Patents

Literature

31results about How to "Consistent friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

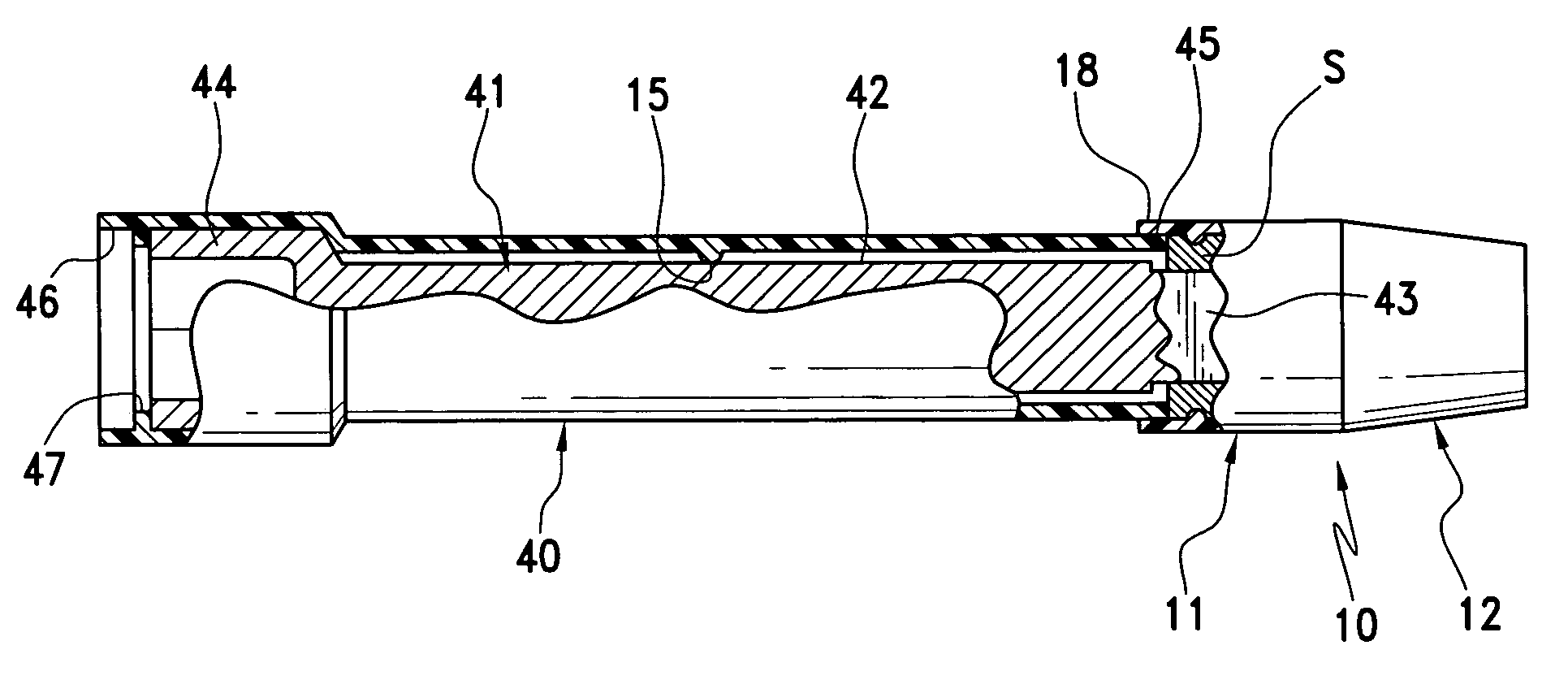

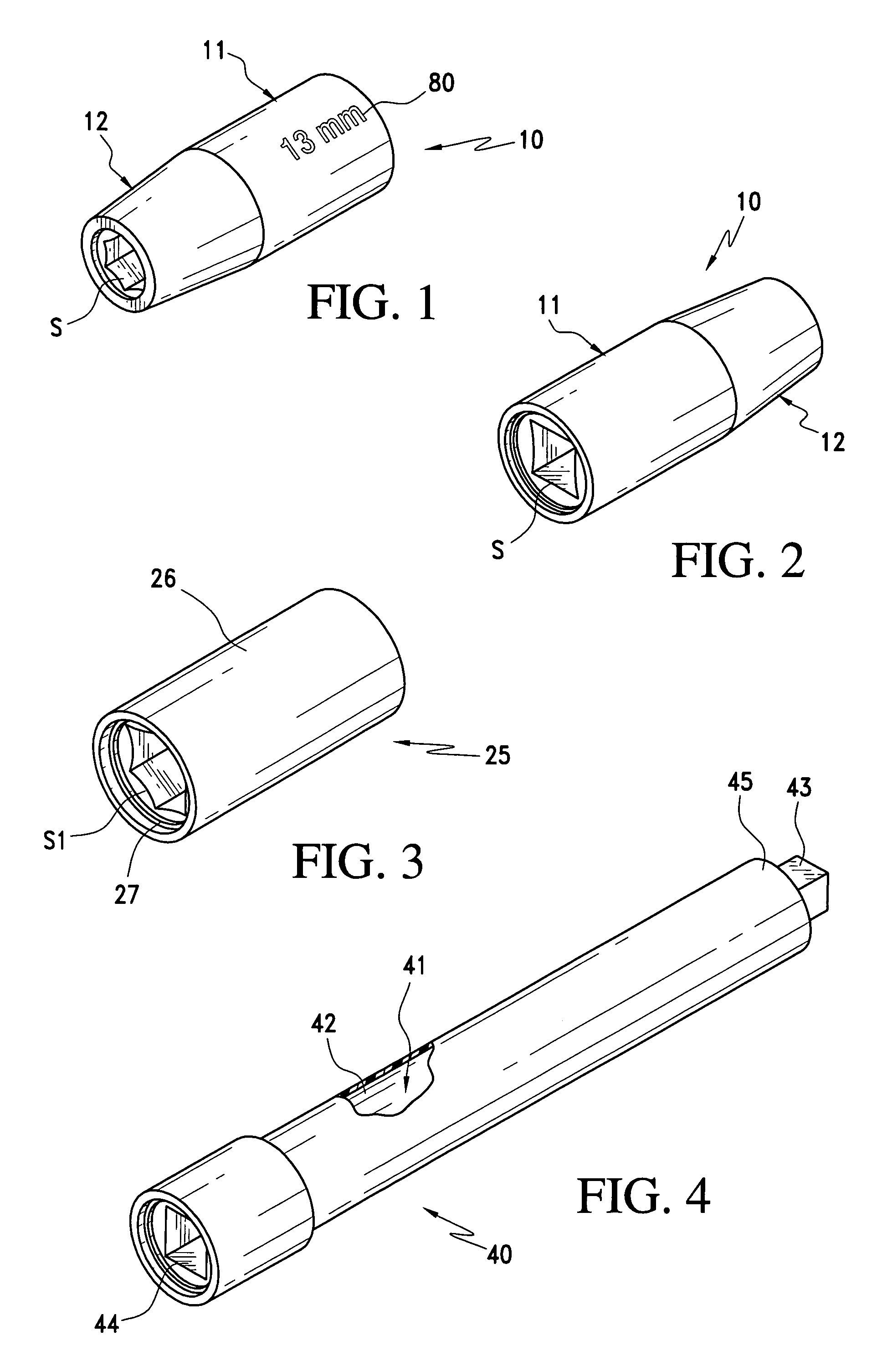

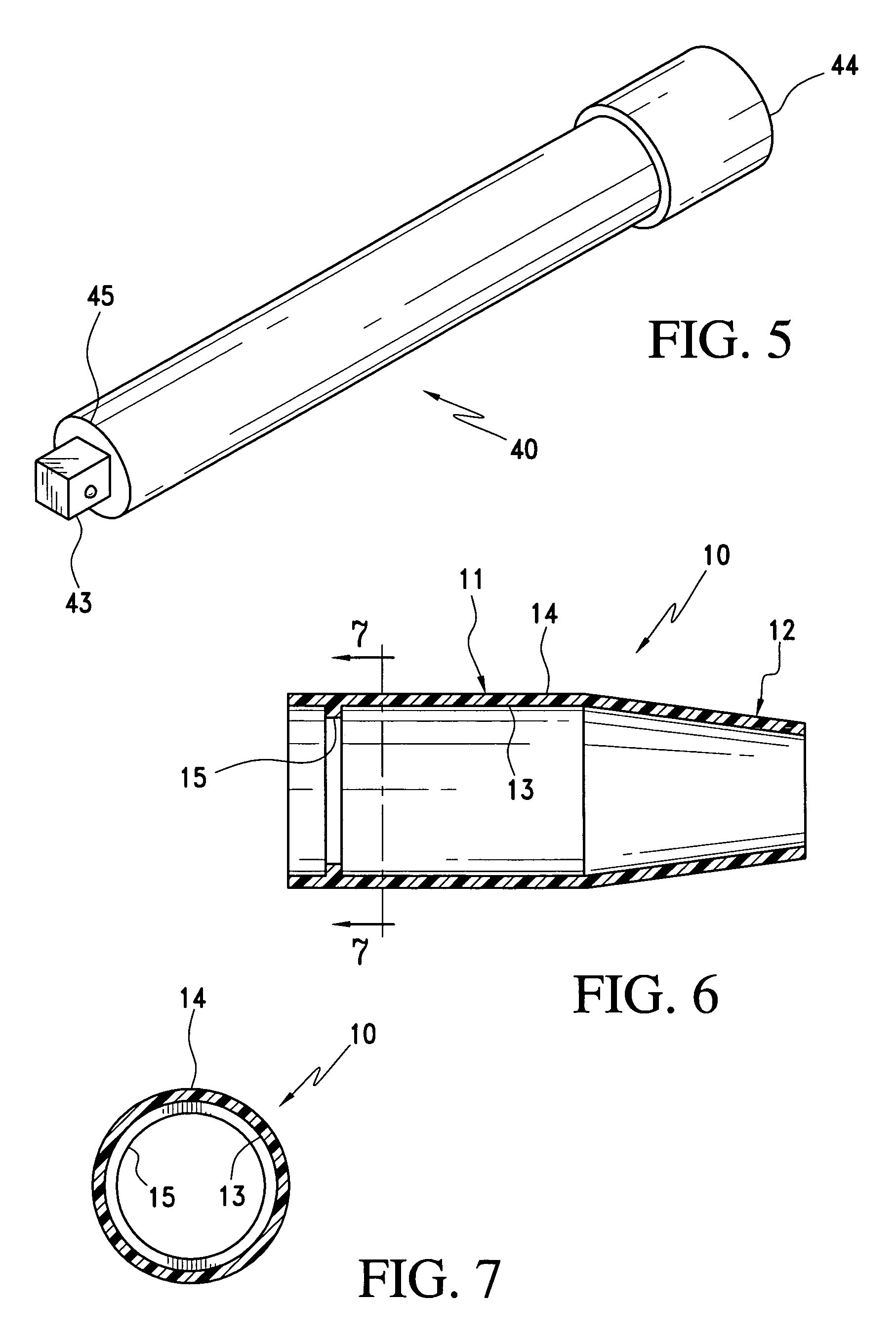

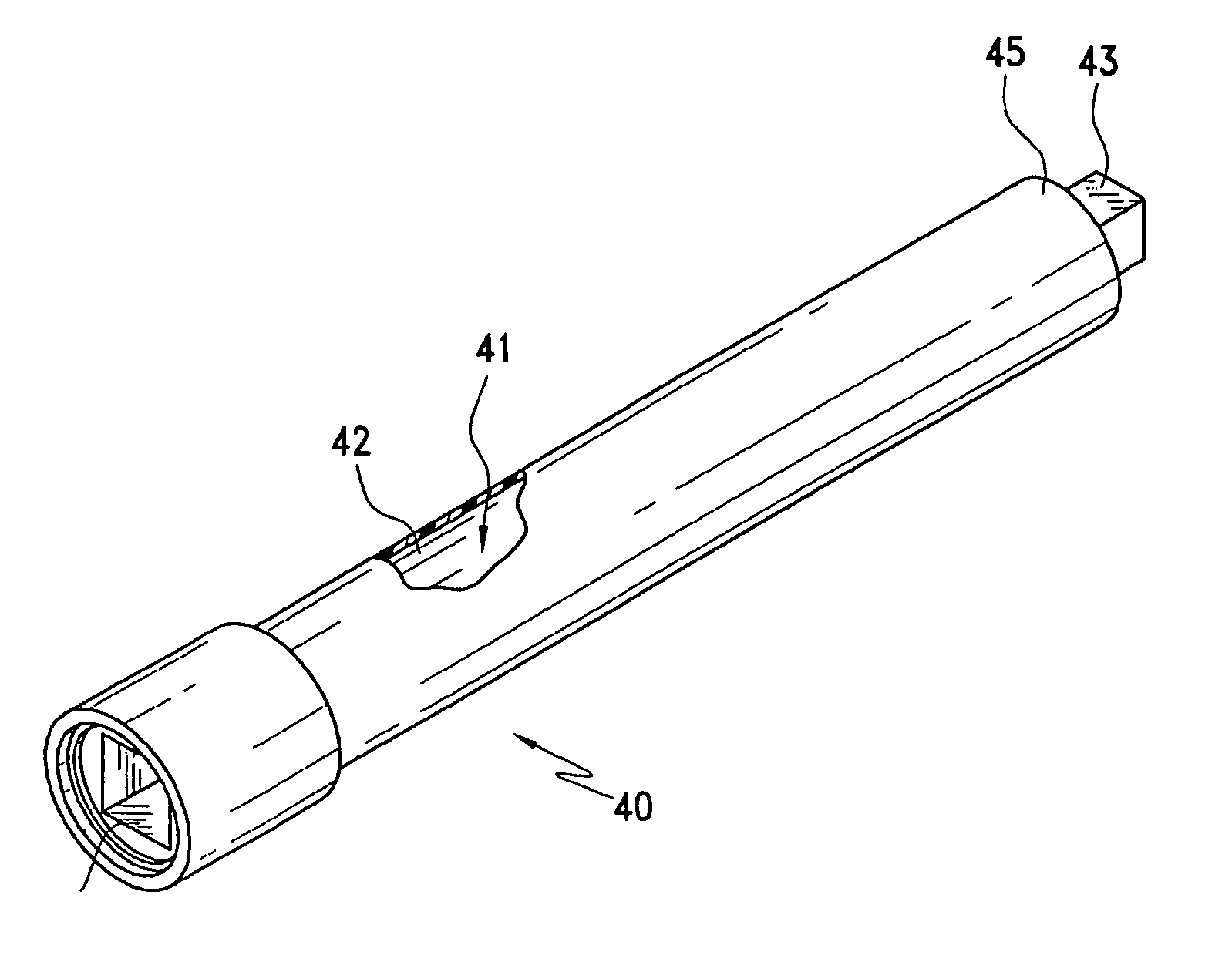

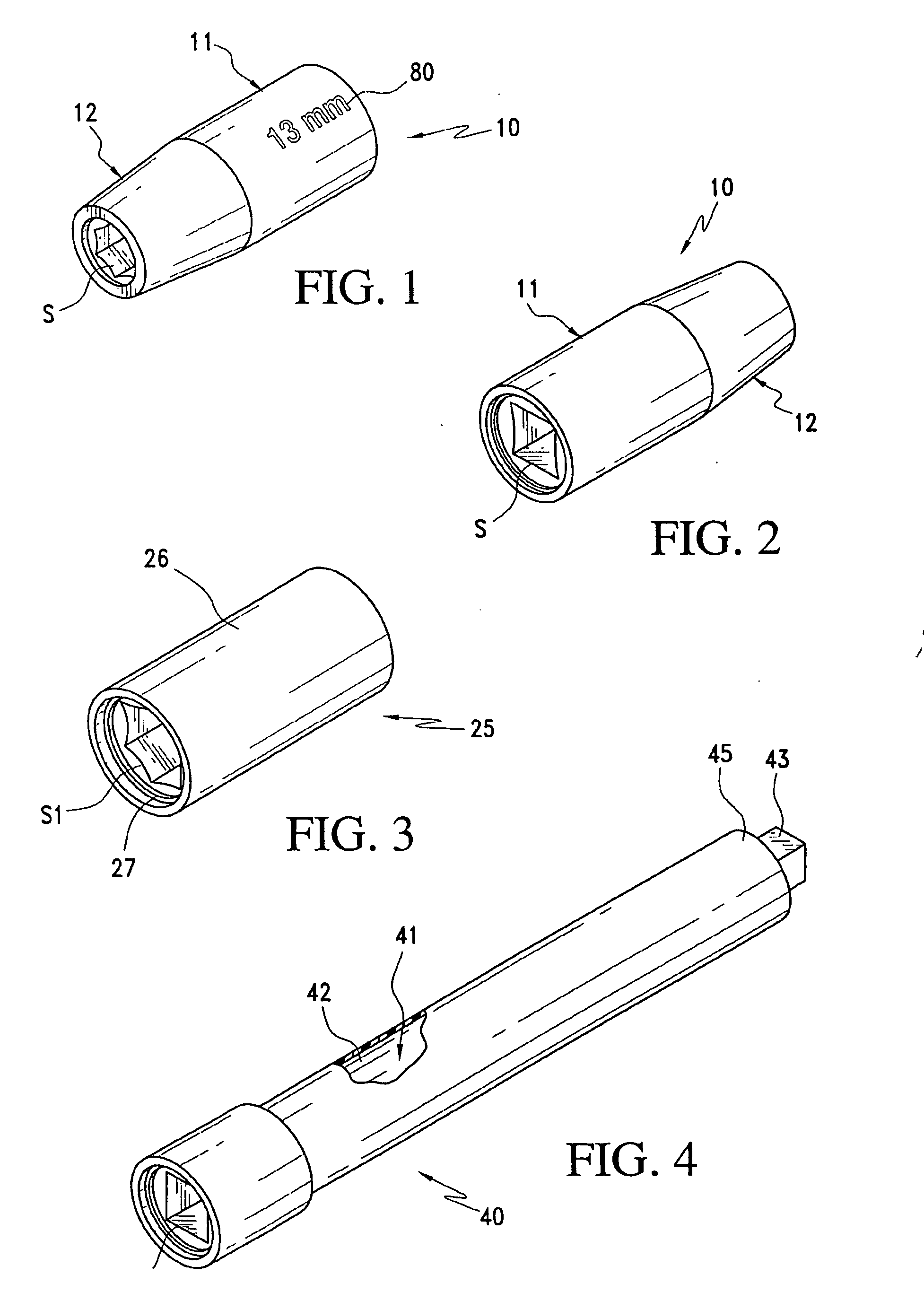

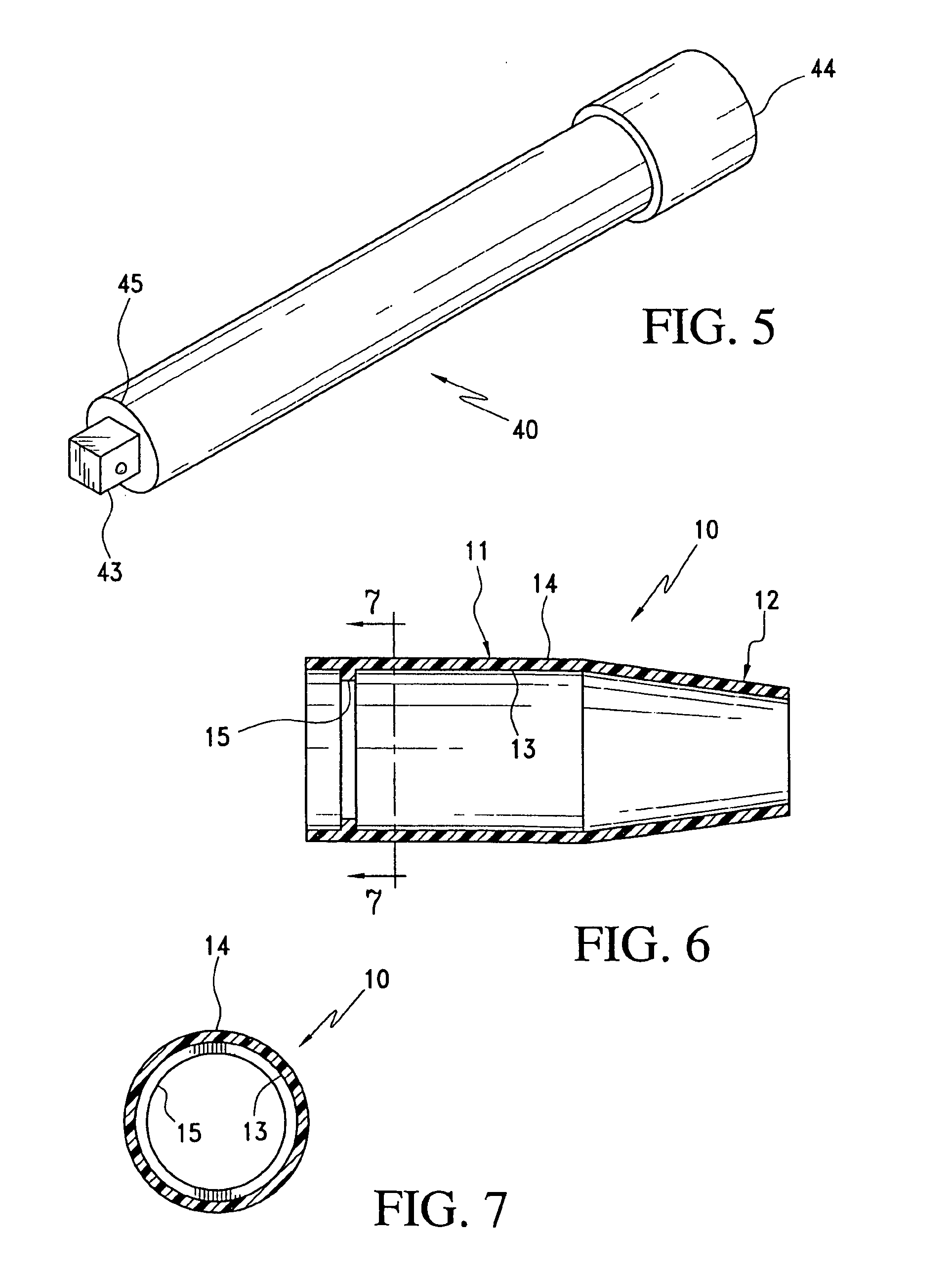

Tool with protective sheath

A protective sheath for tools to prevent marring of finished surfaces when the tool is being used. The sheath is integrally formed as a one-piece elastomeric body that is applied to the exterior surface of the tool, with at least one end of the sheath projecting slightly beyond an end of the tool. In one embodiment the sheath projects at both ends beyond the ends of the tool. One of the projecting ends functions to contact the finished surface and prevent contact between the tool and finished surface, and the other projecting end functions to span the coupling between the tool and another tool. The elastomeric body is freely rotatable relative to the tool and fixed axially relative thereto, and provides a non-rotating surface that may be grasped by a user to support and guide the tool. Annular ribs on the inner surface of the sheath and / or a lubricant incorporated in the material of the sheath provide a reduction in friction, enabling the sheath to rotate freely on the tool even when it is grasped tightly by a person to support and guide the tool.

Owner:APEX BRANDS

Tool with protective sheath

Owner:INT PAPER CO

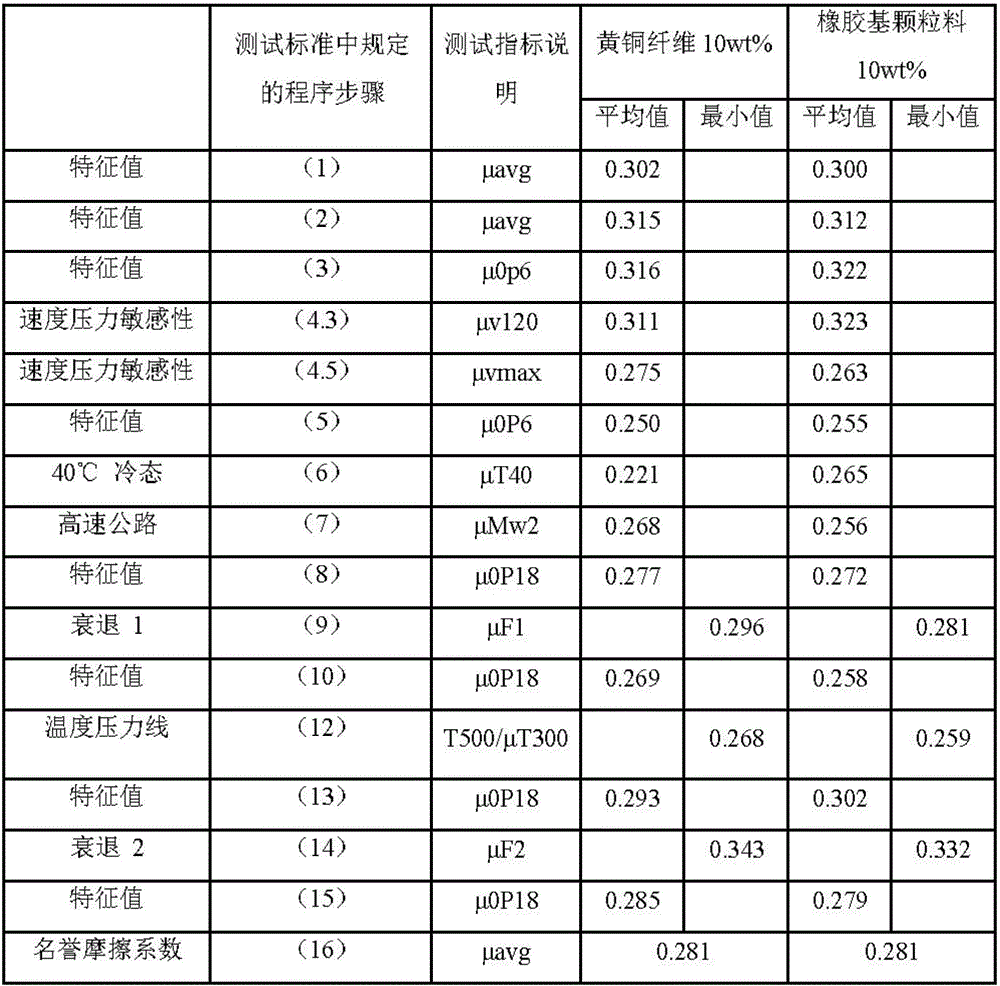

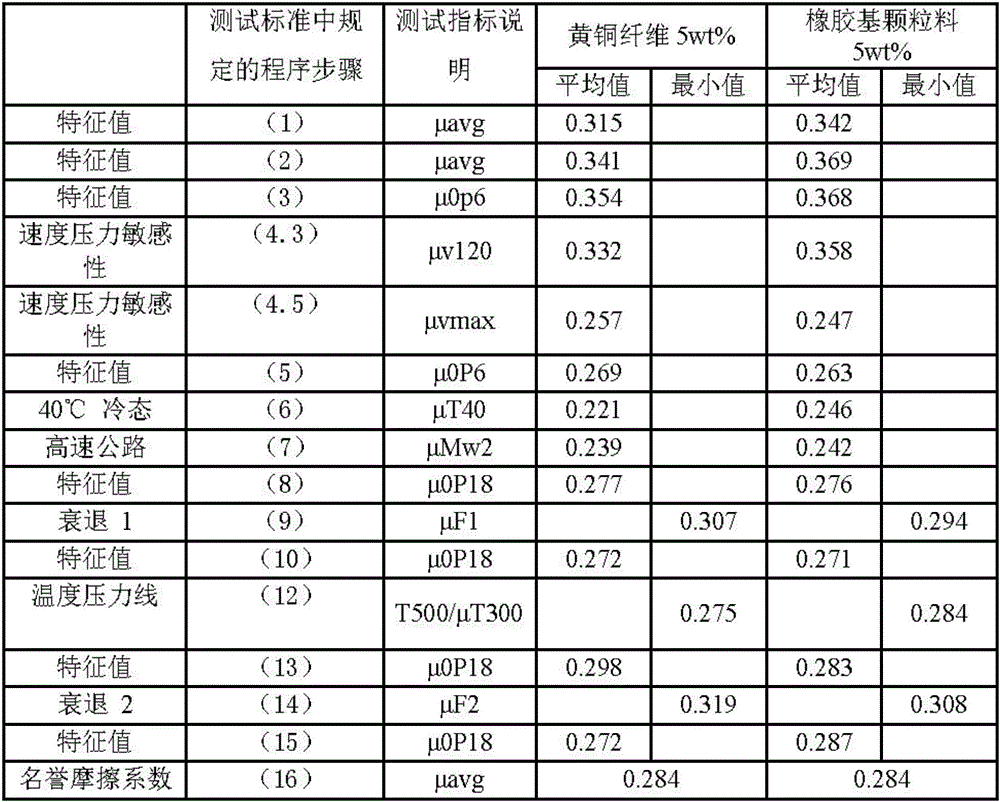

Rubber based granular material and preparation method thereof

ActiveCN106397878ASpeed up heat dissipationAccelerate the lossHeat-exchange elementsFriction liningFiberPolymer science

The invention provides a rubber based granular material and a preparation method thereof, and more specifically relates to the technical field of automobile components. The total mass of raw material components of the rubber based granular material is used as a reference for calculation, and the rubber based granular material comprises the following raw material components in percentages by mass: 7-12% of butyronitrile rubber, 2-5% of styrene butadiene rubber, 3-7% of carbon black, 1-4% of sulphur, 1-3% of a vulcanization accelerator, and 70-85% of a multielement heat-conducting composite powder. The rubber based granular material can replace brass fiber in a friction material in equal proportion, and friction performance and abrasiveness of the prepared friction material are nearly not changed; at the same time, compared with the brass fiber, the noise reduction performance of the rubber based granular material is better, comfort level of a pedal in a braking process is greatly improved, initial performance is excellent when the addition amount is small, and running-in period is shortened; the rubber based granular material has the advantages of cleaning, and environmental protection without pollution.

Owner:SHANDONG GOLD PHOENIX

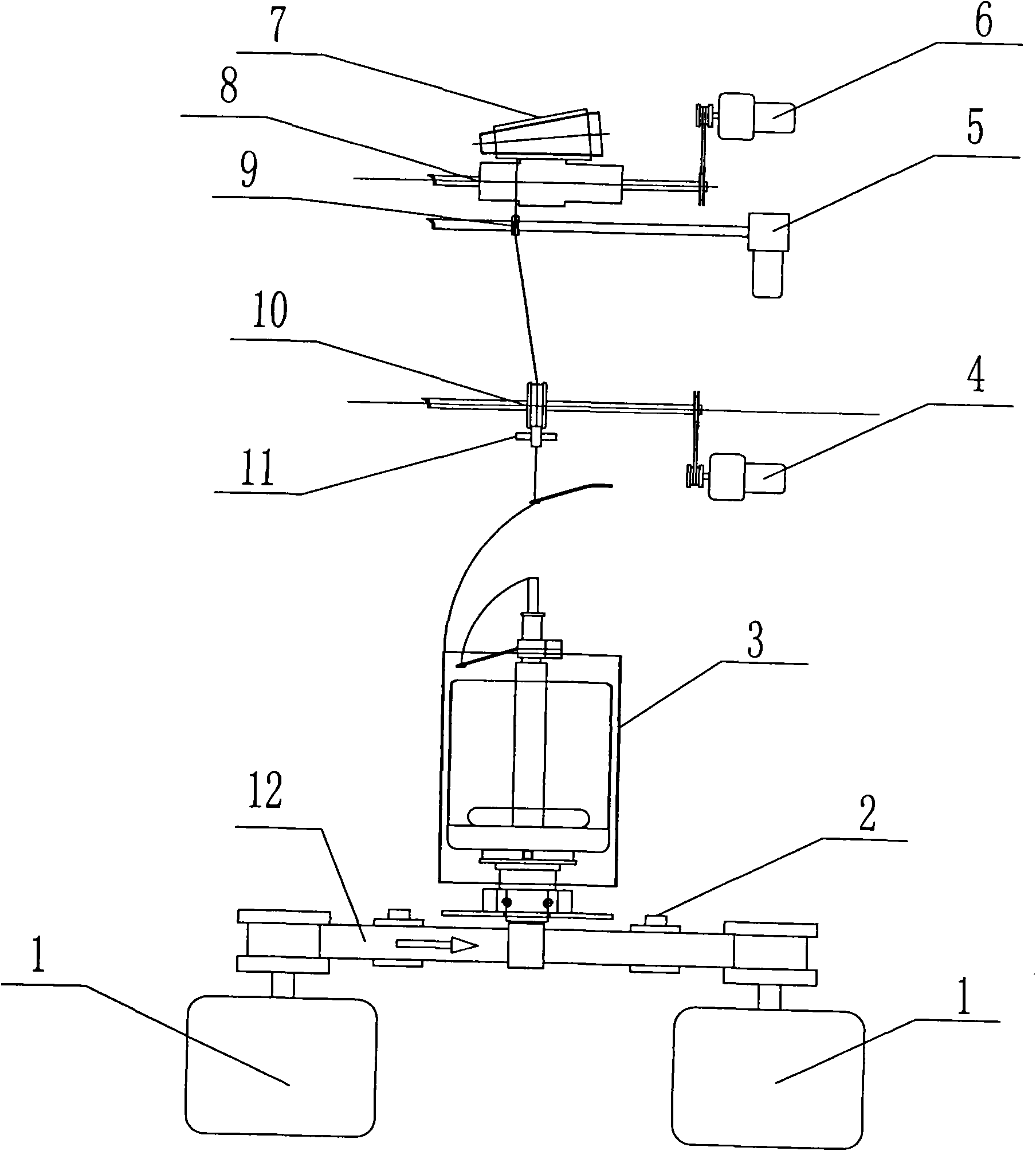

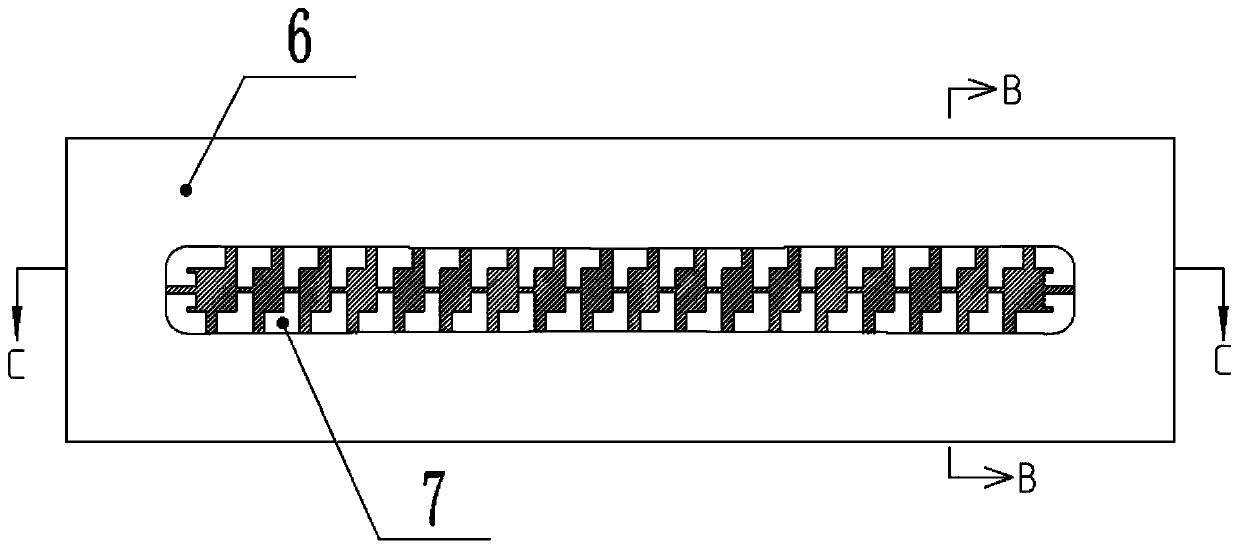

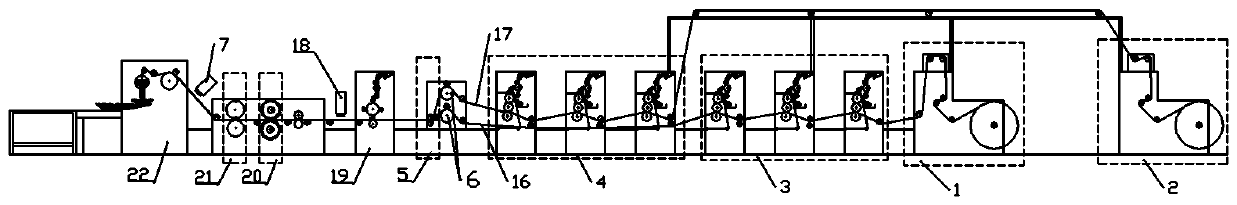

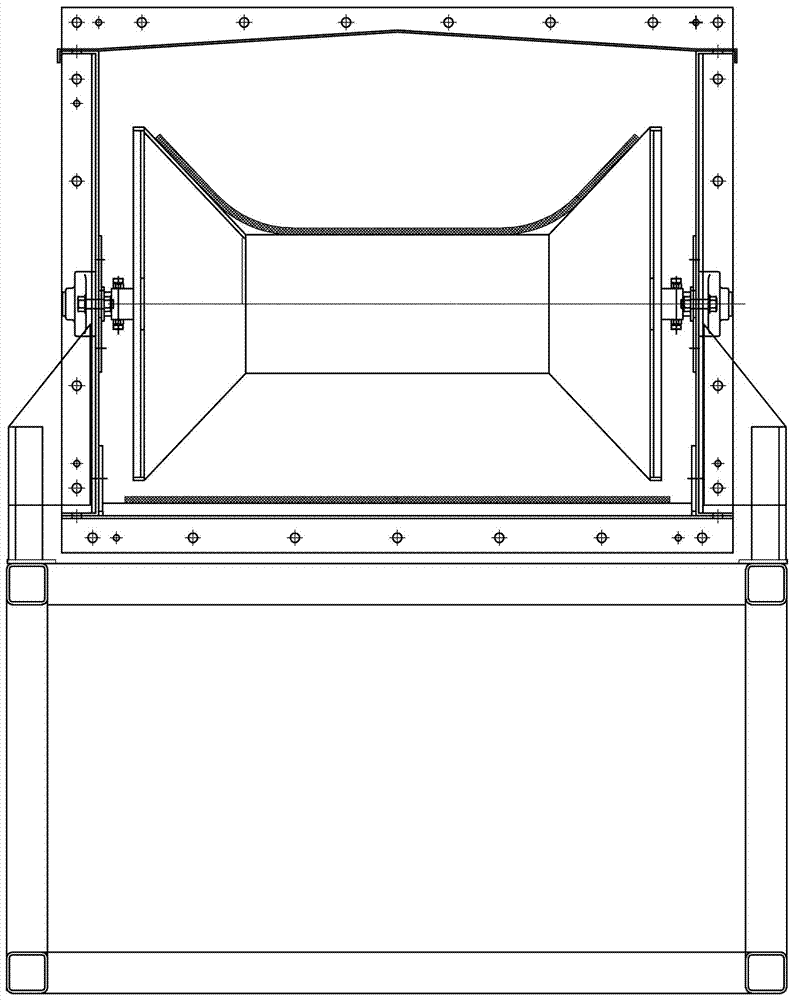

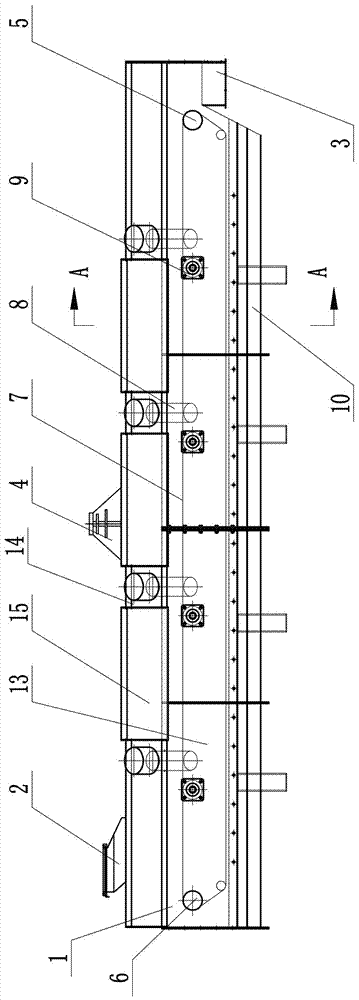

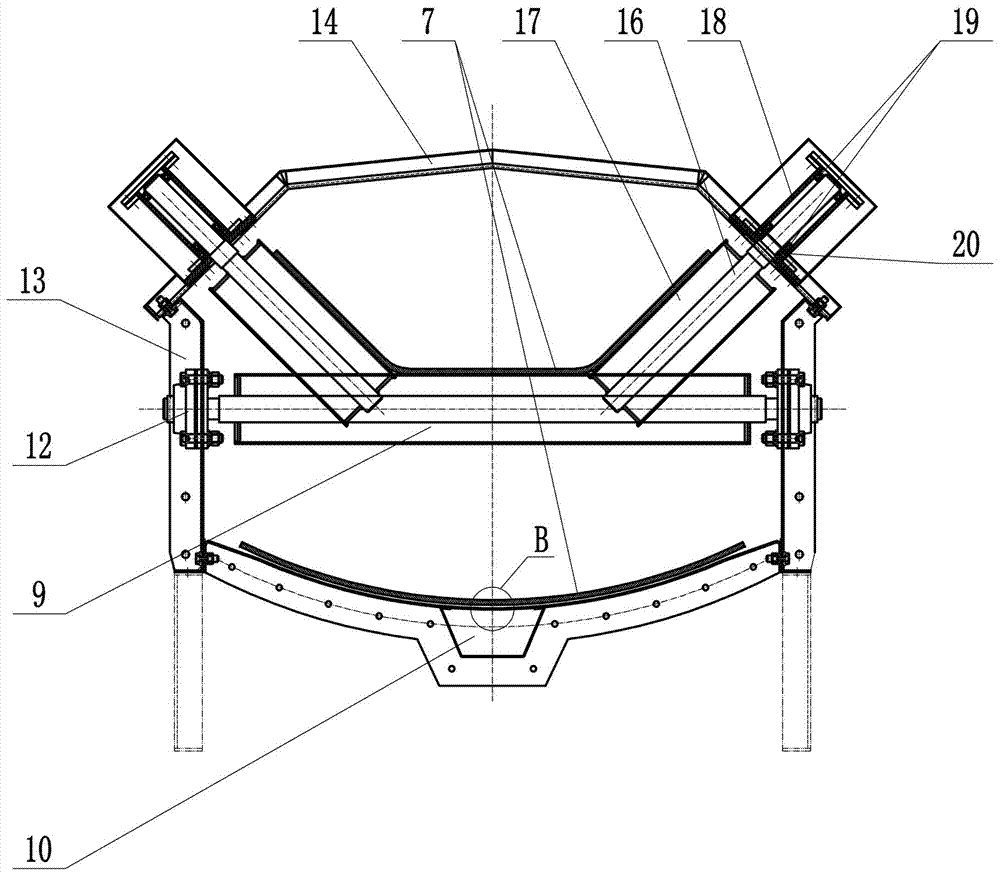

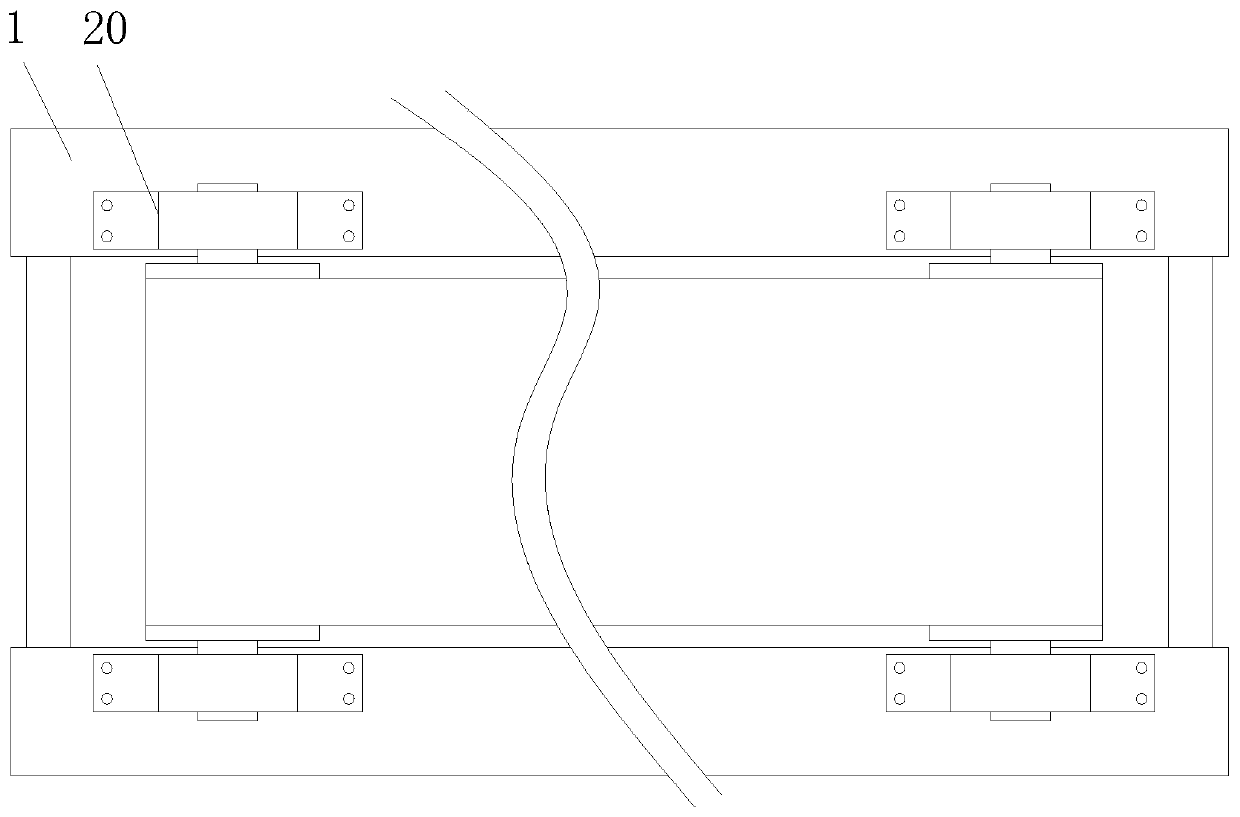

Double twister

InactiveCN101831735ADoes not affect running speedEasy to adjust winding densityTextiles and paperPolyesterYarn

The invention relates to a double twister, which is suitable for double twisting procedure of pure cotton and blended yarn of cotton, wool, polyester and the like in textile industry. The double twister comprises a double twisting mechanism, a traction mechanism, a transversal moving mechanism and a winding mechanism, wherein the double twisting mechanism comprises a spindle component (3), a nylon belt (12) and two nylon belt driving motors (1), wherein the transversal moving mechanism comprises a yarn guiding device (9), a transversal moving device and a transversal moving motor (5); the traction mechanism comprises a traction driving wheel (10), a traction rubber pressing wheel (11) and a traction motor (4); the traction driving wheel (10) and the traction rubber pressing wheel (11) form compression driving; the traction driving wheel (10) is connected with the traction motor (4); the winding mechanism comprises a winding driving wheel (8), a yarn winding barrel (7) and a winding motor (6); and the winding driving wheel (8) is connected with the winding motor (6). The traction driving wheel and the winding driving wheel are respectively driven by the independent motors, the traction motor and the winding motor are combined with electrical control to conveniently adjust the winding density, the yarn running speed is not affected, and the nonuniform twisting index is not affected.

Owner:江阴祥盛纺印机械制造有限公司

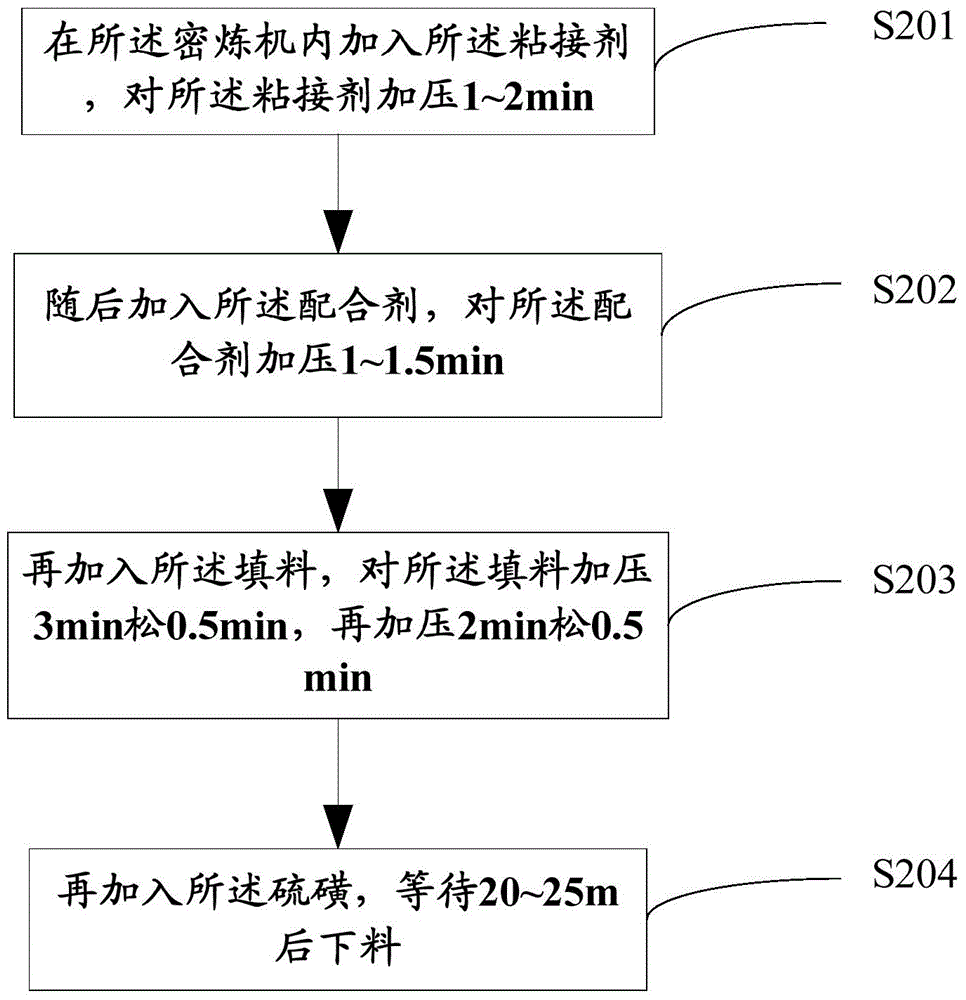

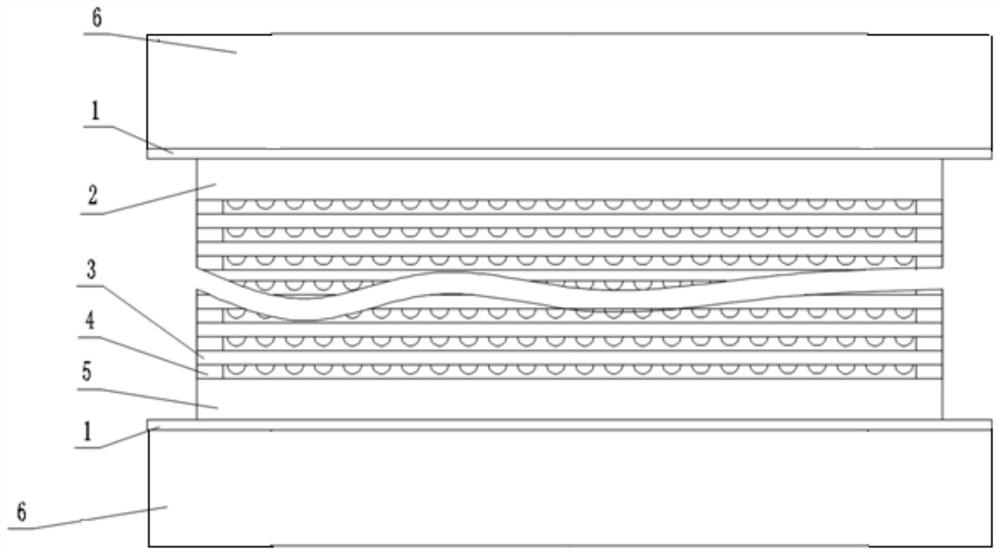

Flexible grease-proof paper-based friction plate and manufacturing method thereof

InactiveCN110118234AGuaranteed oil resistanceConsistent frictionOther chemical processesFriction liningNitrile rubberAdhesive

The invention provides a flexible grease-proof paper-based friction plate and a manufacturing method of the flexible grease-proof paper-based friction plate. The flexible grease-proof paper-based friction plate comprises, by mass, 0.8-1.2 parts of compounding agent; 2.5-5.5 parts of sulfur; 44-73 parts of filler; 8-12 parts of flexible adhesive; 10-20 parts of brittle adhesive; 10-14 parts of nitrile rubber; 0.3-1 part of flexible reinforcing fiber and 0.5-2 parts of carbon fiber. By the adoption of the flexible grease-proof paper-based friction plate and the manufacturing method of the flexible grease-proof paper-based friction plate, the grease resistance of a friction material can be guaranteed, the friction performance existing after oil immersion of the friction plate is identical with that of the friction plate without oil immersion, and a stable friction performance and a high friction coefficient of the paper-based friction plate can be guaranteed; the flexible reinforcing fiber and the carbon fiber with good friction performance are used as reinforcing fiber, the flexible adhesive and the brittle adhesive are used as adhesive, the flexible reinforcing fiber and the carbonfiber are complementary in performance, so that the flexibility of the paper-based friction material is improved, and the friction wear resistance of the paper-based friction material is also improved.

Owner:NANTONG WANDA FRICTION MATERIAL

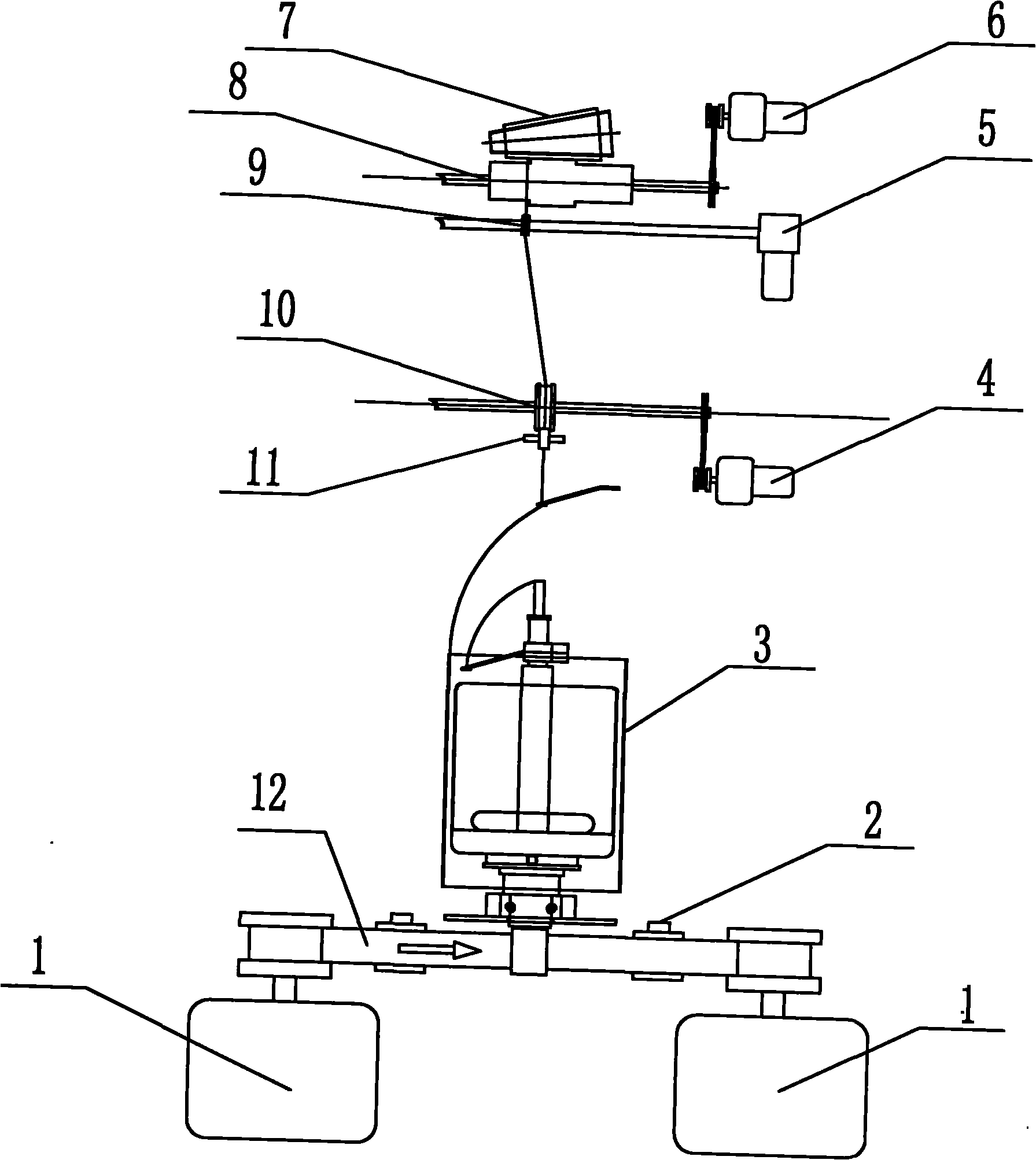

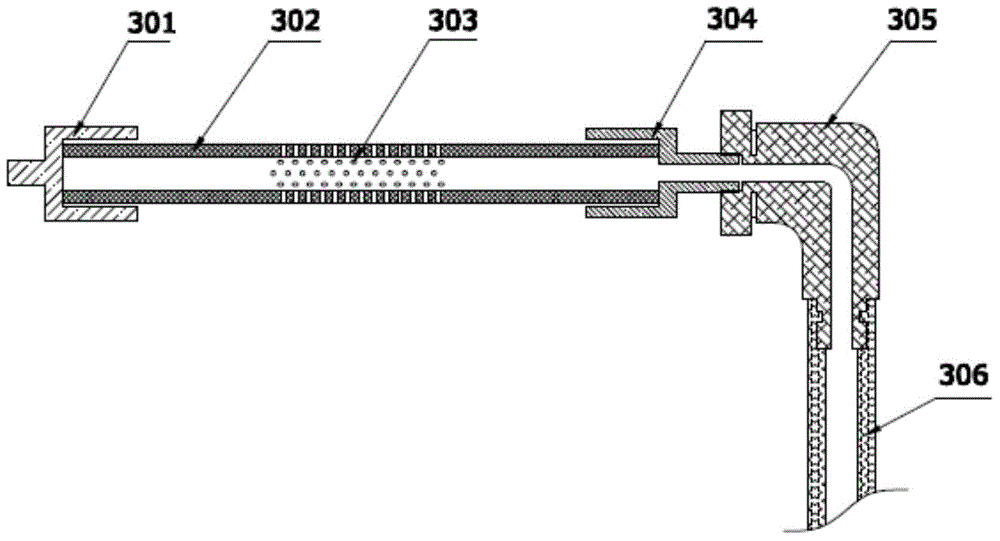

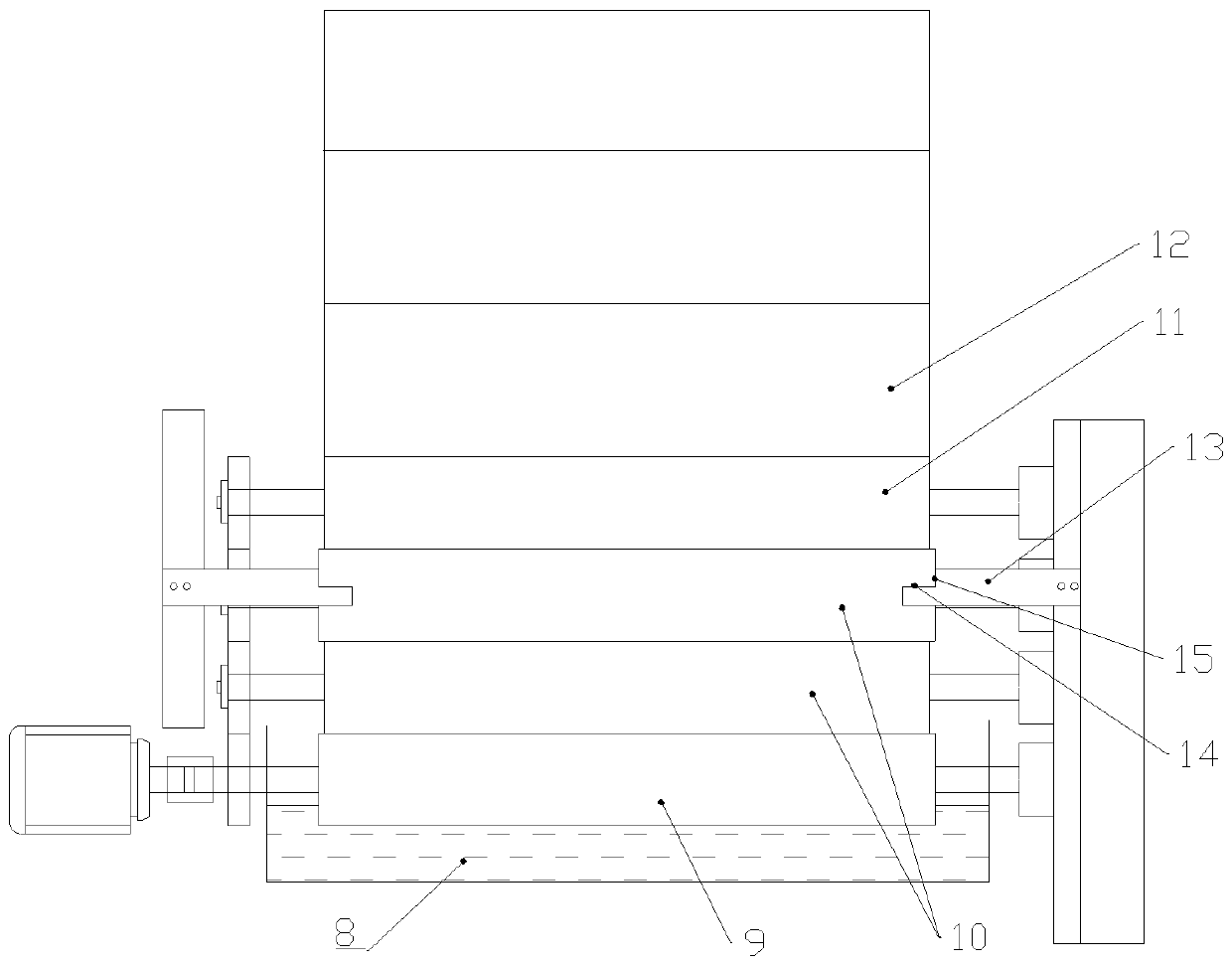

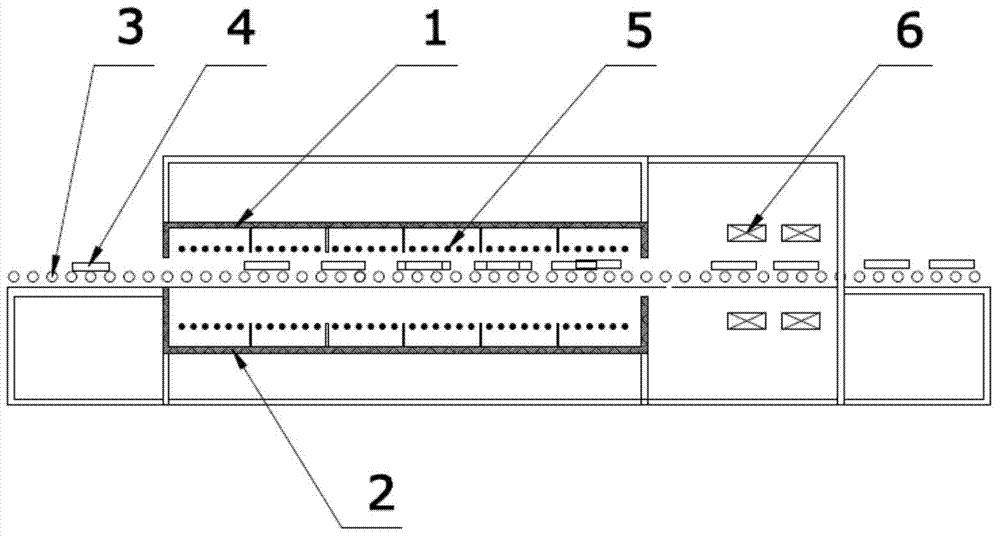

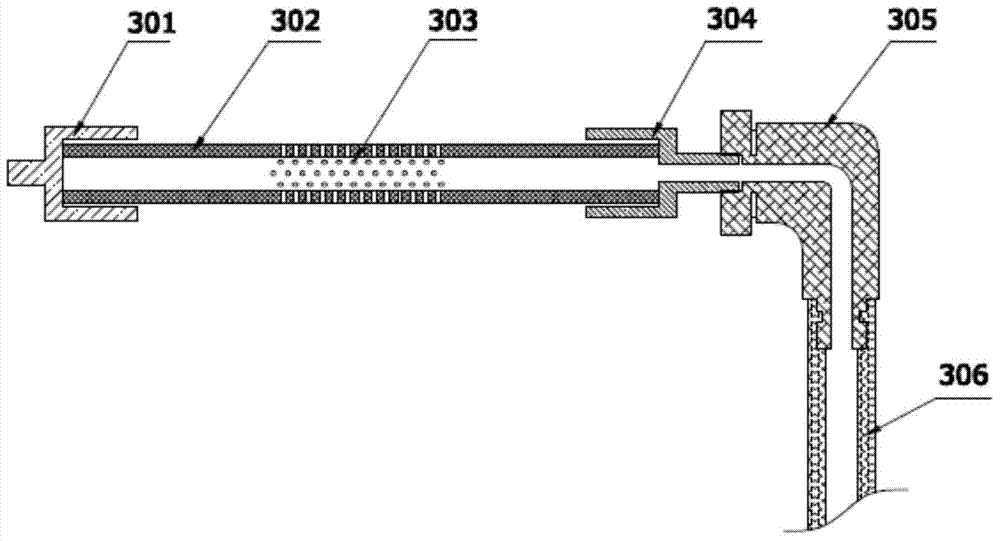

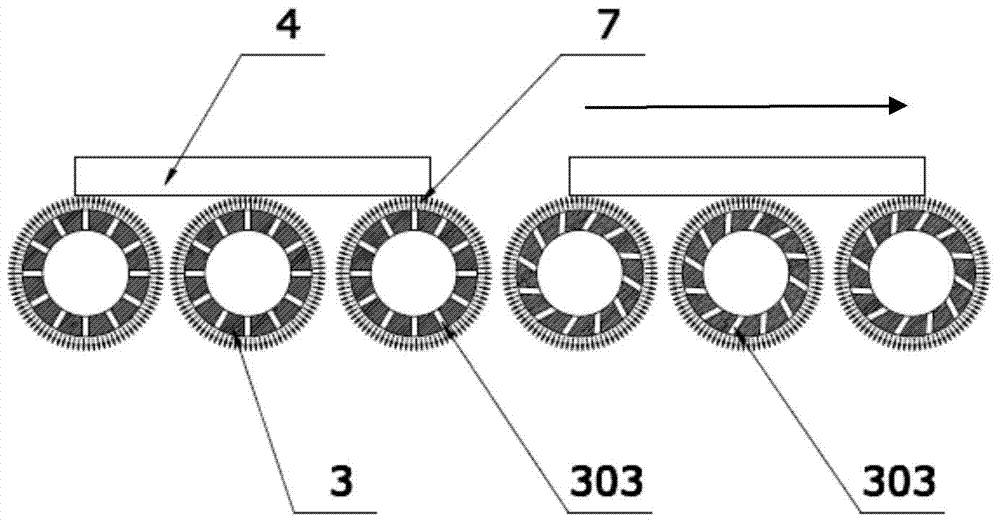

Air-floating roller bed type thermal treatment furnace for semiconductor devices

ActiveCN103557701AConsistent frictionPrevent deviationCharge supportsFurnace typesEngineeringThermal treatment

The invention relates to an air-floating roller bed type thermal treatment furnace for semiconductor devices. The heat-treatment furnace is characterized in that a roller bed for transferring the semiconductor devices comprises a plurality of horizontally-arranged roll shafts capable of reciprocating along self axial lines, at least part of the roll shafts are hollow, a plurality of breathing holes are formed in the parts, where the semiconductor devices pass, of the hollow roll shafts in the radial direction, at least one end of each hollow roll shaft is connected with one air inlet pipe through a rotary joint, and air enters furnace chamber parts where the semiconductor devices pass through the breathing holes in the hollow roll shafts. According to the thermal treatment furnace provided by the invention, the atmosphere and the cleanliness of a center diffusion zone in the furnace are fundamentally ensured, so that the diffusion effect and the quality are improved.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +1

Oil-resistant paper-base friction plate and production method thereof

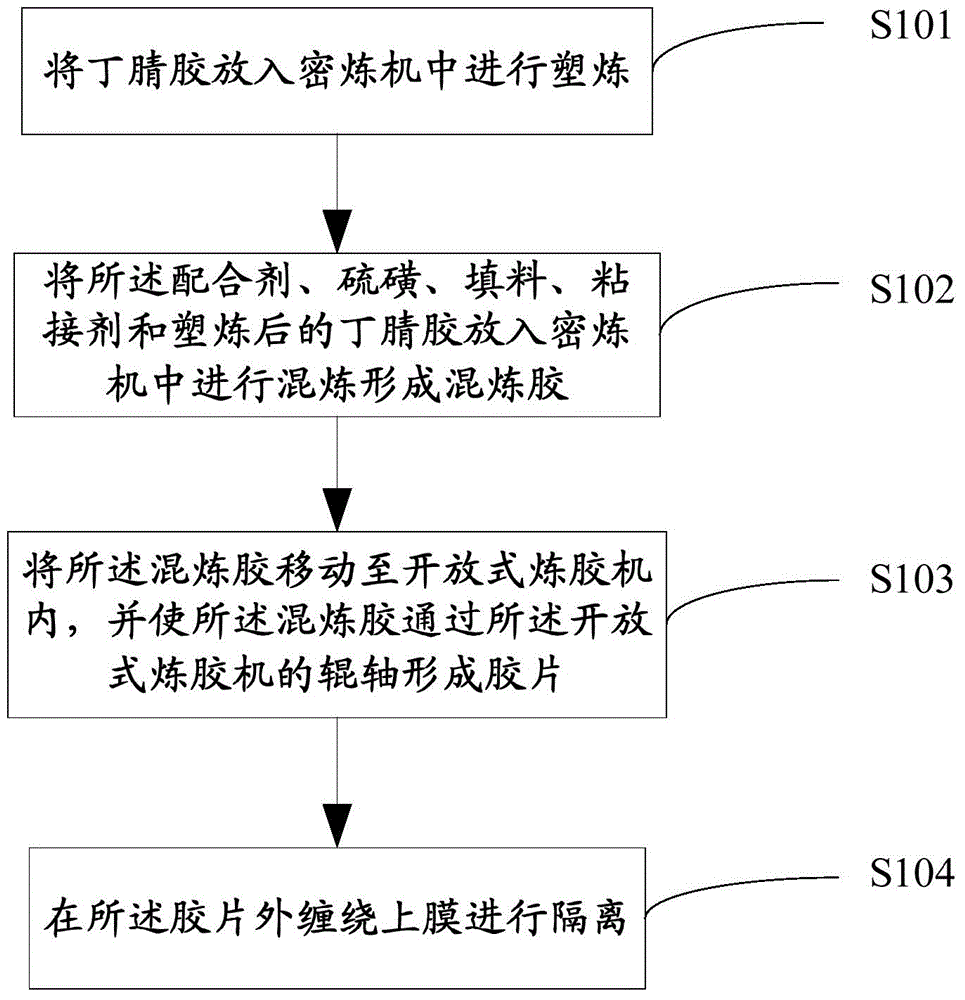

The invention relates to an oil-resistant paper-base friction plate and a production method thereof. The oil-resistant paper-base friction plate comprises the following materials in parts by weight: 0.8-1.2 parts of compounding agent, 2.5-5.5 parts of sulfur, 44-73 parts of filler, 20-28 parts of adhesive and 10-14 parts of butadiene-acrylonitrile rubber. The method comprises the following steps: S101: plastifying the butadiene-acrylonitrile rubber in a Banbury mixer; S102: adding the compounding agent, sulfur, filler, adhesive and plastified butadiene-acrylonitrile rubber into the Banbury mixer, and compounding to form the compounded rubber; S103: moving the compounded rubber into an open rubber mixing mill to form a rubber plate; and S104: winding a film outside the rubber plate for isolation. The production method can ensure the oil resistance of the friction material. The frictional property of the friction plate subjected to oil impregnation is the same as before oil impregnation, thereby simultaneously ensuring the stable frictional property and higher friction factor of the paper-base friction plate.

Owner:NANTONG WANDA FRICTION MATERIAL

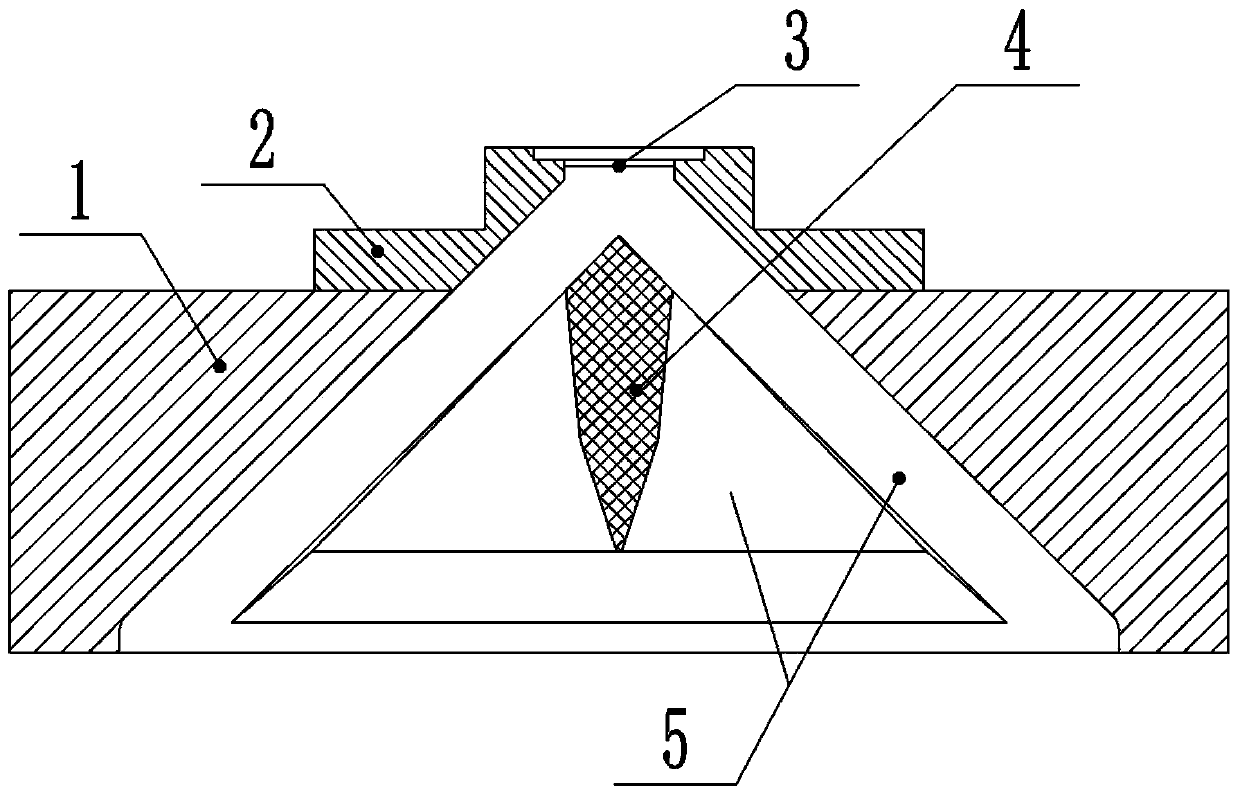

Wood-plastic door plank micro-foaming forming device and using method thereof

The invention relates to the field of wood-plastic production technology, in particular to a wood-plastic door plank micro-foaming forming device and using method thereof. The wood-plastic door plankmicro-foaming forming device comprises an extruder and an extruding mould. The extruding mould comprises a converging module. Core rods are arranged inside the converging module. A separation blade isvertically arranged between the core rods. The upper end face and the lower end face of the separation blade are fixedly connected with the converging module. The device is novel in structure, a wood-plastic material can be cut into a plurality of material units through the separation unit, in this way, the material units do not affect one another, flow crossing among the material units is avoided, balanced material flow and consistent material pressure of the material units are guaranteed, and stable friction force between the material units and the core rods is guaranteed.

Owner:濮阳市东宝科技发展有限公司

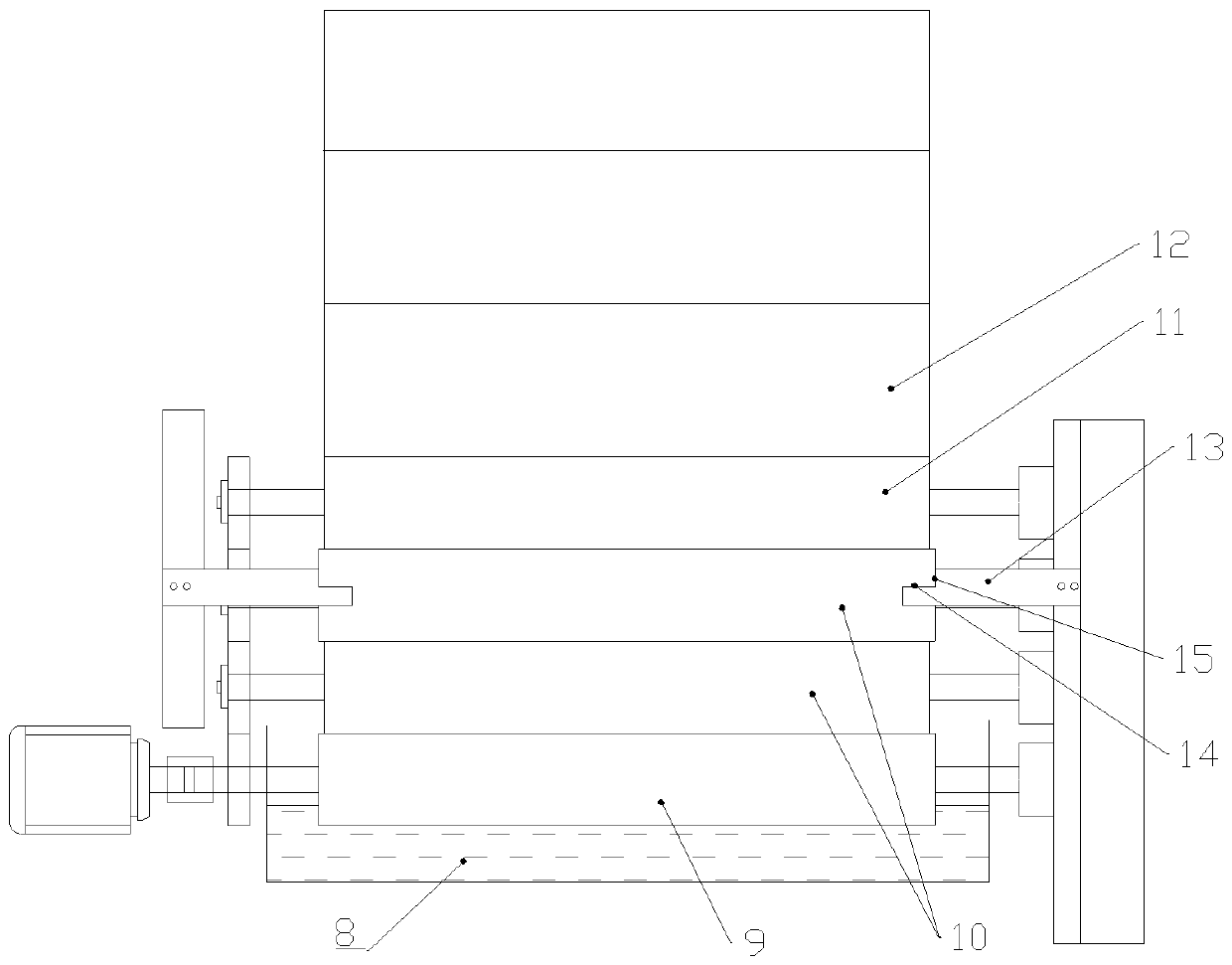

Diffusion welding method for TA2 material micro-channel radiator

PendingCN114012235AImprove welding strengthHigh specific strengthNon-electric welding apparatusPhysicsEngineering

The invention discloses a diffusion welding method for a TA2 material micro-channel radiator. The diffusion welding method comprises the following steps: carrying out etching processing on an annealed-state high-precision plate with a roughness of less than Ra0.4; assembling a plurality of stacked micro-channel etching plates and side plates into a micro-channel core body, and then assembling the micro-channel core body on a positioning rod; placing a layer of graphite paper on each of the uppermost layer and the lowermost layer of the assembled micro-channel core body; ensuring that the center of the core body is consistent with the center of a pressurization mechanism of diffusion welding equipment; when the vacuum degree reaches 6*10<-3> Pa, starting heating; pre-pressing a pressing force of 0.5 MPa on the micro-channel core body; when the temperature reaches 890 + / -5 DEG C, adjusting the pressing force to 3.5 Mpa, and carrying out heat preservation for 180 min at the temperature; after heat preservation is finished, keeping the pressing force of 3.5 Mpa for cooling; and when the temperature of the core body is cooled to 400 DEG C, starting an argon filling cooling mode. According to the invention, the problem of diffusion welding when a TA2 titanium alloy micro-channel radiator comprises hundreds of layers of micro-channel plates is solved.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

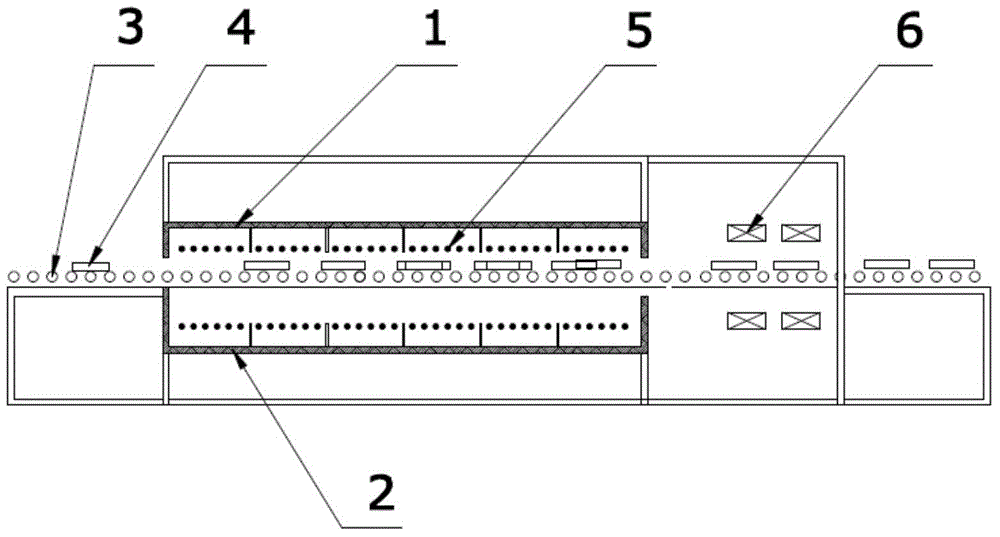

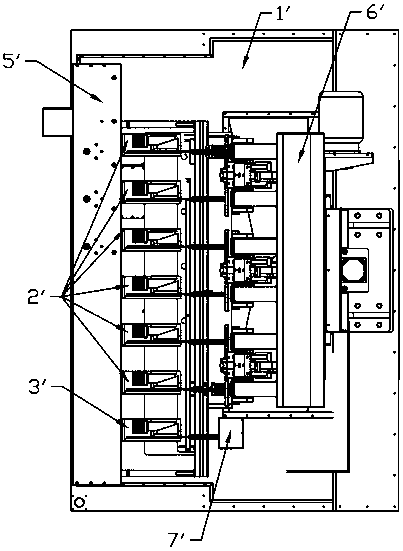

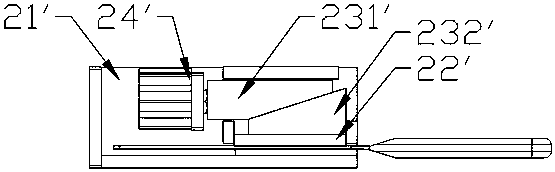

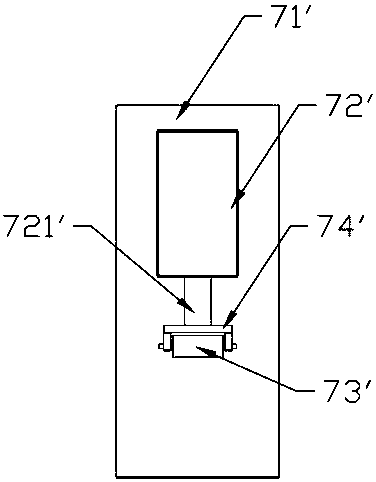

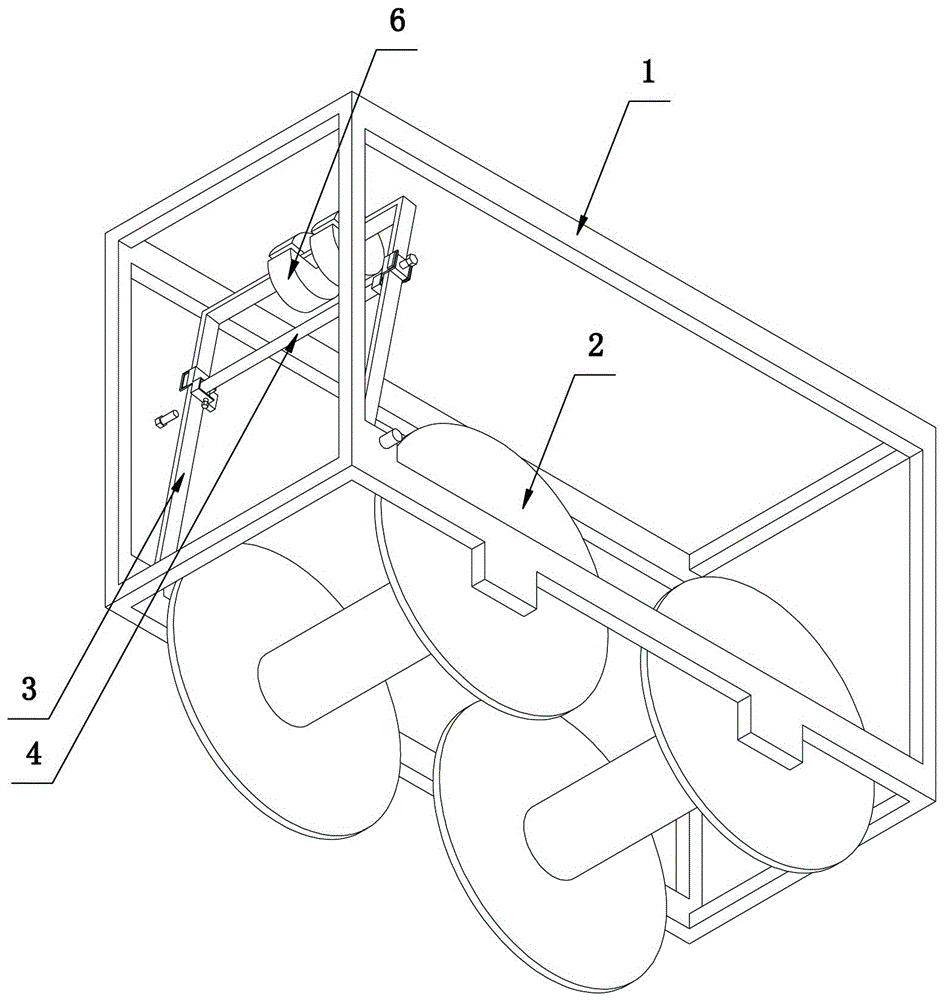

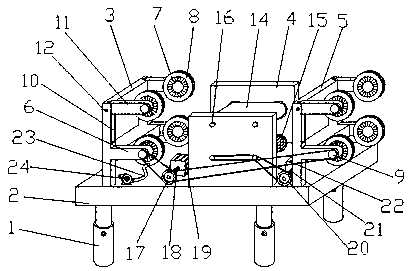

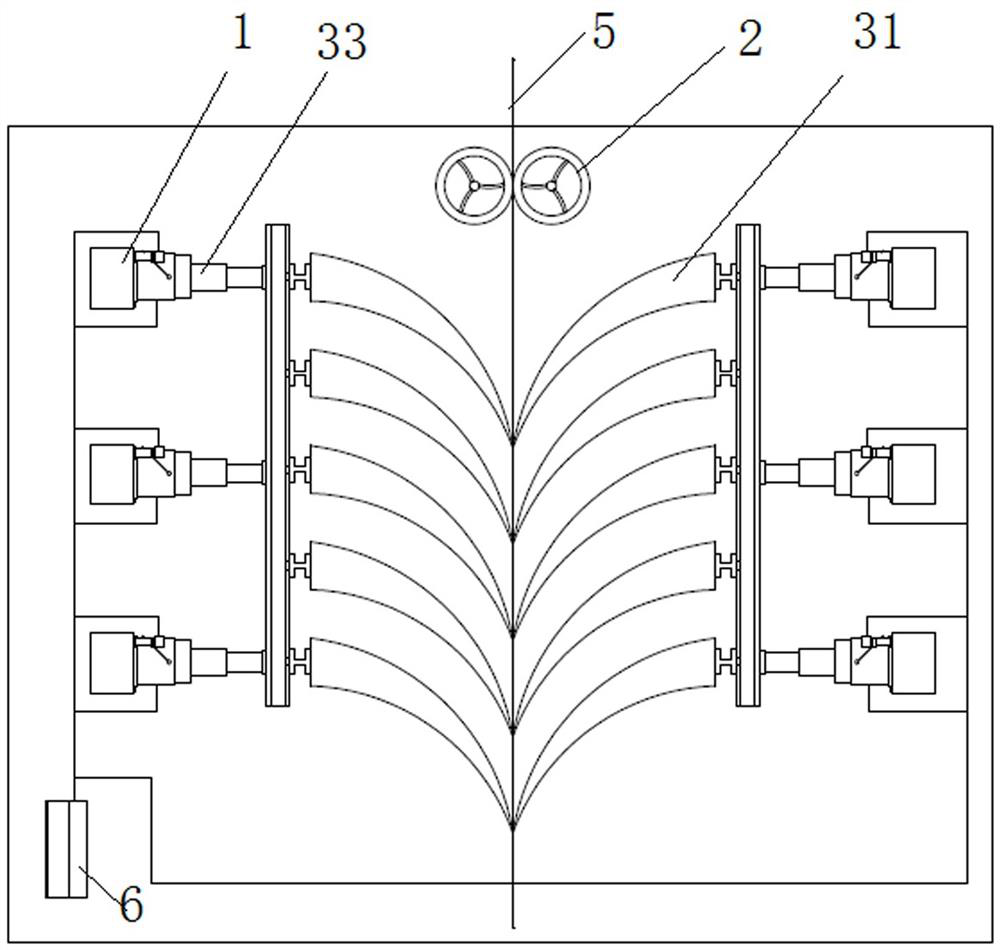

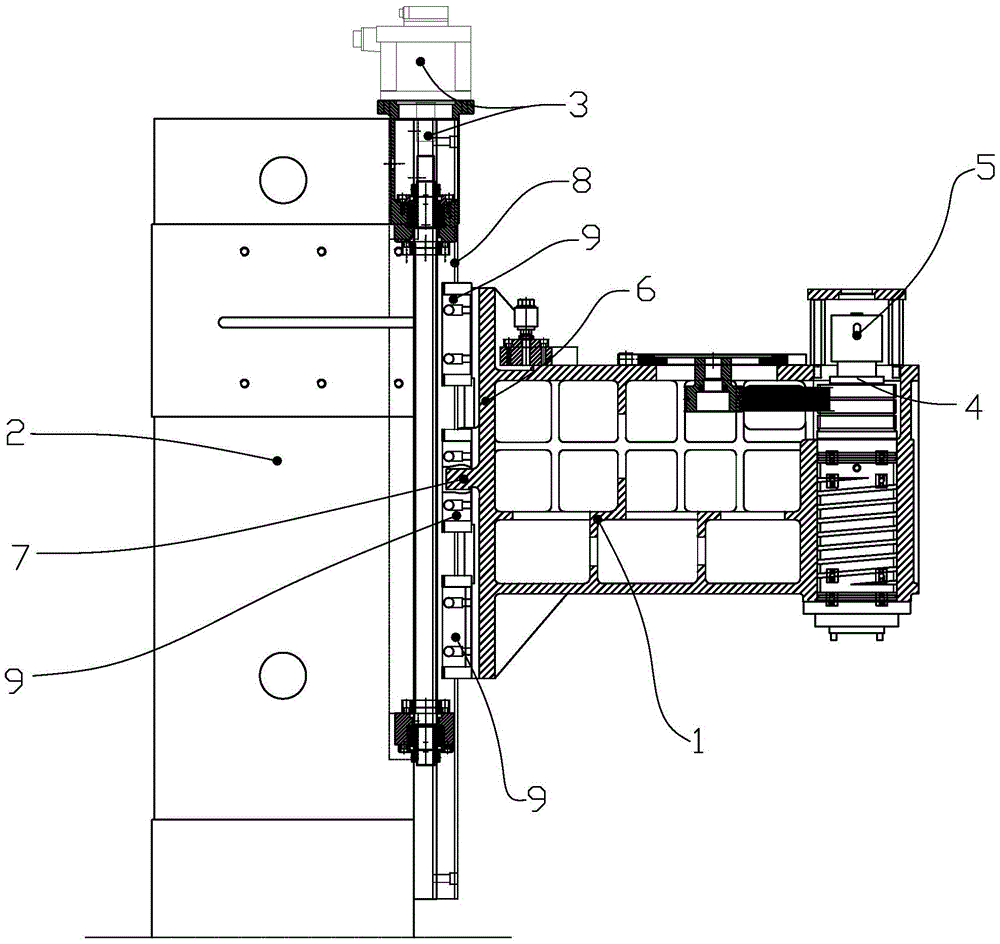

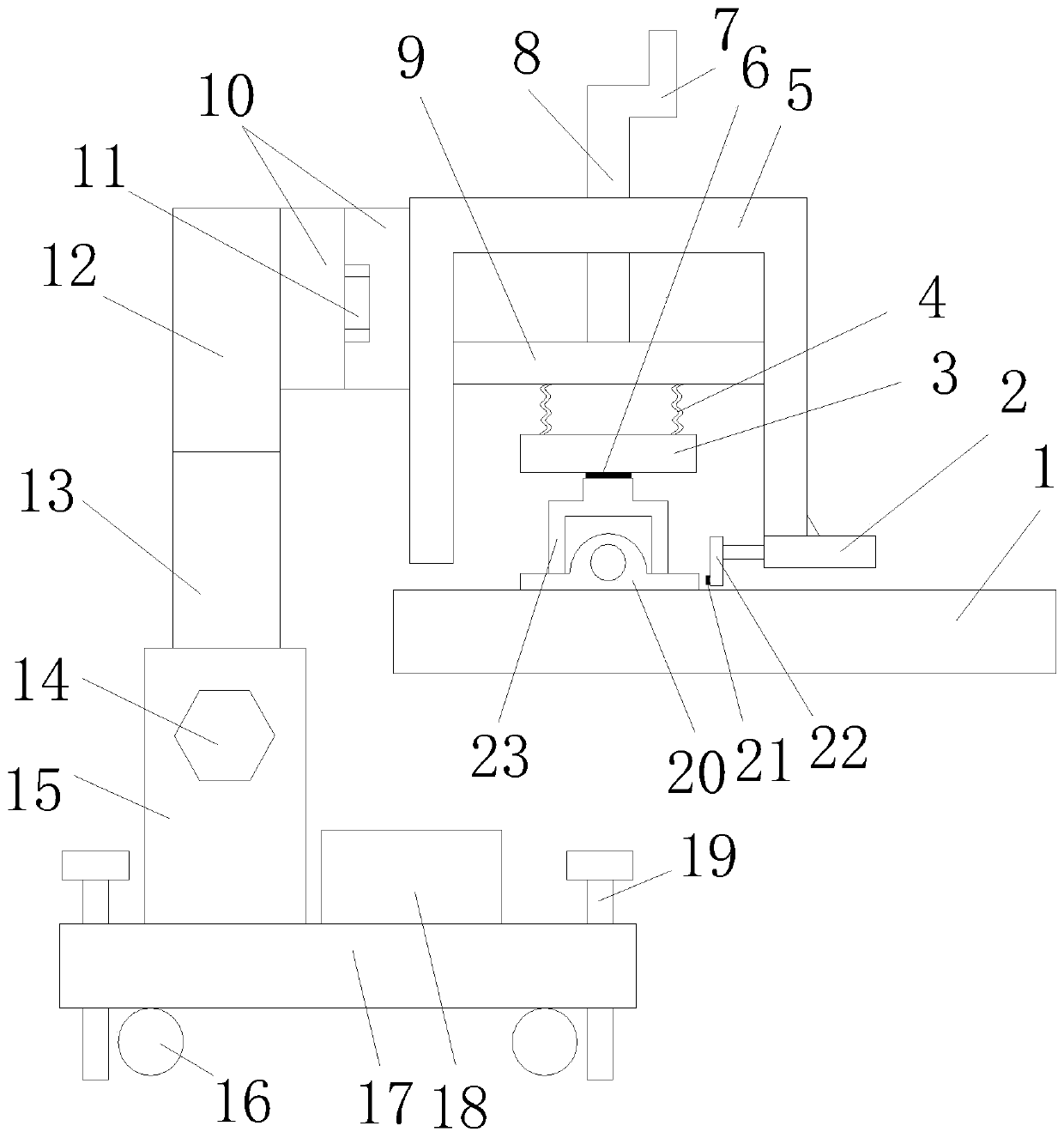

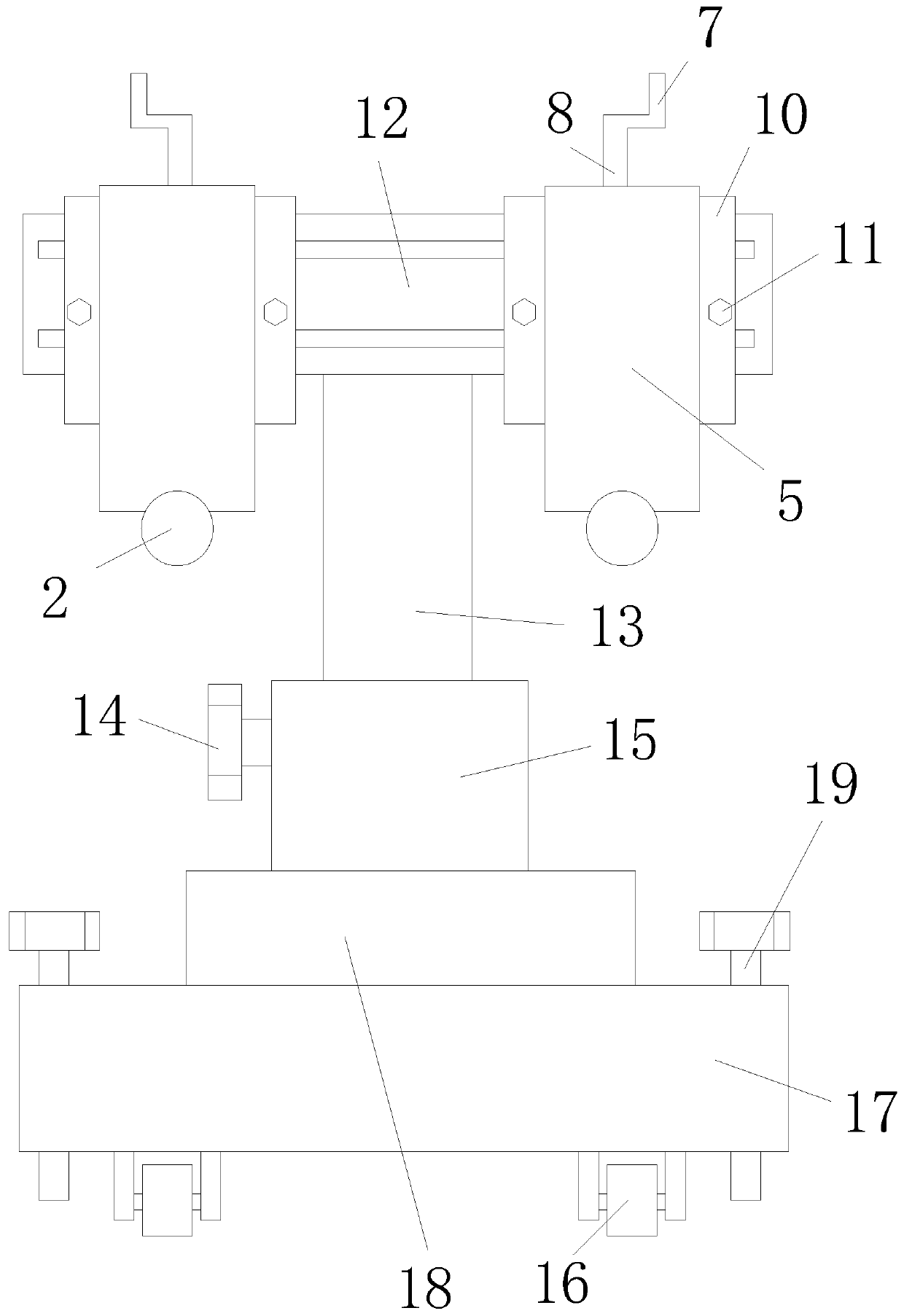

Novel multi-shank polishing machine

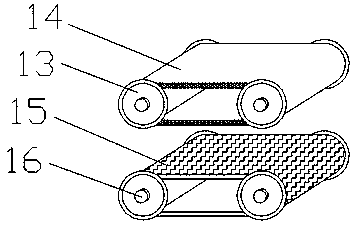

PendingCN107745308AImprove polishing efficiencyConsistent frictionBelt grinding machinesWheel driveEngineering

The invention provides a novel multi-shank polishing machine. The novel multi-shank polishing machine comprises a control system, a stand, multiple cutter clamping tables, a main shaft box, a two-dimensional electric displacement platform and an abrasive belt polishing mechanism; the abrasive belt polishing mechanism comprises an abrasive belt wheel bracket fixed on the stand, a driving abrasive belt wheel fixed on the abrasive belt wheel bracket, a driving abrasive belt wheel driver fixed on the abrasive belt wheel bracket, a driven abrasive belt wheel fixed on the abrasive belt wheel bracket, an abrasive belt matched with the driving abrasive belt wheel and the driven abrasive belt wheel, and multiple supercharging wheels for increasing friction force of the abrasive belt to shanks; themultiple cutter clamping tables are positioned between the driving abrasive belt wheel and the driven abrasive belt wheel; and the multiple supercharging wheels are positioned between the driving abrasive belt wheel and the driven abrasive belt wheel. Compared with the prior art, the contact between the abrasive belt and the shanks is changed from line contact to surface contact, so that the polishing efficiency is greatly improved; and the supercharging wheels enable the abrasive wheel to achieve consistent polishing effects on each shank.

Owner:DONGGUAN EZAT AUTOMATION TECH

Warp constant tension device for ribbon loom

InactiveCN105803641AKeep tension balancedAchieve constant tension fine-tuningLoomsCircular discEngineering

A warp constant tension device for a ribbon loom comprises a frame, a warp beam rotatably arranged on the frame, a tension stand, a regulating mechanism and two tension ropes arranged symmetrically, wherein the warp beam comprises two disks with the circumferential side provided with grooves, the two disks are fixedly connected through a winding post, the two tension ropes wind the upper ends and the lower ends of the left side and the right side of the tension stand respectively to be wound in the grooves of the two disks; the regulating mechanism can be arranged on the tension stand in a vertically movable mode; a plurality of warps are wound on the winding post; and the plurality of warps are pulled above the regulating mechanism and butted against the upper side of the regulating mechanism and then pulled to the ribbon boom. The warp constant tension device for the ribbon loom can guarantee tension balance at both ends of the warp beam, and achieve constant tension of warps of the warp beam, thus stabilizing quality of woven fabric ribbons. In addition, positions of supporting points of warps can be changed under the vertical action of the regulating mechanism; therefore fine adjustment of constant tension of warps can be achieved. Compared with the prior art, the accuracy is remarkably increased.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

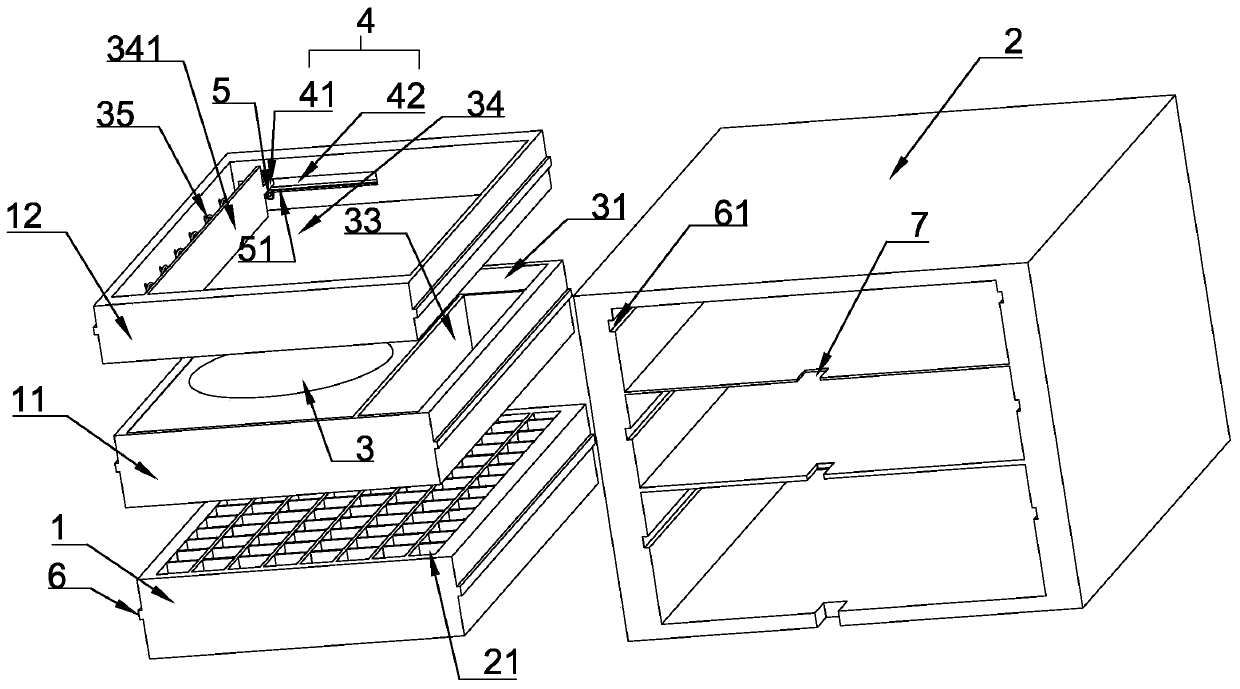

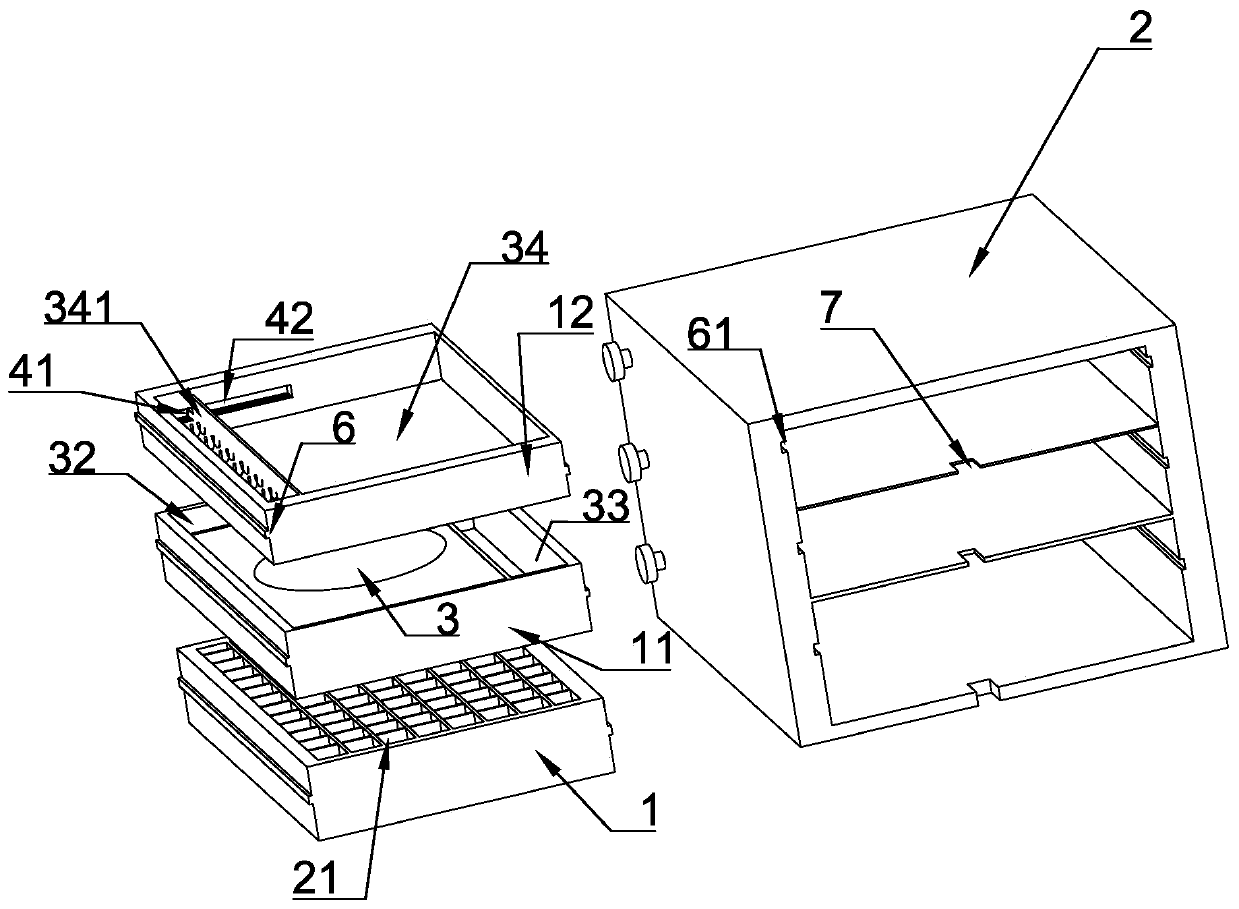

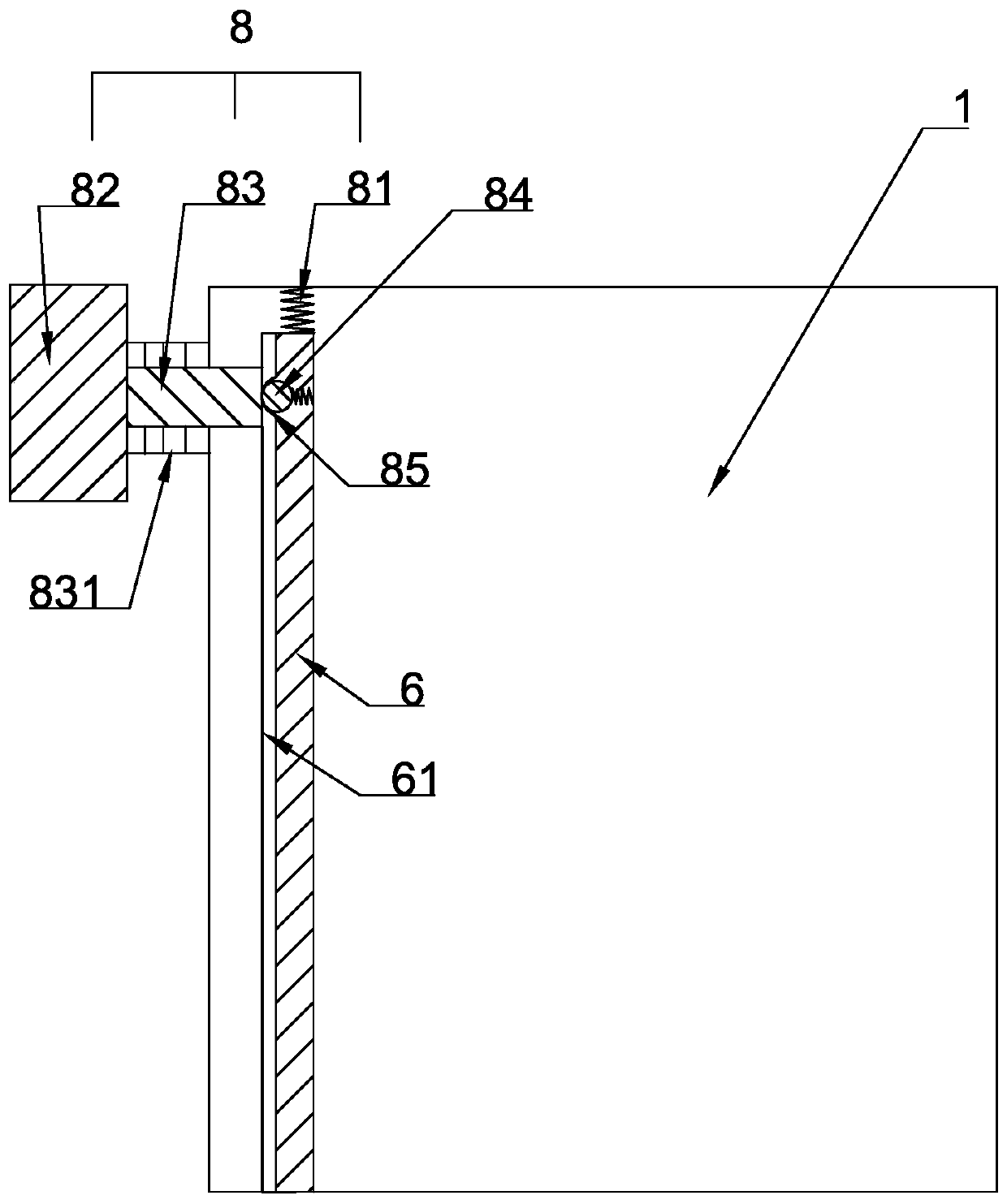

Transportation device for wood movable-type printing device

PendingCN109775084AReduce contact areaIncrease contact areaDrawer-and-shell containersMovable typeEngineering

The invention discloses a transportation device for a wood movable-type printing plate. According to the technical scheme, the transportation device is characterized in that a first storage groove, asecond storage groove and a third storage groove are included, wherein a storage box surrounds the outer portions of the first storage groove, the second storage groove and the third storage groove; storage cavities for containing movable types and filling blocks are evenly distributed in the first storage groove; the first storage groove is internally provided with a circular groove for containing inkstone, a first square groove for containing a transverse brush, a second square groove for containing a vertical brush and a three-dimension groove for containing a plurality of partition strips;the third storage groove is provided with a containing groove for containing wood boards, a telescopic plate is arranged in the containing groove, the face, opposite to the containing groove, of thetelescopic plate is provided with a telescopic spring, one end of the telescopic spring is fixedly connected with the telescopic plate, and the other end of the telescopic spring is fixedly connectedwith the groove wall of the containing groove; the position, close to the end portion, of the telescopic plate is provided with an auxiliary device for assisting telescopic plate sliding; and by meansof the device, a wood movable-type printing tool can be protected against damage in the transportation process.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

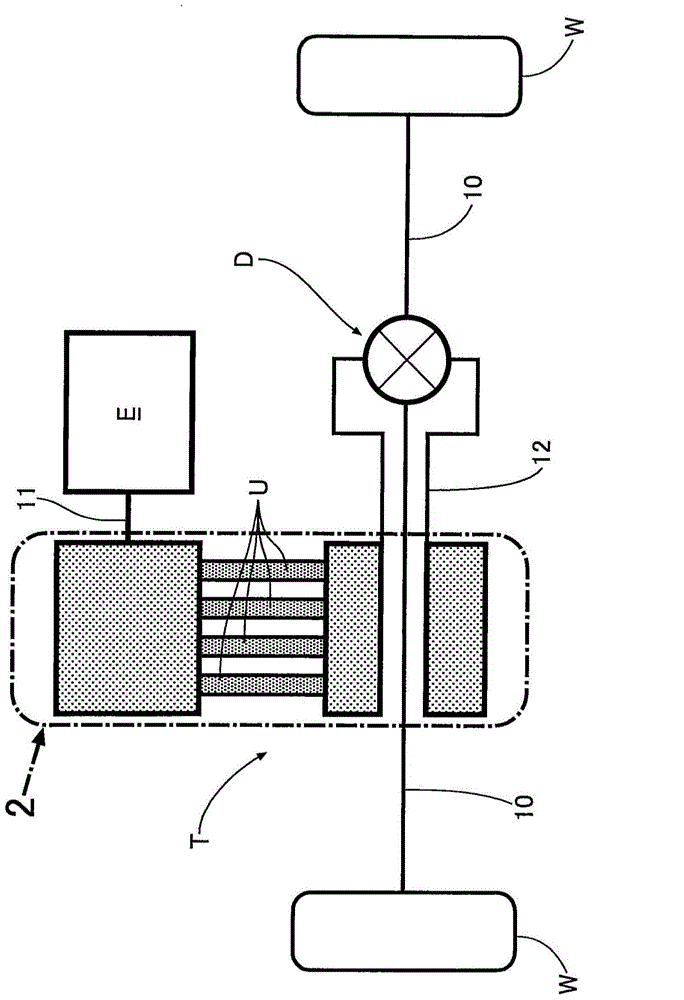

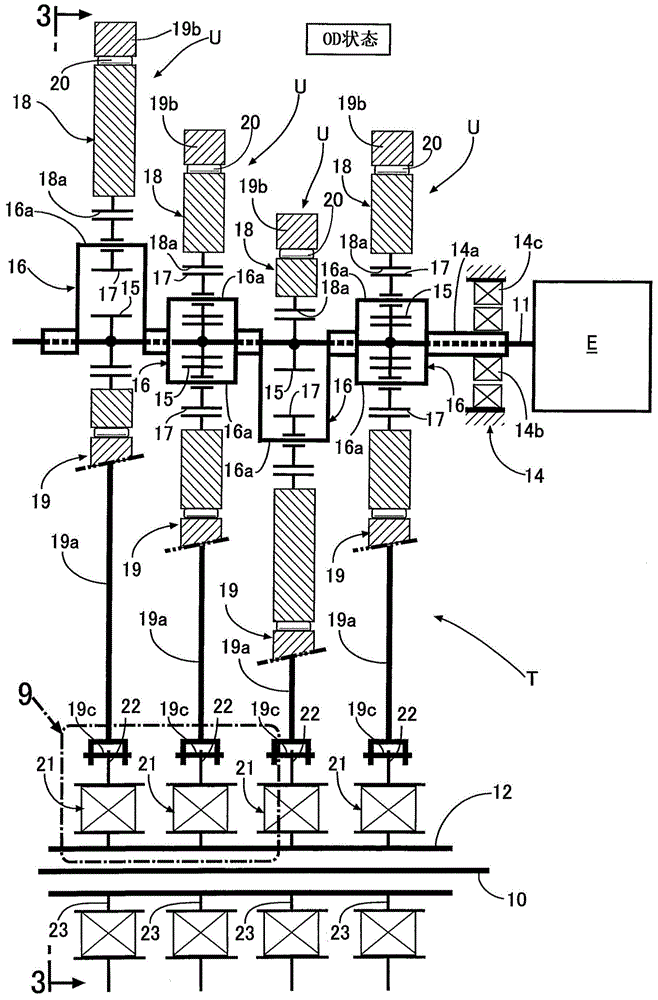

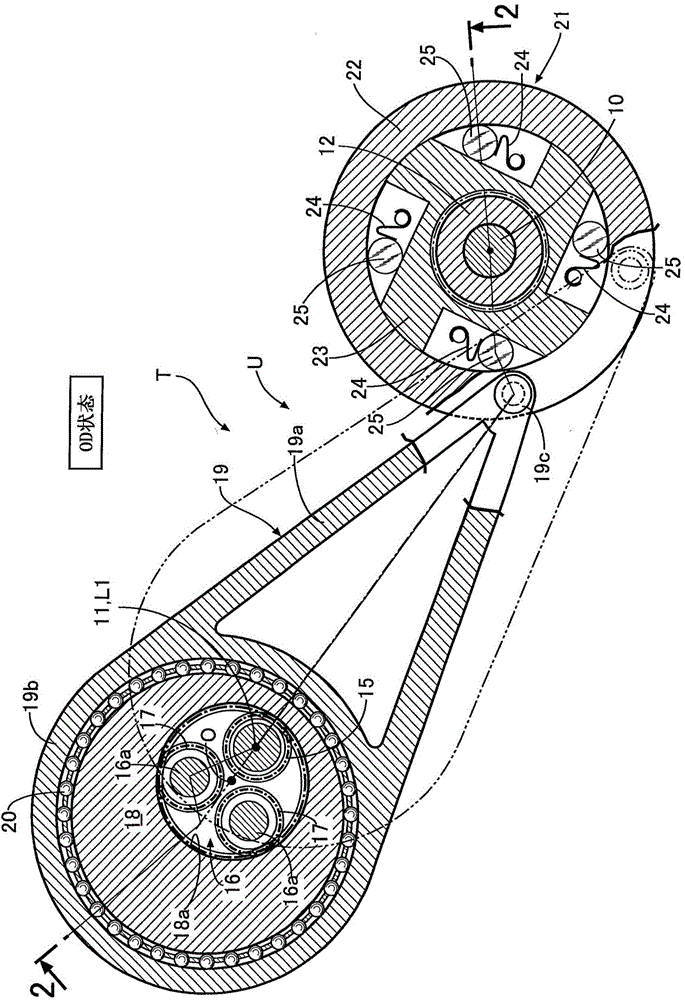

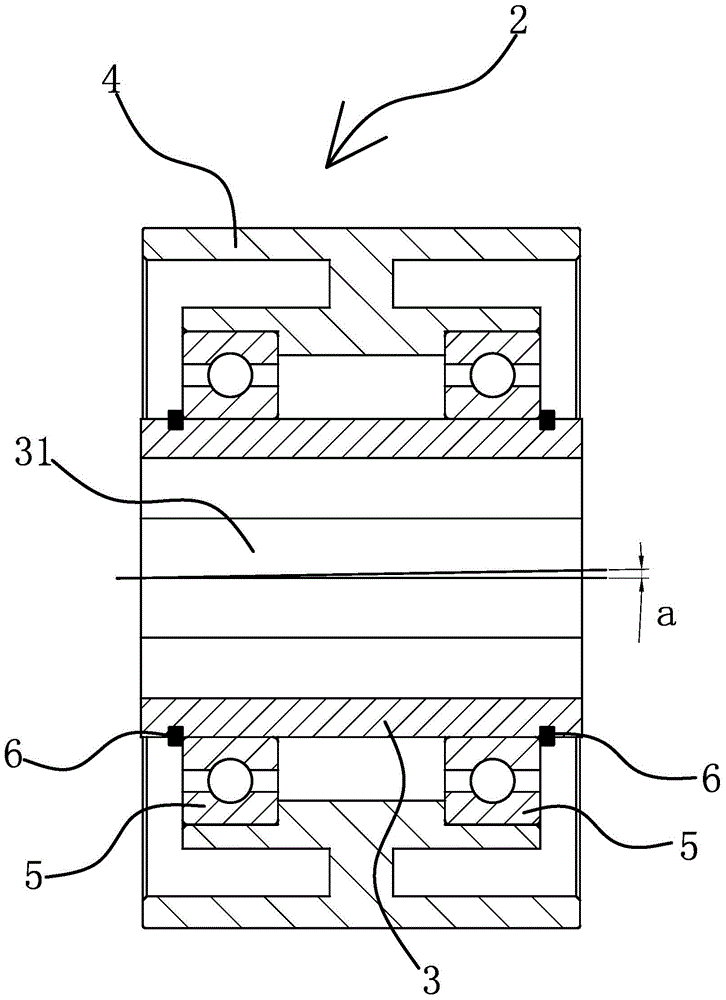

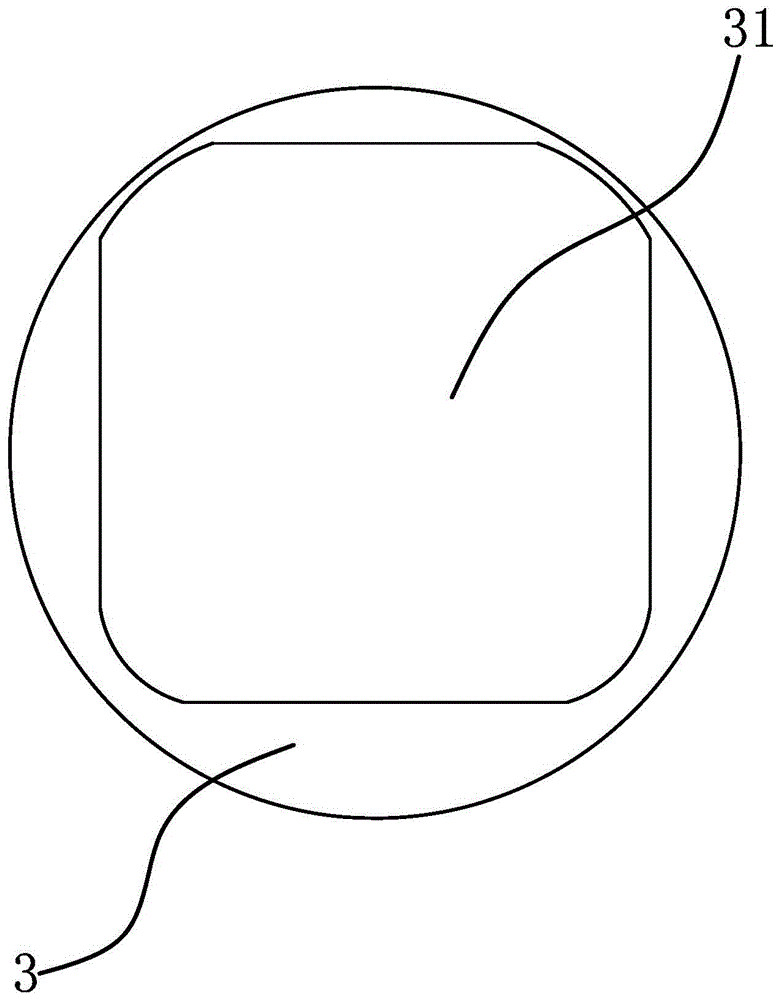

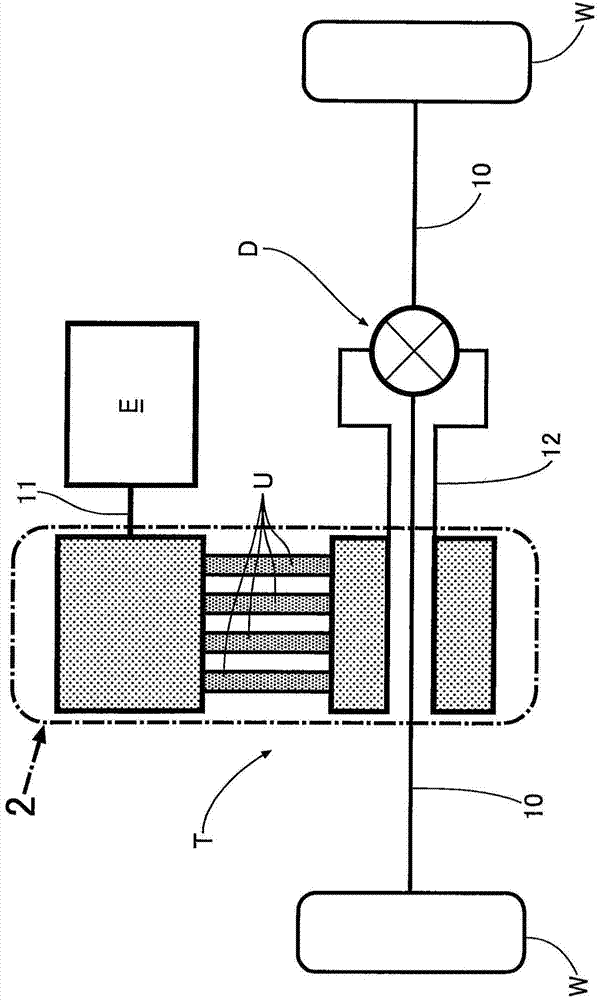

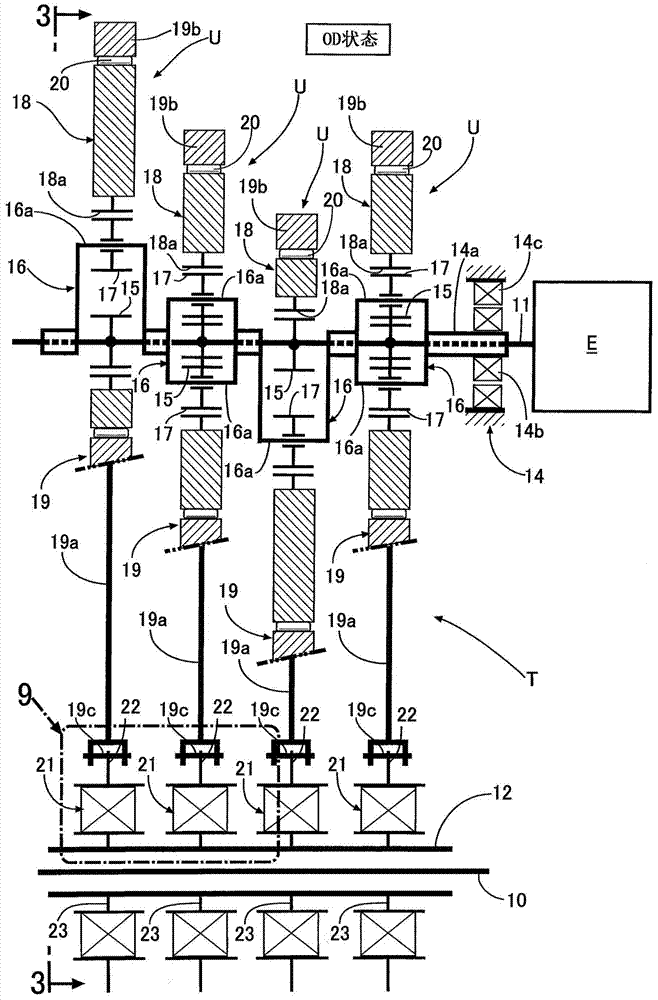

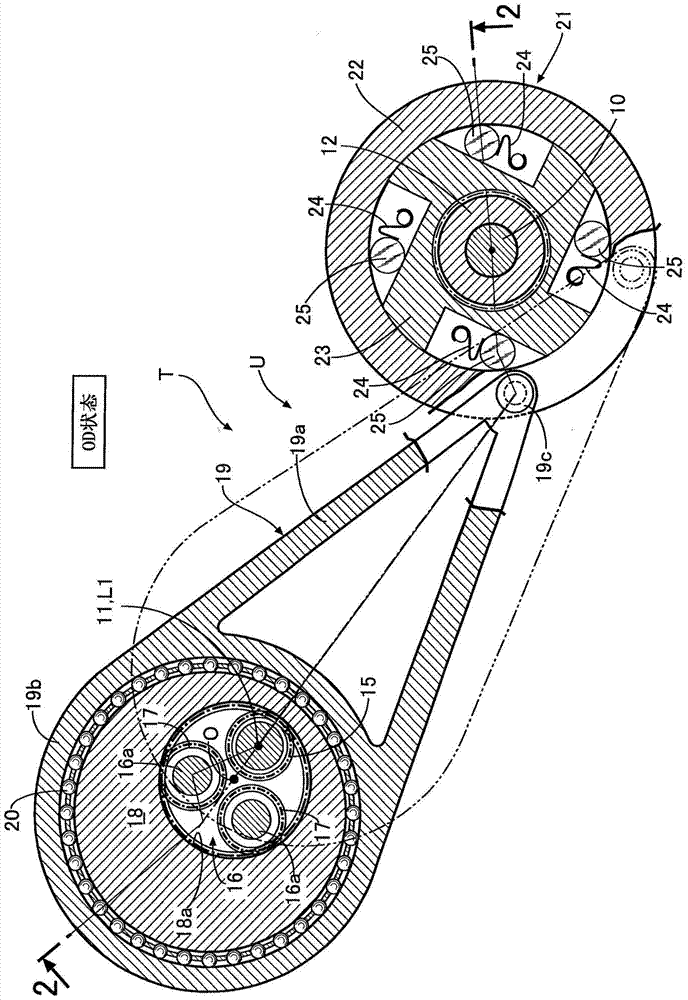

One-way clutch and crank-type continuously-variable transmission

The invention provides a one-way clutch and a crank-type continuously-variable transmission. A peripheral part of an end face of a roller applying a force in an axial direction through an axial spring is preventing from being engaged with a side surface of a maintaining frame. Because a frictional force acting on a first end face (25a) of the roller (25) is consistent with a frictional force acting on a second end face (25b) of the roller (25), thereby preventing the roller (25) from being inclined because of the imbalance between the frictional forces of the first and second end faces (25a, 25b) during the movement from a reference point and an engagement point, preventing the inclined roller (25) from being worn caused by the contact of the first and second end faces (25a, 25b) of the roller (25) with a first side surface (36a) and a second side surface (36b) of an inner ring (36). Moreover, the roller (25) can be enabled to be smoothly engaged between an outer peripheral surface of an internal part (23) and an inner peripheral surface (22a) of an external part (22), thereby improving the joint responsiveness of the one-way clutch (21).

Owner:HONDA MOTOR CO LTD

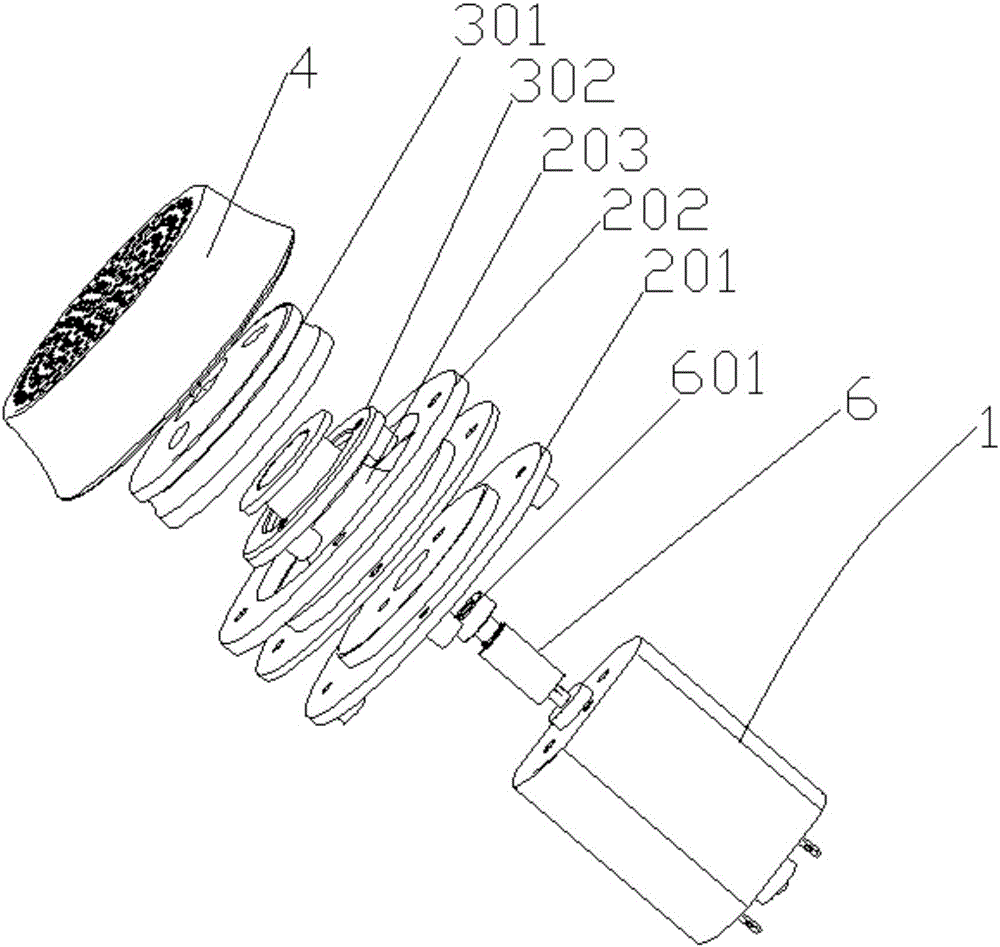

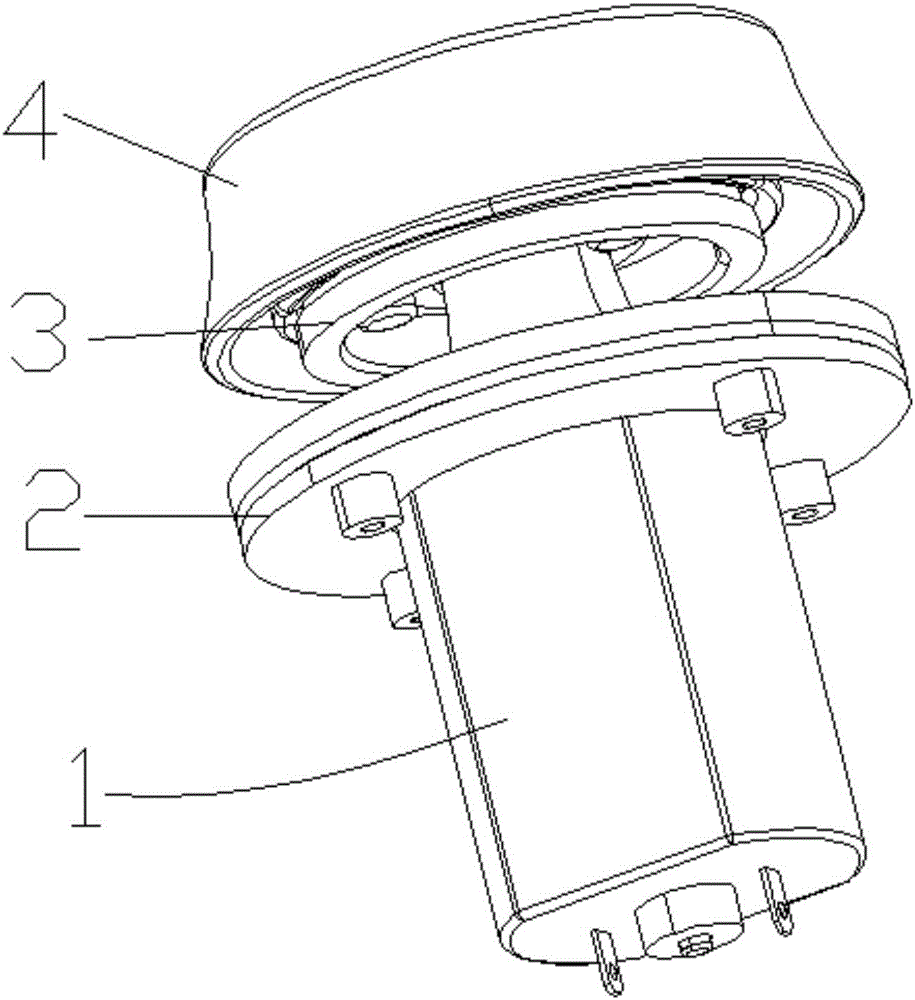

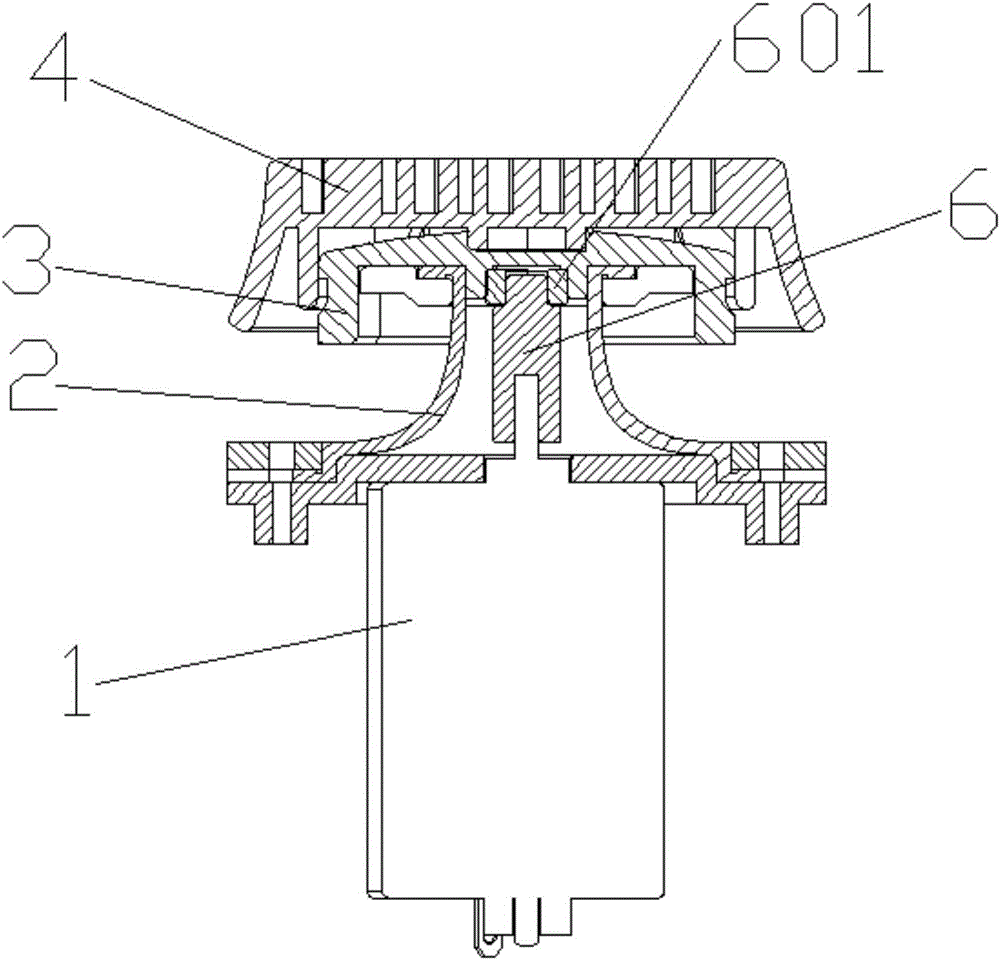

Torsional pendulum type face cleaning device

InactiveCN106235929AAchieve cleaning effectAvoid discomfortBrush bodiesBathroom accessoriesElastomerSkin clean

The invention discloses a torsional pendulum type face cleaning device which comprises a motor. The motor is provided with an elastomer, the elastomer is provided with a cleaning brush mounting base, the cleaning brush mounting base is provided with a cleaning brush, the inner side of the cleaning brush mounting base is provided with a driving mounting hole, a rotating shaft of the motor is provided with a pendulum shaft, one end of the pendulum shaft extends into the driving mounting hole, the pendulum shaft and the rotating shaft of the motor are in an eccentric shape. Therefore, according to the torsional pendulum type face cleaning device, the pendulum shaft is driven by the motor to rotate, and the cleaning brush is driven to swing in the radial direction of the pendulum shaft continuously, so that effects of making the cleaning brush perform friction with the skin and cleaning the skin are achieved. Since the cleaning brush is deflected continuously to be in friction with the skin, it is guaranteed that friction force of the cleaning brush and the skin is consistent, and cleaning evenness and thoroughness are guaranteed. Since the elastomer has good elasticity, the hard contact between the cleaning brush and the skin is not caused, and the discomfort of the skin is avoided.

Owner:ACE TEC CO LTD

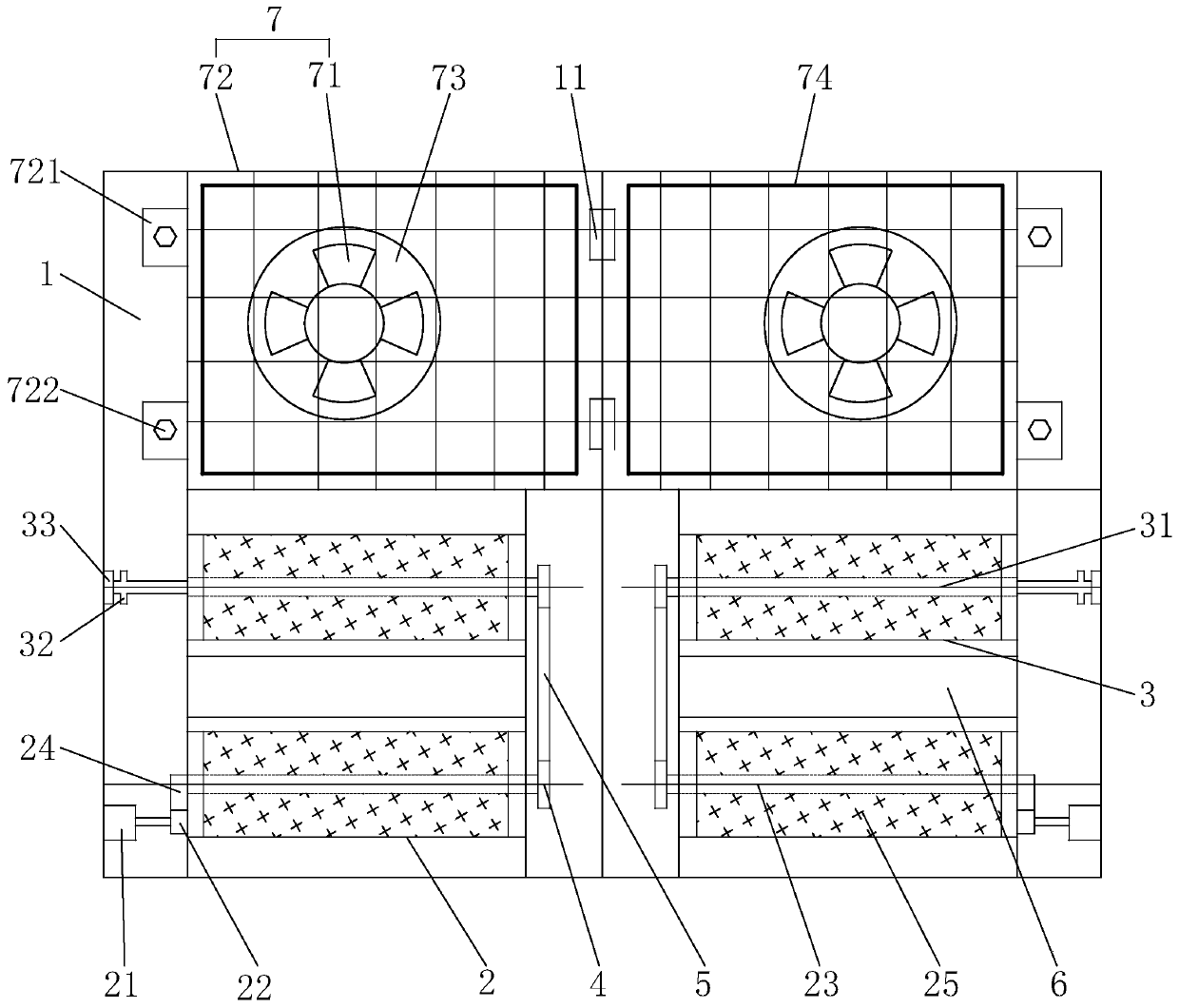

Chassis dynamometer

InactiveCN111207865AConsistent frictionExtended service lifeVehicle testingWork measurementHydraulic cylinderSprocket

The invention relates to a chassis dynamometer. The device comprises a frame, a driving roller and a driven roller, one end of the driving roller in the length direction is in transmission connectionwith a power device; wherein the other end of the frame is fixedly connected with a chain wheel, the outer side of the chain wheel is meshed with a chain, the driven roller is in transmission connection with the driving roller through the chain, a lifting device is arranged between the driving roller and the driven roller and comprises a hydraulic cylinder and a lifting plate which are fixed in the frame, and one end of a piston rod of the hydraulic cylinder is fixedly connected with the lifting plate. An air drying device is arranged on one side of the frame and comprises an air blower and asupporting plate arranged above the air blower, the air blower is fixed in the frame and faces the supporting plate, the supporting plate is detachably and fixedly connected with the frame, and a plurality of ventilation openings are formed in the supporting plate. The strong air exhaust effect of the air blower can blow-dry the tire with water such that the friction force of the wheel is consistent with that during drying, and the detection precision is improved.

Owner:上海昶欣机动车技术服务有限公司

Adjustable clamping plate platform for wood sanding and sanding process

InactiveCN110919503ASmooth connectionConsistent forceGrinding carriagesBelt grinding machinesAir pumpFoam rubber

The invention discloses an adjustable clamping plate platform for wood sanding, which comprises telescopic supporting legs and a smooth table top, wherein a plate feeding supporting frame, a grindingbelt supporting frame and an outgoing plate discharging supporting frame are arranged on the smooth table top, an incoming plate feeding supporting frame is provided with a fixed flat rod and a sliding flat rod, and each of the fixed flat rod and the sliding flat rod is provided with a wheel hub, a vacuum tire and a first driven belt wheel by means of a wheel shaft; belt rollers are erected between two vertical plates of the grinding belt supporting frame, foaming rubber belts are wound around the upper belt rollers, grinding belts are wound around the lower belt rollers, and the belt rollersare connected with a second driven belt wheel; the first driven belt pulley is connected with a first driving belt pulley, and the second driven belt pulley is connected with a second driving belt pulley; and the vacuum tire is communicated with an air pump by means of an air pipe. The adjustable clamping plate platform adopts the vacuum tire for extrusion as a plate conveying and clamping mechanism, adopts reverse extrusion grinding of the grinding belts and the foaming rubber belts, and achieves the processes of two-way extrusion material conveying and two-way extrusion reverse grinding; andadjustable clamping plate platform has small extrusion force, large friction force and high grinding efficiency.

Owner:利辛县爱侣家俱加工有限公司

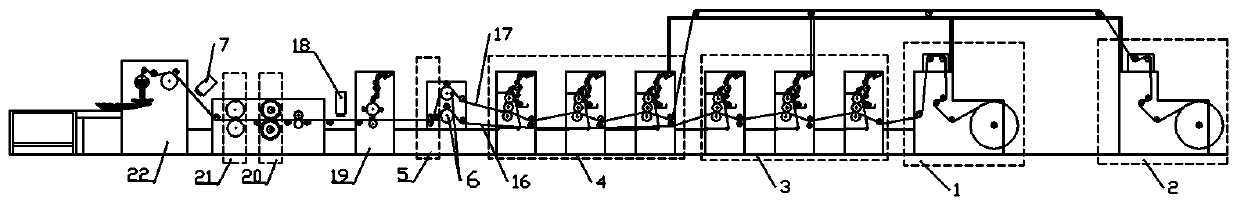

Double-printing equipment for duplex invoice

The invention relates to the field of printing, in particular to double-printing equipment for a duplex invoice. Paper in a paper rolling part A is printed in a printing group C to form a first invoice; paper in a paper rolling part B is printed in a printing group D to form a second invoice; tension monitoring is performed on the first invoice and the second invoice before the first invoice and the second invoice enter a combining part, and the tension of the first invoice and the tension of the second invoice are guaranteed to be consistent during combination, so that the content of the first invoice and the content of the second invoice are completely overlapped and registered. Invoice number printing and locking are performed on the two combined invoices, the invoice subjected to double printing is cut into two independent single invoices, and finally, the two single invoices are folded simultaneously. Thus, double printing of the two invoices is completed simultaneously, and the printing efficiency is 2-3 times higher than that of traditional printing equipment.

Owner:CHONGQING FARSIGHT PRINTING

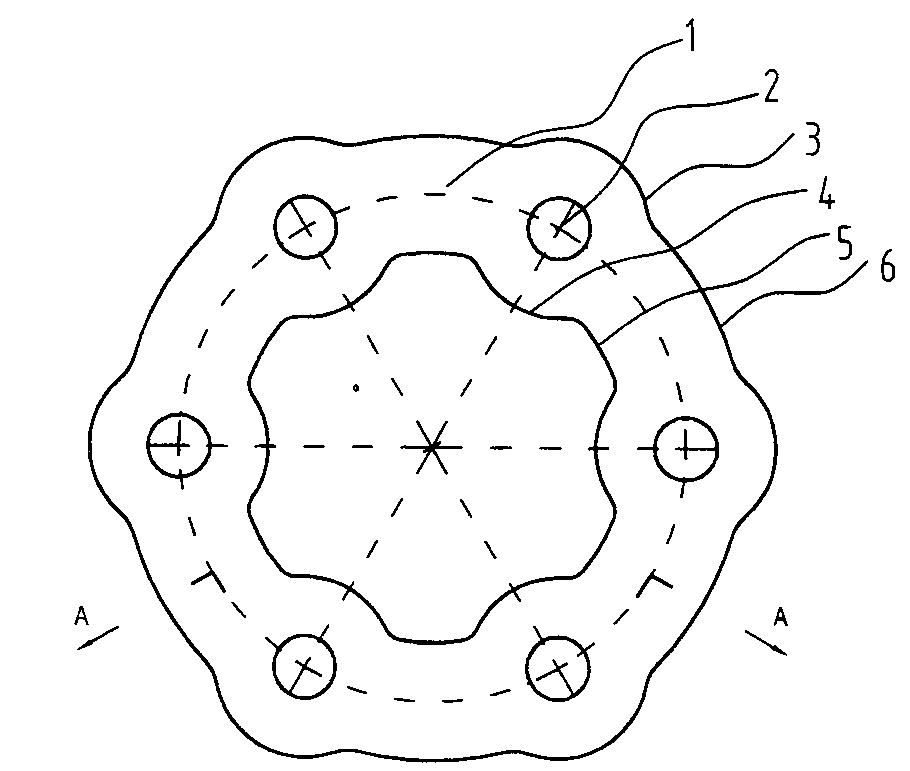

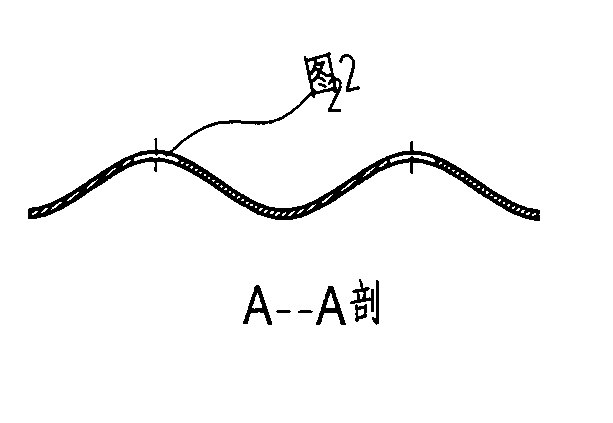

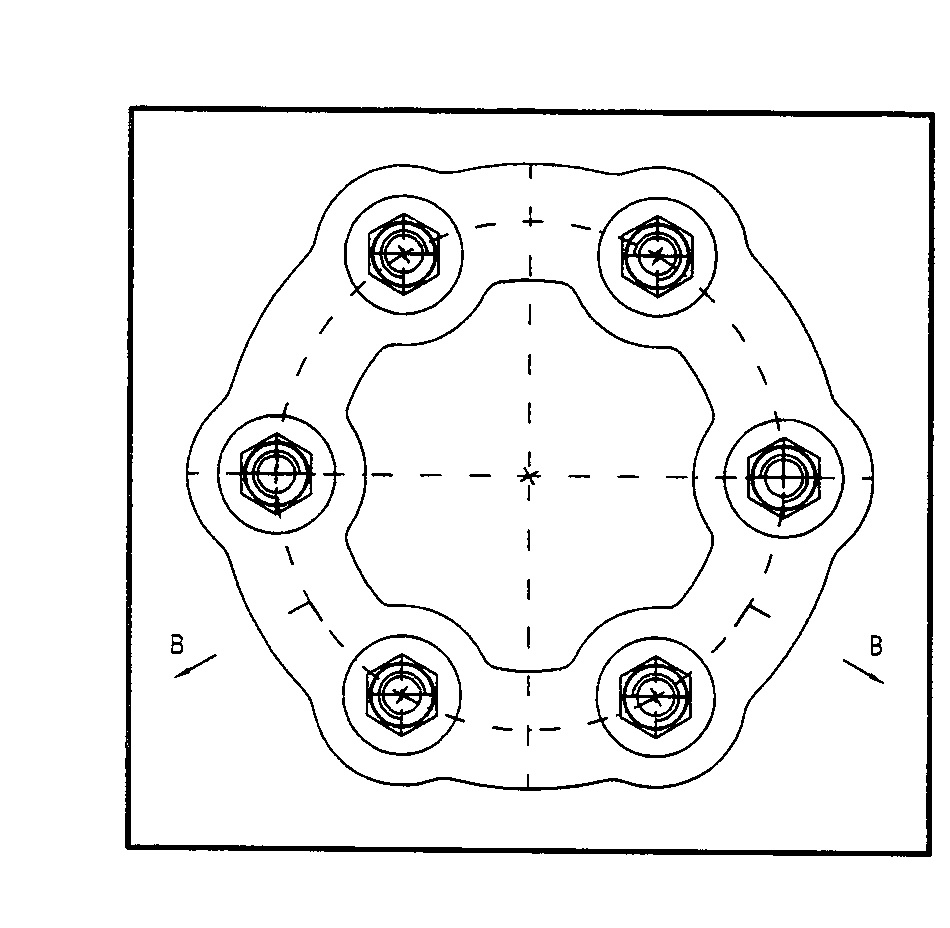

Wave spring

A wave-shaped spring is characterized in that the number of holes (2) of a wave spring (1), namely the number of wave peaks, can be determined as per the number of steel wires; an outer ring convex arc (3) and an inner ring convex arc (4) corresponding to each hole (2) are formed on the two sides of the corresponding hole (2); the outer ring convex arcs (3) are connected with outer ring arcs (6); the inner ring convex arcs (4) are connected with inner ring arcs (5); the wave spring (1) is wave-shaped along the periphery; due to the characteristics of the stressed wave spring (1), when one steel rope or multiple steel ropes of the group of steel ropes are subjected to oversize or underside force, the wave spring (1) deforms correspondingly; during deformation, the force is transmitted to other steel ropes to cause corresponding change to other steel ropes; therefore, when certain force is applied to the steel ropes, the wave spring (1) can uniformly distributes the force to each steel rope, the stress on the steel ropes can be balanced, and the purpose that all ropes in the group of steel ropes are subjected to equivalent force can be realized.

Owner:李军

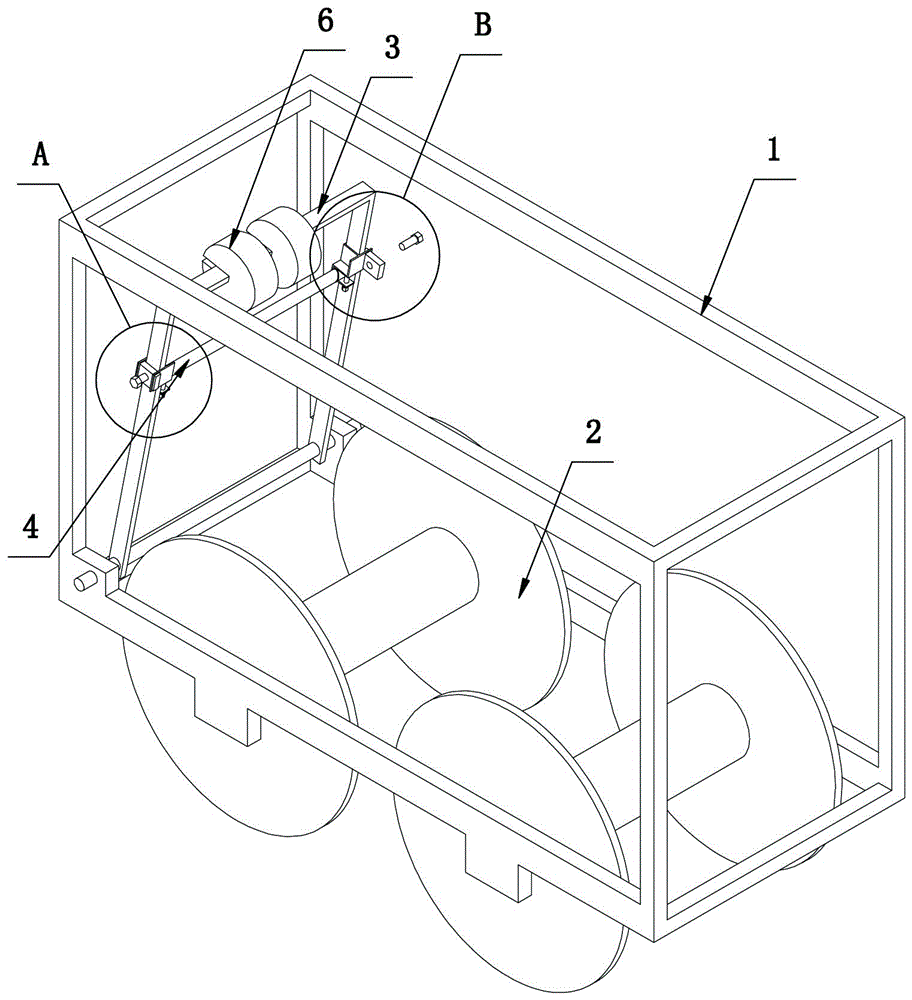

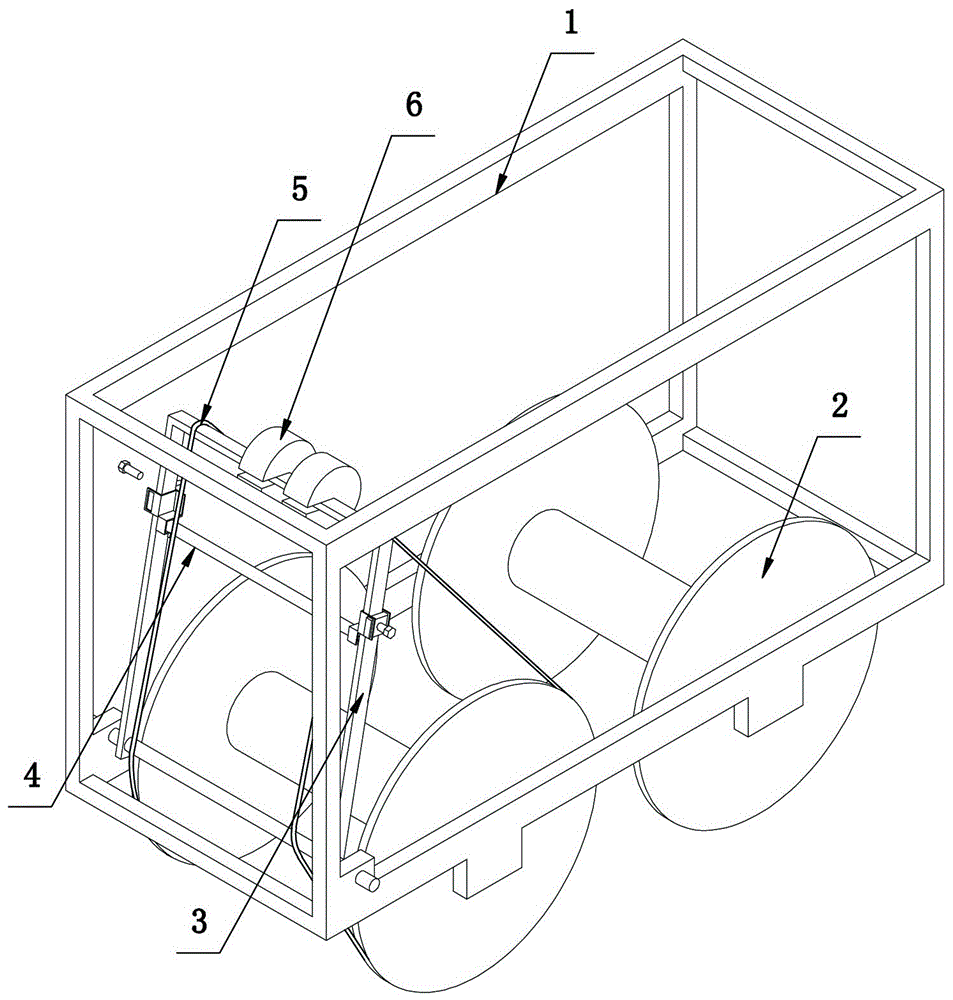

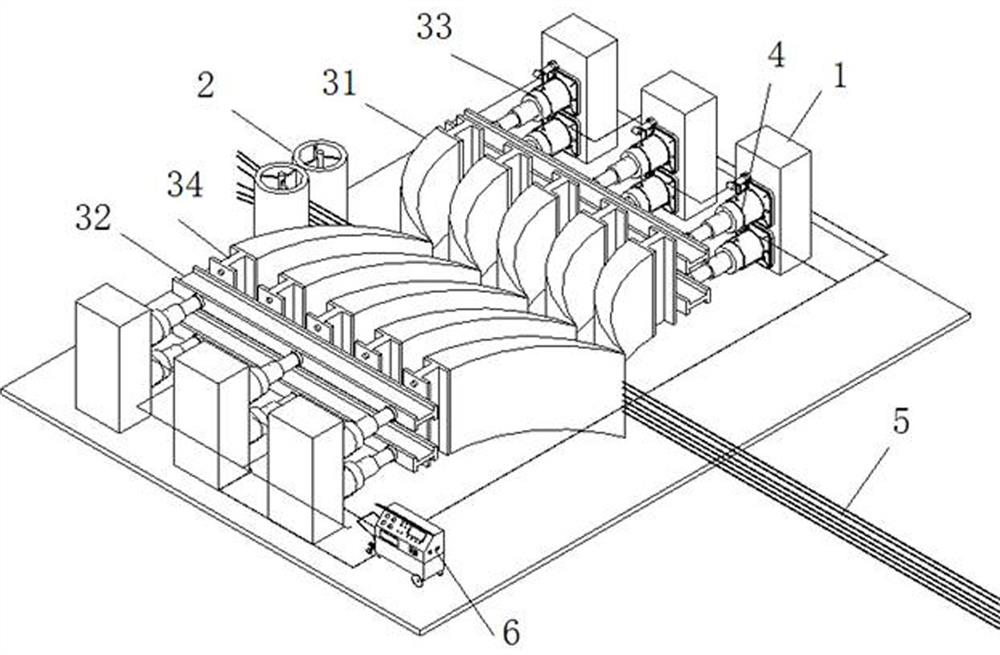

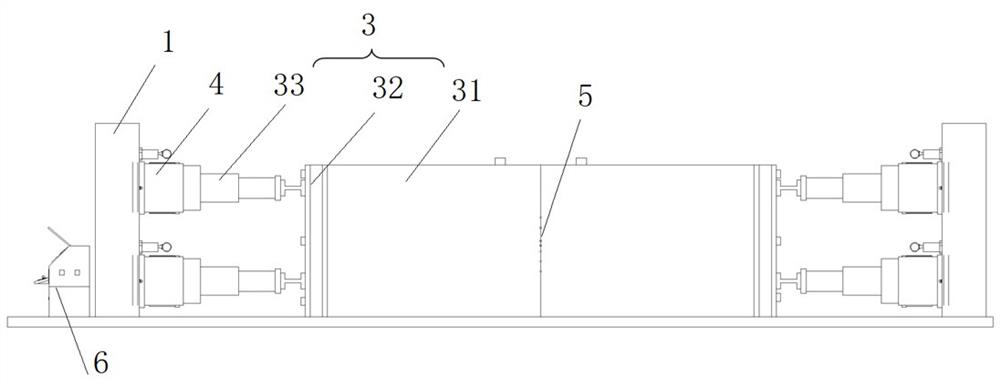

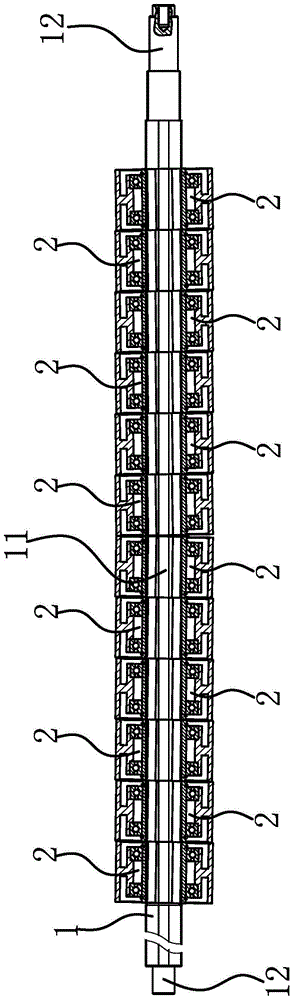

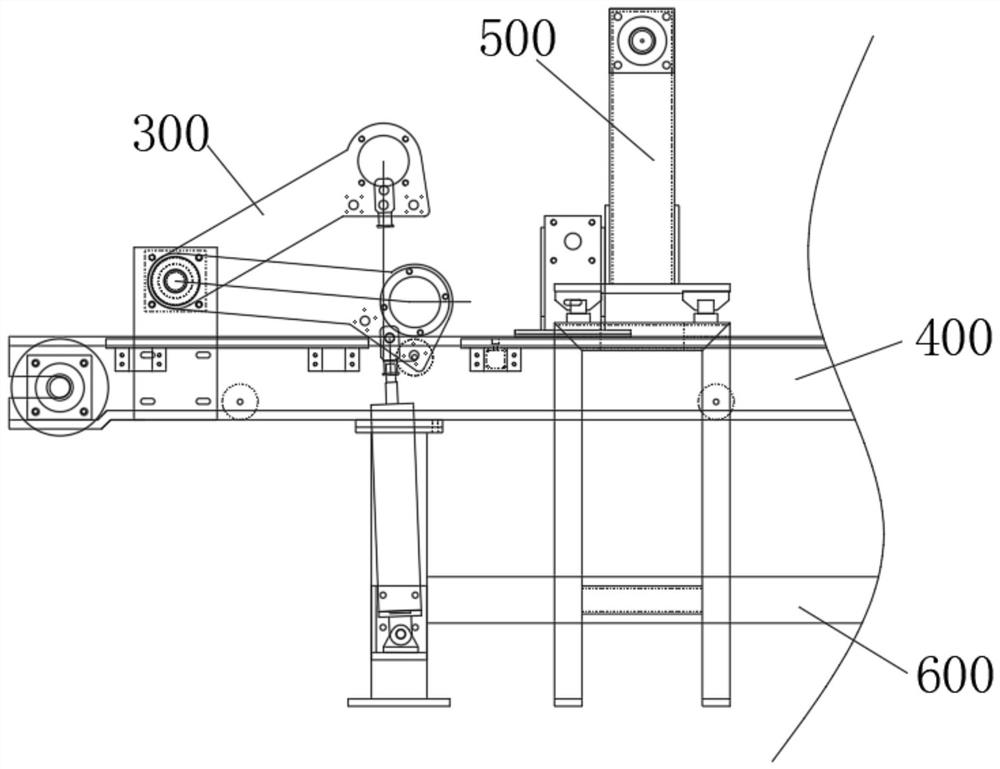

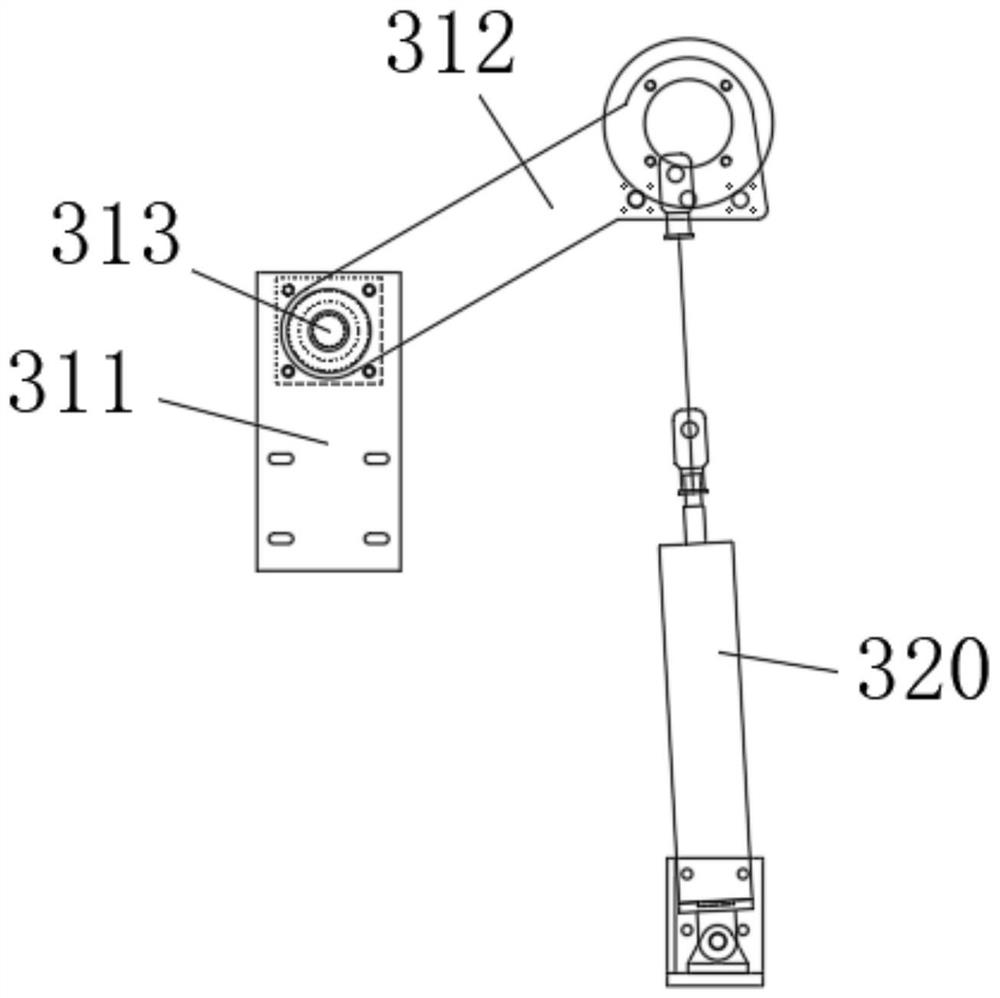

Steel strand braiding initial stress adjusting damping system

The invention discloses a steel strand braiding initial stress adjusting damping system which comprises an outer frame, a preliminary arrangement and positioning device, an initial stress adjusting device and a numerical control center, and the outer frame is used for providing a working face and a working foundation for the whole system; the preliminary arrangement and positioning device is arranged at the starting end of the traction movement direction of steel strands, the multiple steel strands enter the initial stress adjusting area from the preliminary arrangement and positioning device, and preliminary arrangement and positioning are conducted on the steel strands; the initial stress adjusting device is arranged in the initial stress adjusting area and comprises a rubber valve assembly, a fixed beam and a hydraulic jack, the two ends of the rubber valve assembly are fixedly connected with one side of the fixed beam, and the other side of the fixed beam is connected with the hydraulic jack so that pressure can be output through the hydraulic jack; a stress sensor is arranged at the end part of the hydraulic jack; and the numerical control center is respectively in signal connection with the hydraulic jack and the stress sensor.

Owner:中国建筑土木建设有限公司 +1

Air-floating roller bed type thermal treatment furnace for semiconductor devices

ActiveCN103557701BConsistent frictionPrevent deviationCharge supportsFurnace typesEngineeringThermal treatment

The invention relates to an air-floating roller bed type thermal treatment furnace for semiconductor devices. The heat-treatment furnace is characterized in that a roller bed for transferring the semiconductor devices comprises a plurality of horizontally-arranged roll shafts capable of reciprocating along self axial lines, at least part of the roll shafts are hollow, a plurality of breathing holes are formed in the parts, where the semiconductor devices pass, of the hollow roll shafts in the radial direction, at least one end of each hollow roll shaft is connected with one air inlet pipe through a rotary joint, and air enters furnace chamber parts where the semiconductor devices pass through the breathing holes in the hollow roll shafts. According to the thermal treatment furnace provided by the invention, the atmosphere and the cleanliness of a center diffusion zone in the furnace are fundamentally ensured, so that the diffusion effect and the quality are improved.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +1

Closed three-roller air-cushion conveyor

ActiveCN106081544BGuaranteed service lifeReduce frictionConveyorsRollersEnergy consumptionWaste management

Owner:COFCO ENG MAOSHENG EQUIP (HENAN) CO LTD +1

a flattening roller

The invention provides a flattening roller, which belongs to the technical field of machinery, and solves the problems of difficult maintenance and replacement of spare parts of an existing flattening roller. The flattening roller comprises a core shaft, wherein a plurality of cylindrical flattening units are arranged on the core shaft in a sleeved manner along the axial direction; the flattening units and the core shaft are axially located; the central line of each flattening unit inclines relative to the central line of the core shaft; each flattening unit can independently rotate relative to the core shaft; the flattening roller flattens a plastic film in a segmental flattening mode by the plurality of flattening units, so that the local axial force of the plastic film is small, transitional stretching of the plastic film is avoided, and the flattening effect of the plastic film is improved. The core shaft mounting section adopts a polygon structure, and a mounting hole in an inner sleeve of each flattening unit adopts the polygon hole matched with the mounting section, so that the circumferential position precision between the inner sleeve and the core shaft is improved; the central line of the mounting hole in the inner sleeve inclines relative to the central line of the inner sleeve, and the flattening roller is convenient to process.

Owner:郑州华翔电子信息技术有限公司

One-way clutch and crank type continuously variable transmission

The present invention provides a one-way clutch and crank type continuously variable transmission which prevents the outer peripheral portion of the end face of the roller biased in the axial direction by the axial spring from engaging the side surface of the cage. Since the frictional force acting on the first end surface (25a) of the roller (25) is consistent with the frictional force acting on the second end surface (25b) of the roller (25), it is possible to suppress the roller (25) from When the point moves to the meshing point, the first and second end surfaces (25a, 25b) of the roller (25) that prevent inclination and the inner ring The first side (36a) and the second side (36b) of (36) contact and wear, and can make the roller (25) smoothly engage into the outer peripheral surface (23a) of the inner part (23) and the outer part (22) The engagement responsiveness of the one-way clutch (21) is improved between the inner peripheral surfaces (22a) of the one-way clutch (21).

Owner:HONDA MOTOR CO LTD

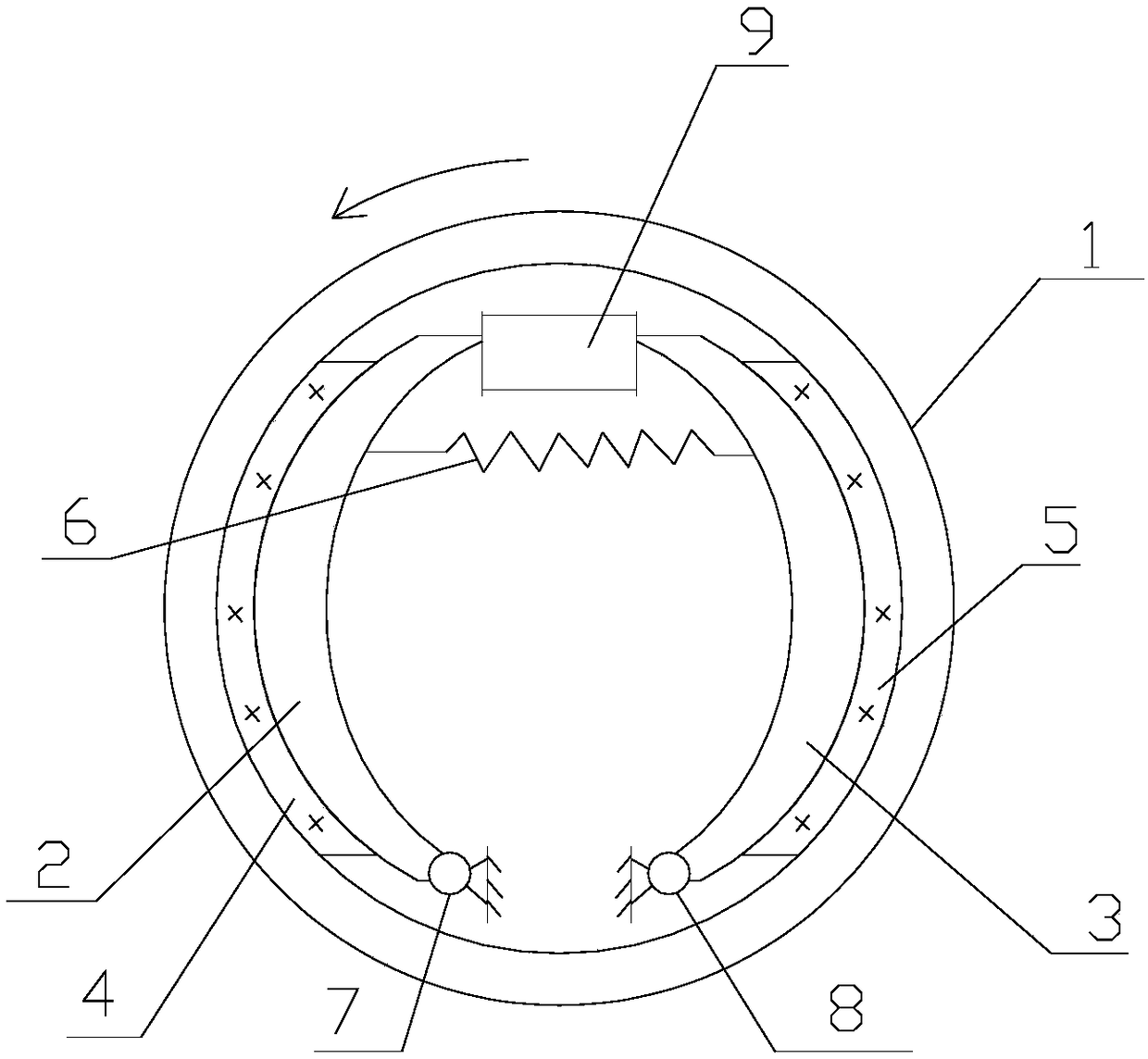

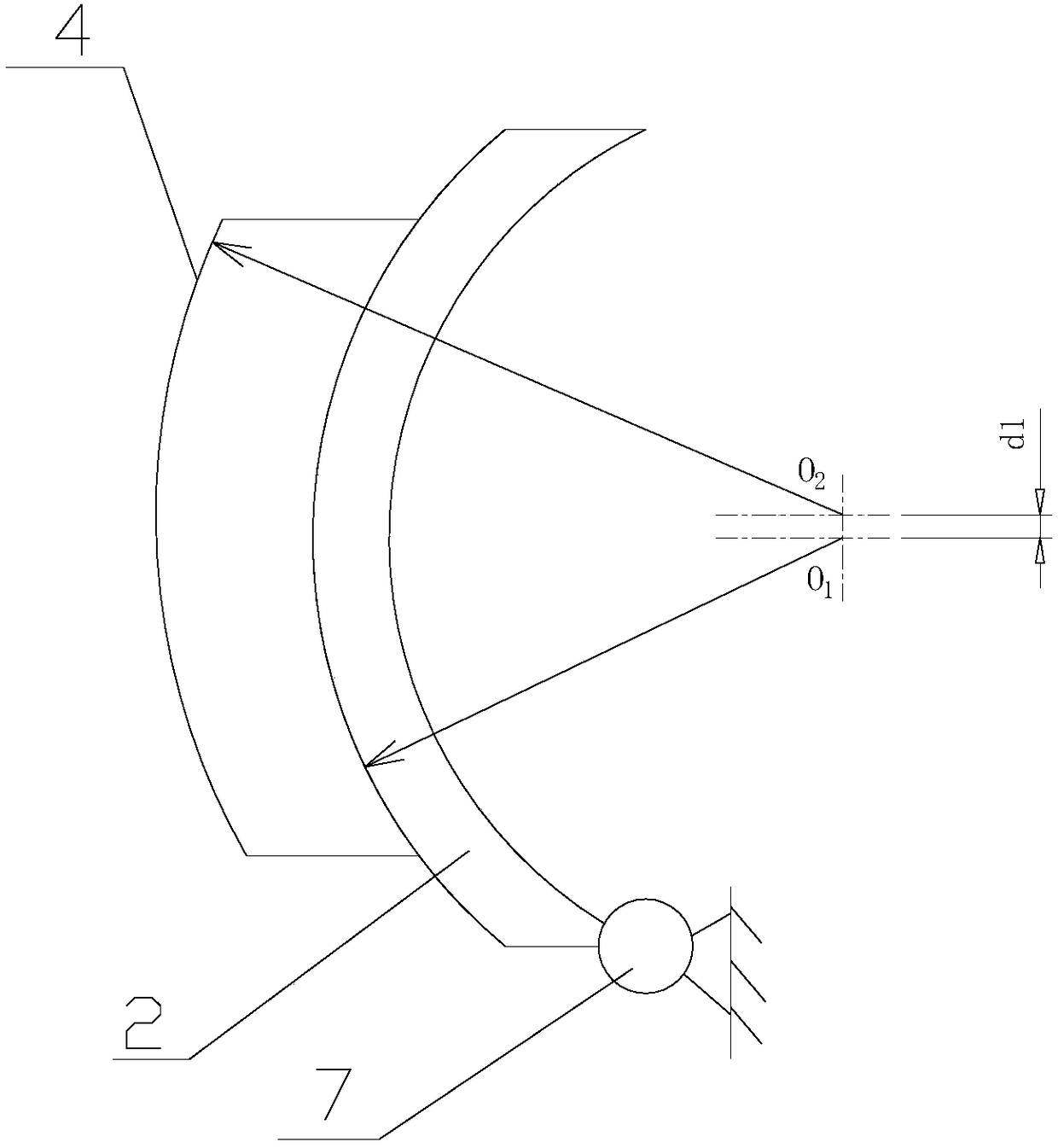

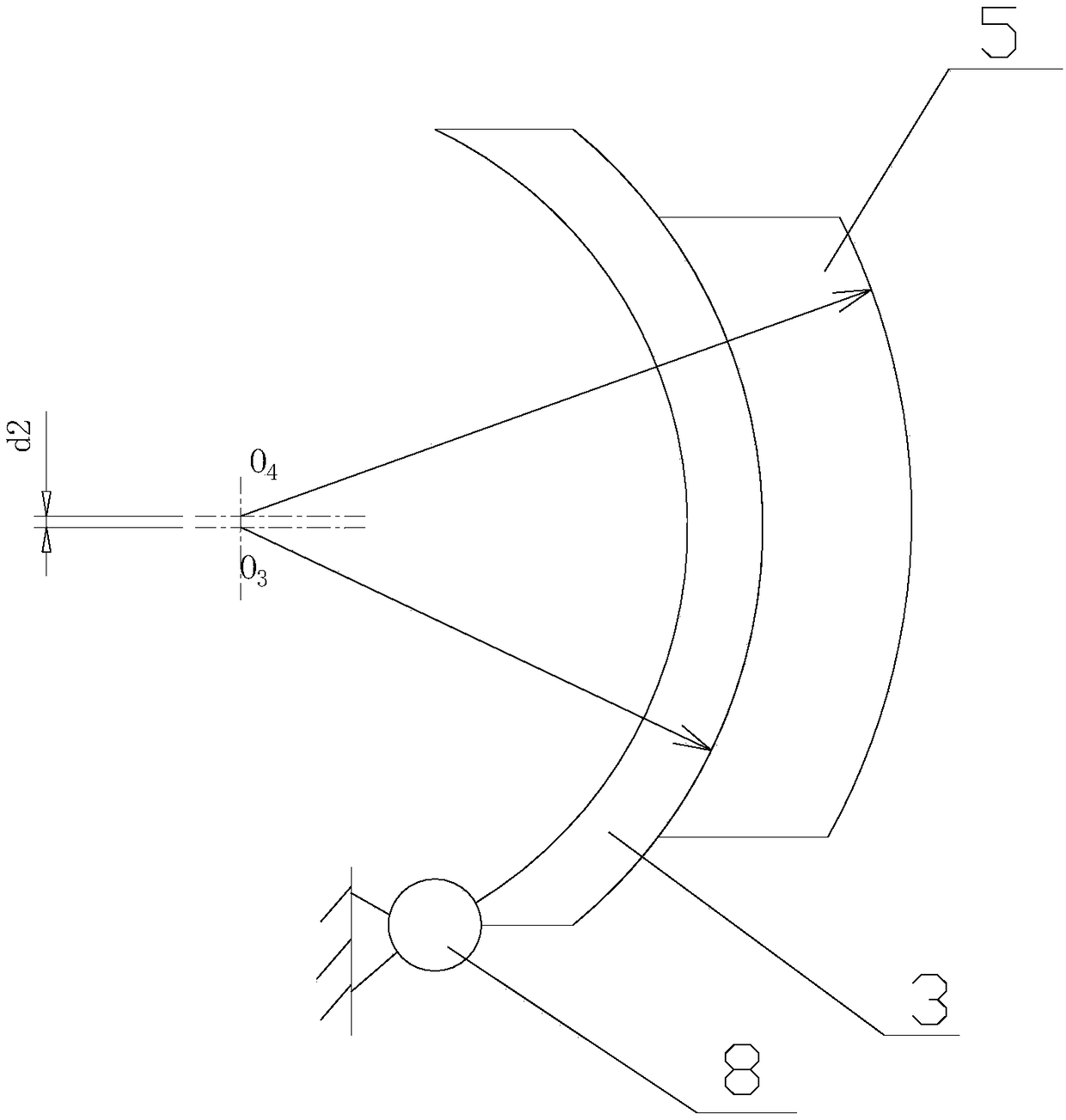

High-stability drum brake

InactiveCN109027054AConsistent frictionConsistent amount of wearMechanically actuated drum brakesMechanical engineeringBrake pad

The invention discloses a high-stability drum brake. The axis of the outer arc surface of a leading shoe brake pad of the high-stability drum brake deviates from the axis of the inner arc surface of the leading shoe brake pad, and the radial thickness of the leading shoe brake pad is gradually increased from the end close to a leading shoe fulcrum to the other end. The axis of the outer arc surface of the leading shoe brake pad is located on the center line of the inner arc surface of the leading shoe brake pad. The axis of the outer arc surface of a trailing shoe brake pad deviates from the axis of the inner arc surface of the trailing shoe brake pad, and the radial thickness of the trailing shoe brake pad is gradually increased from the end close to a trailing shoe fulcrum to the other end. The axis of the trailing shoe brake pad is located on the center line of the inner arc surface of the trailing shoe brake pad. The distance between the axis of the outer arc surface of the leadingshoe brake pad and the axis of the inner arc surface of the leading shoe brake pad is d1, the distance between the axis of the outer arc surface of the trailing shoe brake pad and the axis of the inner arc surface of the trailing shoe brake pad is d2, and d1 is larger than d2.

Owner:泸州开士乐工程技术有限责任公司

Shuangpin printing equipment for double-page invoices

ActiveCN107696677BIncreased printing process efficiencyLow costRotary pressesInvoiceComputer engineering

The invention relates to the field of printing, in particular to double-printing equipment for a duplex invoice. Paper in a paper rolling part A is printed in a printing group C to form a first invoice; paper in a paper rolling part B is printed in a printing group D to form a second invoice; tension monitoring is performed on the first invoice and the second invoice before the first invoice and the second invoice enter a combining part, and the tension of the first invoice and the tension of the second invoice are guaranteed to be consistent during combination, so that the content of the first invoice and the content of the second invoice are completely overlapped and registered. Invoice number printing and locking are performed on the two combined invoices, the invoice subjected to double printing is cut into two independent single invoices, and finally, the two single invoices are folded simultaneously. Thus, double printing of the two invoices is completed simultaneously, and the printing efficiency is 2-3 times higher than that of traditional printing equipment.

Owner:CHONGQING FARSIGHT PRINTING

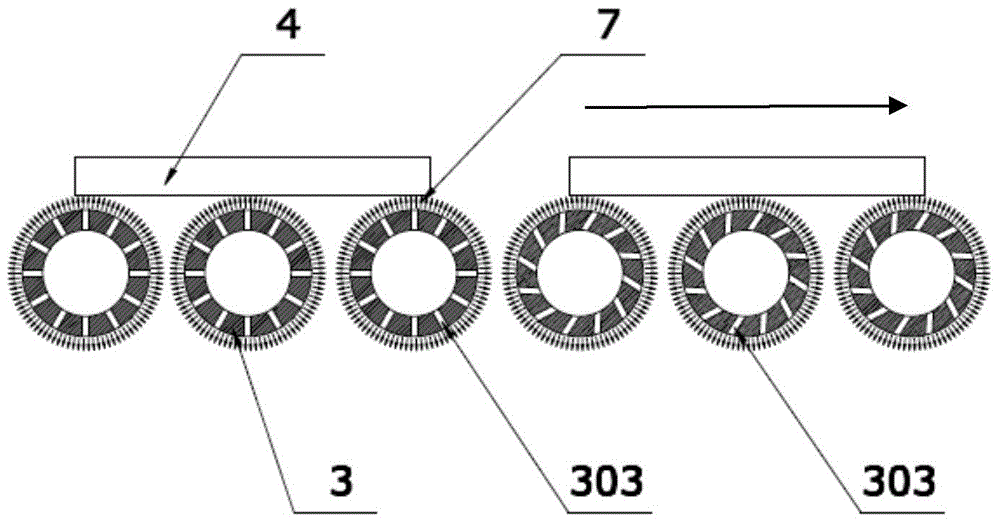

Radial tire material coiling and conveying device

The invention discloses a radial tire material coiling and conveying device. The device comprises a conveying belt and a coiling device arranged on a conveying line of the conveying belt and used forbearing materials. The coiling device comprises a containing device used for containing the materials, a detecting device used for detecting the diameter of a material roll and an adjusting device connected with the detecting device and used for changing the friction force of the material roll. According to the device, it is guaranteed that the friction force of the material roll is kept consistent in the operation process by adjusting the friction force between the material roll and the conveying belt, the material folding phenomenon is avoided, and meanwhile, a cloth liner roll is controlled, so that the tension difference of a cloth liner is avoided, the materials are located in the center of the cloth liner, and waste materials are reduced.

Owner:SAILUN GRP CO LTD

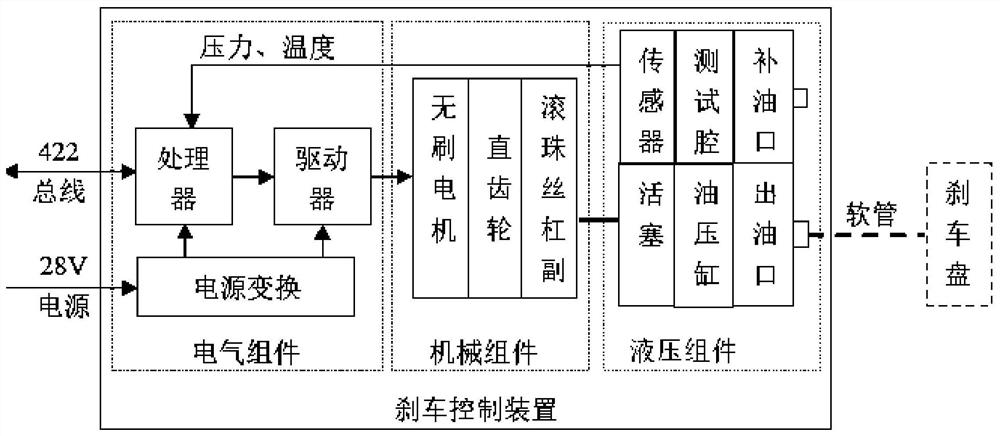

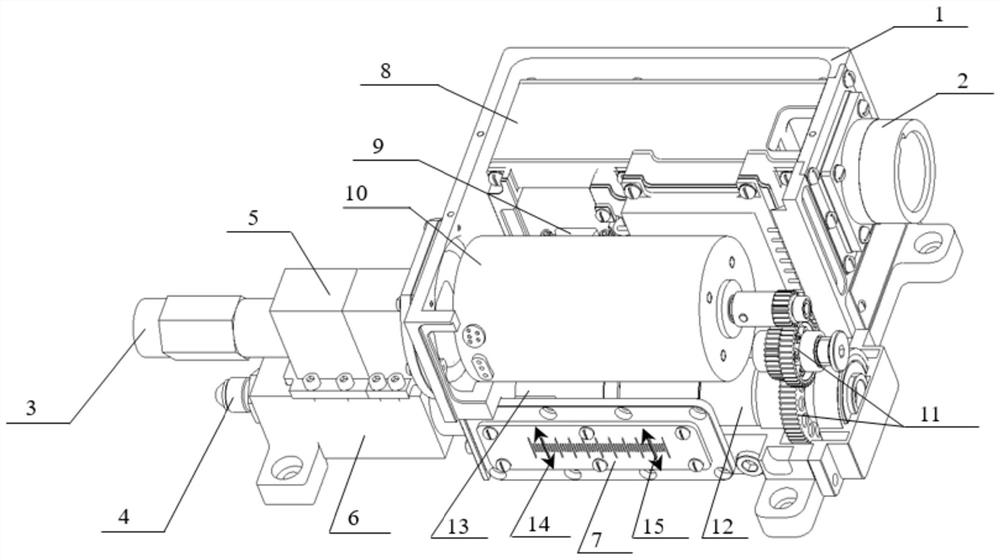

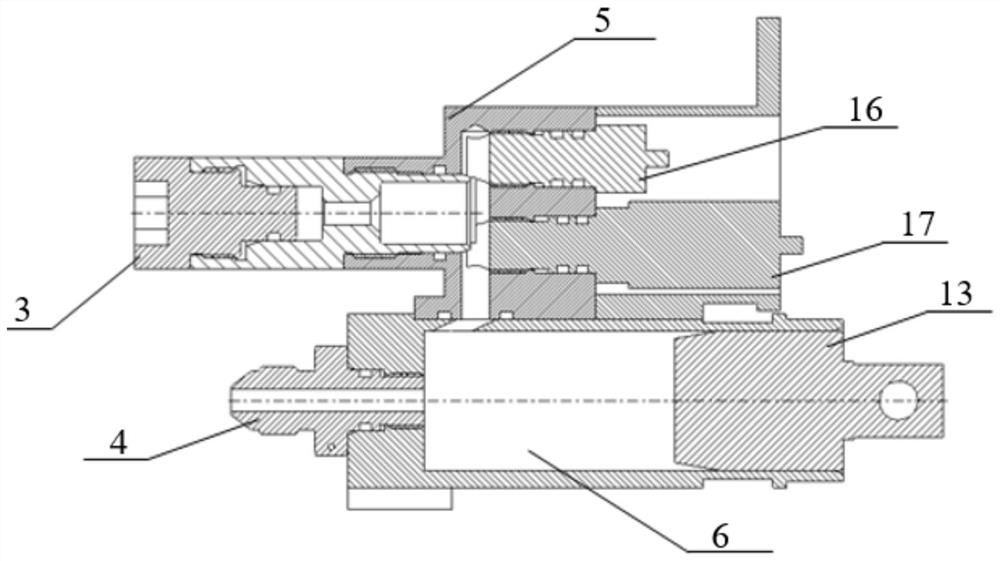

Electro-hydrostatic brake control device for unmanned aerial vehicle and dynamic pressure maintaining method

ActiveCN113716025ASolution volumeSolve poor maintainabilityBraking action transmissionAircraft brake actuating mechanismsActuatorControl theory

The invention discloses an electro-hydrostatic brake control device for an unmanned aerial vehicle and a dynamic pressure maintaining method, belongs to the technical field of aircraft brake control systems, and adopts an integrated electro-hydrostatic brake technology, a piston, a hydraulic cylinder structure and a dynamic pressure maintaining strategy to realize rapid and accurate control of the brake pressure of the unmanned aerial vehicle. The functions of slow braking and snub braking are achieved; the characteristics of long-time pressure maintaining and low power consumption are realized; the device has the advantages of short pressure building time and high in-place pressure precision; the response time of the novel brake control device is shortened by more than 30% compared with that of a previous pump type hydraulic brake control device. A traditional EHA hydraulic transmission structure is abandoned, and the problems that an existing electro-hydrostatic actuator is large in size, poor in maintainability, low in reliability and the like are effectively solved.

Owner:XIAN MICROELECTRONICS TECH INST

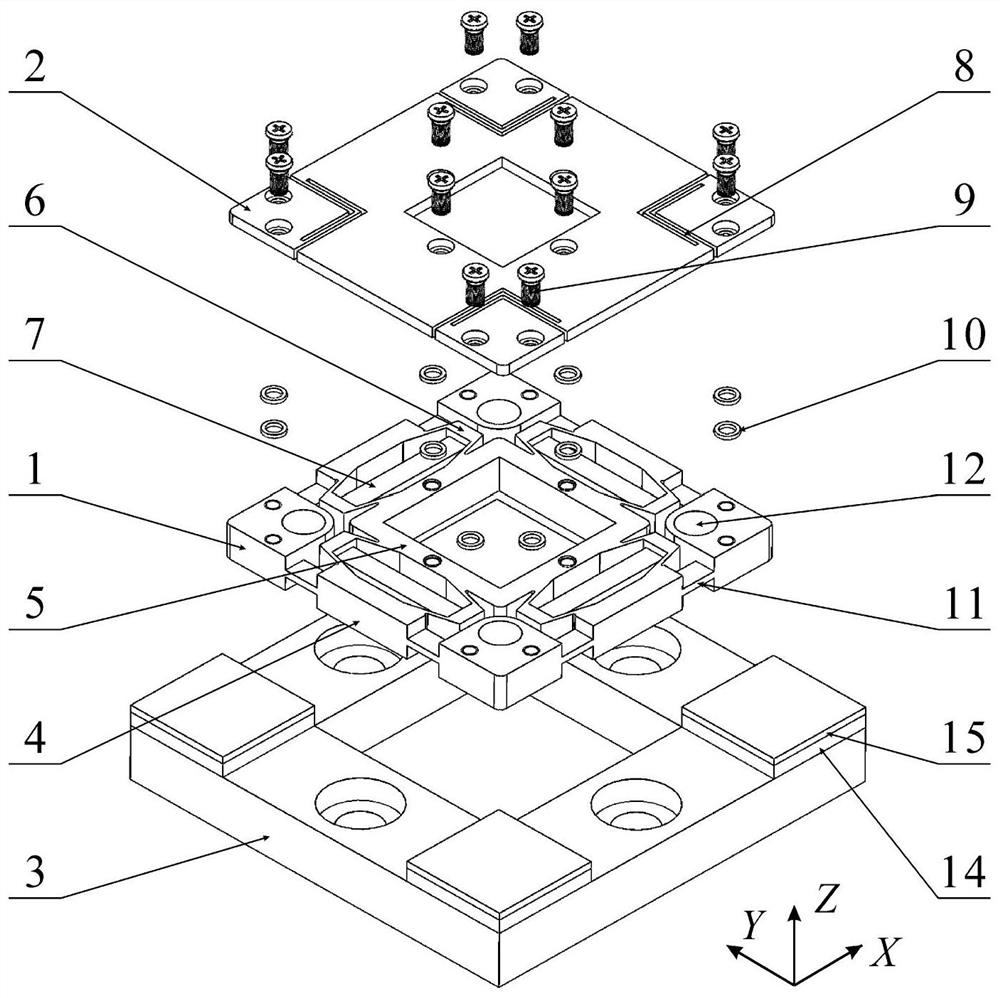

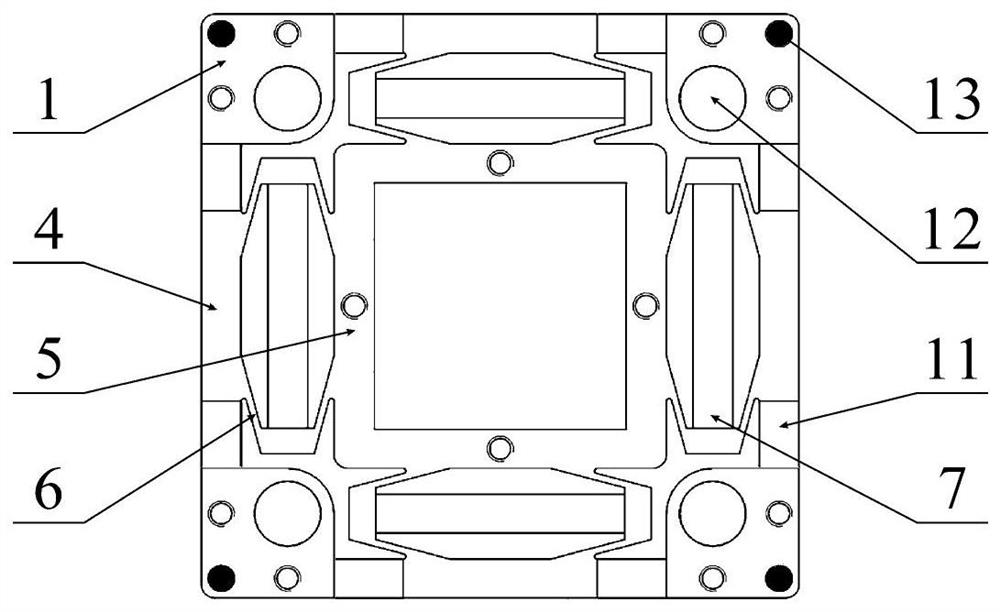

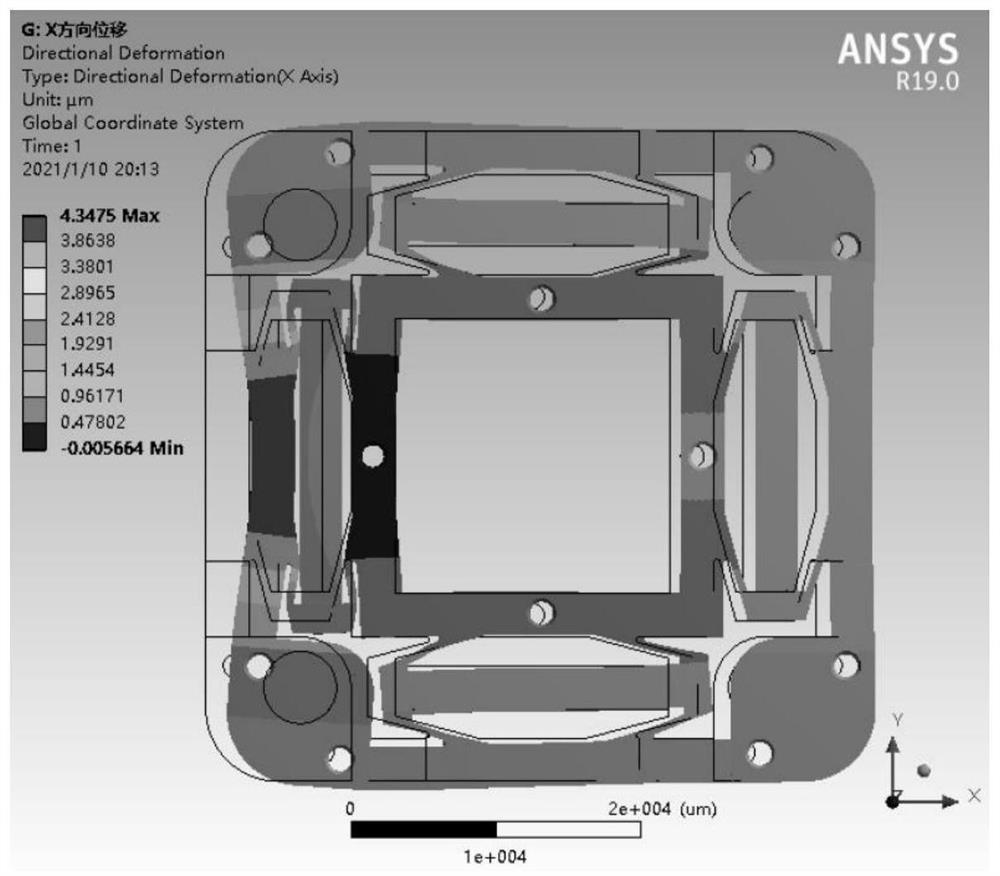

A hollow two-dimensional piezoelectric inertial impact drive platform

ActiveCN112994513BEnsure stabilityAvoid the effects of structural stiffnessPiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringSawtooth wave

The invention discloses a hollow two-dimensional piezoelectric inertial impact drive platform, which includes a square platform, a package cover and a fixed base. The square platform is composed of a square outer frame, a square inner frame, a displacement amplification mechanism and a piezoelectric driver. The package cover is set The flexible mechanism is installed on the upper surface of the square platform, and the square platform is frictionally coupled with the fixed base on the lower surface through the four corners of the square outer frame, and realizes inertial impact motion under the sawtooth wave excitation voltage of the piezoelectric driver. The invention adopts a central hollow structure design to provide an observation aperture, and adopts a frictional coupling adjustment mechanism to ensure the stability of the impact drive, which can further improve the application effect of multi-degree-of-freedom cross-scale precision drive positioning in microscopic imaging systems such as SEM.

Owner:HEFEI UNIV OF TECH

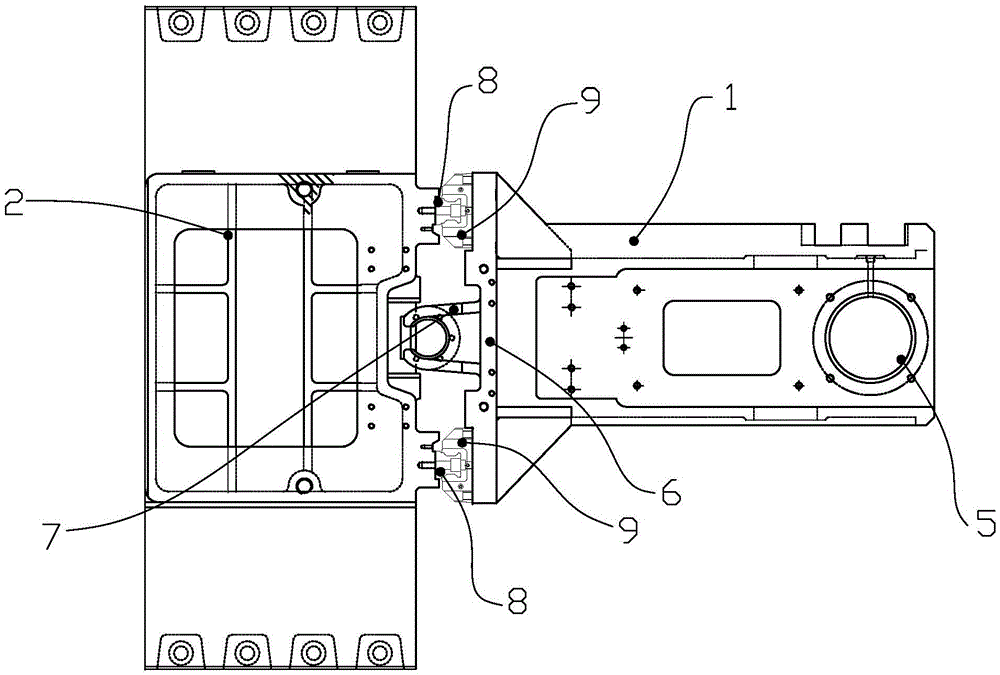

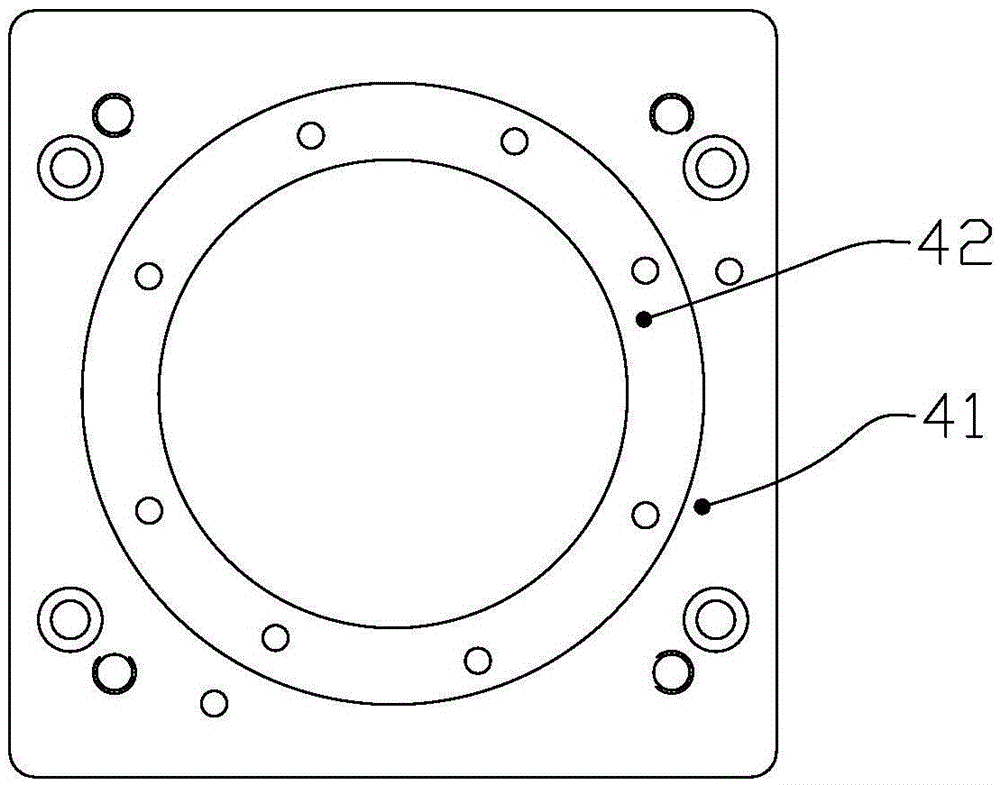

Assembly structure of spindle box of vertical machining center

ActiveCN104353848BReduce the noise decibel valueImprove vibrationLarge fixed membersInterference fitControl theory

The invention discloses an assembling structure for a main shaft box of a vertical type processing center. The assembling structure comprises the main shaft box and a main shaft connection plate with a split type structure, wherein the main shaft connection plate consists of a main shaft box connection plate and a main shaft servo motor connection plate; a circular through hole is formed in the center of the main shaft box connection plate; the apertures of the upper end position and the lower end position of the circular through hole are greater than the aperture of the middle position of the circular through hole; the main shaft servo motor connection plate is a cylinder; a circular through hole coaxial with the main shaft servo motor connection plate is formed in the center of the main shaft servo motor connection plate; the outer circumferential surface is of a one-stage steplike shape, and the upper outer diameter is smaller than the lower outer diameter; the circular circumferential surface of the middle of the circular through hole in the main shaft box connection plate is in interference fit with the outer circumferential surface of the lower end of the main shaft servo motor connection plate. According to the assembling structure, the assembling precision between the main shaft connection plate and the main shaft box as well as between the main shaft connection plate and a main shaft can be respectively adjusted, and the coaxiality error of the main shaft and a main shaft servo motor which are assembled is obviously reduced; the rotating speed of the main shaft is increased to 20,000 r / m; obvious influence on the service life of the main shaft servo motor can be avoided; the noise decibel value of the main shaft is obviously reduced; the vibration of the main shaft box is obviously alleviated.

Owner:临清市顺佳机械设备有限公司

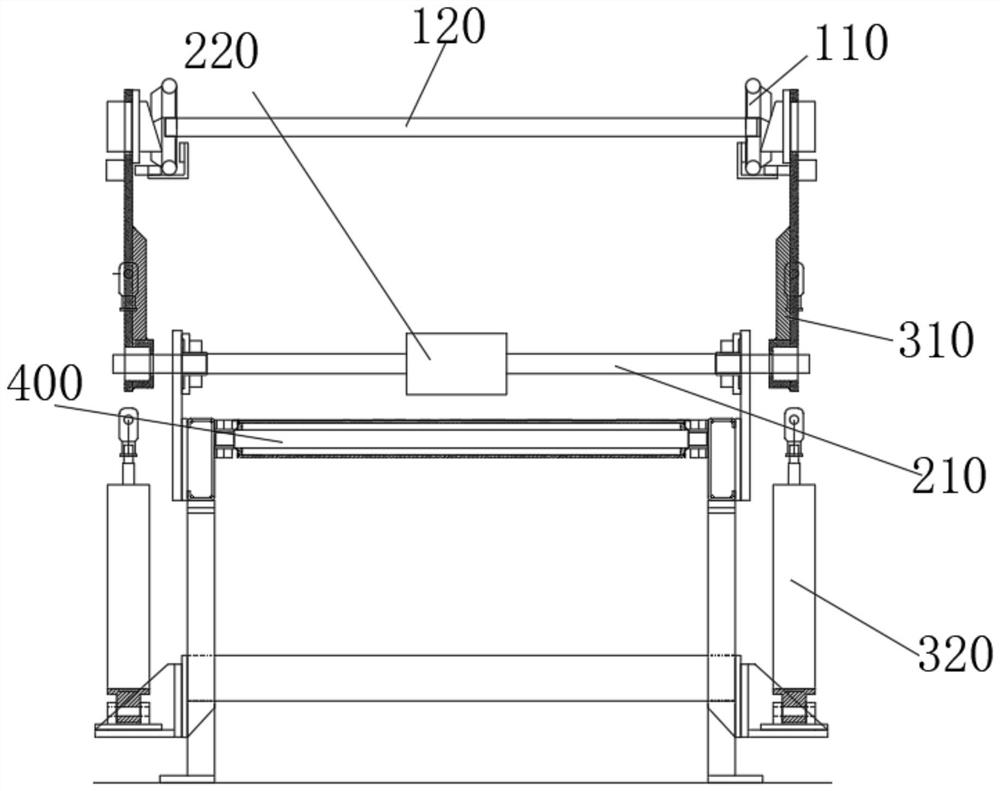

Conveyer installation assisting device

InactiveCN111216071AImprove accuracy and consistencyImprove installation efficiencyMetal-working hand toolsPhysicsTelescopic cylinder

The invention relates to the technical field of assembly of conveyers and particularly relates to a conveyer installation assisting device. The conveyer installation assisting device comprises a support mechanism; the support mechanism is connected with two inverted first U-shaped brackets; a second permanent magnetic plate capable of sliding up and down is connected between two vertical plates ofthe first U-shaped brackets; the middle of the top of the second permanent magnetic plate is rotationally connected a vertically-arranged threaded shaft; a first pressure sensor is arranged between asecond U-shaped bracket and the first permanent magnetic plate; the surface, far away from a dynamic telescopic cylinder, of a top plate is provided with a second pressure sensor; and the first pressure sensor and the second pressure sensor are each electrically connected with a pressure displayer. According to the conveyer installation assisting device, a shaft base is pressed on a rack by virtue of magnetic force; the values of the pressure applied from the two ends of the shaft base to the rack are ensured to be the same by virtue of the pressure sensors so that friction force between therack and the shaft base is kept consistent basically, thus the accuracy and consistency of tensioning force at the two ends in installation of a belt conveyer are greatly improved; and meanwhile the installation efficiency is improved.

Owner:ANHUI QIANGHUI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com