Double-printing equipment for duplex invoice

A technology of printing equipment and invoices, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problem of high cost and achieve the effect of low cost and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

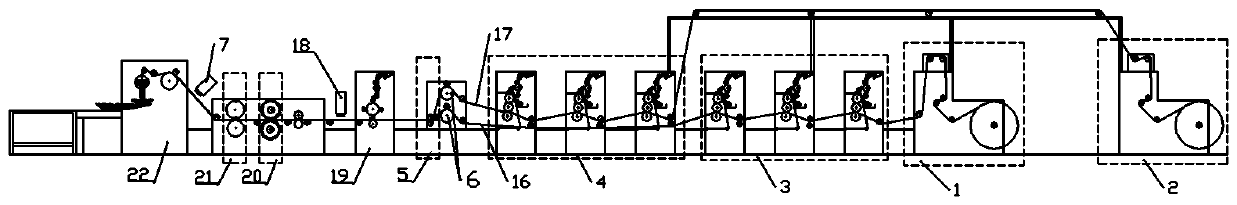

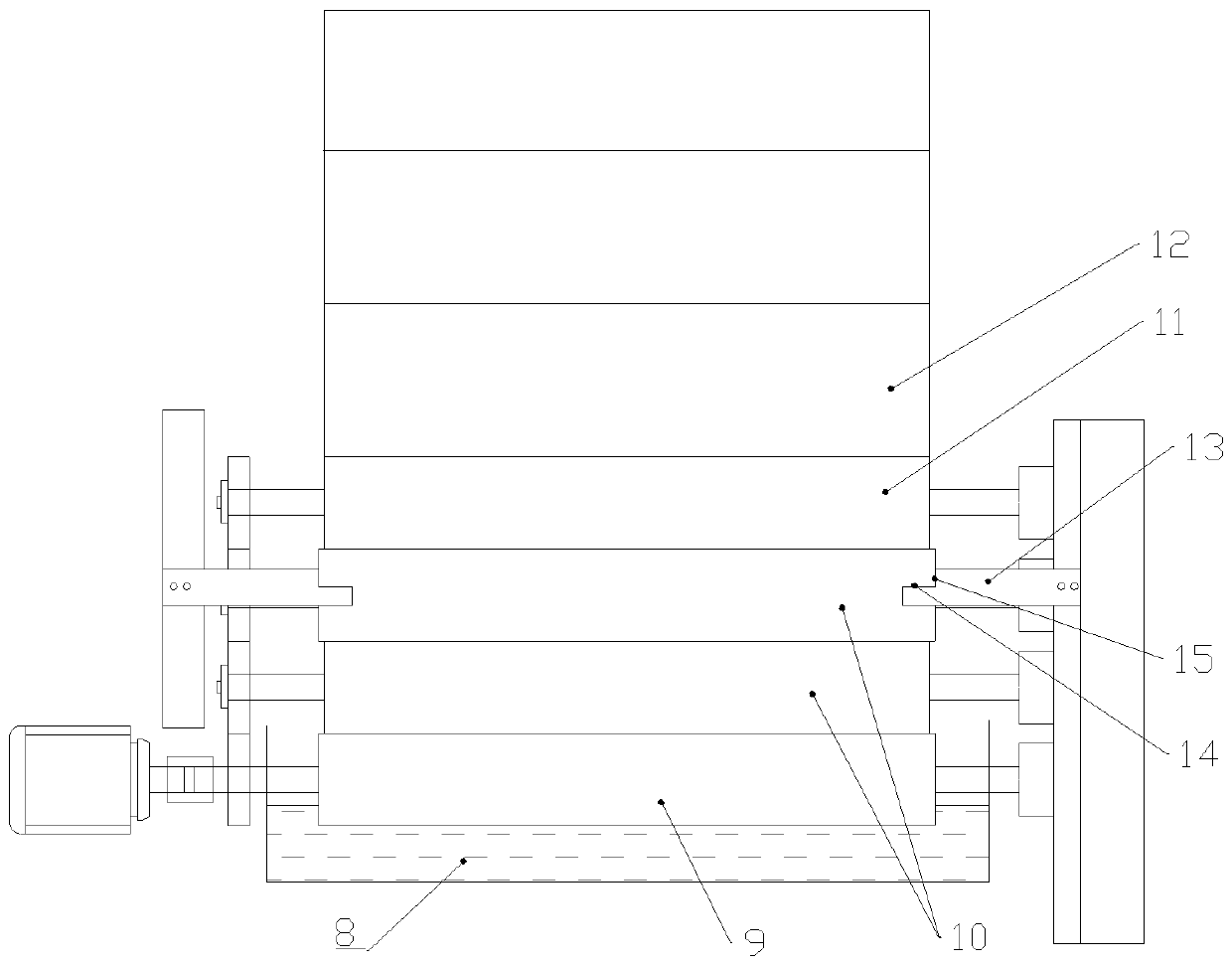

[0023] The reference signs in the drawings of the specification include: roll paper part A1, paper roll part B2, printing group C3, printing group D4, hinge traction mechanism 5, secondary tension controller 6, overprint monitoring equipment 7, water bucket tank 8 , water bucket roller 9, water transfer roller 10, dampening roller 11, printing plate cylinder 12, clamping plate 13, horizontal side 14, vertical side 15, first invoice joint 16, second invoice joint 17, number monitoring equipment 18. Invoice number printing part 19, keyhole part 20, cutting mechanism 21, folding part 22.

[0024] The embodiment is basically as attached figure 1 Shown: double-printing equipment for double-page invoices, including paper feeding part, printing part, invoice number printing part 19, keyhole part 20, folding part 22 and delivery part, and also includes hinge traction mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com