Patents

Literature

125results about How to "No slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

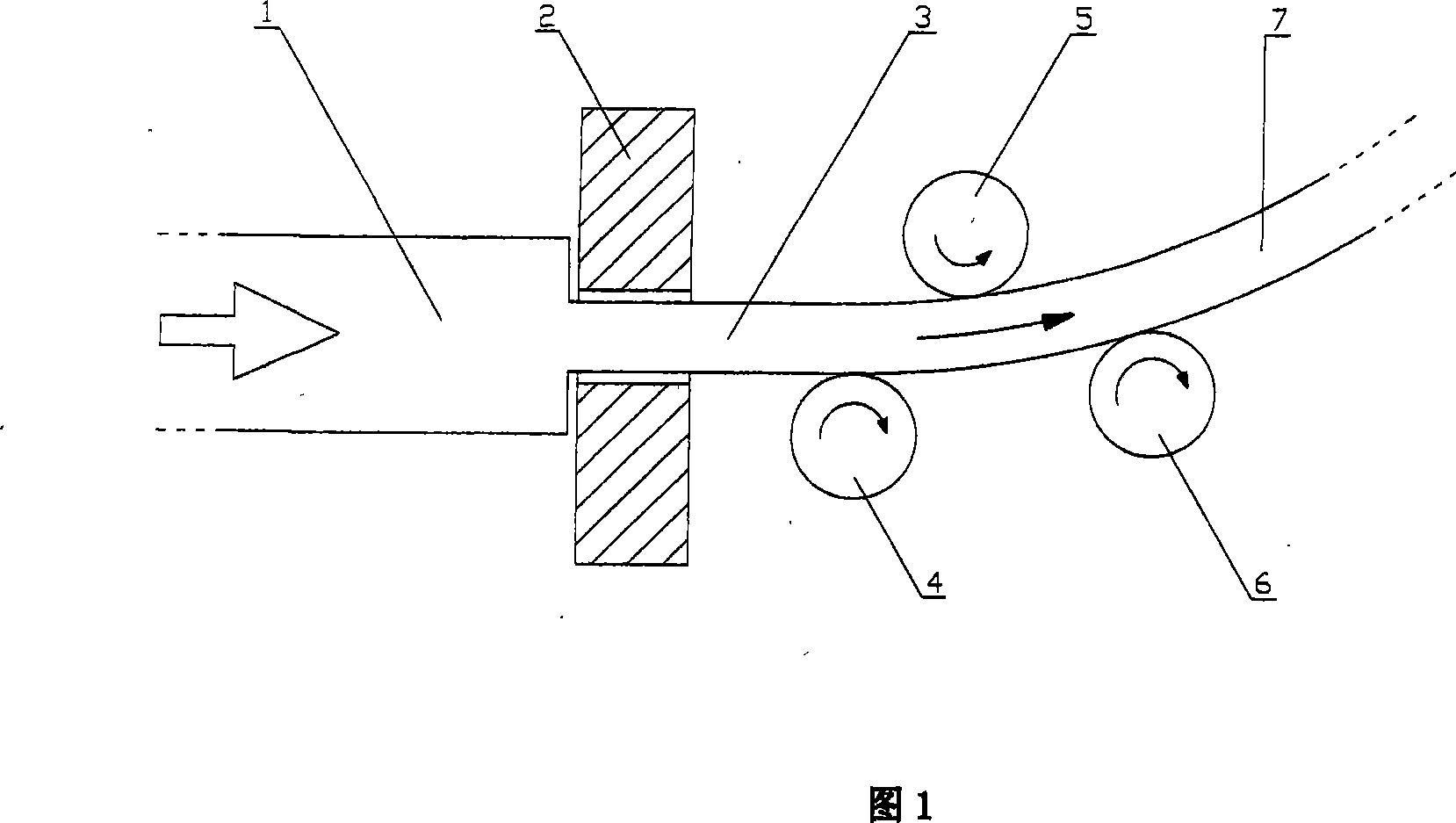

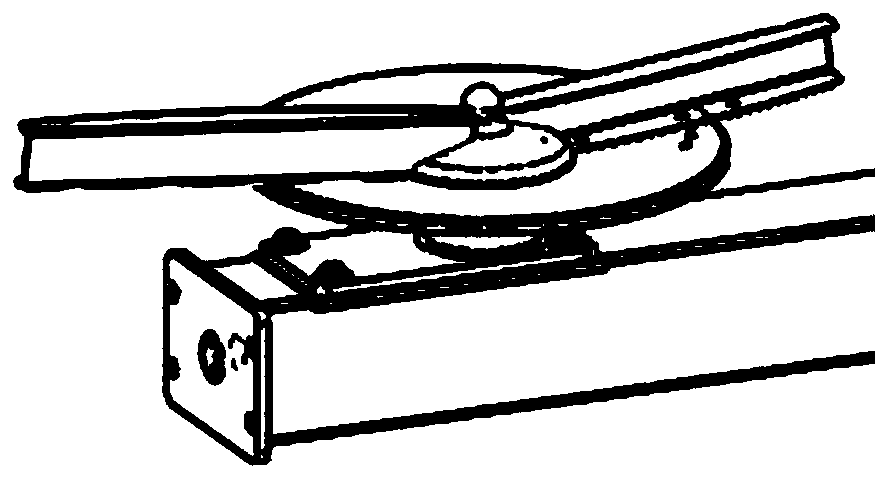

Extruding-bending integral forming method for magnesium alloy profiles

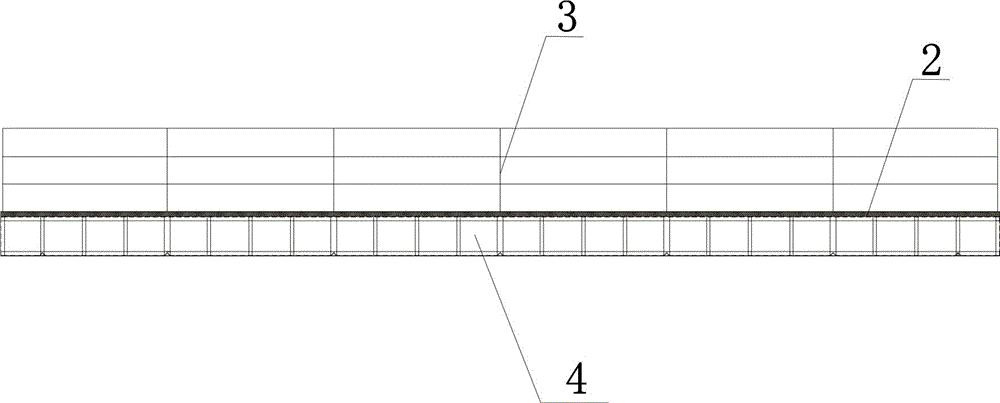

The invention relates to a technical method used for extruding-bending-integral forming of a magnesium alloy sectional material, pertaining to the technical field of plasticity processing. A set of three-wheel roll bending device is arranged near a discharge port of the original horizontal extruding machine, magnesium alloy ingot blanks are molded into the sectional material through hot extrusion, the sectional material is put into the roll bending mechanism directly before being cooled, bending moment is carried out to the sectional materials by the three roll wheels that are arranged on a same surface so as to achieve bending and molding, and the movement and position of the roll wheels are controlled to gain a bending angle and a bending radius that are required. The invention can realize the extrusion, bending and continuous molding of the magnesium alloy sectional material under the condition of only heating original ingot blanks, thereby having high production efficiency and low cost.

Owner:SHANGHAI JIAO TONG UNIV

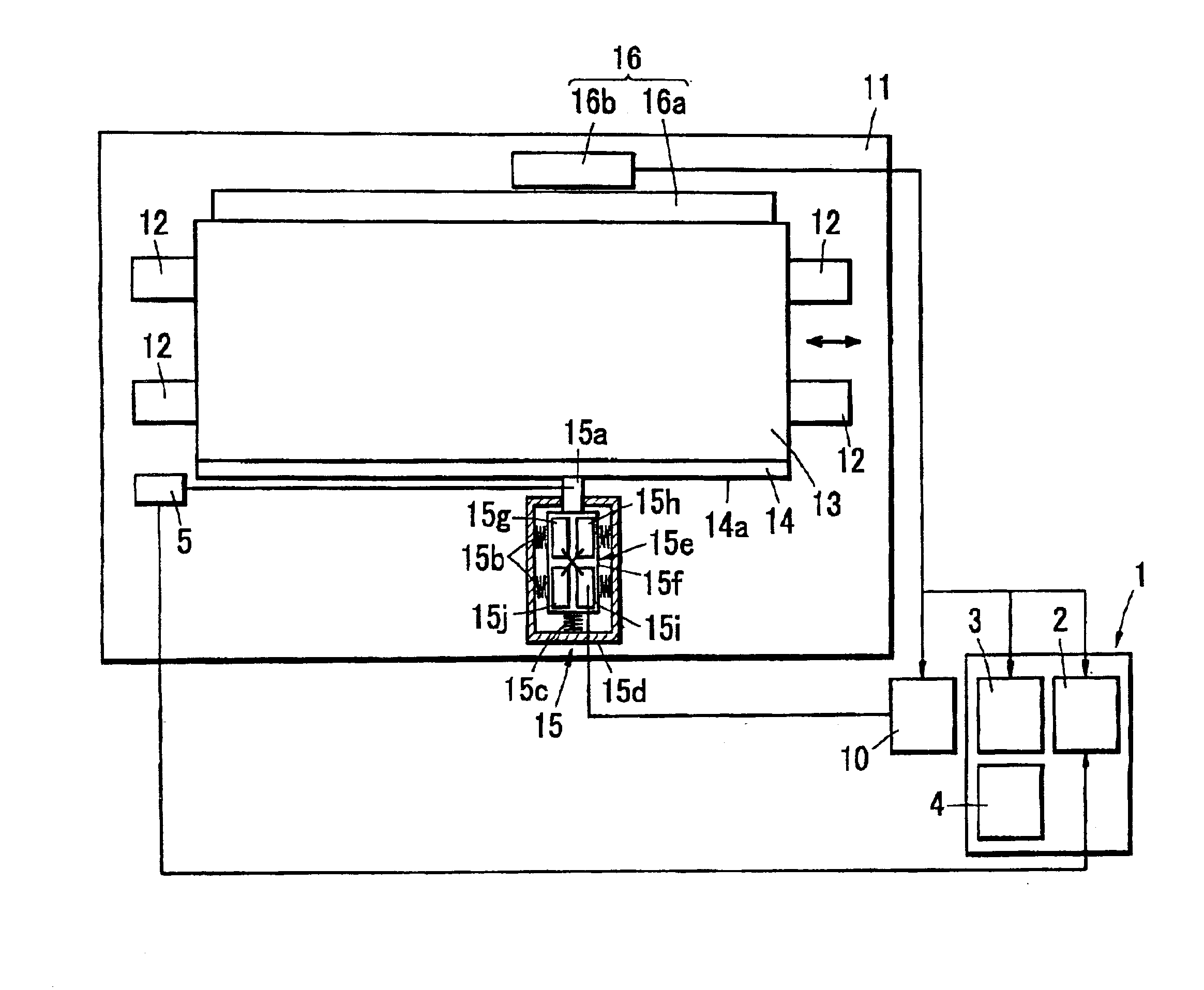

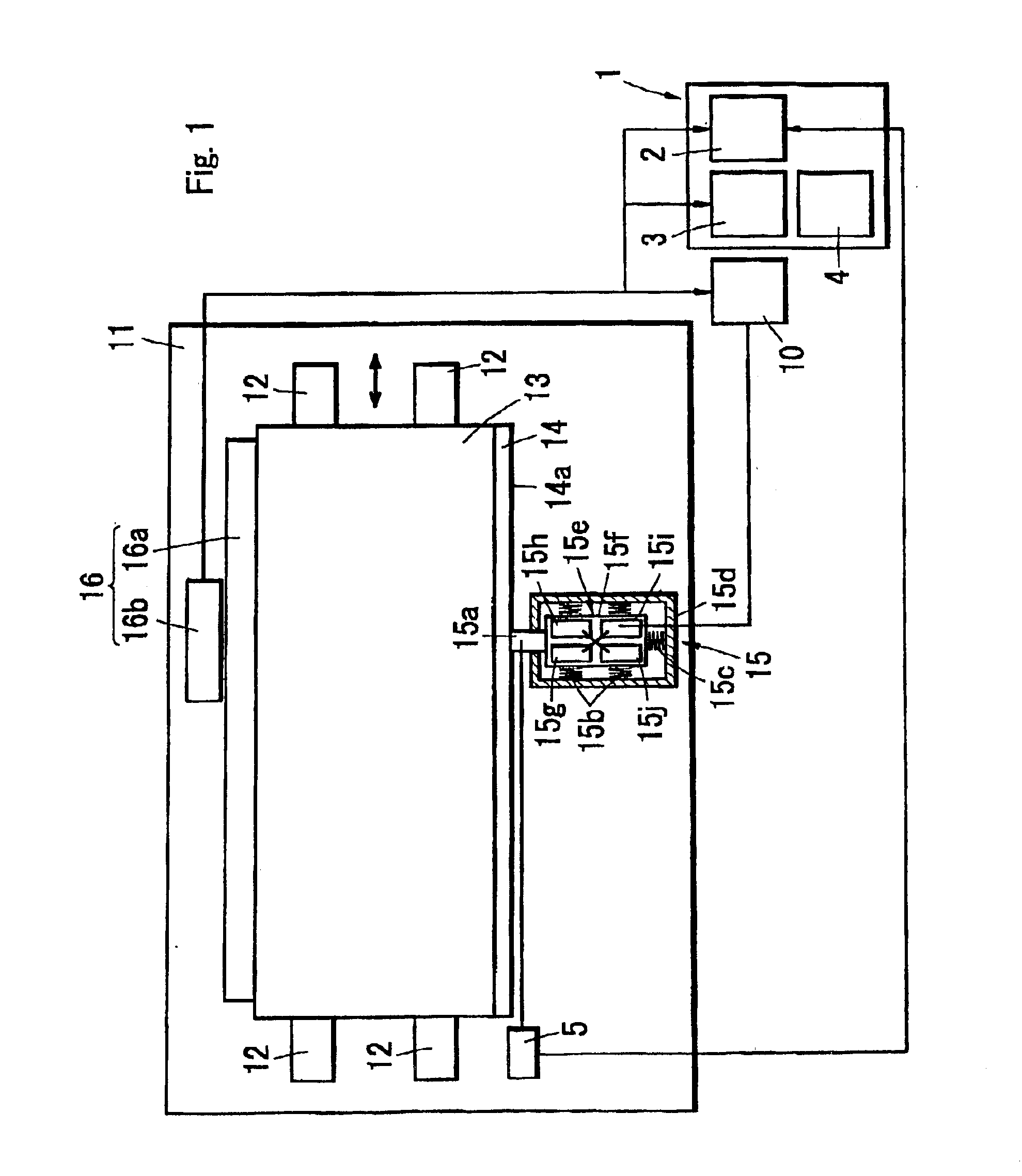

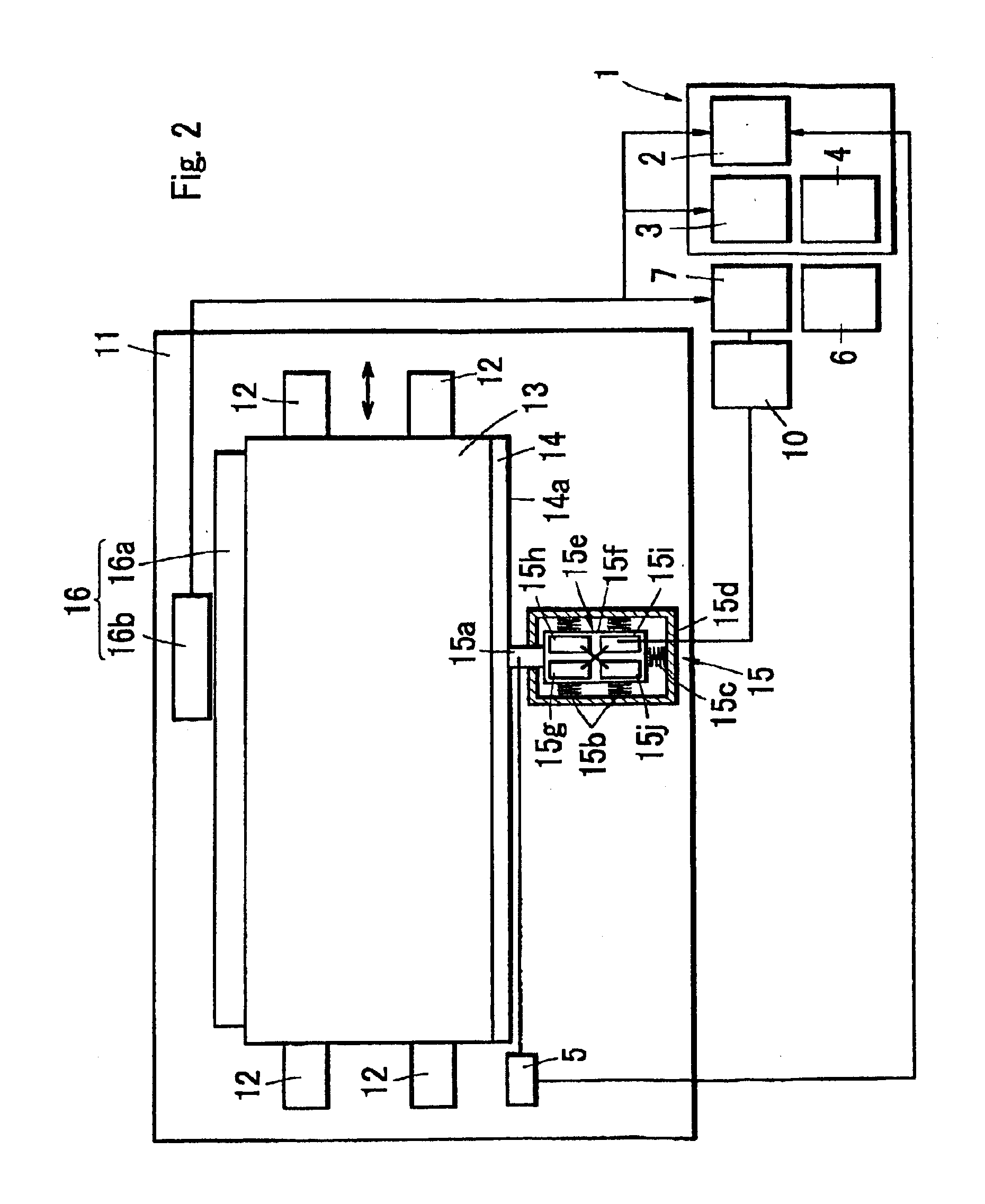

Ultrasonic motor and guide apparatus having the same as driving source of movable body

InactiveUS6897598B2Improve wear resistanceNo slipPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsLocation detectionTangential force

In a guide apparatus having an ultrasonic motor as a driving source of a stage, it is intended to accurately comprehend a degree of abrasion between a friction member of a frictionally driven ultrasonic motor and a drive transmitting member of the stage. A guide apparatus is constructed by an ultrasonic motor, a stage capable of moving on the basis of a friction driving with the ultrasonic motor, a position detecting means for detecting a position of the stage, a driving control portion for outputting a driving command signal to the ultrasonic motor, a non-contact type measuring means for measuring a position information of a friction member in the ultrasonic motor, a slip distance measuring portion for calculating a slip distance of the friction member in the ultrasonic motor, and a monitoring portion 1 equipped with tangential force measuring portion for calculating a tangential force applied to a driving surface of the drive transmitting member in the stage on the basis of the friction driving with the ultrasonic motor.

Owner:KYOCERA CORP +2

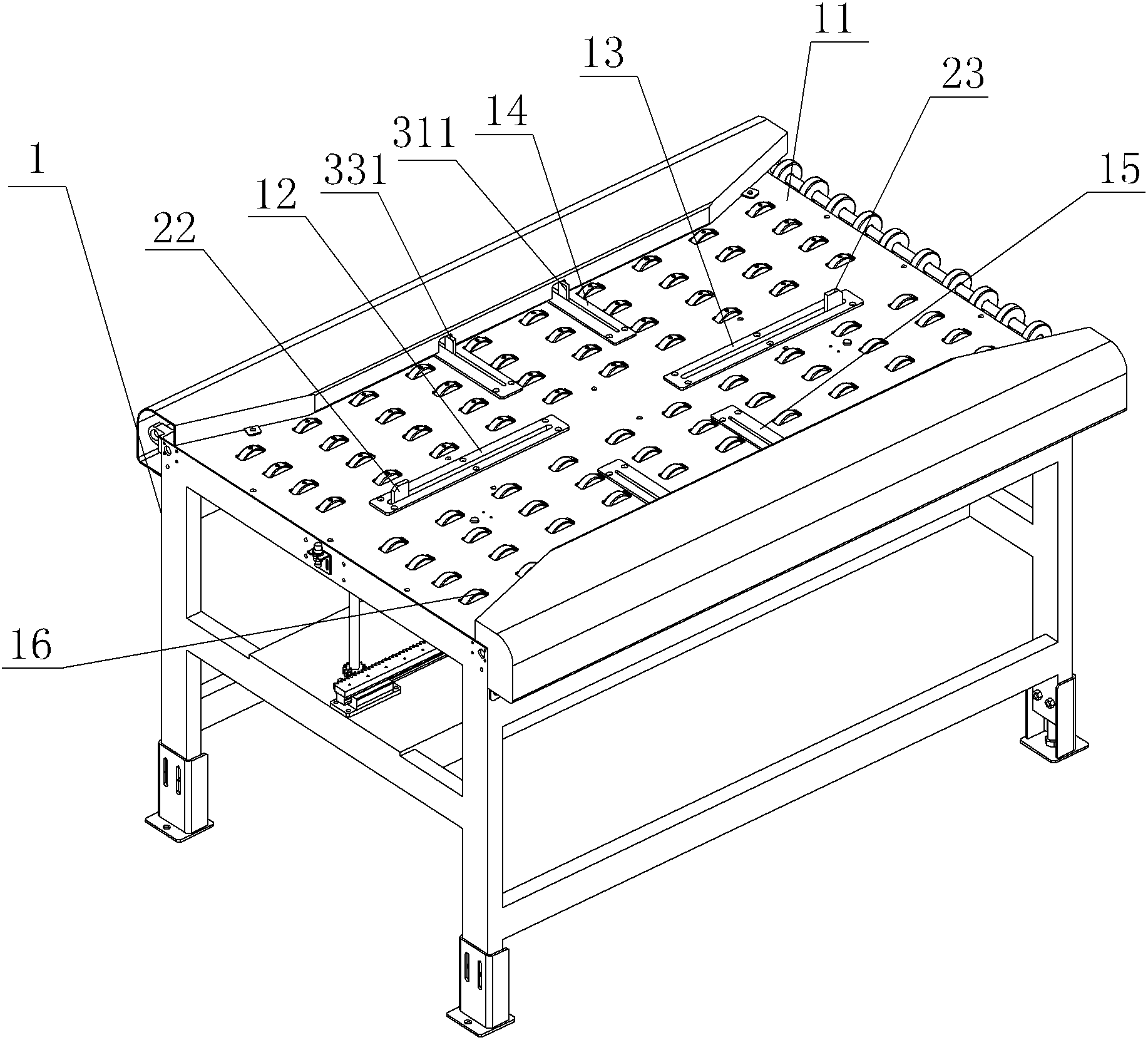

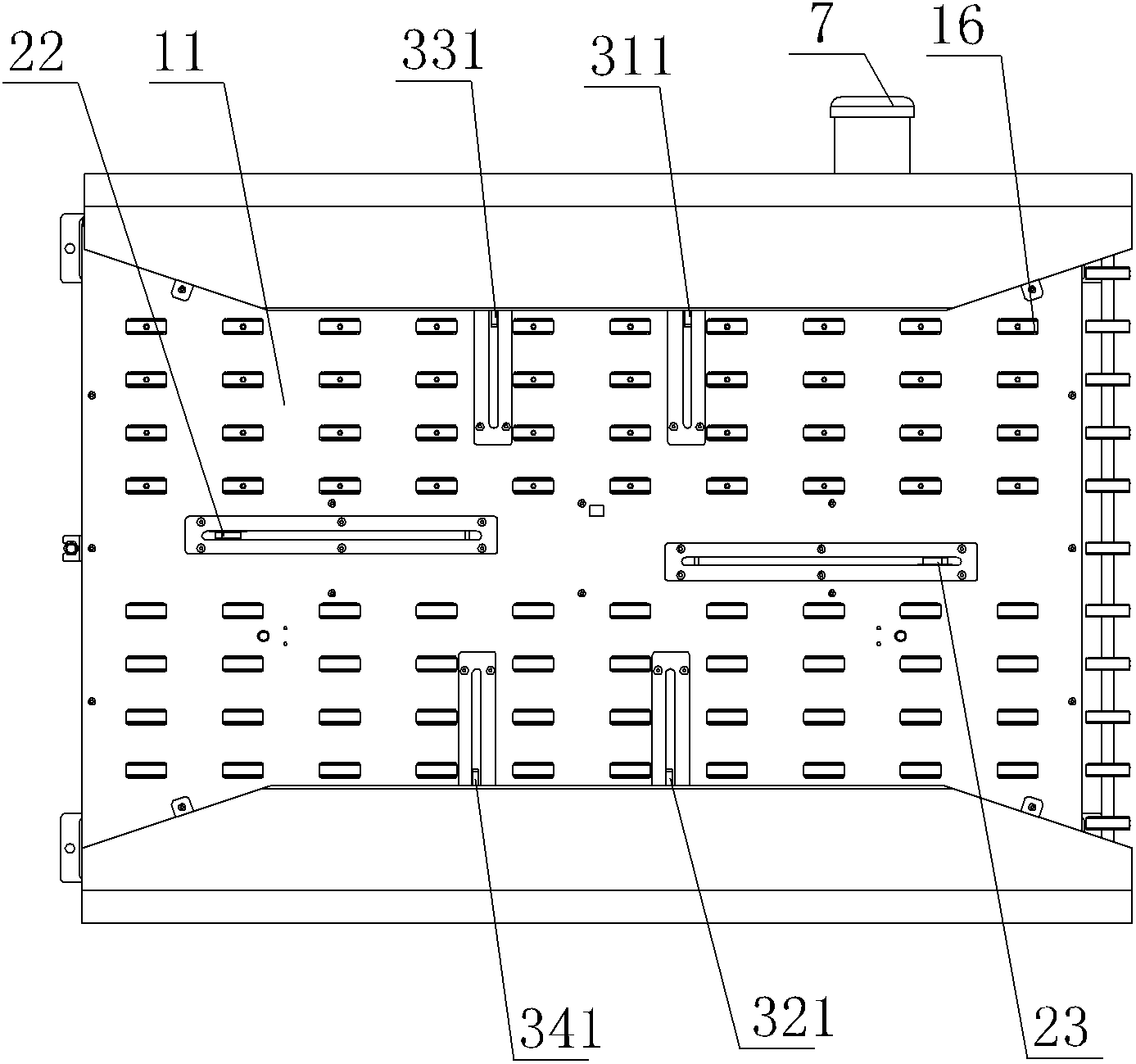

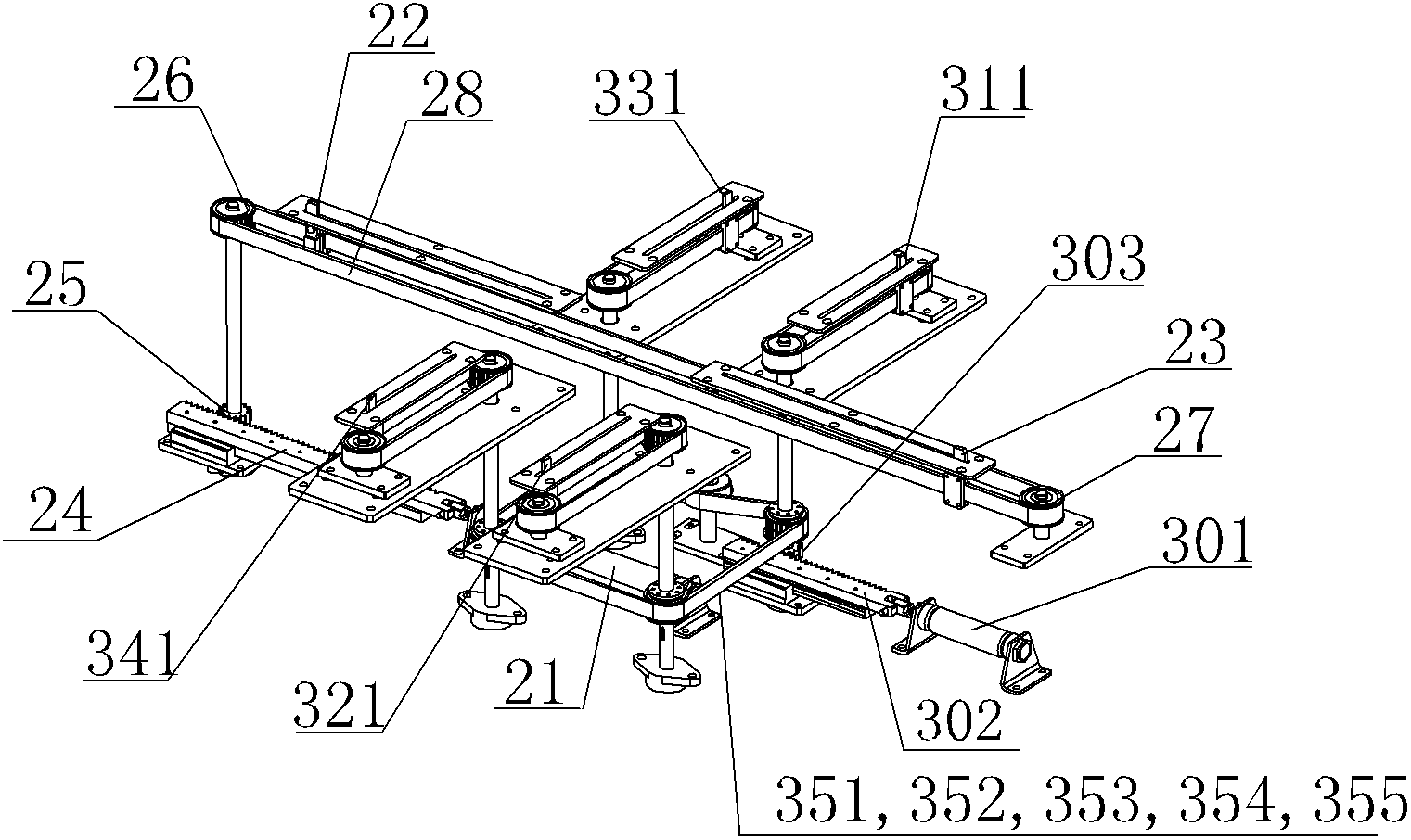

Alignment location device

ActiveCN102849444AGuaranteed synchronicityImprove alignment rateConveyor partsEngineeringElectrical and Electronics engineering

Owner:SHENNAN CIRCUITS

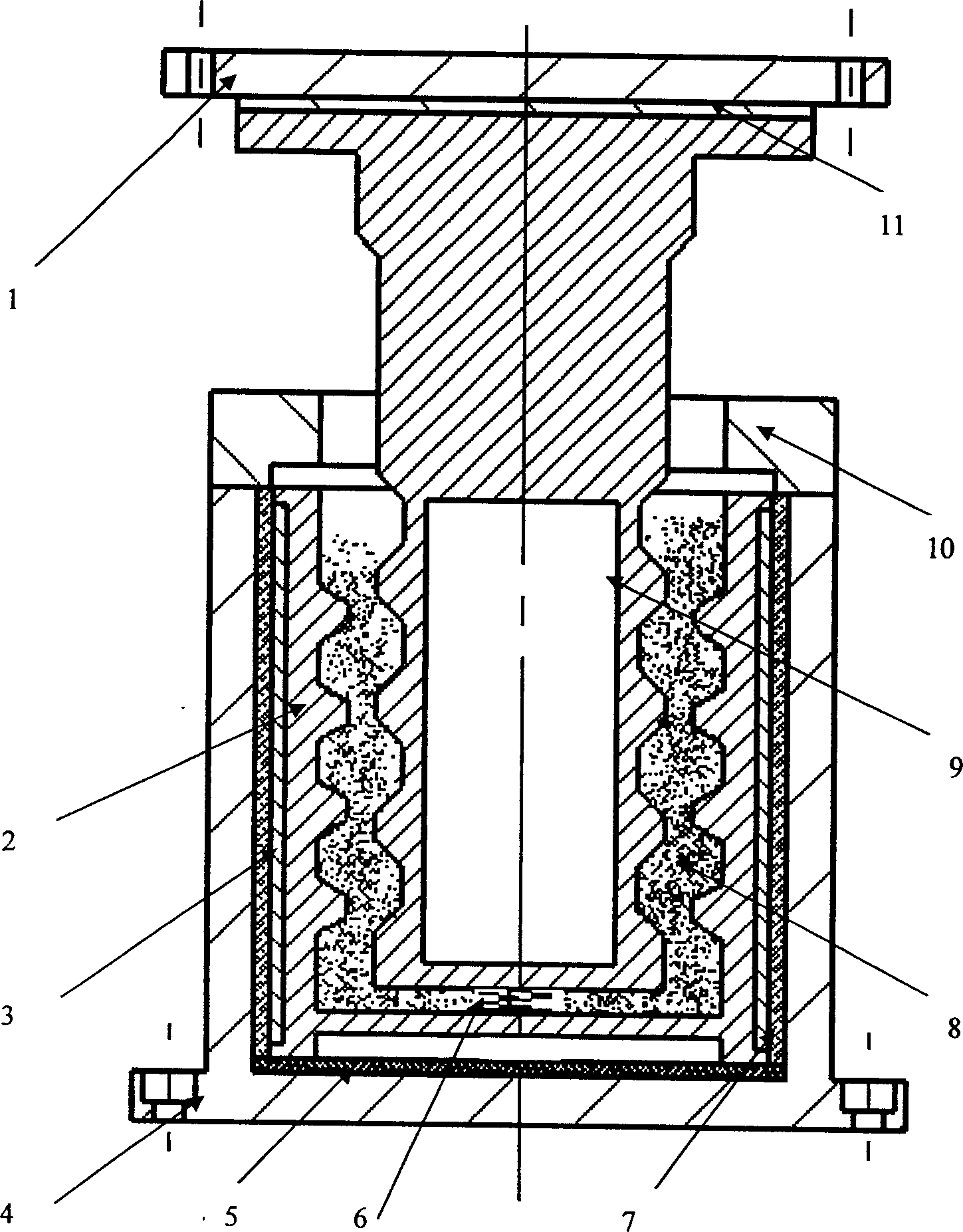

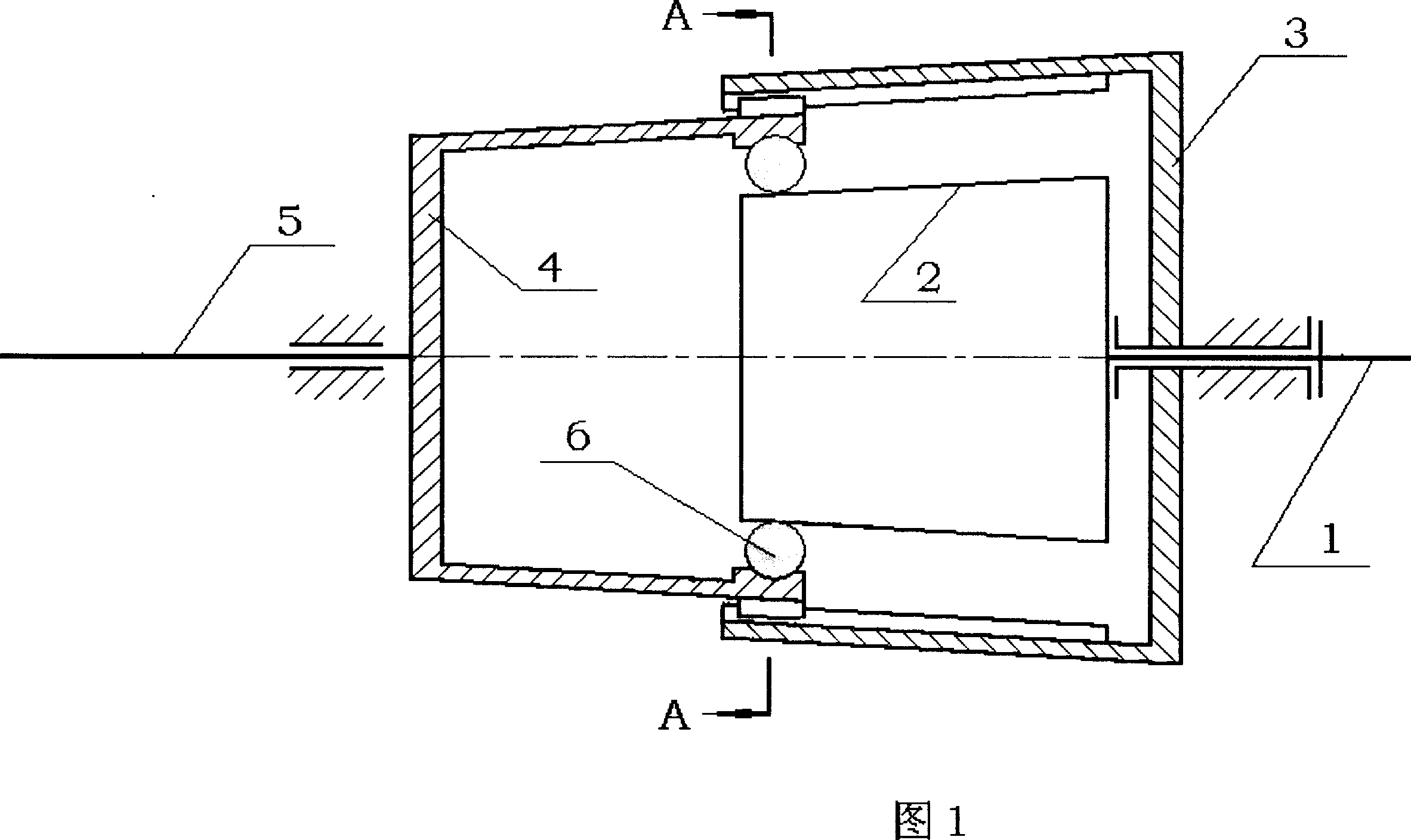

Follower location unit in non-stress space

InactiveCN101004239ANo additional stressInelastic deviationMachine framesFastening meansEngineeringUltimate tensile strength

The present invention discloses a stressless space follower positioning equipment. It is characterized by that it has a base seat, the upper portion of said base seat is a cylindrical hollow cavity, the lower bottom surface of said hollow cavity is equipped with a plate-shaped heat-insulating layer, the inner wall of the cylindrical hollow cavity is equipped with a ring-shaped heat-insulating layer, in the heat-insulating layer interior a positioning sleeve is set, in the exterior of positioning sleeve an electric heater or electromagnetic coil is fixed, in the interior of said positioning sleeve a supporting bar is set, between the interior of positioning sleeve and supporting bar low-melting point metal or magnetorheologic fluid is filled, the supporting bar and bottom portion of said positioning sleeve are equipped with supporting spring respectively, in the upper portion of said supporting bar a heat-insulating plate and a supporting flange are fixed, and in the upper portion of said base seat an end cover is mounted.

Owner:ZHEJIANG UNIV

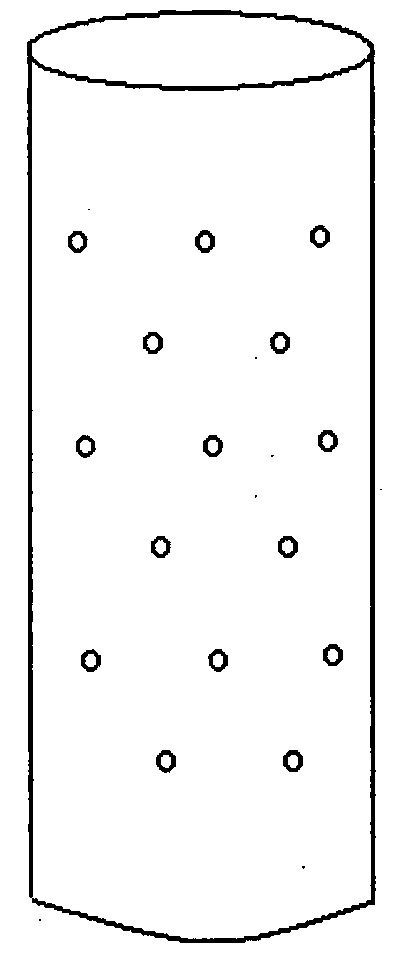

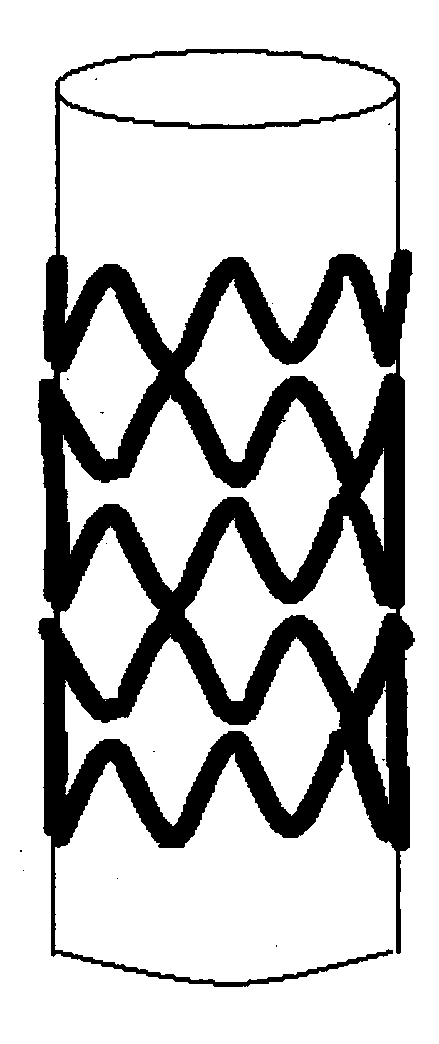

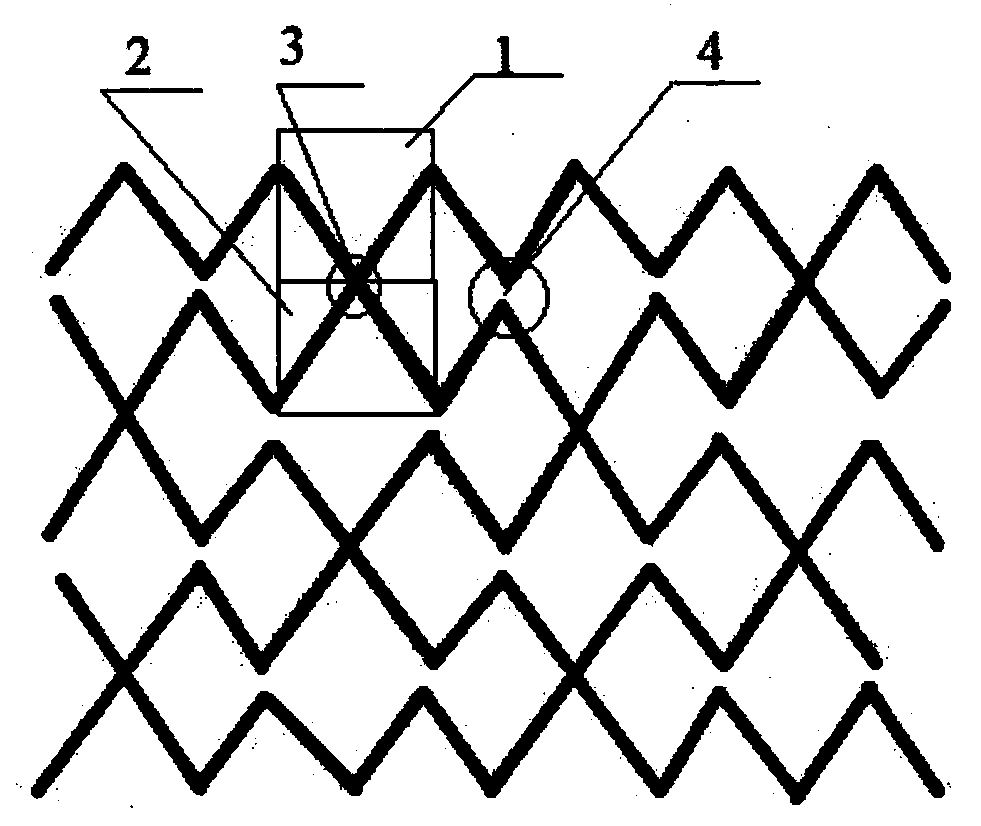

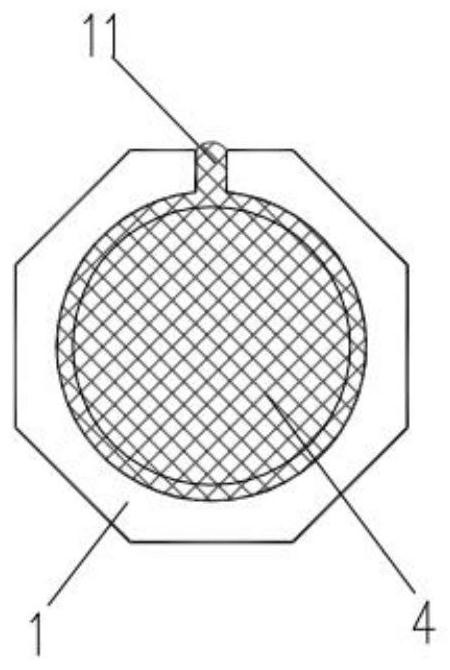

Biodegradable intravascular stent and production method thereof

The invention provides a biodegradable intravascular stent and a production method thereof. The biodegradable intravascular stent is characterized in that the biodegradable intravascular stent comprises an annular net structure made of biodegradable fiber braided threads; the annular net structure is composed of a plurality of rows of wavy structures; each row of wavy structure is composed of a plurality of V-shaped structure units; every two rows of wavy structures are parallel to each other; the endpoint in the middle of each V-shaped structure unit is connected with the endpoint in the middle of the symmetrical V-shaped structure unit in the adjacent row once every other two non-joint points to form a joint point. The biodegradable intravascular stent low in axial shortening rate can radially deform greatly due to the annular net structure, and the V-shaped structure units of two adjacent rows are connected once every other two non-joint points, so that the length of the stent is not changed greatly under the condition of great change of radial diameter of the stent, and the intravascular stent can be implanted conveniently by means of a conveyor.

Owner:DONGHUA UNIV

Modular PE pipe water activity platform

InactiveCN104627329ASo as not to damageWill not polluteFloating buildingsPipe waterReinforced concrete

A modular PE pipe water activity platform comprises a PE pipe floating body, single-section floating raft platforms and a floating raft guardrail, wherein the PE pipe floating body is formed by connecting a plurality of hollow PE pipes of which both ends are sealed; each single-section floating raft platform is of a reinforced concrete structure; the single-section floating raft platforms and the PE pipe floating body are connected into a whole by a fixing frame; plurality of the single-section floating raft platforms are fixedly connected into a floating raft platform assembly; and the floating raft guardrail is fixedly installed on the floating raft platform assembly. According to the invention, the characteristics of light weight, corrosion resistance, long service life, capability of being recycled and high strength of reinforced concrete of the PE pipe are fully combined, manufacturing and construction are simple, safety and reliability are realized, and maintenance is simple. Due to the adoption of modular production and flexible assembly, the water-surface construction operation difficulty of a large platform is greatly reduced, the construction cycle is shortened, and economic benefits and environmental benefits are greatly enhanced.

Owner:YICHANG HONGJIAN NEW MATERIAL

Antiskid polyurethane paint and its prepn

InactiveCN1453319ASolve self-leveling problemsShorten drying timePolyurea/polyurethane coatingsSolventTolylene Diisocyanate

The antiskid polyurethane paint is prepared with tolylene diisocyanate, polyether N210, trihydroxymethyl propane, butyl acetate, acetone, dibutyltin dilaurate, benzoyl chloride, antioxidant, 1,2-propylene glycol and water absorbent, and through dewatering butyl acetate, acetone and polyether N210 in reactor at 90-100 deg.c; adding trihydroxymethyl propane into the reactor before heating and stirring to dewater; adding benzoyl chloride, antioxidant and tolylene diisocyanate, heating and adding dibutyltin dilauratel; reflux evaporating solvent butyl acetate or acetone; packing the prepolymer into paint tank; and mixing prepolymer, xylene or butyl acetate or acetone, 1,2-propylene glycol and water absorbent in certain proportion to obtain the paint. The paint has simple preparation process,strong adhesive force, high wear resistance, high weather resistance and other advantages.

Owner:INST OF AQUATIC LIFE ACAD SINICA

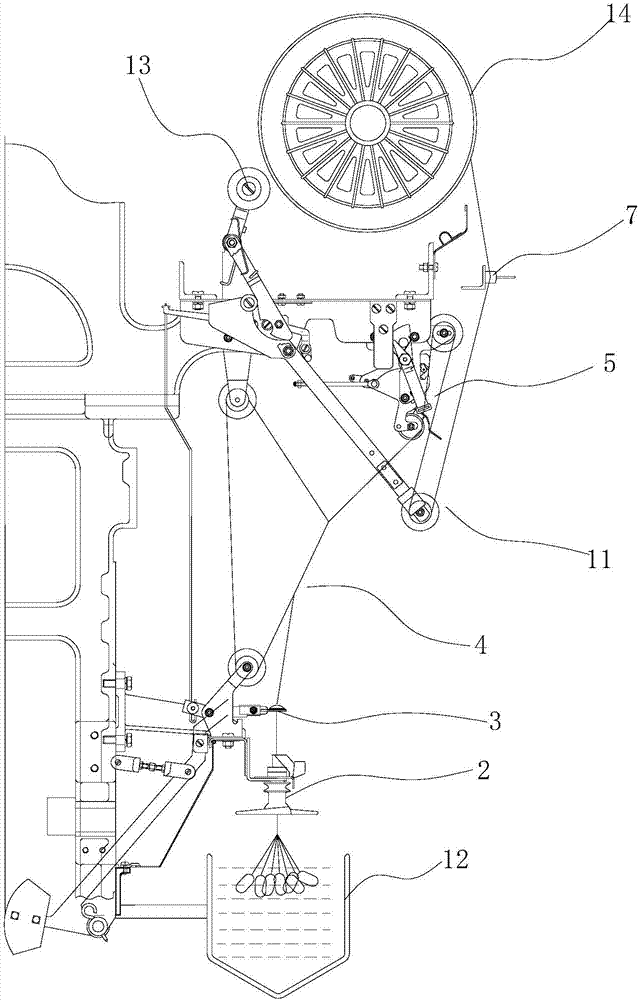

Wire arranging compensation device and wire arranging compensation method of wire cutting all-powerful winding machine

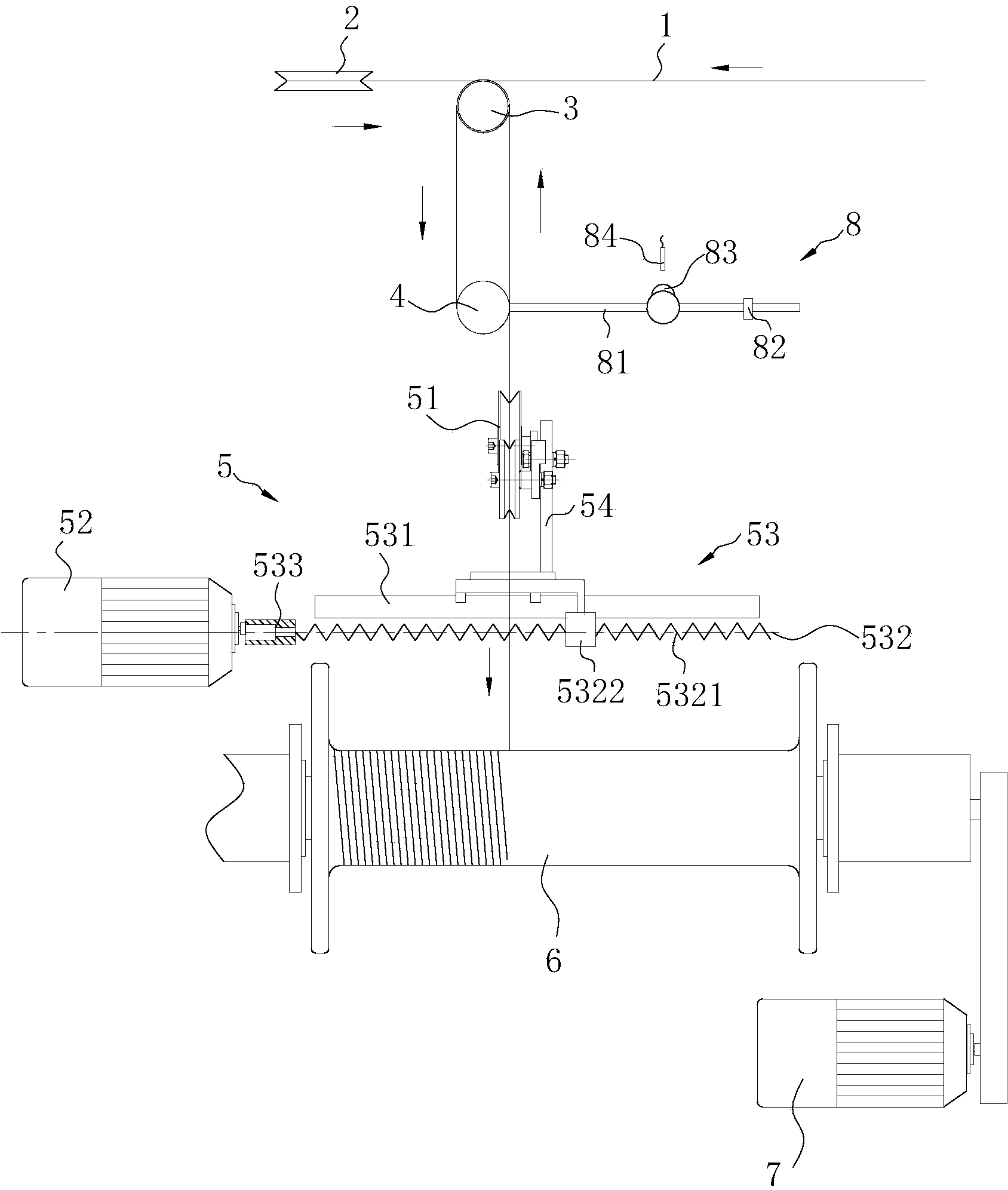

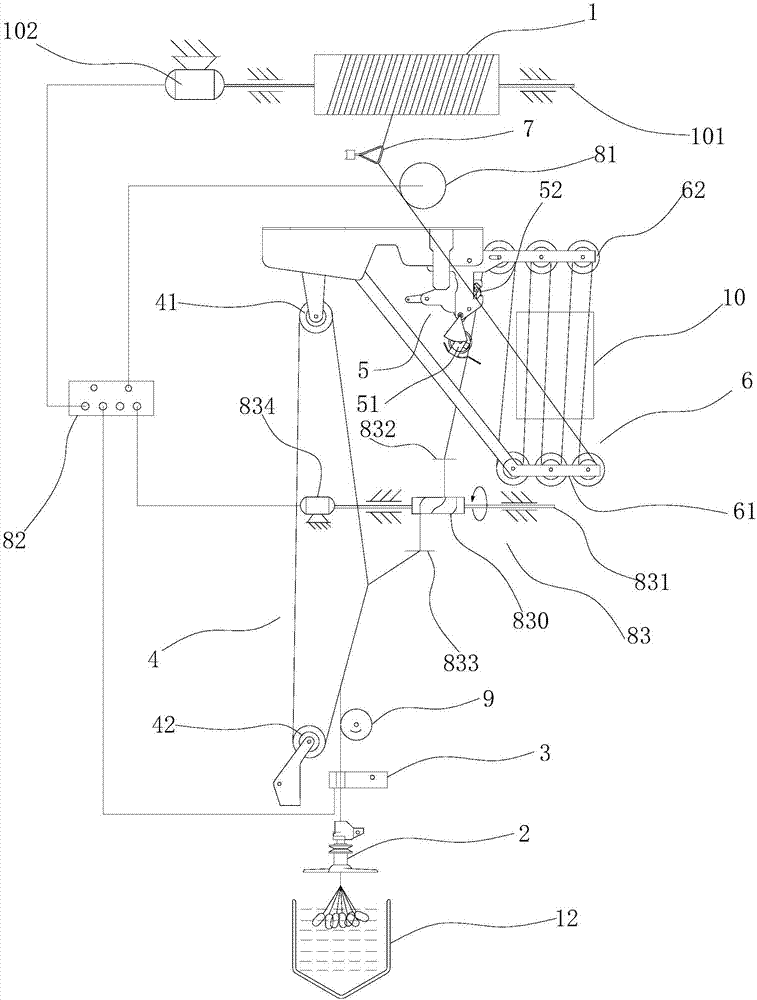

ActiveCN103588025AReduce changeover timeCommutation neatlyFilament handlingWinding machineWire cutting

The invention discloses a wire arranging compensation device of a wire cutting all-powerful winding machine. The wire arranging compensation device comprises steel wires, a first guide wheel, a second guide wheel, a third guide wheel, a wire arranging device and a winding wheel. The steel wires are sent in the main machine direction, sequentially pass through the guide wheels and the wire arranging device and are wound around the winding wheel. One end of the winding wheel is provided with a winding motor. The wire arranging device comprises a wire arranging guide wheel and a wire arranging motor. The output shaft end of the wire arranging motor is connected with the wire arranging guide wheel through a horizontal moving assembly so that the wire arranging motor can push the wire arranging guide wheel to move in the horizontal direction in a reciprocating mode. One side of the third guide wheel is provided with a tension oscillating bar device used for detecting tension variation of the steel wires, and the tension oscillating bar device is connected with a PLC. The output end of the PLC is connected with the wire arranging motor and the winding motor, and the wire arranging motor is a servo motor. The wire arranging compensation device of the wire cutting all-powerful winding machine is simple in structure, convenient to operate, capable of reducing reversing time of the wire arranging guide wheel, free of slip frequency, and capable of ensuring neatness of the wires arranged on the winding wheel.

Owner:WUXI SUNLIT SCI & TECH

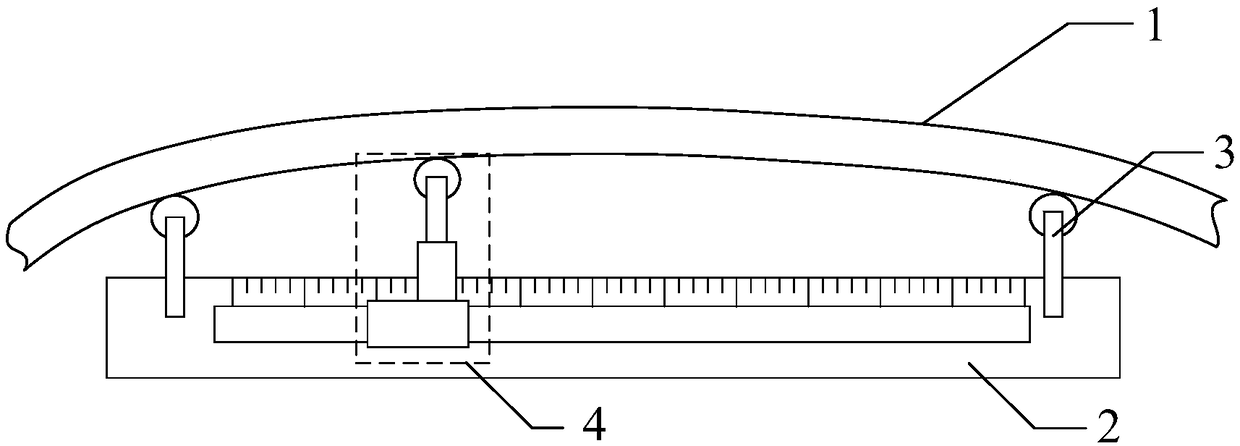

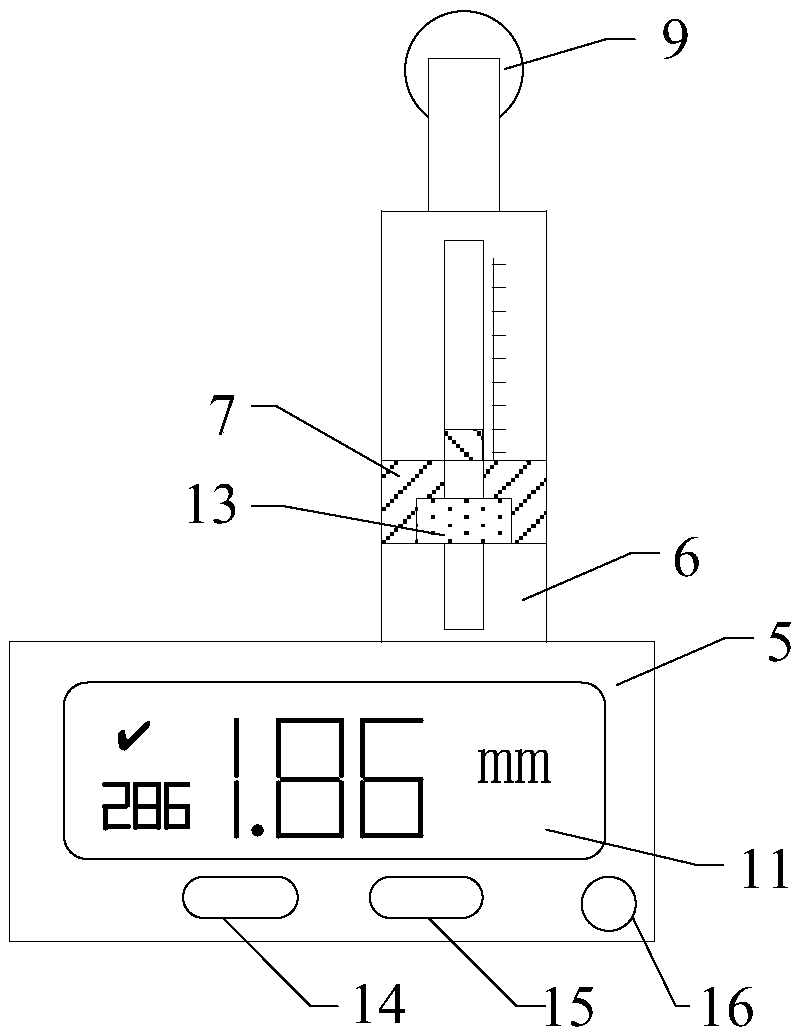

Cable bending displacement measuring device

InactiveCN109405718ANo slipEasy to measureMechanical counters/curvatures measurementsMeasurement deviceEngineering

The invention discloses a cable bending displacement measuring device which comprises a lateral measuring ruler and an offset measuring unit. Supporting portions are arranged at the two ends of the measuring ruler. The offset measuring unit includes a measuring rod, a sliding seat in sliding connection with the measuring ruler horizontally, and a sliding cylinder fixed on the sliding seat vertically. A sliding block in sliding connection with the sliding cylinder is fixed at one end of the measuring rod and the other end of the measuring rod extends out of the sliding cylinder. A lateral displacement sensor is arranged at the sliding seat and a bending displacement sensor is arranged at the sliding block. During measurement, the measuring ruler is in close contact with a to-be-measured cable by the supporting portions; the offset measuring unit slides from one end of the measuring ruler to the other end and the outer end portion of the measuring rod is kept to be abutted against the outer surface of the to-be-measured cable during the sliding process; the lateral displacement sensor measures the lateral move displacement amount of the sliding seat in real time and the bending displacement sensor measures the bending displacement amount of the cable in real time during the sliding process; and the measurement data are displayed in real time by a display panel. The measurement becomes simple and convenient and the accuracy is high.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

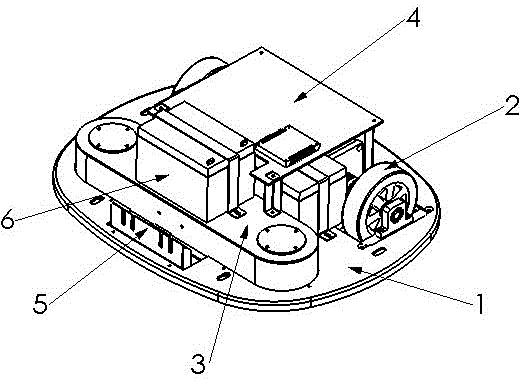

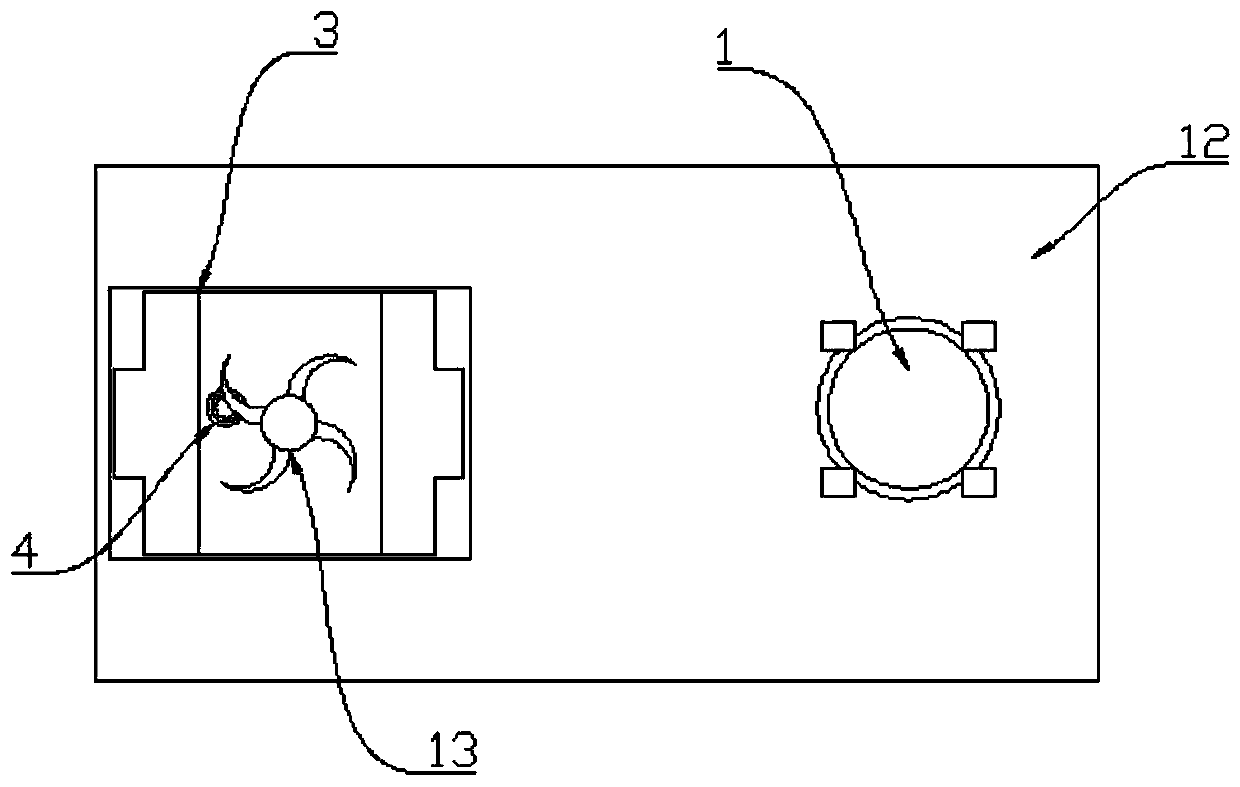

Moving chassis for indoor service robot

ActiveCN105835988AImprove filtering effectImprove passabilityElectric propulsion mountingVehiclesDrive wheelEngineering

The invention discloses a moving chassis for an indoor service robot. The moving chassis comprises a bottom plate, a driving mechanism, a universal wheel mechanism, a sensing system and a power supply system, wherein the universal wheel mechanism comprises universal wheel bases, two groups of universal wheels arranged in the universal wheel bases, and universal wheel support plates fixedly connected with the two groups of universal wheels; the universal wheel support plates are rotationally connected to the universal wheel bases through linear bearings; the upper surfaces of the two ends of the universal wheel support plates are provided with springs respectively; spring pressing plates are fixedly arranged at the upper ends of the springs; the spring pressing plates are fixed to the universal wheel bases. By adopting the moving chassis, on one hand, the four-wheel chassis has a relatively high motion speed and a turning feature on one hand; on the other hand, a seesaw type structural design is adopted for the universal wheel mechanism, and the universal wheel mechanism has high adaptive adjustability to small steps or ditches on road surfaces, so that effective filtering is realized, and the advancing stability and reliability of driving wheels are ensured.

Owner:SUZHOU SERVICH ROBOT CO LTD

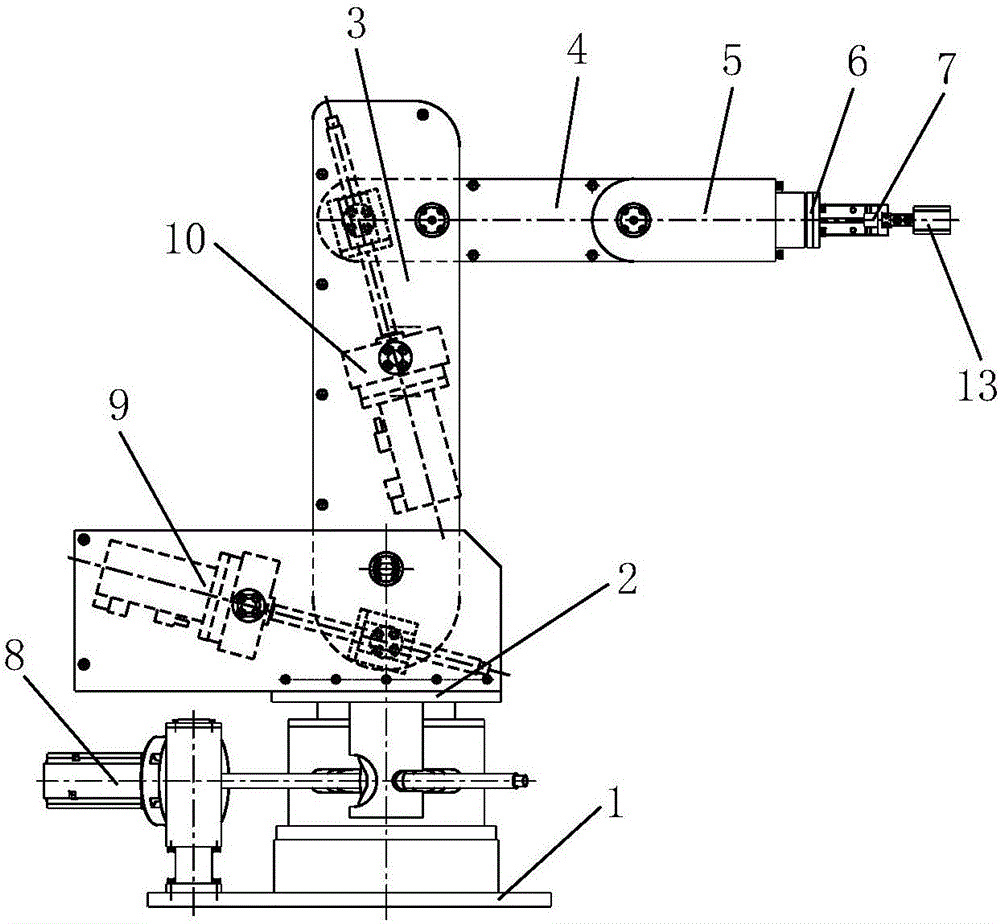

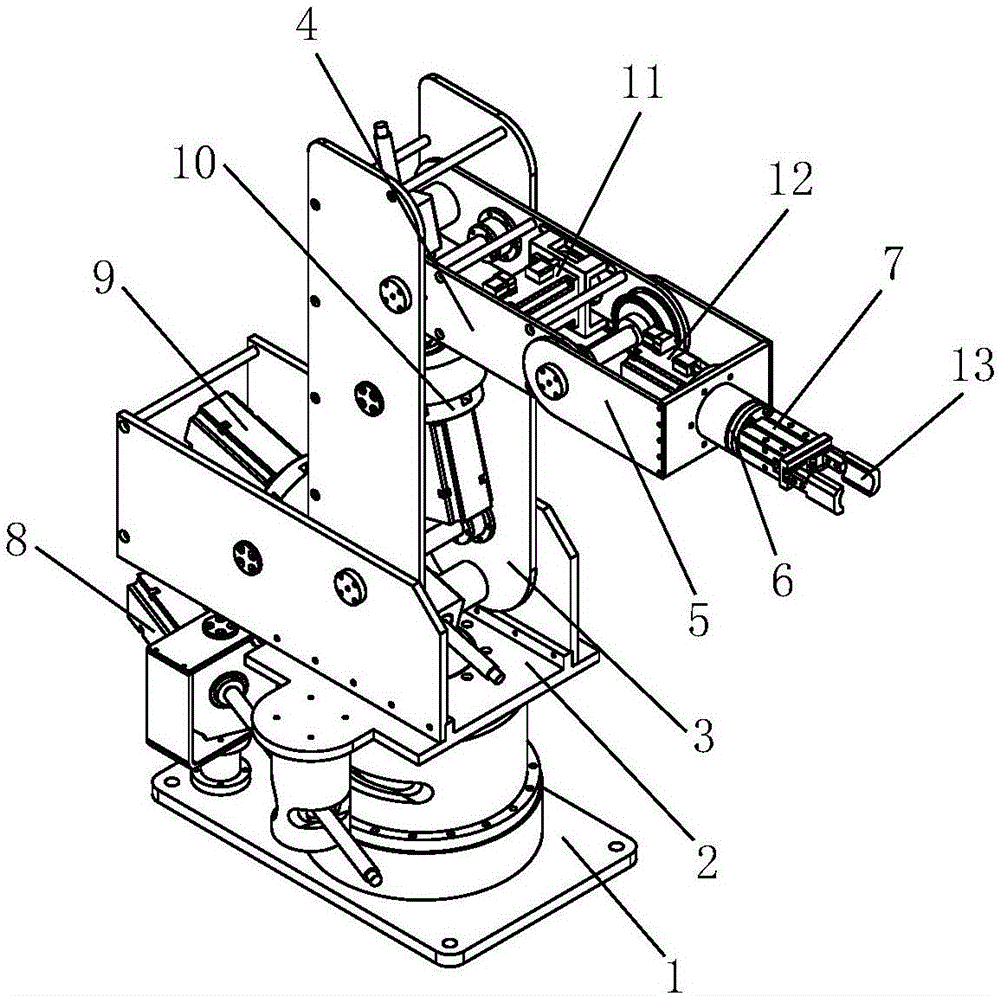

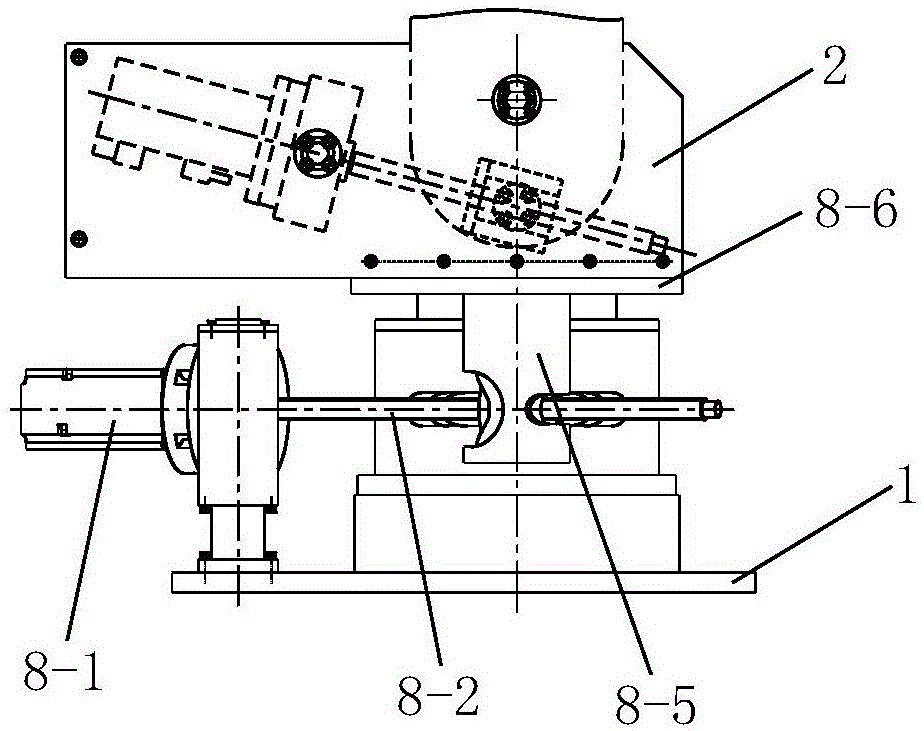

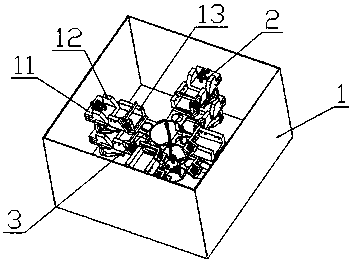

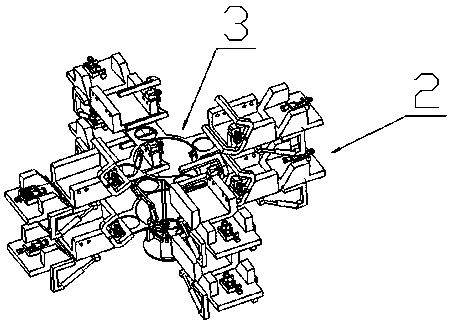

Robot for precise assembling

ActiveCN106426177ALess varietyReasonable structureProgramme-controlled manipulatorGripping headsBall screw driveEngineering

The invention discloses a robot for precise assembling. The robot for precise assembling comprises a base, a rotary table, a large arm, a small arm, a wrist joint, a front end rotational joint and a pneumatic clamping device. The rotary table is rotationally installed on the base. One end of the large arm is hinged to the rotary table, and the other end of the large arm is hinged to one end of the small arm. The other end of the small arm is hinged to one end of the wrist joint, and the front end rotational joint is rotationally installed at the other end of the wrist joint. The pneumatic clamping device is installed at the outer end of the front end rotational joint. A rotary table ball screw driving mechanism used for driving the rotary table to rotate is installed on the base, a large arm ball screw driving mechanism used for driving the large arm to rotate is installed on the rotary table, a small arm ball screw driving mechanism used for driving the small arm to rotate is installed on the large arm, a wrist joint driving mechanism used for driving the wrist joint to rotate is installed on the small arm, and a front end joint driving mechanism used for driving the front end rotational joint to rotate is installed on the wrist joint. The robot for precise assembling is stable in transmission, high in positioning precision and production efficiency, long in service life and wide in application range.

Owner:THE NORTHWEST MACHINE

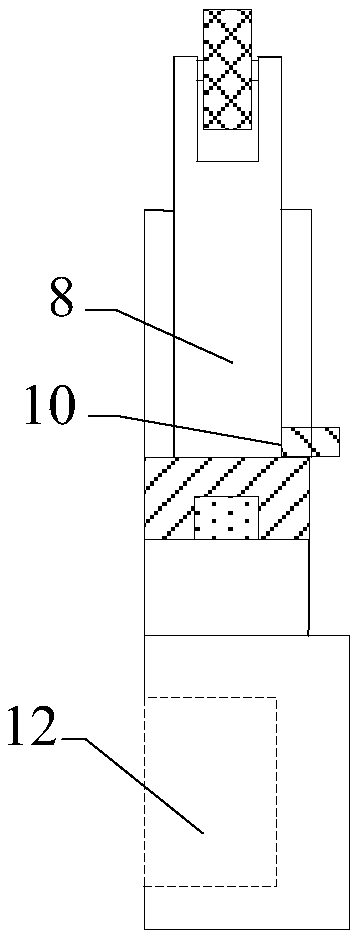

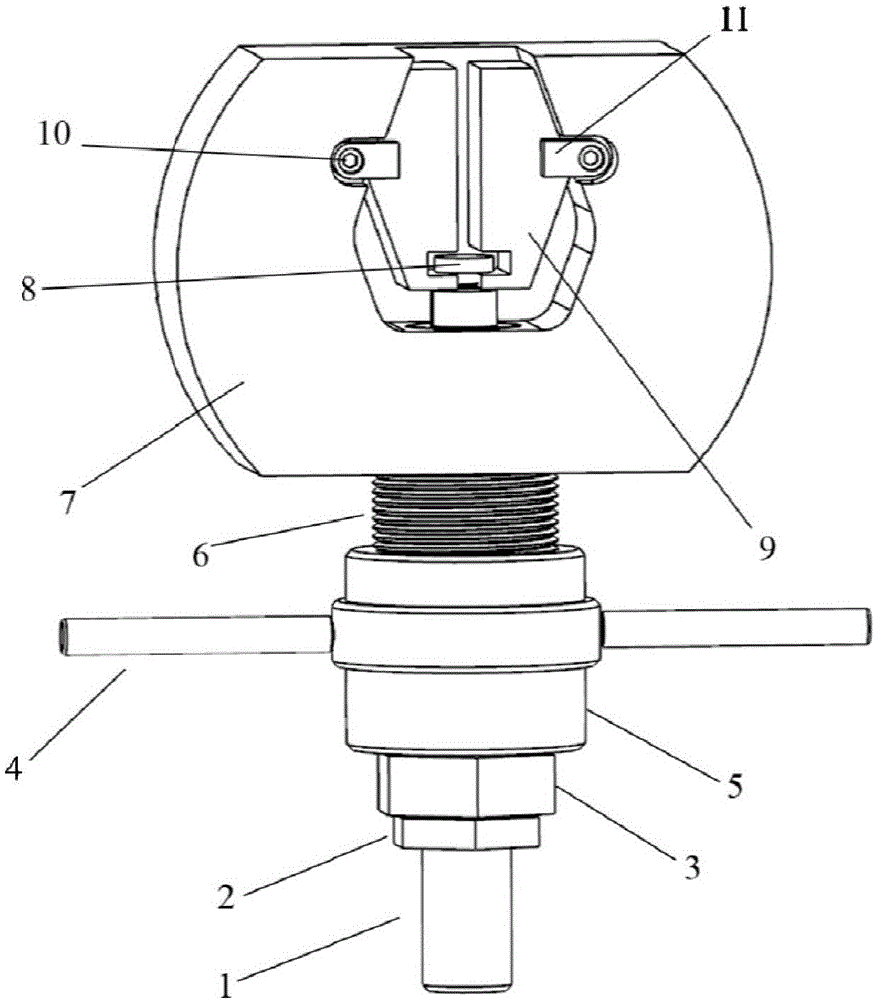

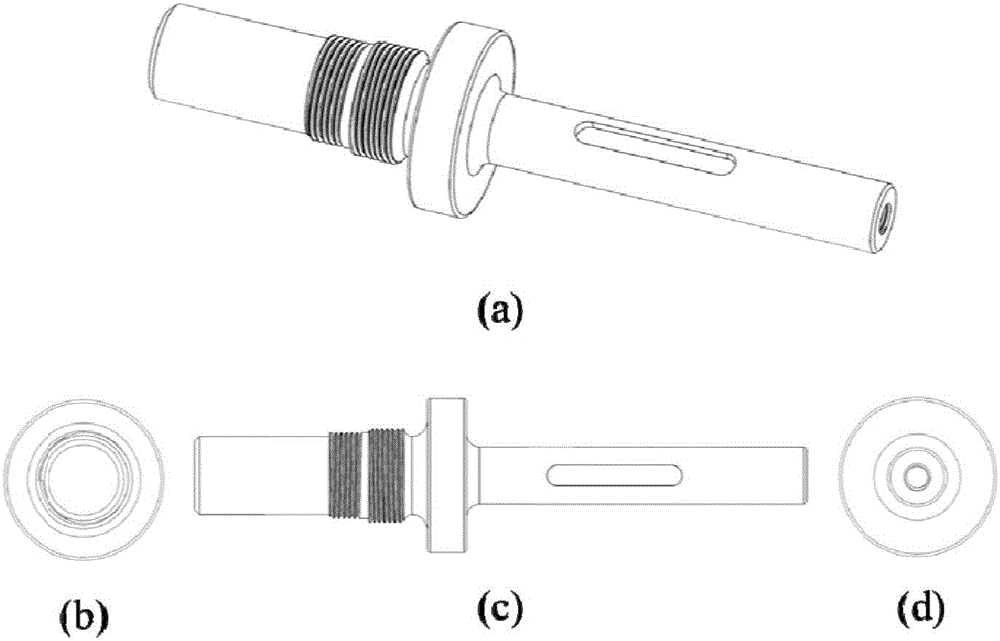

High temperature tensile fatigue test fixture for panel test piece and method

ActiveCN106840867AStable clampingAchieving Stretch FatigueMaterial strength using tensile/compressive forcesTensile fatigueTest fixture

The invention discloses a high temperature tensile fatigue test fixture for a panel test piece and a method. The clamping for the panel test piece in a high temperature test is realized, so that the tensile fatigue test for the panel test piece can be performed under a high temperature condition. A hydraulic chuck of a fatigue machine is used for clamping an optical rod end of a central shaft and is connected with a connecting rod through a sleeve; a fixing nut is arranged on the central shaft; the fixing nut is used for limiting the downward movement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is in threaded connection with a wedge-shaped chuck body; the central shaft passes through a through hole in the middle of the connecting rod; a shaft end is connected with a guiding platform; the guiding platform is located in a groove between two wedge-shaped clamp blocks and is used for guiding the wedge-shaped clamp blocks to move up and down; the test piece is clamped by the wedge-shaped clamp blocks in the wedge-shaped chuck body; the bottoms of the wedge-shaped clamp blocks are propped by the top end of the guiding platform; the two sides are in contact with the wedge-shaped plane in the wedge-shaped chuck body; the upwards movement of the wedge-shaped clamp blocks is limited. The high temperature tensile fatigue test fixture can meet the requirement for stably clamping the panel test pieces in various sizes and can realize the single-shaft tensile fatigue under the high temperature condition.

Owner:BEIHANG UNIV

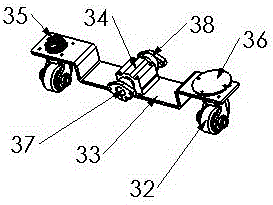

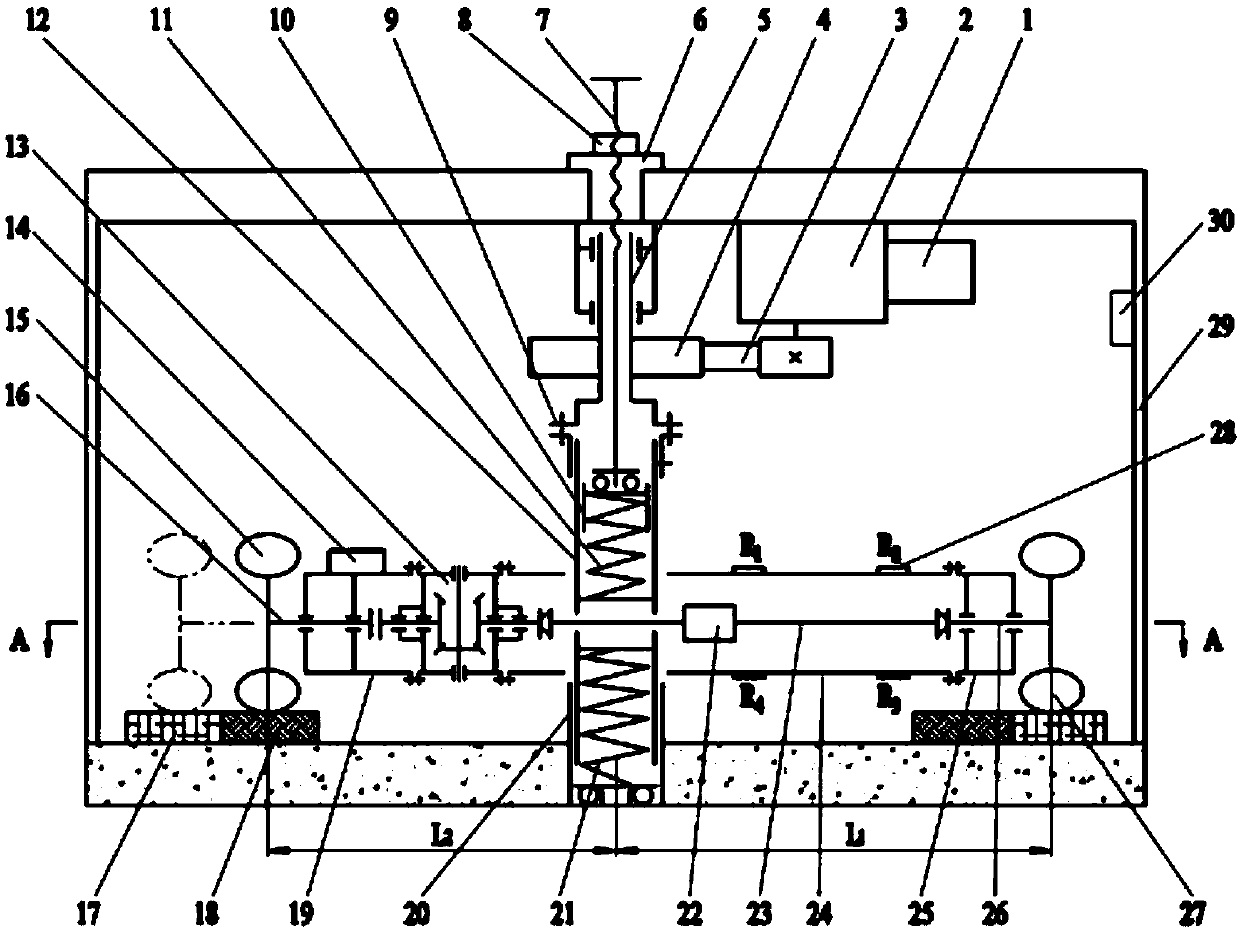

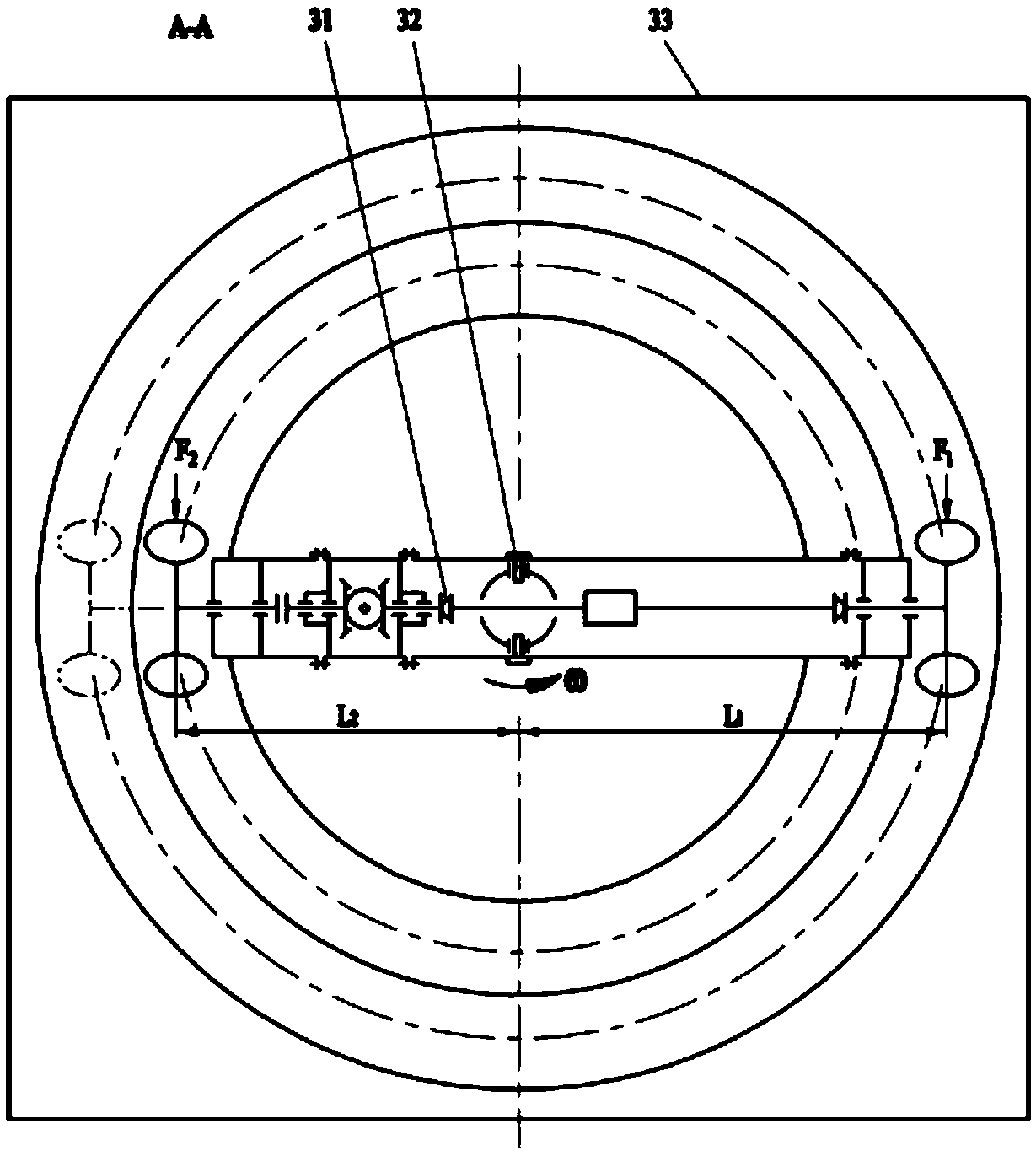

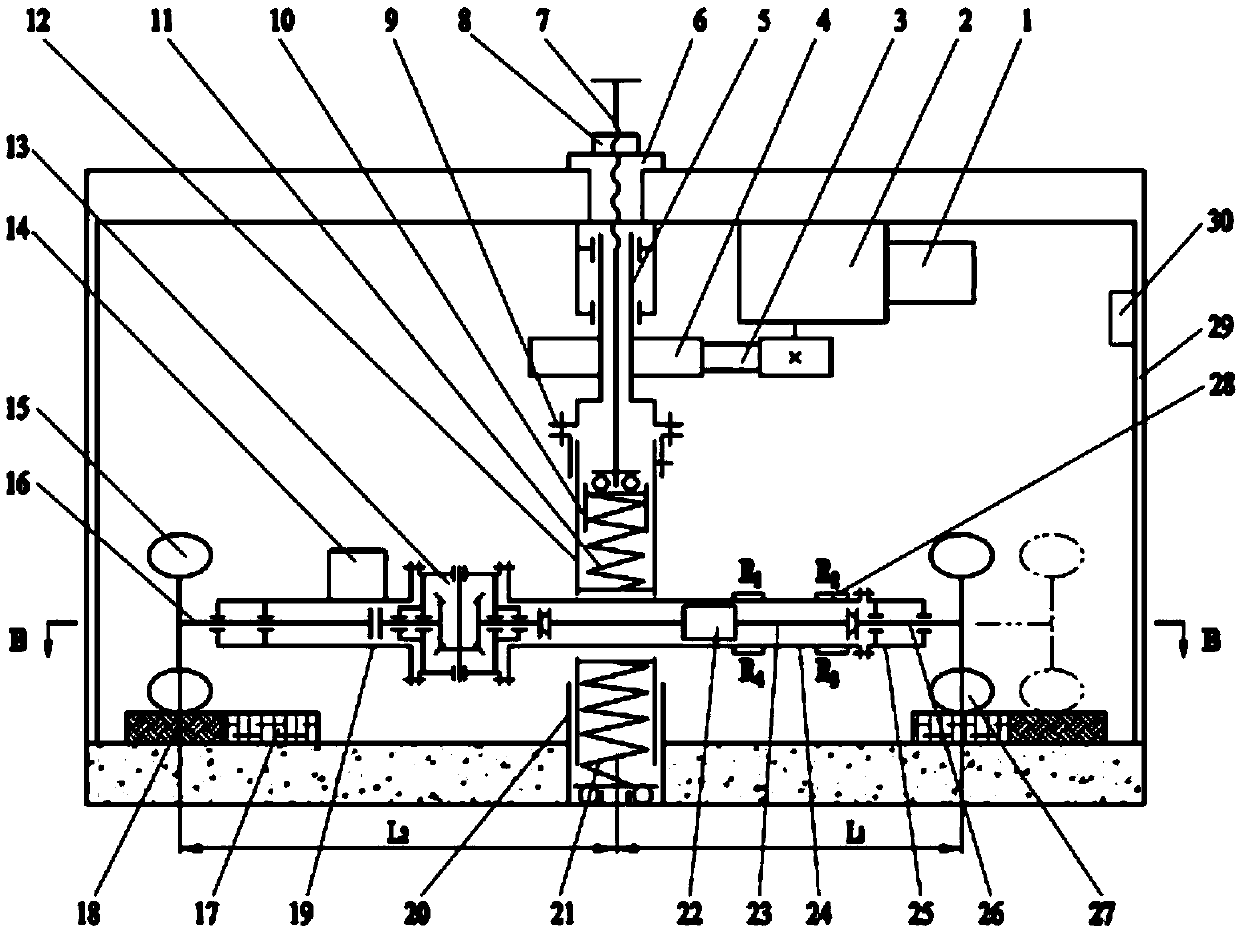

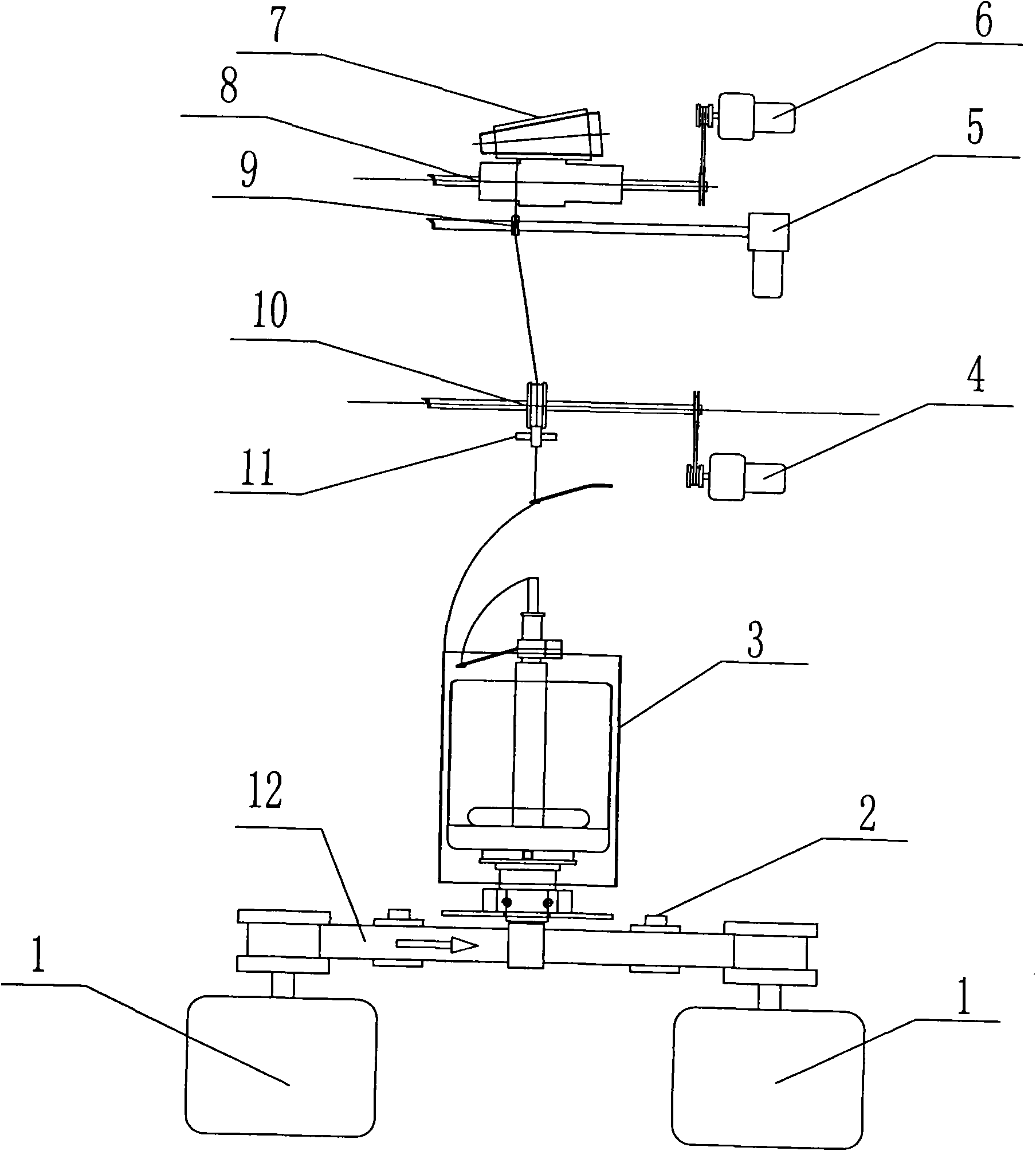

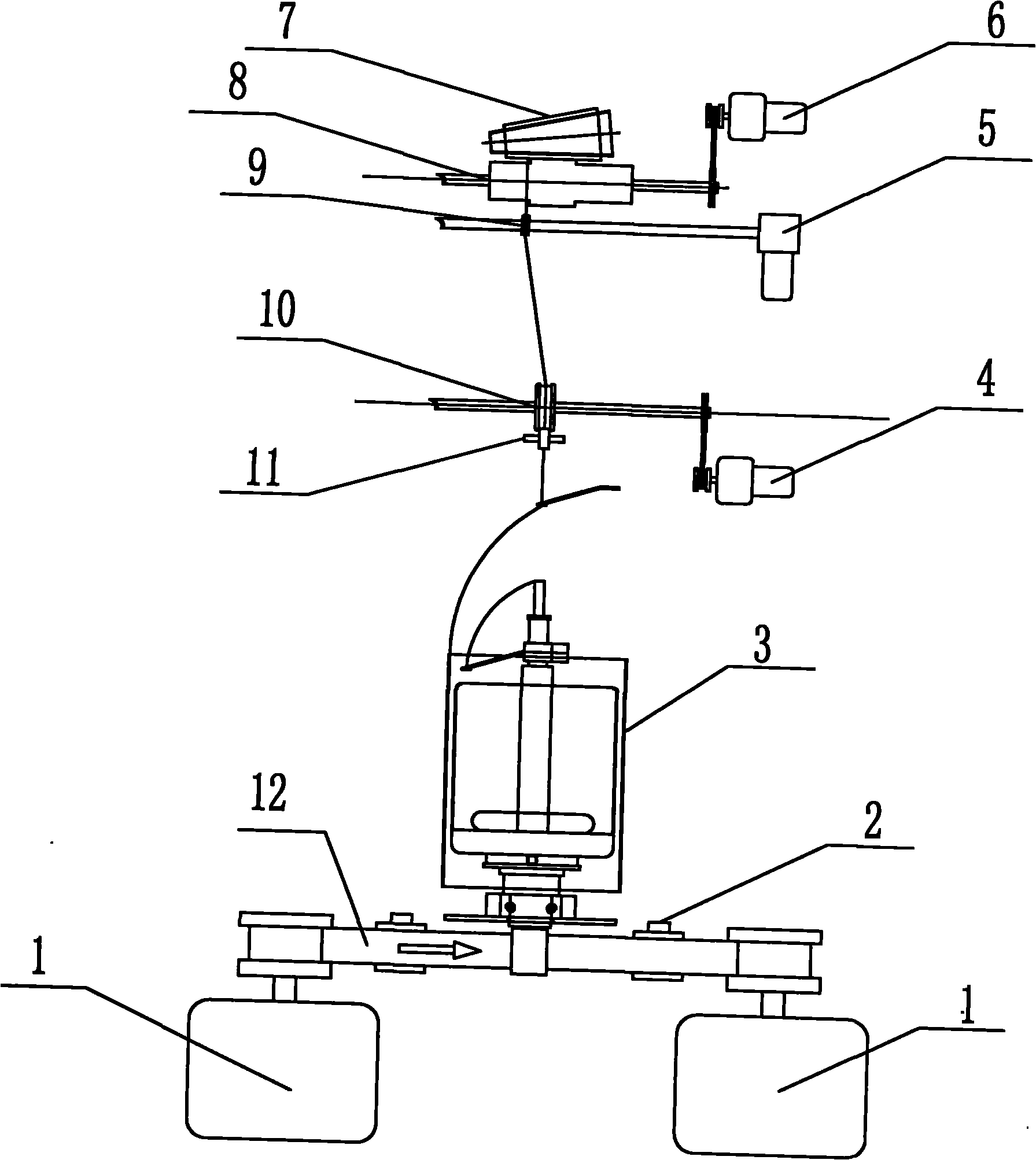

Test device and method for researching friction characteristics between tire and actual pavement

PendingCN109612929AExtended service lifeEliminate the influence of other additional loads such as centrifugal forceUsing mechanical meansVehicle tyre testingWear patternRoad surface

The invention discloses a test device and method for researching friction characteristics between a tire and an actual pavement, and belongs to the technical field of detecting equipment. Actual working conditions of the tire with load running on different pavements are well simulated through mechanical structures such as a loading sleeve, a loading sleeve base, a rotary arm and a rack, the test device and method for researching friction characteristics between the tire and the actual pavement can be used for testing a friction factor between the tire and the pavement and researching wear pattern between the tire and the pavement, compression amount of a loading spring can be adjusted through a loading screw according to requirements, and thus a test load is adjusted; meanwhile tire running speed is adjusted through a transmission system; changing is conducted on a slip rotary rate or a slip shift rate between the tire and a pavement through adjusting a connected relation between a tested wheel and an auxiliary wheel, multiple kinds of running conditions of the tire on the pavement are simulated, data such as the load, a rotate speed and a torque are detected in real time through asensor, and thus the friction factor between the tested tire and the tested pavement is obtained by formula calculation.

Owner:西安凯德液压机电有限责任公司

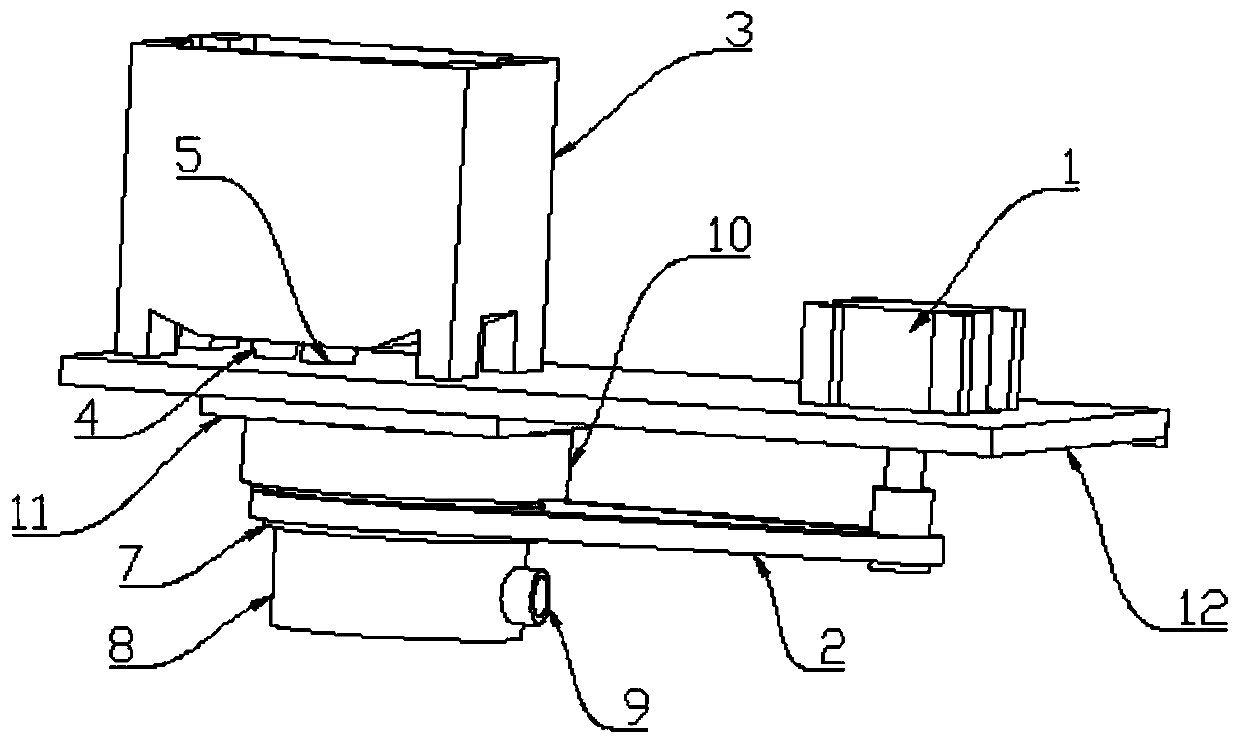

Double twister

InactiveCN101831735ADoes not affect running speedEasy to adjust winding densityTextiles and paperPolyesterYarn

The invention relates to a double twister, which is suitable for double twisting procedure of pure cotton and blended yarn of cotton, wool, polyester and the like in textile industry. The double twister comprises a double twisting mechanism, a traction mechanism, a transversal moving mechanism and a winding mechanism, wherein the double twisting mechanism comprises a spindle component (3), a nylon belt (12) and two nylon belt driving motors (1), wherein the transversal moving mechanism comprises a yarn guiding device (9), a transversal moving device and a transversal moving motor (5); the traction mechanism comprises a traction driving wheel (10), a traction rubber pressing wheel (11) and a traction motor (4); the traction driving wheel (10) and the traction rubber pressing wheel (11) form compression driving; the traction driving wheel (10) is connected with the traction motor (4); the winding mechanism comprises a winding driving wheel (8), a yarn winding barrel (7) and a winding motor (6); and the winding driving wheel (8) is connected with the winding motor (6). The traction driving wheel and the winding driving wheel are respectively driven by the independent motors, the traction motor and the winding motor are combined with electrical control to conveniently adjust the winding density, the yarn running speed is not affected, and the nonuniform twisting index is not affected.

Owner:江阴祥盛纺印机械制造有限公司

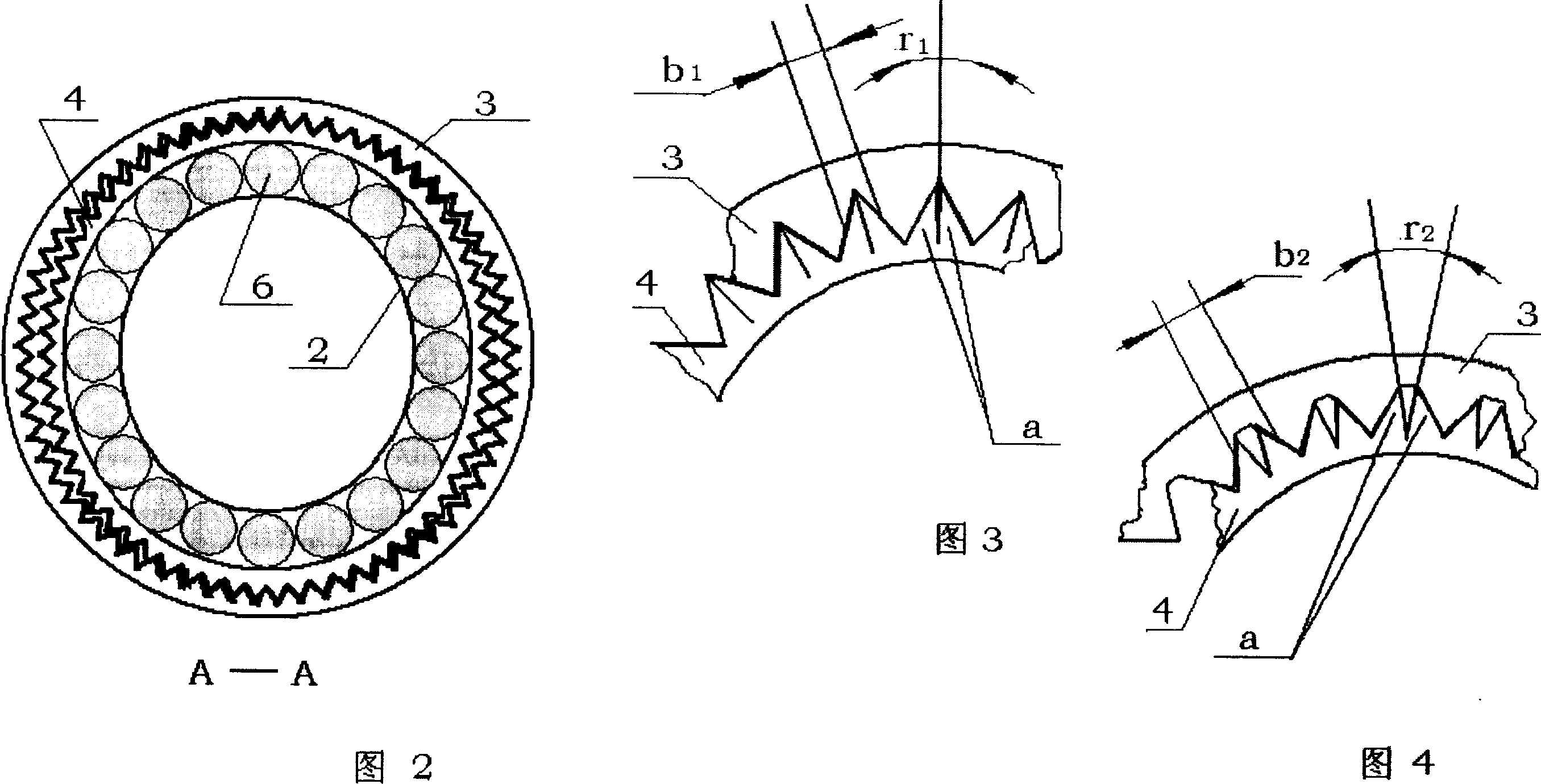

Harmonic teeth-driving stage-less speed variator

InactiveCN101126436ASave the hassle of shifting gearsEasy to change speedFriction gearingsGear driveDrive shaft

The invention belongs to the field of mechanical stepless transmission and includes a harmonic gear-driving stepless transmission, which is composed of a driving shaft, a driven shaft, a rigid gear, a flexible gear, a wave generator and a roller; the flexible gear can make axial movement relative to the rigid gear, the teeth of the flexible gear are composite teeth, which are composed of two branch teeth. When the flexible gear makes axial movement relative to the rigid gear, the angle between the two branch teeth of the composite teeth and the tooth thickness are variable, when the rigid gear keeps stationary and the driving shaft actuates the wave generator to rotate, the wave generator forces the flexible gear to generate continuous elastic deformation by the roller, and the tooth thickness of the composite teeth of the flexible gear also changes with the deformation of the flexible gear; because the tooth thickness or the width between the teeth keeps variable when the teeth number of the rigid gear is fixed, although the teeth number ratio of the flexible gear and the rigid gear keeps unchanged, the arc length passing the nodal circle is variable, and the stepless transmission can be realized so long as the flexible gear makes axial movement relative to the rigid gear.

Owner:李维农

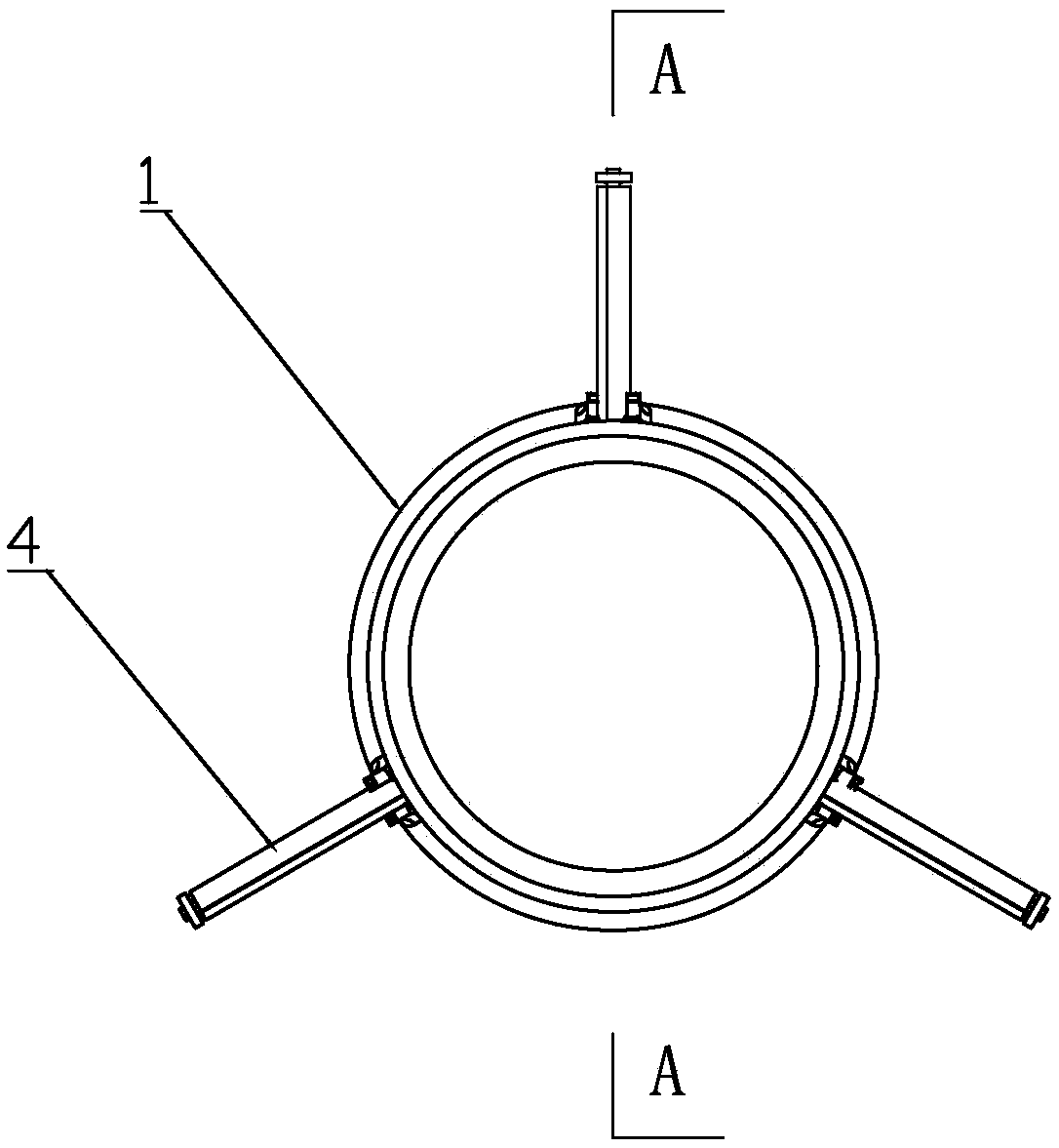

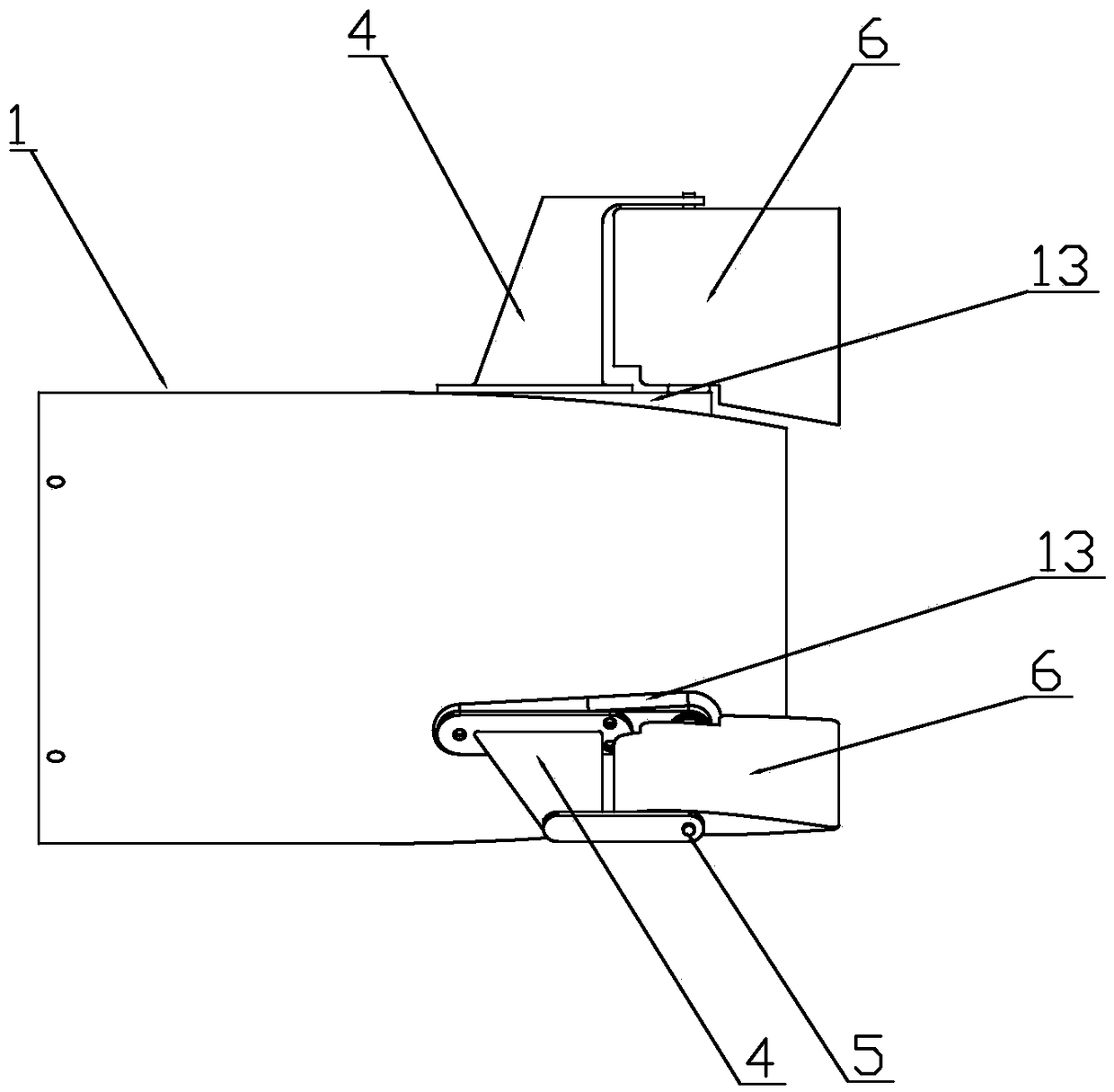

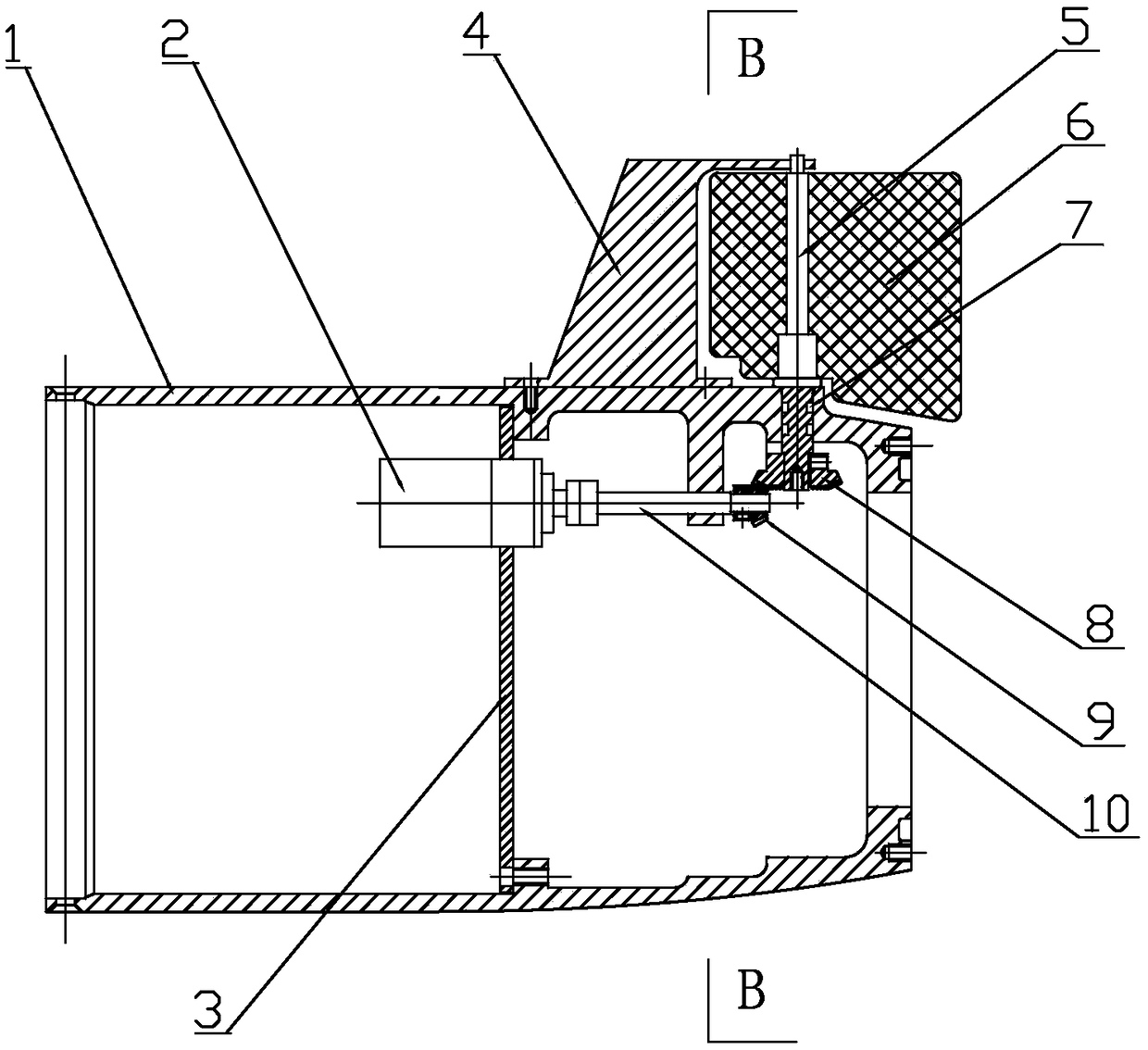

A tail rudder of an underwater vehicle

PendingCN109250056ACompact structureImprove stabilityUnderwater vesselsUnderwater equipmentAttitude controlControl models

The invention discloses a tail rudder of an underwater vehicle, which comprises a housing, a steering gear, a steering gear mounting plate, a tail wing plate, a steering gear plate shaft, a steering gear plate, a bevel gear and a steering gear shaft. Three steering gear lug plates and three rudder shaft lug plates are uniformly arranged at equal distances in the housing; three rudder platforms arearranged on the outside, and rudder shaft lug plates are arranged on the inside of the rudder platforms; the steering mounting plate is screwed on the steering gear lug plate, and three groups of steering gears are arranged on the steering gear mounting plate; at that out end of the rudder platform and the steering gear plate bevel gear, a flap rudder is arranged; and at the outer end of the rudder platform and the rudder plate bevel gear, a flap rudder is arranged. The steering gear bevel gear and the rudder plate bevel gear are mutually meshed and driven. The invention adopts a three-axis rudder tail rudder arrangement mode, which saves cost and improves system reliability. The control model is simplified and the control difficulty is reduced; it has compact structure and high stability. The rudder plate adopts the flap structure to improve the rudder efficiency and the attitude control ability of the underwater vehicle. The electromagnetic interference is reduced, the stress structure of the rudder shaft is improved, the damage probability of the rudder shaft caused by the trailer is reduced, and the safety of the rudder shaft is improved.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T +1

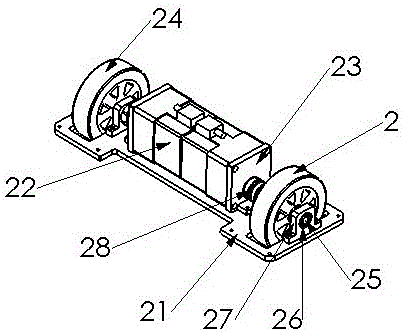

Four-wheel drive differential steering method of mobile welding robot

InactiveCN102991578AEasy to controlEasy to implementNon-deflectable wheel steeringDrive wheelControl theory

The invention discloses a four-wheel drive differential steering method of a mobile welding robot. The mobile welding robot comprises a first driving wheel, a second driving wheel, a third driving heel, a fourth driving wheel, a mobile body, a first revolving pair between the first driving wheel and the body, a second revolving pair between the second driving wheel and the body, a third revolving pair between the third driving wheel and the body and a fourth revolving pair between the fourth driving wheel and the body, and is characterized in that the sizes of speeds VR of the first and second driving wheels and the sizes of deflection angles of the first and second driving wheels are the same all the time, and the directions of the deflection angles are reverse; and the sizes of speeds VL of the third and fourth driving wheels and the sizes of deflection angles of the third and fourth driving wheels are the same all the time, and the directions of the deflection angles are reverse. The four-wheel drive differential steering method has the advantages of simple control, easiness in implementation, low cost, capability of realizing steering of any radius, no need of a steering mechanism, no slip during steering, accurate steering and high reliability. Meanwhile, since four-wheel drive is adopted, the stability and the load capacity of the method are greatly improved compared with two-wheel differential steering.

Owner:NANCHANG UNIV

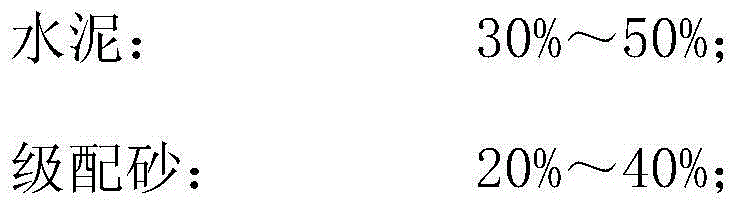

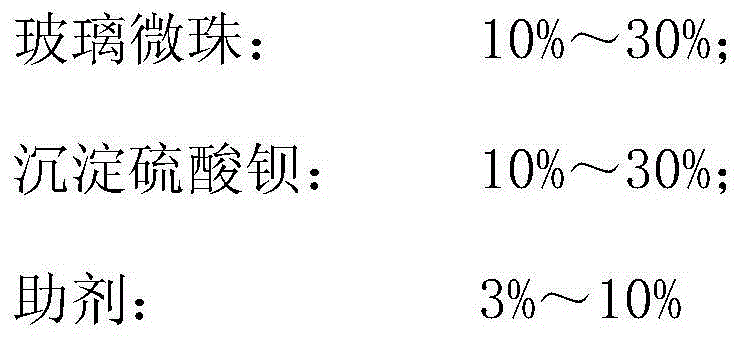

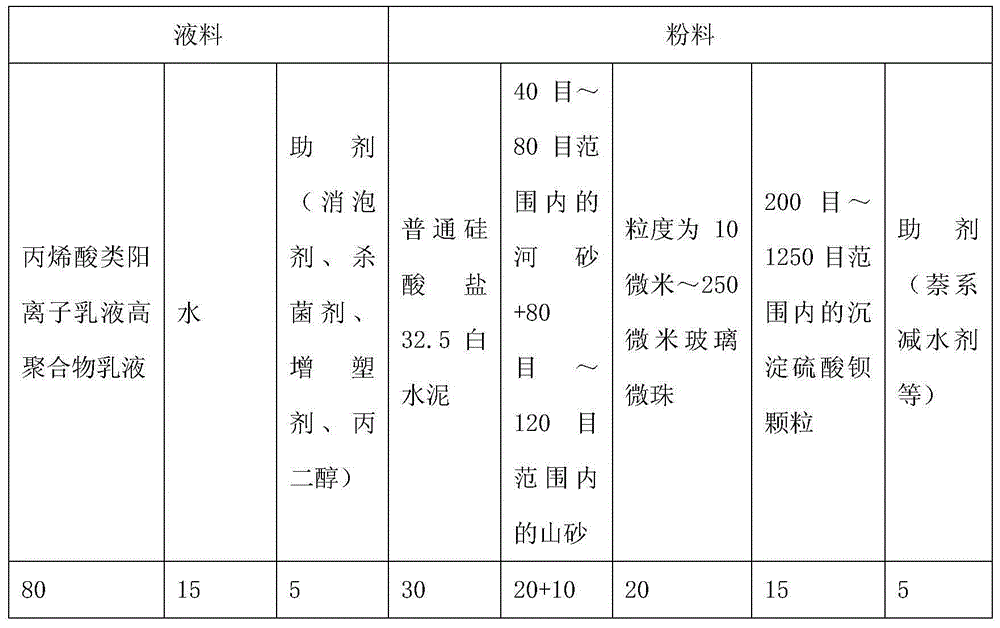

Thick-painted cement-based waterproof coating

The invention discloses a thick-painted cement-based waterproof coating, which consists of liquid materials and powder materials, wherein the liquid materials and the powder materials are made from raw materials with parts by weight: the liquid materials comprise high polymer emulsion 80%-90%, water 10%-20% and auxiliaries 3%-10%, the powder materials comprise cement 30%-50%, graded sands 20%-40%, glass beads 10%-30%, precipitated barium sulphate 10%-30% and auxiliaries 3%-10%. The thick-painted cement-based waterproof coating can achieve a thickness which is required by standard construction through once thick-painted construction in the non-cracking condition, saves time and labor, and greatly saves cost for building construction. Experimental results show, the thick-painted cement-based waterproof coating uses roll coating, brush coating and roll coating modes to construct, can achieve 1.5mm-2.0mm construction thickness, can achieve above 3.5MPa bonding strength, can achieve above 250% elongation at break, and does not have unhealthy phenomena of cracking, sagging and slipping and the like.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

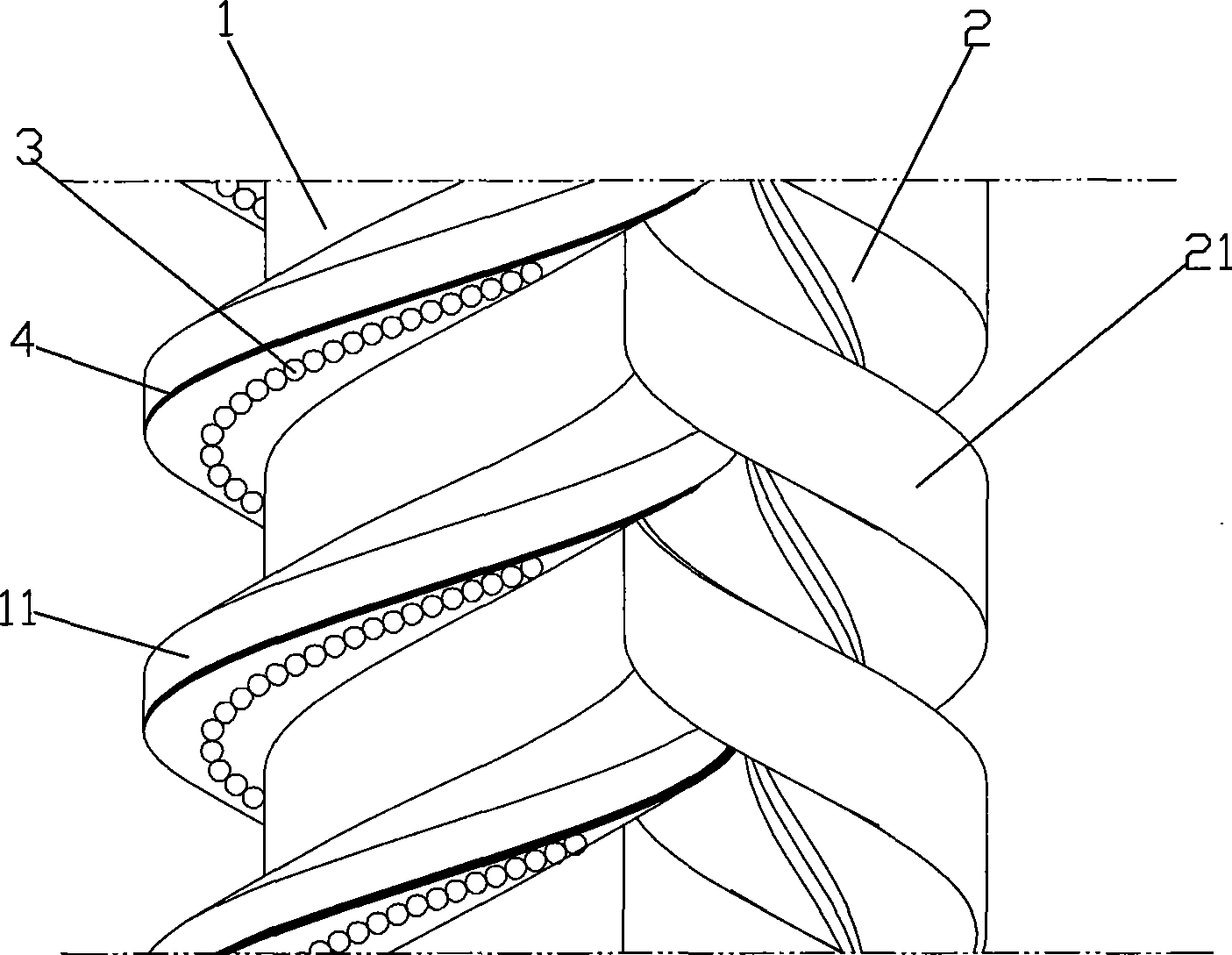

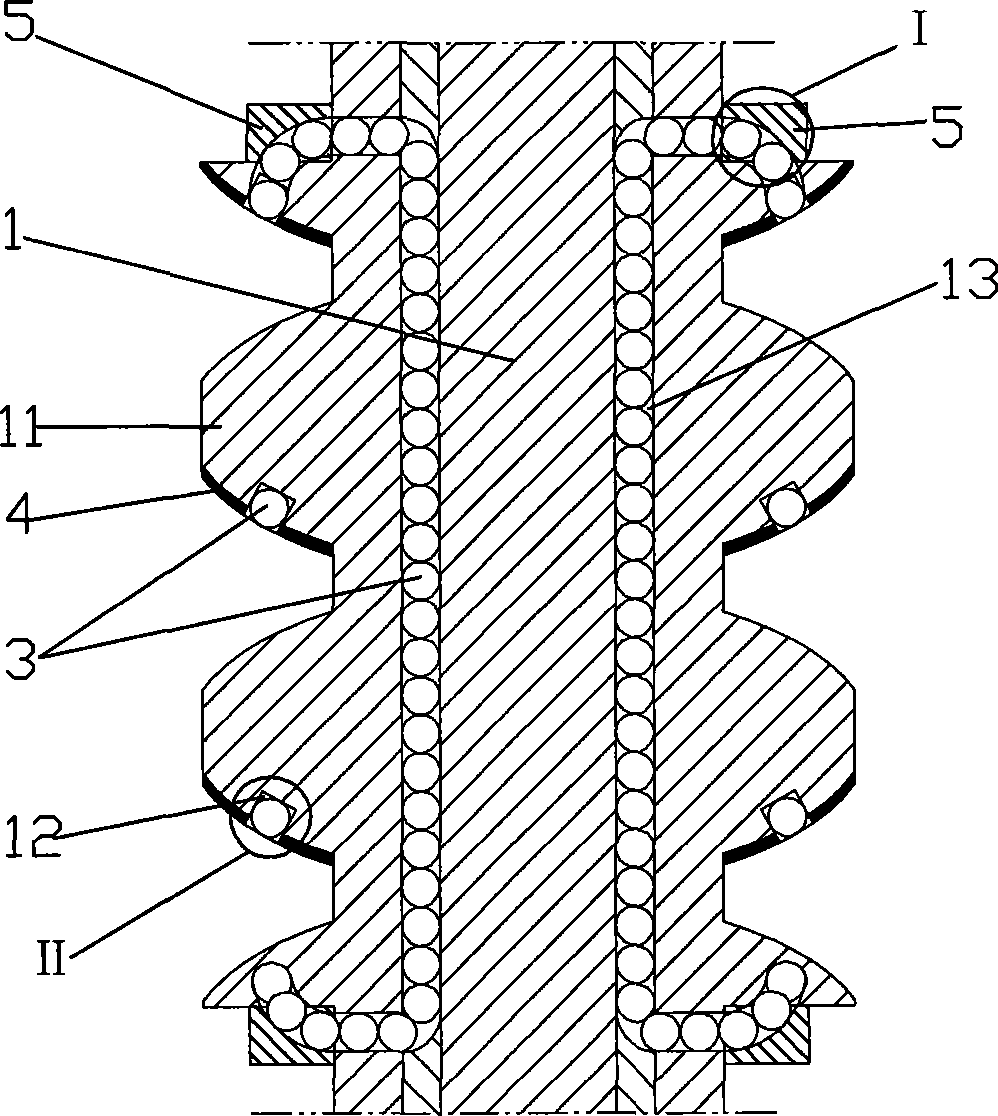

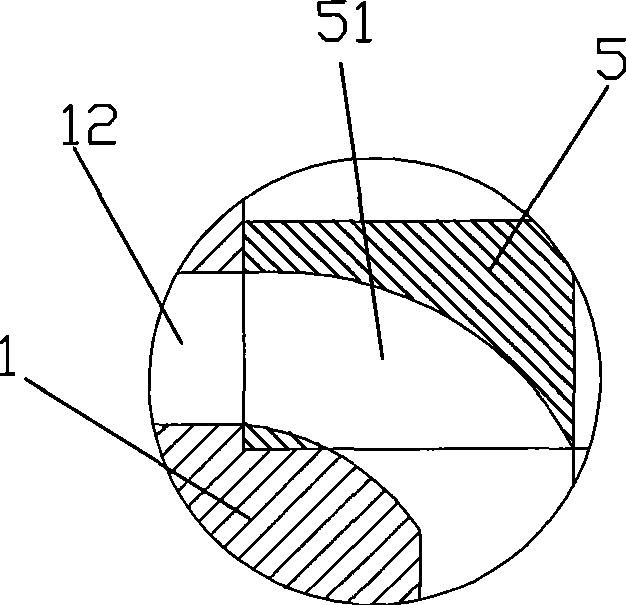

Ball bearing screw pump

InactiveCN101532490AExtended service lifeImprove delivery efficiencyRotary piston pumpsRotary piston liquid enginesBall bearingEngineering

The invention discloses a ball bearing screw pump comprising a driving and a driven screw meshed with each other. A ball bearing trough is arranged on a spiral surface where the driving and driven screws are meshed along a spiral line of the driving and driven screws. Ball bearings are arranged in parallel in the ball bearing trough. Diameter of the ball bearing is greater than depth of the ball bearing trough. The invention realizes point contact rolling friction, which can reduce friction among spiral surfaces when the pump operates, and prolong service life of the driving and driven screws as well as saves driving energy. For medium with stronger adaptability, the invention is applicable for medium with self-lubricating effect which is not high; the invention operates stably; reacts agilely without retardarceand slippage, which can obtain greater synchronous effect. An elastic sealing layer is arranged on the mesh surface correspondingly and the mesh surface is compensated by the sealing layer from hard contact, which ensures meshing effect to improve medium convey efficiency and reduce noise of spiral meshing motion.

Owner:CHONGQING UNIV

Efficient silk making device

ActiveCN108004599AIncrease productivitySimple structureSilk reelingTextile/flexible product manufactureMotor driveElectric machinery

The invention relates to the technical field of silk making, in particular to an efficient silk making device comprising a plurality of silk making units which are independent mutually. Each silk making unit is provided with a regulating system, a unit barrel and a winding motor driving the unit barrel to rotate, each regulating system comprises a detector for detecting silk strip tension, a signal processor and an adjusting structure, each adjusting structure is arranged between a sheath twisting structure and an exploring structure and comprises a silk guide roller, an upper silk guide button, a lower silk guide button and a rotating motor, a roller shaft of each silk guide roller is connected with an output shaft of the corresponding rotating motor, and each signal processor is connected with the corresponding rotating motor, the corresponding winding motor and the corresponding detector. When silk strip tension is too small, the rotating motor reduces rotating speed of the silk guide rollers to decrease silk strip winding speed, loose winding of silk strips is avoided, and the silk strip tension is increased gradually; when the silk strip tension is too large, the rotating motor increases the rotating speed of the silk guide rollers to avoid the silk strips being wound too tightly, and the silk strip tension is lowered gradually; a silk barrel is loose outside and tight inside, so that shaping is good, and phenomena of silk sliding, silk embedding and silk breaking are avoided.

Owner:ZHEJIANG SCI-TECH UNIV +2

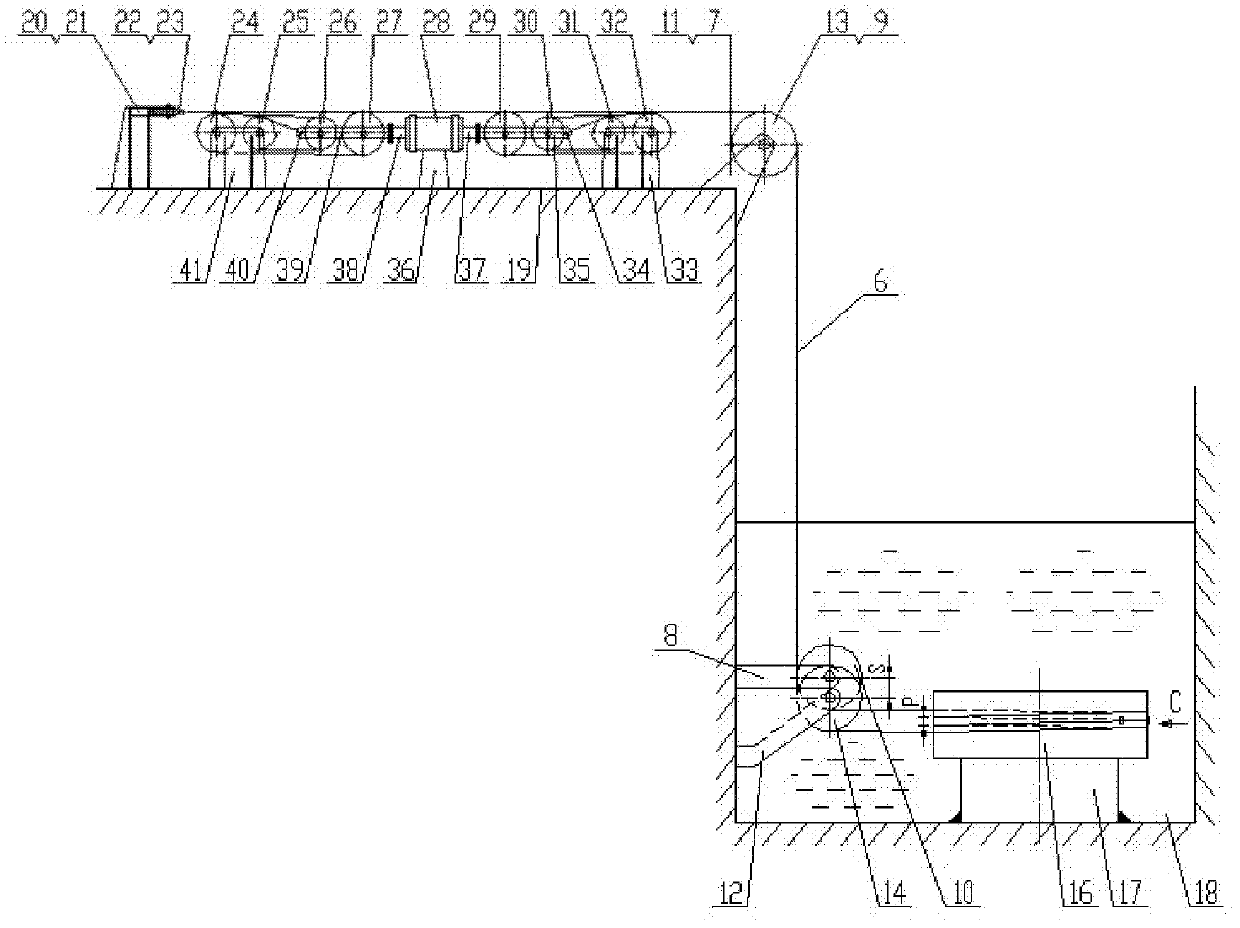

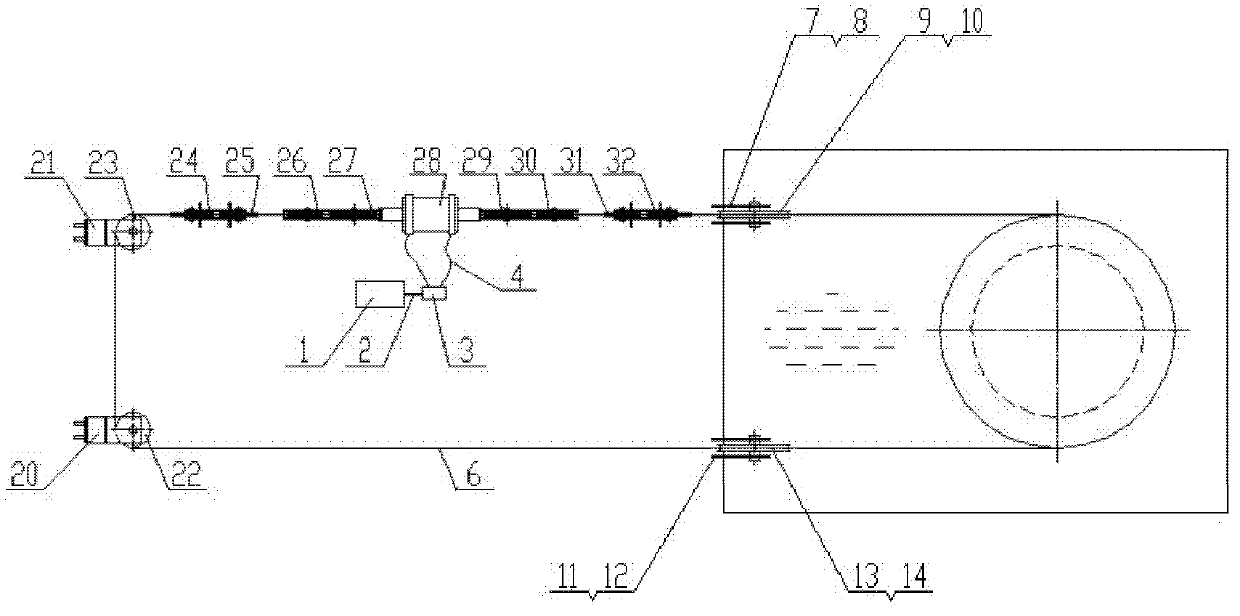

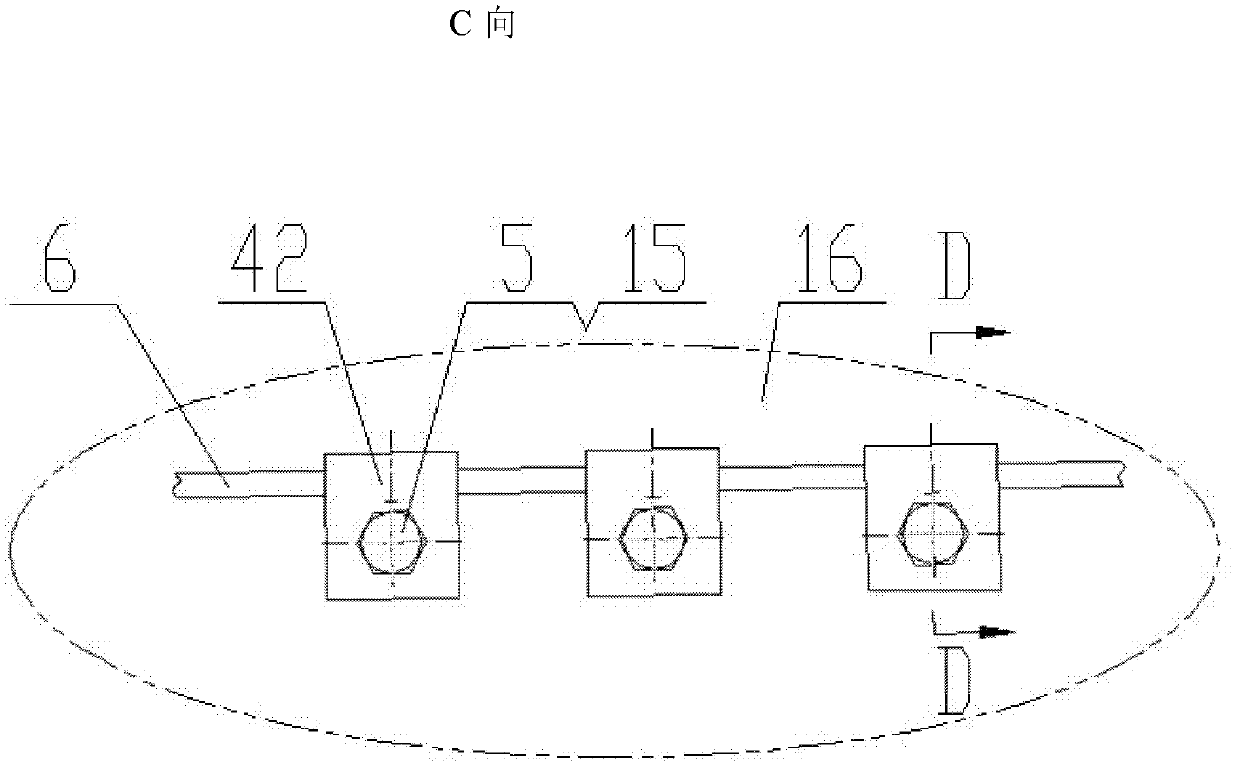

Traction type reciprocator for single point mooring liquid slip ring test

ActiveCN102889964AReasonable designSimple structureMachine part testingFluid-tightness measurementPistonEngineering

The invention belongs to marine engineering machinery, and relates to a traction type reciprocator for a single point mooring liquid slip ring test. The traction type reciprocator is characterized in that a hydraulic cylinder is arranged on a mounting platform; a cylinder piston A at one end of the hydraulic cylinder drives a traction pulley block A consisting of a pulley J, a pulley I, a pulley H, a pulley G, a pulley F, a pulley E, a pulley C and a pulley D through a steel wire rope; and a cylinder piston B at the other end of the hydraulic cylinder drives a traction pulley block B consisting of a pulley K, a pulley L, a pulley M, a pulley N, a pulley A and a pulley B through a steel wire rope, the pulley K and the pulley L are arranged on a support H, the pulley M and the pulley N are arranged on the support G, the pulley A is arranged on the support A, and the pulley B is arranged on the support B. The traction type reciprocator is reasonable in design and simple in structure; even if the rope of the pulley block on one side of the cylinder is stored, the rope of the pulley block on the other side of the cylinder is released, and then a reciprocating function of the reciprocator is realized; and moreover, the traction type reciprocator is easy to manufacture and maintain, low in failure rate, low in manufacturing cost, quite convenient to operate and use, simple, practical, safe and reliable, and the steel wire ropes are anti-slip.

Owner:DALIAN HUARUI HEAVY IND GROUP

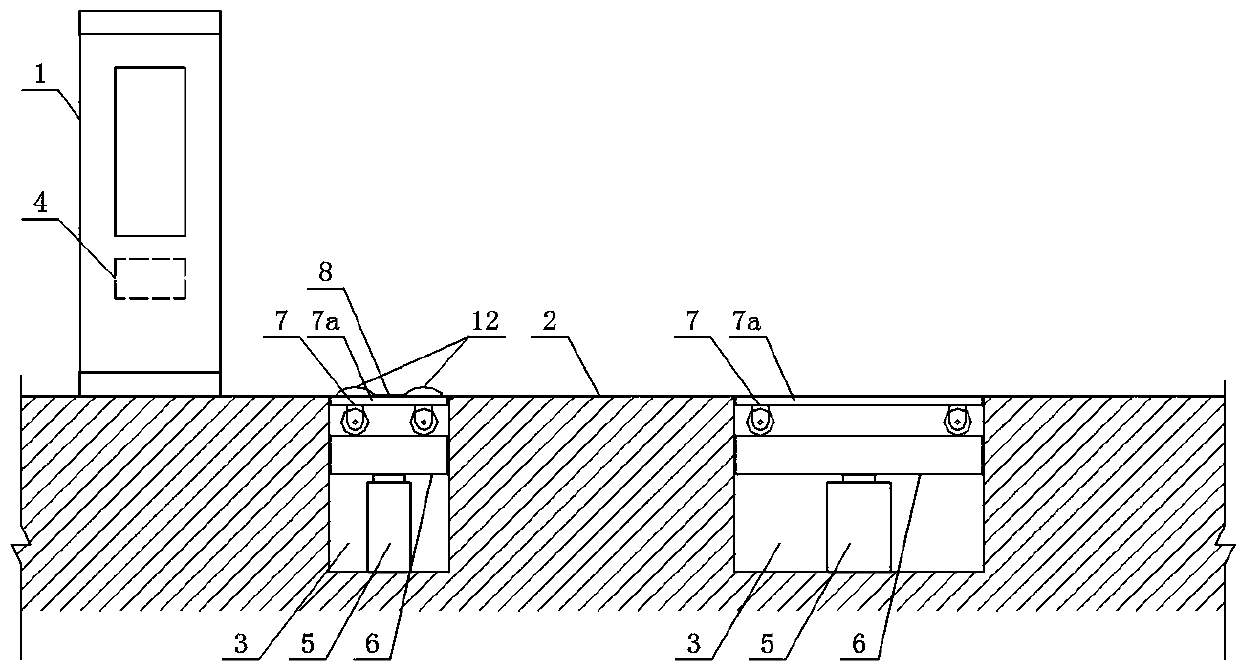

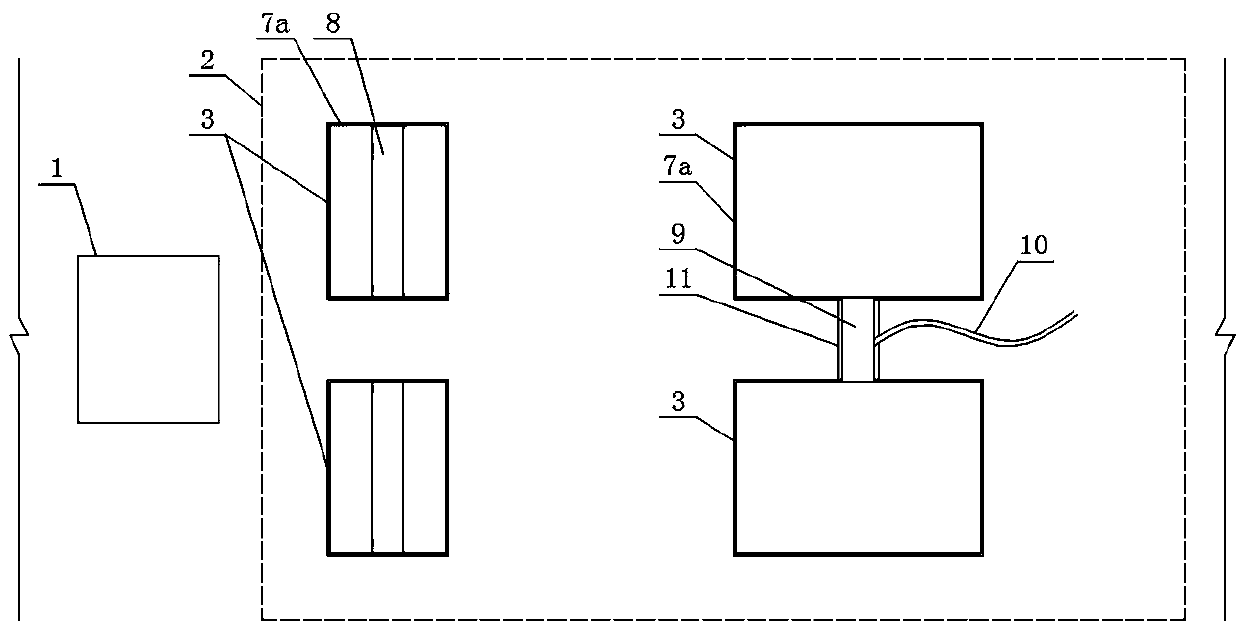

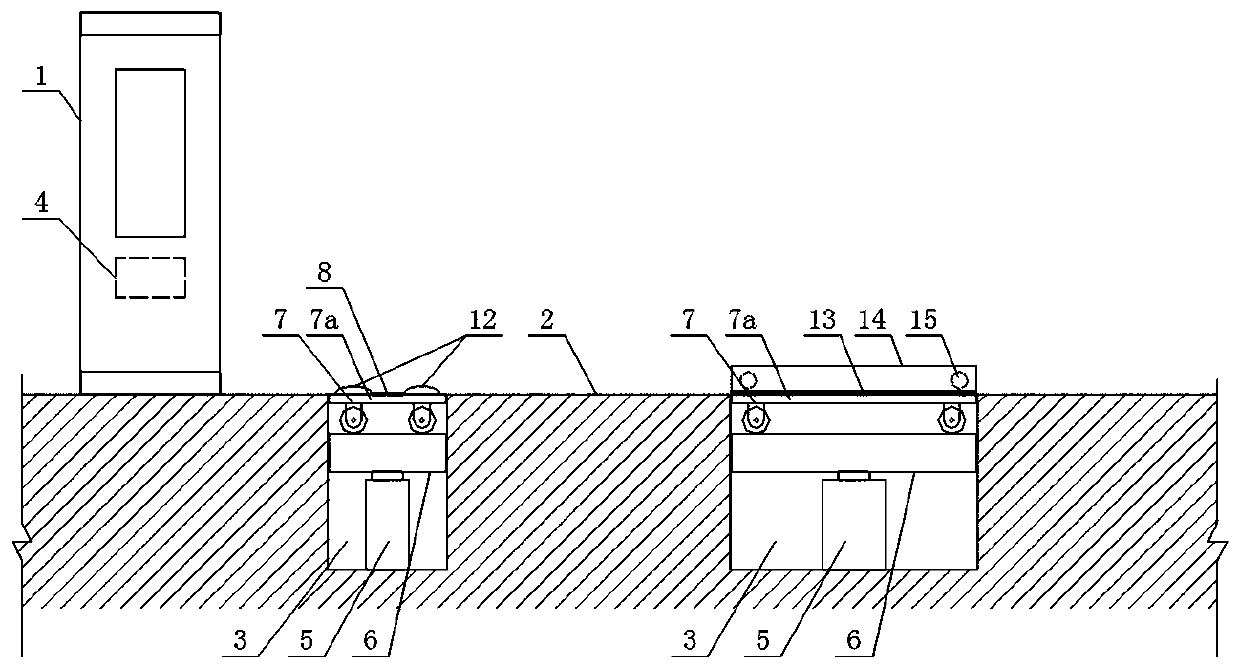

Charging pile system of new energy vehicle

ActiveCN110254277AAccurately monitor whether the stop is in placeAvoid occupyingCharging stationsElectric vehicle charging technologyNew energyAlternative fuel vehicle

The invention discloses a charging pile system of a new energy vehicle. The charging pile system comprises a charging pile body, wherein a parking region is arranged on a ground position in front of the charging pile body; four rectangular foundation pits are formed in the parking region; the positions of the four foundation pits correspond to those of four wheels of the new energy vehicle; a wheel assisting mechanism is arranged in each foundation pit, and the wheel assisting mechanism is used for bearing and moving the wheel, which is on the position of the wheel assisting mechanism, of the new energy vehicle, and the wheel assisting mechanism is controlled to start and stop by a PLC of the charging pile body. According to the charging pile system disclosed by the invention, the wheel assisting mechanisms for bearing and moving the four wheels of the new energy vehicle are separately arranged on the parking region, so that the problems that other new energy vehicles needing charging cannot be charged as the parking region is occupied, and the charging pile cannot be effectively used are radically solved.

Owner:郑州叮叮智能科技有限公司

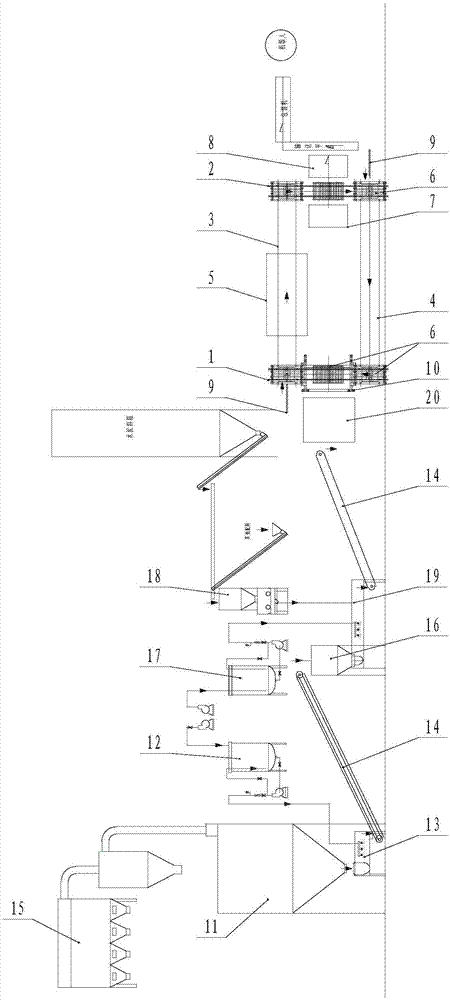

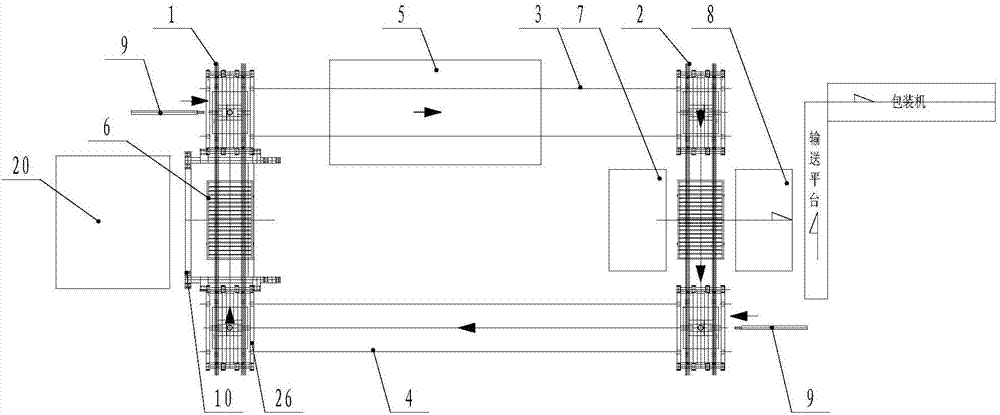

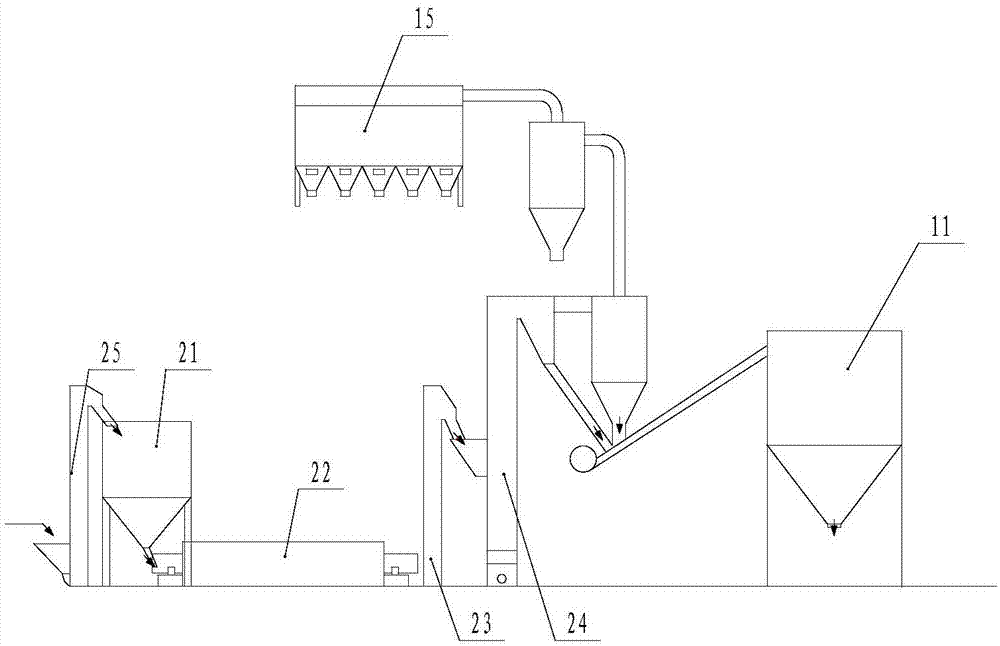

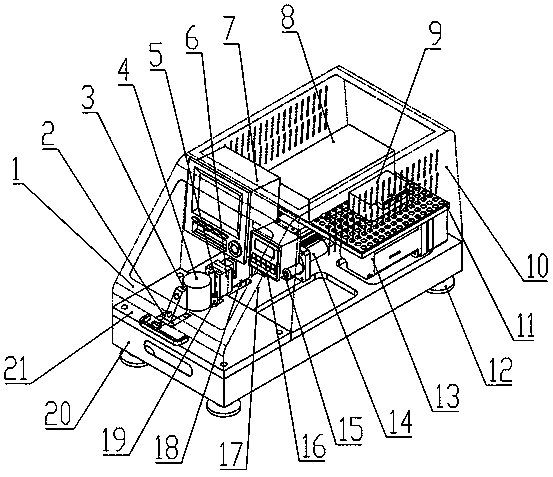

Full-automatic production device for expanded perlite heat preserving board

ActiveCN107571388ASave manpower and investmentStable transmissionCeramic shaping plantsAuxillary shaping apparatusPerliteProcess engineering

The invention discloses a full-automatic production device for an expanded perlite heat preserving board and relates to the field of heat preserving board production devices. The full-automatic production device for the expanded perlite heat preserving board is used for overcoming the defects that in the process of producing the expanded perlite heat preserving board, cost is high, efficiency is low, consumed time is long and assembly line production cannot be achieved. The full-automatic production device for the expanded perlite heat preserving board comprises a material mixing device, a board pressing device, a drying device and a packaging platform; the material mixing device is used for conveying materials to the board pressing device after the materials are mixed uniformly; the boardpressing device is used for pressing the mixed materials into the heat preserving board; the drying device is used for drying the heat preserving board; and then the dried heat preserving board enters the packaging platform to be packaged. The full-automatic production device for the expanded perlite heat preserving board is used for assembly line production of the expanded perlite heat preserving board.

Owner:华亿建材科技有限公司

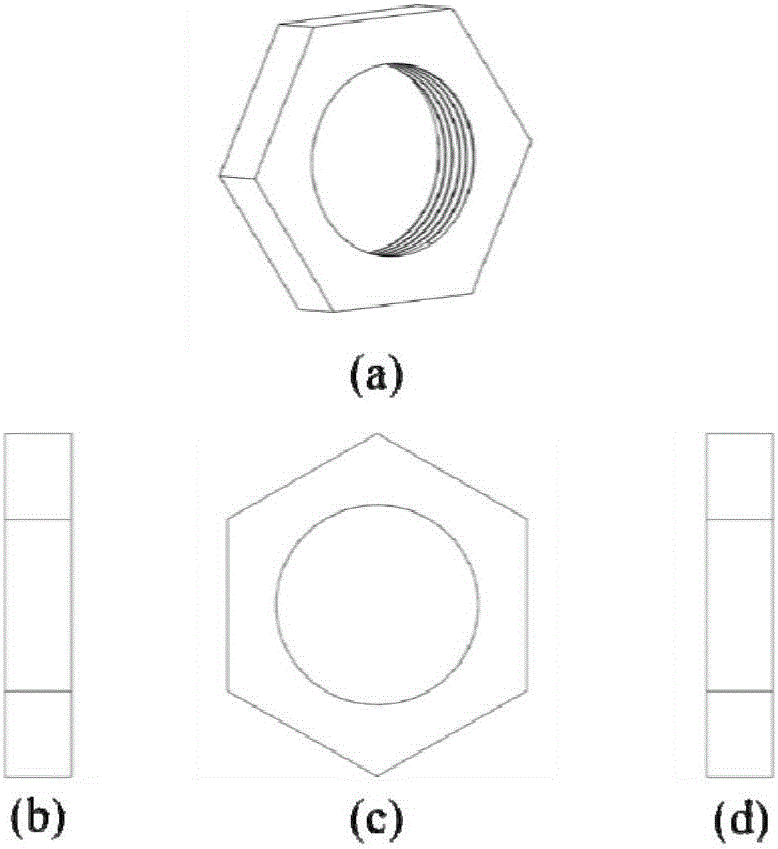

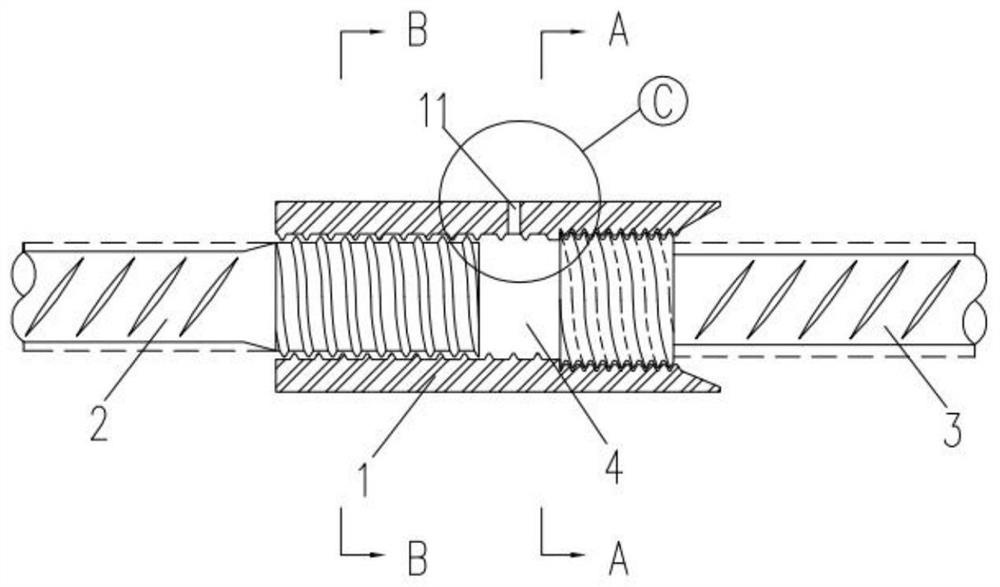

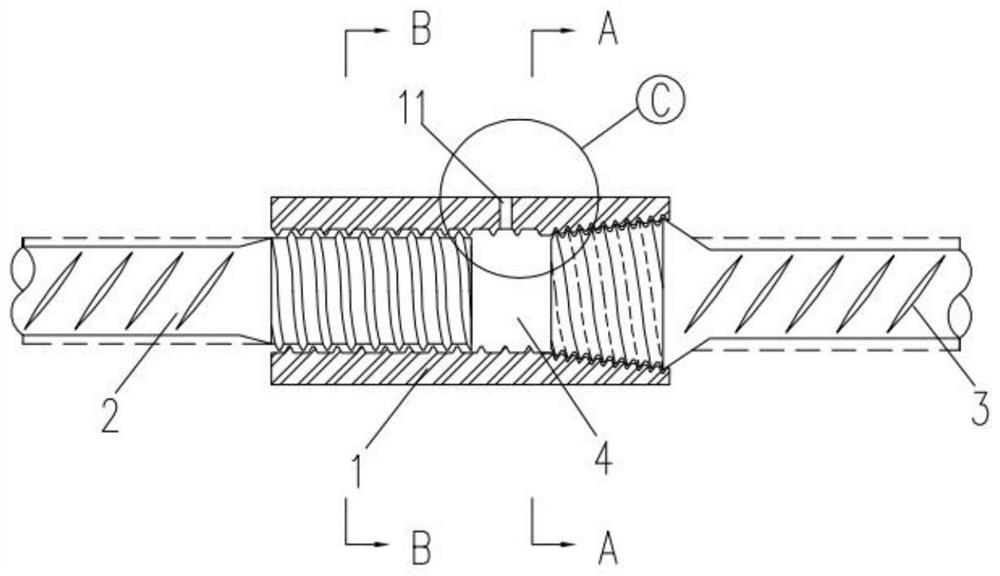

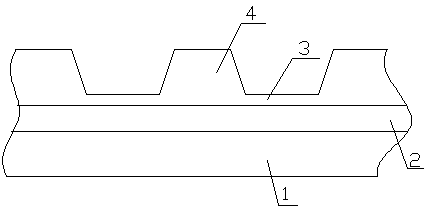

Half-thread glue injection type connecting sleeve design method, thread glue injection type steel bar connecting sleeve, and mounting method thereof

InactiveCN112761308AFirmly connectedWith correction functionBuilding reinforcementsAdhesiveEngineering

The invention discloses a half-thread glue injection type connecting sleeve design method, a half-thread glue injection type steel bar connecting sleeve, and a mounting method thereof. The half-thread glue injection type connecting sleeve is formed by combining a steel sleeve, two steel bars with threads at the ends, and an adhesive. One end of the inner surface of the steel sleeve and the outer surfaces of the ends of the corresponding reinforcing steel bars are machined into threads which are in weak engagement. After the steel sleeve is screwed with the two reinforcing steel bars, internal gaps between the steel sleeve and the reinforcing steel bars are filled with the adhesive, and the two reinforcing steel bars are connected into a whole after the adhesive is cured. Thread pitch of the weak occlusion threads is long, and thread teeth are narrow, so that the steel sleeve can connect two steel bars at any interval, and the other ends of the weak occlusion threads are in weak occlusion connection. After the gaps between the steel sleeve and the weakly-engaged reinforcing steel bars are filled with the adhesive, the strong connection between the two reinforcing steel bars by the connecting sleeve can be realized; and the required connecting strength index can be met by adjusting the length of a connecting thread section between the steel sleeve and the weakly-engaged steel bars.

Owner:TONGJI UNIV

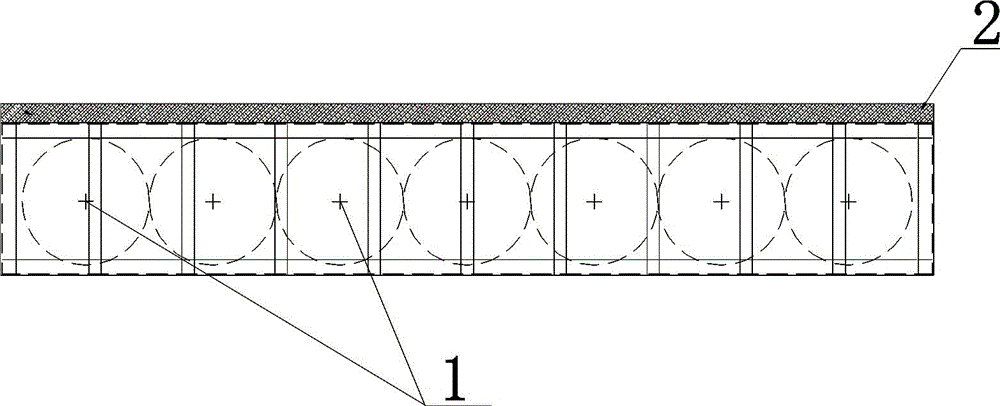

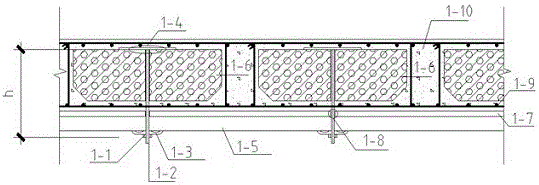

Method for preventing flotation of light solid composite core formwork of composite floor system

InactiveCN106013569ASimple construction processEasy to installFloorsBuilding material handlingEngineeringBatten

The invention discloses a method for preventing flotation of a light solid composite core formwork of a composite floor system. The method comprises the following construction steps that firstly, an inner formwork arrangement diagram is drawn before an inner formwork is constructed, and the number of required accessories is determined according to the inner formwork arrangement diagram; secondly, anti-flotation accessories of the core formwork are manufactured; thirdly, the core formwork of the composite floor system is installed and constructed; fourthly, concrete pouring of the composite floor system is conducted; and fifthly, after concrete is poured and cured, nuts, a batten, clamps of three types and a bottom formwork of the floor system are dismantled, the exposed portions of screws are cut off, and the flatness of the bottom of the floor system is guaranteed. According to the method for preventing flotation of the light solid composite core formwork of the composite floor system, the effect that a core formwork box does not float upwards or slide is guaranteed; in addition, the construction technique is simple, and the accessories are convenient to manufacture and install; furthermore, the practicability is high, and manufacturing and machining are convenient; and moreover, the cost is low, and the control effect is remarkable.

Owner:CHINA MCC17 GRP

Fracturing type rock tensile strength test apparatus and method

ActiveCN108562479ASolve instabilityGuaranteed damageMaterial strength using tensile/compressive forcesTest efficiencyFracture type

The invention discloses a fracturing type rock tensile strength test apparatus and method. A test object is a cylindrical soil or soft rock test sample. The fracturing type rock tensile strength testapparatus comprises a mechanical structure and a control apparatus; the test sample is installed between a passive fracturing rod and an initiative fracturing rod which are vertically arranged, and the test sample is centered by virtue of an adjusting centering frame and fit to the passive fracturing rod; the initiative fracturing rod is propelled along a horizontal direction so as to fracture thetest sample; the propelling rate of the initiative fracturing rod is controlled by a rate controller of the control apparatus; a data acquisition module acquires and stores the pressure and displacement data and display the data on a display screen in a graphic manner in real time; and after the test is ended, a data analysis module calculates a tensile strength value. The fracturing type rock tensile strength test apparatus is light and compact in structure; the test needs no additional component, and the system error is small; the test sample is convenient to install, the operation is simple, and the test efficiency is high; and the test sample is vertically arranged and is firm without slippage, the test sample position is stipulated by adopting the centering frame, the generation of deviatoric stress is avoided, the uniformity of the test sample destruction effect is ensured, and the test result is accurate and reliable.

Owner:TAIYUAN UNIV OF TECH

Football storage device

The invention provides a football storage device and belongs to the technical field of teaching tools. The invention adopts the technical scheme that the football storage device comprises a container,a storage device arranged on the inner side wall of the container and a fetching device arranged in the container. The football storage device provided by the invention has the beneficial effects that a large amount of footballs can be stored, so that the problem of less football storage amount in the common container is solved, and the purpose of convenient football fetching can be achieved; byadoption of the technical scheme, the space in a sports equipment room can be saved.

Owner:李志伟

Fertilizer distributing mechanism

PendingCN109804762AAvoid lossAvoid uniformityFertiliser distributersAgriculture gas emission reductionImpellerEngineering

The invention discloses a fertilizer distributing mechanism. The fertilizer distributing mechanism comprises a feeding device anda rotary dripping mechanism, and further comprises a base plate, the feeding device comprises a material storage box, a mixing motor, a mixingimpeller, a feed delivery pipe and a material rotating plate, a material falling hole is formed in the edge of the bottom of theinner side of the material storage box, the material falling hole is connected with the cone-shaped feed delivery pipe, a passing hole is formed in the base plate, and the feed delivery pipe penetrates through the passing hole and communicates with a counterbore formed in the upper surface of the material rotating plate; the center of the material rotating plate is a round hole, and ring-shaped grooves are formed in the inner sidethe round hole and communicates with the counterbore; and the rotary dripping mechanism comprises a fertilizer throwing barrel, a synchronous belt, a fertilizer throwing driving motor, a fixed rod and a bearing, the fixed rod is located in the center of the center round hole of the material rotating plate, the fertilizer throwing barrel is located between the fixed rod and the material rotating plate and is rotatably connected with the fixed rod through the bearing, and a material falling hole duct communicates with a discharging pipe and the ring-shaped grooves. According to the fertilizer distributing mechanism, a totally enclosed type is adopted in delivery and dripping offertilizer, and the dripping velocity is controllable.

Owner:YANCHENG INST OF TECH

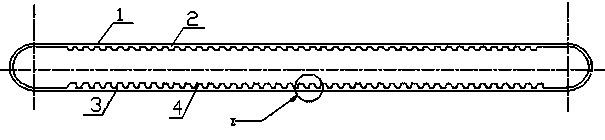

Rubber concave-convex inner tooth guiding type synchronous polyester conveying belt

InactiveCN103991672AMesh closelyAvoid problems such as poor bondingConveyorsIsosceles trapezoidPolyester

A rubber concave-convex inner tooth guiding type synchronous polyester conveying belt comprises upper covering rubber, a framework layer and lower covering rubber which are attached to one another in sequence. The rubber concave-convex inner tooth guiding type synchronous polyester conveying belt is characterized in that concave-convex inner tooth guiding bars are evenly distributed on the outer side of the lower covering rubber in the horizontal direction; the length of each concave-convex inner tooth guiding bar is the same as the width of a conveying belt body; the section of each concave-convex inner tooth guiding bar is in an isosceles trapezoid shape, and the wide bottom face of each concave-convex inner tooth guiding bar and the lower covering rubber are combined. The rubber concave-convex inner tooth guiding type synchronous polyester conveying belt has the advantages that a special metal mold is used for vulcanization, the concave-convex inner tooth guiding bars and the conveying belt body are integrally formed and vulcanized in one time, the problem that the concave-convex inner tooth guiding bars and the lower covering rubber are not firmly bonded due to secondary vulcanization is avoided, the concave-convex inner tooth guiding bars are firm and durable, precise power transmission can be guaranteed, meshing is tight, slipping is avoided, transmission efficiency is high, operation is stable, reliability is good, vibration is low, noise is low, bending rigidity is low, transmission resistance can be reduced, energy saving is facilitated, and fatigue life is greatly prolonged.

Owner:山东道远橡胶科技有限公司

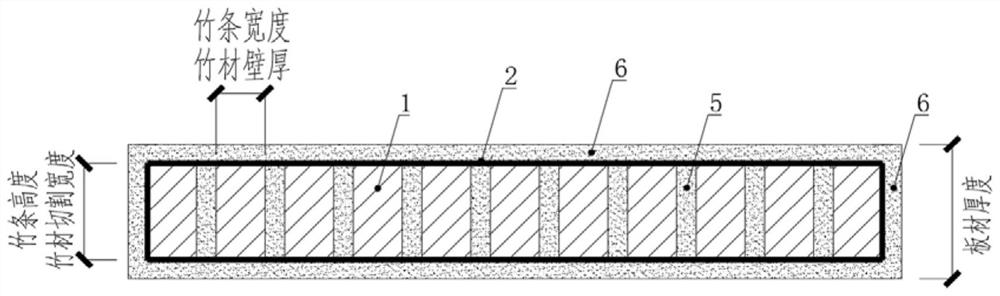

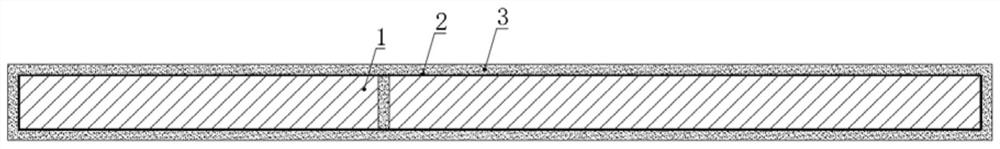

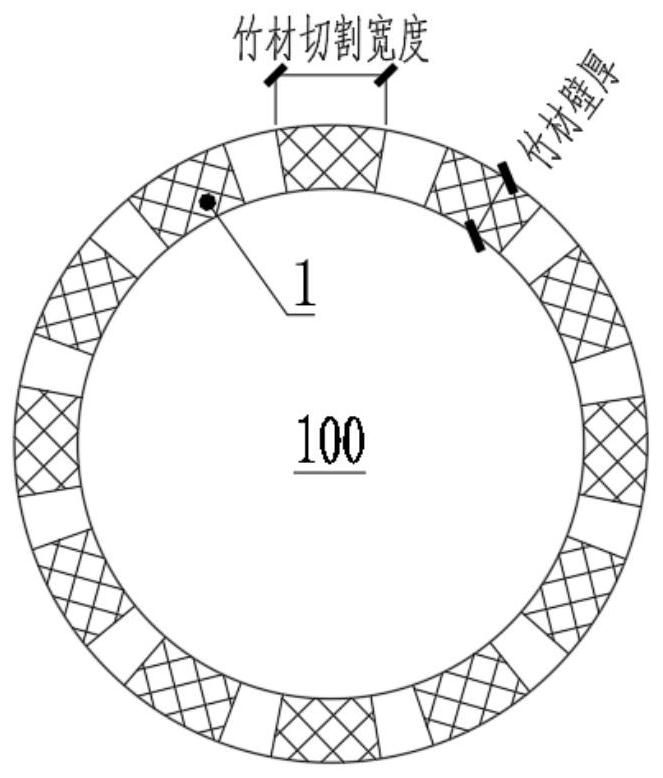

Permanent bamboo-based composite bearing plate and processing technology

The invention relates to a permanent bamboo-based composite bearing plate. The permanent bamboo-based composite bearing plate comprises assembly bamboo canes, fiber gridding cloth and a cementing material, wherein the assembly bamboo canes are formed by longitudinally cutting bamboos, the bamboo canes are vertically placed during assembly, and first gaps are formed between the adjacent bamboo canes at intervals; the fiber gridding cloth is attached to the upper surfaces and the lower surfaces of the assembly bamboo canes and completely wraps the side surfaces and the end surfaces of the assembly bamboo canes from the peripheries; the cementing material is poured into the first gaps, as well as the upper surface and the lower surface of the outer side and the peripheral side surface of thefiber gridding cloth, the cementing material in the first gaps forms thin-wall connecting supporting ribs, and the cementing material on the upper surface and the lower surface of the outer side and the peripheral side surface of the fiber gridding cloth forms a bearing protection bonding layer. The permanent bamboo-based composite bearing plate not only can give consideration to bearing strength,but also can realize the advantages of energy conservation, environmental protection, safety, low consumption, high temperature resistance, low temperature resistance, wear resistance, corrosion resistance, seepage resistance and high fire resistance.

Owner:西藏涛扬集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com