a flattening roller

A technology for flattening rollers and mandrels, applied in the field of machinery, can solve the problems of inconvenient maintenance and replacement of parts, wrinkles of plastic films, poor flattening effect, etc., and achieves convenient processing, consistent friction, and good flattening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

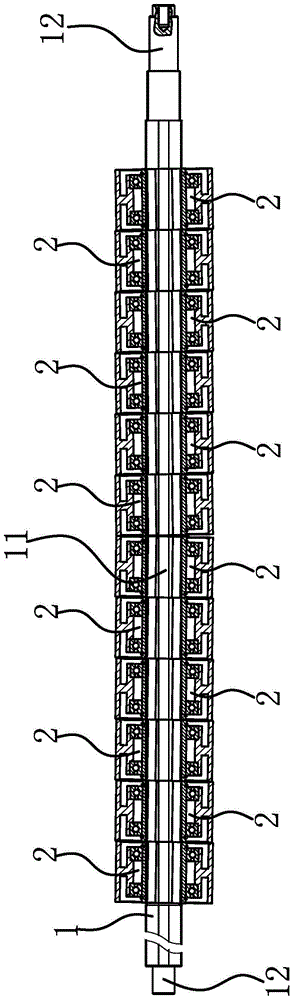

[0029] The flattening roller includes a mandrel 1 and a flattening unit 2 .

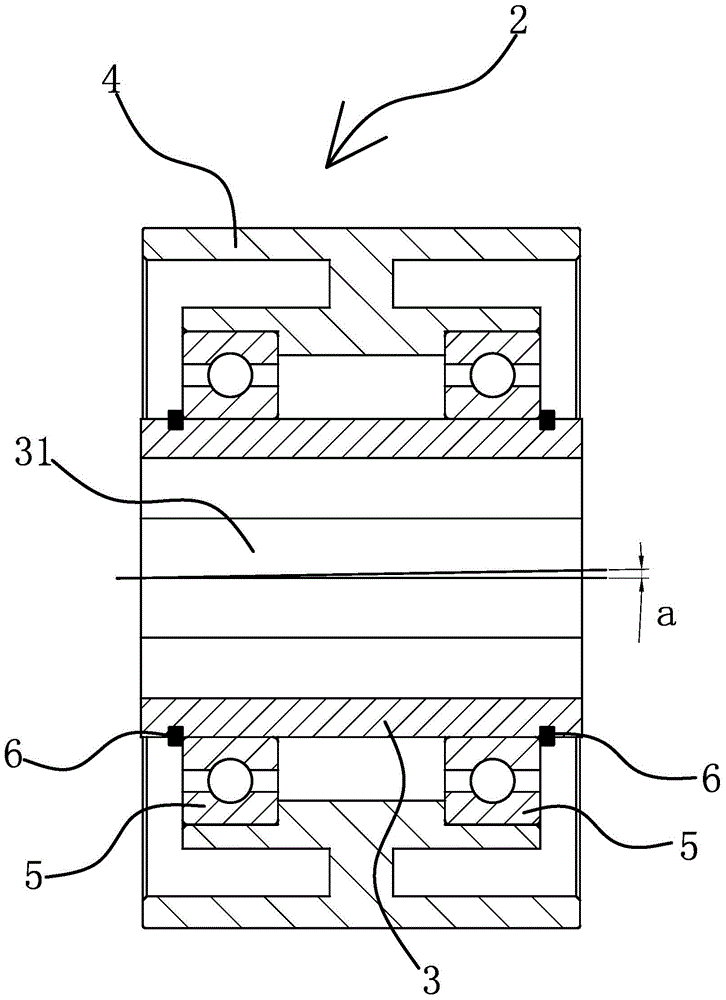

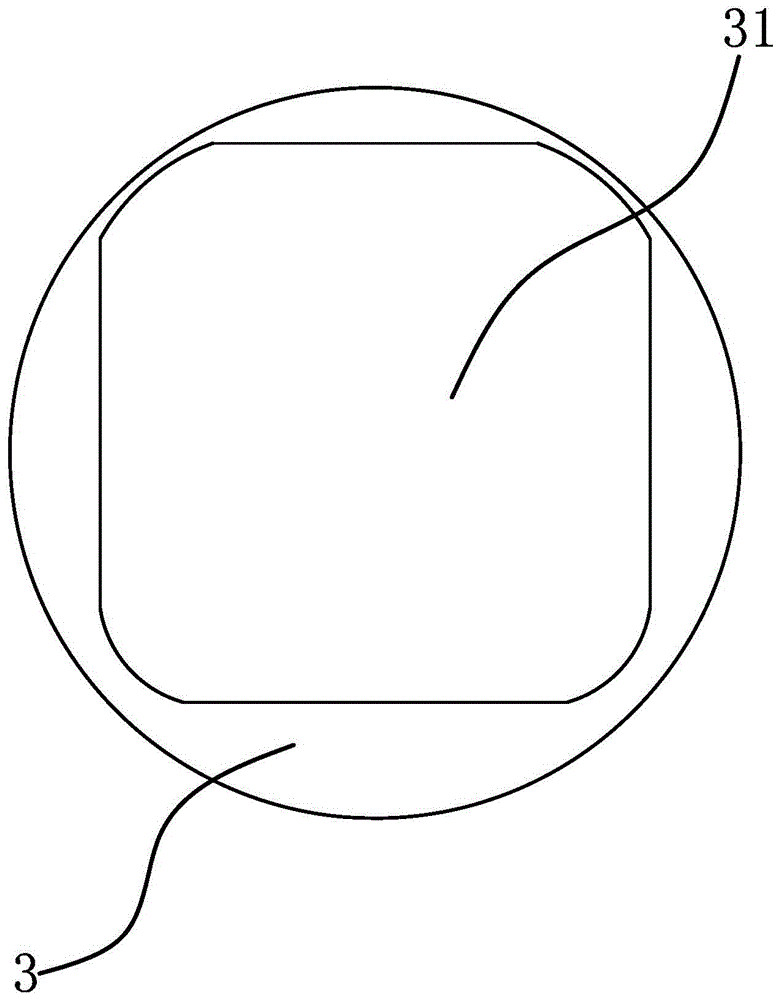

[0030] Specifically, as figure 1 As shown, the mandrel 1 includes a mounting portion 11 for mounting the flattening unit 2 and connecting portions 12 located at both ends of the mounting portion 11 . The flattening unit 2 is cylindrical, and the flattening unit 2 is axially positioned with the mandrel 1 through a positioning member, and there is a gap between adjacent flattening units 2 . The centerline of each flattening unit 2 is inclined relative to the centerline of the mandrel 1 , and each flattening unit 2 can rotate independently relative to the mandrel 1 . In this embodiment, the installation part 11 is columnar, the cross section of the installation part 11 is a centrally symmetrical polygon, and the centerline of the installation part 11 and the centerline of the mandrel 1 are on the same straight line. In an actual production and manufacturing process, the cross section of the installati...

Embodiment 2

[0035] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the mandrel 1 has a mounting part 11 for mounting the flattening unit 2, a connecting part 12 and a mounting part 11 adopts split structure. The installation part 11 is columnar, the cross section of the installation part 11 is a centrally symmetrical polygon, and the centerline of the installation part 11 is inclined relative to the centerline of the mandrel 1 . The outer surface of the flattening unit 2 is inclined relative to the centerline of the mandrel 1 by processing the mounting portion 11 into a structure inclined relative to the centerline of the mandrel 1 . The flattening unit 2 includes an outer cover 4, and a cylindrical inner cover is arranged between each outer cover 4 and the installation part 11. The center of the inner cover has a mounting hole 31 corresponding to the shape of the installation part 11, an...

Embodiment 3

[0037] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1 or Embodiment 2, the difference is that in this embodiment, the angle a formed by the centerline of the mounting hole 31 and the centerline of the inner sleeve 3 is 0.6 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com