Patents

Literature

57results about How to "Accurate overprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

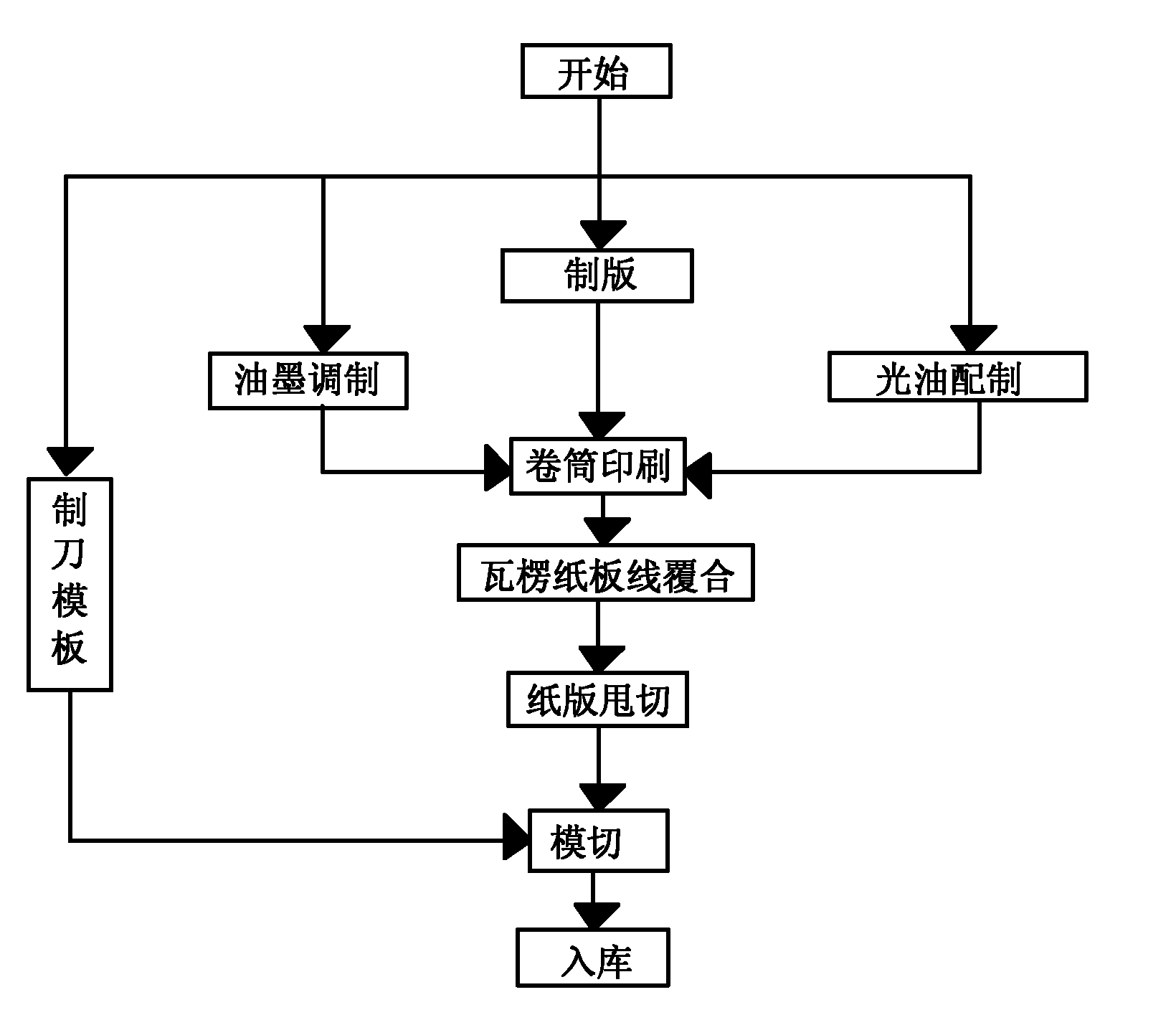

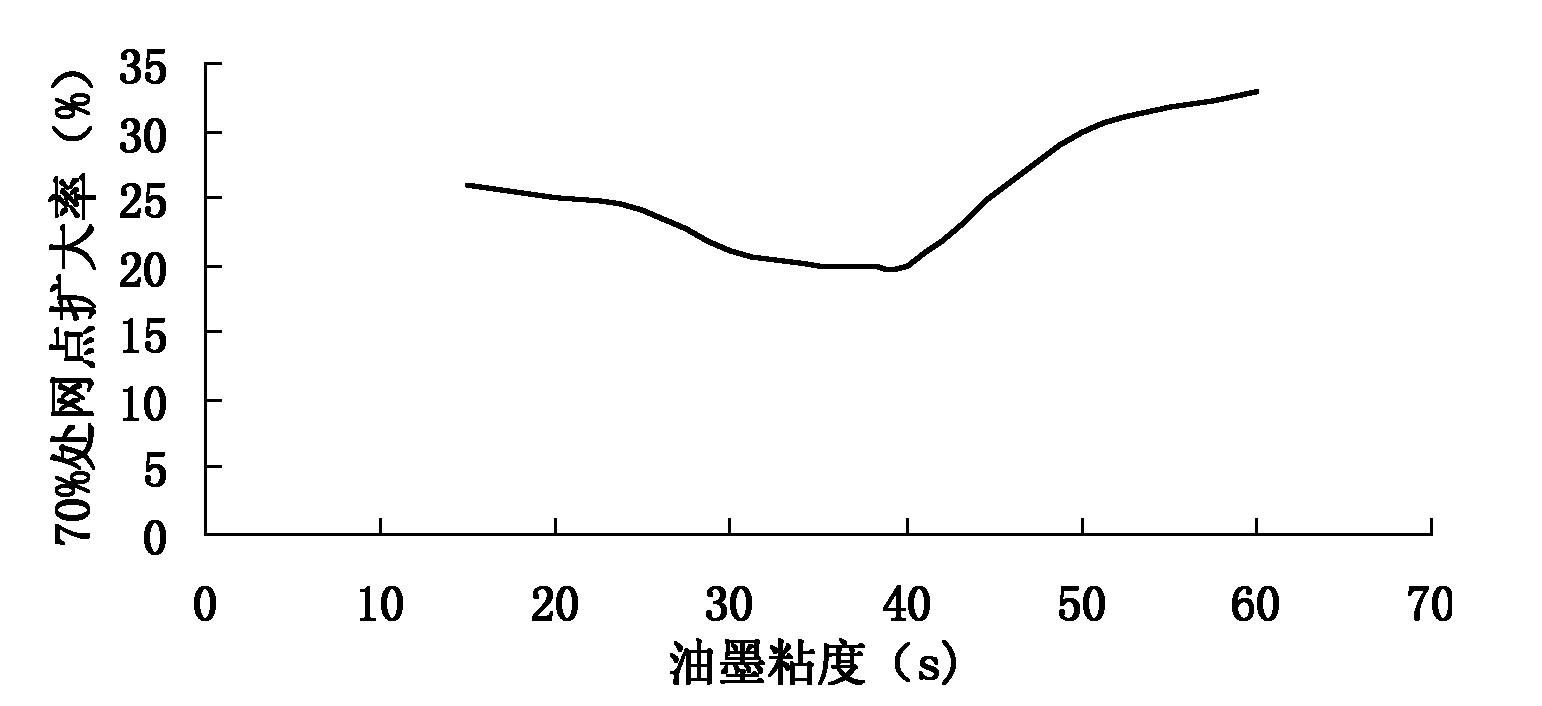

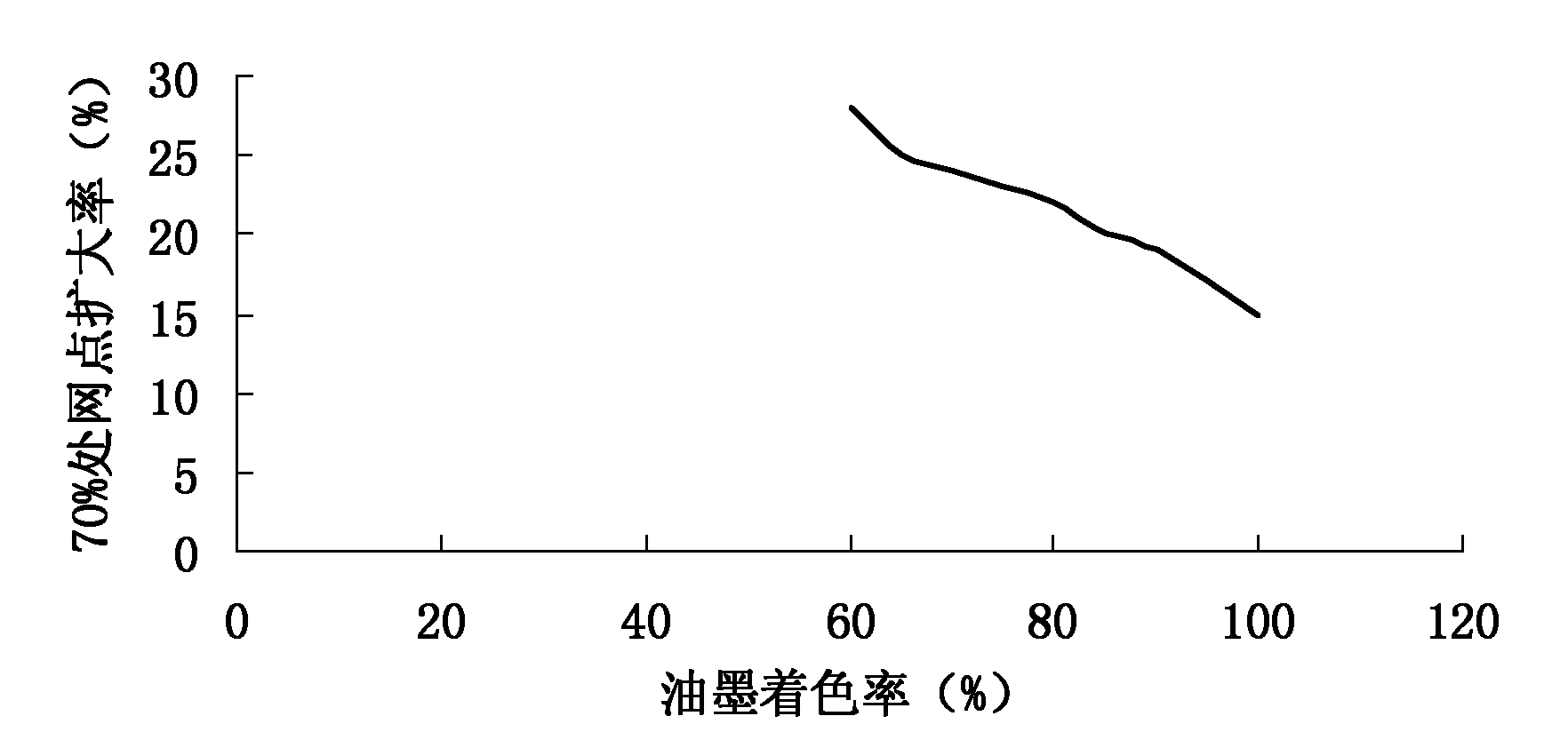

Method for manufacturing wide-width color flexible preprinted corrugated carton

ActiveCN101941307AColorfulAccurate overprintContainer making machineryTemperature resistanceEngineering

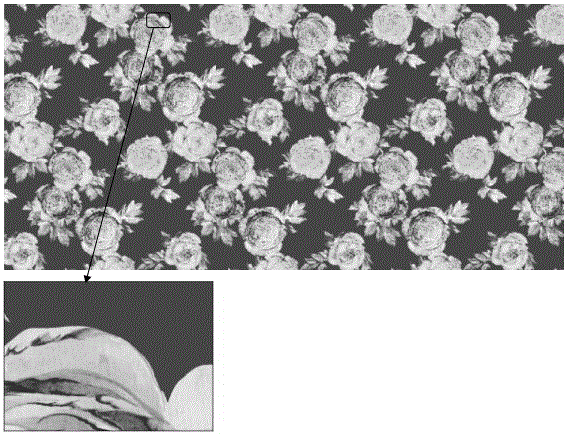

The invention discloses a method for manufacturing a wide-width color flexible preprinted corrugated carton, which comprises the steps of: plate making, ink preparing, varnish preparing, web-feed printing, cardboard flailing, cutter template manufacturing, die cutting and the like. Printed products manufactured by the method have bright color, accurate chromatograph, thick ink layers and vivid pattern restoration, can synchronously realize indexes of gloss, abrasion resistance, skid resistance and high-temperature resistance. In the method, an international environmentally-friendly honeycomb ceramic roll with water-based ink, water-based varnish and high reticles and the shortest ink transferring path are adopted, so the printing cost is saved, and the product quality and production efficiency are improved greatly.

Owner:湖北合信智能包装科技有限公司

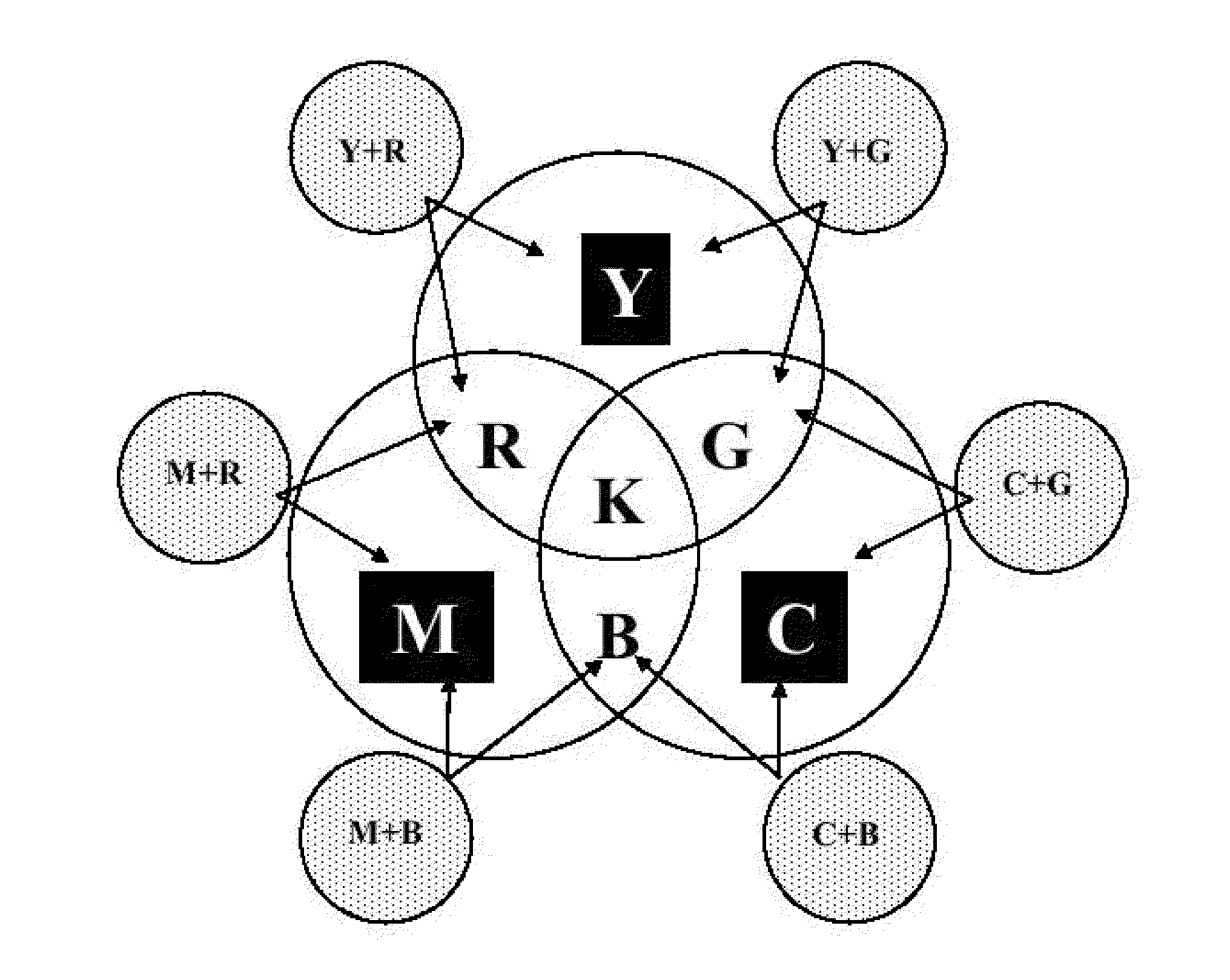

Method for controlling multicolor print quality

InactiveUS20120008170A1Misalignment of informationAccurate overprintVisual presentationColour-separation/tonal-correctionColor changesComputer science

A method for controlling multicolor print quality including a) placing color patches onto a print substrate; b) combining primary colors C, M, and Y to form secondary colors and overprinting the secondary colors and an opposite primary color thereof in a pre-determined halftone % to yield neutral grey tone; c) comparing the neutral grey tone with a black “K” halftone as a monochrome gray reference in the color patches, and d) amending the color patches to control color changes.

Owner:YAN TAK KIN ANDREW

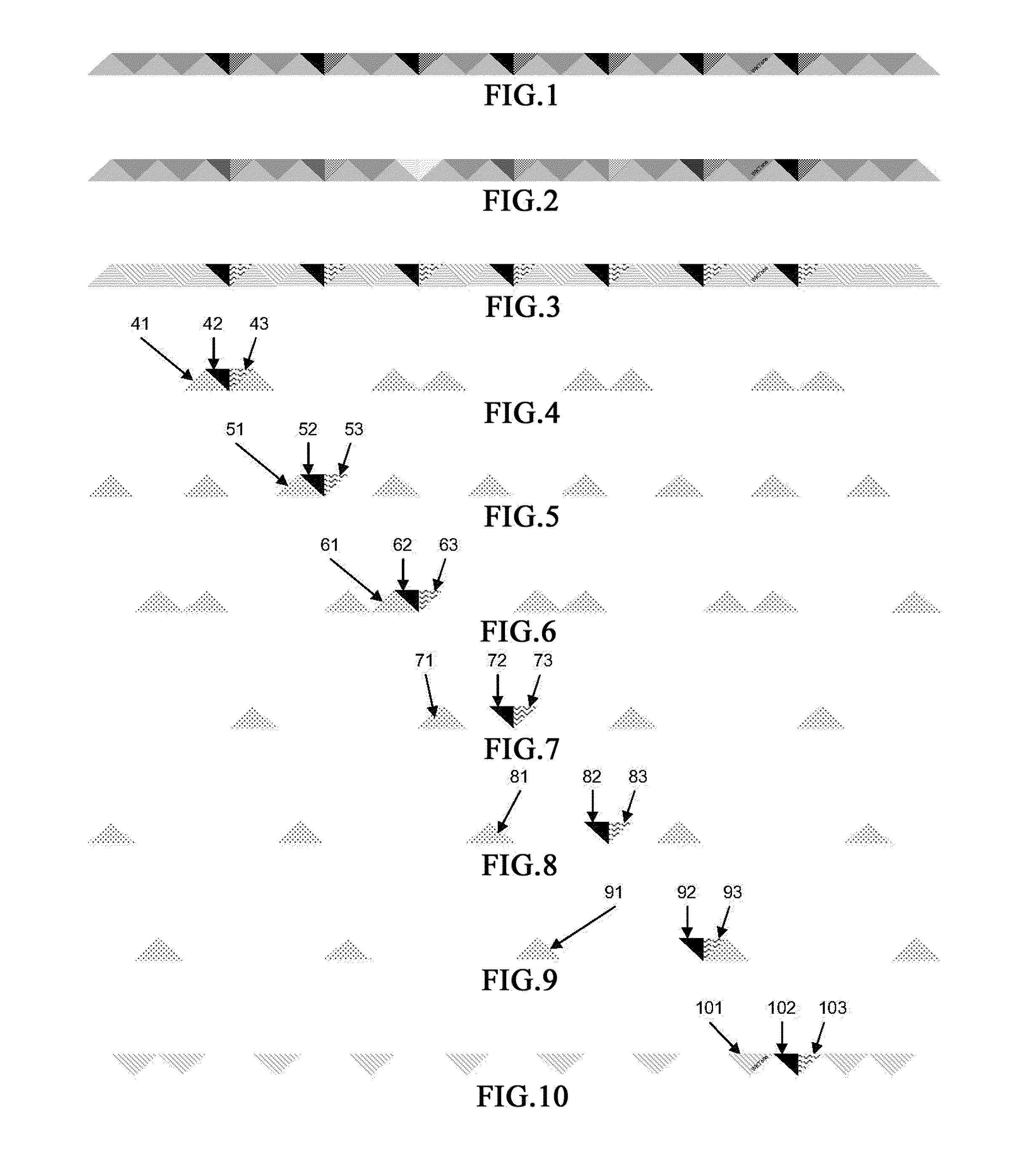

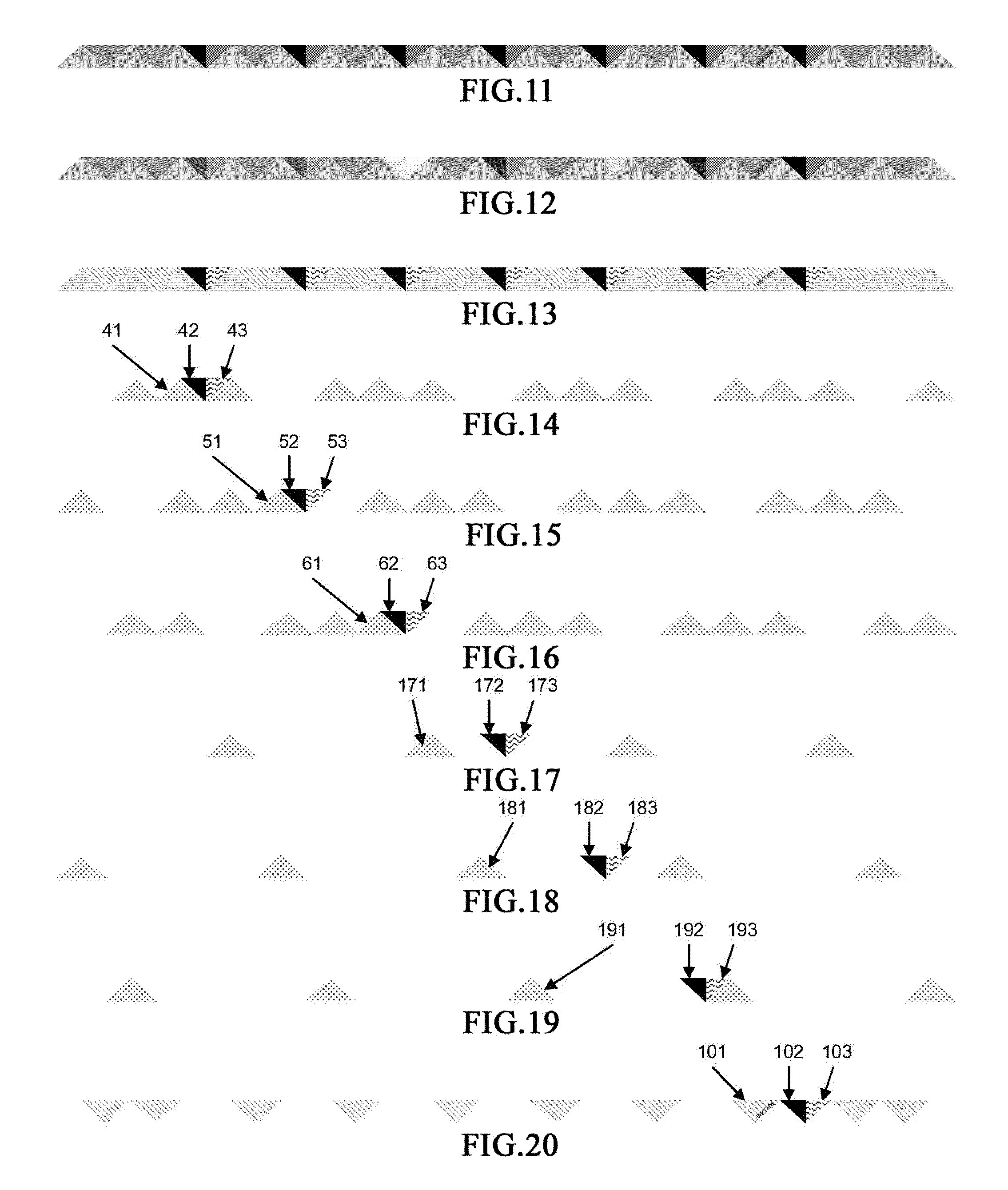

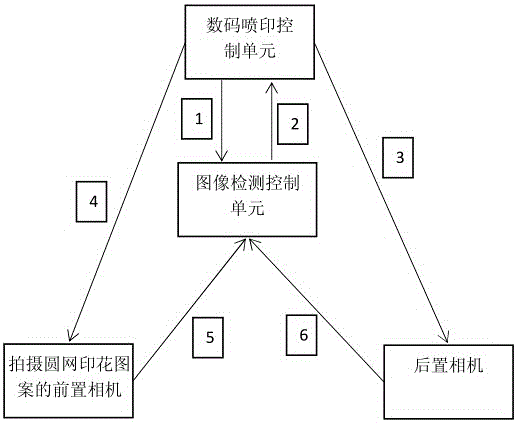

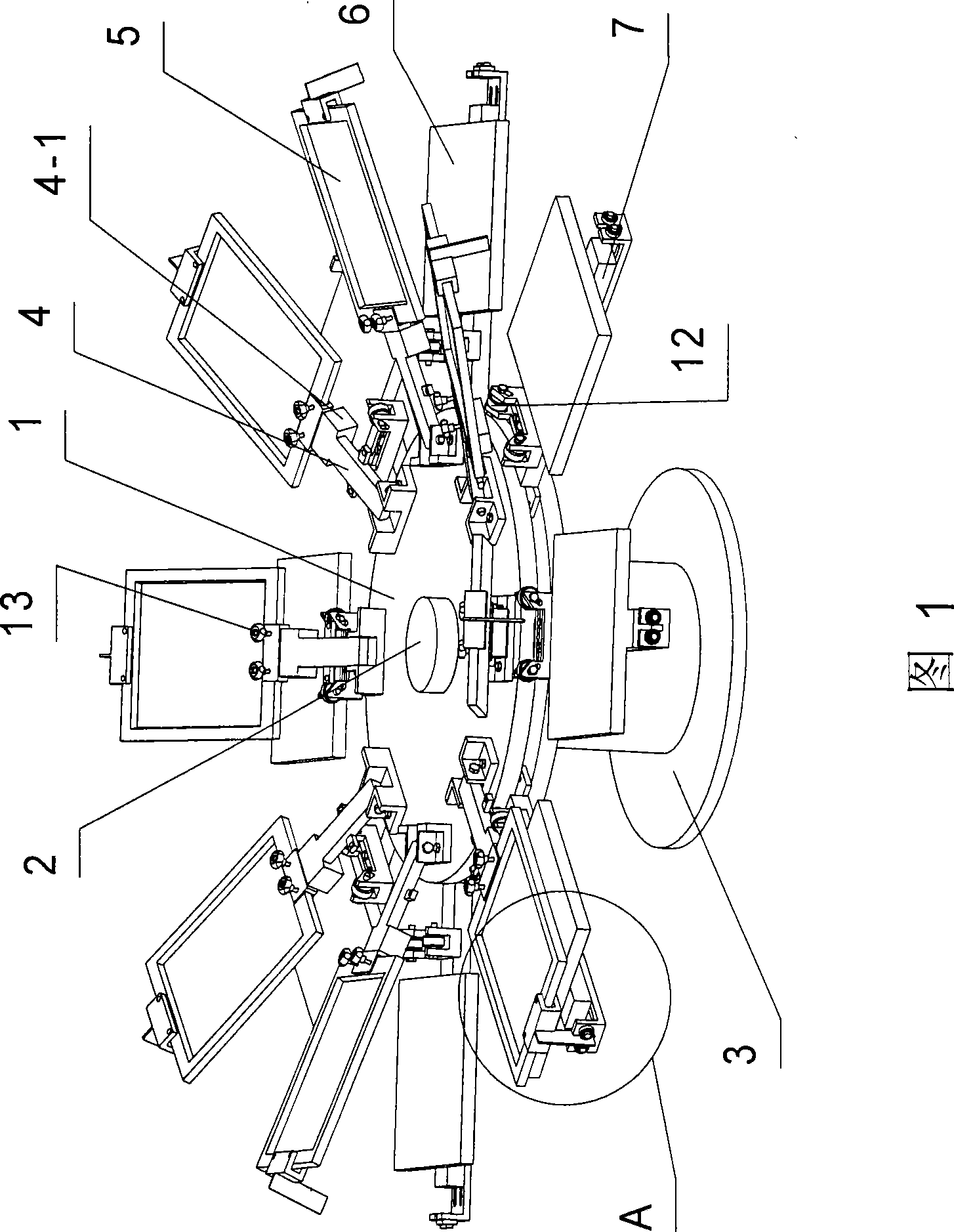

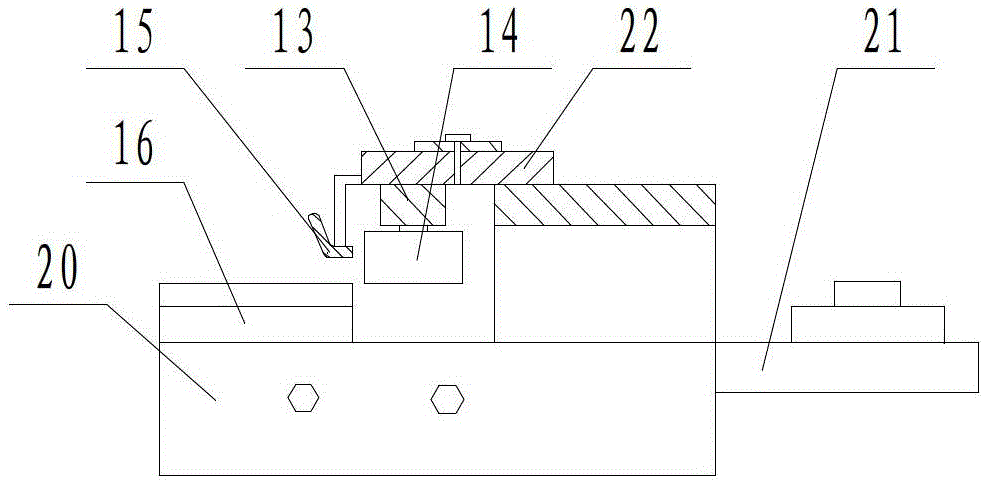

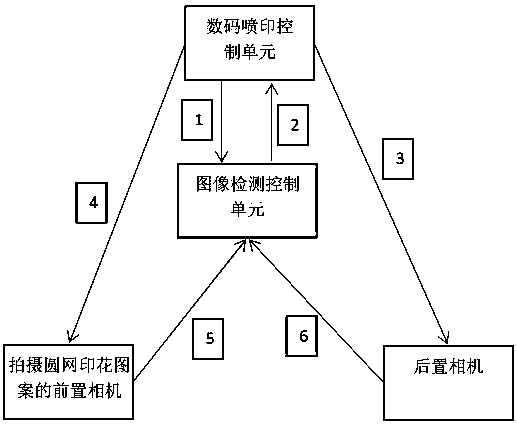

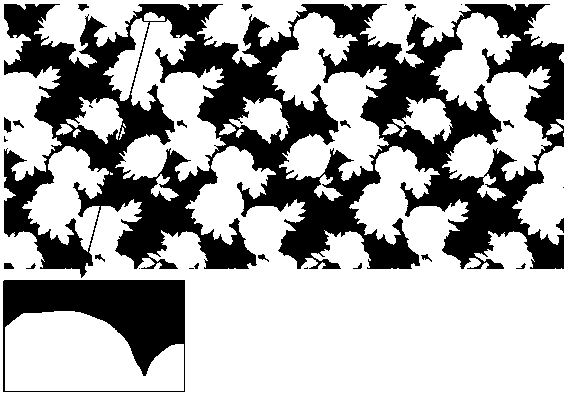

Printing mechanism achieving synchronous digital printing and rotary screen printing and printing method

ActiveCN105882129AEnsure accurate registrationPrecise registrationScreen printersTypewritersDigital printingEngineering

The invention relates to a printing mechanism achieving synchronous digital printing and rotary screen printing and a printing method. A printing method for effectively combining digital printing and rotary screen printing to finish synchronous overprinting is hardly achieved at present. The printing method comprises the following steps that firstly, a rotary screen conducts printing on a printed fabric, and a screen printing pattern is formed; secondly, feature points are assigned on the screen printing pattern, feature points in a front rotary screen circumference and a rear rotary screen circumference are shot through a front camera, and the deviation value of the rotary screen is obtained; thirdly, the digital printing pattern is subjected to corresponding zooming operation according to the deviation value of the rotary screen, and after digital printing, a combined printing pattern is formed on the printed fabric; and fourthly, corresponding feature points of the combined printing pattern or corresponding feature points of the screen printing pattern and the digital printing pattern are shot through a rear camera, whether deviation exists between digital printing and rotary screen printing or not is detected, and whether an accurate overprinting effect is completely achieved or not is judged. According to the printing mechanism and the printing method, respective advantages of digital printing and rotary screen printing are truly and effectively combined.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Double-sided color electric aluminum hot stamping foil and production method thereof

InactiveCN105500853AAccurate overprintStrong glossSynthetic resin layered productsMetal layered productsHot stampingComposite film

The present invention provides a double-sided color electric aluminum hot stamping foil and a production method thereof. According to the present invention, after the double-sided color electric aluminum hot stamping foil is subjected to hot stamping on a transparent material, the front surface and the back surface of the stamped material can display the same or different colors; after the double-sided color electric aluminum hot stamping foil is used for plastic composite film printing, the hot stamping picture-text can be lined while the printing on the back surface, and the precise chromatograph edition of the hot stamping pattern and the ink printing picture-text can be achieved; and after the product is compounded, the printing layer and the hot stamping layer are positioned on the inner surface of the printed film, the gloss is strong, and the scratch caused by external force cannot be generated.

Owner:KUNSHAN SHENGLI PACKAGING MATERIALS

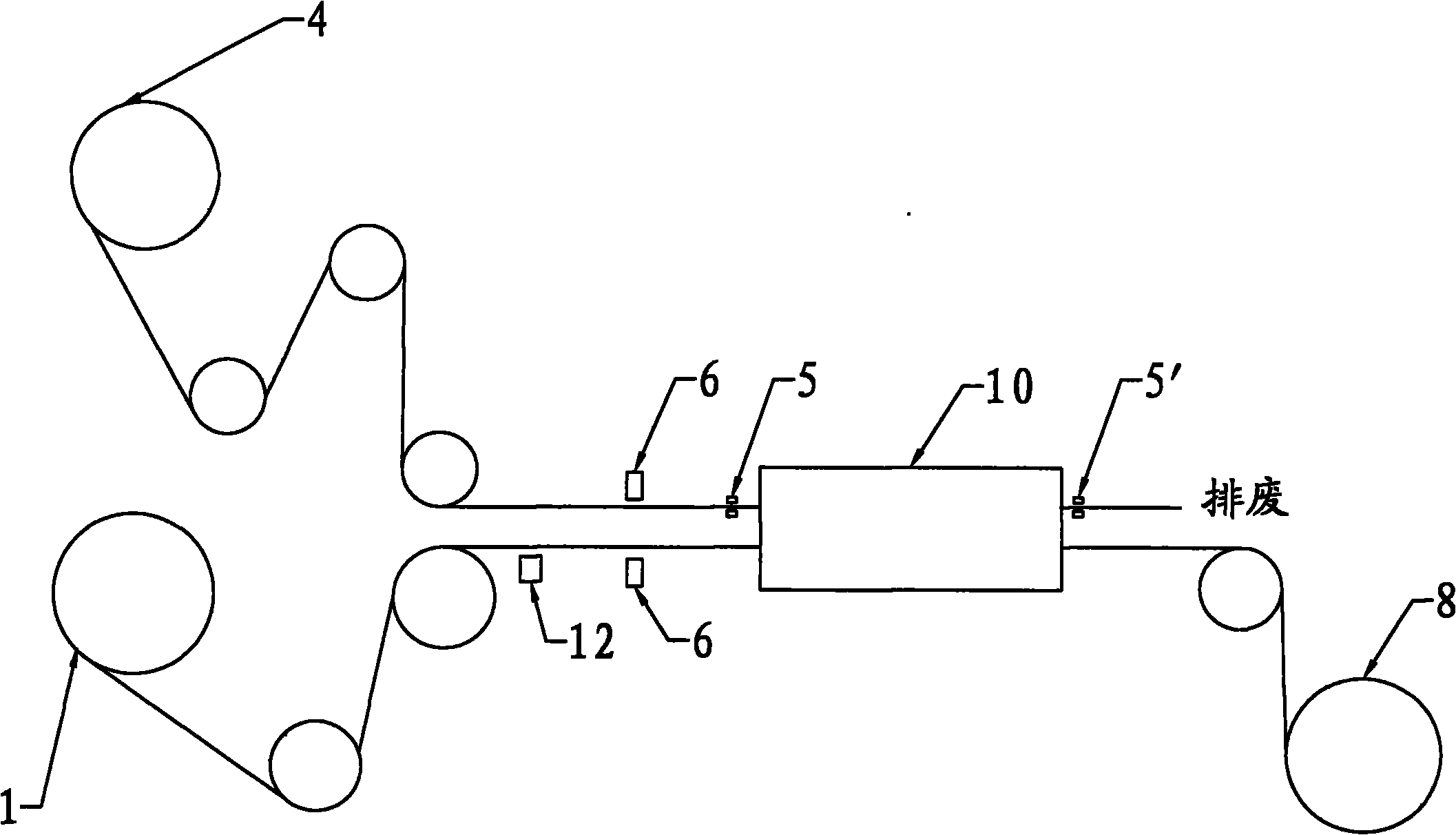

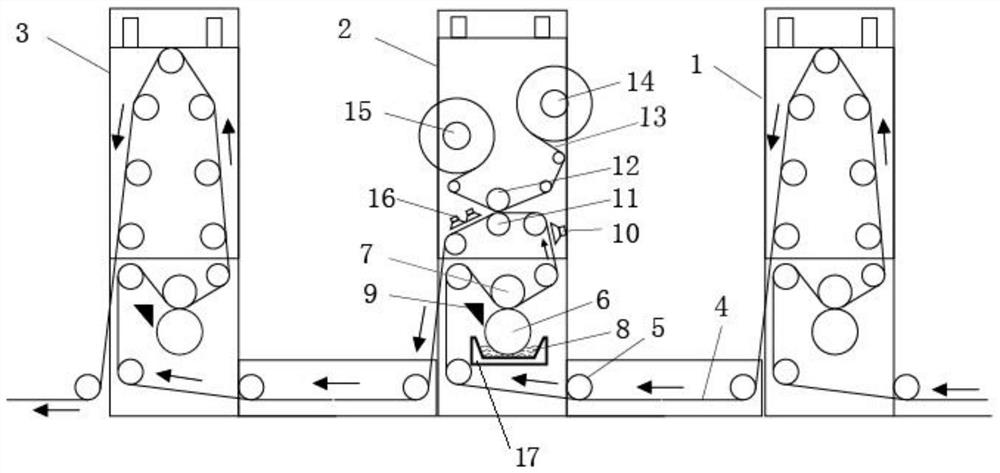

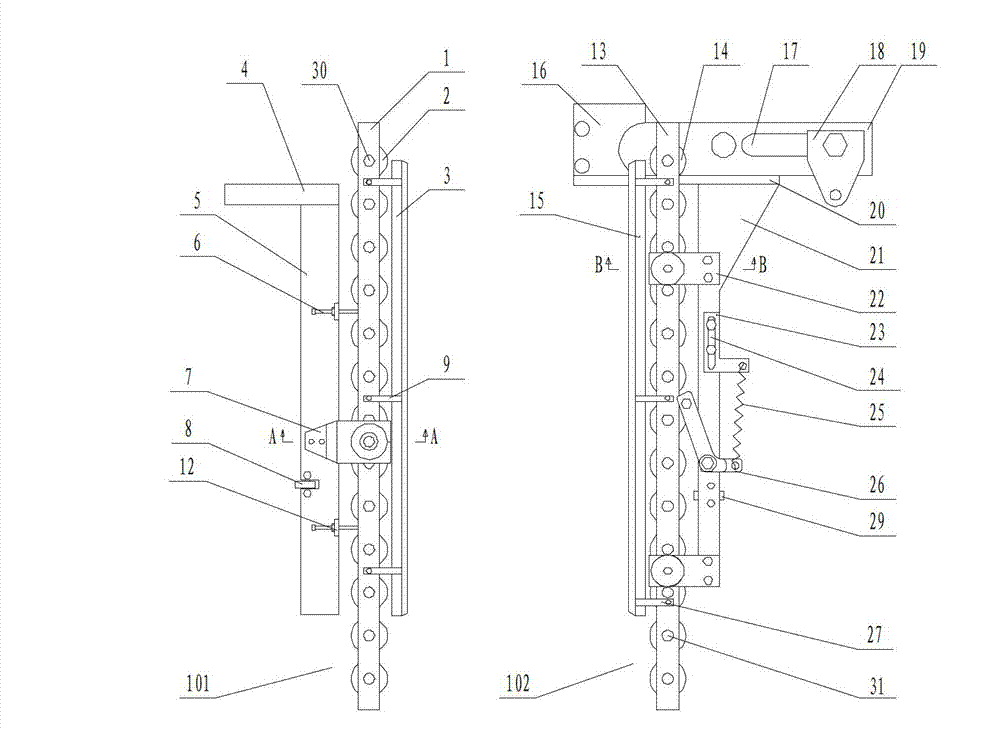

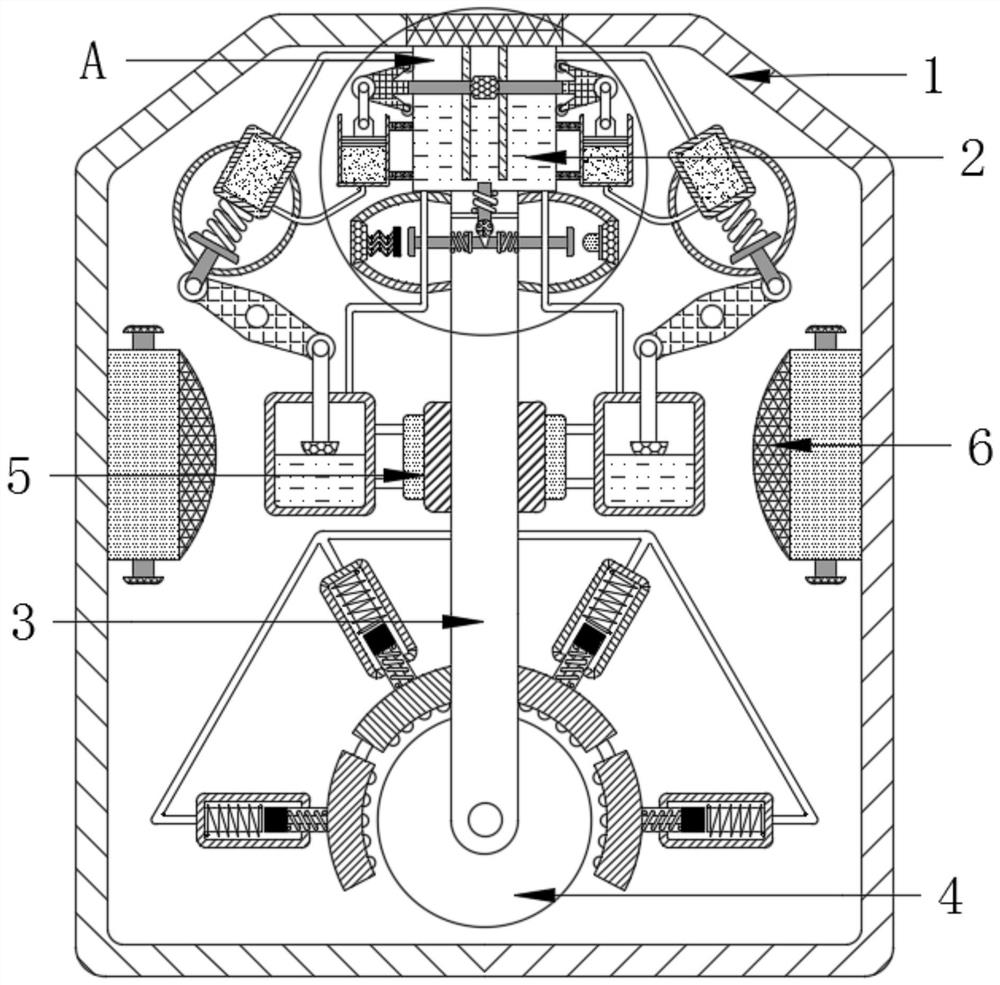

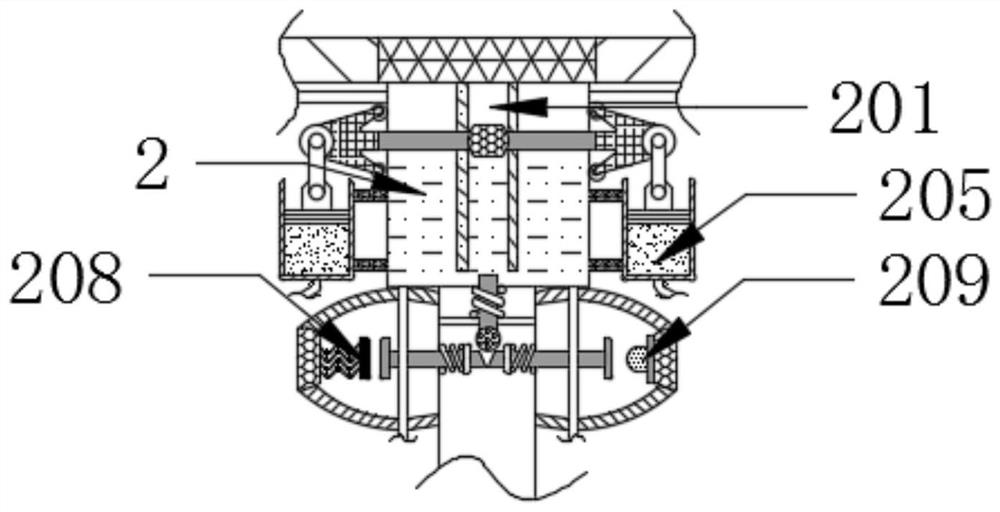

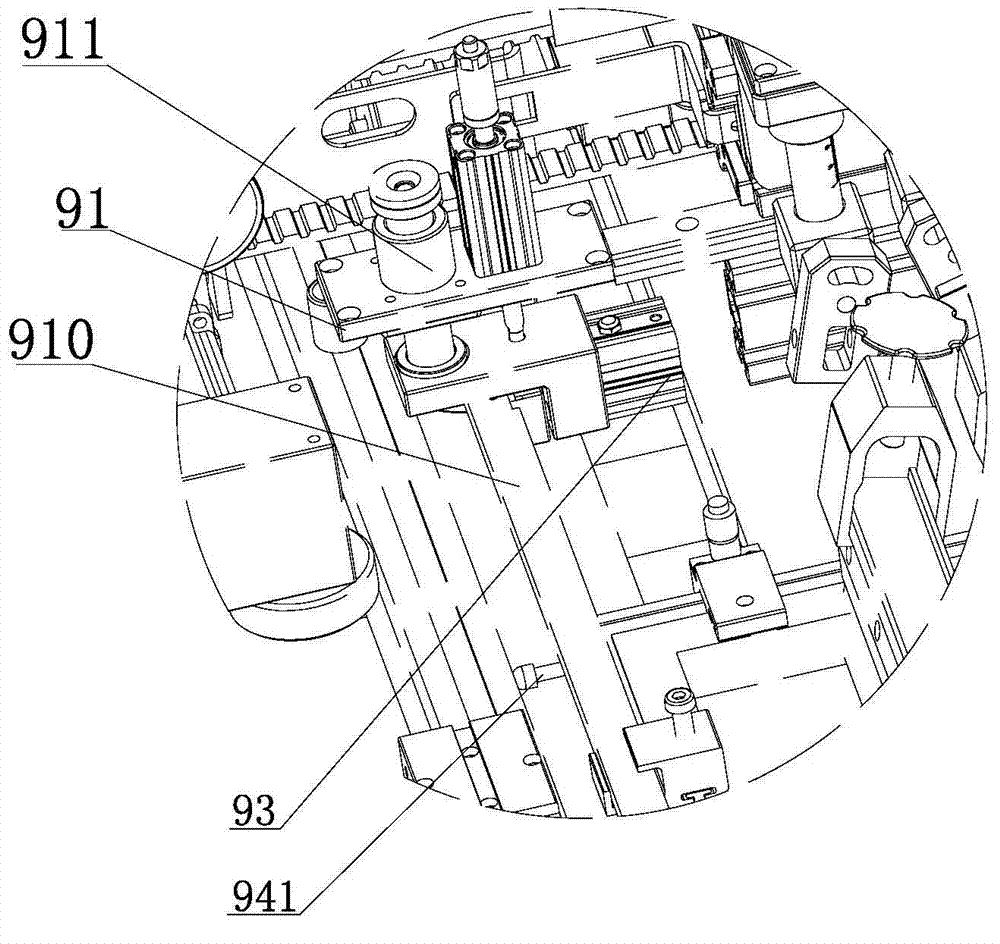

Group-type logistics bidirectional holographic positioning overprinting machine

InactiveCN101934627AAvoid safety hazardsImprove yieldRotary pressesPrinting press partsLogistics managementEngineering

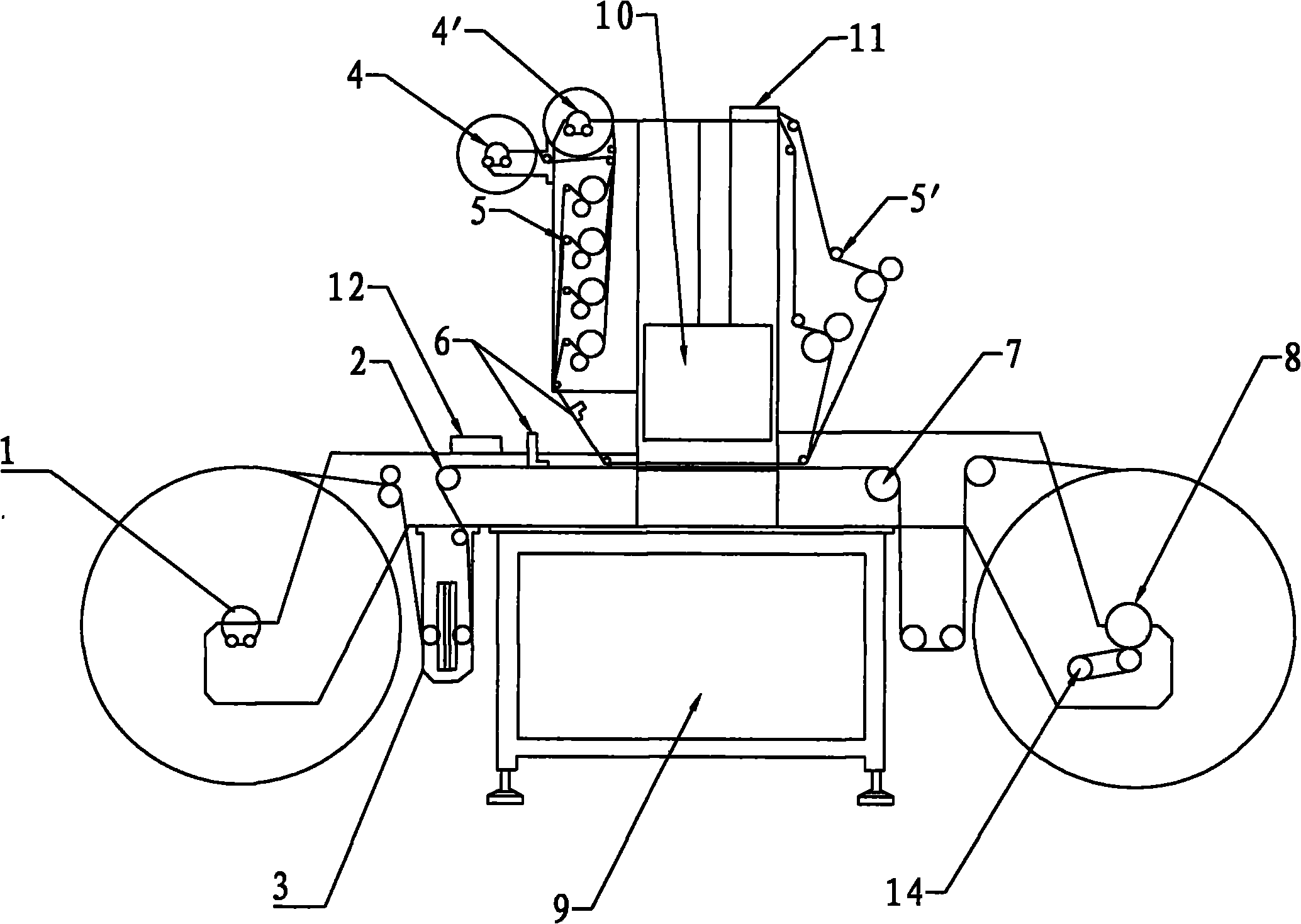

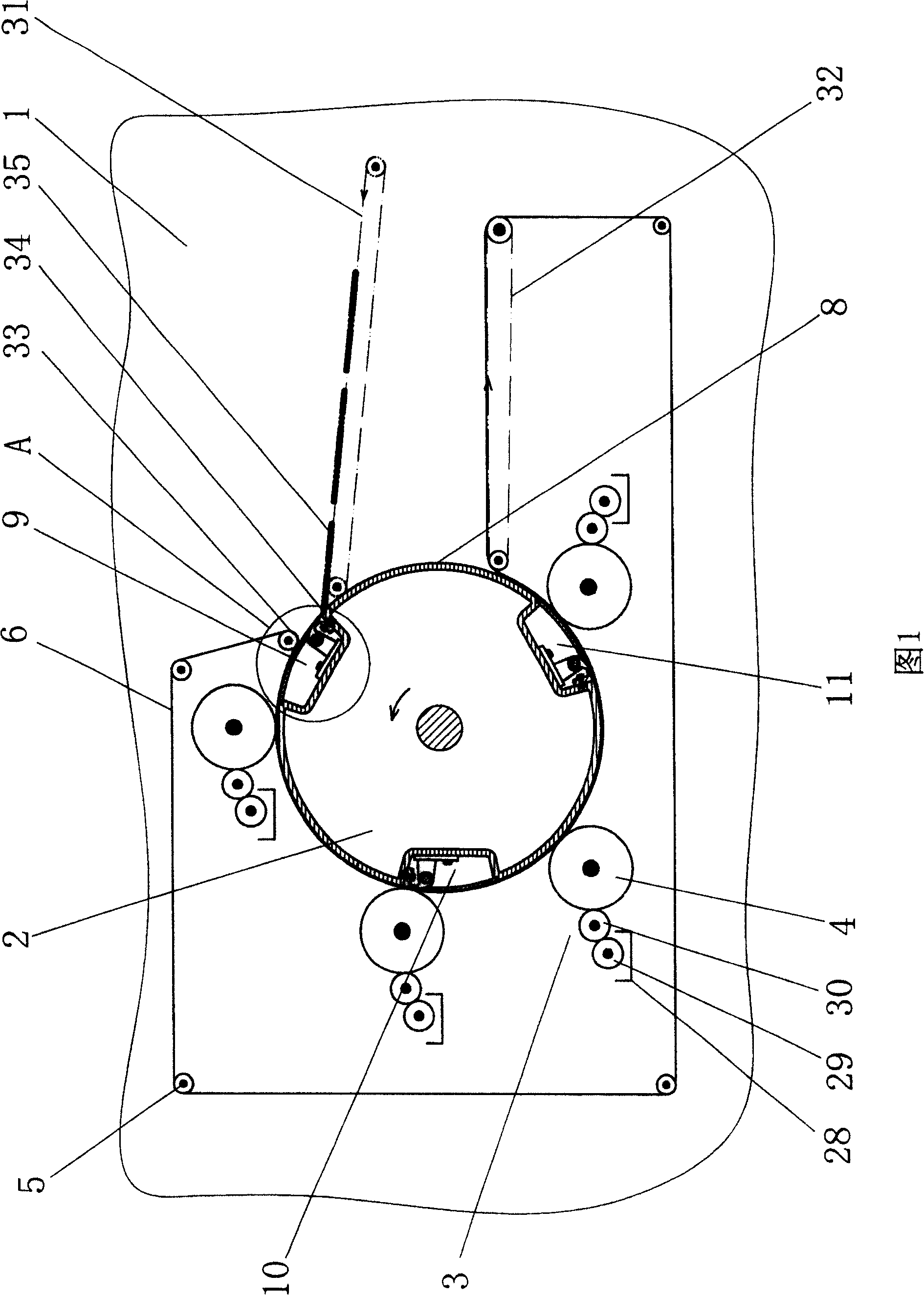

The invention relates to a group-type logistics bidirectional holographic positioning overprinting machine, which belongs to the technical field of anti-counterfeit printing equipment. The overprinting machine is characterized by consisting of an unwinding device, a photoelectric recognition control device, an electric control base, a traction device, an overprinting device and a winding device, wherein the winding and unwinding devices are integrated with the electric control base; the overprinting device is positioned above the electric control base; the winding and unwinding devices are positioned on both sides of the overprinting device; the photoelectric recognition control device is arranged in front of the overprinting device and matched with the unwinding device; the unwinding device consists of a group of reel printing stock unwinding devices and multiple groups of reel holographic anti-counterfeit film unwinding devices; each unwinding device corresponds to a group of photoelectric recognition control devices; the unwinding modes of the multiple groups of reel holographic anti-counterfeit film unwinding devices are independent unwinding; and group sequence arrangement patterns correspond to preserved overprinting regions of reel printing stocks one by one. The equipment of the invention has the advantages of realizing correct and continuous overprinting, reducing rejection rate, shortening production period, effectively lowering production cost and greatly improving production efficiency.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

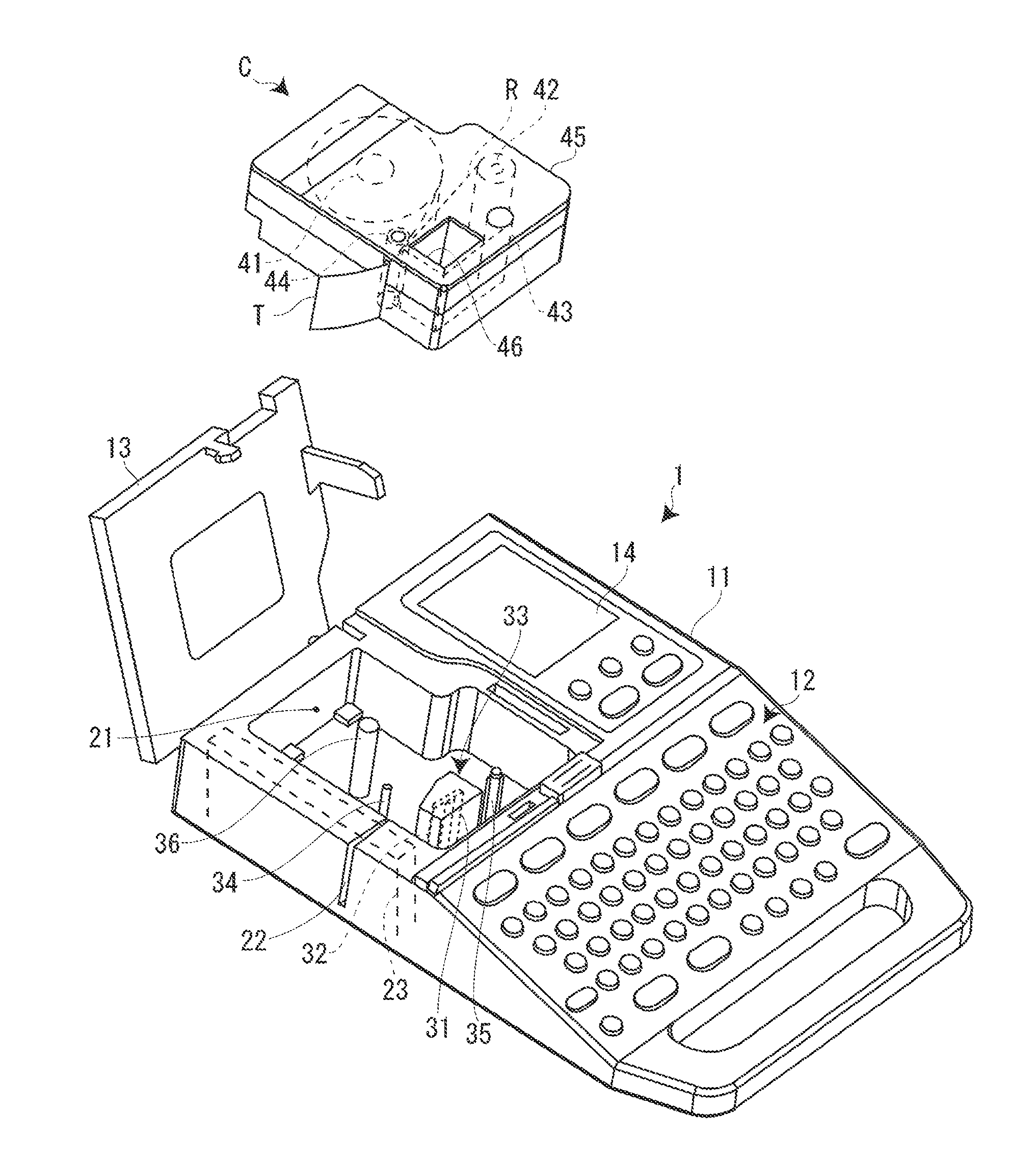

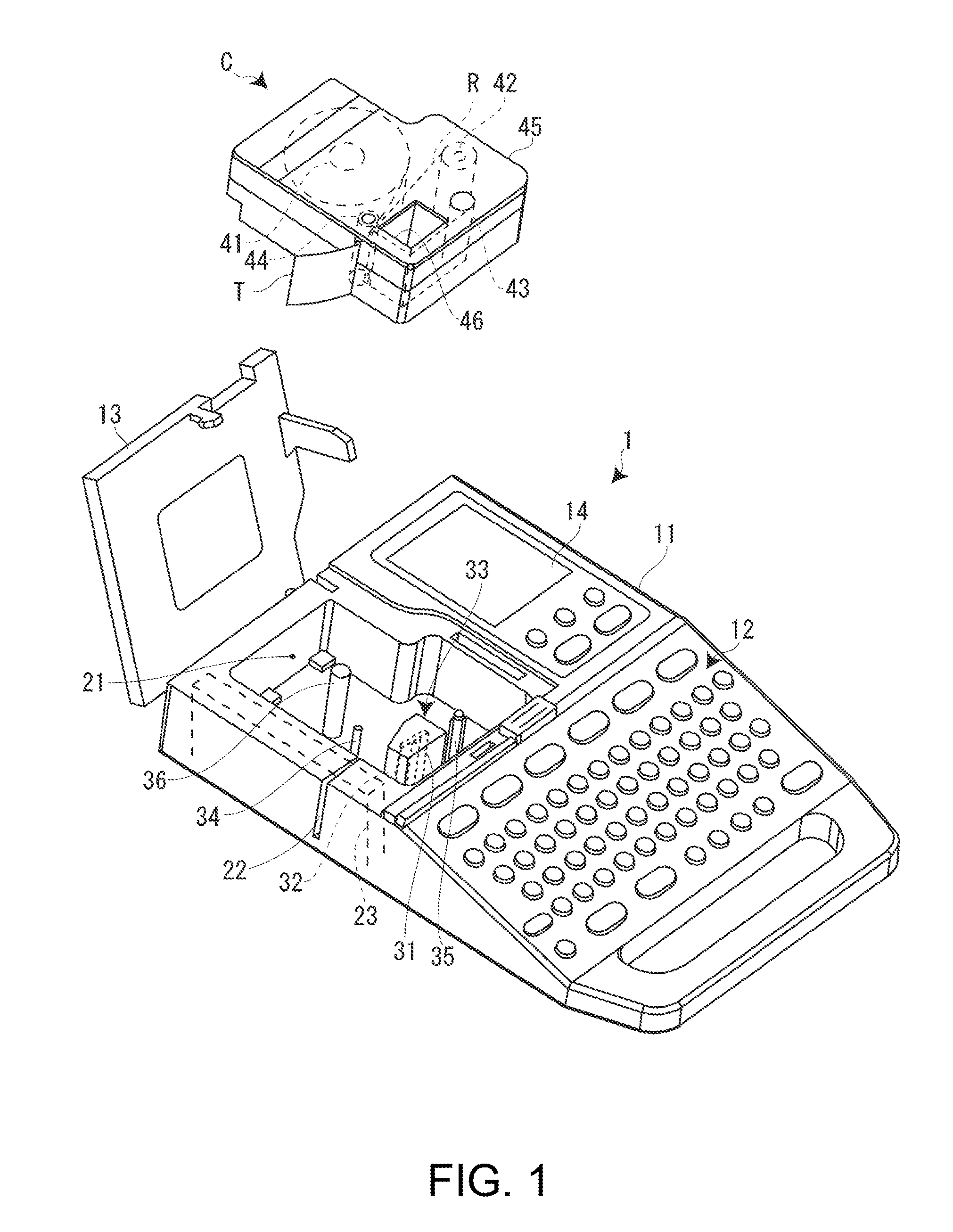

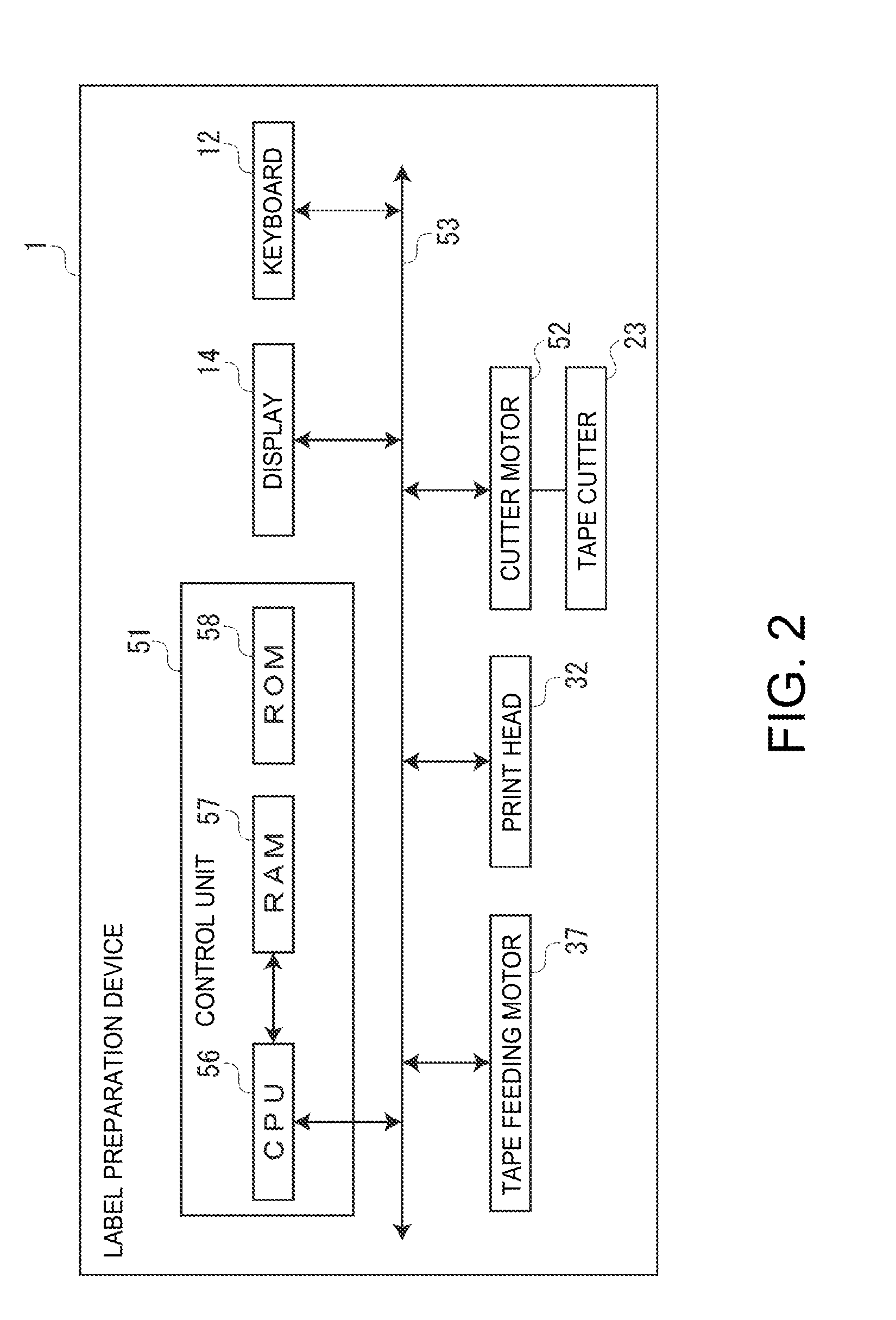

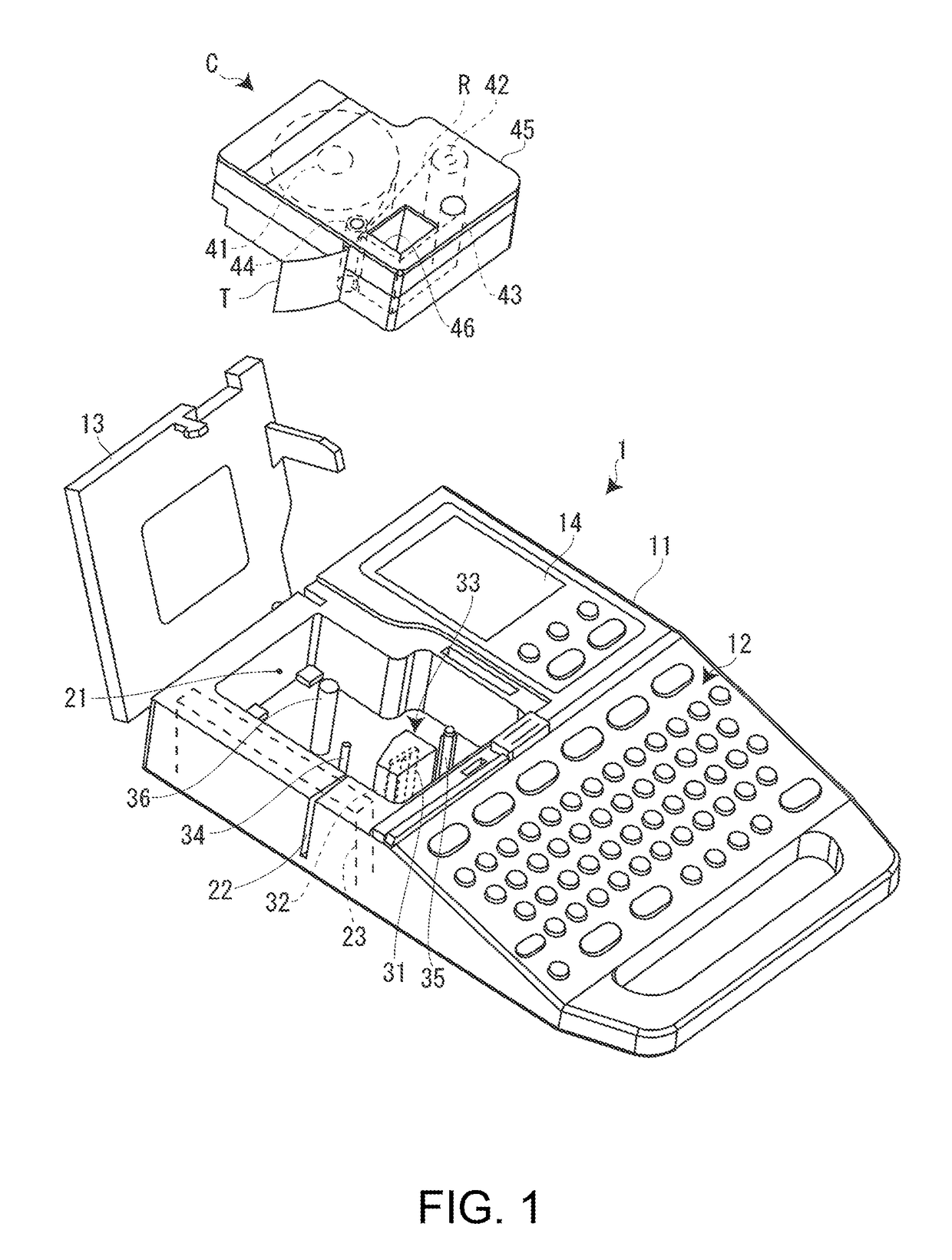

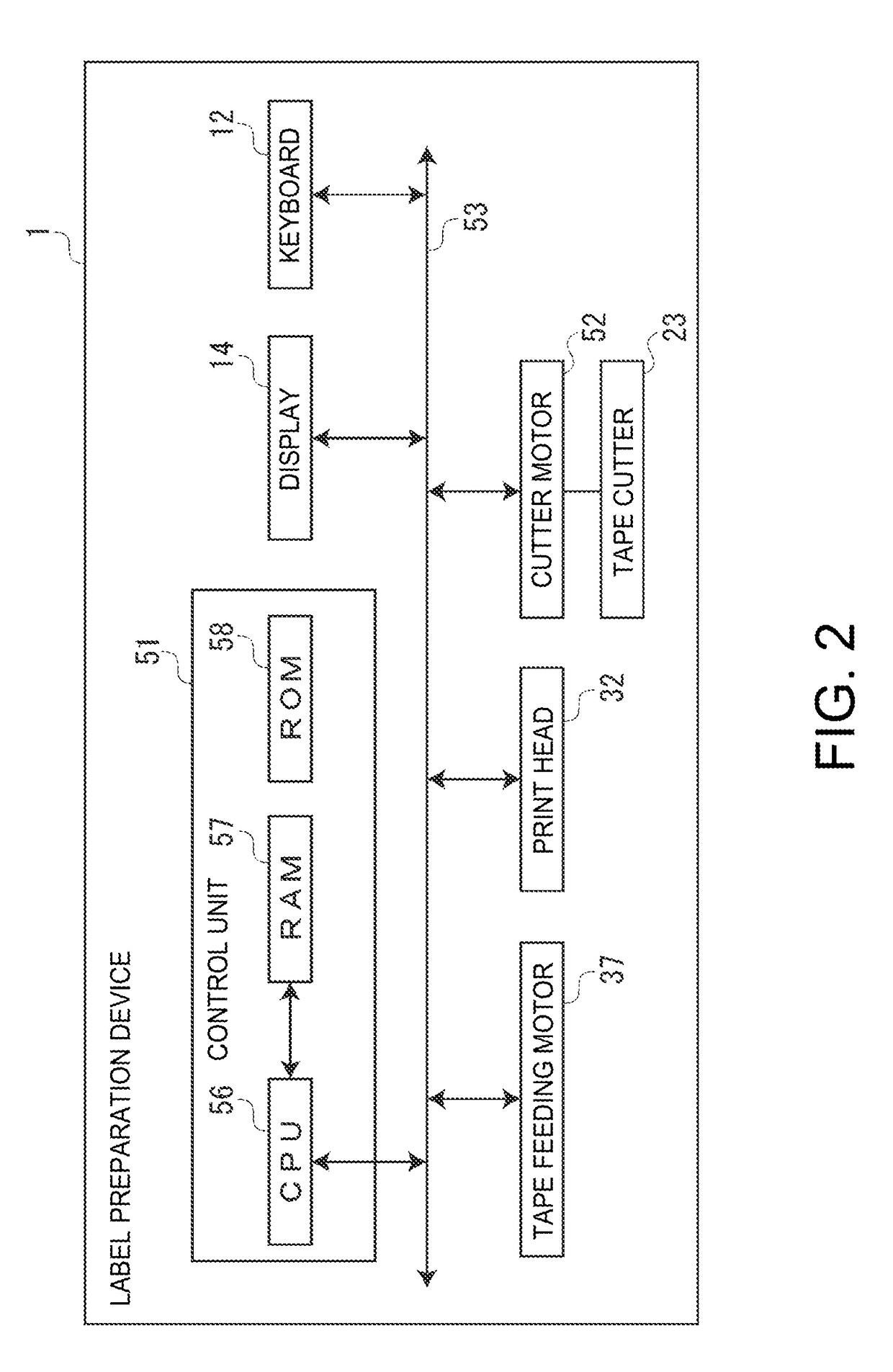

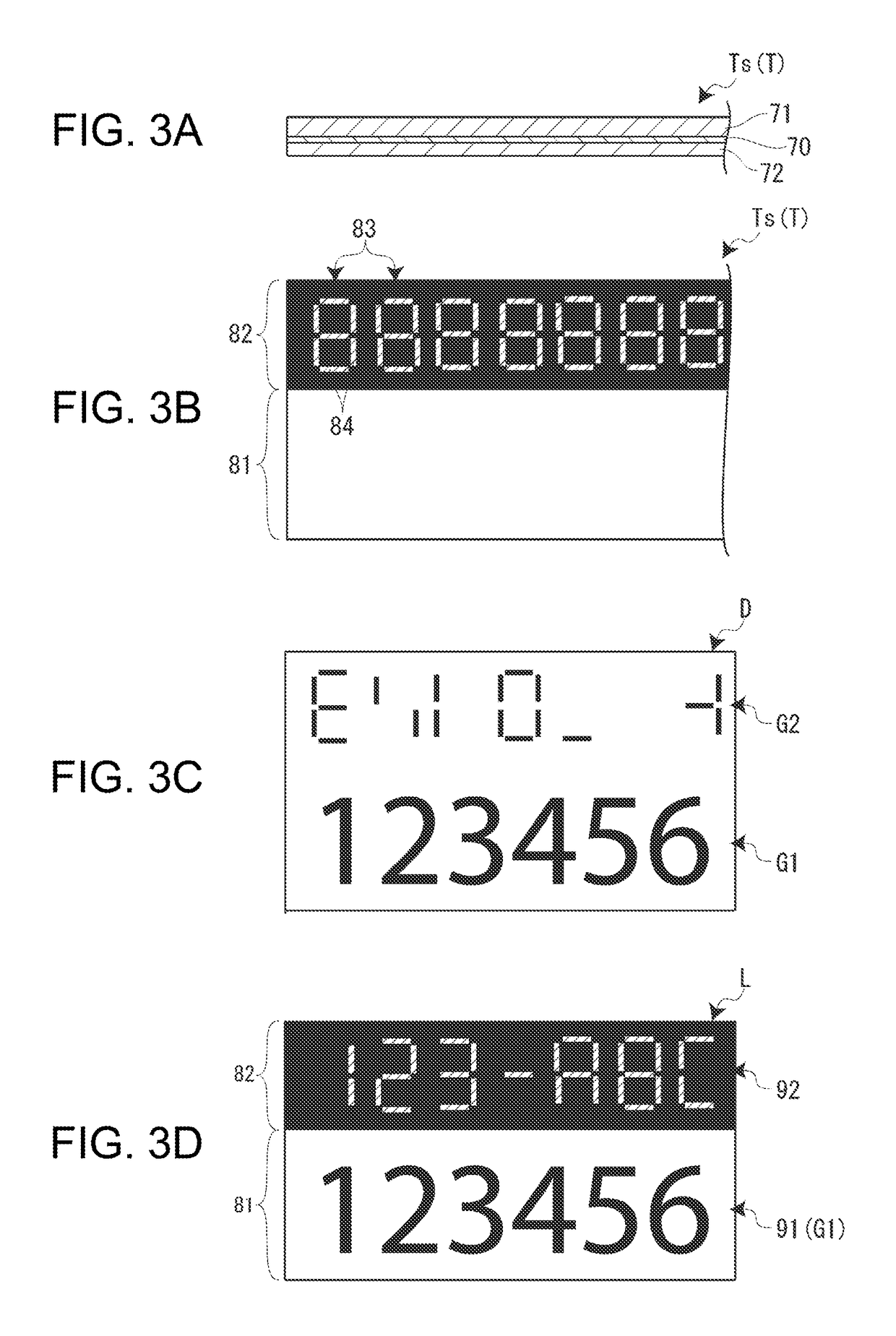

Print medium, printing device, and printing method for printing device

InactiveUS20150273865A1Change colorSimple configurationStampsOther printing matterComputer engineeringBackground color

A print medium, on which individual labeling information made up of one or more labeling elements that are selectively shown, of common labeling information made up of a plurality of labeling elements, is formed by a printing device, wherein the common labeling information is printed in advance and a background color of an area where at least a plurality of labeling elements is printed is a print color that is printable by the printing device, is disclosed.

Owner:SEIKO EPSON CORP

Full-automatic embossing machine

InactiveCN103158340AImprove efficiencyReduce the number of plate changesScreen printersPrinting press partsEngineeringUltimate tensile strength

The invention discloses a full-automatic machine which comprises an embossing machine body and a plurality of clamps used for locating the embossing machine body. The embossing machine body is arranged on table boards, an operating rail of the embossing machine body is arranged on the table boards, the number of the table boards is plural, and the table boards are arranged side by side and connected through turning systems, a shifting car and turning rails of the shifting car are arranged on the turning systems, the shifting car is used for shifting the embossing machine body, a signal emission device is arranged on the shifting car, the turning rails are rectilinear rails and perpendicular to the plane of the table boards, and included angles of 90 degrees are formed between the turning rails and the table boards. The full-automatic machine has the advantages of being high in automation degree and capable of enlarging product category, improving efficiency for dozens of times, improving product quality, reducing labor intensity and reducing production cost and complexity of labor.

Owner:山东宏美数码科技股份有限公司

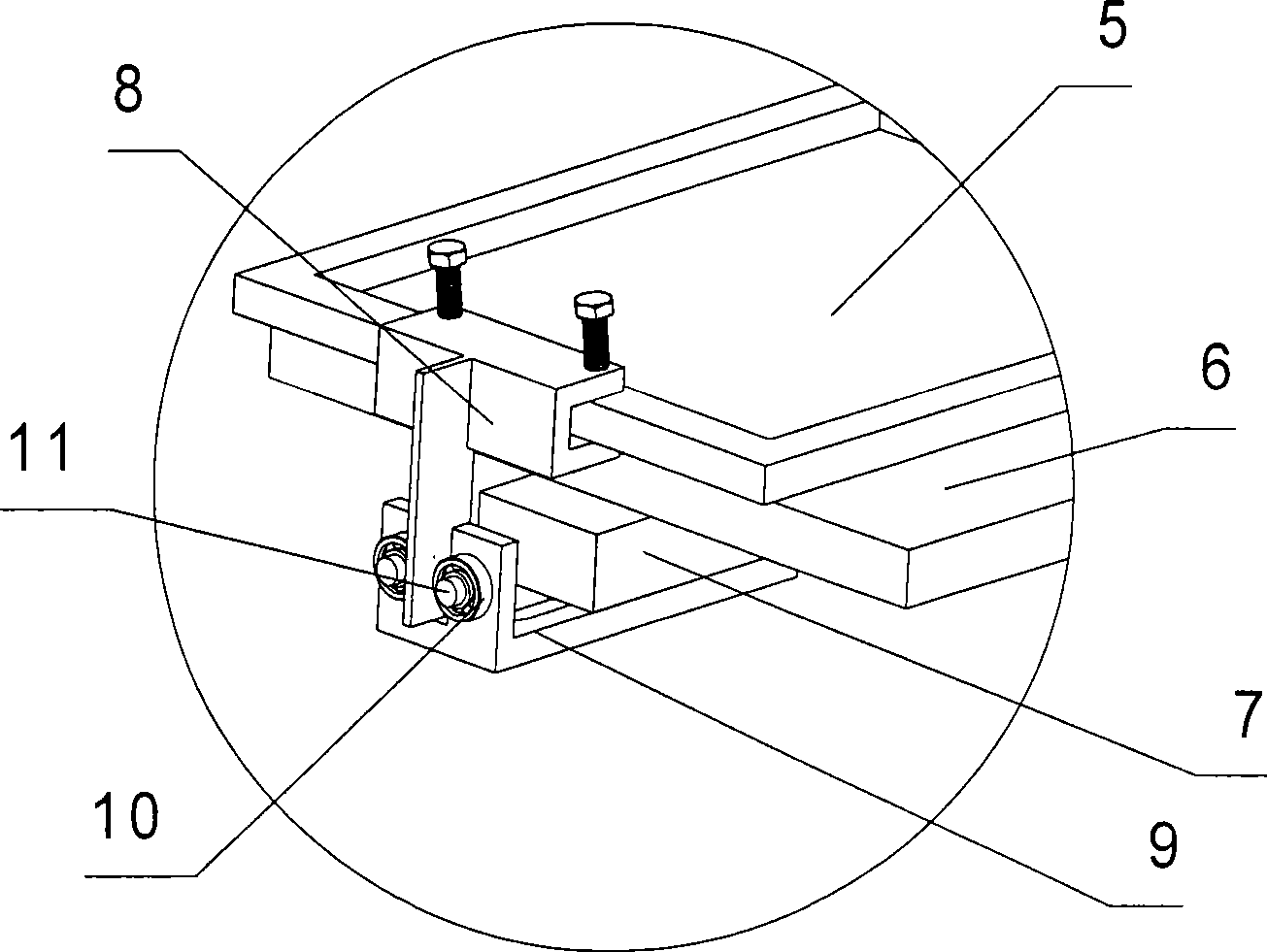

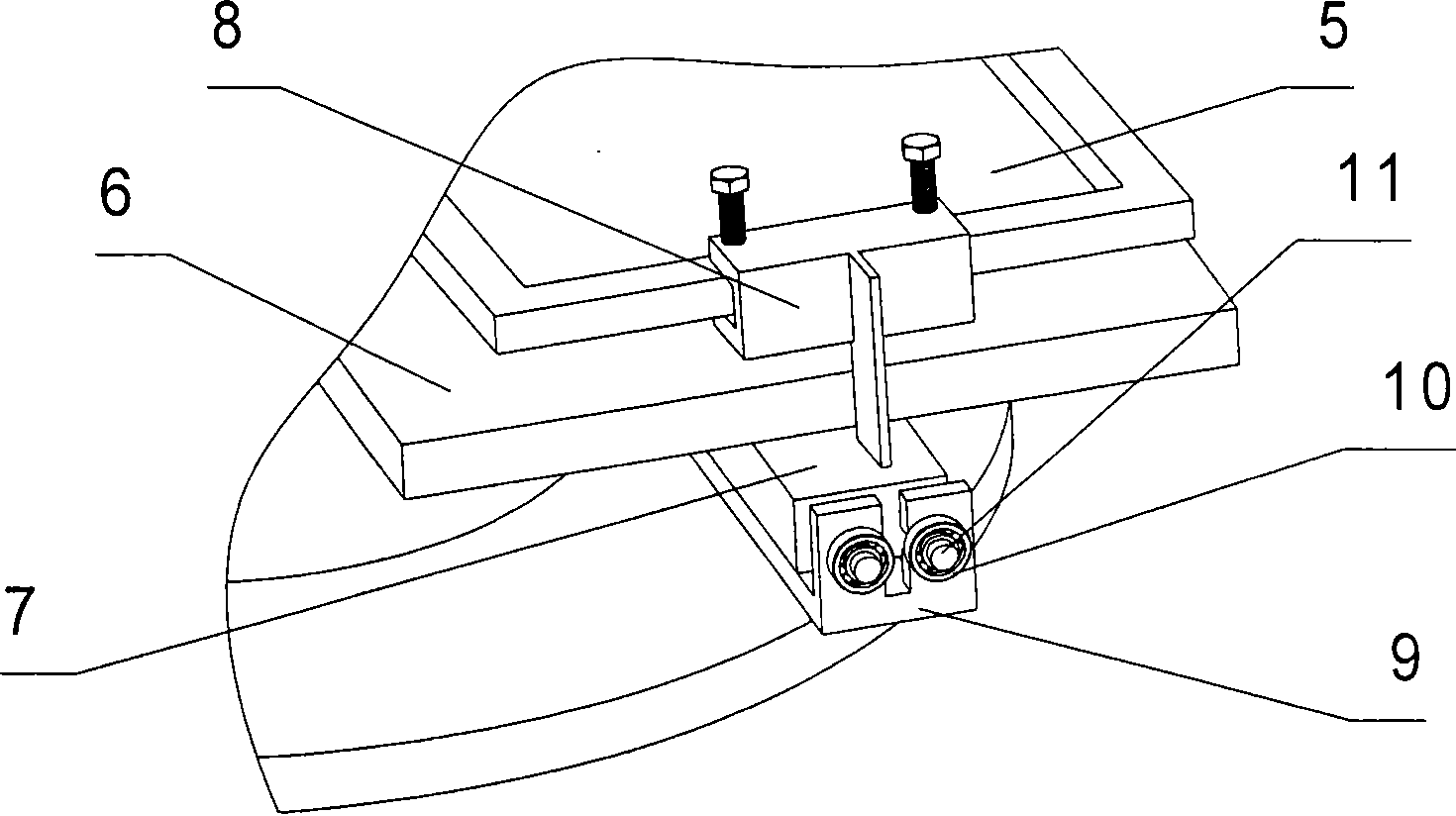

Positioning device for manual silk-screen wheel transfer printing machine

The invention discloses a locating device used for a manual silk screen and wheel-rotating printing machine, pertaining to a technical field of printing devices. The device includes an ink pad arranged on supporting legs and a screen board arranged on a rotary table by a cantilever; wherein, the outer end of the supporting leg is provided with a locating base which is provided with a transverse locating slot and a vertical locating slot. A pair of core shafts pass through the transverse locating slot and are fixedly installed in the slot, and the pair of core shafts are provided with a pair of bearings locked by nuts. The outer end of the otter board is provided with a locating plate which can be inserted into the vertical locating slot and the gap between the two bearings and can form leak proof fit with the bearings. The device can discover and correct the displacement of the screen board in time, therefore, the accurate locating and overprinting of the screen board and the ink pad can be ensured, the printing product has good quality and high level, the waste product is eliminated, the work efficiency is improved, and the manufacture cost is reduced greatly. The device can be used for monochromatic multi-color overprinting with clearance and zero-distance multi-color overprinting.

Owner:刘志江

Wood texture type UV offset printing technology

InactiveCN109278431AAccurate overprintImprove printing efficiencyPattern printingOther printing apparatusScreen printingPulp and paper industry

The invention discloses a wood texture type UV offset printing technology. The technology comprises the following steps: 1, drawing patterns of shadow and line of a wood texture effect, and printing down; 2, printing bottom gloss oil on the pattern with the wood texture effect; and 3, printing top gloss oil on the basis of the printed bottom gloss oil, wherein the dyne after bottom gloss oil printing is 24-28; and the dyne after top gloss oil printing is not less than 38. With the adoption of the technology, the wood texture effect can be printed at one time; and moreover, the chromatography is accurate; the matte effect is realized; the sense of concavo-convex is achieved; a traditional silk-screen printing technology can be replaced; and the printing efficiency is improved.

Owner:广东启晨数字科技有限公司

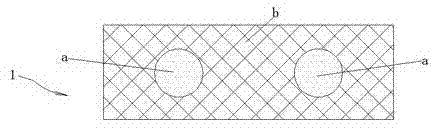

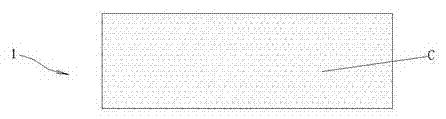

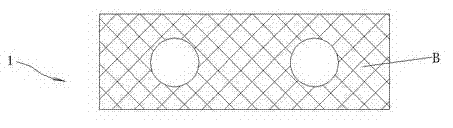

Precise positioning to form local laser pattern process

InactiveCN102285264AIngeniously solve the problem that the printing cannot be directly and accurately positionedPrecise positioningPattern printingLaser patterningPrinting ink

The invention relates to a process for forming local laser patterns by accurately positioning, which sequentially comprises the following steps of: (1) designing ideal positions and shapes for a laser patterned area and an ink printed area, and sleeving a designed ink printed area b at the periphery of a designed laser patterned area a; (2) forming a semi-finished laser patterned area C on a printing-bearing film, and enabling the laser patterned area C to cover the designed laser patterned area a and exceed the designed laser patterned area a from each direction all around; and (3) accurately printing ink on the designed ink printed area b by using an ink-printing manner to form an ink printed area B, wherein the ink fills up concave and convex grains of laser patterns on an overlapped part of the ink printed area B and the semi-finished laser patterned area C, the laser effect of the overlapped part vanishes, the semi-finished laser patterned area is shortened to a laser patterned area A and then the printing-bearing film capable of being accurately sleeved with the laser patterned area A and the ink printed area B is obtained. The process for forming the local laser patterns byaccurately positioning can enable the ink printed area to be accurately sleeved with the laser patterned area.

Owner:SHANTOU KINGSPACK TECH

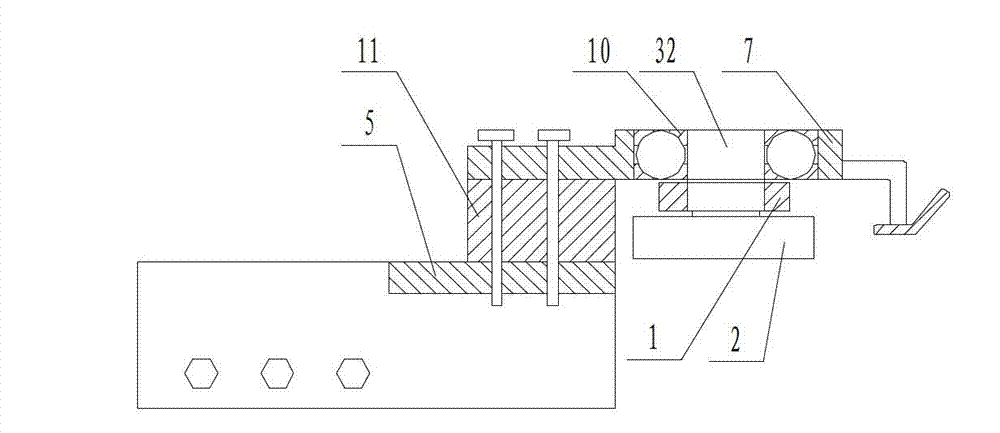

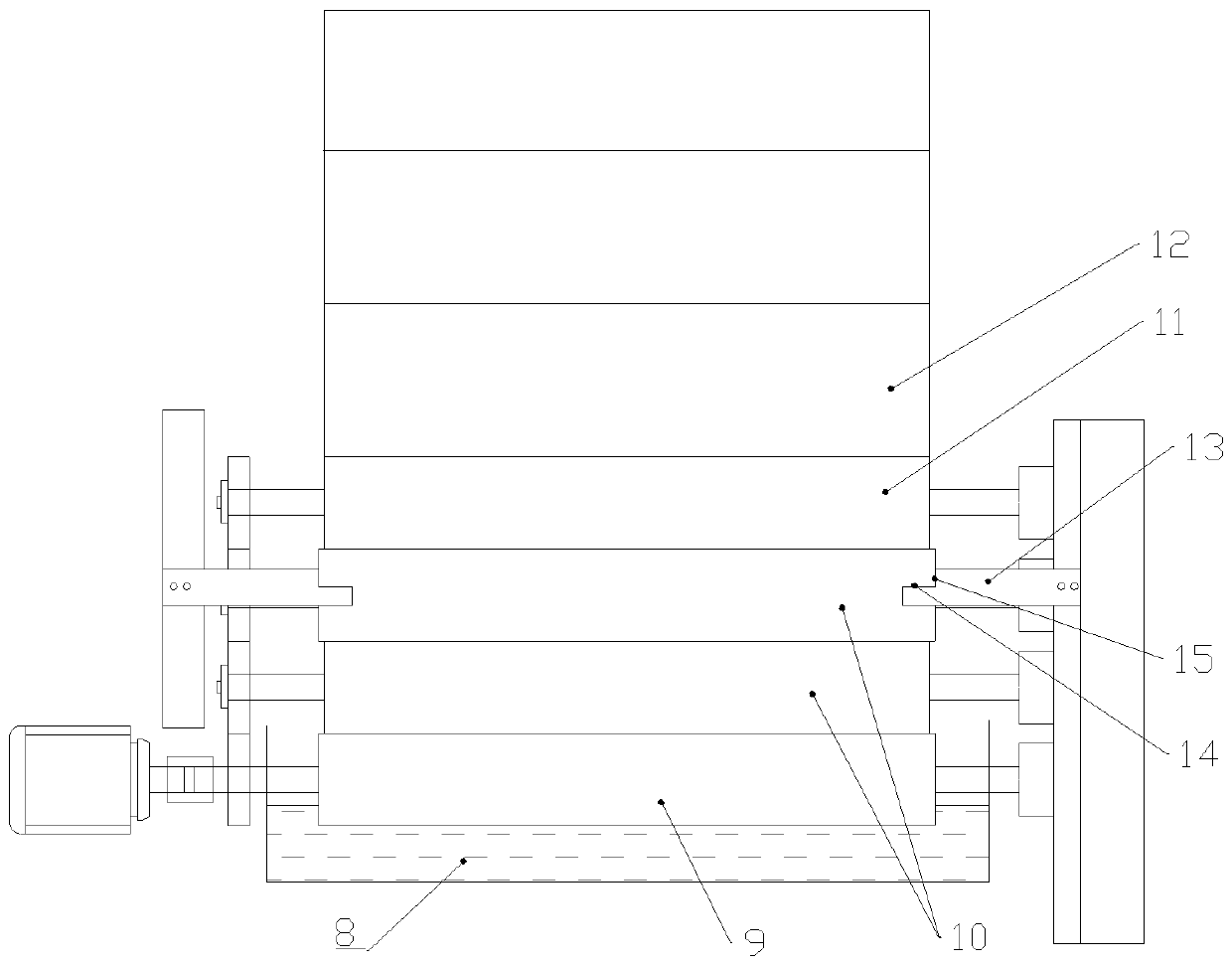

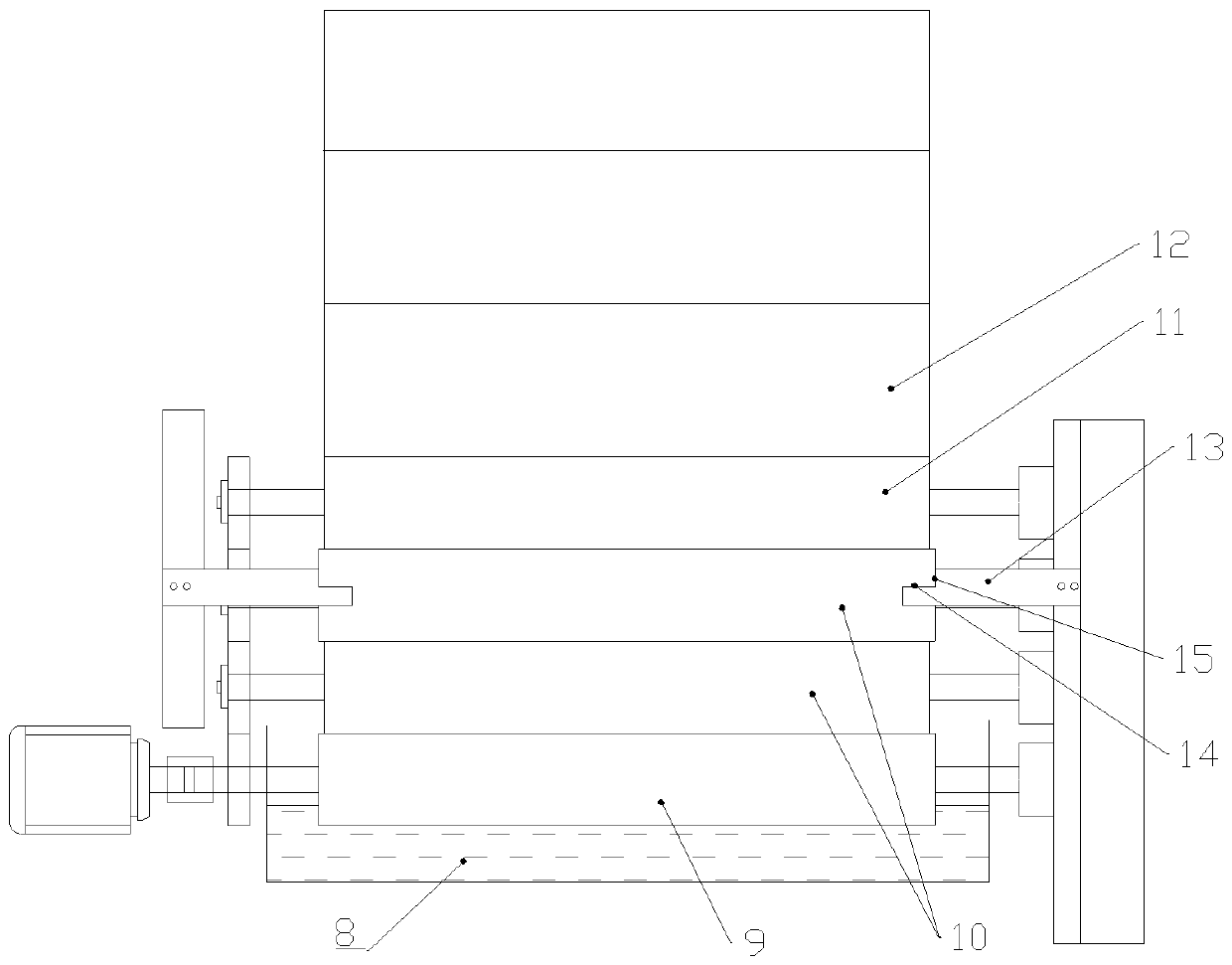

Tipping paper gravure online fine gold stamping device and gold stamping process

InactiveCN111806077AImprove thickness uniformityFine hot stamping effectDecorative surface effectsRotary pressesWinding machineStamping process

The invention provides a tipping paper gravure online fine gold stamping device and gold stamping process. The device is mounted between a final-stage printing color set of a gravure press and a glazing machine unit. The device comprises a gravure cold stamping machine rack. Paper guide rollers are mounted on the two sides of the lower portion of the gravure cold stamping machine rack. A glue tank, a cold stamping plate roller set, a pre-curing UV lamp, a cold stamping press roller set, a curing UV lamp set, a winding machine and an unwinding machine are mounted in the gravure cold stamping machine rack from bottom to top in sequence. The winding machine and the unwinding machine are used in cooperation to complete winding and unwinding of a cold stamping film. The cold stamping plate roller set coats cold stamping glue to tipping paper. The cold stamping press roller set laminates the tipping paper with the cold stamping film to complete transfer of the gold stamping effect without aheating device. Energy consumption is reduced, and the overprinting effect is accurate.

Owner:QINGDAO JUSTO PACKAGING

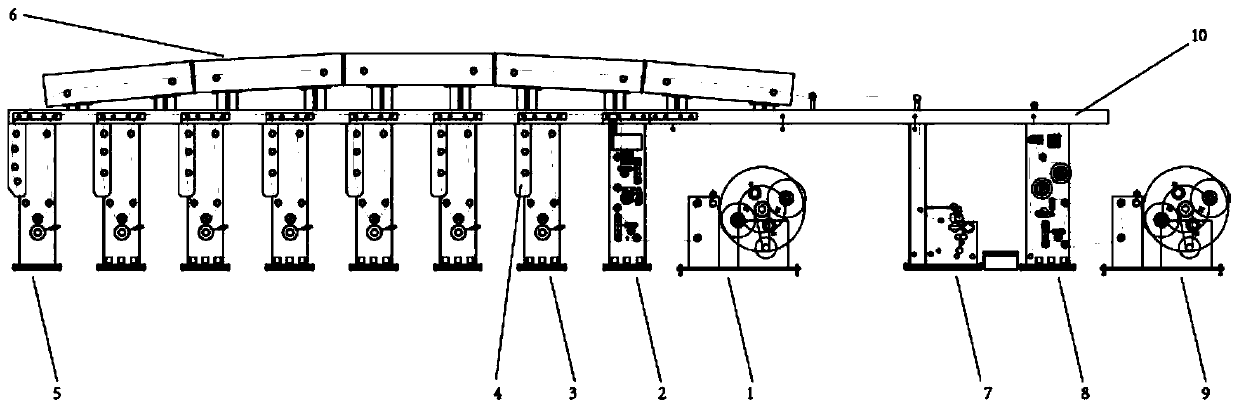

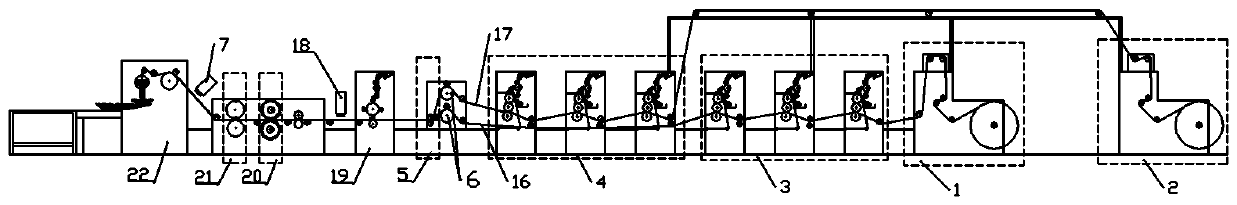

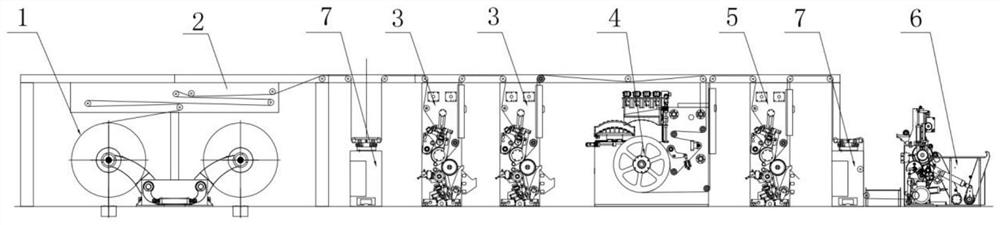

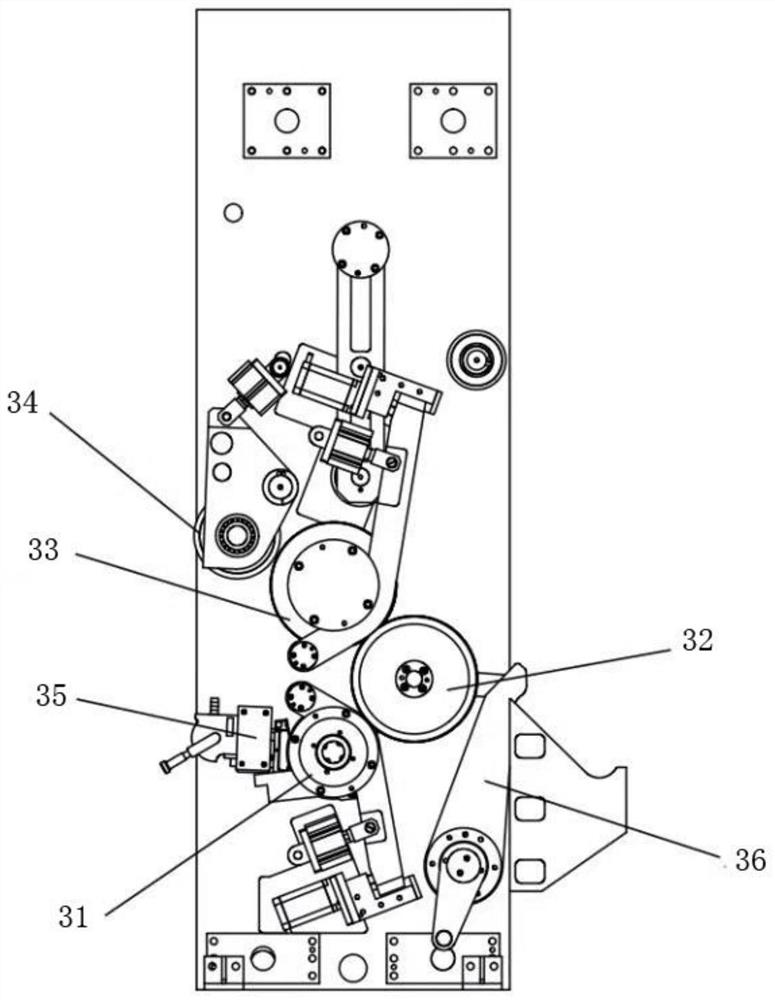

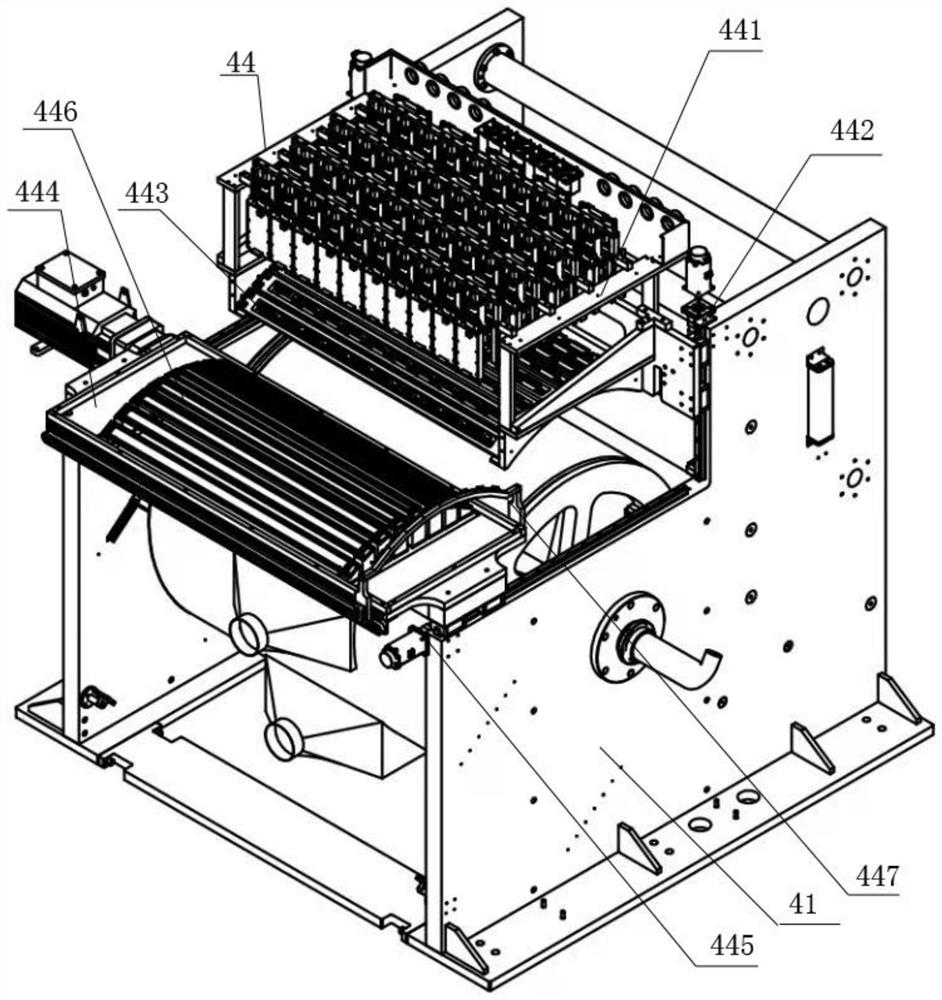

Multifunctional micro-nano structure color film production device and work method

The invention discloses a multifunctional micro-nano structure color film production device and a work method. The multifunctional micro-nano structure color film production device comprises an unreeling device which unreels a plastic film, a drawing device which draws the plastic film so as to convey the plastic film forward, an intaglio printing device which performs image-text printing on the plastic film, a first drying oven heating system which performs printing ink drying on the plastic film, a scraper coating device which coats the surface of the plastic film with a resin layer, a second drying oven heating system which performs resin layer drying on the plastic film, a micro-nano structure impressing device which performs micro-nano structure image impressing, a cooling device which performs cooling on the plastic film, a coiling device which coils the plastic film and a bridge crossing guide roller which guides feeding of the film, wherein the intaglio printing device and themicro-nano structure impressing device realize printing image-text and micro-nano structure image-text overprinting. The multifunctional micro-nano structure color film production device can realize production of a micro-nano structure color film, and can does not use printing ink for printing at all or only use a small amount of environmentally-friendly ink for the printing.

Owner:浙江上峰包装新材料有限公司

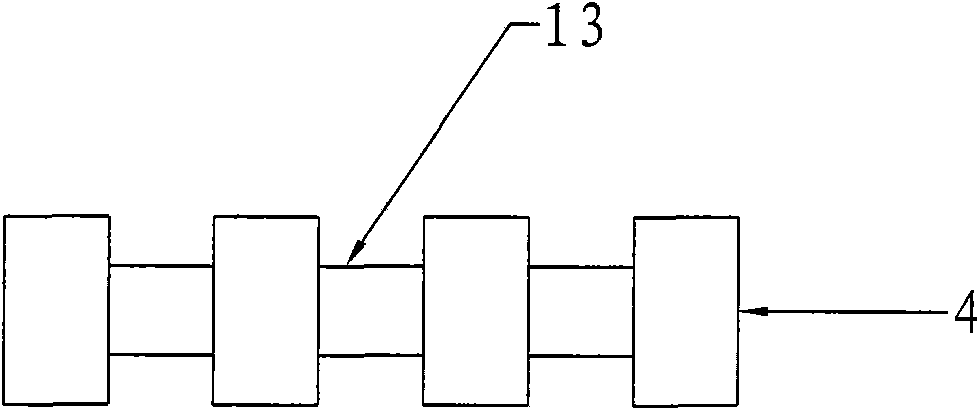

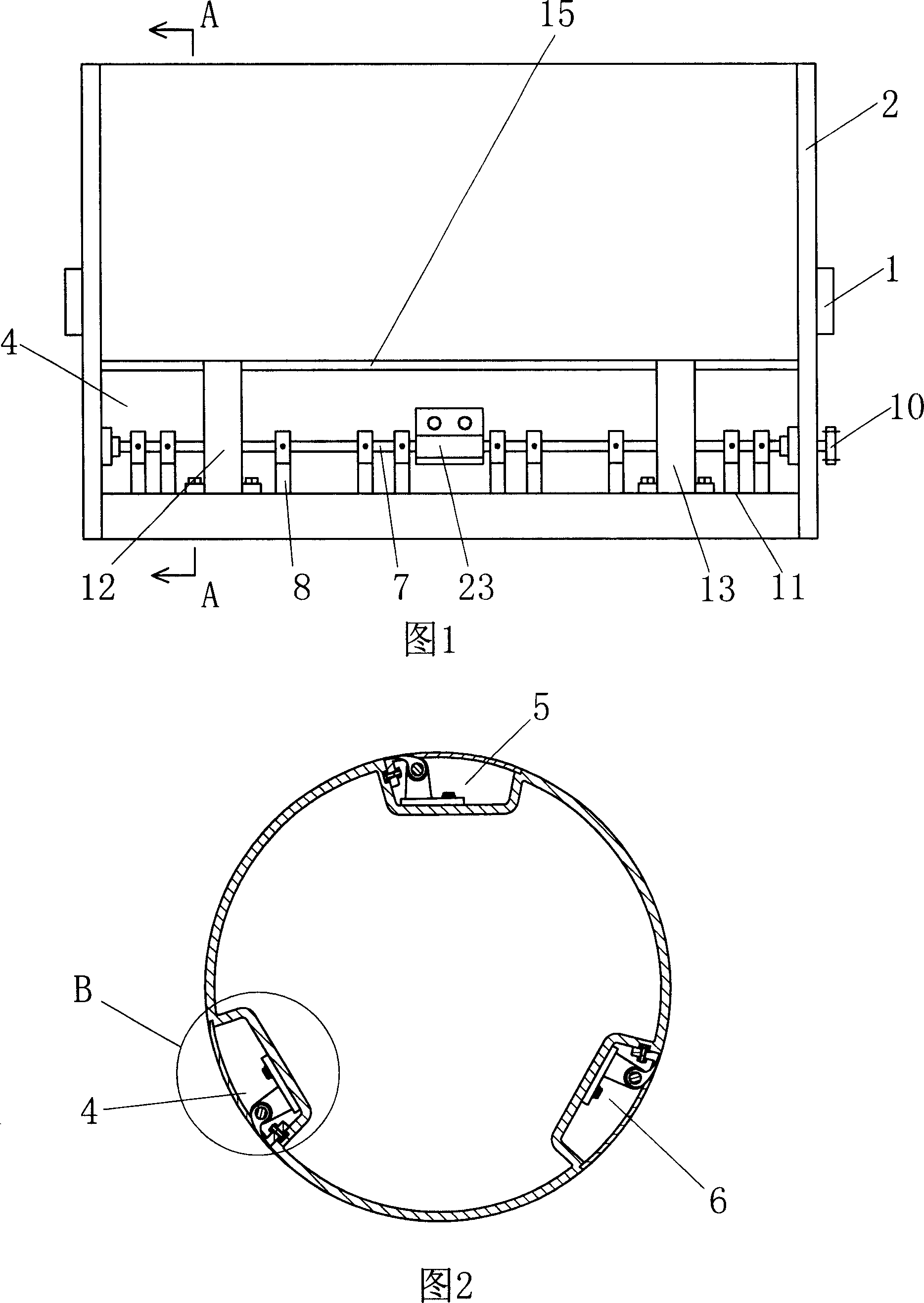

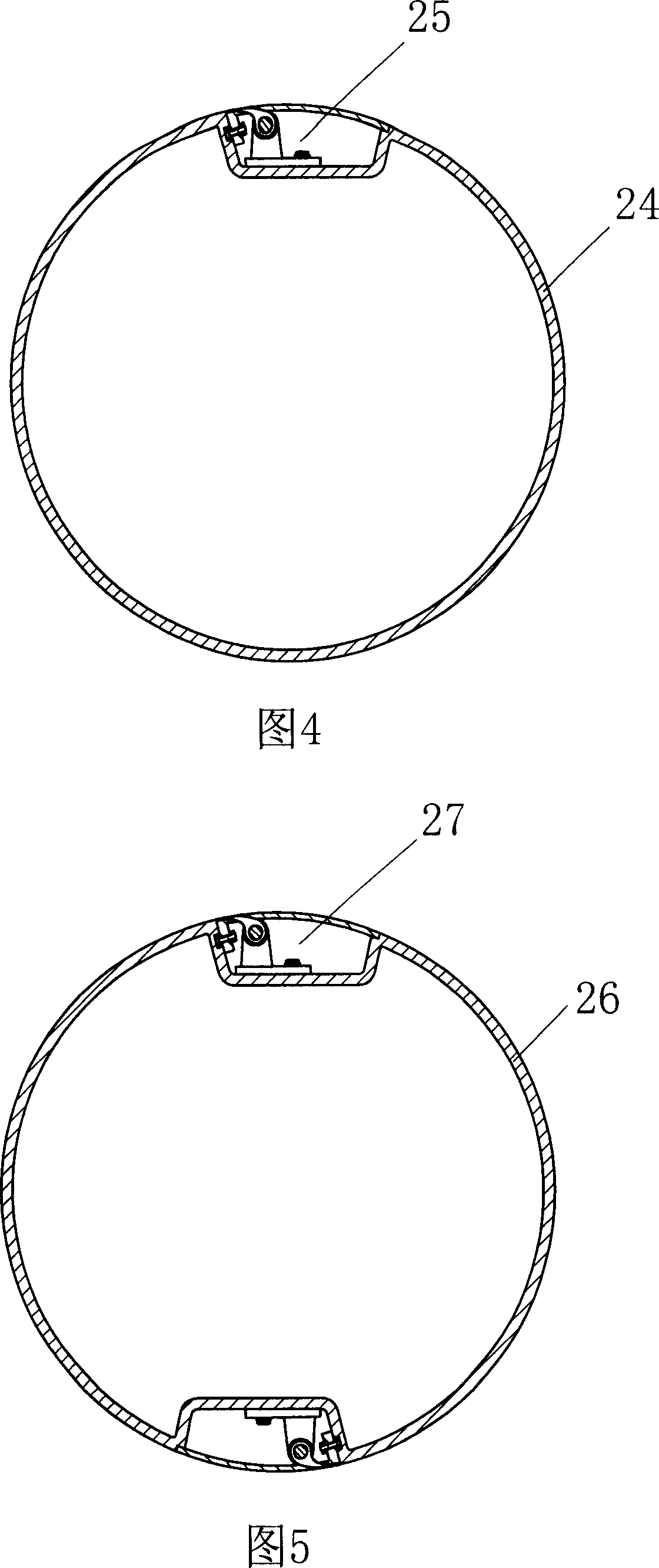

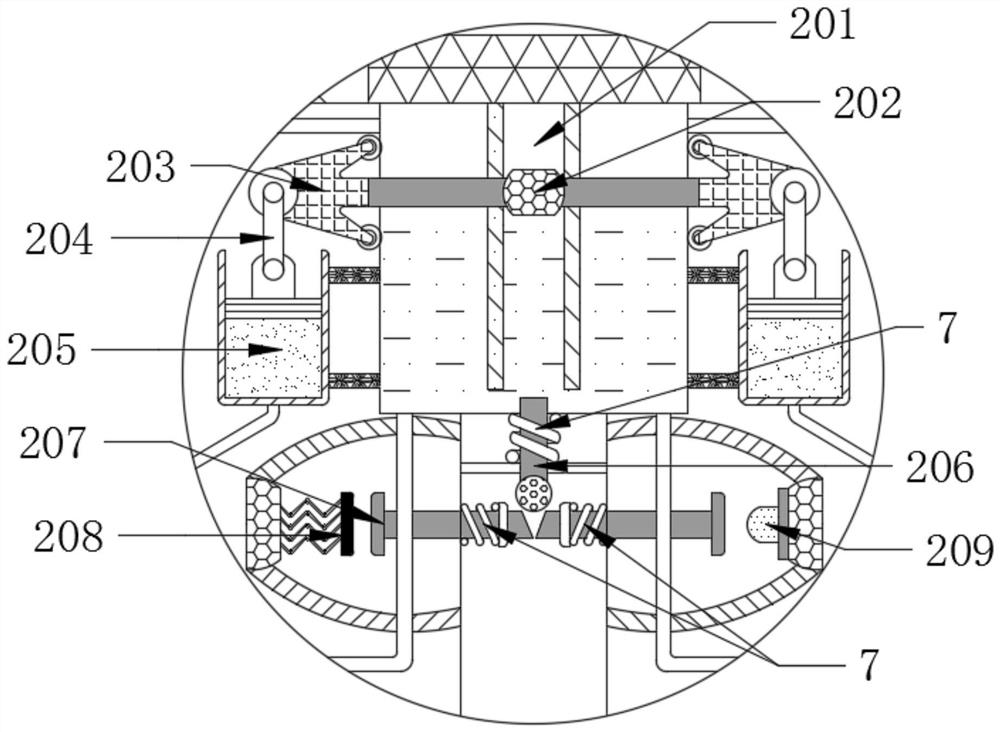

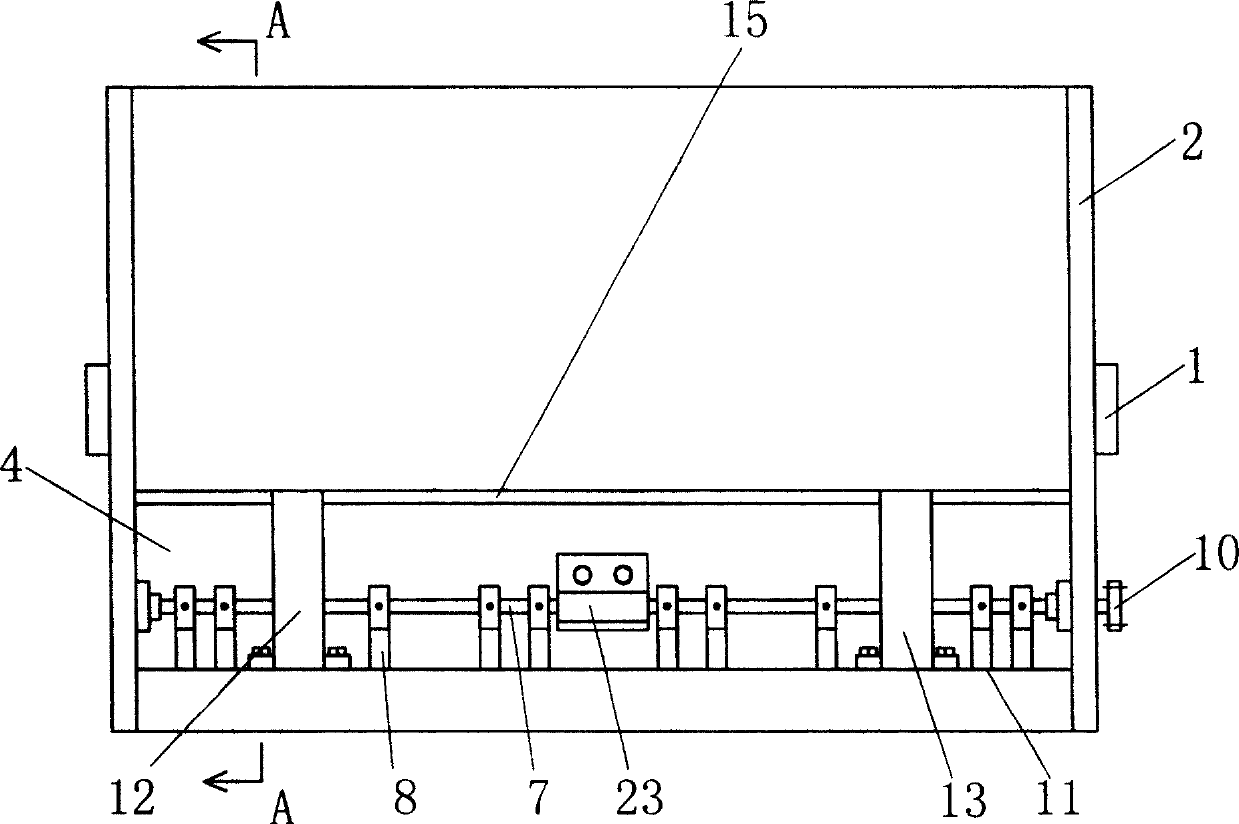

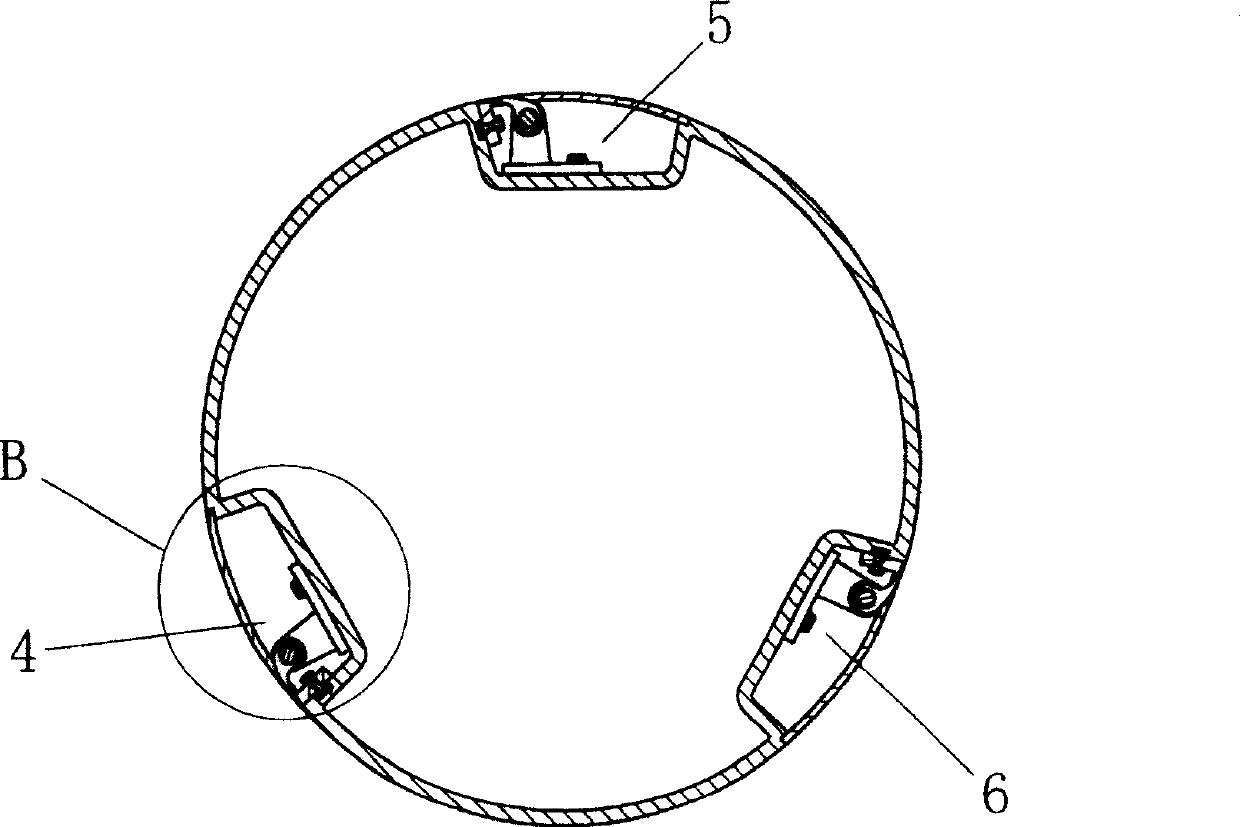

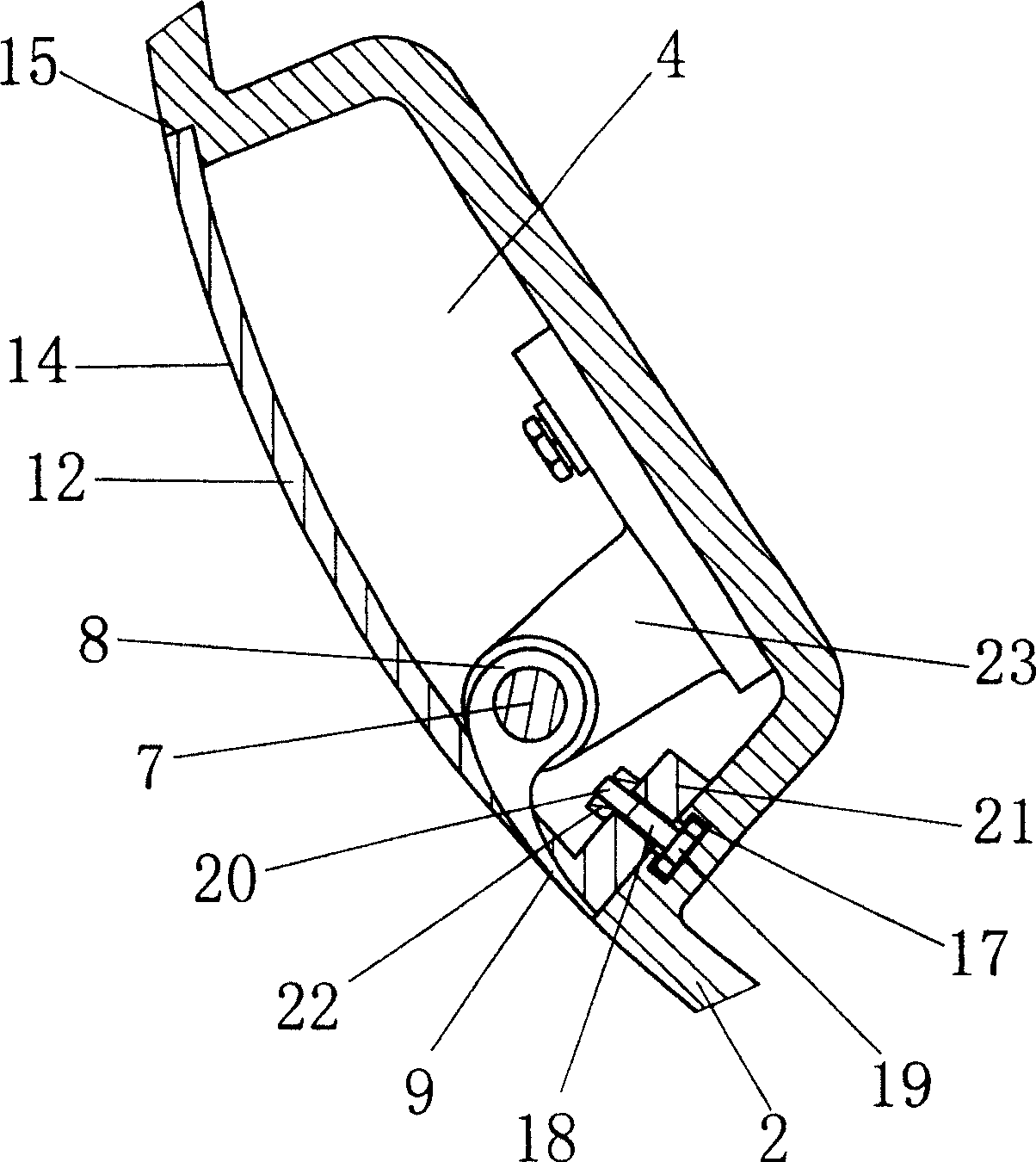

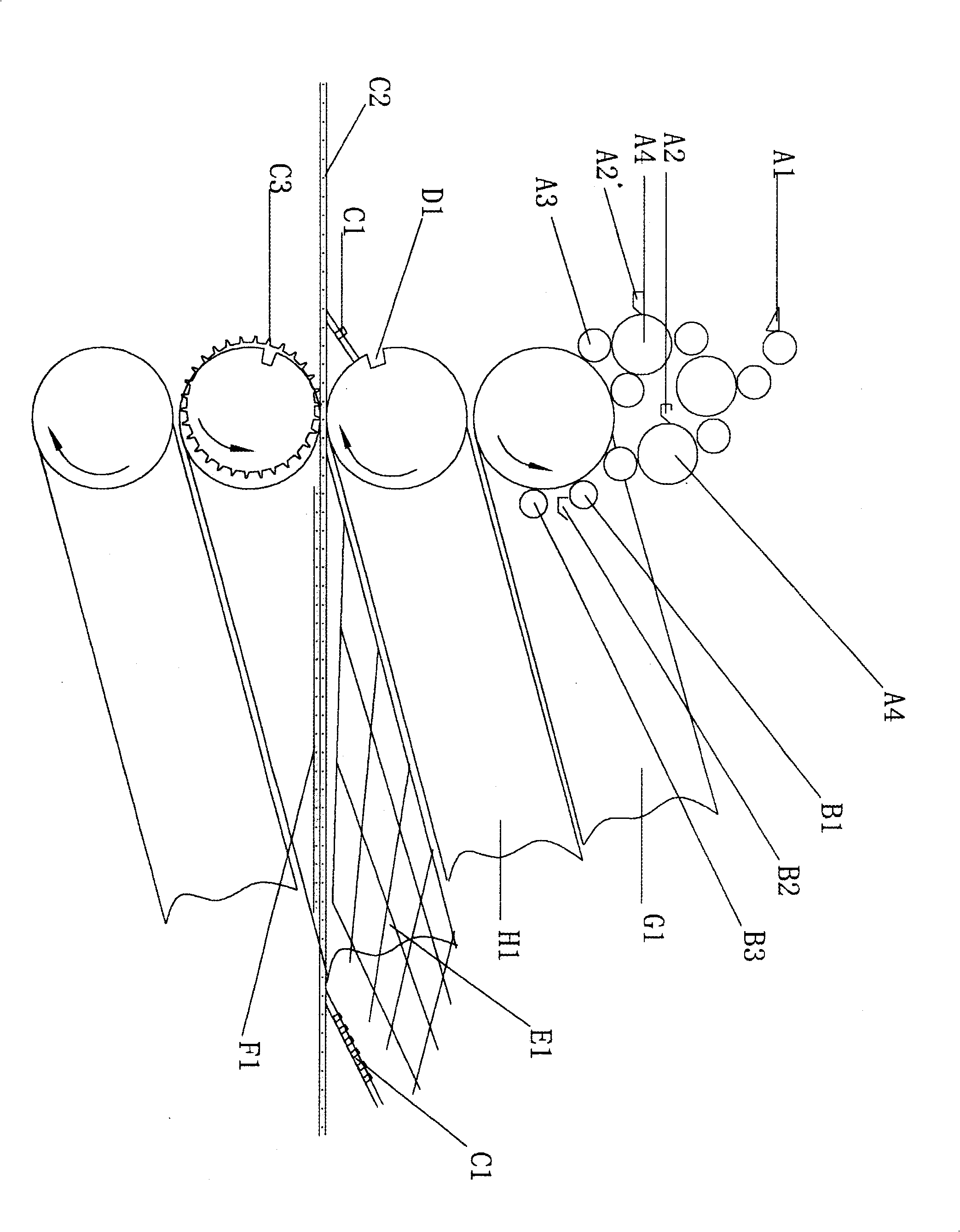

Big stamping roller for planetary type flexible printer

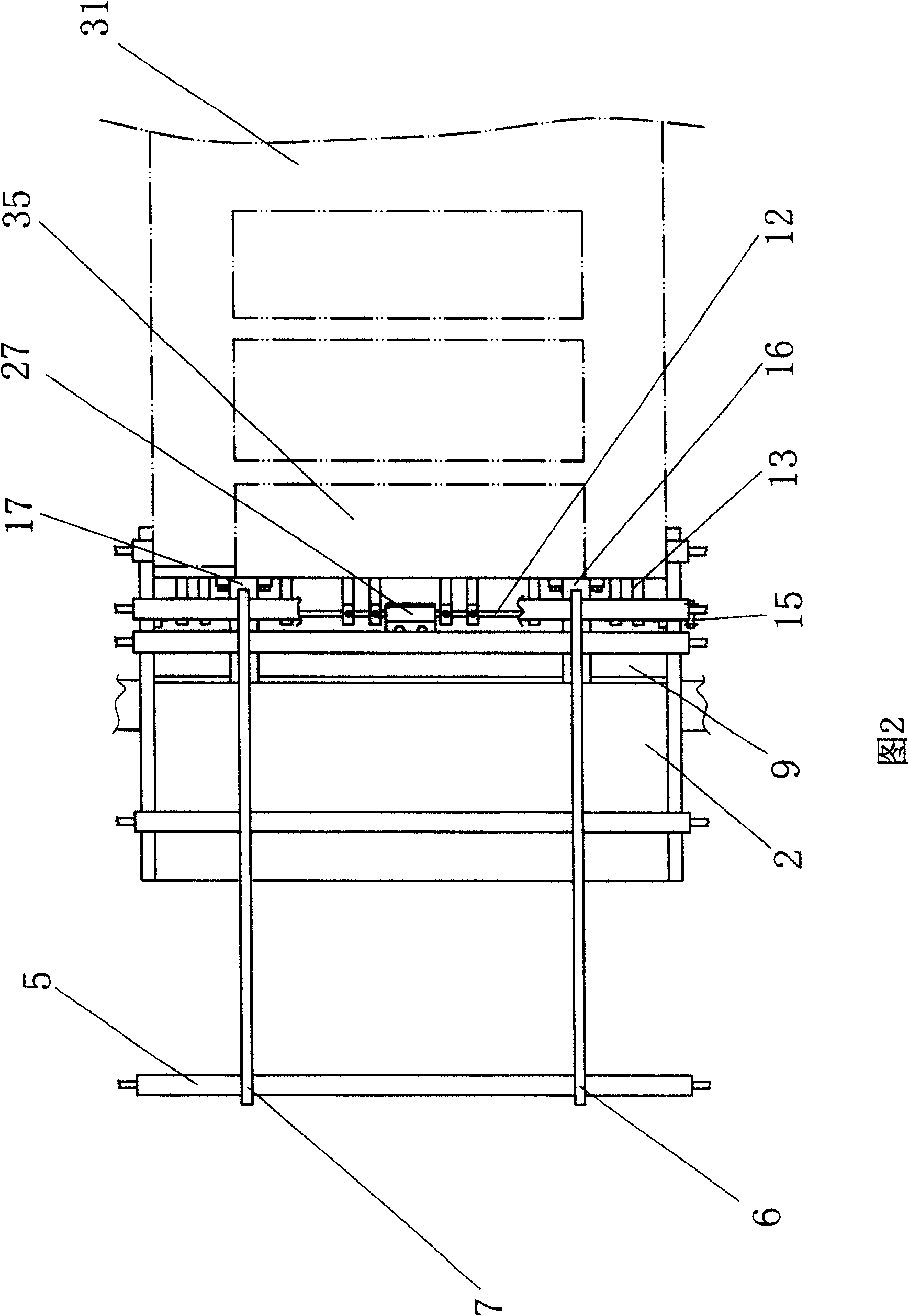

InactiveCN1970293AAccurate overprintImprove printing qualityRotary pressesPrinting press partsMechanical engineeringSatellite

It relates to the compressing big roller for the satellite soft printing machine. It solves the inaccurate chromatograph and overall figure deviation and unable to introduce convex clamp to improve the printing quality. It features in the round cylinder with central axle, with the round arc surface of the round cylinder having more than one grooves distributed along the shaft, a clamping shaft along the axle inside each groove to coordinate with the rotation, each claws having the end matched with the mouth of the groove, drive end of the clamp shaft sticking out of one side of the round cylinder, over one clamping bridge plates supporting the clamping belt along the circumference at each groove notch, top of the clamping bridge plate surface sharing the same curve of the round cylinder.

Owner:SHANTOU OLGER PACKING MACHINERY

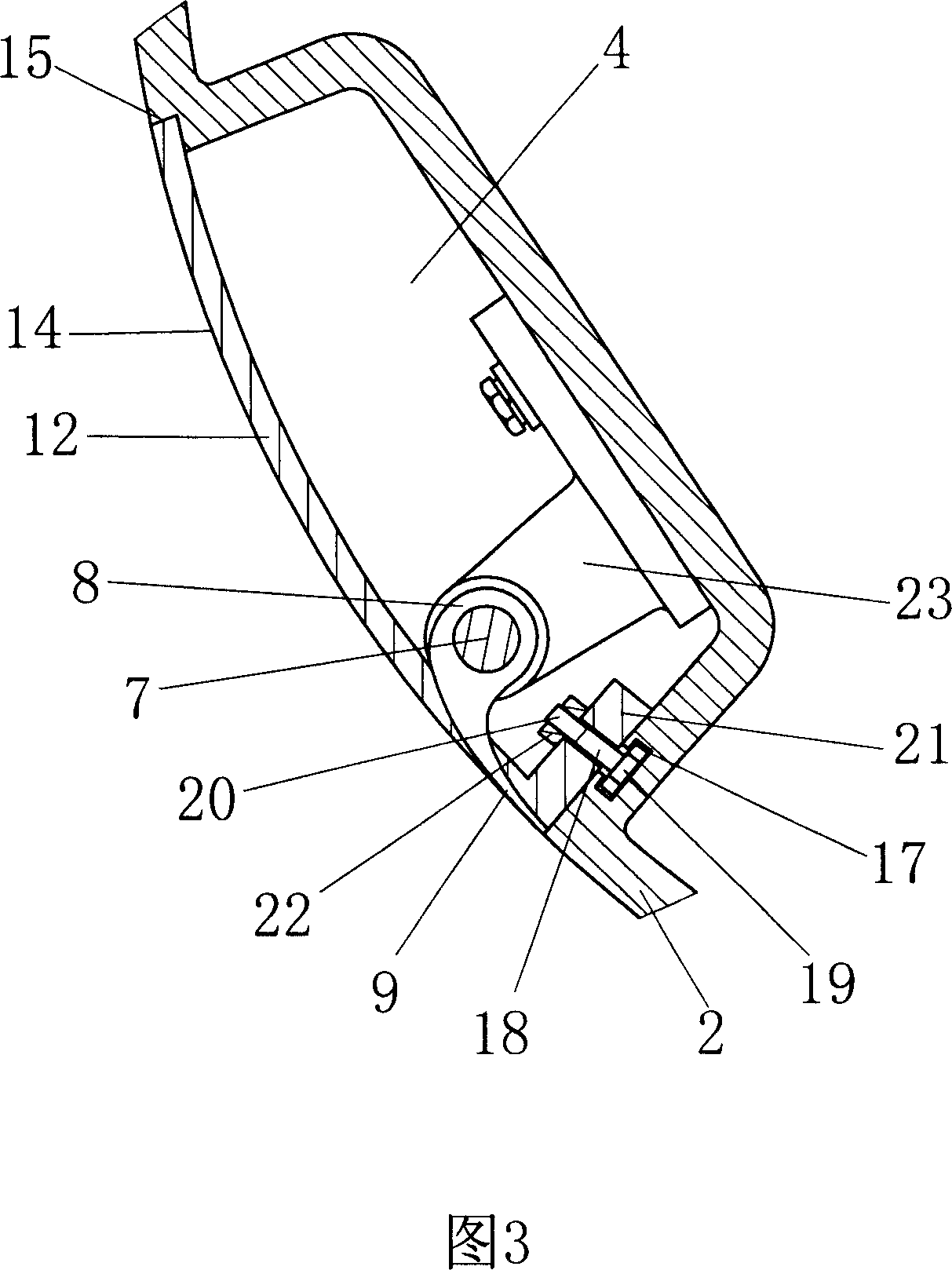

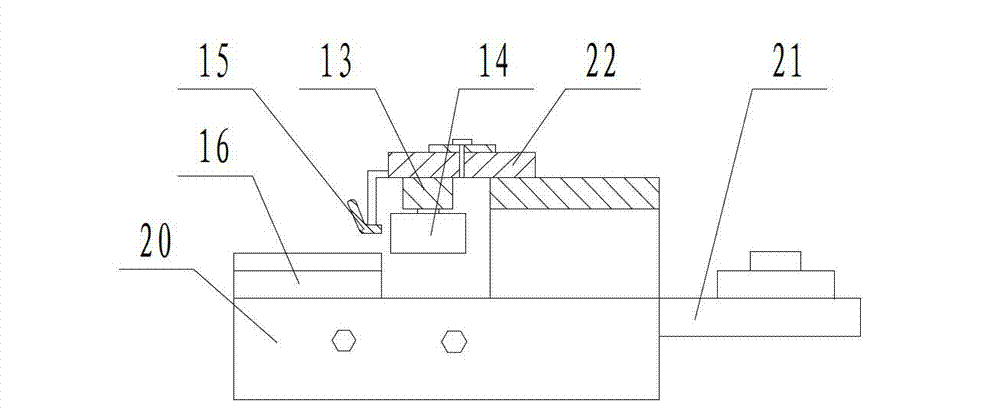

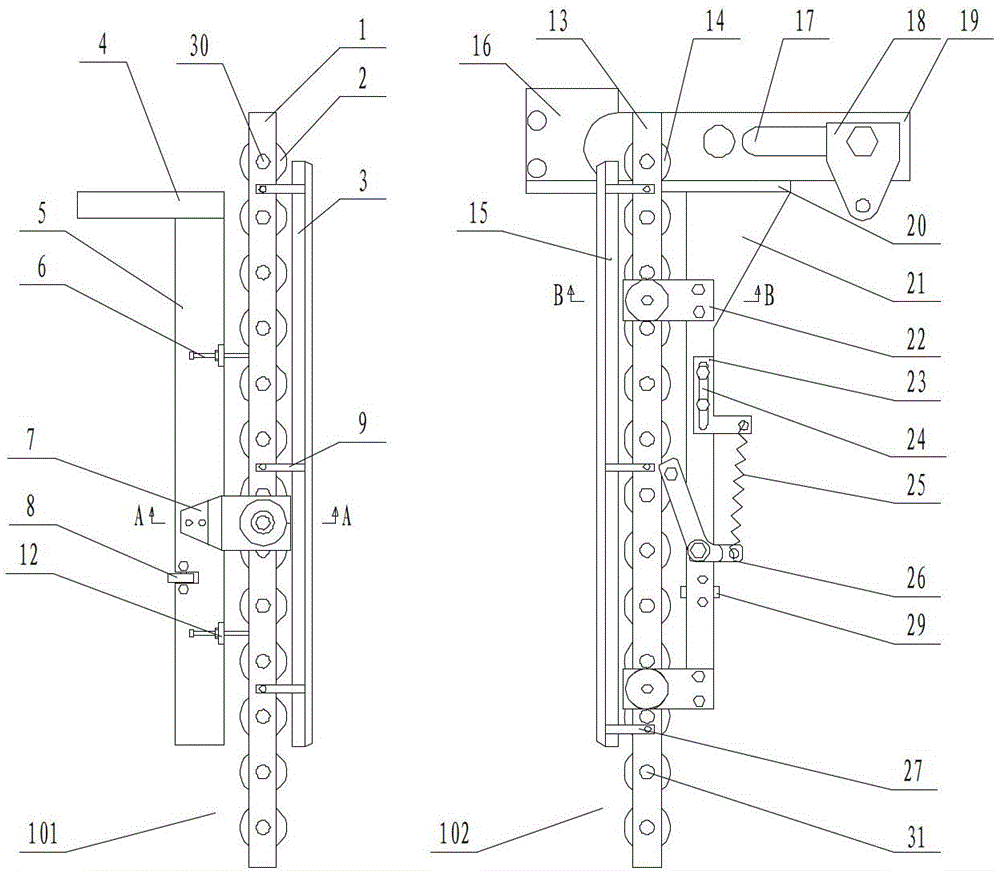

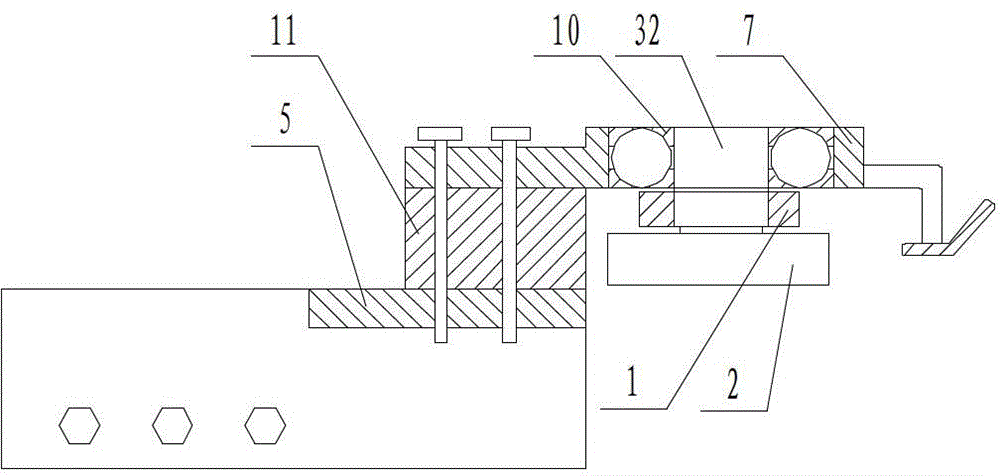

Volute iron printing side mark device

ActiveCN102922872AStable performanceAccurate overprintRotary pressesMechanical engineeringRaw material

The invention relates to a volute iron printing side mark device of an iron printing machine, which belongs to the field of iron printing equipment, and is mainly used for solving the problems of low utilization ratio of raw materials and increased labor cost because the conventional iron-printing equipment of the prior art cannot normally and accurately print volute irons. The volute iron printing side mark device is realized through the following technical scheme that the volute iron printing side mark device comprises a leaning body and a side mark, wherein the leaning body comprises a main support rod A, a lateral support A, a longitudinal support A and a space regulation device, and a bearing pack A is installed on the main support rod A, is connected with a pressing plate of the leaning body through a connecting rod A and is connected with the longitudinal support A through a connecting part A; and the side mark comprises a main support rod B, a lateral support B, a longitudinal support B and a pressing regulation device, wherein a bearing pack B is fixedly installed on the main support rod B, is connected with the pressing plate of the side mark through a connecting rod B and is connected with the longitudinal support B through a connecting part B. The volute iron printing side mark device is mainly used in the volute iron printing equipment.

Owner:SHANDONG HUANQIU TINPLATE CAN MAKING

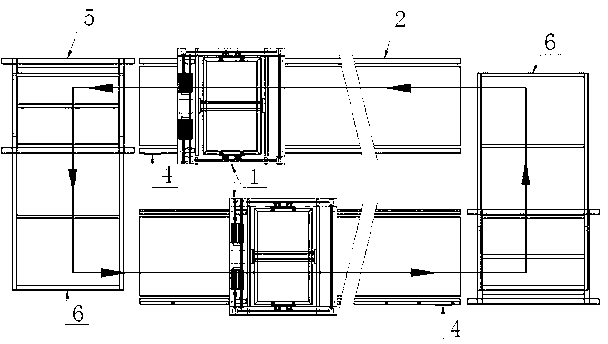

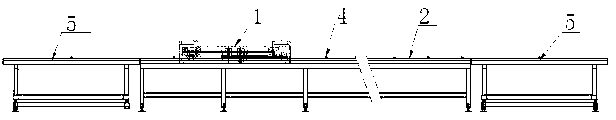

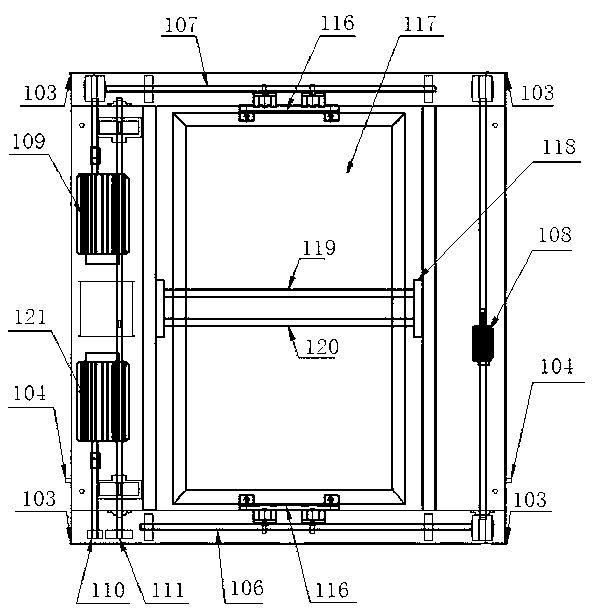

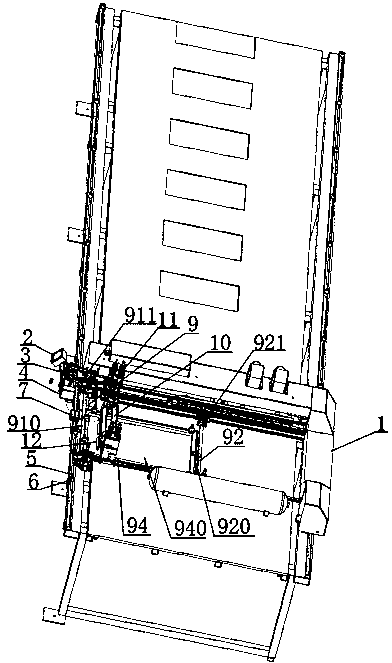

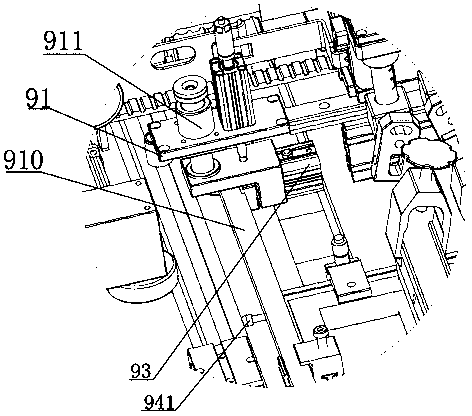

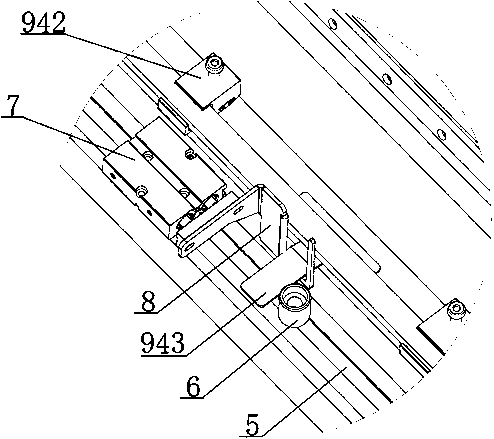

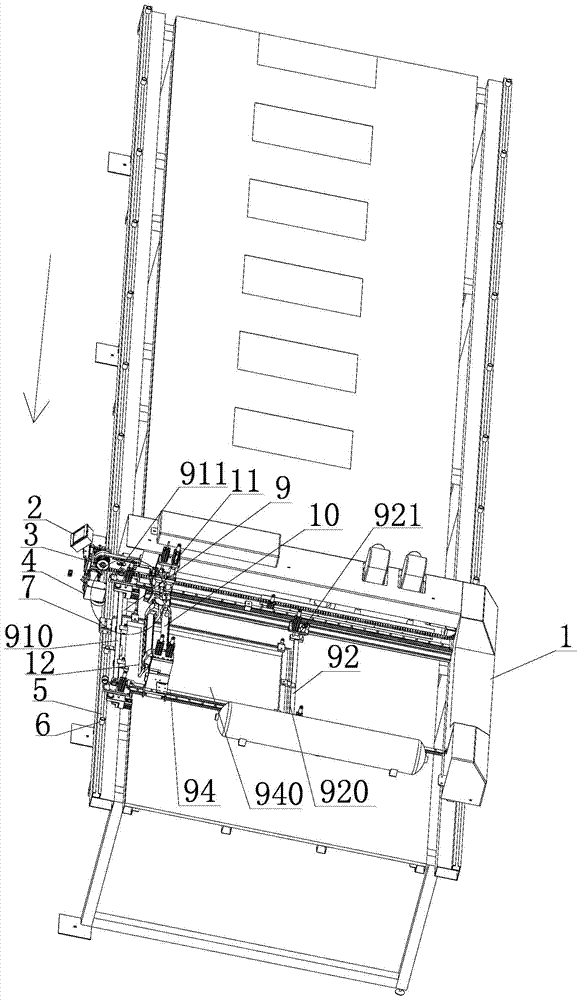

Screen frame positioning equipment and screen frame positioning method

InactiveCN104354456APrecise positioningAccurate overprintScreen printersPositioning equipmentEngineering

The invention provides screen frame positioning equipment and a screen frame positioning method. The screen frame positioning equipment comprises a base, a worktable, a conveying device, a driving device, guide rails, positioning pillars, a dual-rod left-and-right positioning cylinder, a positioning push block, an artificial screen frame positioning device, a cross beam, a cross beam cylinder and a scraper assembly. The screen frame positioning equipment and the screen frame positioning method have the benefits that the mounting and dismounting are convenient, and a screen frame does not need to be changed; the safety is achieved, the manual positioning can be simulated, and the positioning is accurate; after power failure, the manual operation can be automatically converted; panels are called out, the overprinting is accurate, and the efficiency is high.

Owner:宋其斌

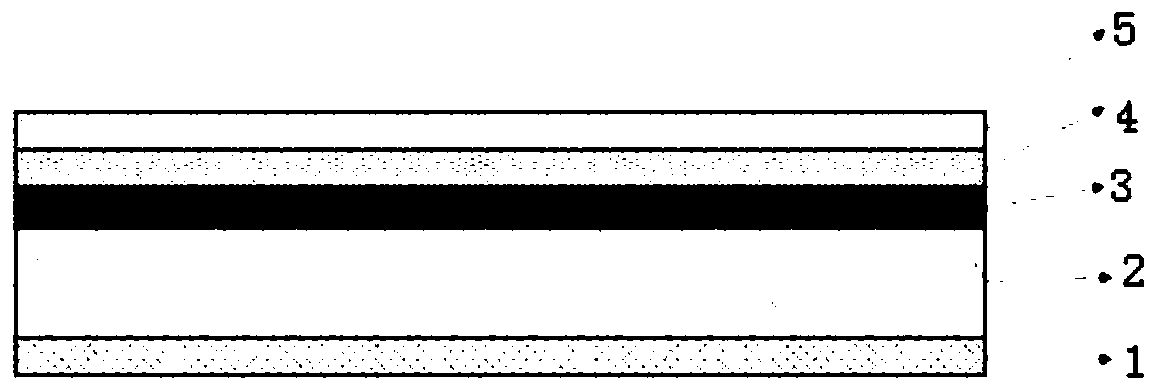

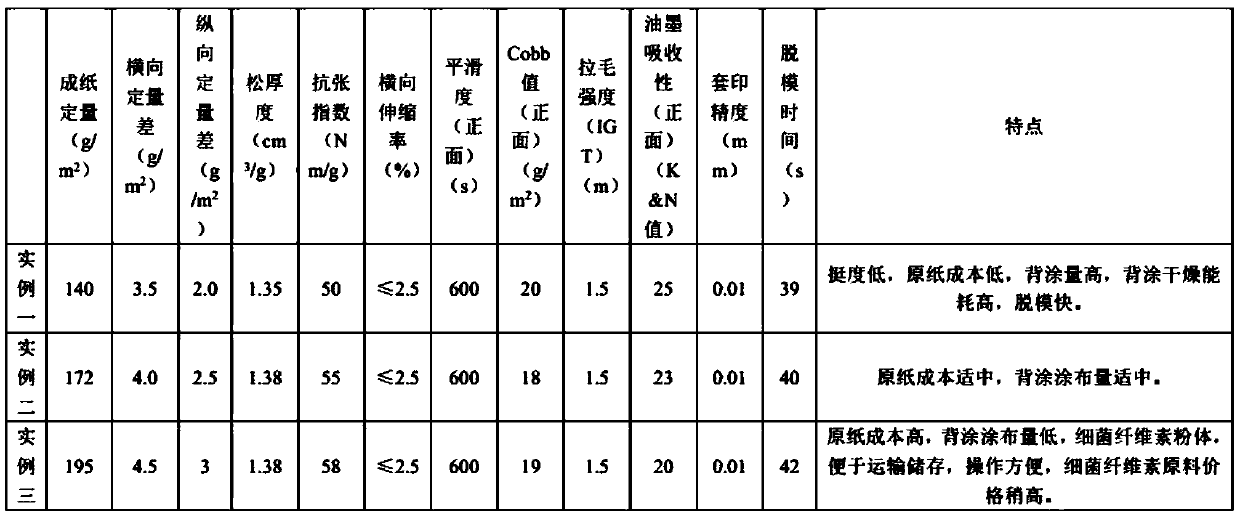

Water transfer paper and preparation method thereof

ActiveCN111472205AAccurate overprintGood printabilitySpecial paperPaper/cardboardSolid contentMaterials science

The invention discloses water transfer paper and a preparation method thereof. The water transfer paper comprises a back coating layer, base paper, a prime coating layer, a water-soluble coating layerand a waterproof coating layer which are distributed layer by layer. Coating of the back coating layer comprises 8-15 parts by weight of a bacterial cellulose wet film; 0.08-0.15 part by weight of hydrogen peroxide, 0.1-0.2 part by weight of sodium hydroxide and 30-40 parts by weight of water, and is prepared by shearing and dispersing at 70-90 DEG C in a high-speed dispersion machine for 30-45 min, adding 40-60 parts by weight of water for dilution, and then sieving the mixture to obtain the back coating, with the solid content of the coating being 2-5%. According to the prepared water transfer paper, on the premise that the water permeation speed of the paper is guaranteed, the back face is coated with the bacterial cellulose glue solution, and the water transfer paper which is stable in size, high in demolding speed and excellent in printing and transferring effect is prepared.

Owner:山东金蔡伦纸业有限公司

Manufacturing method of high-precision intaglio roller

InactiveCN112848642AMeet the production needs of products with high precision requirementsMeet production needsPlate printingPrinting roller shellsMicrometerCopper

The invention discloses a manufacturing method of a high-precision intaglio roller. The manufacturing method comprises the following steps that a steel roller base body is manufactured firstly, then the steel roller base body is plated with copper, wherein the thickness of the plated copper ranges from 200 micrometers to 300 micrometers, and the surface hardness of the plated copper ranges from 195 HV to 215 HV; secondly, the surface of the copper surface is treated, the eccentricity of a roller body needs to be measured firstly, after the eccentricity is confirmed to be 0-30 microns, the copper surface is turned and ground, the copper surface with the thickness being 20 microns is reserved after turning and grinding are performed, the copper surface is subjected to grinding machining of 800-mesh coarse grinding and 2500-mesh fine grinding, the roughness Ra after grinding is 0.25-0.35 microns, then the copper surface is polished, and the roughness Ra of the polished copper surface is 0.03-0.04 microns; and meanwhile, an image file can be made, and finally the roller surface is engraved and chromeplated. The problems that a traditional printing roller machining method is not high in machining precision, turning and grinding lines or grinding lines are prone to being generated, and consequently products are unqualified are solved.

Owner:HUANGSHAN JINGGONG GRAVURE CYLINDER

Device capable of automatically feeding ink and giving alarm when ink is empty and preventing inaccurate overprinting caused by static electricity

InactiveCN113276547AAvoid wastingAchieve a beautiful effectElectrostatic chargesPrinting press partsTextile printerStatic electricity

The invention relates to the technical field of film printing, and discloses a device capable of automatically feeding ink and giving an alarm when ink is empty and preventing inaccurate overprinting caused by static electricity. The device comprises a mounting frame, an ink tank is fixedly connected to the middle of the inner side of the top of the mounting frame, a supporting rod is fixedly connected to the bottom of the ink tank, and an ink roller is rotatably connected to the bottom of the supporting rod; and a fixing seat is fixedly connected to the outer side of the middle of the supporting rod, and humidifiers are fixedly connected to the two sides of the interior of the mounting frame. After printing for a period of time, the liquid level in the ink box is lowered, a floating rod drives a rotating rod to rotate, a supporting column extrudes an air bag, the air bag is pressed to exhaust air into the ink box through an air pipe, ink in the ink box is conveyed into the ink box under the influence of air pressure, and the automatic ink feeding effect is achieved; and meanwhile, when the ink in the ink tank is used up, a floating column slides downwards to the bottom of the ink tank along the inner wall of a sliding groove to extrude a sliding rod to move, push rods drive the sliding rod to extrude a buzzer, and at the moment, the buzzer starts to give a sound alarm to remind a worker to add ink.

Owner:张雪玲

Double-printing equipment for duplex invoice

The invention relates to the field of printing, in particular to double-printing equipment for a duplex invoice. Paper in a paper rolling part A is printed in a printing group C to form a first invoice; paper in a paper rolling part B is printed in a printing group D to form a second invoice; tension monitoring is performed on the first invoice and the second invoice before the first invoice and the second invoice enter a combining part, and the tension of the first invoice and the tension of the second invoice are guaranteed to be consistent during combination, so that the content of the first invoice and the content of the second invoice are completely overlapped and registered. Invoice number printing and locking are performed on the two combined invoices, the invoice subjected to double printing is cut into two independent single invoices, and finally, the two single invoices are folded simultaneously. Thus, double printing of the two invoices is completed simultaneously, and the printing efficiency is 2-3 times higher than that of traditional printing equipment.

Owner:CHONGQING FARSIGHT PRINTING

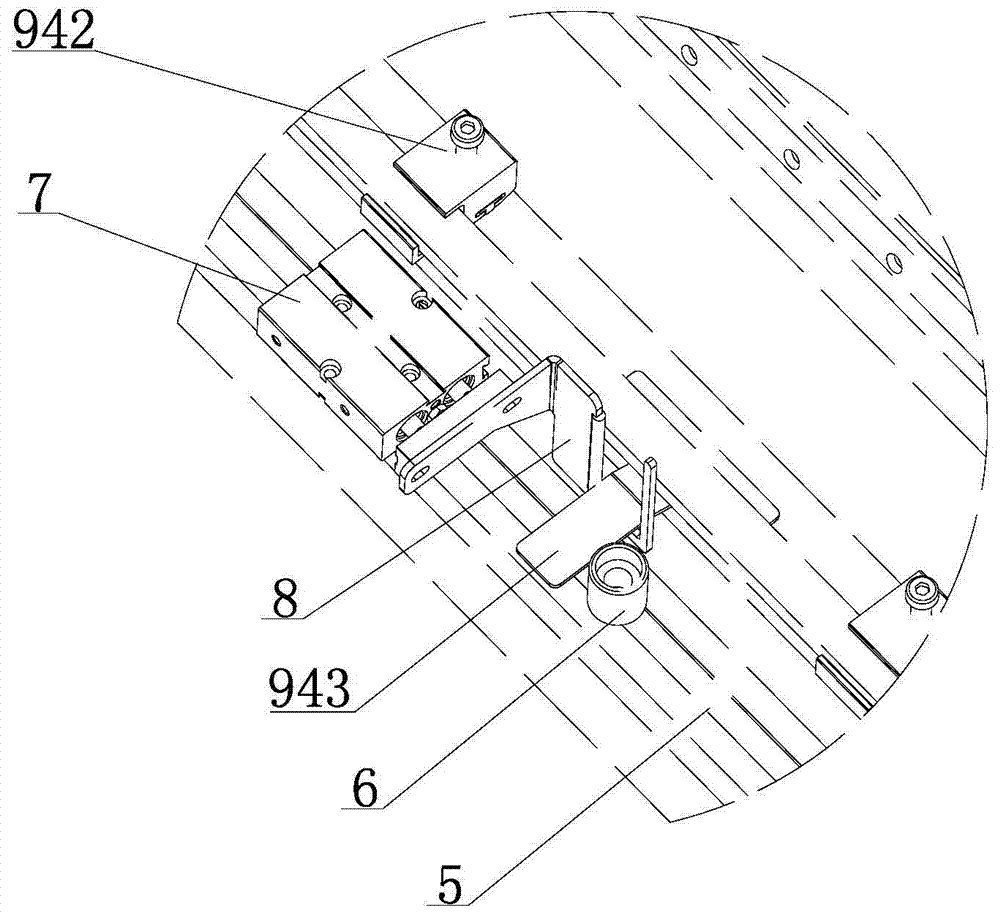

Screen frame positioning equipment and screen frame positioning method

InactiveCN104842637AEasy to install and disassemblePrecise positioningScreen printersEngineeringPositioning equipment

The invention provides screen frame positioning equipment and a screen frame positioning method. The screen frame positioning equipment comprises a base, a worktable, a conveying device, a driving device, guide rails, positioning pillars, a dual-rod left-and-right positioning cylinder, a positioning push block, an artificial screen frame positioning device, a cross beam, a cross beam cylinder and a scraper assembly. The screen frame positioning equipment and the screen frame positioning method have the benefits that the mounting and dismounting are convenient, and a screen frame does not need to be changed; the safety is achieved, the manual positioning can be simulated, and the positioning is accurate; after power failure, the manual operation can be automatically converted; panels are called out, the overprinting is accurate, and the efficiency is high.

Owner:厦门福源智印科技有限公司

Print medium, printing device, and printing method for printing device

InactiveUS10183501B2Simple configurationAccurate overprintStampsTypewritersComputer engineeringBackground color

A print medium, on which individual labeling information made up of one or more labeling elements that are selectively shown, of common labeling information made up of a plurality of labeling elements, is formed by a printing device, wherein the common labeling information is printed in advance and a background color of an area where at least a plurality of labeling elements is printed is a print color that is printable by the printing device, is disclosed.

Owner:SEIKO EPSON CORP

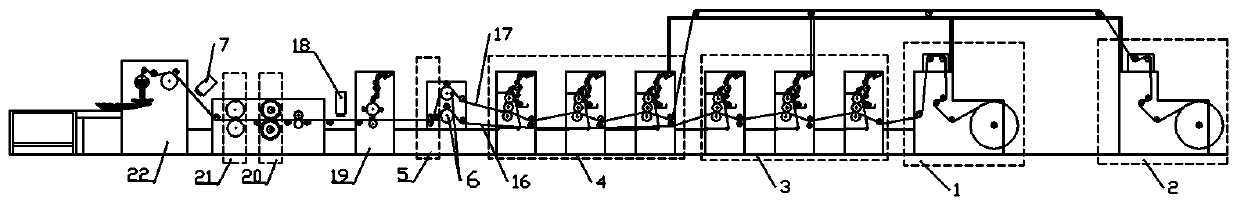

Composite printing machine

PendingCN112829468AImprove stabilityGood stability, good printing accuracyOther printing apparatusColor printingDigital printing

The invention belongs to the technical field of printing, and particularly relates to a composite printing machine. The machine comprises an unwinding unit, a base material receiving unit, a unit printing mechanism, a digital printing mechanism, a unit gloss oil applying mechanism and a winding unit which are sequentially arranged. The digital printing mechanism comprises a jet printing rack, a jet printing roller and a pressing roller are rotatably mounted on the jet printing rack, and a jet printing assembly is arranged at the position, located above the jet printing roller, of the jet printing rack. According to the composite printing machine, spot color printing is conducted on a printing base material through the unit printing mechanism, digital printing is conducted on the printing base material through the digital printing mechanism, the printing base material is wound around the jet printing roller for ink jet printing in the digital printing process, and the printing base material is good in conveying stability and high in printing precision and is matched with the unit printing mechanism to achieve complementary advantages; and wide-width high-speed full-color printing of the printing base material is achieved, the width of the base material can exceed 1 m, and the conveying speed of the base material is high and exceeds 100 m / min.

Owner:潍坊彩鸿数码科技有限公司

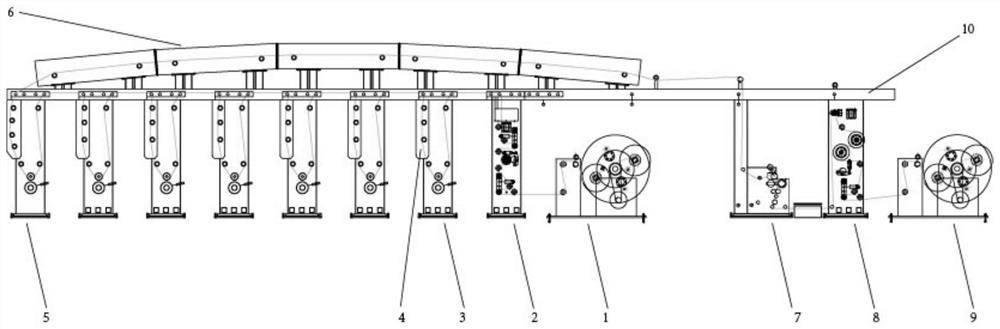

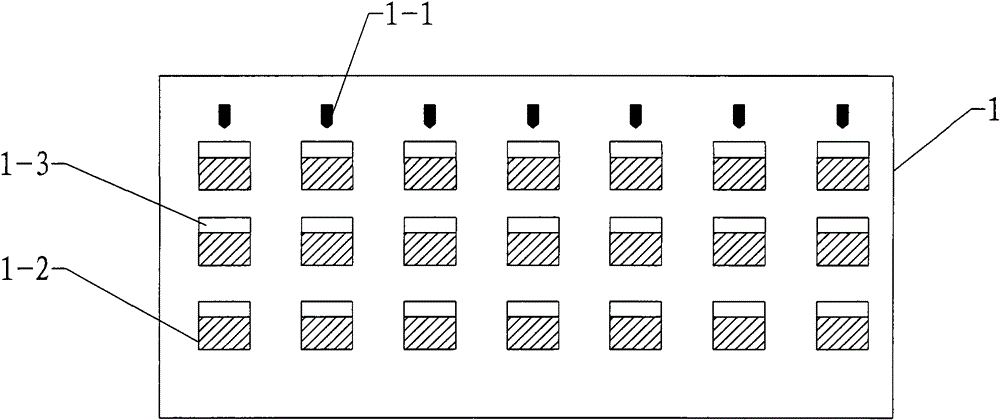

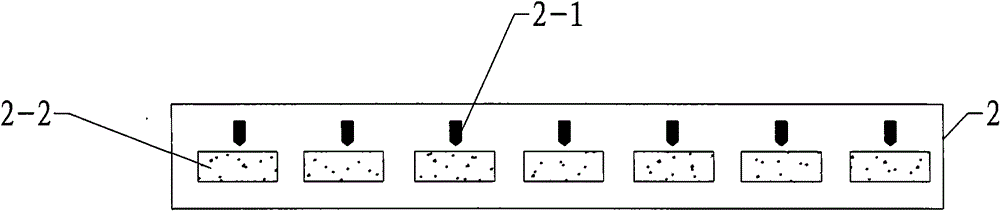

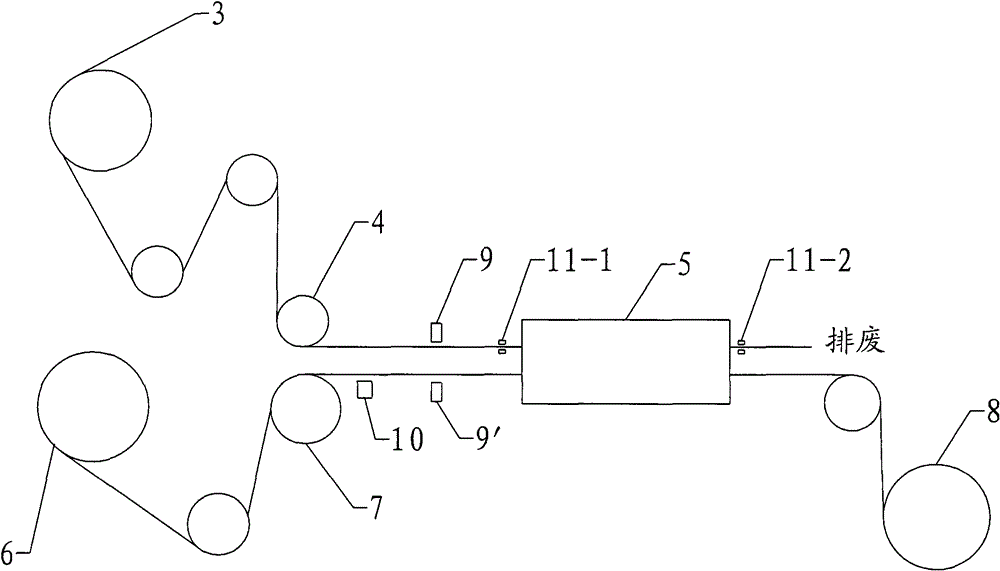

A multifunctional micro-nano structural color thin film production equipment

The invention discloses a multi-functional micro-nano structured color film production equipment and a working method, comprising: an unwinding device for unwinding the plastic film; a traction device for pulling the plastic film forward; a gravure printing device for unwinding the plastic film Graphic printing; the first oven heating system, drying the printing ink on the plastic film; the scraper coating device, coating the resin layer on the surface of the plastic film; the second oven heating system, drying the resin layer on the plastic film; micro-nano structure The embossing device is used to emboss micro-nano structure patterns; the cooling device is used to cool the plastic film; the winding device is used to rewind the plastic film; the bridge guide roller is used to guide the film feeding; The structural embossing device realizes the overprinting of printed graphics and micro-nano structured graphics. The invention can realize the production of the micro-nano structural color thin film, and can print without ink or a very small amount of environmentally friendly ink.

Owner:浙江上峰包装新材料有限公司

Holographic positioning overprinting method between coils

InactiveCN101890846BSimultaneous overprintingAccurate overprintTransfer printingPattern printingEngineeringSecurity printing

The invention discloses a holographic positioning overprinting method between coils and belongs to the field of anti-counterfeiting printing technology. Substantially, a holographic pattern on a drum holographic anti-counterfeiting film is positioned and overprinted on a drum printing stock; and the method is characterized in that: 1) each specific pattern or each group of specific patterns on the drum holographic anti-counterfeiting film and the drum printing stock have an axial positioning cursor; 2) the drum holographic anti-counterfeiting film and the drum printing stock are put into an overprinter unwinding device, respectively pass through a traction roll and enter an overprinting device; after overprinting, the anti-counterfeiting film is stripped and winding is performed; and before overprinting, the two kinds of drums are respectively horizontally and axially positioned and then subjected to continuous overprinting. The method can realize accurate and continuous overprinting between the coils, improve overprinting accuracy and efficiency and reduce the reject rate.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Big stamping roller for planetary type flexible printer

InactiveCN100506532CAccurate overprintImprove printing qualityRotary pressesPrinting press partsEngineeringPrinting press

The utility model relates to a large embossing cylinder of a satellite type flexographic printing machine. The purpose of the invention is to solve the problems of inaccurate overprinting and overall pattern deviation in existing satellite flexo printing machines that use entrainment, and the problem that the groove jaw structure cannot be directly introduced to improve printing quality. Main points of the technical solution: It is a cylindrical body with a central axis, and its characteristics are: the arc surface of the cylindrical body has one or more grooves distributed along the circumferential direction, and each groove is rotated and fitted with a The jaw shaft is arranged in the axial direction. Several jaws are fixed on the jaw shaft. The claw end of the jaw matches the edge of the notch of the groove. The driving end of the jaw shaft protrudes from the side of the cylinder. Each groove One or more entrainment bridge plates arranged along the circumferential direction for supporting entrainment are provided on the notches, and the top surface of the entrainment bridge plate is an arc surface with the same radian as the arc surface of the cylinder.

Owner:SHANTOU OLGER PACKING MACHINERY

Volute iron printing side mark device

The invention relates to a volute iron printing side mark device of an iron printing machine, which belongs to the field of iron printing equipment, and is mainly used for solving the problems of low utilization ratio of raw materials and increased labor cost because the conventional iron-printing equipment of the prior art cannot normally and accurately print volute irons. The volute iron printing side mark device is realized through the following technical scheme that the volute iron printing side mark device comprises a leaning body and a side mark, wherein the leaning body comprises a main support rod A, a lateral support A, a longitudinal support A and a space regulation device, and a bearing pack A is installed on the main support rod A, is connected with a pressing plate of the leaning body through a connecting rod A and is connected with the longitudinal support A through a connecting part A; and the side mark comprises a main support rod B, a lateral support B, a longitudinal support B and a pressing regulation device, wherein a bearing pack B is fixedly installed on the main support rod B, is connected with the pressing plate of the side mark through a connecting rod B and is connected with the longitudinal support B through a connecting part B. The volute iron printing side mark device is mainly used in the volute iron printing equipment.

Owner:SHANDONG HUANQIU TINPLATE CAN MAKING

A printing mechanism and printing method for synchronous digital printing and rotary screen printing

ActiveCN105882129BPrecise registrationTo achieve the purpose of synchronous overprintingScreen printersTypewritersScreen printingEngineering

The invention relates to a printing mechanism and a printing method for synchronizing digital printing and rotary screen printing. It is still difficult to effectively combine digital and rotary screen printing to complete the printing method of synchronous overprinting. The steps of the printing method of the present invention are as follows: (1) use a rotary screen to print on the printed fabric to form a screen printing pattern; (2) designate feature points on the screen printing pattern, and use the front camera to take pictures of the features in the front and back of the two flowers. Points to get the deviation value of the rotary screen; (3) According to the deviation value of the rotary screen, the digital printing pattern is scaled accordingly, and after digital printing, a combined printing pattern is formed on the printed fabric; (4) After using the The camera shoots the combined printing pattern or the corresponding feature points of the screen printing pattern and the digital printing pattern, detects whether there is a deviation between the digital printing and the rotary screen printing, and judges whether the effect of accurate overprinting has been fully achieved. The invention effectively combines the respective advantages of digital printing and traditional rotary screen printing.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Printing delivery device of satellite type flexible printer

InactiveCN100455435CAccurate overprintImprove printing qualityRotary letterpress machinesPrinting press partsEngineeringPrinting press

The invention relates to a printer transmitter of planet flexible printer. Wherein, it comprises printing larger roller on the frame, several printer units, and transmitter. The invention is characterized in that: the arc surface of roller has one or more grooves along the axles; each groove has rotational claw axle along the axle fixed with several claws; the end of claw is matched with the cut of groove; the driver of claw axle is extended outside one side of roller; the cut is arranged with one or several clamping plates along circumference to support the clamping band, whose top surface is arc same as the arc surface.

Owner:陈鸿奇

Printer

InactiveCN101259774AReduce wasteSimple and scientific structureRotary lithographic machinesPrinting press partsEngineeringHome appliance

The invention provides a novel single-paper press which is different from the existing offset press in the aspects of two functions: first, an ink-controlling device for and adjusting and controlling ink supply of an inking roller is not required to adjust and control mass color in the whole process of printing due to the ink supply of printed material so that automatic mass color control is achieved; an electric device which can be used for heating and adjustment is arranged in an ink-stirring roller and an ink-ending controlling device; second, the new process in which the printing can be completed only by taking printing stocks in an exchange way changes the original multi-exchange process. In the attached drawing, only a double-side printing monochromatic group is provided; the press with the printing process can be connected with two, four, five and six color classes as well as connected with double-side printing and single-side printing. Moreover, the press provided by the invention can be produced in large size and can print thick material, namely such thick plane plates as PVC, metal, etc; furthermore, the press ensures that the offset press plays a more important role in commercial products such as decoration, packaging, etc., of home appliance.

Owner:罗贤义

Shuangpin printing equipment for double-page invoices

ActiveCN107696677BIncreased printing process efficiencyLow costRotary pressesInvoiceComputer engineering

The invention relates to the field of printing, in particular to double-printing equipment for a duplex invoice. Paper in a paper rolling part A is printed in a printing group C to form a first invoice; paper in a paper rolling part B is printed in a printing group D to form a second invoice; tension monitoring is performed on the first invoice and the second invoice before the first invoice and the second invoice enter a combining part, and the tension of the first invoice and the tension of the second invoice are guaranteed to be consistent during combination, so that the content of the first invoice and the content of the second invoice are completely overlapped and registered. Invoice number printing and locking are performed on the two combined invoices, the invoice subjected to double printing is cut into two independent single invoices, and finally, the two single invoices are folded simultaneously. Thus, double printing of the two invoices is completed simultaneously, and the printing efficiency is 2-3 times higher than that of traditional printing equipment.

Owner:CHONGQING FARSIGHT PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com