Water transfer paper and preparation method thereof

A technology of water transfer printing paper and water-soluble coating, which is applied in the field of papermaking processing, can solve the problems of reduced water permeability of paper, increased difference of water transfer printing paper, and affecting demoulding speed, etc., to achieve saturated color, vivid images, Uniform demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

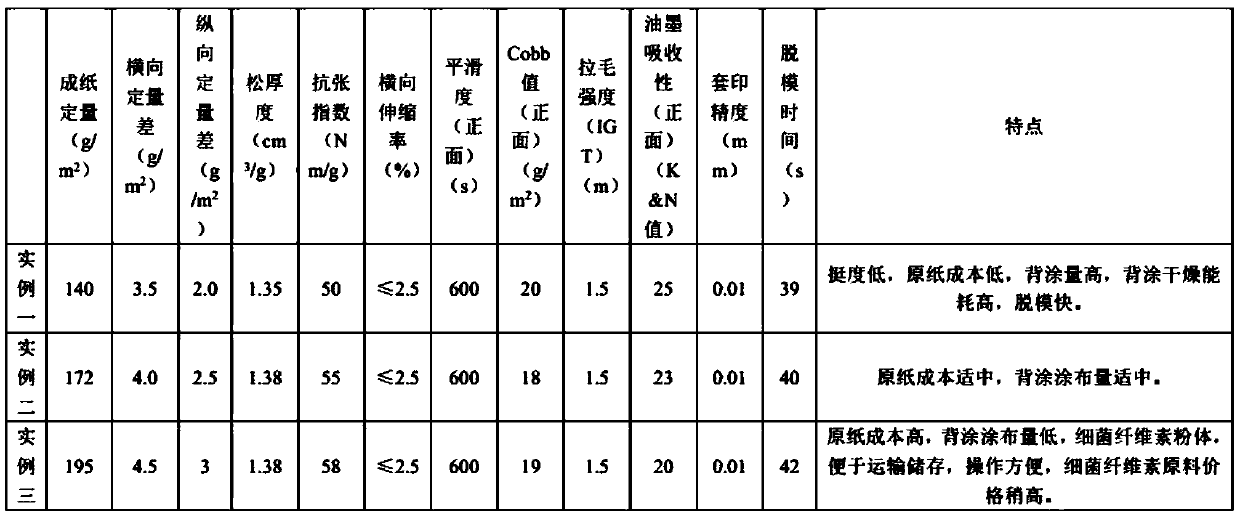

Examples

Embodiment 1

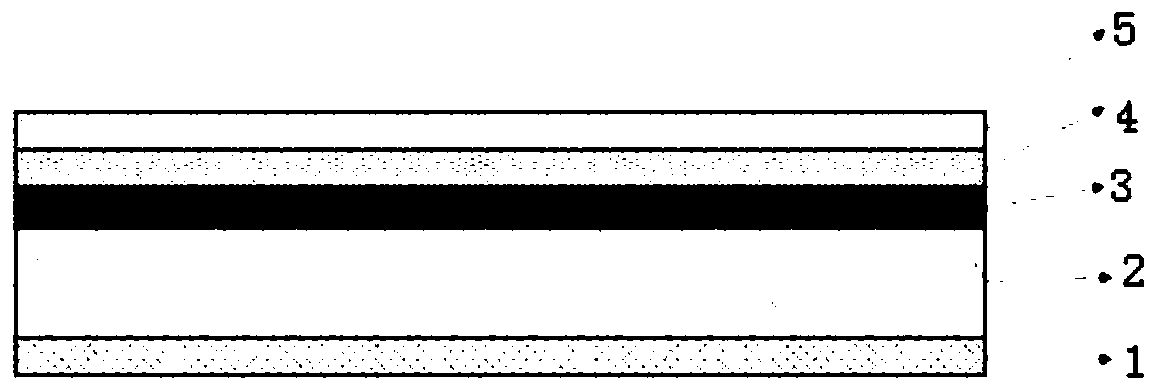

[0031] Such as figure 1 As shown, the present embodiment illustrates a kind of water transfer printing paper, comprising a layer-by-layer backcoat coating 1, base paper 2, primer coating 3, water-soluble coating 4 and waterproof coating 5, the backcoat The coating composition of coating 1 is: 8-15 parts by weight bacterial cellulose wet film, 0.08-0.15 parts by weight hydrogen peroxide, 0.1-0.2 parts by weight sodium hydroxide, 30-40 parts by weight water at 70-90 ° C, Shearing and dispersing in a high-speed disperser for 30-45 minutes, adding 40-60 parts by weight of water to dilute, and then passing through a 20-mesh sieve to prepare a back-coating paint with a solid content of 2-5%.

[0032] This embodiment also illustrates a method for preparing water transfer printing paper, which specifically includes the following steps:

[0033] 1. Base paper 2: 20-40 parts of bleached softwood pulp and 60-80 parts of bleached hardwood pulp are mixed and beaten to 28-35°SR, and 0.1-0....

Embodiment 2

[0044] 1. Base paper 2: Use commercially available water transfer printing base paper as the base paper.

[0045] The key indicators of raw paper are as follows:

[0046] Base paper weight: 160±5g / m 2 ,

[0047] Banner deviation: ≤2.5%,

[0048] Surface sizing degree (sizing surface): ≤60g / m 2 ,

[0049] Smoothness (gluing surface): ≥25s,

[0050] Tensile strength (longitudinal): ≥6.0KN / m

[0051] Stiffness: 3mN·m

[0052] Bulk thickness: ≥1.3cm 3 / g

[0053] The paper surface is required to be smooth as a whole without creases, dust, spots and other paper defects.

[0054] 2. Primer coating 3: 50-60 parts of calcium carbonate, 20-30 parts of kaolin, 12-16 parts of oxidized starch, 5-8 parts of styrene-butadiene latex, 0.5-1 part of carboxymethyl cellulose, 0.1-0.3 1 part of sodium hexametaphosphate, 0.1-0.5 part of sodium hydroxide, and 0.01-0.05 part of an organosilicon defoamer are prepared into primer coatings with a solid content of 50-65 percent and a viscosity...

Embodiment 3

[0061] 1. Base paper 2: Use commercially available water transfer printing base paper as the base paper.

[0062] The key indicators of raw paper are as follows:

[0063] Base paper weight: 180±5g / m 2 ,

[0064] Banner deviation: ≤2.5%,

[0065] Surface sizing degree (sizing surface): ≤60g / m 2 ,

[0066] Smoothness (glue surface): ≥22s,

[0067] Tensile strength (longitudinal): ≥8.0KN / m

[0068] Stiffness: 4mN·m

[0069] Bulk thickness: ≥1.4cm 3 / g

[0070] The paper surface is required to be smooth as a whole without creases, dust, spots and other paper defects.

[0071] 2. Primer coating 3: 50-60 parts of calcium carbonate, 20-30 parts of kaolin, 12-16 parts of oxidized starch, 5-8 parts of styrene-butadiene latex, 0.5-1 part of carboxymethyl cellulose, 0.1-0.3 1 part of sodium hexametaphosphate, 0.1-0.5 part of sodium hydroxide, and 0.01-0.05 part of a defoamer are prepared into a primer coating, the solid content of the coating is 50-65%, and the viscosity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com