Oil-resistant paper-base friction plate and production method thereof

A paper-based friction plate and production method technology, applied in the field of friction plates, can solve the problems of inapplicability of wet clutches, etc., and achieve the effect of high friction coefficient and ensuring oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention provides an oil-resistant paper-based friction sheet, which comprises the following materials in mass fractions: compounding agent: 0.8-1.2; sulfur: 2.5-5.5; filler: 44-73; adhesive: 20-28; nitrile rubber: 10 ~14.

[0018] The oil-resistant paper-based friction sheet in the present invention increases the oil resistance of the friction sheet by using nitrile rubber, and at the same time ensures other physical properties and mechanical properties of the friction sheet, has a high friction coefficient and is resistant to oil. The lower friction performance remains the same.

[0019] Optionally, the compounding agent includes the following materials in mass fraction: Accelerator: 0.4-0.6; Anti-aging agent: 0.4-0.6.

[0020] Optionally, the filler includes materials with the following mass fractions: zinc oxide: 1.5-3.5; carbon black: 6-10; graphite: 6-10; chromite powder: 6-10; petroleum coke powder: 3-5 ; Precipitated barium sulfate: 16~20; Coumarone: 2.5~...

Embodiment 2

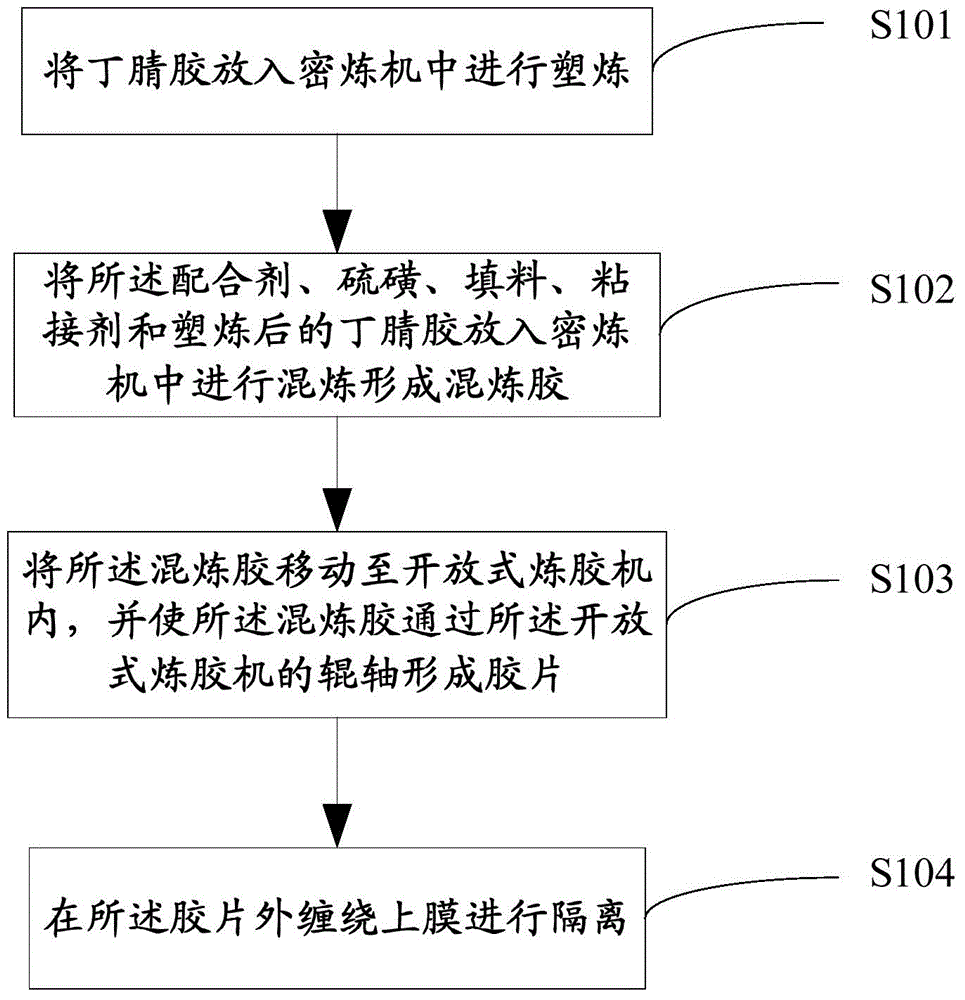

[0025] The present invention also provides a production method of the above-mentioned oil-resistant paper-based friction plate, the flow chart is as follows figure 1 shown, including steps:

[0026] S101: putting the nitrile rubber into an internal mixer for masticating;

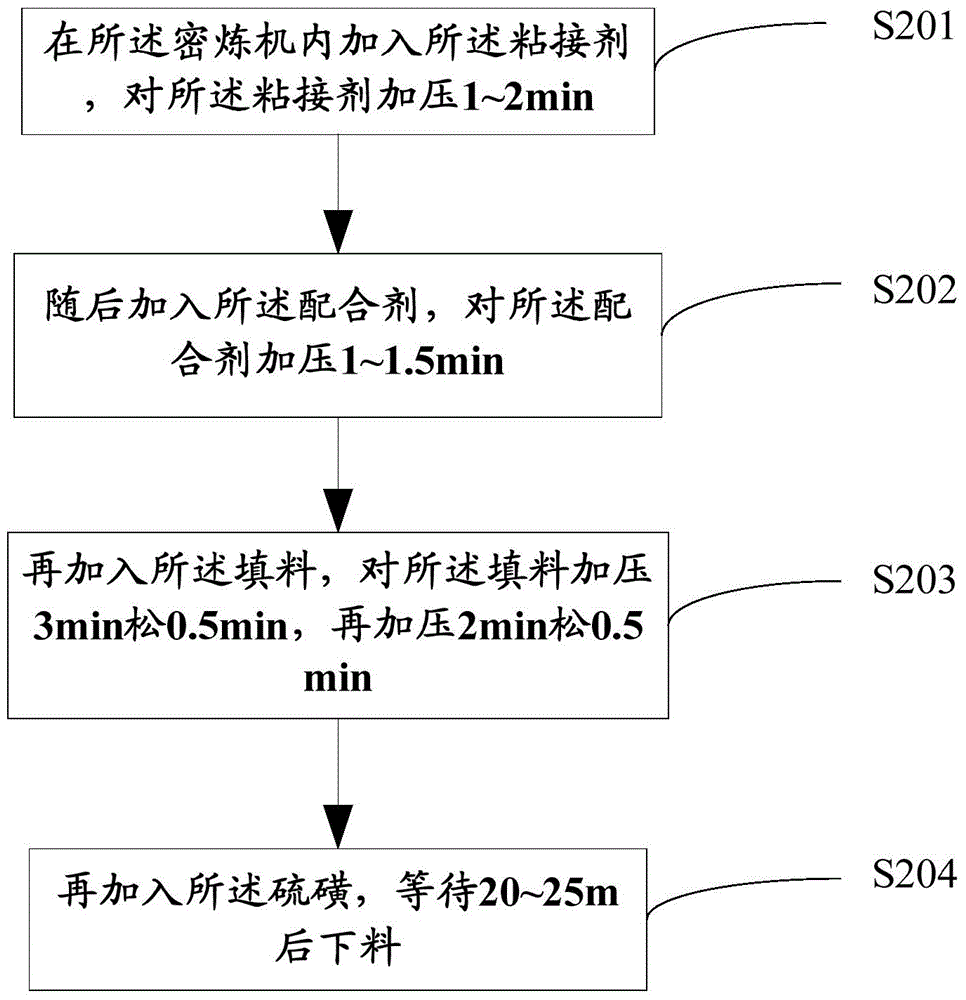

[0027] S102: Put the compounding agent, sulfur, filler, adhesive and masticated nitrile rubber into an internal mixer for mixing to form a mixed rubber;

[0028] S103: moving the mixed rubber into an open rubber mixing machine, and making the mixed rubber pass through the rollers of the open rubber mixing machine to form a film;

[0029] S104: Wrap a film around the film for isolation.

[0030] The production method in the present invention is aimed at the production method of the above materials, and the produced paper-based friction sheet has high friction coefficient, stable friction performance and certain friction performance under the condition of oil immersion.

[0031] Optionally, in the step S101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com