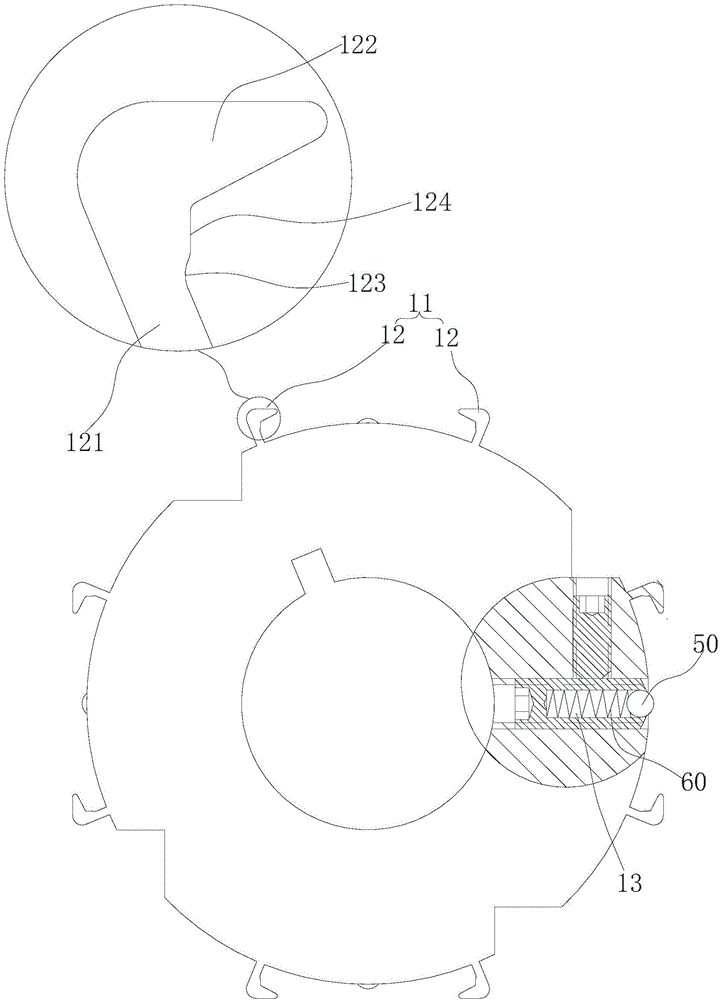

Partitioned motor

ActiveCN104868669AEasy to installWith correction functionMagnetic circuit stationary partsWindings conductor shape/form/constructionMechanical engineeringStator

The invention discloses a partitioned motor, which comprises a connection block, multiple coils, and an elastic piece, wherein the periphery of the connection block is provided with multiple mounting parts, and each mounting part comprises two hooks respectively; multiple partitioned stators are arranged at intervals along the circumferential direction of the connection block and connected with the mounting parts respectively; the multiple coils are wound on the multiple partitioned stators respectively, a mounting groove is arranged between the two hooks of each mounting part respectively, and each mounting groove is internally provided with a mobile abutting ball along the axial direction of the mounting groove; and two ends of the elastic piece abuts against the bottom wall of the mounting groove and the abutting ball so as to enable the abutting ball to abut against the partitioned stator. According to the partitioned motor of the embodiment of the invention, mounting of the partitioned stator on the connection block is firmer, an alignment function is provided, coils wound on the multiple partitioned stator can be easily combined via the connection block, the partitioned stators can be uniformly and symmetrically distributed, and the partitioned stator combination success rate is improved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

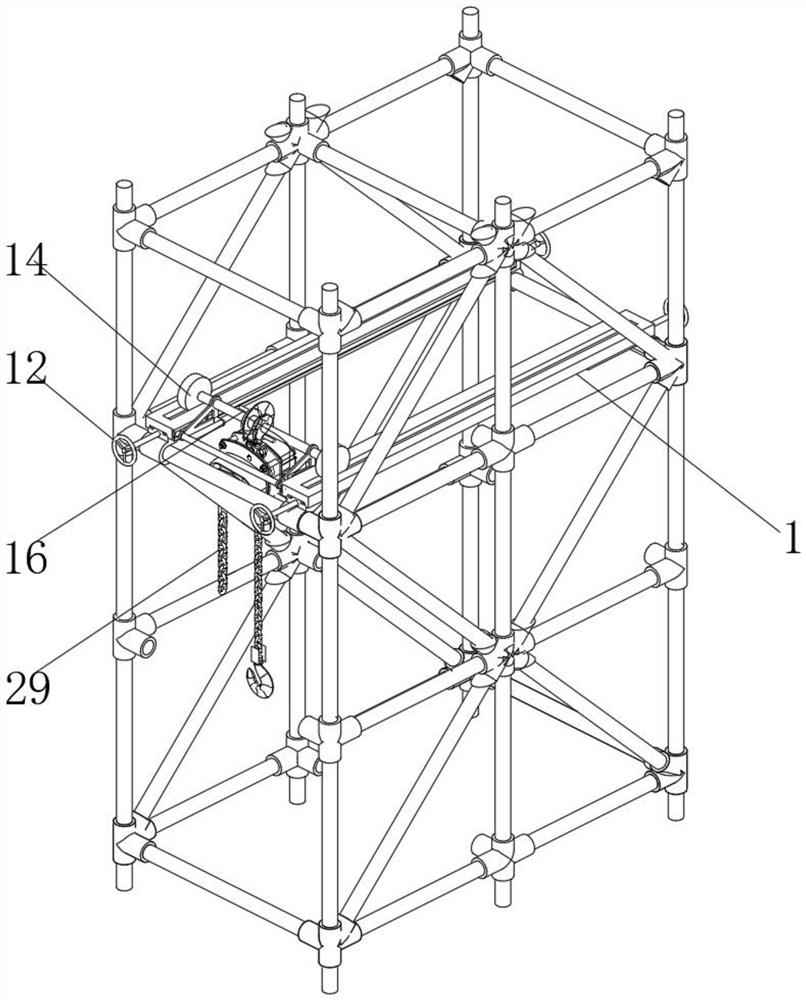

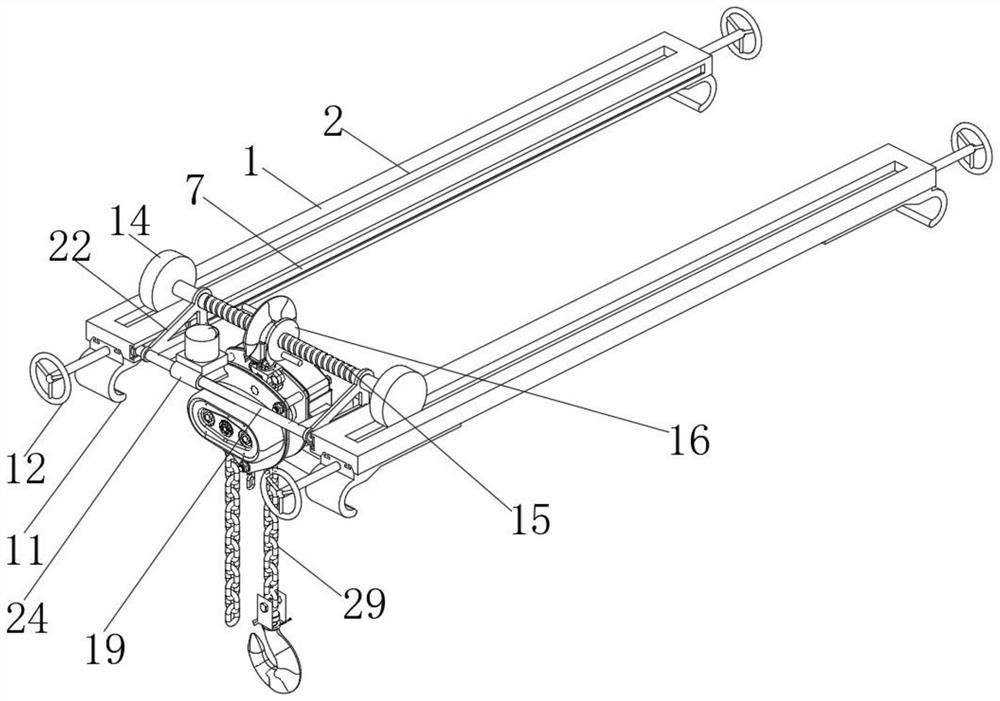

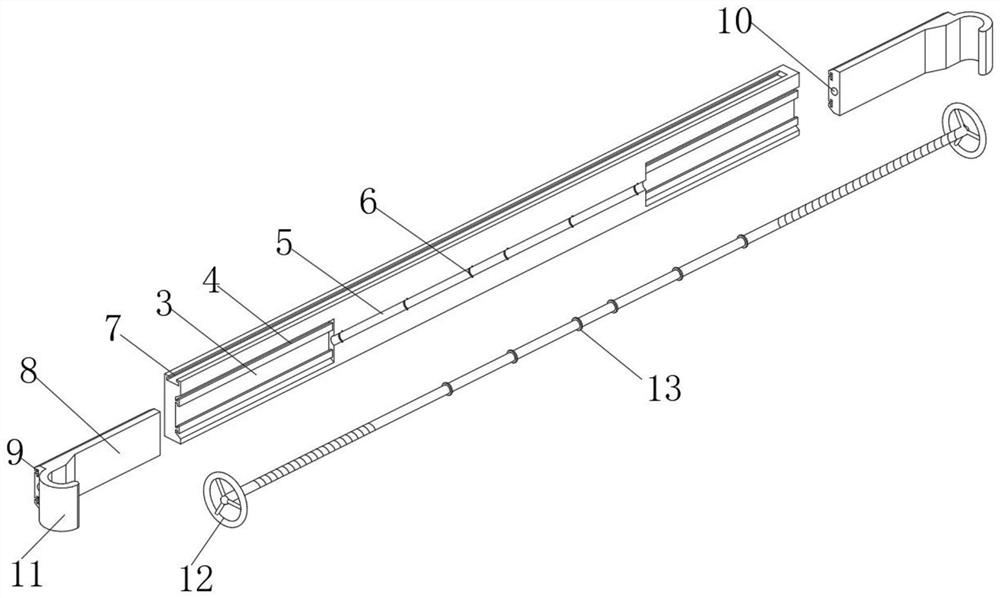

Building embedded part installing and moving device with correction function

ActiveCN113833285AWith correction functionEasy to moveBuilding material handlingPhotovoltaic energy generationArchitectural engineeringScrew thread

The invention discloses a building embedded part installing and moving device with a correction function. The device comprises a sliding rail mounted on a scaffold, connecting frames, first rollers, a connecting pipe, a bracket and a connecting seat; the connecting frames capable of sliding are installed at the two ends of the sliding rail; the two sets of first rollers are installed in an upper sliding groove formed in the upper end of the sliding rail; a threaded rod is fixed between the two sets of first rollers; the connecting pipe is movably installed on the threaded rod; second rollers are fixed to the two ends of the bracket; the second rollers are installed in a side sliding groove; and the connecting seat is installed on the bracket and can move and rotate on the bracket. The bracket is pushed to enable the first rollers and the second rollers to move in the upper sliding groove and the side sliding groove, the threaded rod and the bracket are moved to an embedding position, and therefore when an embedded part moves to the embedding position, the position deviation is not relatively large, and the correction time is shortened.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Heating process of intelligent heating system for forging and casting

PendingCN114739180AWith correction functionEasy to correctCharge supportsWork holdersEngineeringHeating system

The invention discloses a heating process of an intelligent forging and casting heating system with a correction function, and belongs to the technical field of forging and casting machining.The intelligent forging and casting heating system with the correction function comprises a base, a first swing plate, a transmission wheel and a first push plate, and a rotating disc is arranged on the surface of the base; the top of the rotating disc is provided with a rotating rod for driving the first swinging plate to swing, and the tail of the first swinging plate is fixedly connected with a first connecting plate. The intelligent forging and casting heating equipment with the correction function and the use method are high in applicability, and during use, the intelligent forging and casting heating equipment can clamp a forging and casting by controlling a clamping plate; and the equipment is prevented from displacement during heating, the mounting table can be driven to move through the first transmission rod during heating, the flexibility of the equipment is greatly improved, the forged castings can be conveniently corrected, and after machining is completed, the forged castings can be automatically transferred.

Owner:YIXING GUOCHANG ROLLER CO LTD

Method for building sequencing library by hybridization

ActiveCN102409047BImprove introduction efficiencyAvoid wastingLibrary creationProtein nucleotide librariesNucleotideNucleic acid sequencing

Owner:BGI TECH SOLUTIONS

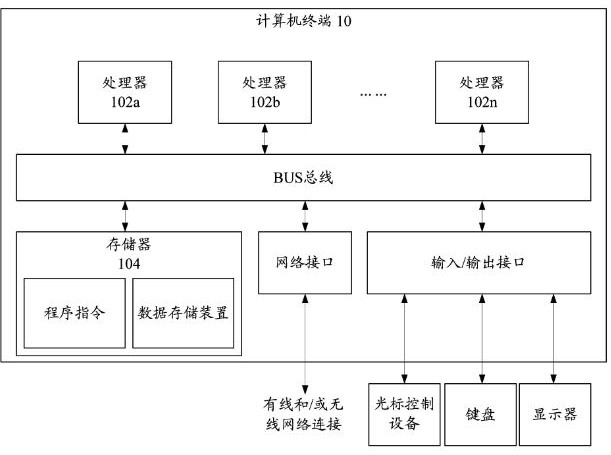

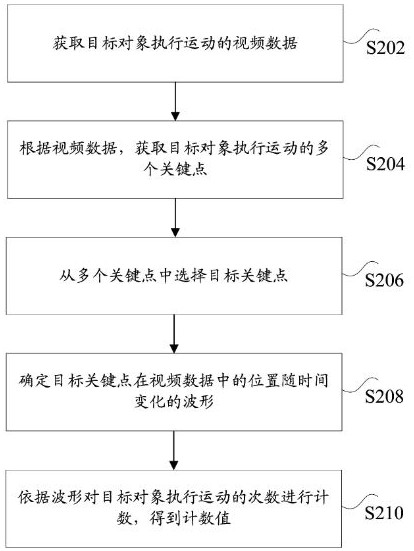

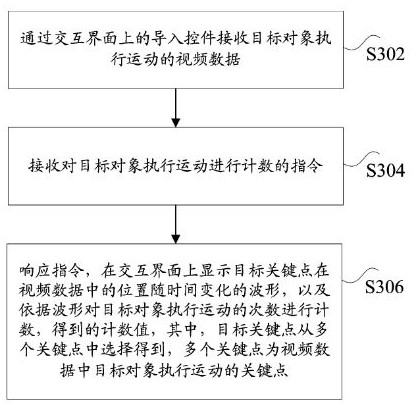

Data processing method, device, computer equipment and computer readable storage medium

InactiveCN113689457AReal-time feedback on the number of movementsStable and smooth waveformImage analysisComputer hardwareEngineering

The invention discloses a data processing method, a device, computer equipment and a computer readable storage medium. The method comprises the following steps: collecting video data of motion execution of a target object; according to the video data, obtaining a plurality of key points of motion execution of the target object; selecting a target key point from the plurality of key points; determining a time-varying waveform of the position of the target key point in the video data; and counting the number of times of motion execution of the target object according to the waveform to obtain a count value. According to the invention, the technical problem of inaccurate counting during motion counting in the prior art is solved.

Owner:ALIBABA DAMO (HANGZHOU) TECH CO LTD

Calibration and detection equipment of vehicle main girder

InactiveCN101734234AImprove efficiencyShorten the timeMeasurement devicesVehicle servicing/repairingMarine engineering

Owner:傅景宽

Forging and Casting Intelligent Heating Equipment with Correction Function and Its Application Method

ActiveCN113727479BWith correction functionEasy to correctInduction heatingWork holdersEngineeringRotating disc

Owner:宜兴市国昌轧辊有限公司

A method and device for X-ray thickness measurement

InactiveCN103206931BWith correction functionThe problem of inaccurate customer service measurementUsing wave/particle radiation meansAttenuation coefficientUltrasound attenuation

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com