Automatic cloth paving equipment for wind power blade girder

A wind power blade and cloth spreading technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of tediousness, unstable cloth placement, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the purpose, structure and function of the present invention, a wind power blade girder automatic spreading equipment of the present invention will be further described in detail in conjunction with the accompanying drawings.

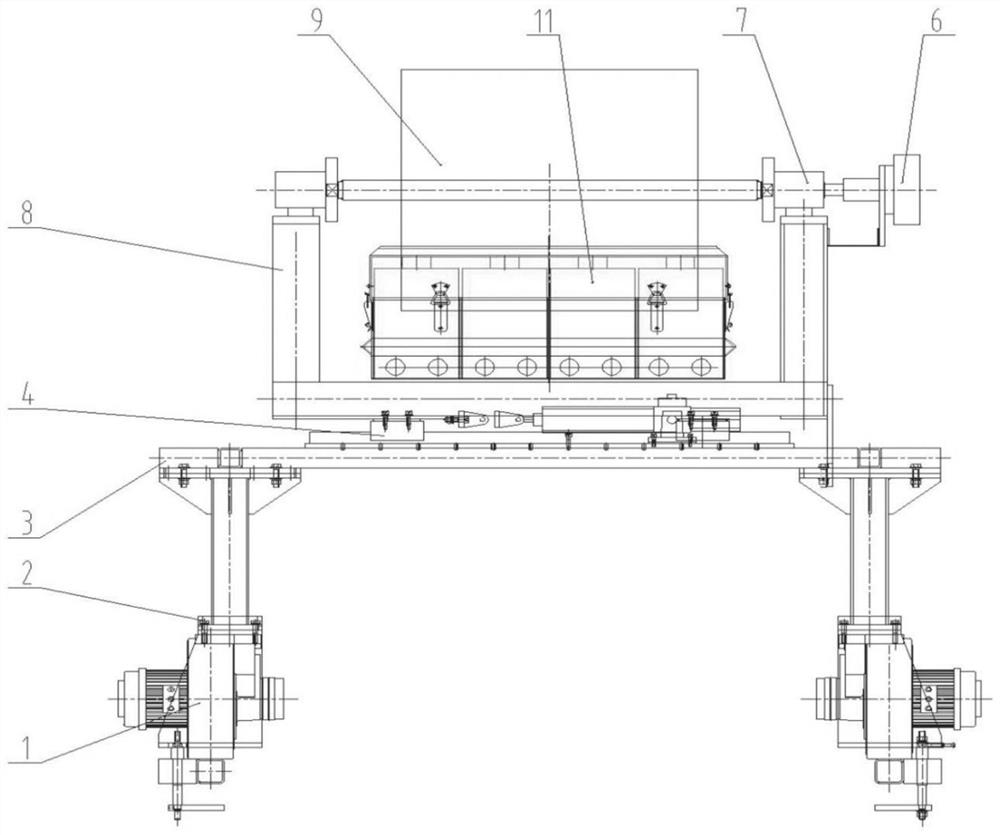

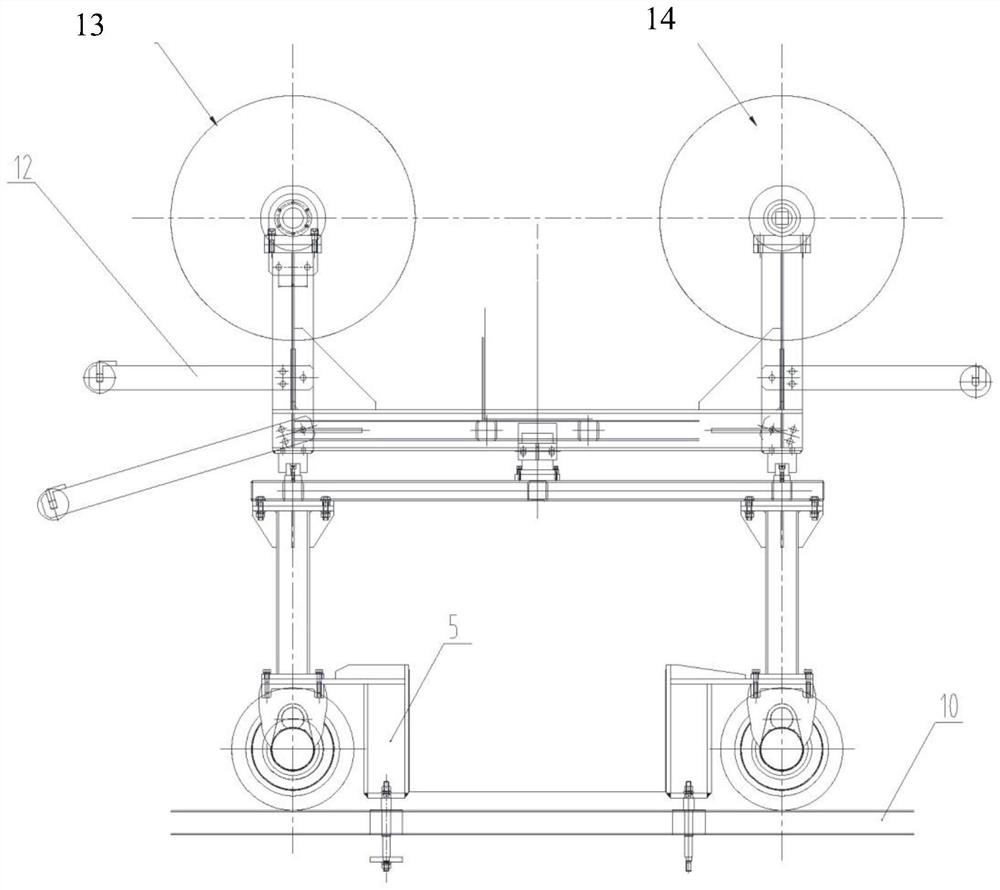

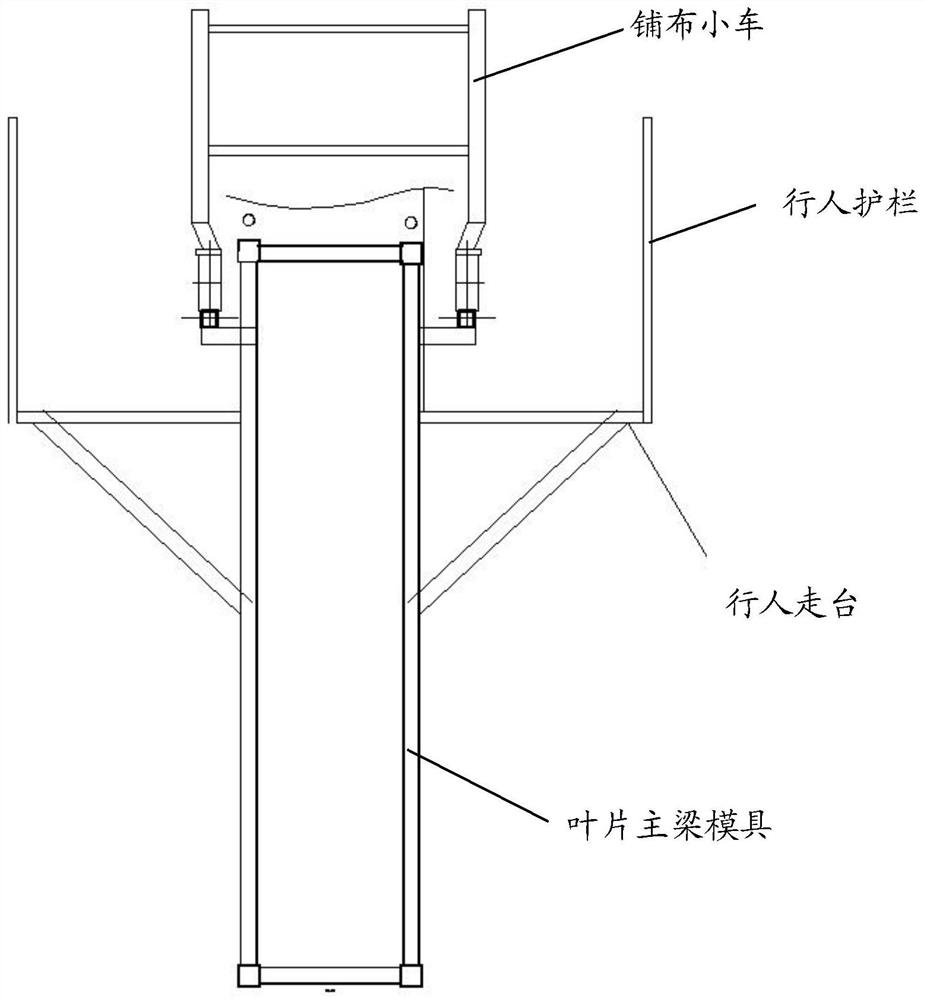

[0028] Such as Figure 1 to Figure 4 As shown, it is shown as a wind power blade girder automatic spreading equipment of the present invention, which is used on the blade main beam mold, such as image 3 As shown, the operator can stand on the pedestrian walkway to observe the working state of the automatic cloth spreading equipment of the present invention, and control the cloth rolls on both sides to reciprocate and uninterrupted spreading to realize the layering of the blade girder mold.

[0029] Specifically, a wind power blade girder automatic spreading equipment of the present invention includes a track 10, a spreading trolley (wheel 1, guide wheel 5) and a cloth roll for spreading the first cloth roll and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com