Printing delivery device of satellite type flexible printer

A technology of flexographic printing machine and conveying device, which is applied to general parts of printing machinery, printing machine, rotary printing machine, etc. The effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

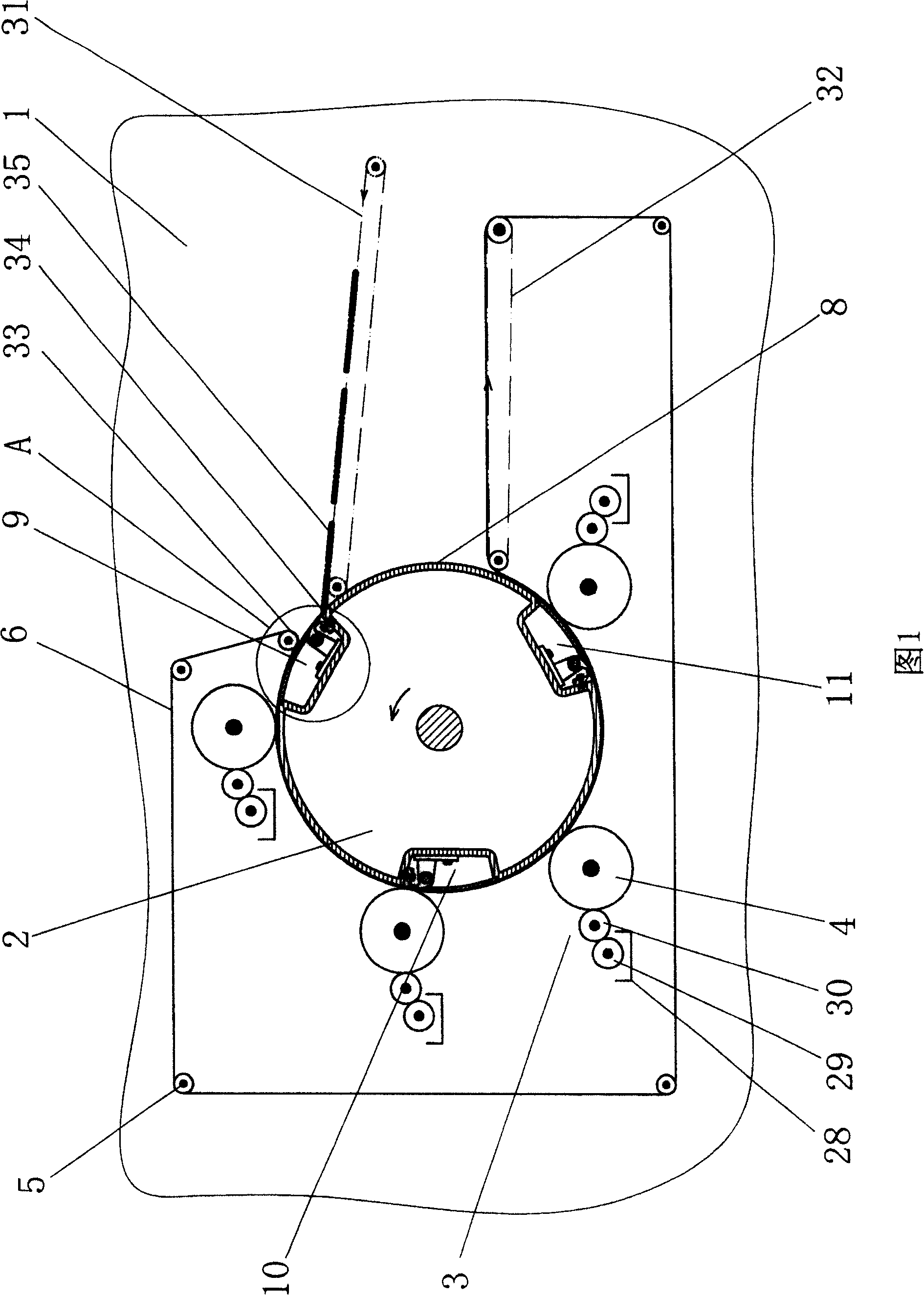

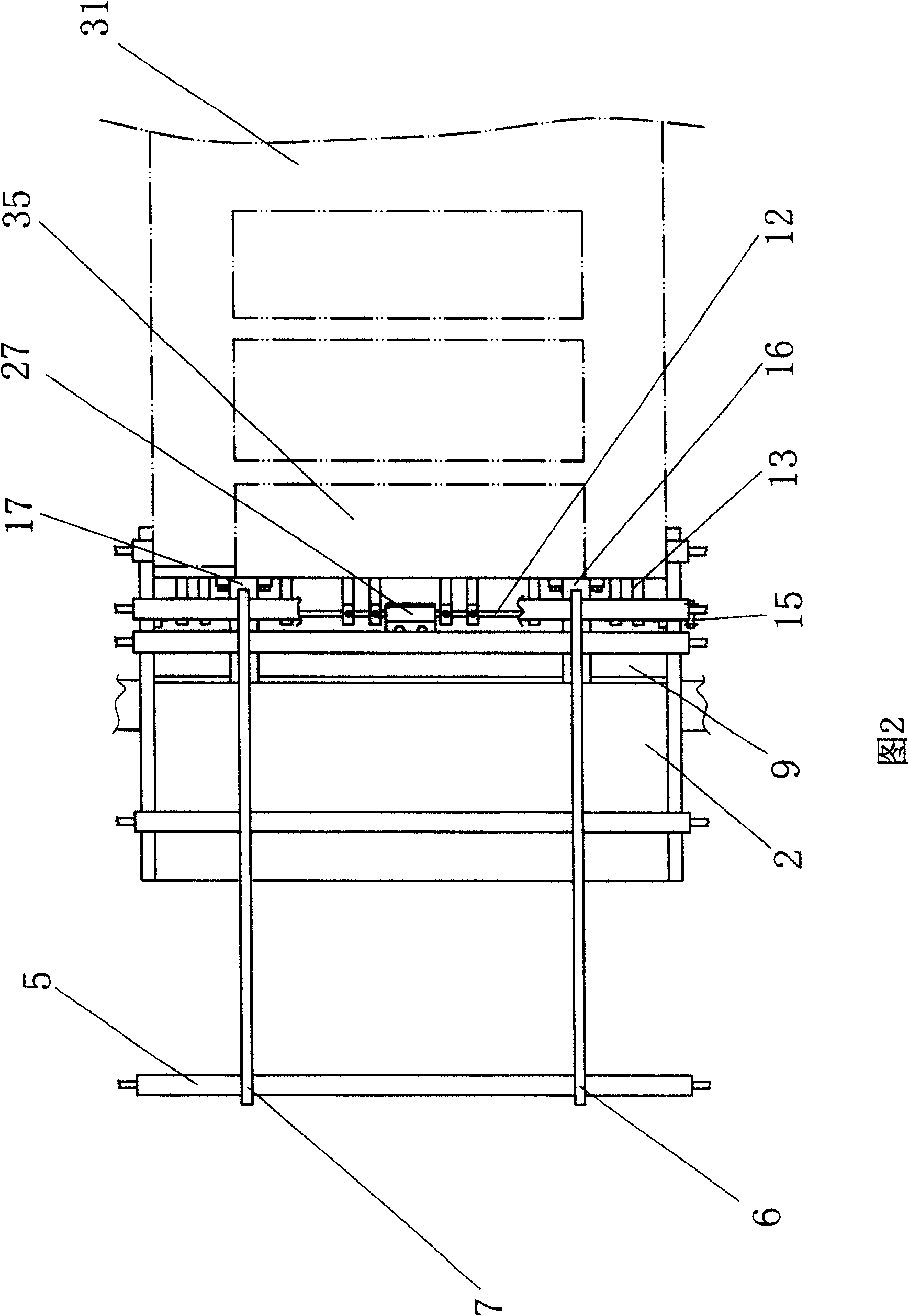

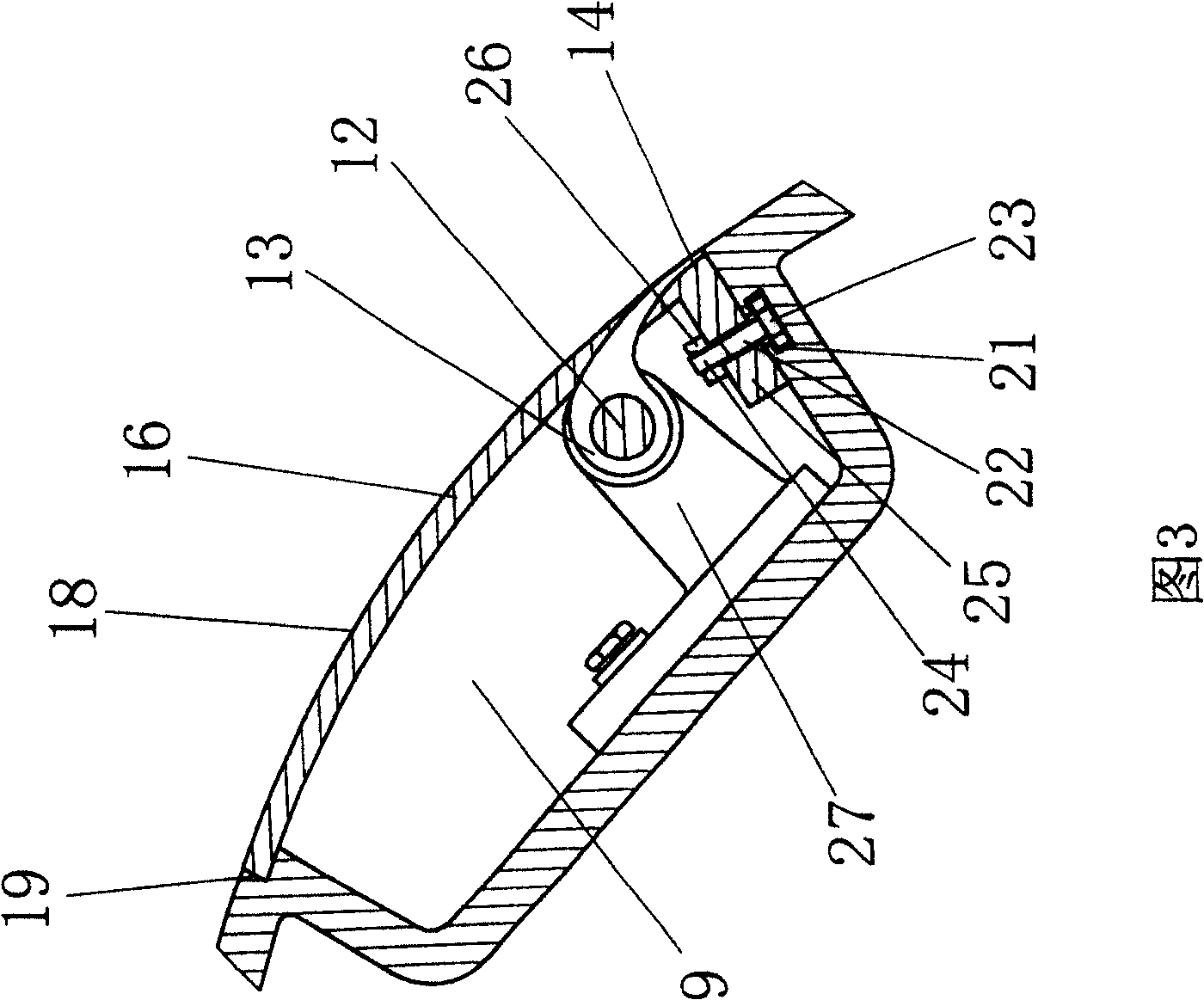

[0017] Referring to Figures 1 to 3, the printing conveying device of the satellite flexographic printing machine includes a large impression cylinder 2 installed on the frame 1 of the printing machine, and four sets of printing plate units arranged around the periphery of the large impression cylinder 2 3 etc. Conveying mechanism, wherein the plate roller 4 of the printing plate unit 3 cooperates with the large imprinting cylinder 2 for printing. The cylinder 2 and the conduction roller 5 etc. are rotated and fitted on the frame 1 of the printing machine, and the entrainment belts 6 and 7 are tightly fitted with the big embossing cylinder 2. It is characterized in that the arc surface 8 of the large embossing cylinder 2 has three The grooves 9, 10, 11 extending in the direction of the groove, each groove 9 is rotated and fitted with a jaw shaft 12 arranged along the axial direction, and several jaws 13 are fixed on the jaw shaft 12, and the claws of the jaws 13 End 14 cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com