Big ring, small ring and blocking piece string equipment for correction tape automatic production

A technology for automatic production and correction of belts, which is applied to conveyors, packaging, mechanical conveyors, etc., can solve problems such as low assembly quality, low production efficiency, and inaccurate positioning, and achieve high automation, improve processing efficiency, and accurate positioning. Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

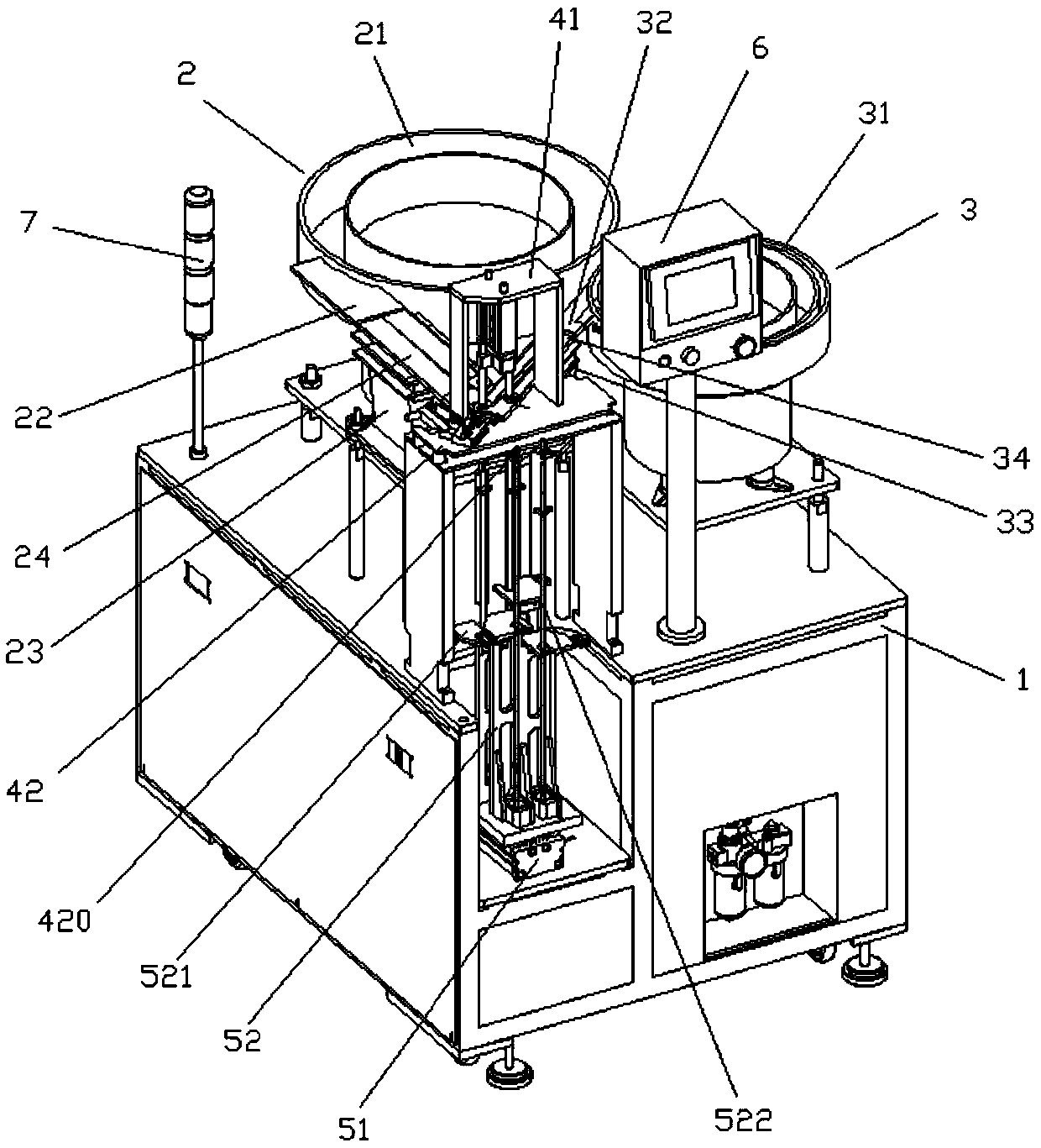

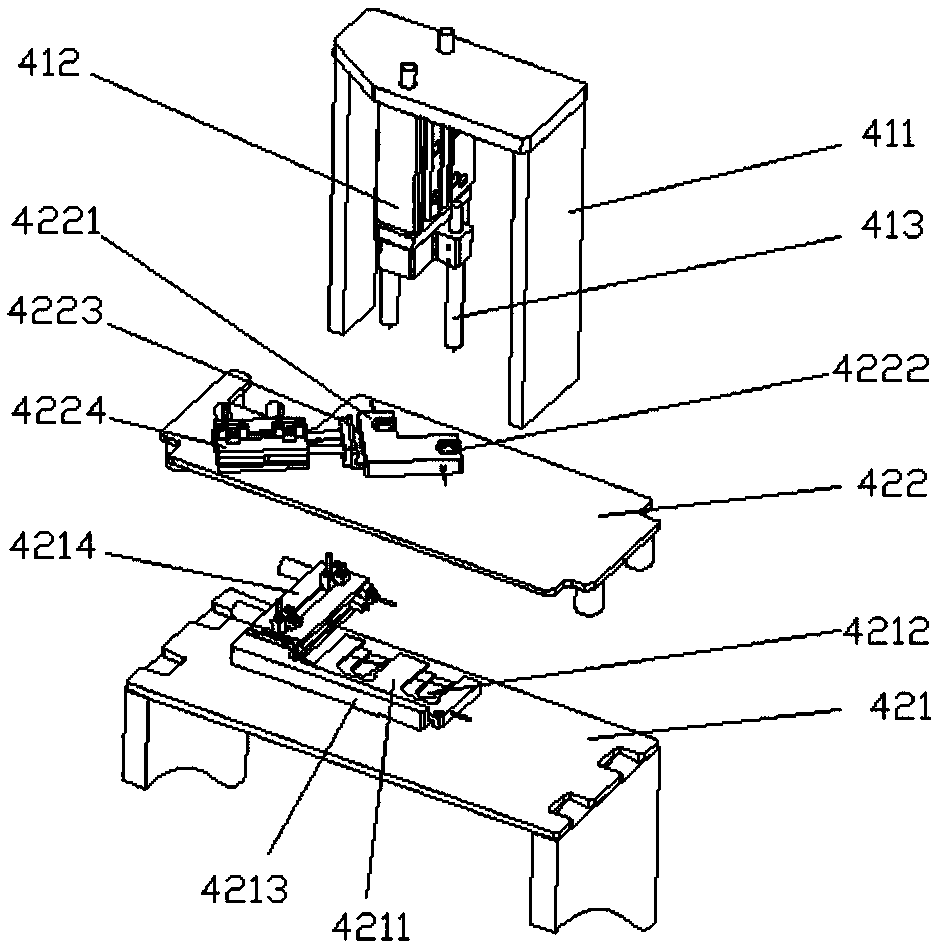

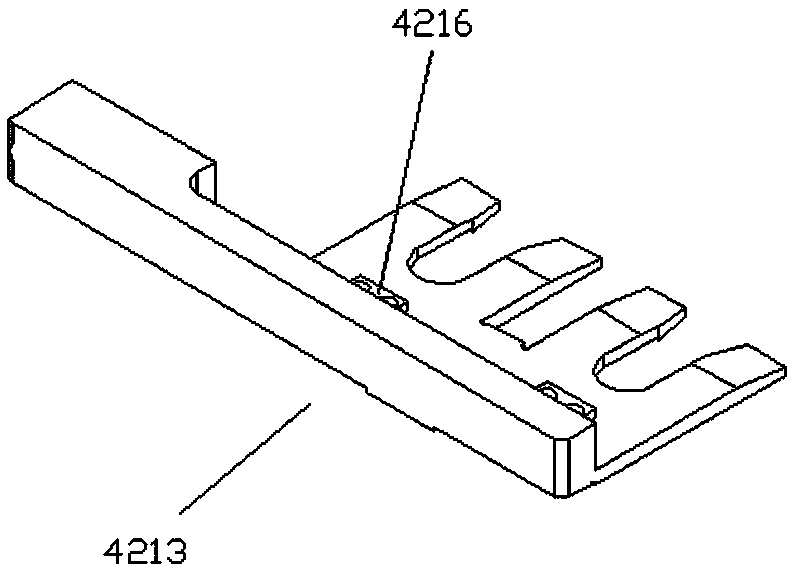

[0029] Such as Figure 1 to Figure 2 As shown in the figure, a large and small ring stopper rod stringing equipment for automatic production of correction tapes comprises a frame 1 on which a first feeding mechanism 2, a second feeding mechanism 3, a pressing mechanism and a lower The feeding mechanism, the pressing mechanism includes a material guide part 41 and a pressing part 42, the pressing part 42 includes a first bracket 421 arranged on the frame 1, and the middle part of the first bracket 421 is provided with a first through hole that runs through its body longitudinally , the upper end of which is provided with a baffle receiving seat 4211, and the baffle receiving seat 4211 is provided with a first feeding hole 4212 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com