Double twister

A two-for-one twister and twisting mechanism technology, which is applied in textiles and papermaking, can solve the problems of affecting the running speed of the yarn, the uneven twist index is unstable, and cannot be adjusted, so as to achieve convenient winding density, consistent friction, and The effect of adjusting the winding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

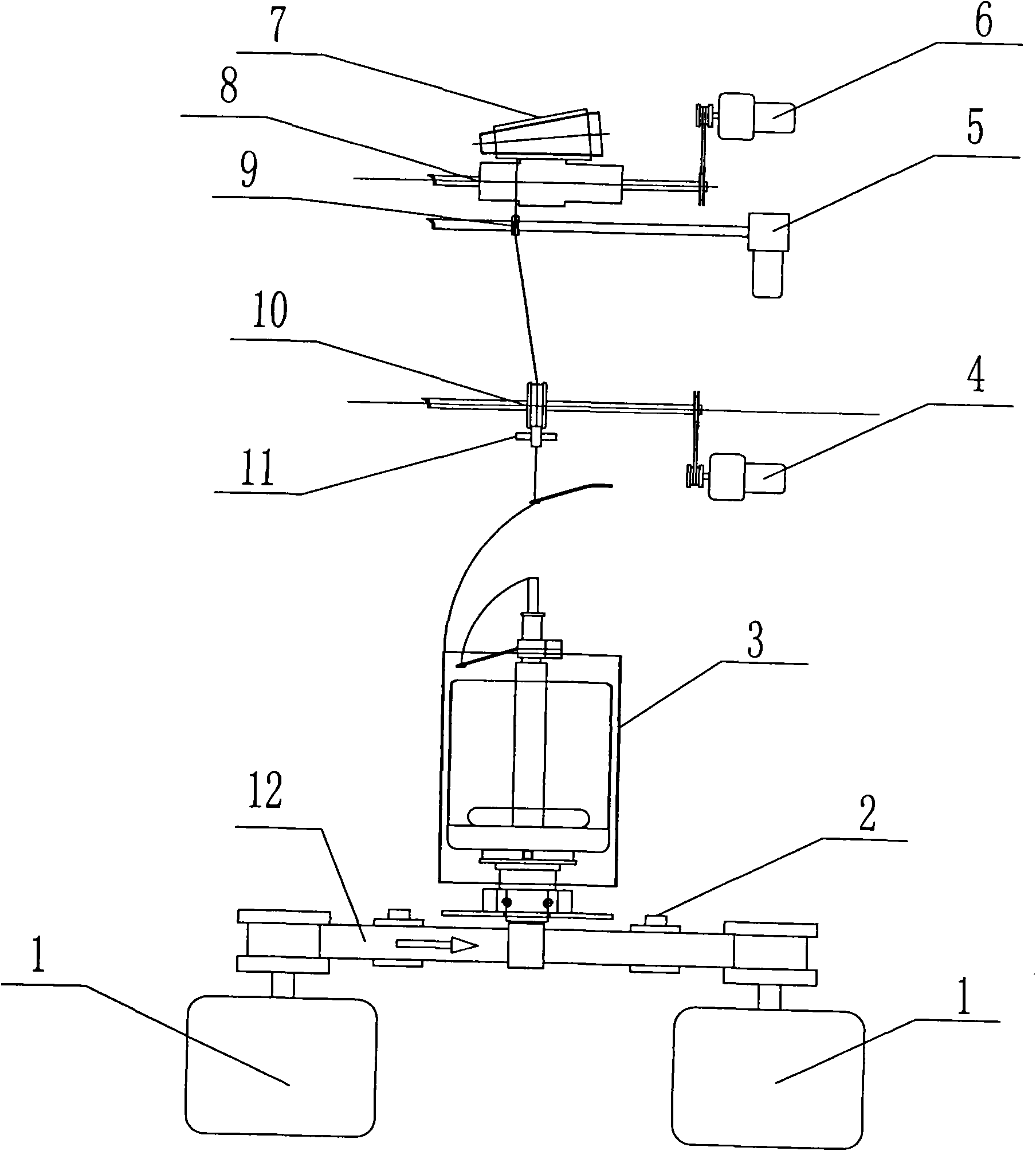

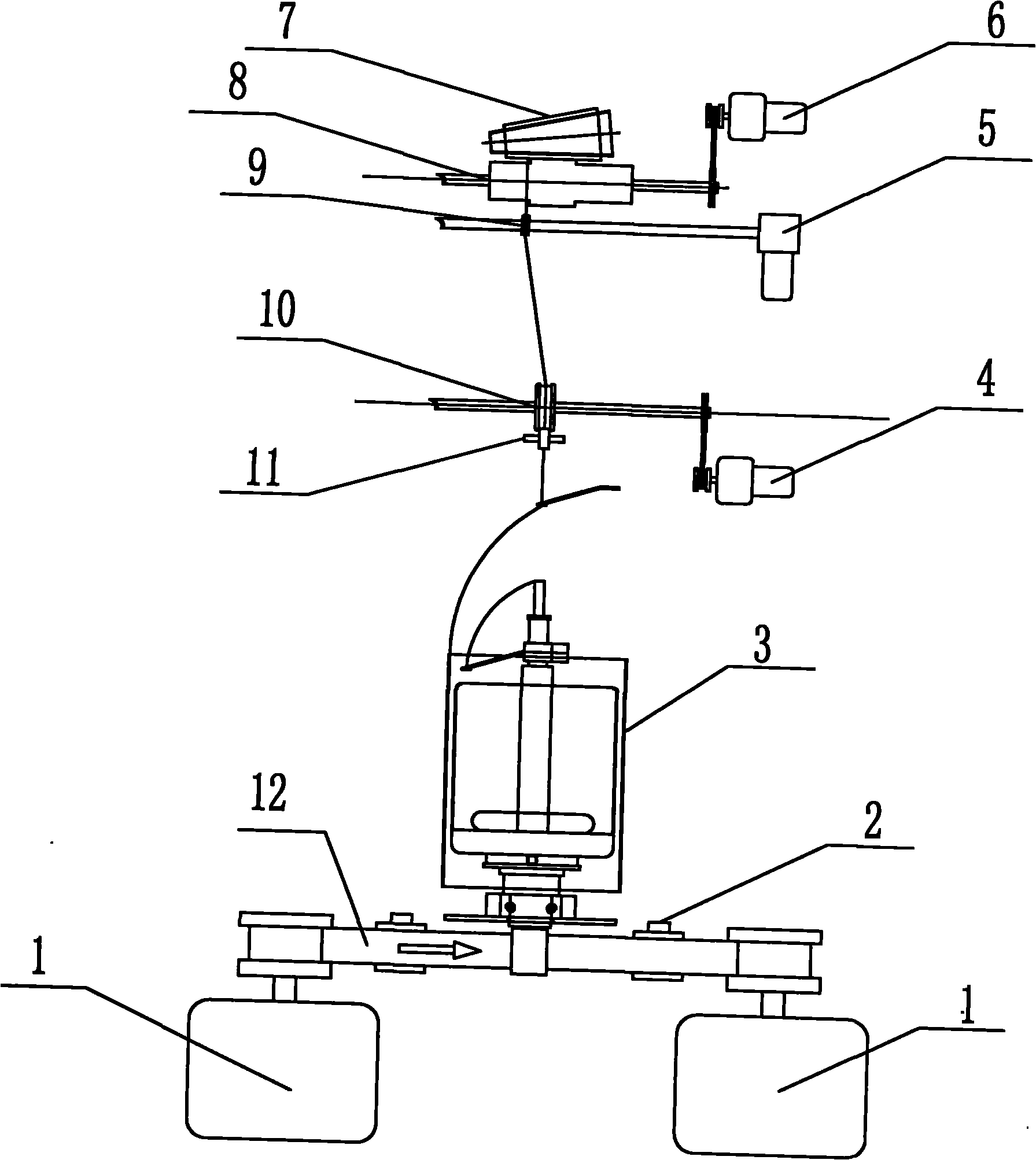

[0013] see figure 1 , figure 1 It is a schematic diagram of the overall structure of the two-for-one twister of the present invention. Depend on figure 1 It can be seen that the two-for-one twister of the present invention includes a twisting mechanism, a traction mechanism, a traverse mechanism and a winding mechanism, and the twisting mechanism includes a spindle part 3, a dragon belt 12, a dragon belt transmission motor 1 and a dragon belt tensioning mechanism. Wheel 2, the dragon belt transmission motor 1 has two parts, the spindle part 3 is installed on the dragon belt 12, the dragon belt 12 is connected with the dragon belt transmission motor 1, and the dragon belt transmission motor 1 drives the spindle part 3 on the dragon belt 12 Make a rotating motion. Described traction mechanism comprises traction driving wheel 10, traction rubber pressure wheel 11 and traction motor 4, traction driving wheel 10 and traction rubber pressure wheel 11 press fit transmission, tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com