Half-thread glue injection type connecting sleeve design method, thread glue injection type steel bar connecting sleeve, and mounting method thereof

A technology for connecting sleeves and connecting sleeves of steel bars, applied in structural elements, building components, building reinforcements, etc., can solve problems such as safety accidents, difficulty in adopting, and difficulty in controlling and detecting grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

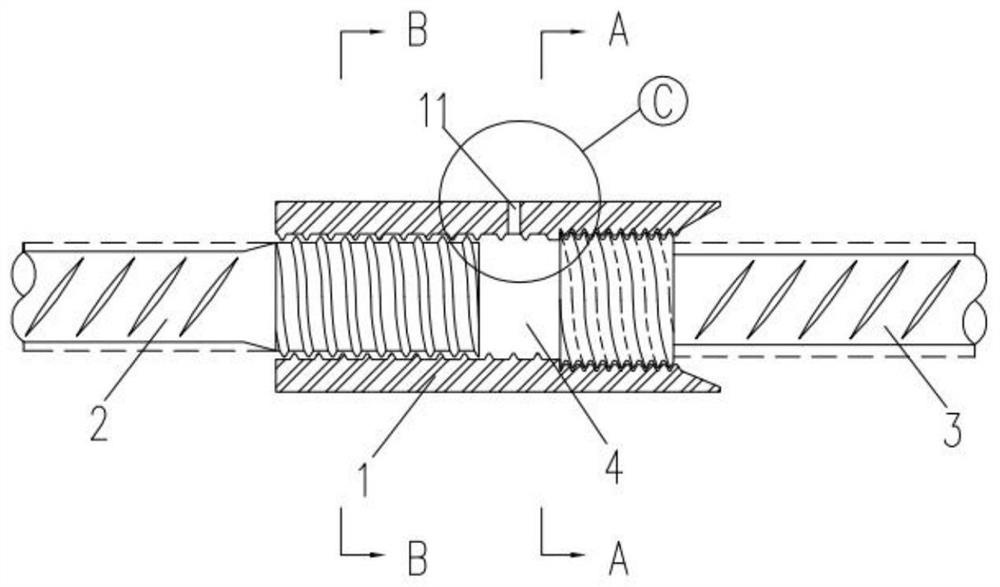

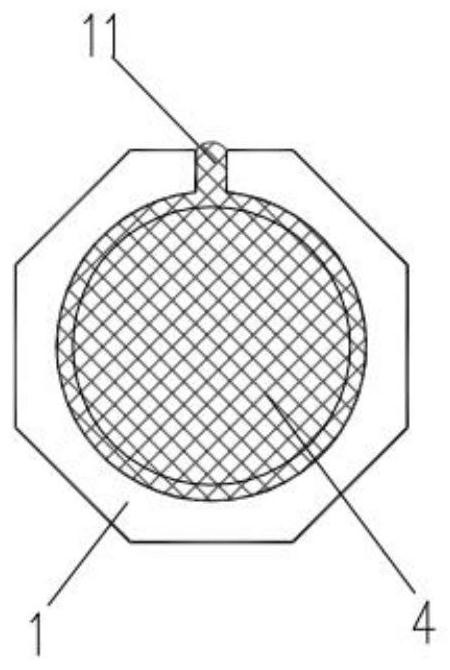

[0029] The outer surface of the steel sleeve (1) is an equilateral octagonal prism face, and the opposite side dimension is 44mm, and the length of the thread matched with the first steel bar (2) is 70mm, and the length of the thread matched with the second steel bar (3) is 25mm. And set a horn-shaped opening with a length of 10mm, the total length of the steel sleeve is 120mm; the longitudinal slope of the cone surface of the horn-shaped opening is 1:2; the thread corresponding to the steel sleeve and the first steel bar (2) is Tr28 trapezoidal thread, and the tooth type adopts Tr28X3 Trapezoidal thread specification, the width of the thread groove bottom is 4.1mm, the pitch is 6mm, and the lead is 6mm; The distance is 6mm; the inner middle side of the steel casing (1) is provided with a 3mm diameter circular glue injection hole 11;

[0030] The first steel bar (2) is a ribbed steel bar with a diameter of 25. The external thread is processed after the pier head at the end. Th...

Embodiment 2

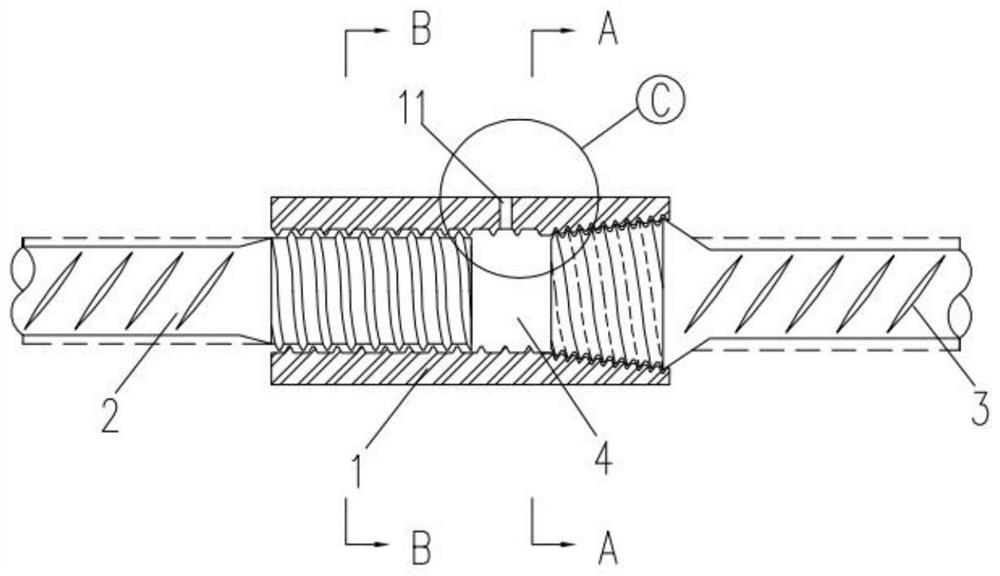

[0040] The outer surface of the steel sleeve (1) is an equilateral hexagonal prism, and the opposite side dimension is 36mm. The length of the thread matched with the first steel bar (2) is 50mm, and the length of the thread matched with the second steel bar (3) is 20mm. The total length of the sleeve is 80mm; the thread corresponding to the steel sleeve and the first steel bar (2) is Tr23 trapezoidal thread, the tooth type adopts Tr23X3 trapezoidal thread specification, the width of the bottom of the thread groove is 4.1mm, the pitch is 6mm, and the lead is 6mm; The double-line trapezoidal thread corresponding to the steel sleeve and the second steel bar (3) is Tr29×6 (P3), the pitch is 3mm, and the lead is 6mm; the inner middle side of the steel sleeve (1) is provided with a 3mm diameter circular glue injection hole 11;

[0041] The first steel bar (2) is a ribbed steel bar with a diameter of 20. The external thread is processed after the pier head at the end. The length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com