Charging pile system of new energy vehicle

A new energy vehicle and charging pile system technology, applied in the field of new energy vehicle charging pile system, can solve the problems that charging piles cannot be used effectively, new energy vehicles cannot be charged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

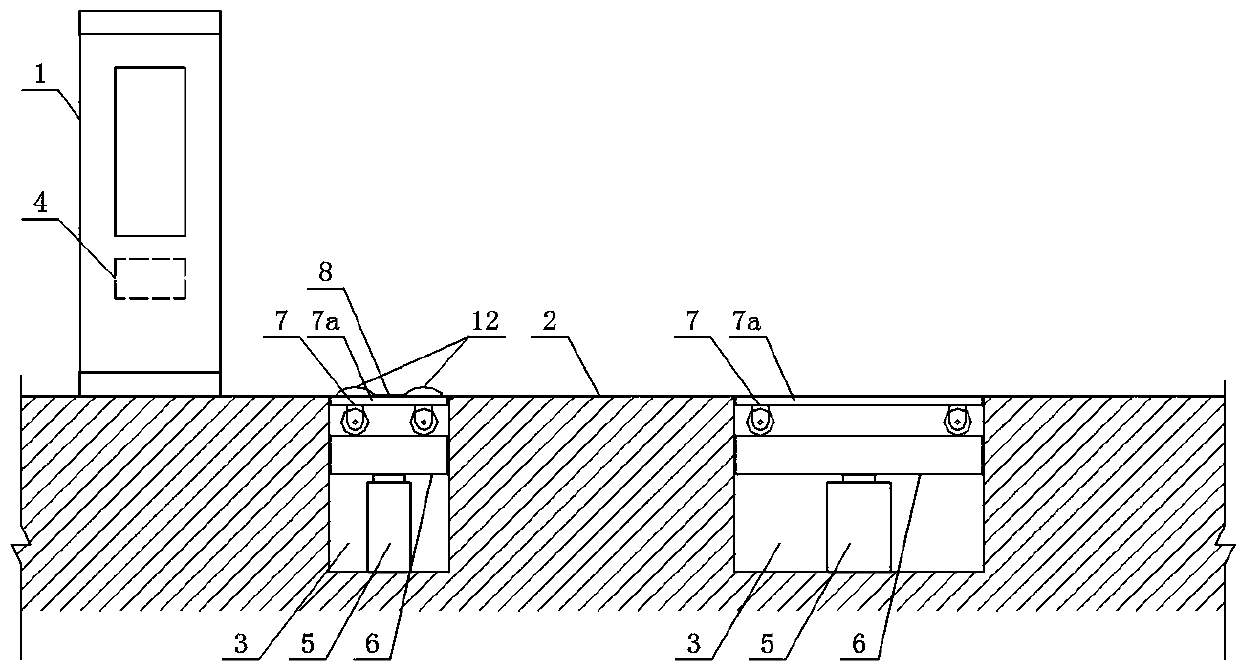

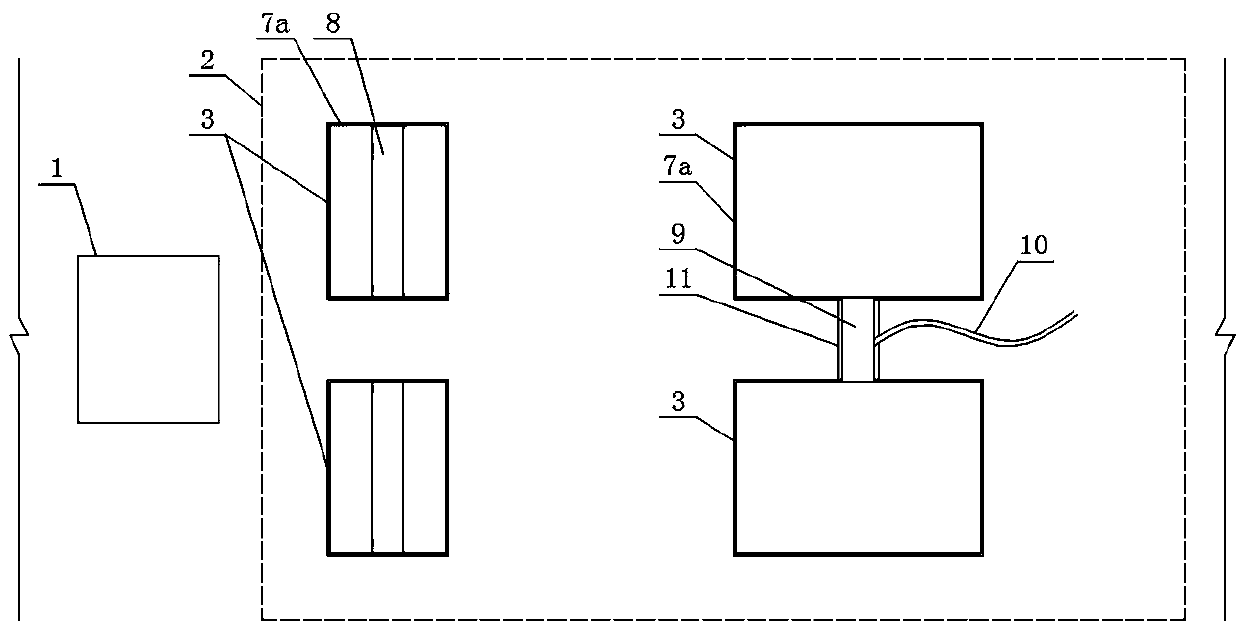

[0044] Such as figure 1 and figure 2 As shown, a new energy vehicle charging pile system includes a charging pile body 1, and the ground position in front of the charging pile body 1 is set as a parking area 2, and the parking area 2 is provided with four rectangular foundation pits 3. The positions of the four foundation pits 3 correspond to the positions of the four wheels of the new energy vehicle, and each foundation pit 3 is provided with a wheel auxiliary mechanism, which is used for carrying, moving and assisting the wheels. The position of the mechanism corresponds to the wheel of the new energy vehicle, and the opening and closing of the wheel auxiliary mechanism is controlled by the PLC controller 4 of the charging pile body 1 .

[0045] The wheel auxiliary mechanism includes an automatic telescopic cylinder 5 vertically arranged in the foundation pit 3, a rectangular bearing plate 6 is arranged on the top of the automatic telescopic cylinder 5, and a flat trolley ...

Embodiment 2

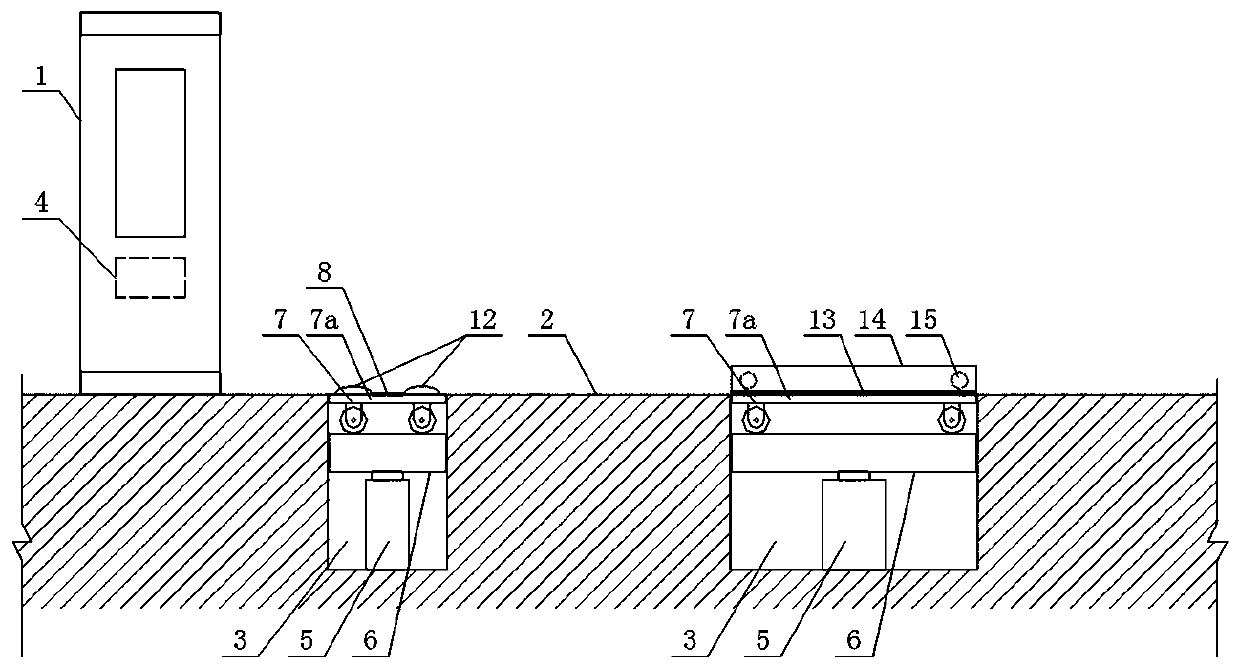

[0053] Such as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that the flat trolley 7 of the two wheel auxiliary mechanisms far away from the charging pile body 1 is longer than the flat trolley of the two wheel auxiliary mechanisms close to the charging pile body 1 7, and the outer side of the flatbed trolley 7 of the two wheel auxiliary mechanisms far away from the charging pile body 1 is equipped with a tightening mechanism, which is used for tightening and temporarily fixing the new energy vehicle Wheels; the tightening mechanism includes a horizontal extension plate 13 arranged on the outside of the flat trolley 7 car plate 7a away from the charging pile body 1, the outer end of the extension plate 13 is provided with a vertical plate 14, and the inner side of the vertical plate 14 A tightening plate 16 is provided through the automatic telescopic rod 15, and the tightening plate 16 is used to tighten the outer surface of the wheel of the new energy...

Embodiment 3

[0059] Such as Figure 5 and Figure 6 As shown, the difference between it and the second embodiment is that the four sides of the bearing plate 6 are connected with the inner side of the corresponding foundation pit 3 through a slide rail chute structure that can slide relative to each other in the vertical direction, and the slide rail The chute structure includes slide rails 17 arranged on the four inner sides of the foundation pit 3, and the side surfaces of the bearing plate 6 and the side surfaces of the flat trolley 7 vehicle plate 7a are all provided with sliding rails 17 that cooperate with the slide rails 17. The chute 18.

[0060] In this embodiment, in order to ensure that the flat trolley and the bearing plate can slide vertically relative to the foundation pit smoothly, and at the same time provide the lateral support force for the flat trolley when carrying the wheels of new energy vehicles, avoid The offset causes the flat trolley to tilt, and the four sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com