A printing mechanism and printing method for synchronous digital printing and rotary screen printing

A technology of digital printing and rotary screen printing, applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problem of short printing and dyeing cycle, the inability to realize the perfect combination of rotary screen printing and digital inkjet printing, and not to mention the accuracy Overprinting and other issues to ensure accurate overprinting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0031] Examples.

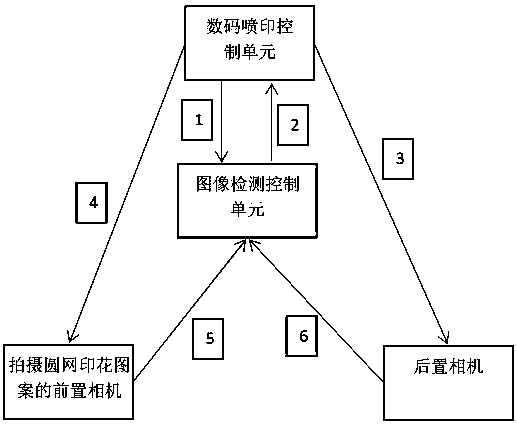

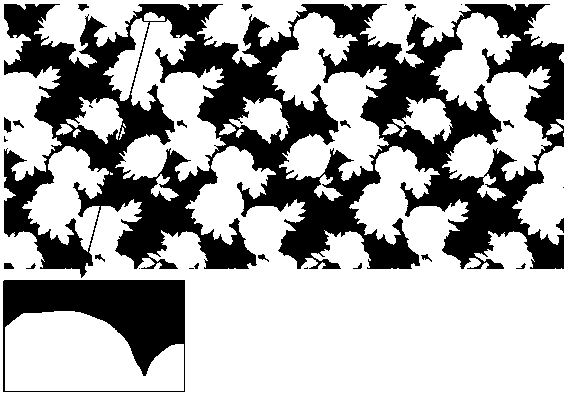

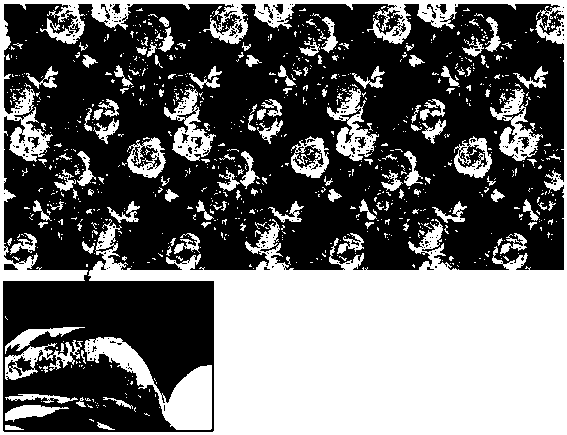

[0032] See Figure 1 to Figure 4 In this embodiment, the digital printing and rotary screen printing synchronous printing mechanism includes a digital printing device 5, a rotary screen printing device 3, and a rewinding and unwinding device of the printing medium, which is used to photograph the front of the screen printing pattern after rotary screen printing. A camera 1 and a rear camera 2 for shooting combined printing patterns after rotary screen printing and digital printing.

[0033] The digital printing device 5 in this embodiment is a continuous digital printing device 5 that conveys the printing medium in a belt type. The digital printing device 5 and the rotary screen printing device 3 share the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com