Fertilizer distributing mechanism

A technology of driving motor and stirring motor, which is applied in fertilization devices, fertilizer distributors, applications, etc., can solve the problems of burning seedlings, wilting of plants, and uneven throwing, and achieves a large range of transmission ratios, stable transmission, and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

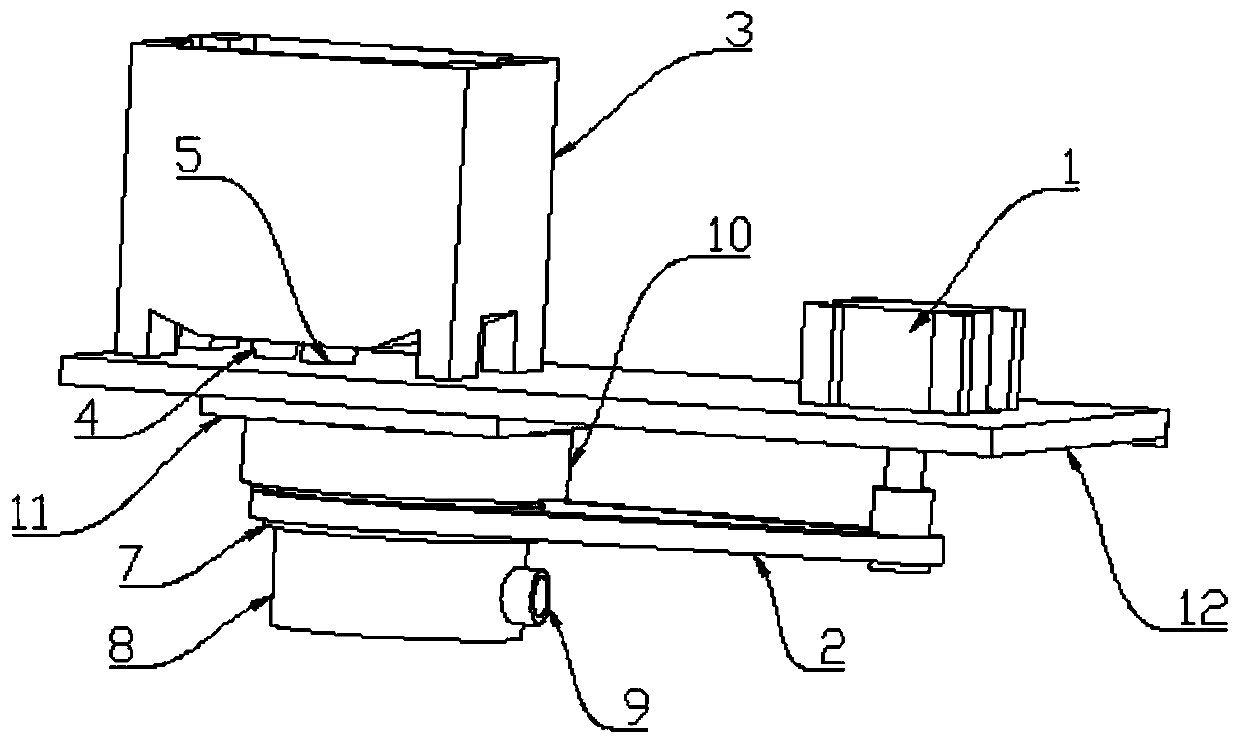

[0028] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

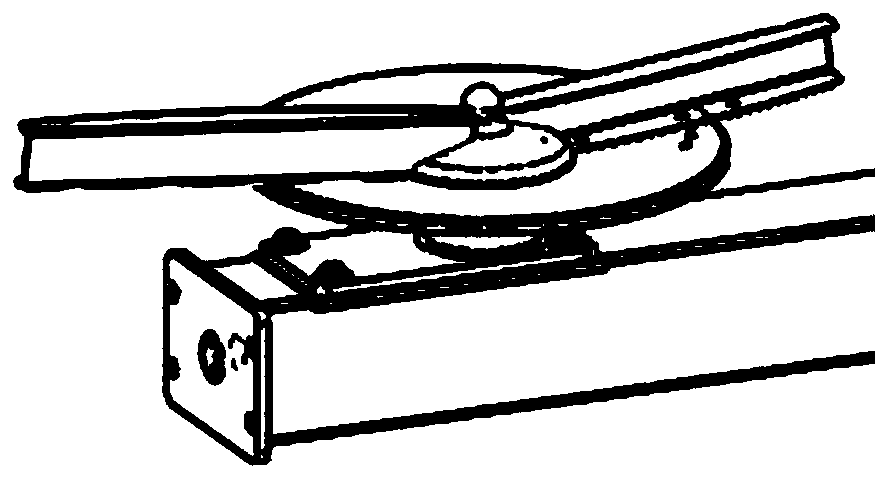

[0029] Such as Figure 2-4 As shown, a fertilizer spreading mechanism includes a feeding device, a rotary throwing mechanism, and a base plate 12,

[0030] The base plate 12 is installed on the fertilizer throwing machine and is a rectangular stainless steel plate,

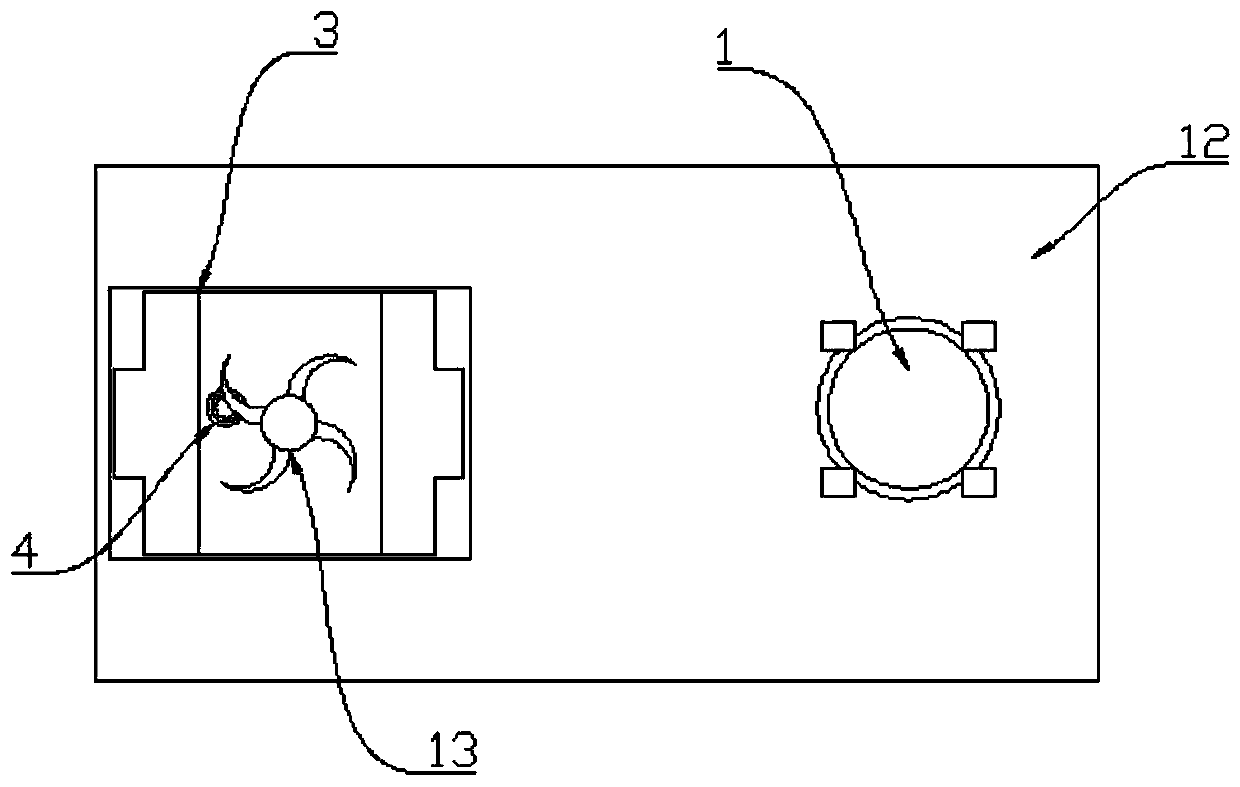

[0031] The feeding device comprises a material storage box 3, a stirring motor 5, a stirring impeller 13, a feed pipe 4, and a material transfer tray 10, and the inner bottom edge of the material storage box 3 is provided with a blanking hole, and the blanking hole is connected to the The tapered feed pipe 4 is connected, and the base plate 12 is provided with a through hole, and the feed pipe 4 passes through the through hole and communicates with the counterbore on the upper surface of the transfer tray 10;

[0032] The transfer plate 10 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com