Pneumatic clamp with rotary suction cup

A technology of pneumatic clamps and rotary suction cups, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as high defective rate, lack of rotation function, and inability to achieve consistency, and achieve high reliability , fully functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

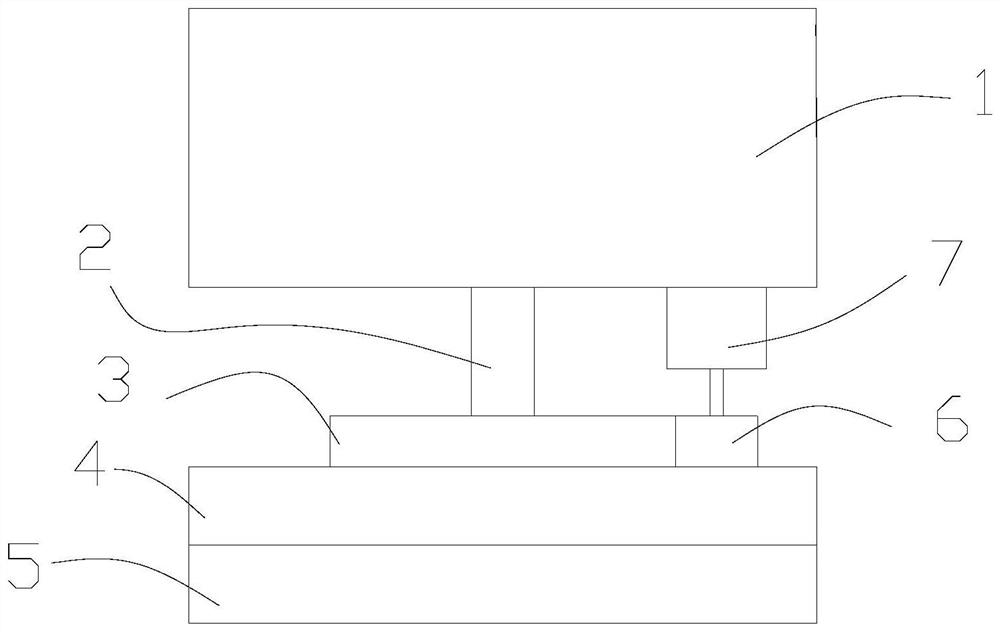

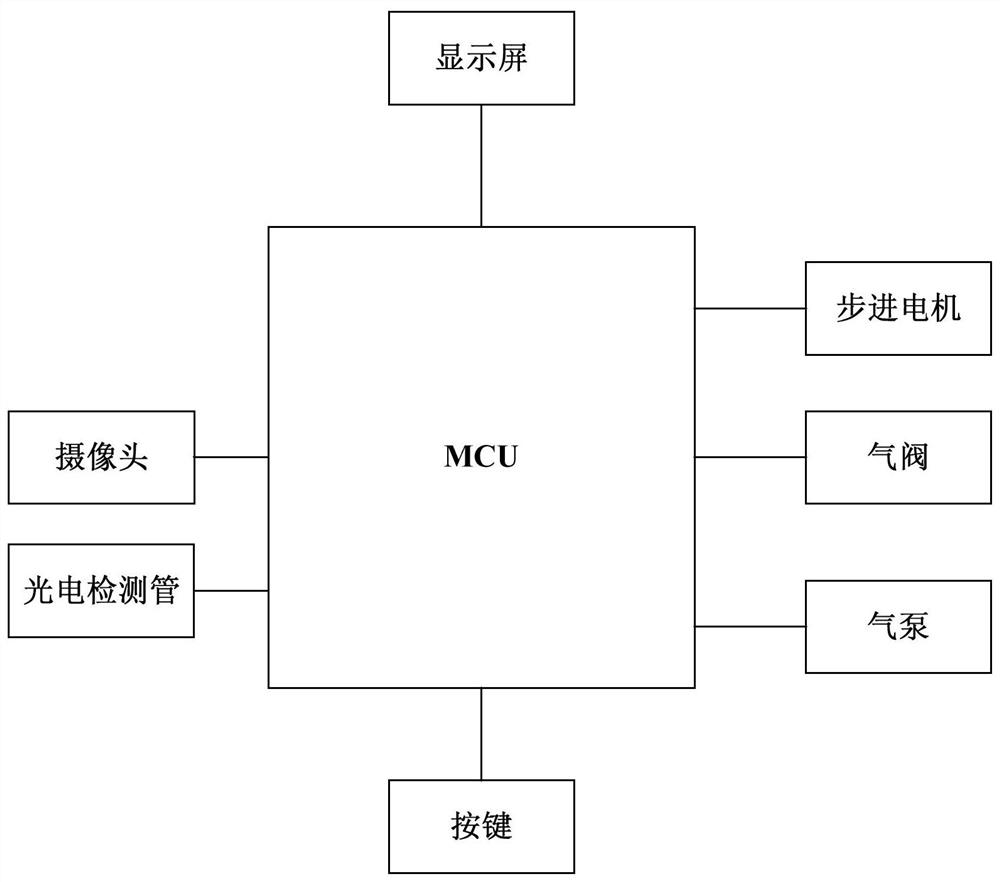

[0021] Embodiment 1: as Figure 1-4 , a pneumatic clamp with a rotating suction cup, comprising a lifting platform 1, a rotating shaft 2, a suction cup mounting plate 4 and a suction cup 5; the lower end of the lifting platform where the rotating shaft is vertically installed, and the suction cup mounting plate is fixed on the lower end of the rotating shaft; the suction cup is installed on the suction cup installation board;

[0022] The lifting platform is provided with a motor 7, and the main shaft of the motor is provided with a driving gear 6; the rotating shaft is also provided with a driven gear 3, and the driven gear meshes with the driving gear.

[0023] The lifting platform is driven by cylinders.

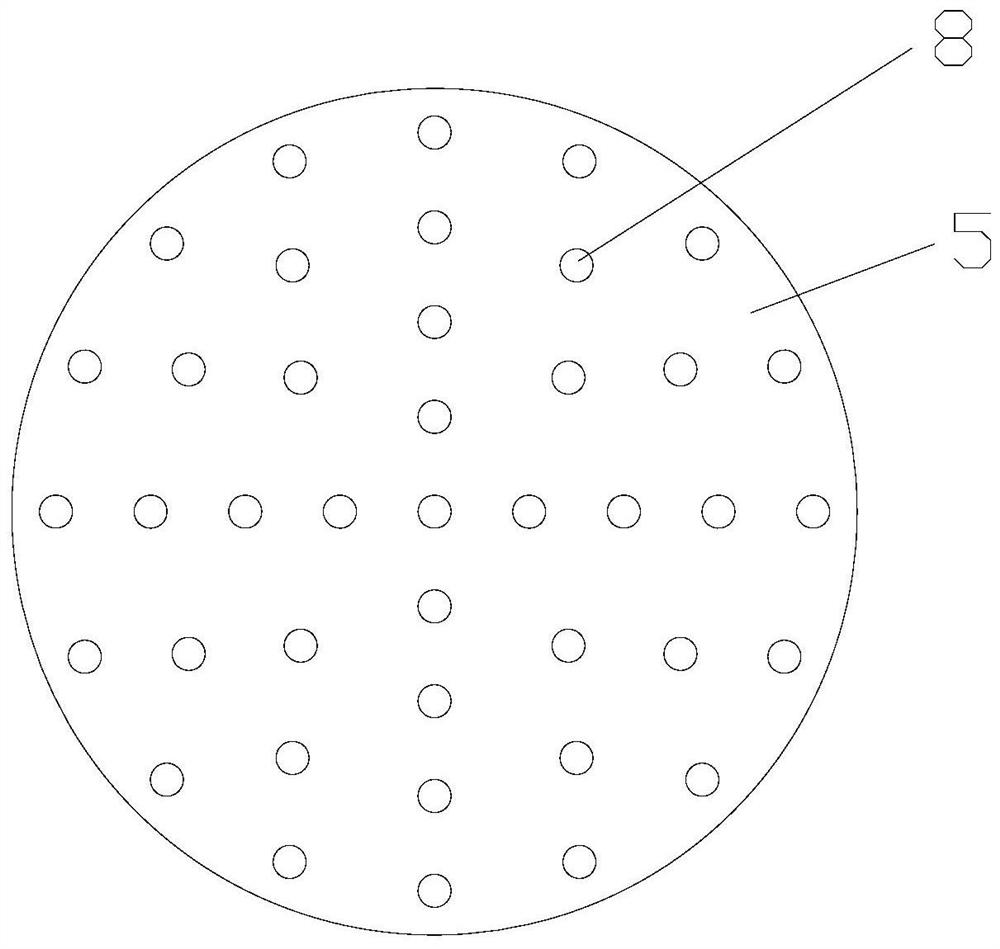

[0024] The suction cup is provided with a plurality of air holes 8, and the air holes communicate with the suction port connected to the air pump.

[0025] The pores are multi-circle, and the multi-circle pores are arranged in concentric circles.

[0026] The motor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com