Multifunctional micro-nano structure color film production device and work method

A technology of micro-nano structure and production equipment, which is applied to the printing of special varieties of printed matter, printing process, thin material treatment, etc., can solve the problems of VOCs residue in packaging products, ink discoloration, VOCs pollution, etc., and avoid multiple times on the machine , Simplify the production process, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

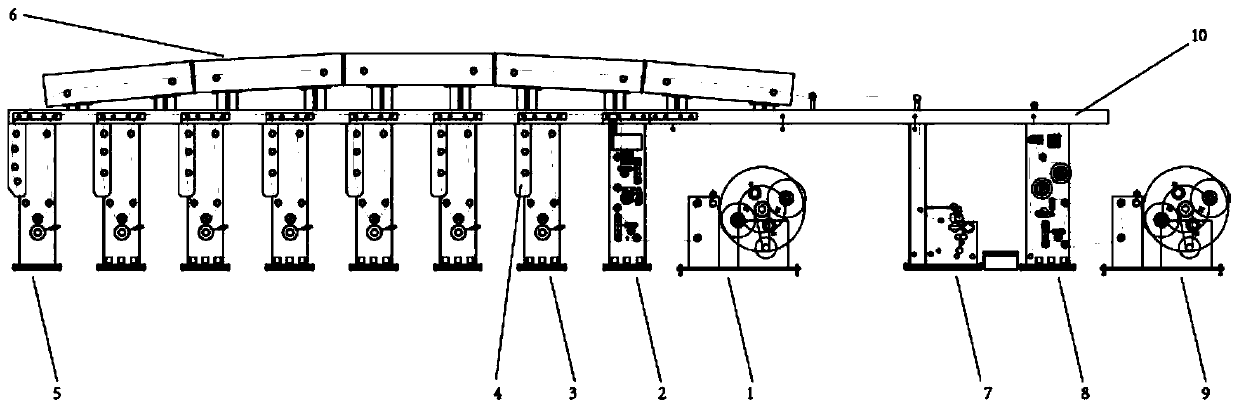

[0078] In this example, a multifunctional micro-nano structured color film production equipment is used as a fully automatic in-line printing-coating-molding machine to perform fully automatic non-stop in-line printing, coating and holographic pattern molding to manufacture micro-nano structured color films product.

[0079] refer to figure 1 As shown, the working process is as follows: the plastic film is unwound from the double-station unwinding device 1, conveyed forward through the traction device 2, and then printed on the gravure printing device 3 while drying the printing ink through the oven system 4, Print graphics and texts through multiple printing devices in sequence, then coat the resin layer through the doctor blade coating device 5, then enter the oven system 6 to dry the resin layer, and then pass through the micro-nano structure imprinting device 7 to imprint the micro-nano structure pattern It is overprinted with the printed graphics, and then the film is co...

Embodiment 2

[0083] In this example, a multi-functional micro-nano structured color film production equipment is used as a fully automatic in-line molding-printing-coating machine for fully automatic non-stop in-line holographic pattern molding, printing and coating to manufacture micro-nano structured color films product.

[0084] refer to figure 1 As shown, the working process is as follows: the film that has been coated with resin coating is unwound from the double-station unwinding device 1, and enters the micro-nano structure imprinting device 7 through the bridge guide roller on the frame 10 for micro-nano structure imprinting device 7. Structural color patterns are embossed, and then pass through the bridge guide rollers on the frame 10 and enter the traction device 2 to be transported forward, and then pass through the gravure printing device 3 for graphic printing and overprinting with the micro-nano structural color patterns, and at the same time pass through the oven system 4. ...

Embodiment 3

[0087] In this embodiment, a multi-functional micro-nano structured color film production equipment is used as a fully automatic coating machine for fully automatic non-stop coating to manufacture various coated film products.

[0088] refer to figure 1 As shown, the working process is as follows: the plastic film is unwound from the double-station unwinding device 1, conveyed forward through the traction device 2, and then enters the scraper coating device 5 through the bridge guide roller on the frame 10 for coating , and then enter the oven system 6 to dry the coating layer, then pass through the cooling device 8 for film cooling, and finally enter the double-station winding device 9 for non-stop film winding to become a finished coating film.

[0089] In this embodiment, new and different feeding methods are adopted to realize thin film coating, which can be used as a coating machine to improve the use of equipment and expand the application of thin film coating products. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com