Patents

Literature

77results about How to "Tension balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

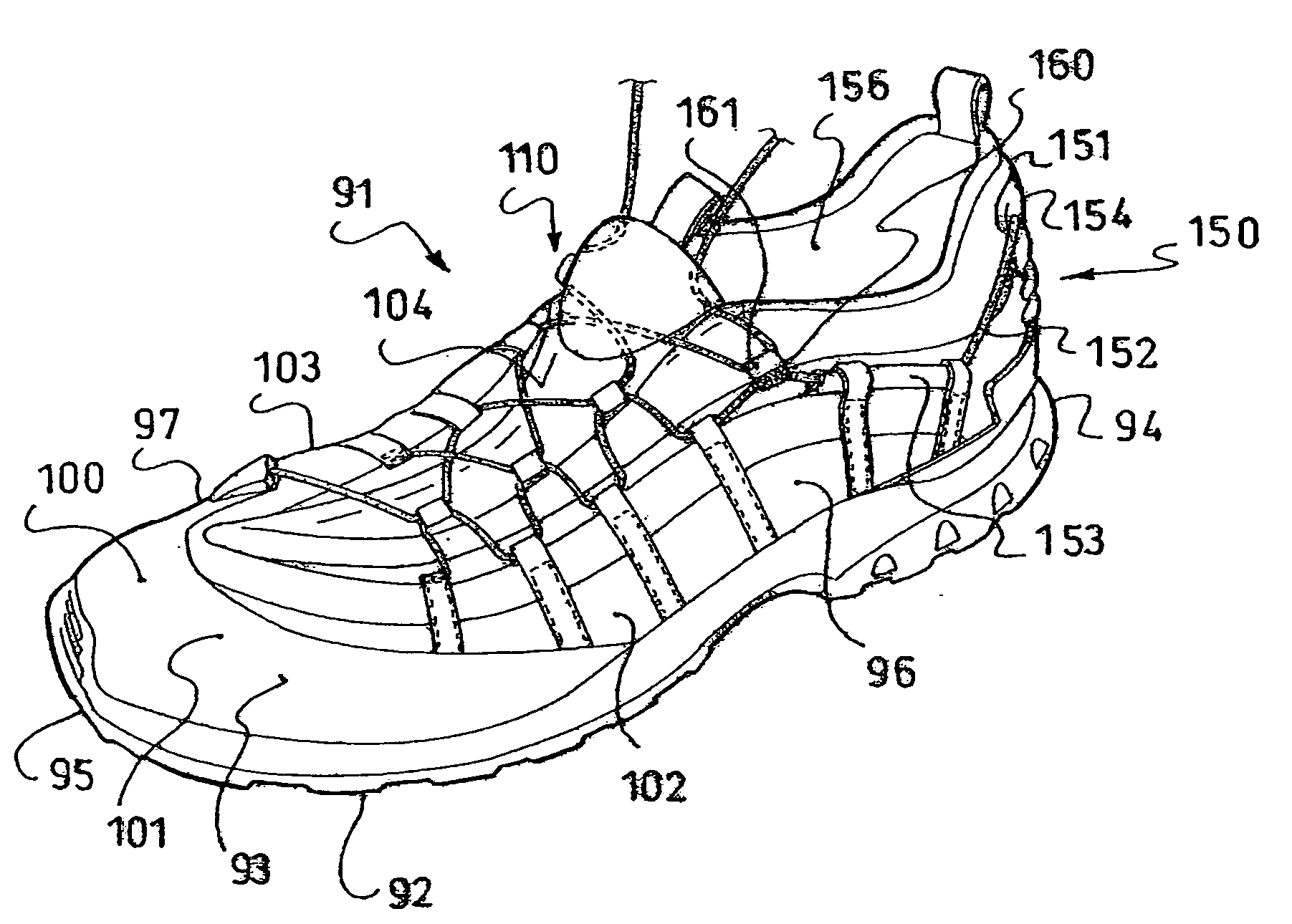

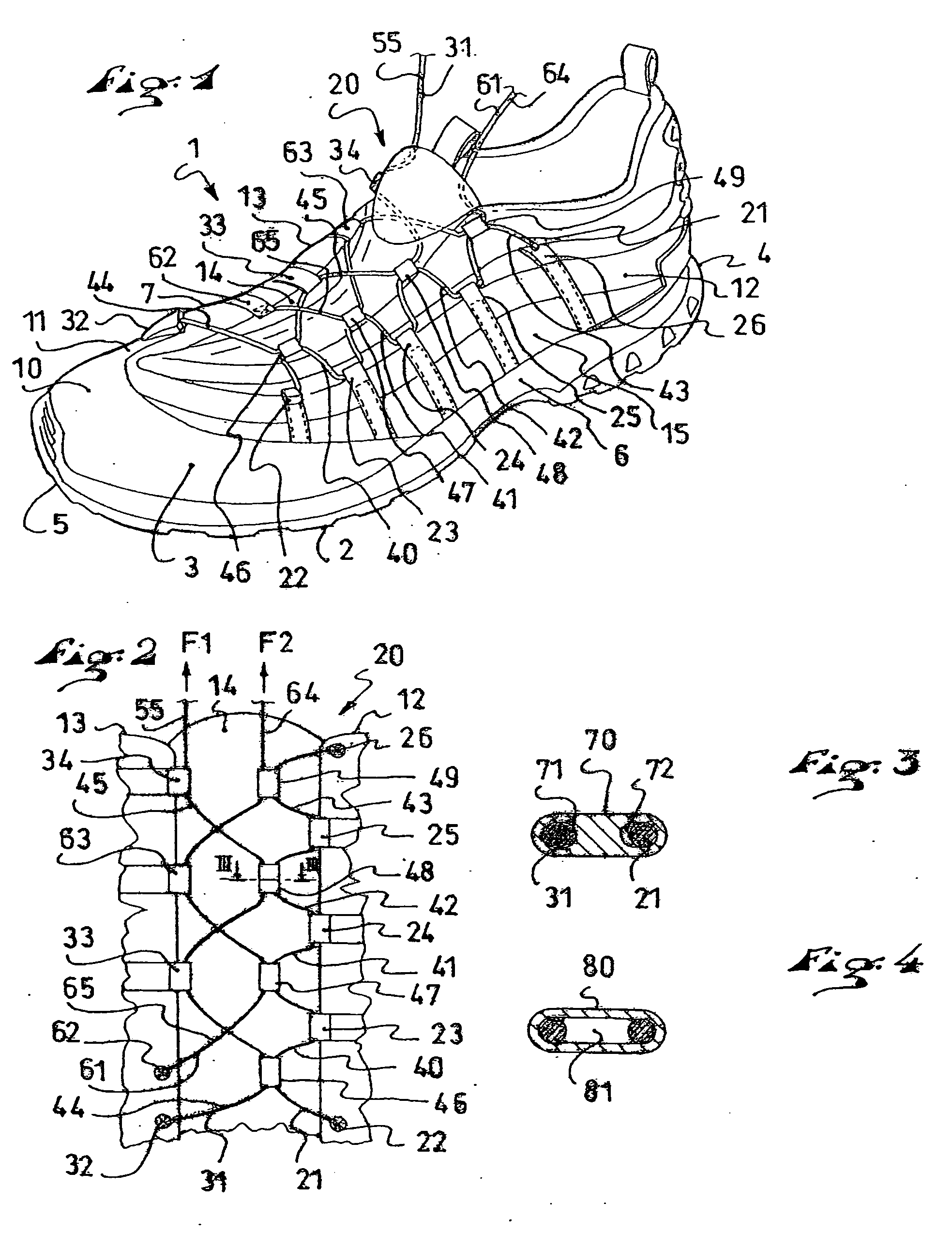

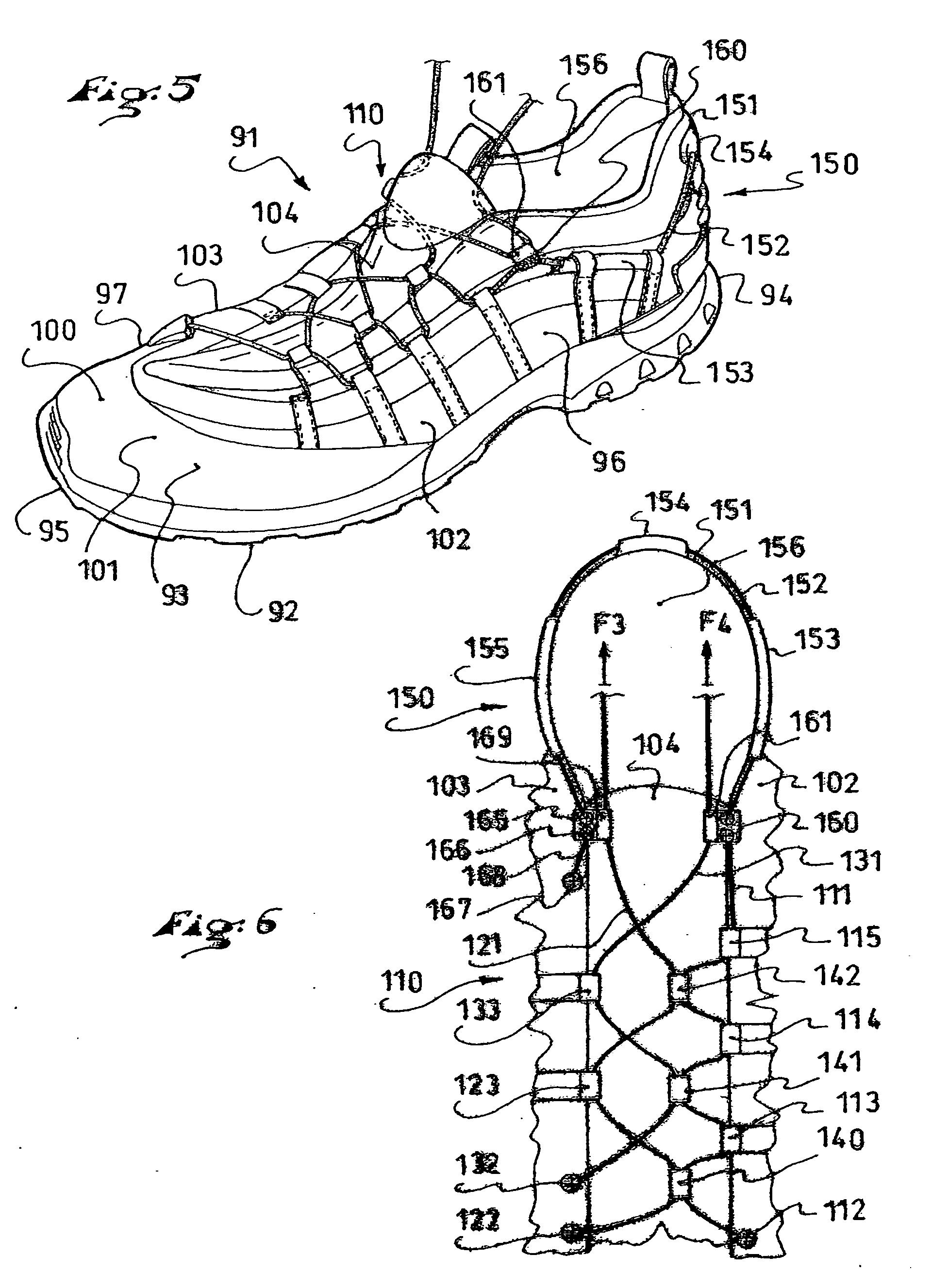

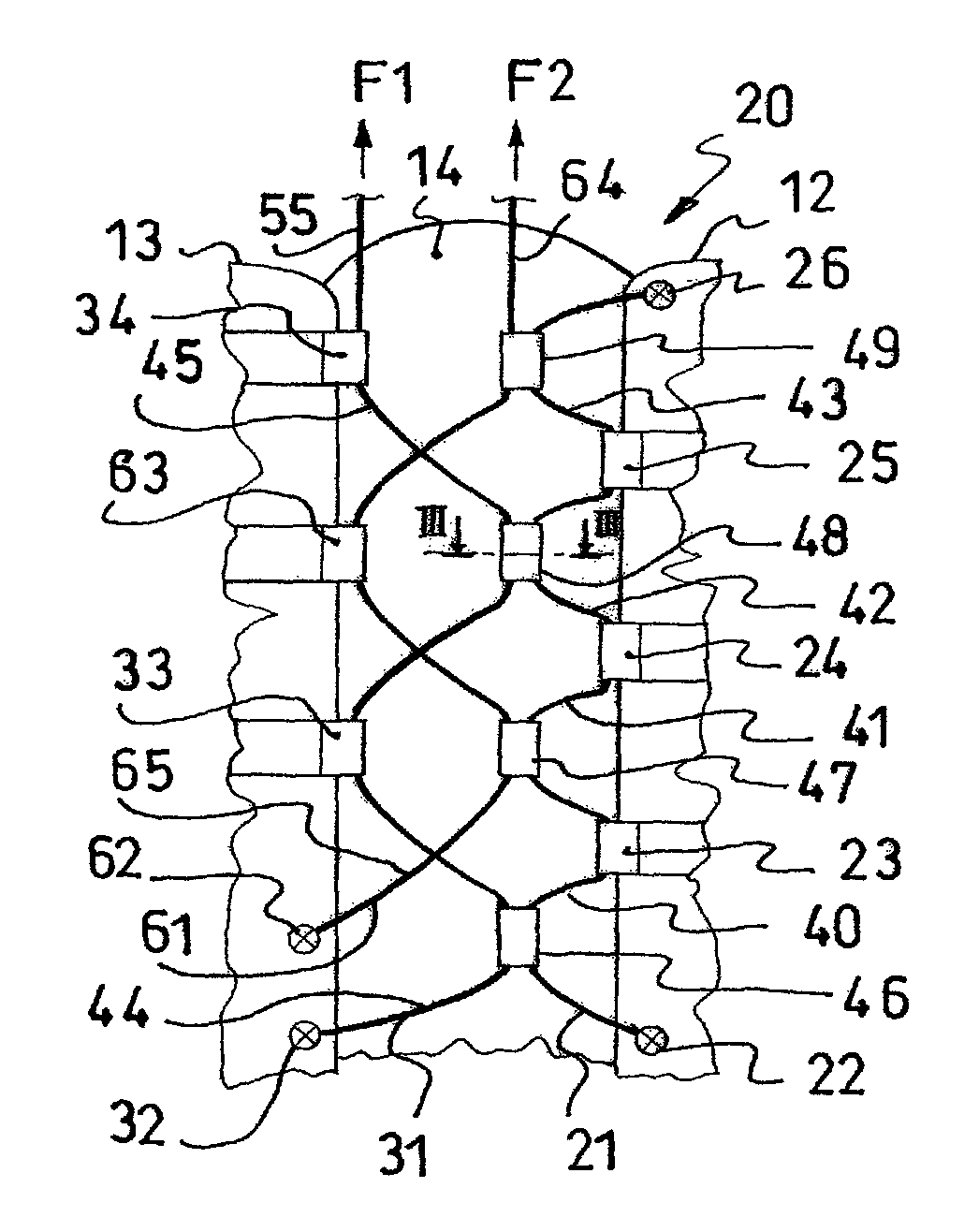

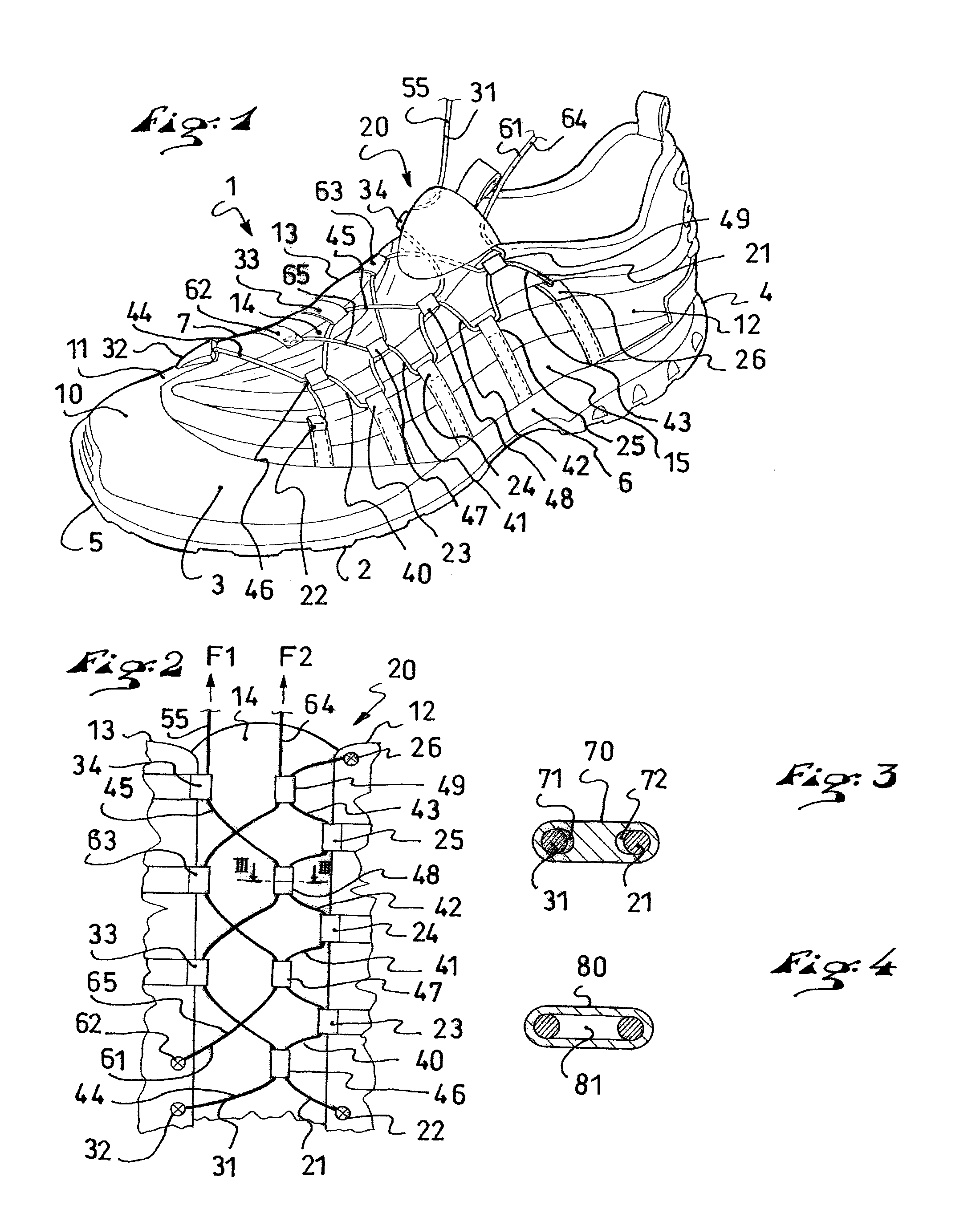

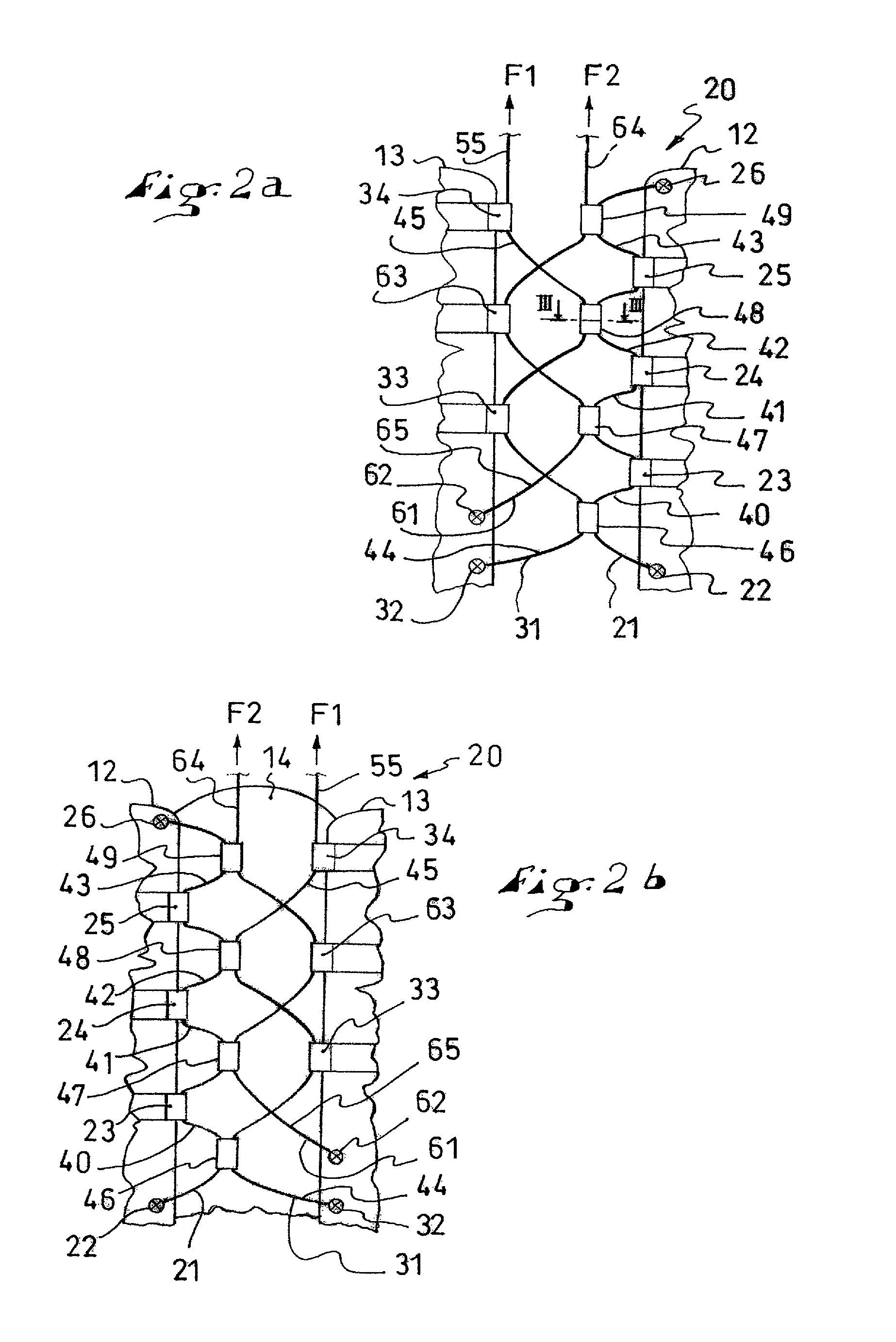

Footwear with improved tightening of the upper

InactiveUS20070068040A1High retention rateImproved tension distributionShoe lace fasteningsHaberdasheryEngineering

Owner:SALOMON SA

Footwear with improved tightening of the upper

InactiveUS7841106B2High retention rateOptimize allocationShoe lace fasteningsHaberdasheryEngineering

Owner:SALOMON SA

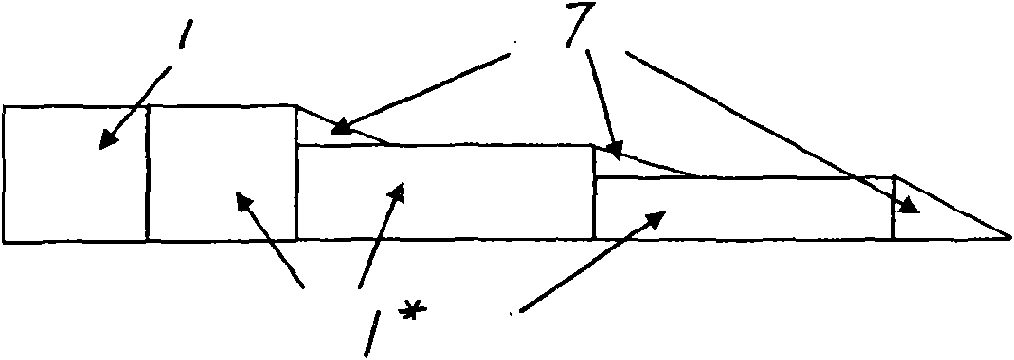

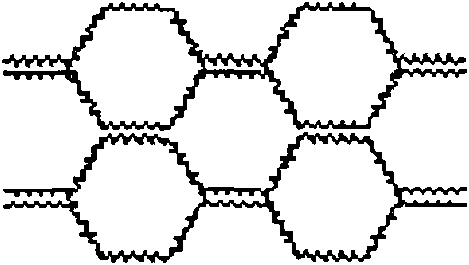

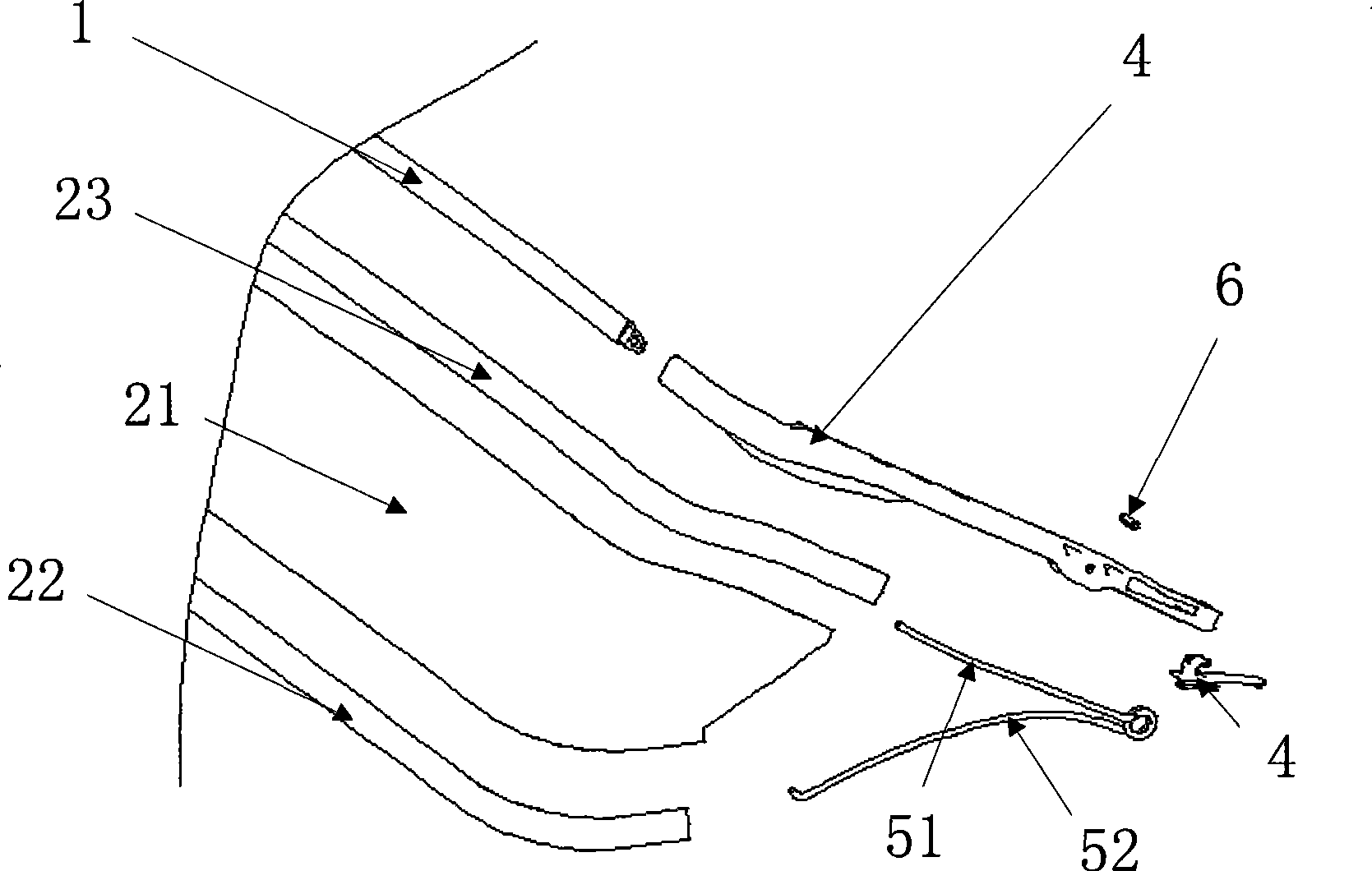

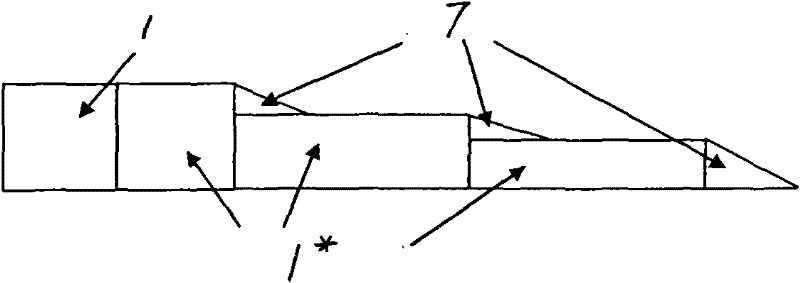

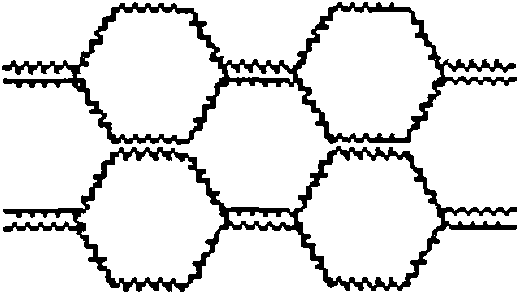

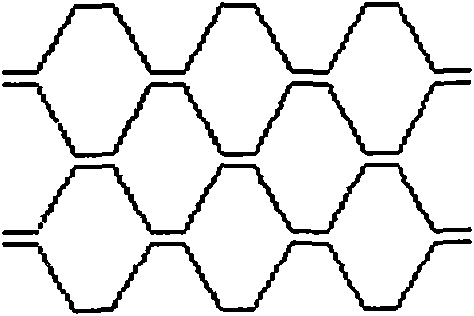

Wind turbine blade structure, processing and forming method and applications thereof

InactiveCN101666290AEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

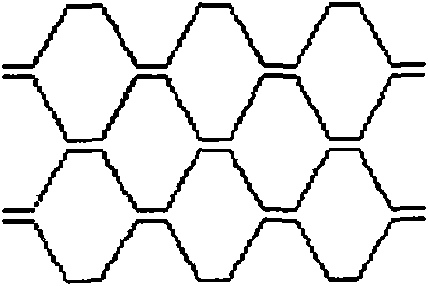

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the rootsegment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

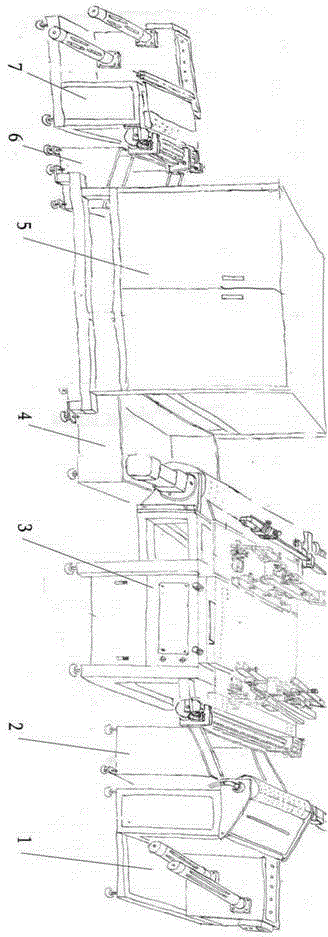

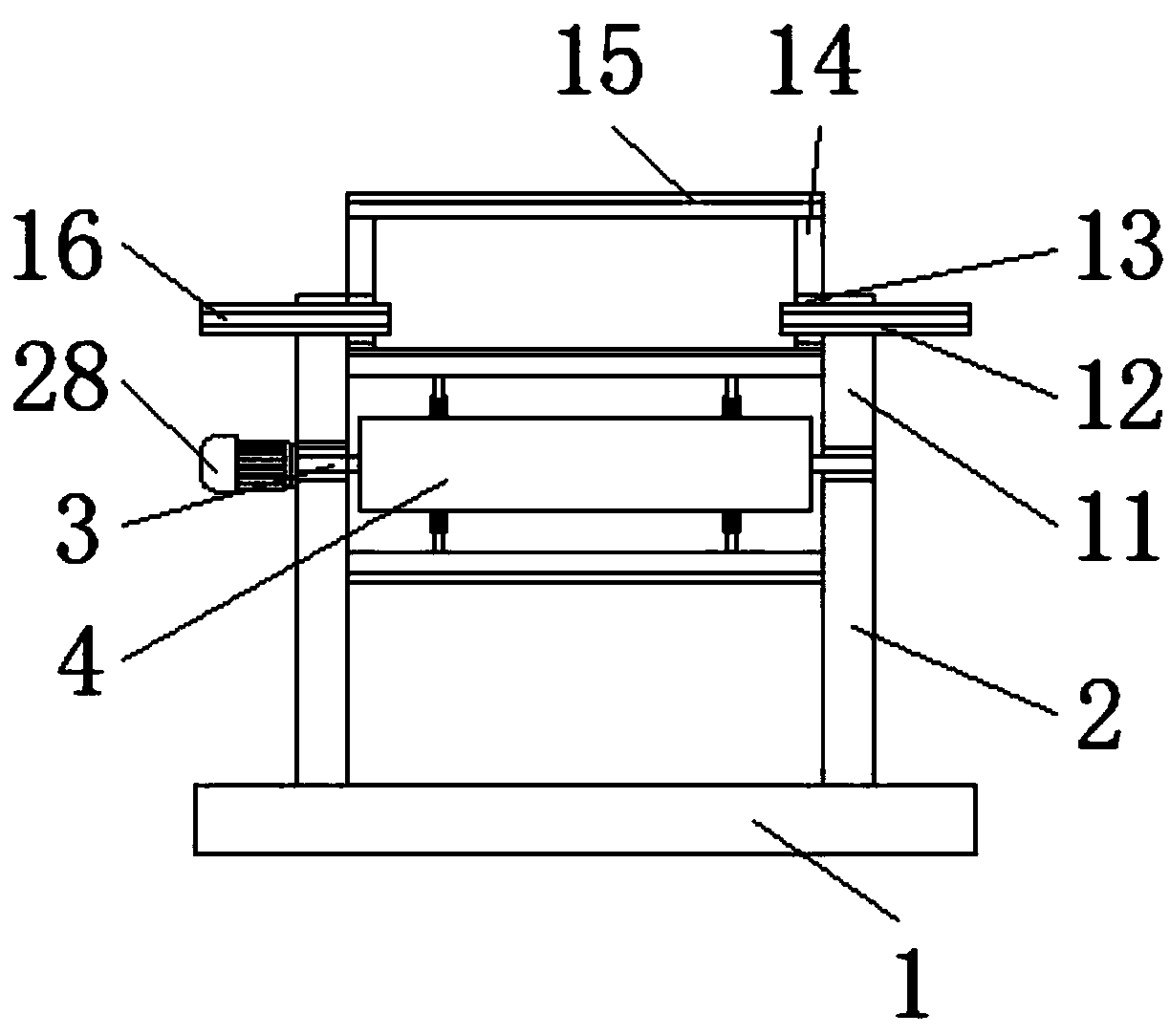

Reeling machine

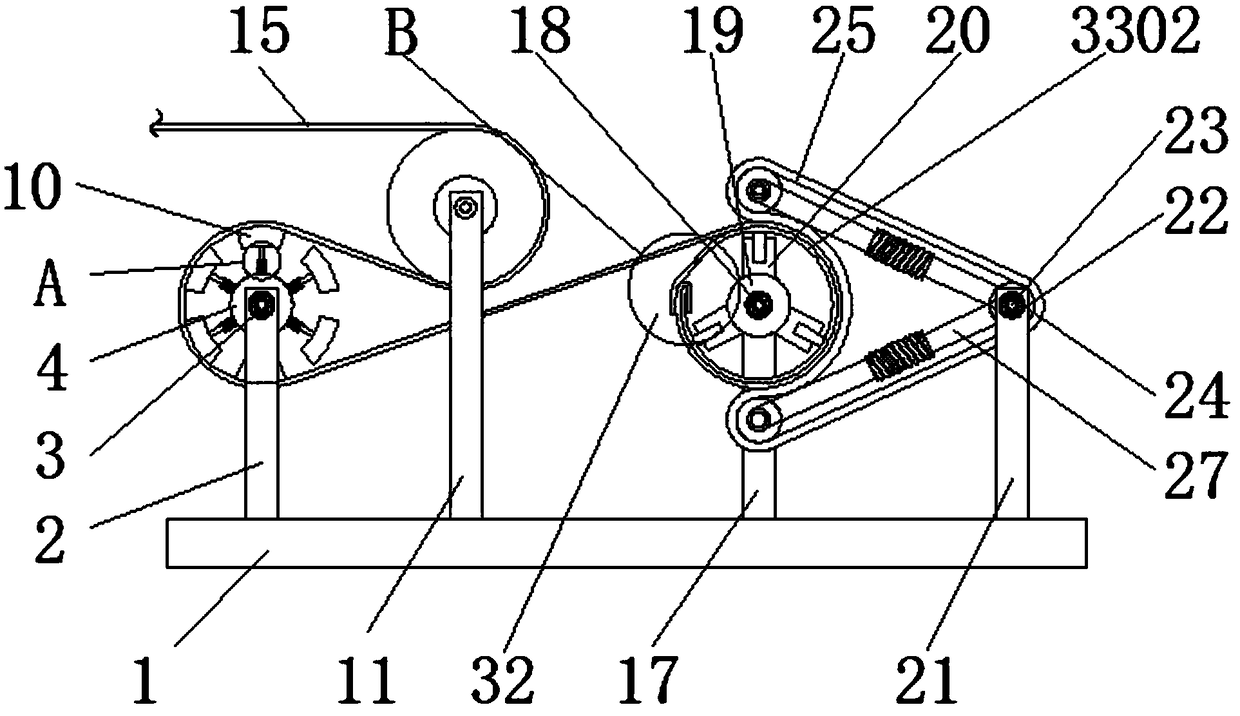

ActiveCN104009249ATension balanceStable tensionPrimary cell manufactureAssembling battery machinesControl engineeringMachine

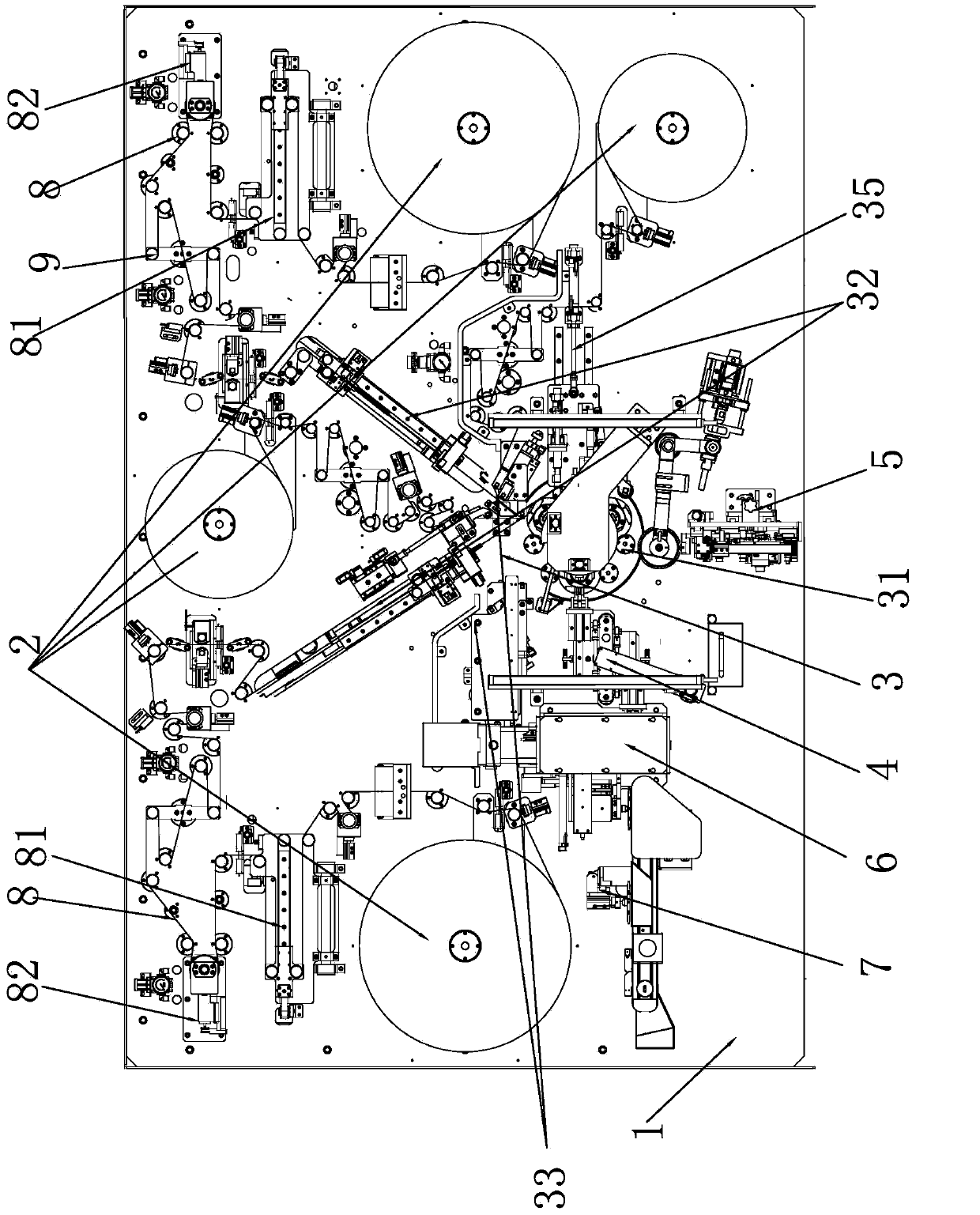

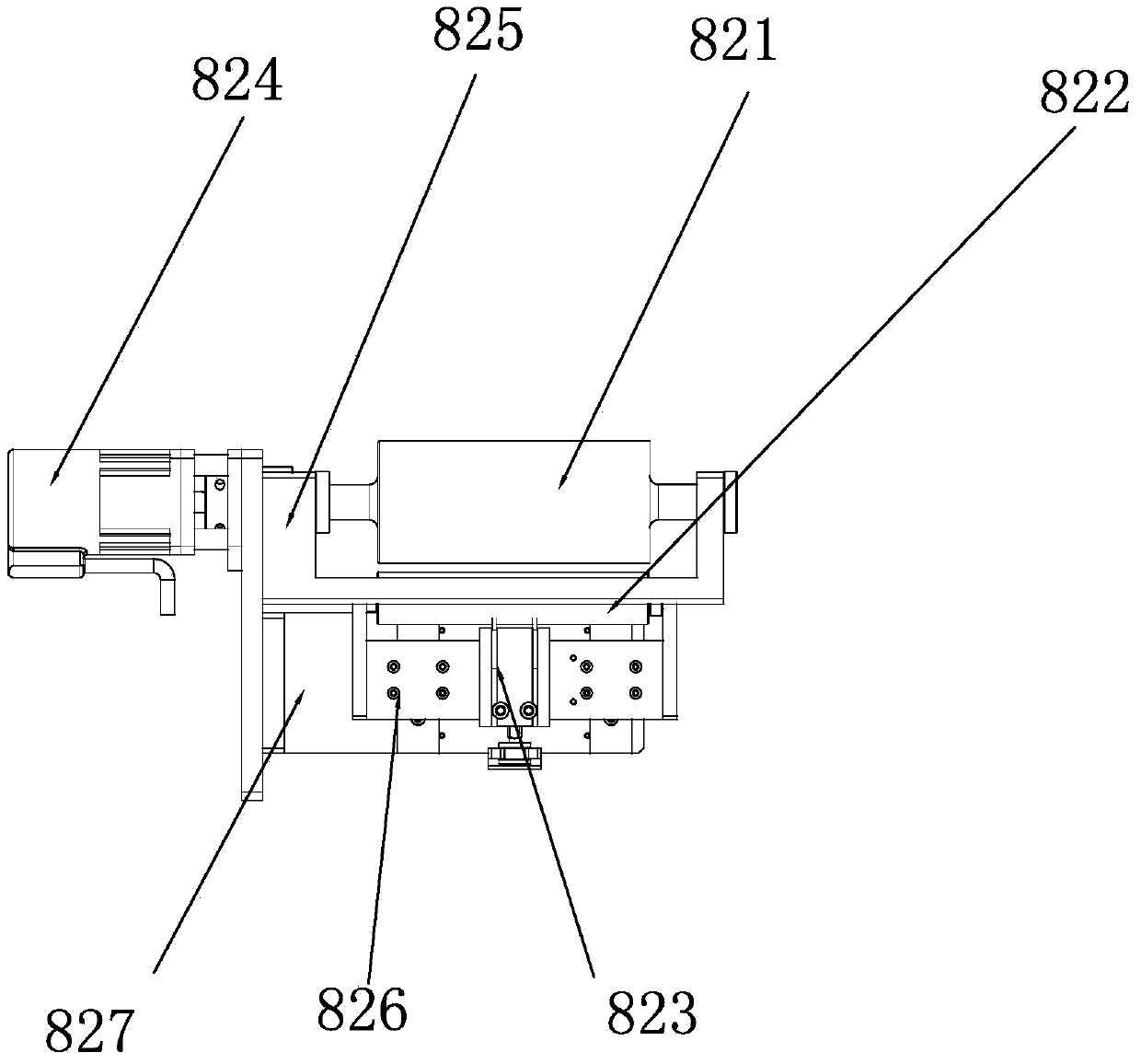

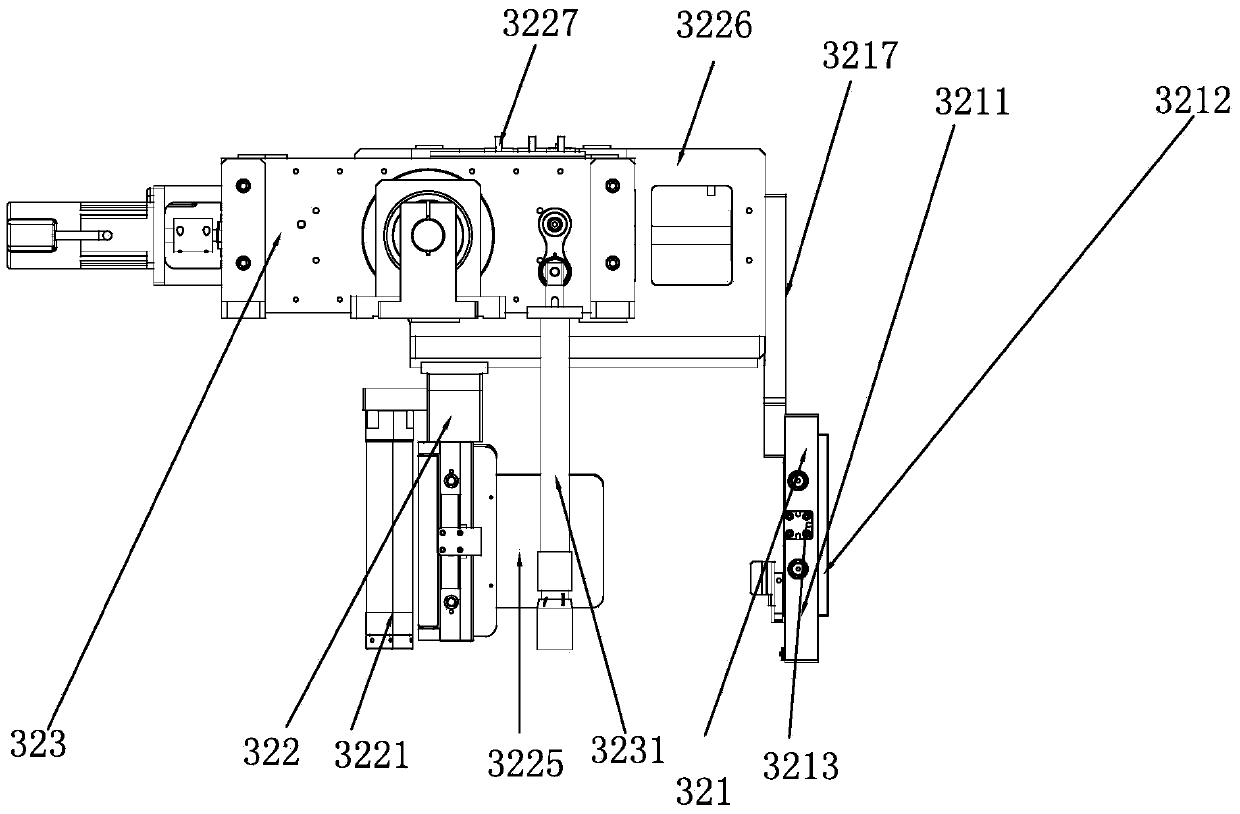

The invention discloses a reeling machine which comprises a rack assembly, an unreeling mechanism, a reeling mechanism, a feeding mechanism, a rubberizing device and a tension control mechanism, wherein the tension control mechanism comprises a pole piece deviation correcting device and a driving device which are arranged between the unreeling mechanism and the reeling mechanism; a reeling needle of the reeling mechanism performs a cam motion; the driving device is used for driving a pole piece to be synchronous with the traction of the reeling needle performing the cam motion to the pole piece and simultaneously preventing the unreeling of the pole piece and an deviation correcting operation from influencing the tension of the pole piece. According to the reeling machine, the stable tension control is effectively realized.

Owner:SHENZHEN YINGHE TECH

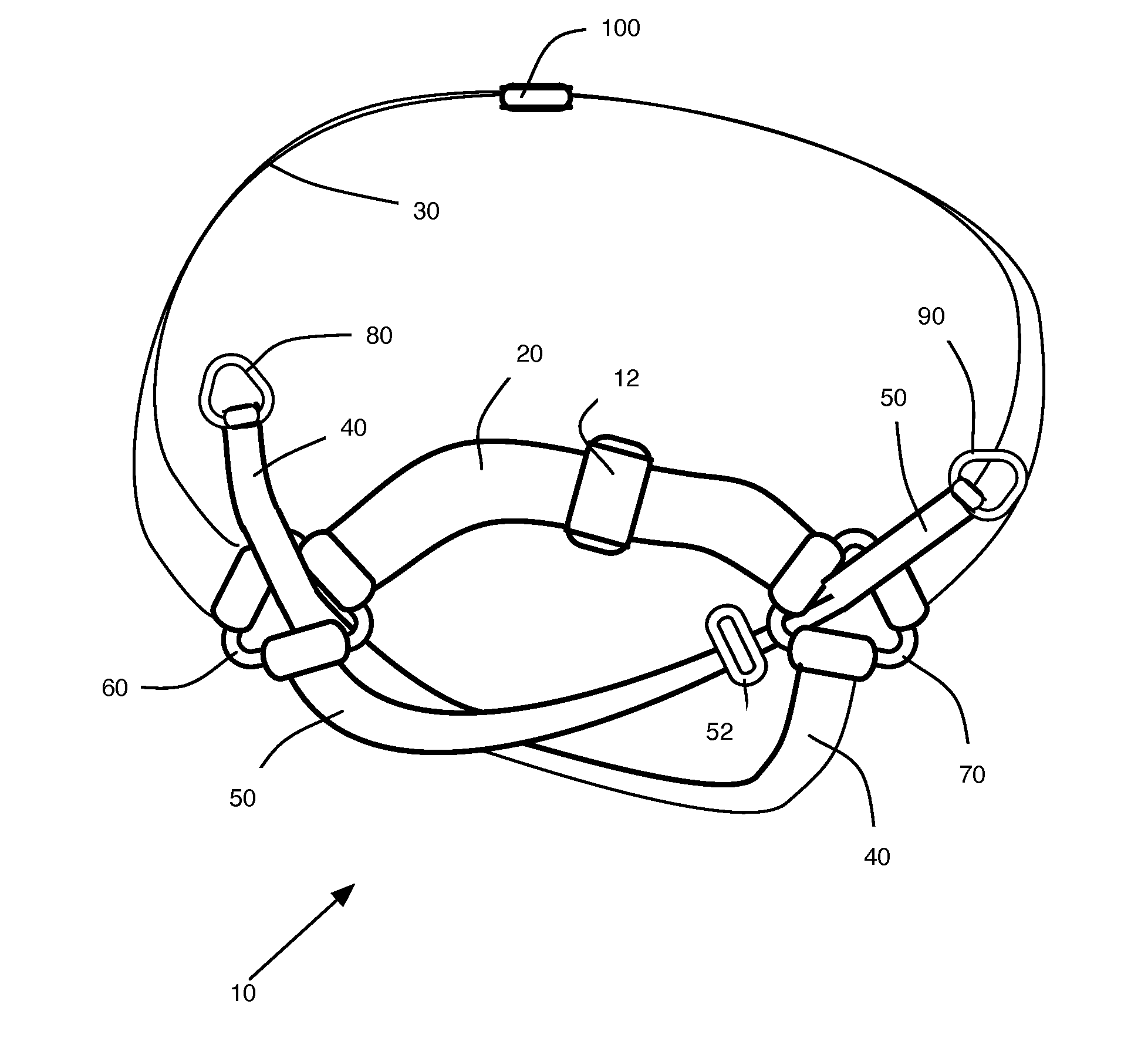

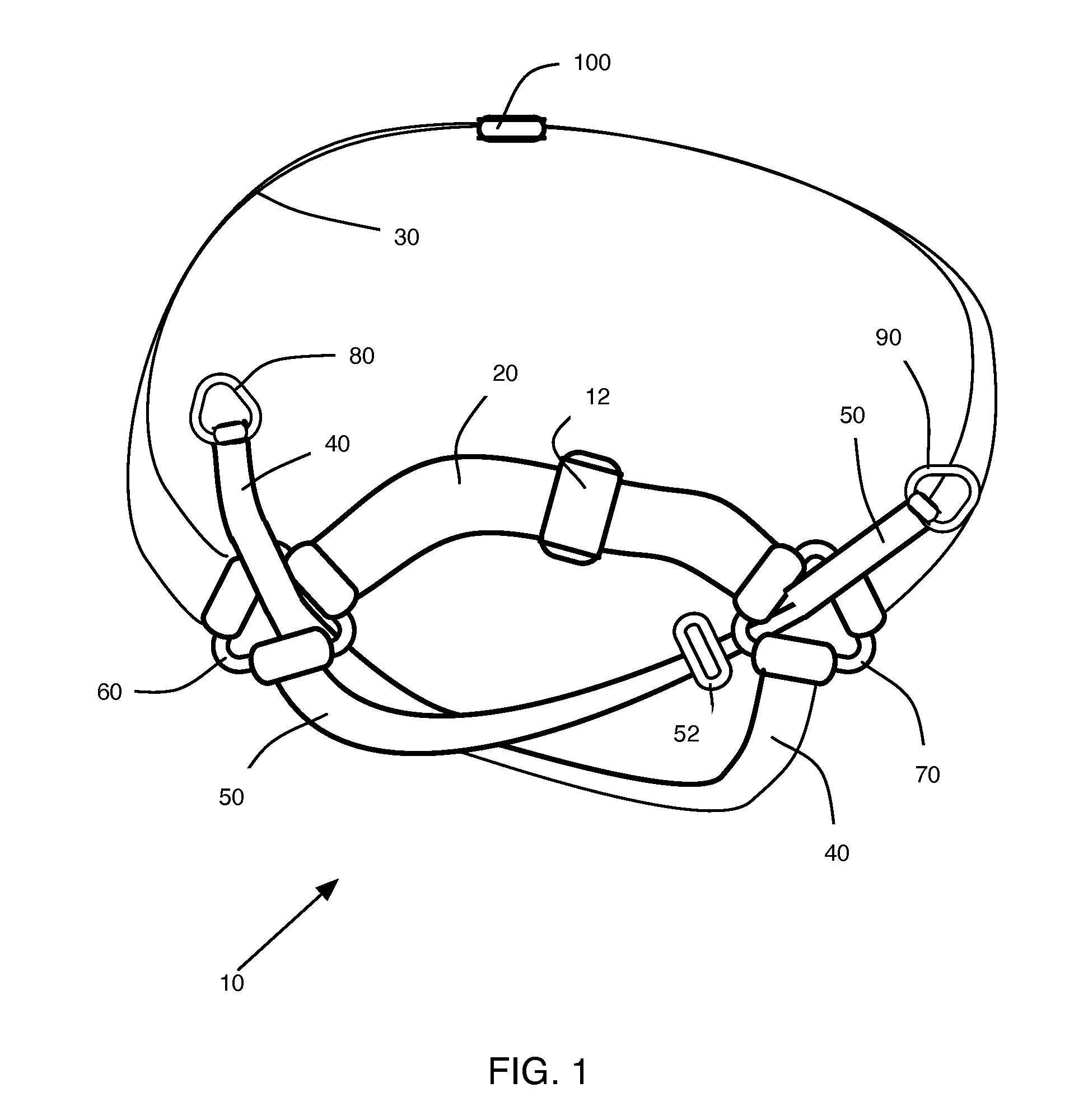

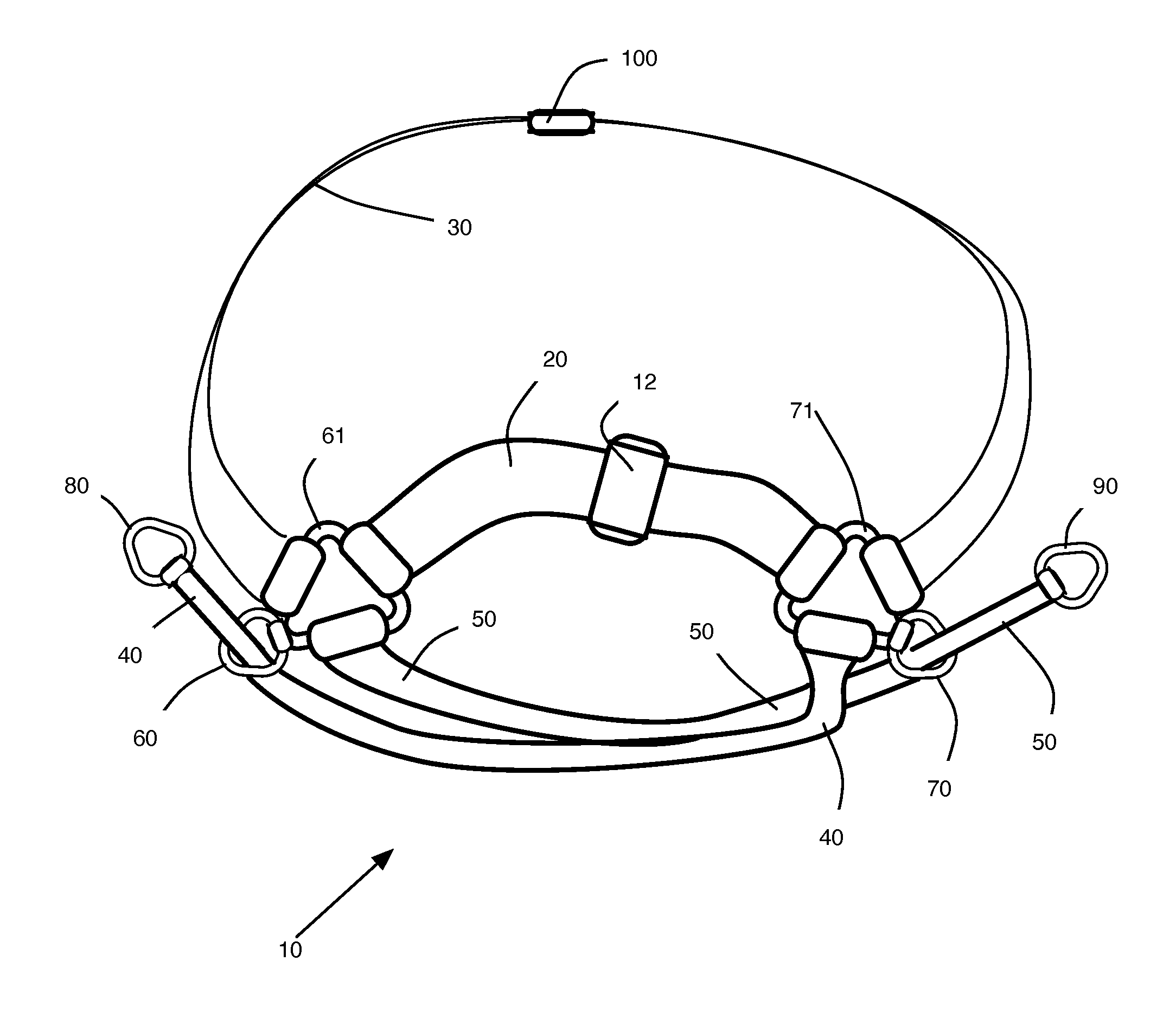

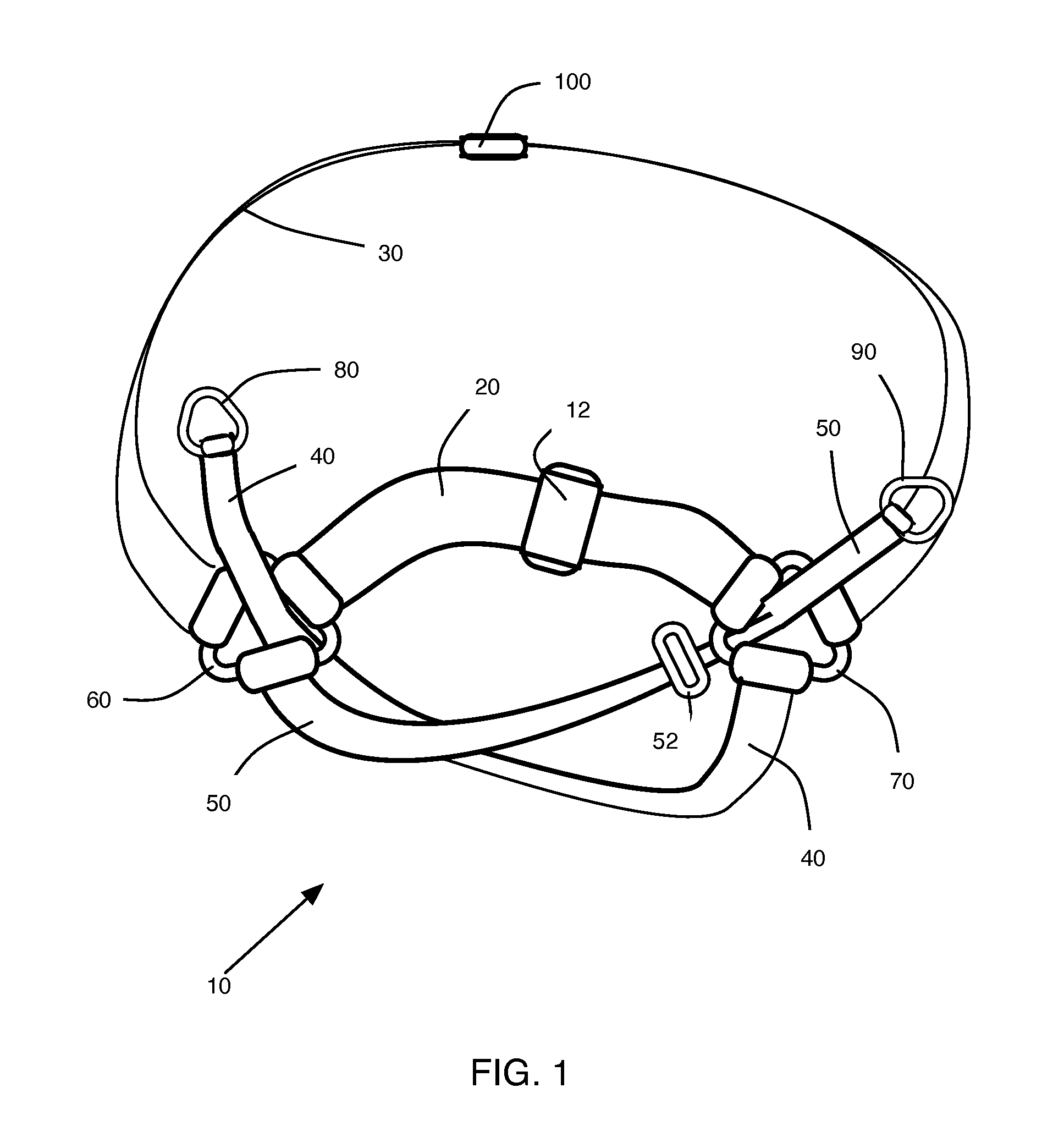

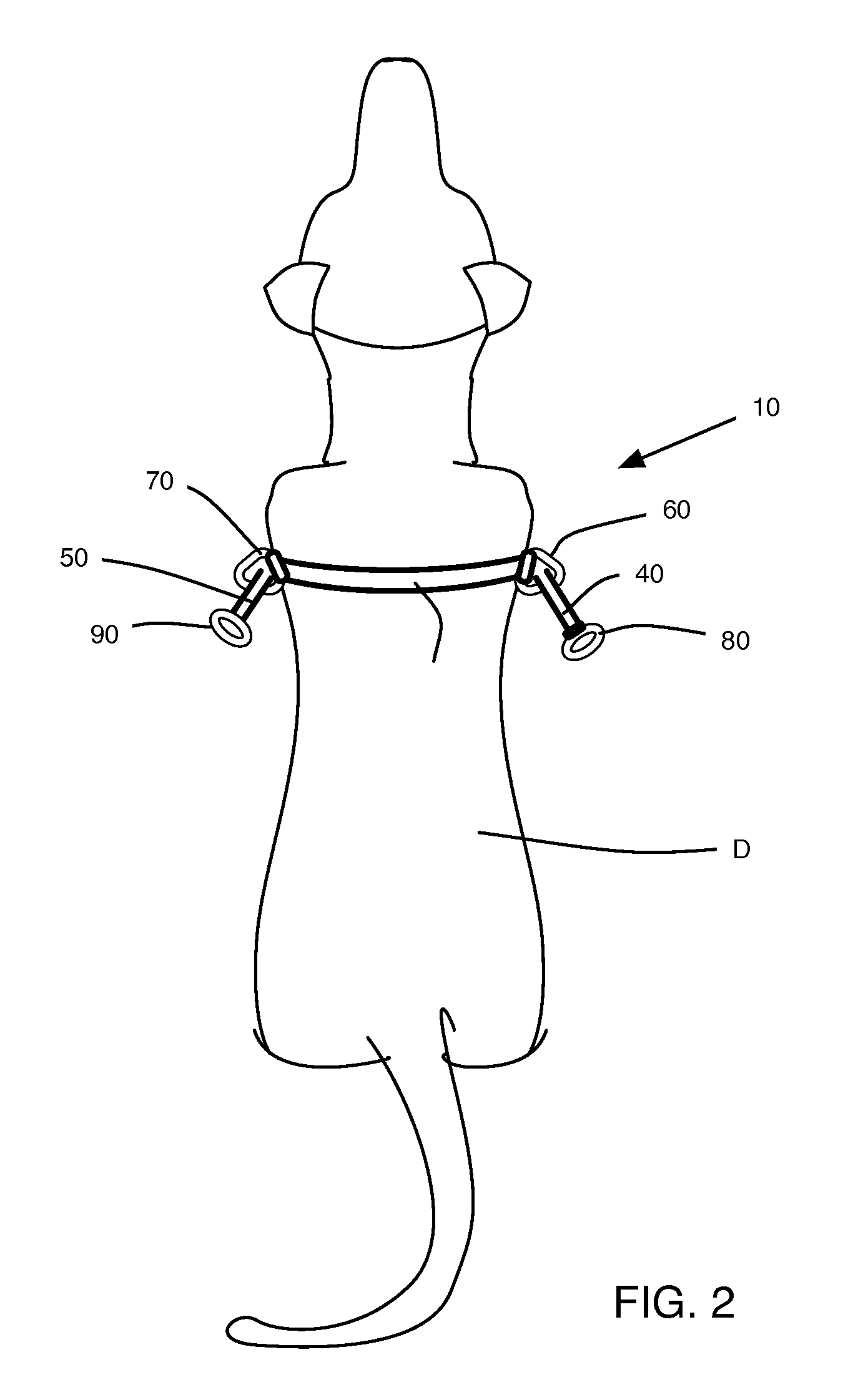

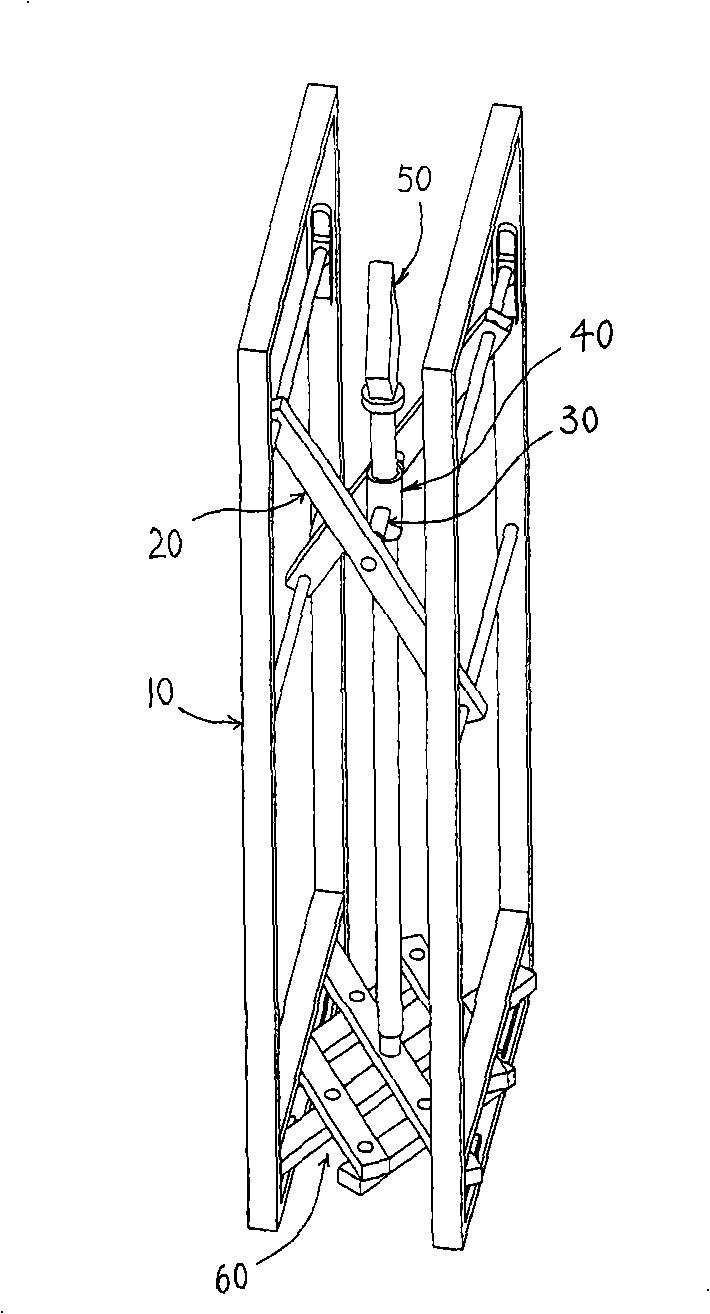

Animal Harness Device and Method

ActiveUS20150007778A1Transmission easilyEasy to handleSafety beltsTaming and training devicesEngineeringCanis lupus familiaris

Owner:YAMIN NANCY

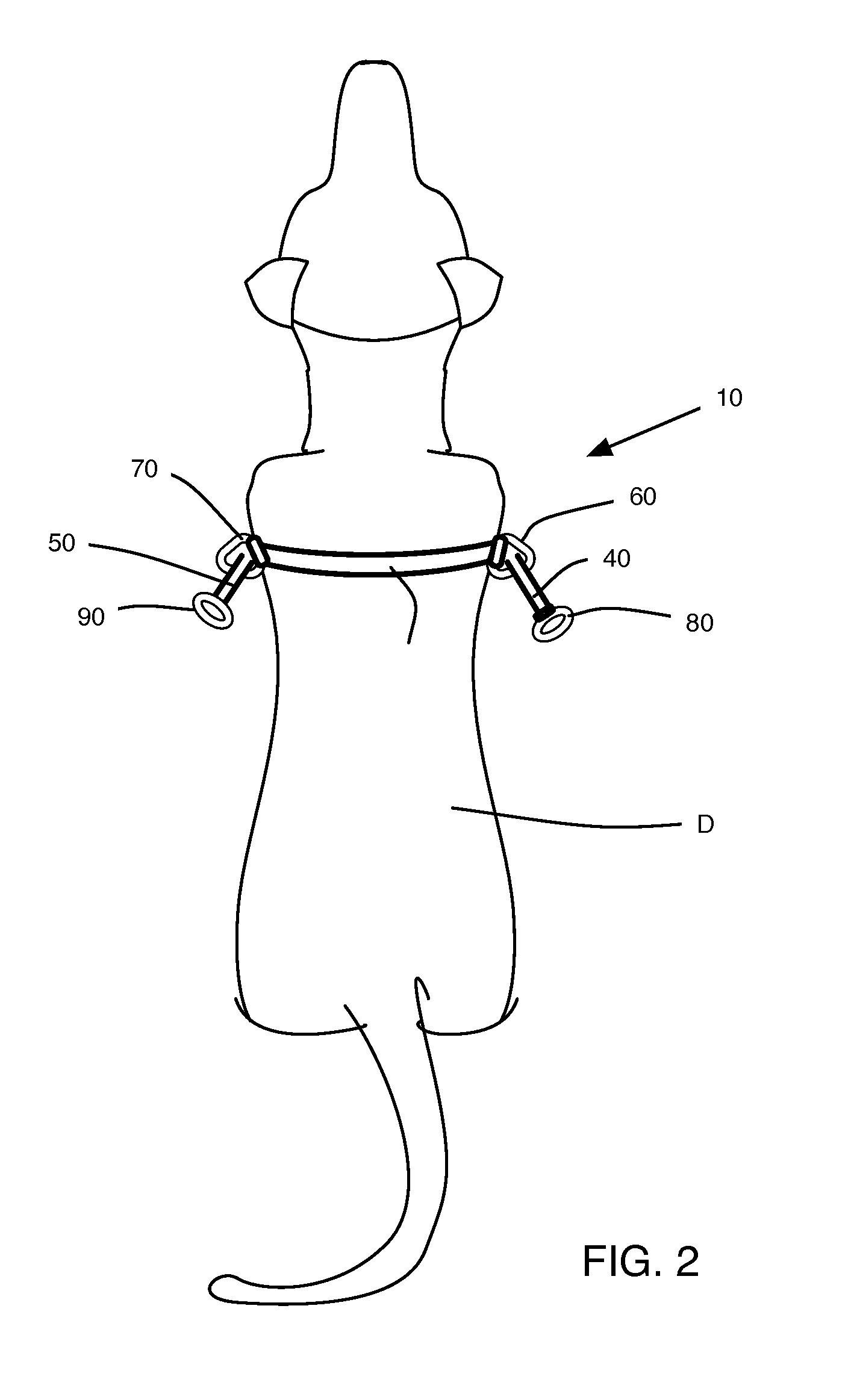

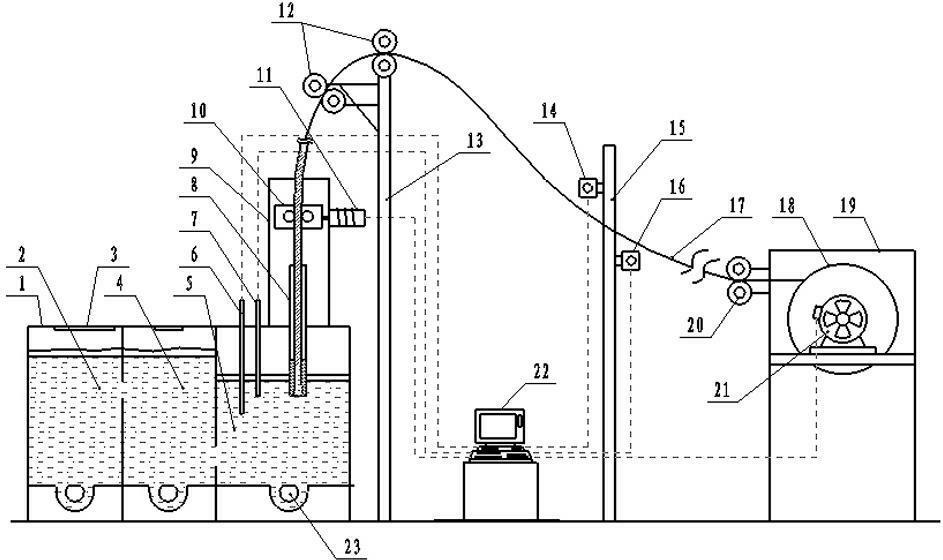

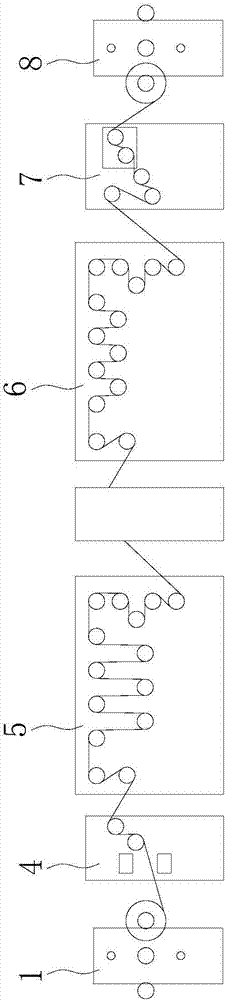

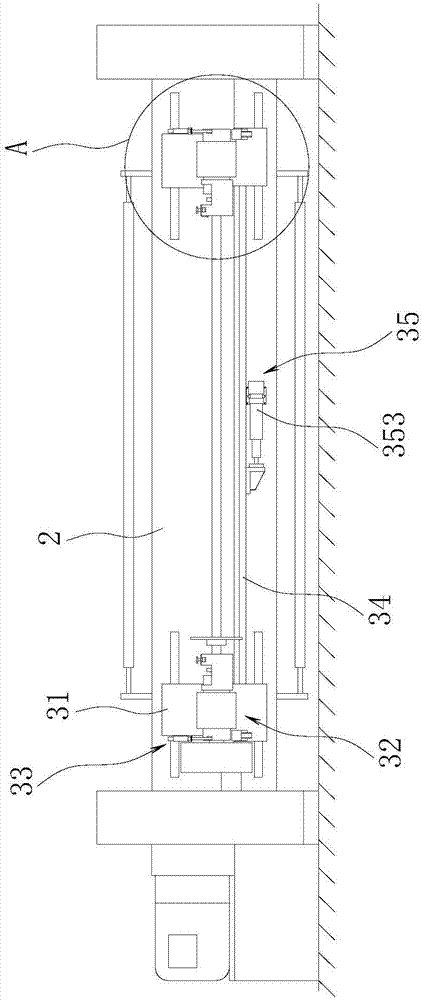

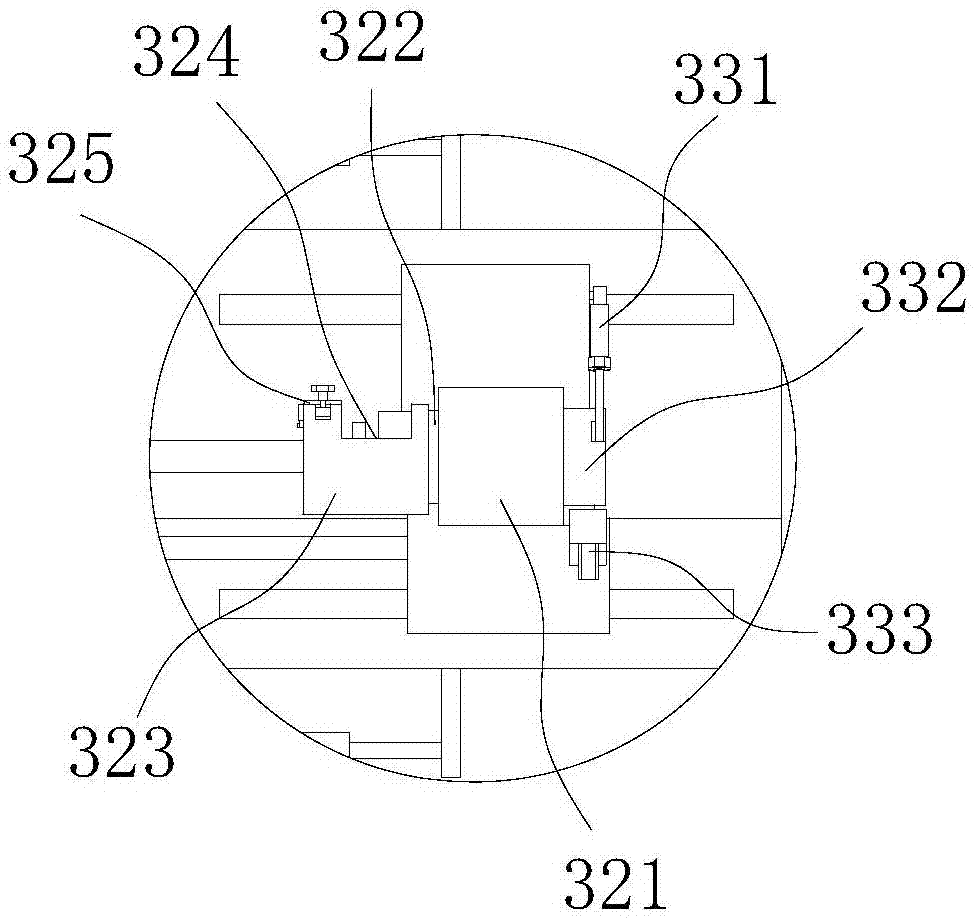

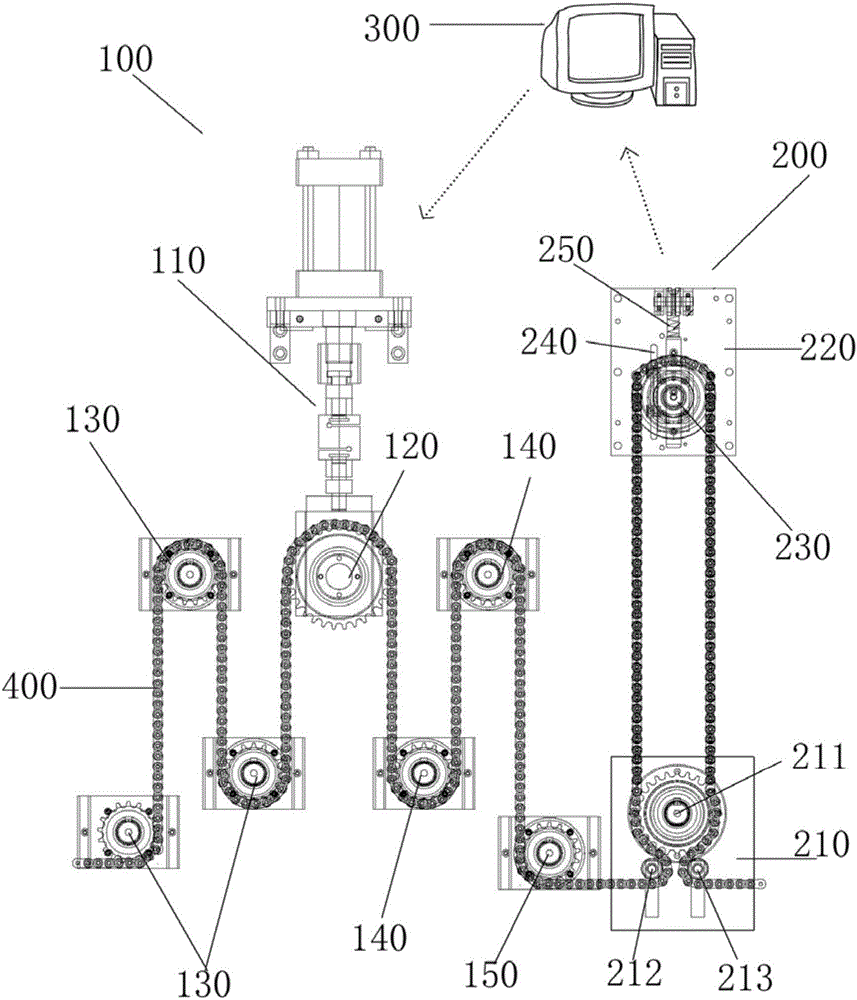

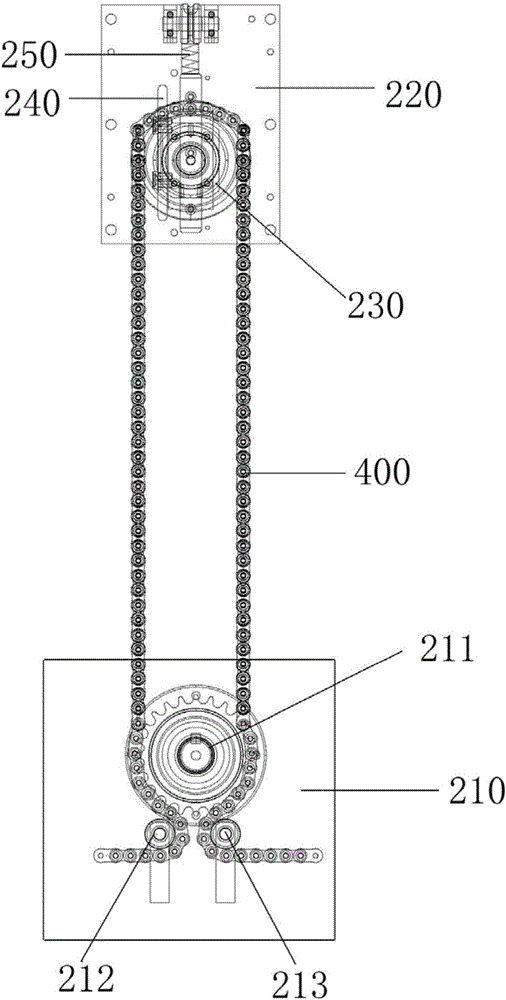

Oxygen-free copper rod production line

An oxygen-free copper rod production line comprises a melting furnace, an up-draw mechanism, a take-up mechanism and a production speed control system. The production speed control system comprises a computer, a temperature sensor, a pressure sensor, an up-draw motor, a take-up motor and infrared sensors, wherein the temperature sensor, the pressure sensor, the up-draw motor, the take-up motor and the infrared sensors are connected with the computer. During production, when the quantity of molten copper in the melting furnace is changed, the pressure sensor above a draw area timely transmits pressure data to the computer, and the computer timely adjusts the speed of drawing up a copper rod, so that the solidification pressure of molten copper in a crystallizer is kept constant. When the temperature in the up-draw area is different, the temperature sensor transmits data to the computer, and the computer controls the crystallization quality of the copper rod by adjusting up-draw speed and controlling the temperature of a constant-temperature heating device. When the speed of drawing up the copper rod is changed, the copper rod at the front end of the take-up mechanism can sink or rise. When the copper rod touches the infrared sensors at two ends of a sensor support, the infrared sensors can inform the computer of controlling take-up speed.

Owner:云南通变电磁线有限公司

After-treatment production line having automatic roll changing and winding function

ActiveCN107381161ATension balanceReduce scrap rateWebs handlingElectric machineryStructural engineering

The invention discloses an after-treatment production line having an automatic roll changing and winding function and belongs to the technical field of copper foil after-treatment equipment. The after-treatment production line is characterized by comprising a first rack, a first rotating seat is movably on the first rack along the horizontal direction, and unwinding units are arranged on two sides of the first rotating seat respectively; the first rotating seat is connected with a first rotation driving motor, and one unwinding unit after being rotated by 180 degrees by taking the first rotating seat as a rotating shaft is coincident with the other unwinding unit; the first rack is sequentially provided with an unwinding connection device, an unwinding foil storage device, a copper foil after-treatment device, a winding foil storage device, a winding connection device and a winding and roll changing device along the copper foil advancing direction. The after-treatment production line is convenient to use and good in effect and used for copper foil production.

Owner:MEIZHOU WEILIBANG ELECTRONICS TECH CO LTD

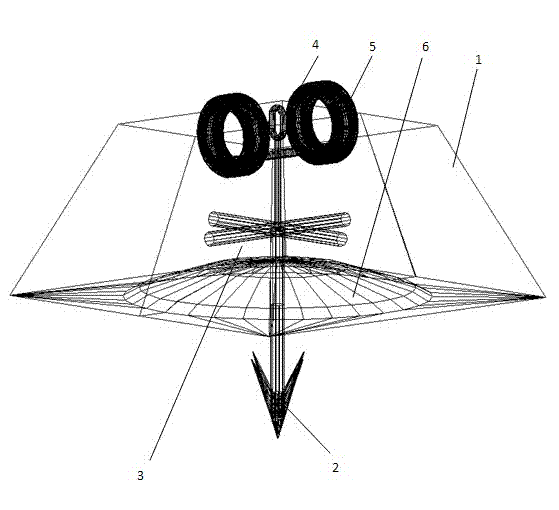

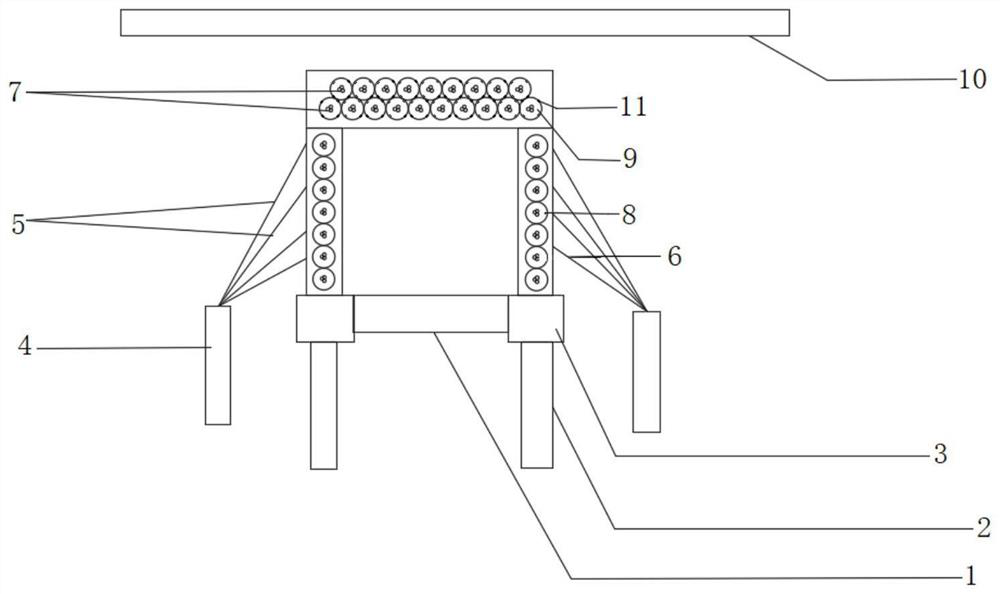

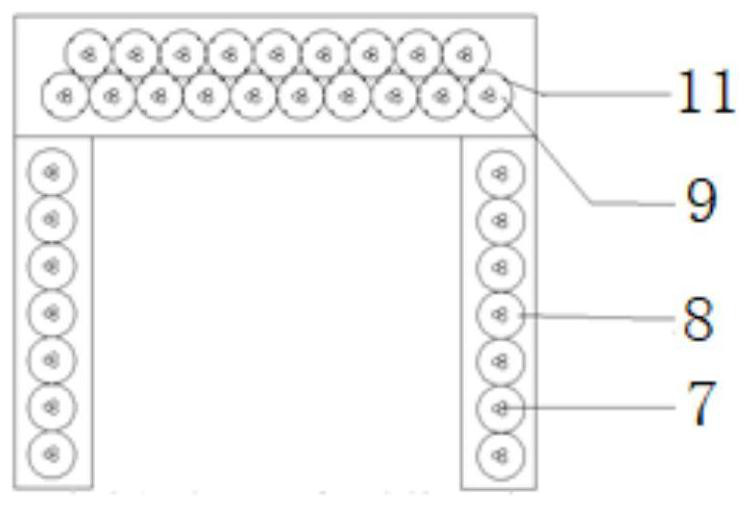

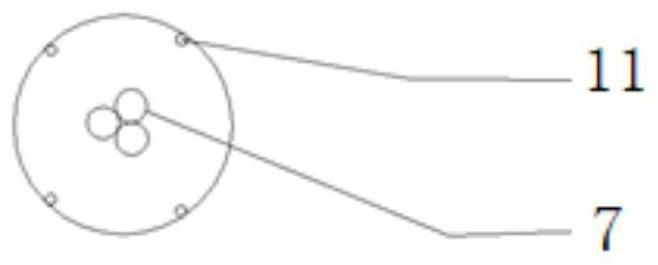

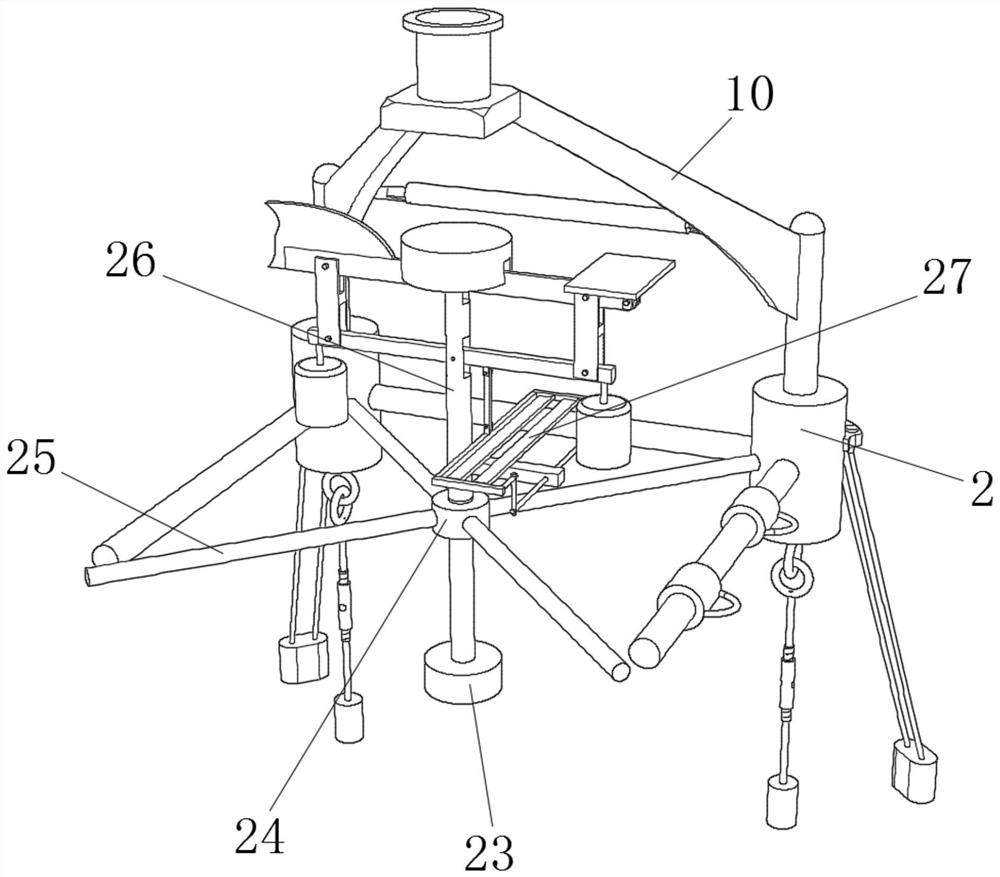

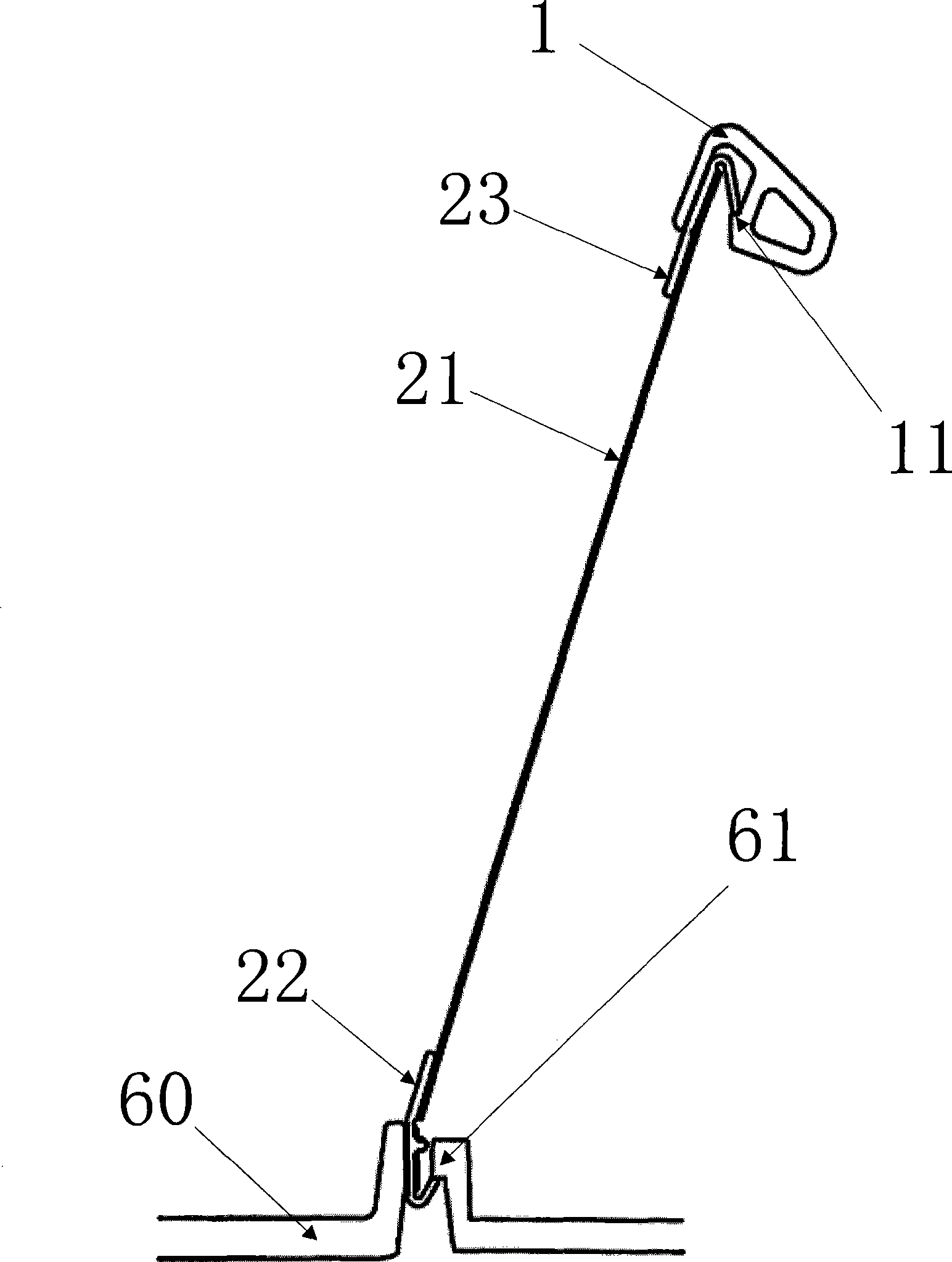

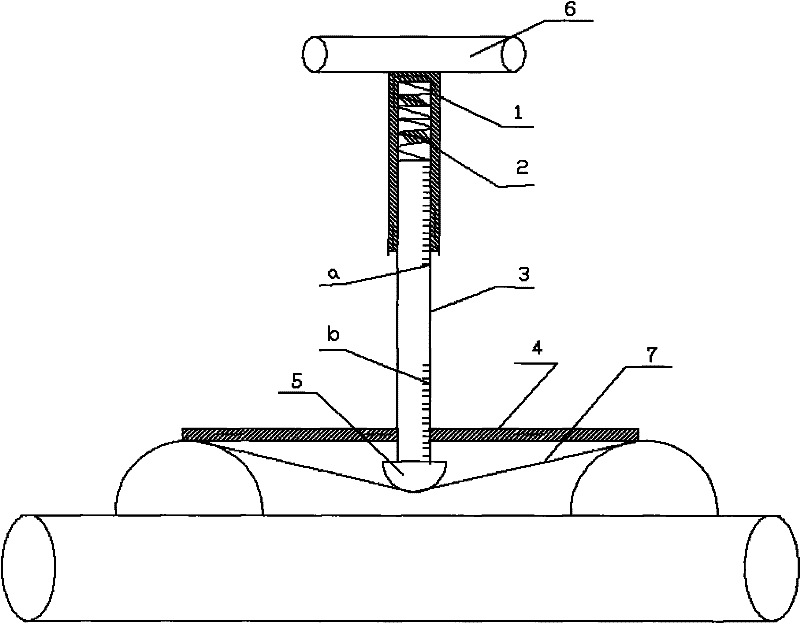

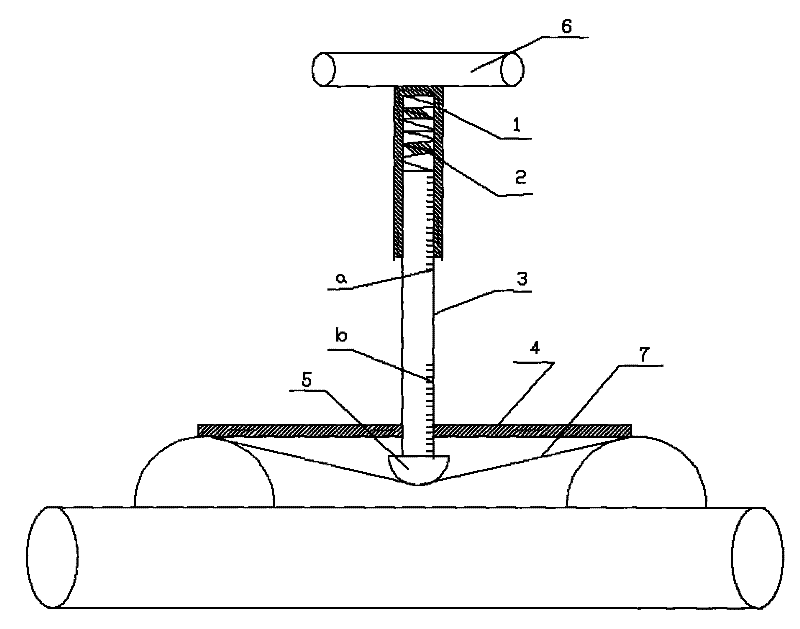

Floating raft-anchoring device applicable to silty bottoms

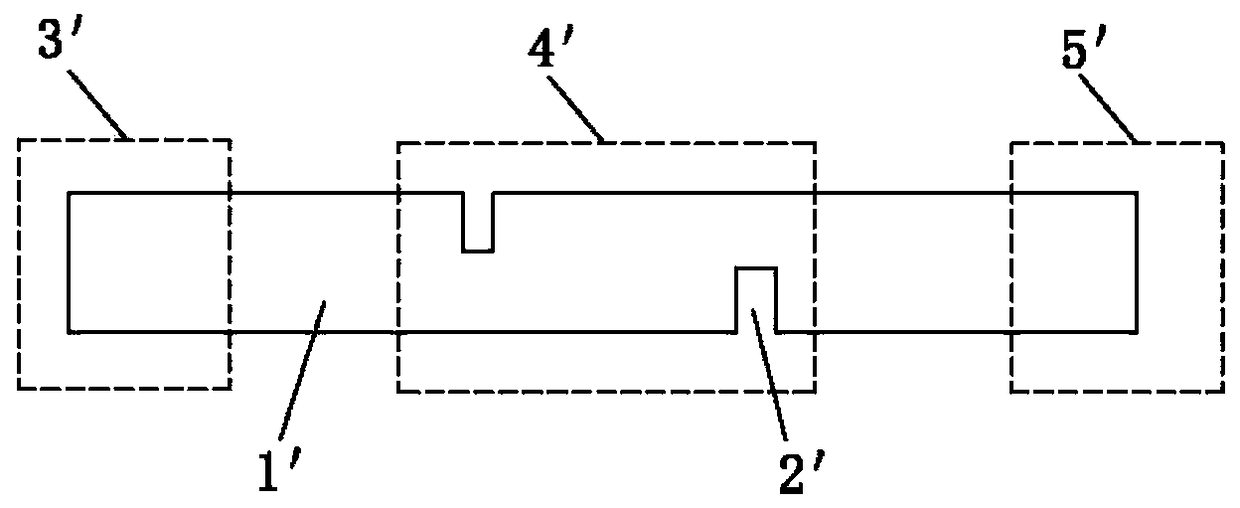

InactiveCN103026993ASimple structureIngenious designClimate change adaptationPisciculture and aquariaShaped beamEngineering

The invention discloses a floating raft-anchoring device applicable to silty bottoms. The floating raft-anchoring device is characterized in that: the floating raft-anchoring device comprises a sunken cement block (1), the longitudinal section of which is trapeziform, a holding anchor (2) is longitudinally arranged in the sunken cement block (1), the bottom end of the holding anchor (2) is located outside the sunken cement block (1), the part of the holding anchor (2), which is located in the sunken cement block (1), is provided with a cross-shaped beam (3) as well, the cross-shaped beam (3) is perpendicular to the holding anchor (2), an anchor ring (4) which is located outside the sunken cement block (1) is also fixed on the top end of the holding anchor (2), and rubber rope rings (5) are arranged on the top of the sunken cement block (1) as well. The structure of the floating raft-anchoring device is simple, the design is ingenious, and the floating raft-anchoring device can provide high anchoring force for a raft or an aquaculture net cage, and can ensure that raft aquaculture is safe and smooth.

Owner:DALIAN OCEAN UNIV +1

Full automatic reel-to-reel screen process press

The invention discloses a full automatic reel-to-reel screen process press. The full automatic reel-to-reel screen process press comprises a coil stock placing device, a printing device, a drying device and a winding device, the coil stock placing device comprises a double-shaft device and a negative pressure drum which are arranged on the coil stock placing device; the printing device comprises a drum half-negative-pressure concave-convex guiding and left-right adjusting and clamping device which is arranged on a printer frame and is fixed with a damp sucker, an electric-eye tracking socket and a negative pressure drum film-drawing device; the drying device comprises a thermostat, the inner top part of the thermostat is provided with a hot air box, the bottom part of the thermostat is relatively provided with a suction box device, a guide left-right adjusting and limiting mechanism and a position monitoring device, and a thermostat conveyor belt is provided with adsorption holes; the coil stock placing device comprises a double-shaft device which is arranged on a winder frame and a drum half-negative-pressure concave-convex guiding and left-right adjusting and locating device. According to the full automatic reel-to-reel screen process press provided by the invention, an adsorption drying and hanging type tension-free drying system and a suction locating mechanism can be adopted to control wind strength, stabilize a traveling film and monitor the position of the film, is precise to register, balanced in tension, is free from stretching, and is not in contact with a surface.

Owner:QINGTIAN RIJIA OPTICAL GLASSES CO LTD

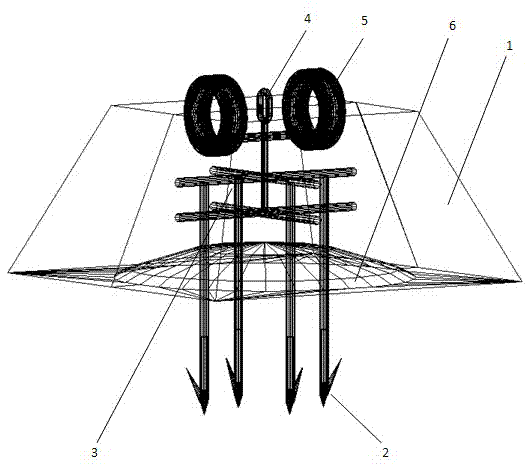

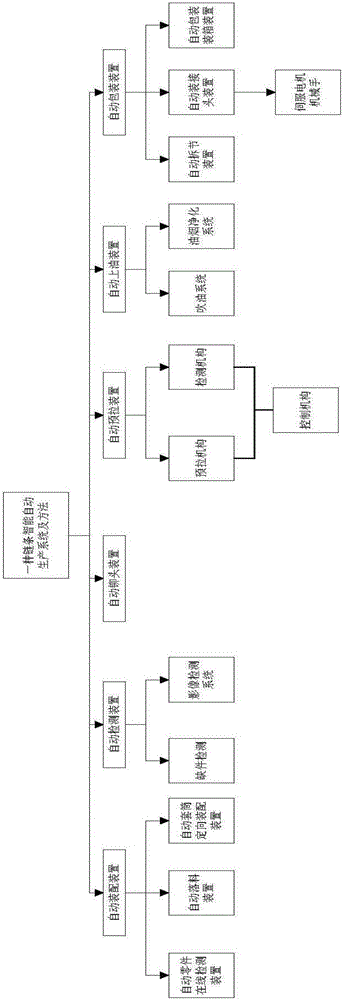

Automatic production system of chain

The invention discloses an automatic production system of a chain. The automatic production system comprises an automatic assembling device, an automatic detecting device, an automatic head riveting device, an automatic pretensioning device, an automatic oiling device and an automatic packaging and boxing device, all of which are sequentially arranged in the chain advancing direction. The automatic pretensioning device comprises a pretensioning mechanism, a detecting mechanism and a control mechanism, the pretensioning mechanism and the detecting mechanism allow the chain to penetrate in sequence, and the control mechanism is connected to the pretensioning mechanism and the detecting mechanism in a communication manner. The tension with the adjustable magnitude is provided by the pretensioning mechanism to tension the chain. The detecting mechanism is used for detecting the tensioning state of the chain. The control mechanism receives signals about the tensioning state of the chain from the detecting mechanism and indicates the pretensioning mechanism to adjust the magnitude of the tension according to the signals. The system is convenient to operate and high in automation degree, the tension can be detected and adjusted in real time in the pretensioning process, and the production efficiency and the product percent of pass are effectively improved.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

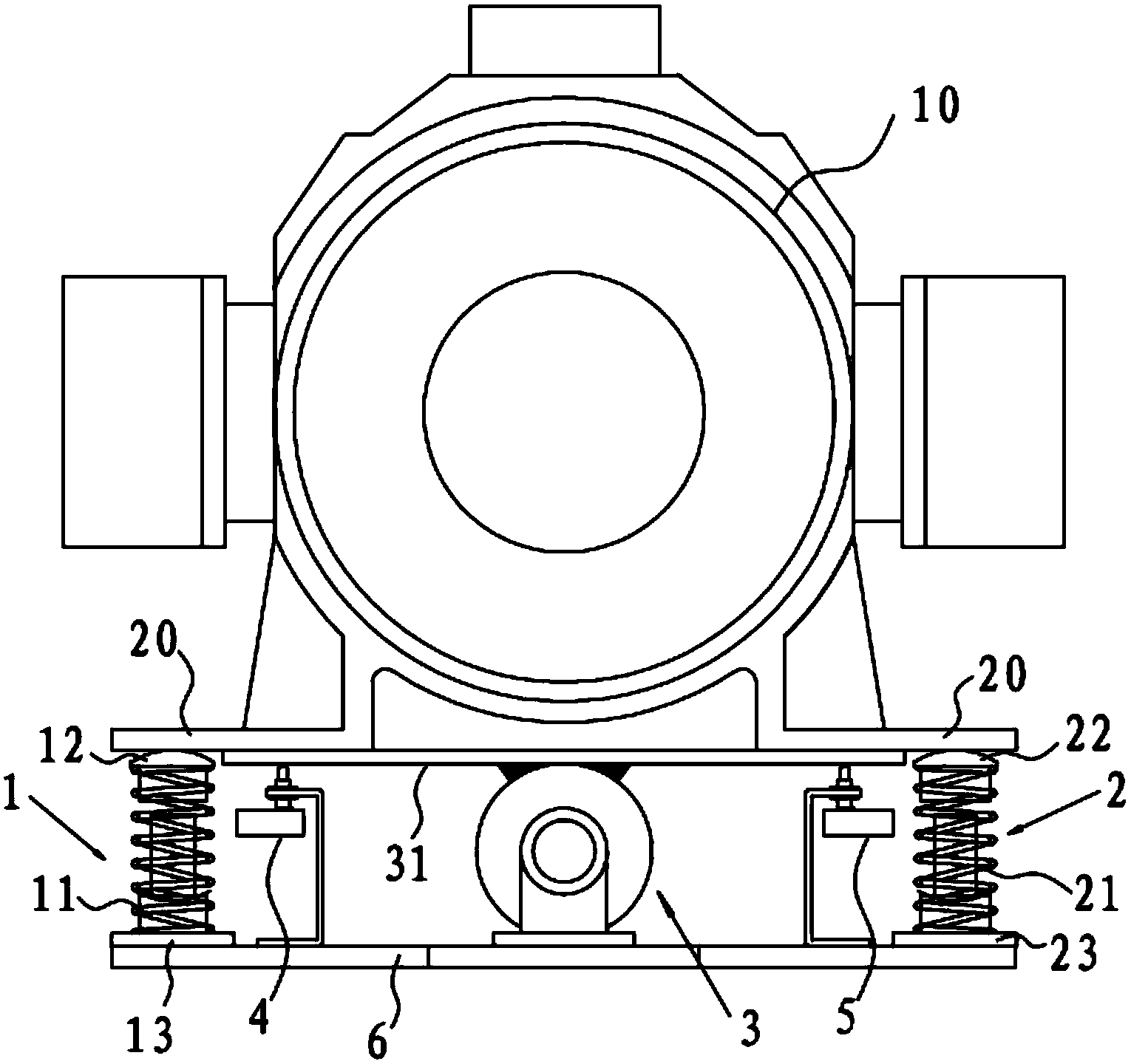

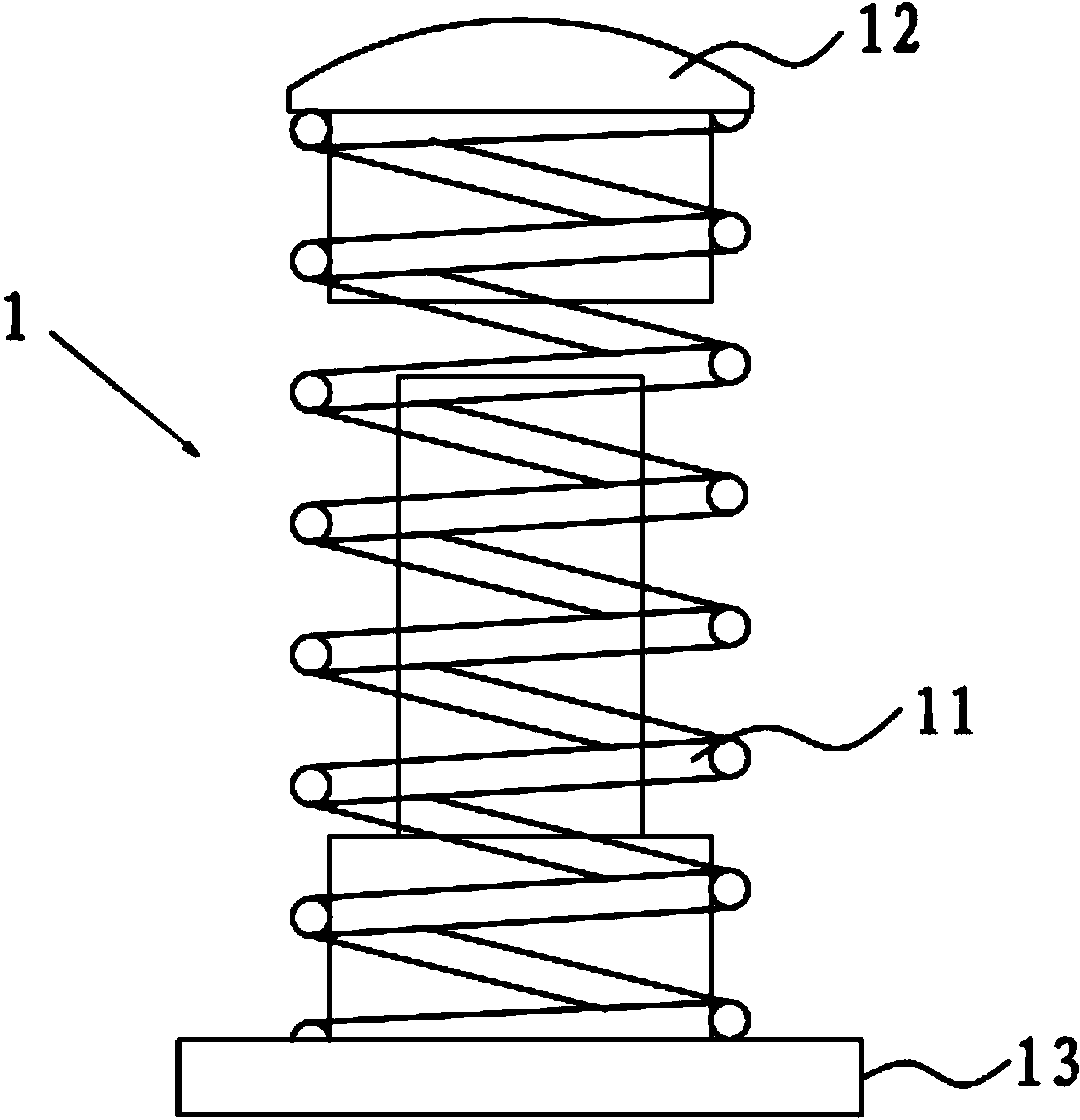

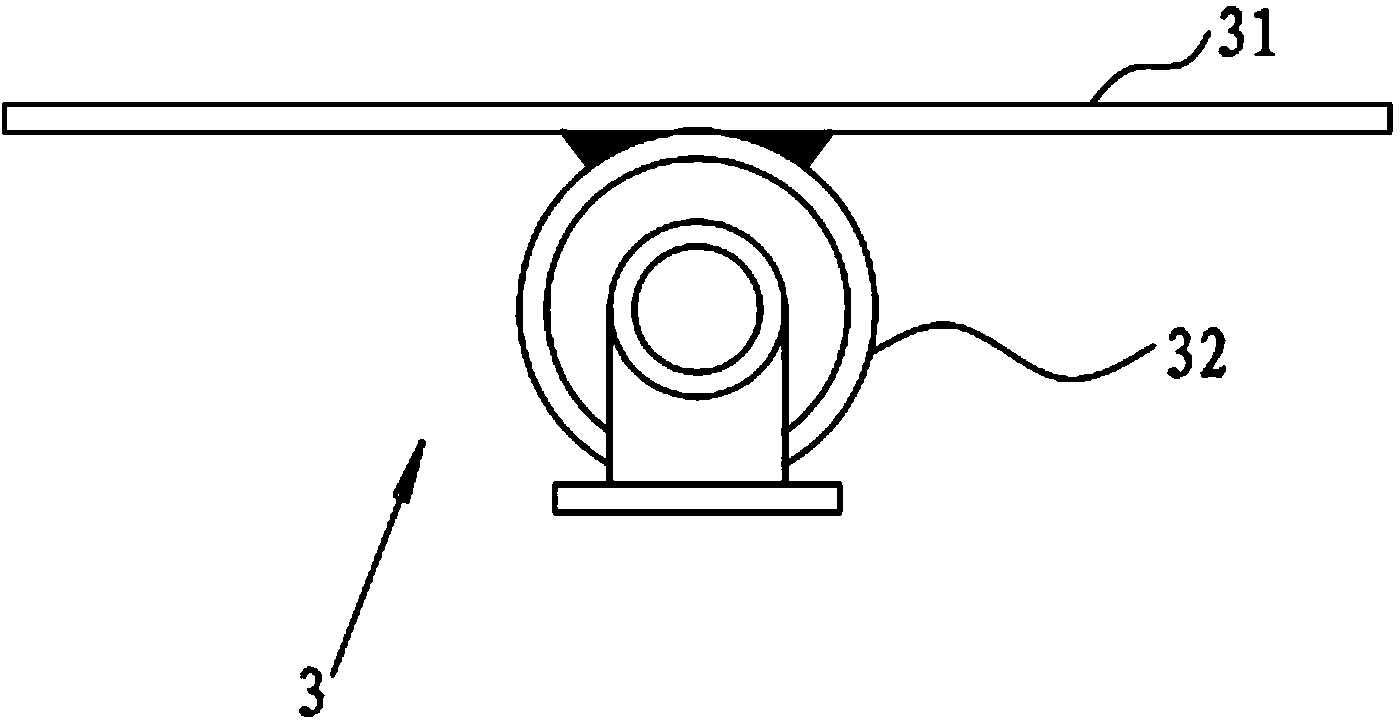

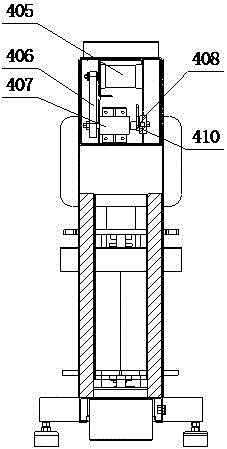

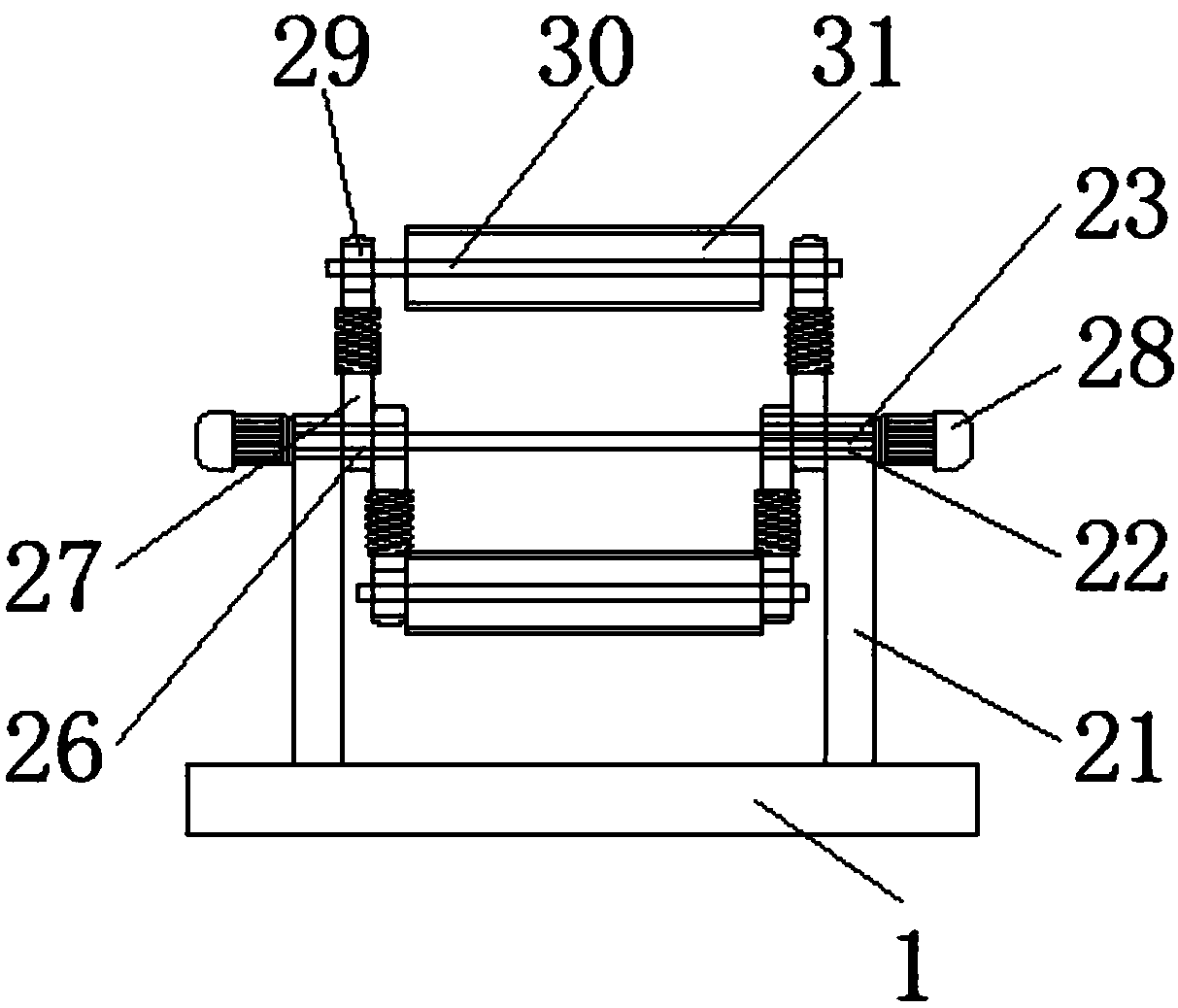

Automatic balancing mechanism of traction machine

InactiveCN104044980ATension balanceIncrease swingRotating bodies balancingBuilding liftsSimulationControl circuit

The invention discloses an automatic balancing mechanism of a traction machine, comprising a first elastic element, a second elastic element, a floating device, a first travel switch and a second travel switch, wherein the first elastic element and the second elastic element are arranged on two sides of the traction machine for supporting the traction machine; the floating device is positioned between the first elastic element and the second elastic element for supporting the traction machine; the first travel switch and the first elastic element are arranged correspondingly; the second travel switch and the second elastic element are arranged correspondingly; the position of the traction machine can be changed by means of the first elastic element and the second elastic element; as the first travel switch and the second travel switch are arranged, a control circuit of an elevator can regulate the counterweight of the elevator, and new balance of the traction machine in different locations can be realized. The automatic balancing mechanism of the traction machine, disclosed by the invention, has the characteristics of being simple in structure, reducing the driving moment of the elevator, facilitating control over the elevator car and achieving safety and reliability in use.

Owner:广东德奥电梯科技有限公司

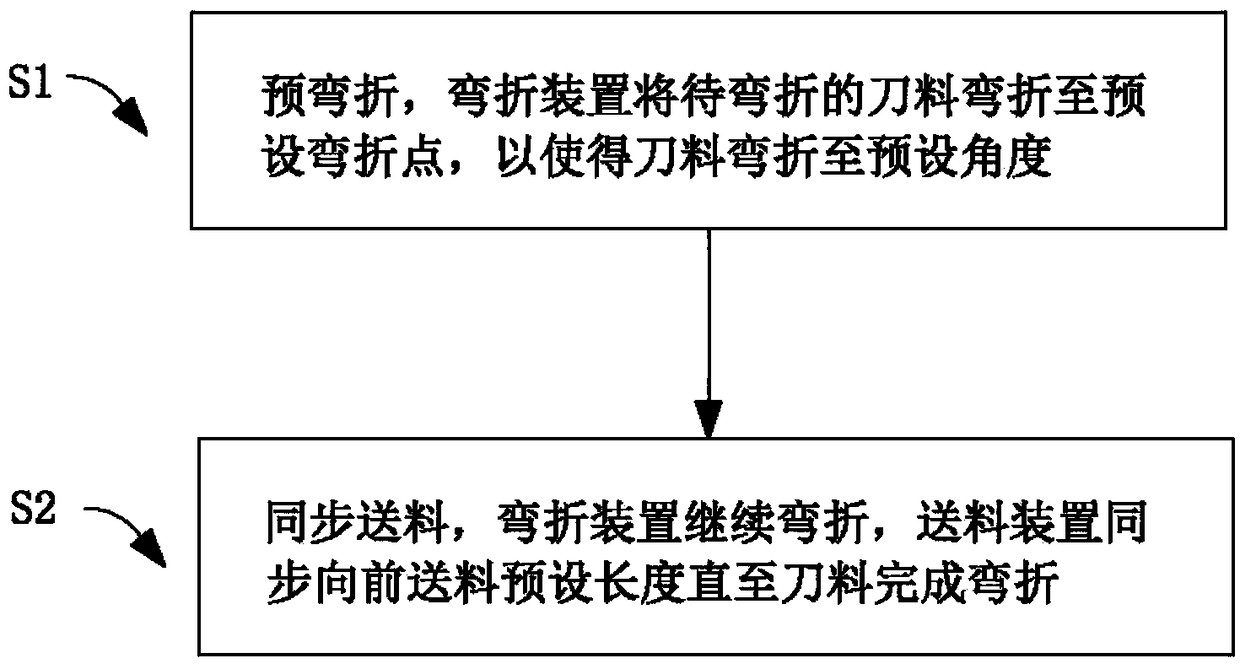

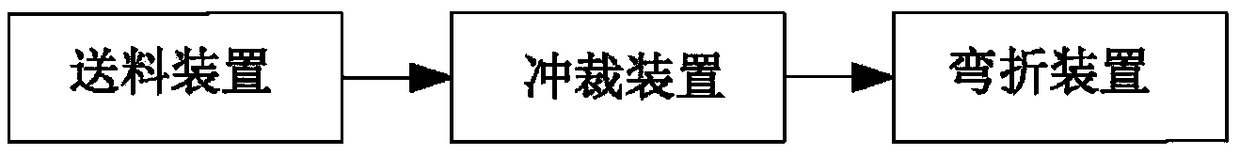

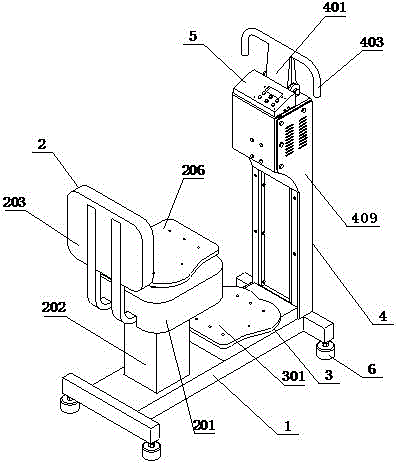

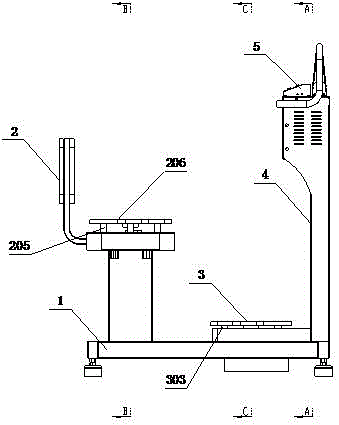

Large angle bending method of automatic knife bending machine

The invention relates to a large angle bending method of an automatic knife bending machine. The method includes the following steps that pre-bending is performed, wherein a bending device bends a to-be-bent knife to a preset bending point so that the knife can be bent to a preset angle; synchronous feeding is performed, wherein the bending device continues to bend the knife, and a feeding devicesynchronously feeds the knife forward to a preset length until the knife is bent. According to the method, the knife is bent to the preset bending point by pre-bending, then the feeding device synchronously feeds the knife forward to a preset length in the subsequent bending process, thus tension is balanced in the subsequent bending process, the accuracy of a bending position is ensured, the influence of the bending tension is eliminated, and thus the effect of tension balance and high precision is achieved.

Owner:深圳市骏昊自动化科技有限公司

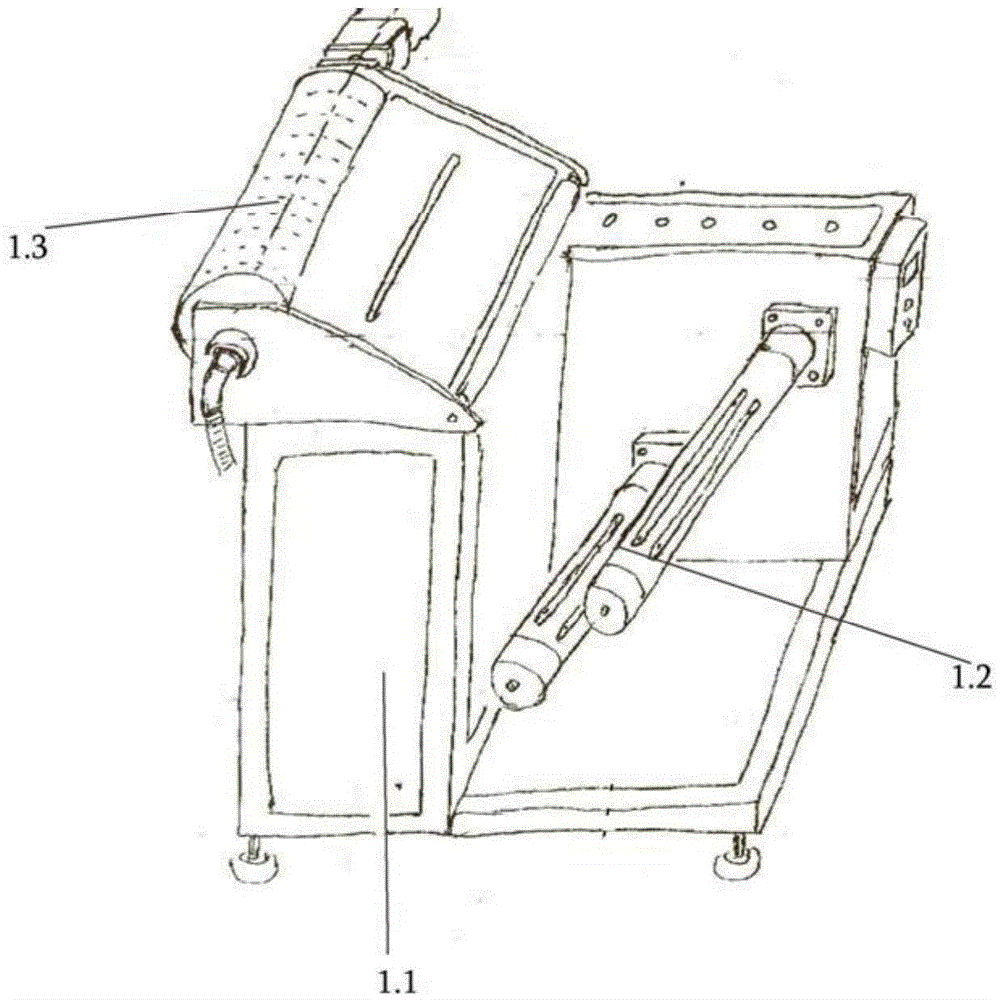

Spine-vibrating passive movement external force machine

The invention relates to a spine-vibrating passive movement external force machine. The spine-vibrating passive movement external force machine comprises a base, a hip jigging mechanism, a foot jigging mechanism, an arm back-and-forth movement mechanism and a controller. The hip jigging mechanism is arranged at one end of the base, the arm back-and-forth movement mechanism is arranged at the other end of the base, the foot jigging mechanism is arranged between the hip jigging mechanism and the arm back-and-forth movement mechanism, and the controller is arranged on the surface of the arm back-and-forth movement mechanism. Compared with the prior art, the spine-vibrating passive movement external force machine has the advantages of being simple in structure, reasonable in design, convenient to use, scientific, practical, capable of conducting passive movement and fluttering jigging, free of injection and medication, environmentally friendly, safe, reliable, free of side effects and the like, and has the effects of inducing generation of nitric oxide, balancing hormones, conditioning sub-health and prolonging life by making in-vivo cells strike one another for rearrangement through movement and jigging of the machine for nourishing the spine, building the body and preventing senescence and degeneration of the body.

Owner:沈阳北星脊柱梳理有限公司

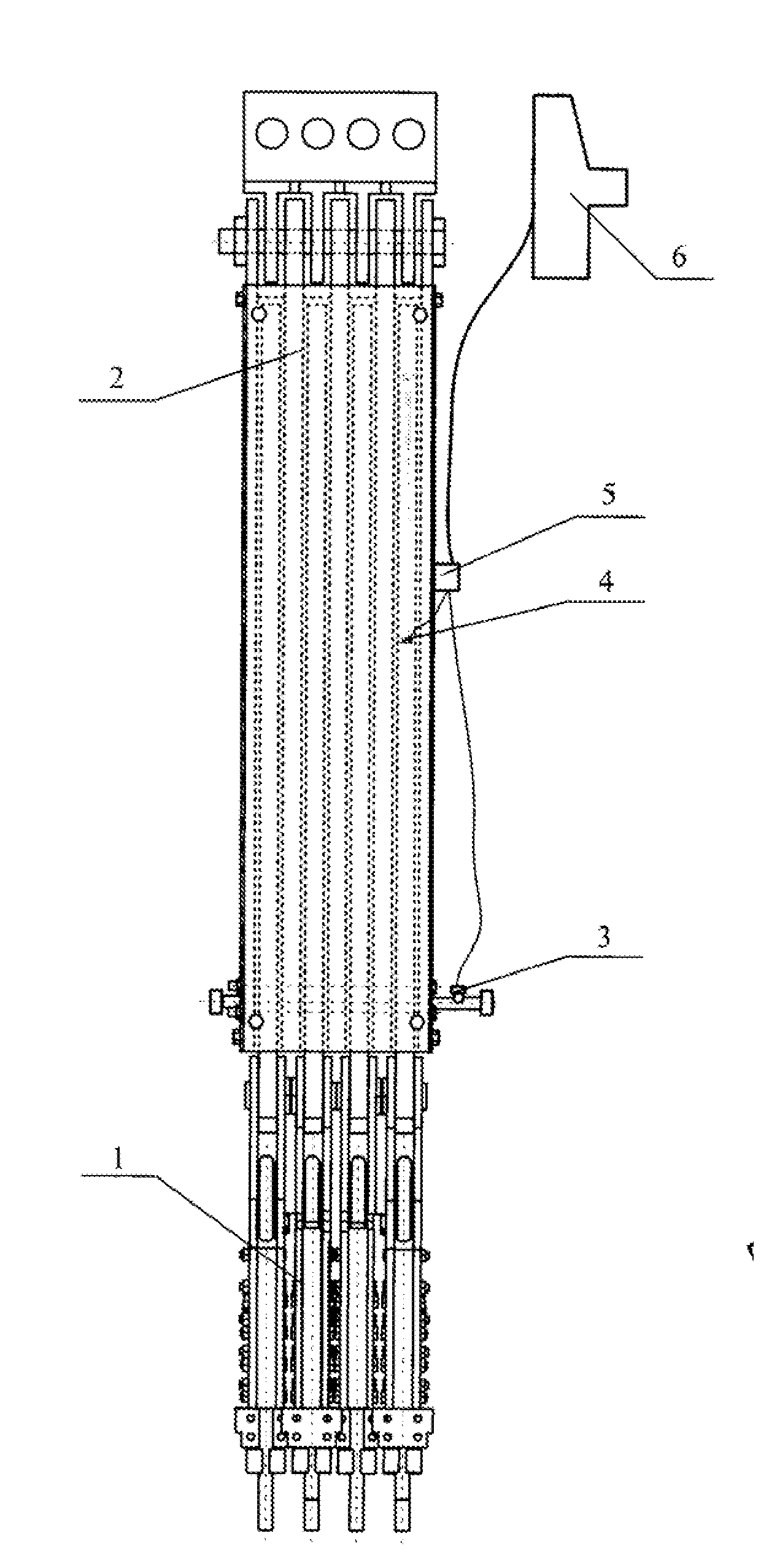

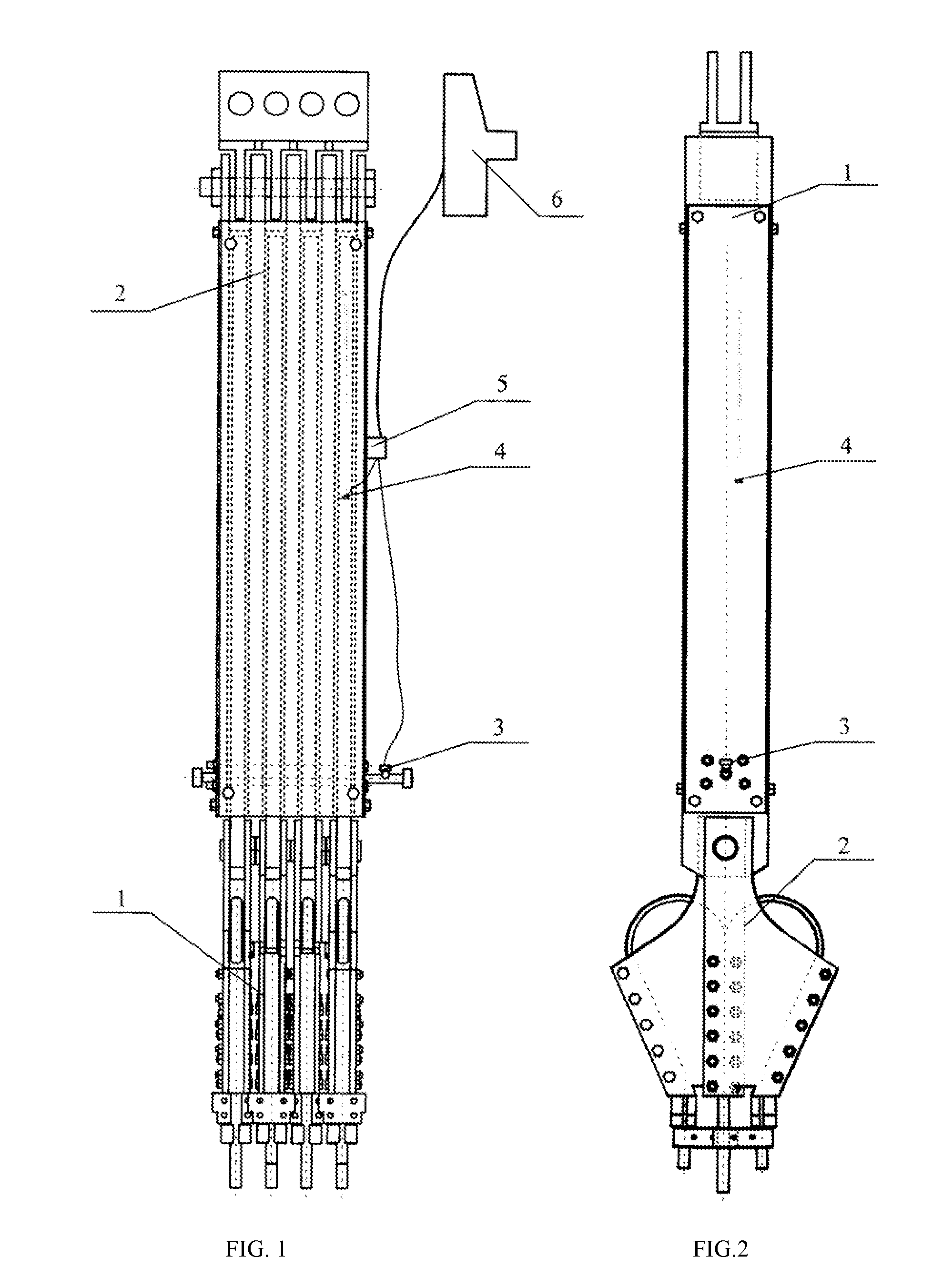

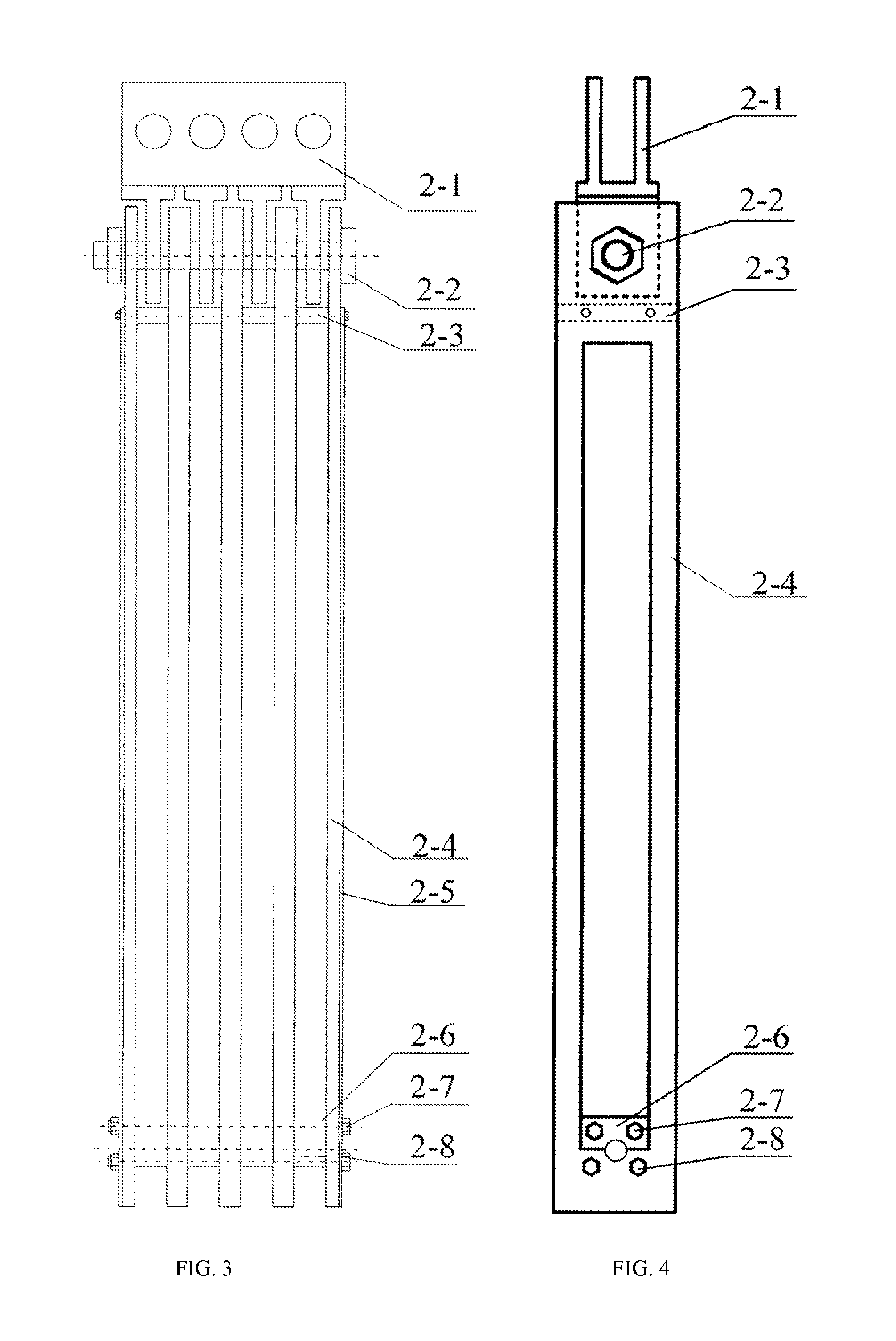

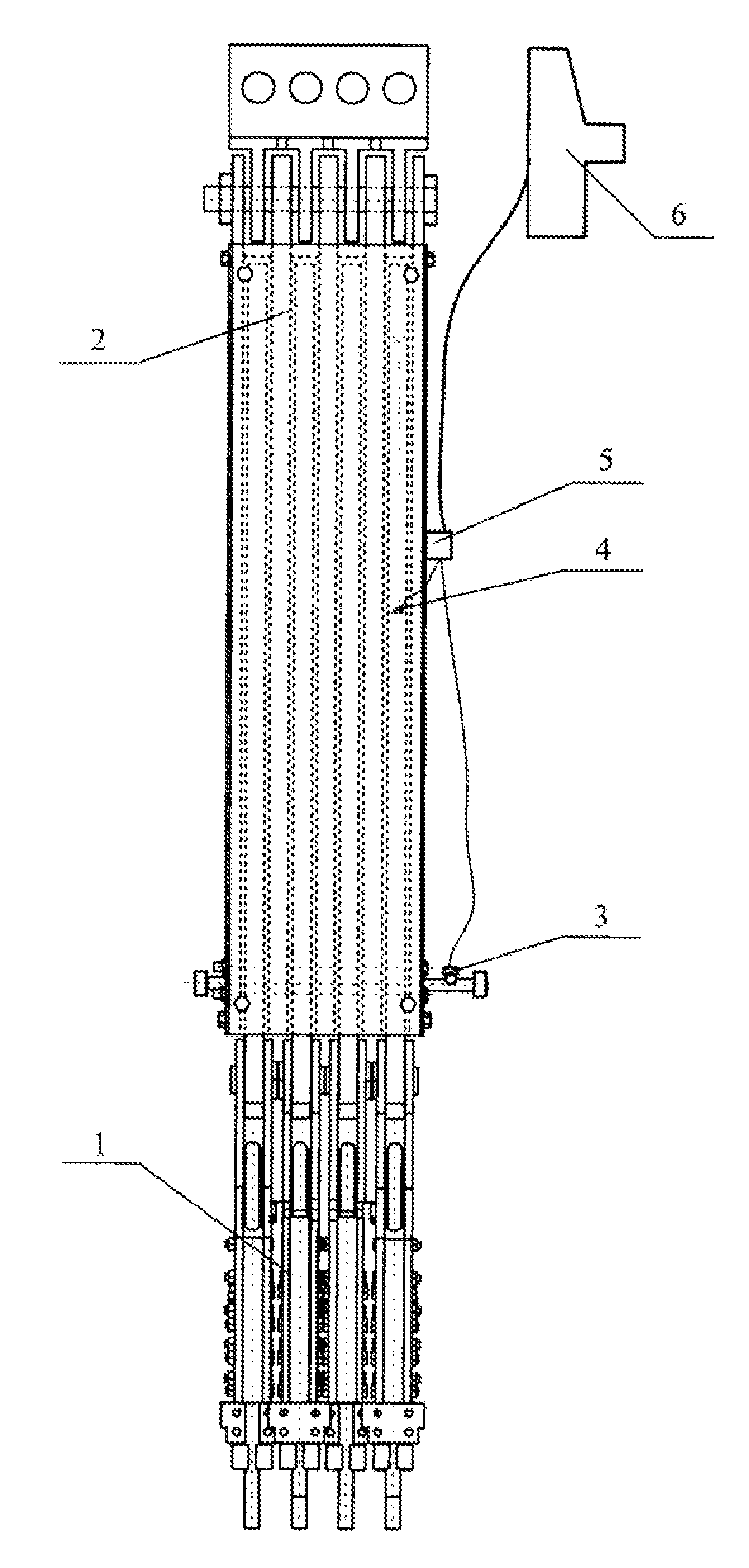

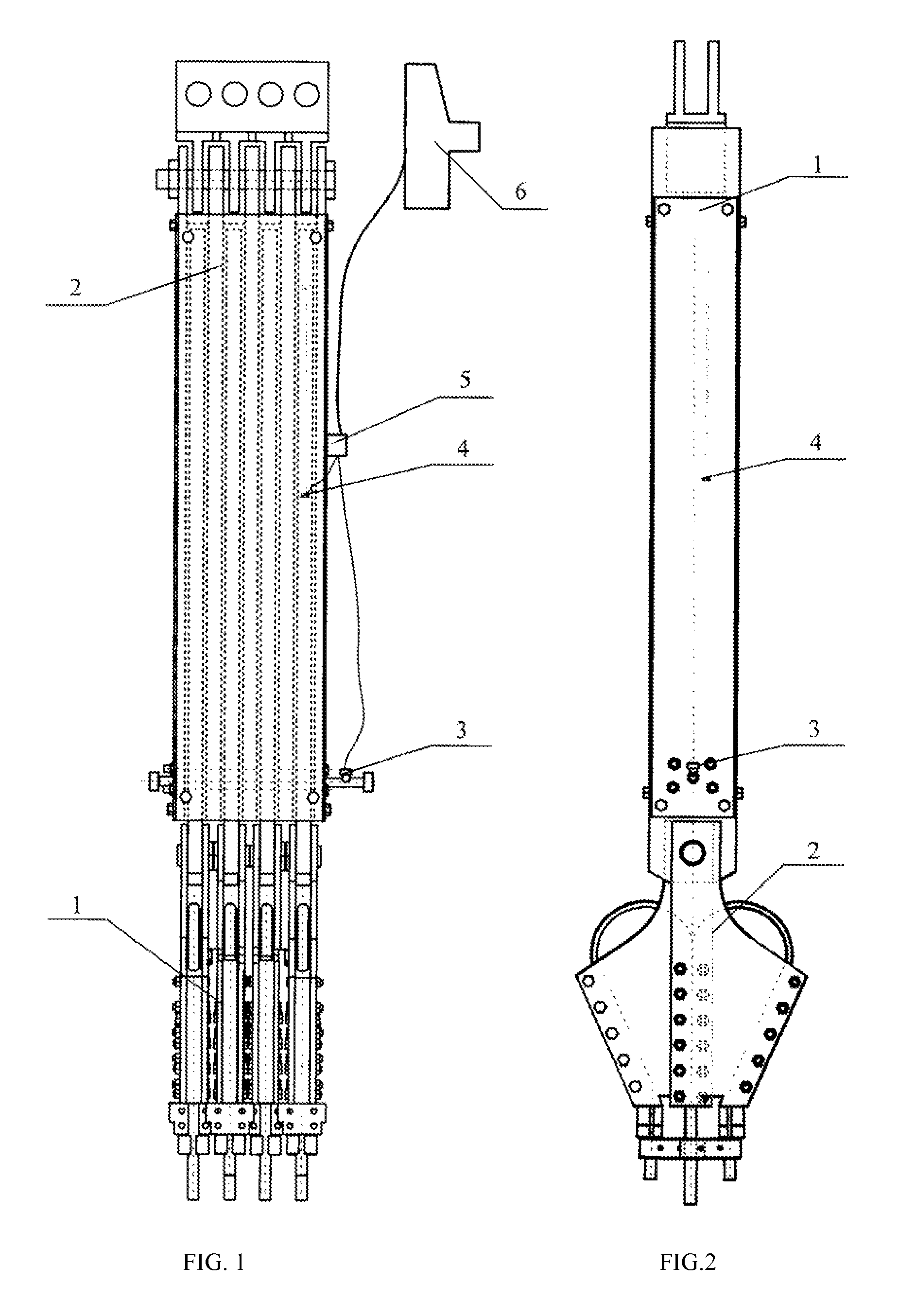

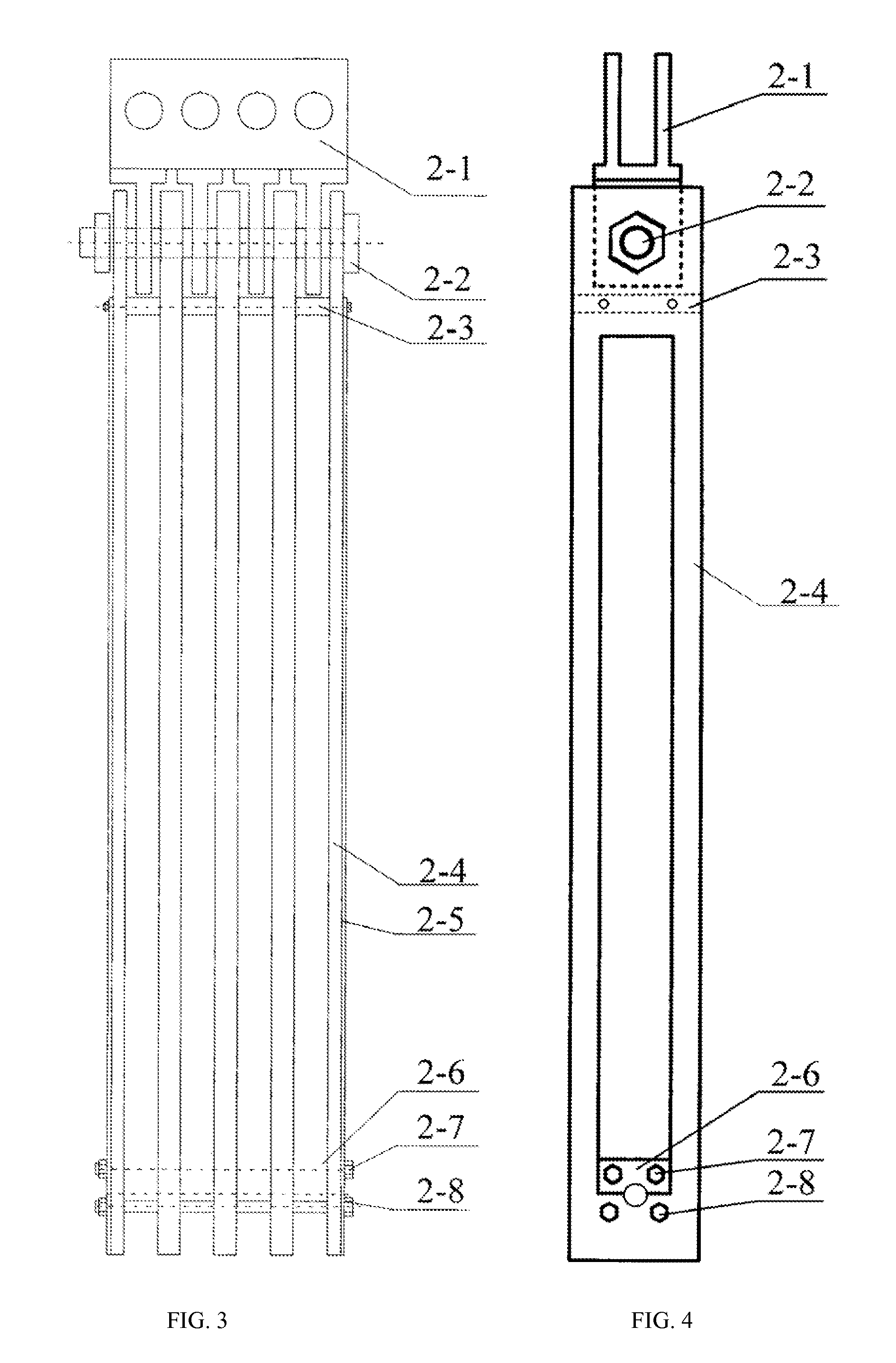

Mining elevator traction cable connecting apparatus and measuring method therefor

ActiveUS20130056313A1Simple structureGuaranteed uptimeAlarmsElevatorsHydraulic cylinderRelative displacement

A mining elevator traction cable connecting apparatus and a measuring method therefor, for use in a mining elevator serving a deep-mine. The apparatus includes an industrial personal computer (IPC), a signal collector connected to the IPC, multiple symmetrically arranged cable rings for use in connecting to one end of a traction cable, and a traction cable tension adjusting apparatus connected to the multiple of cable rings. Arranged within the traction cable tension adjusting apparatus are a plurality of hydraulic cylinders, and a plurality of draw wire displacement sensors for use in monitoring the relative displacement between each hydraulic cylinder plunger and a corresponding hydraulic cylinder body. The draw wire displacement sensors and an oil pressure sensor connected to a hydraulic pipeline are connected to the IPC via the signal collector, forming a traction cable tension and degree of adjustment measuring system.

Owner:CHINA UNIV OF MINING & TECH +1

Animal harness device and method

ActiveUS9491931B2Transmission easilyEasy to handleTaming and training devicesEngineeringTraining methods

Owner:YAMIN NANCY

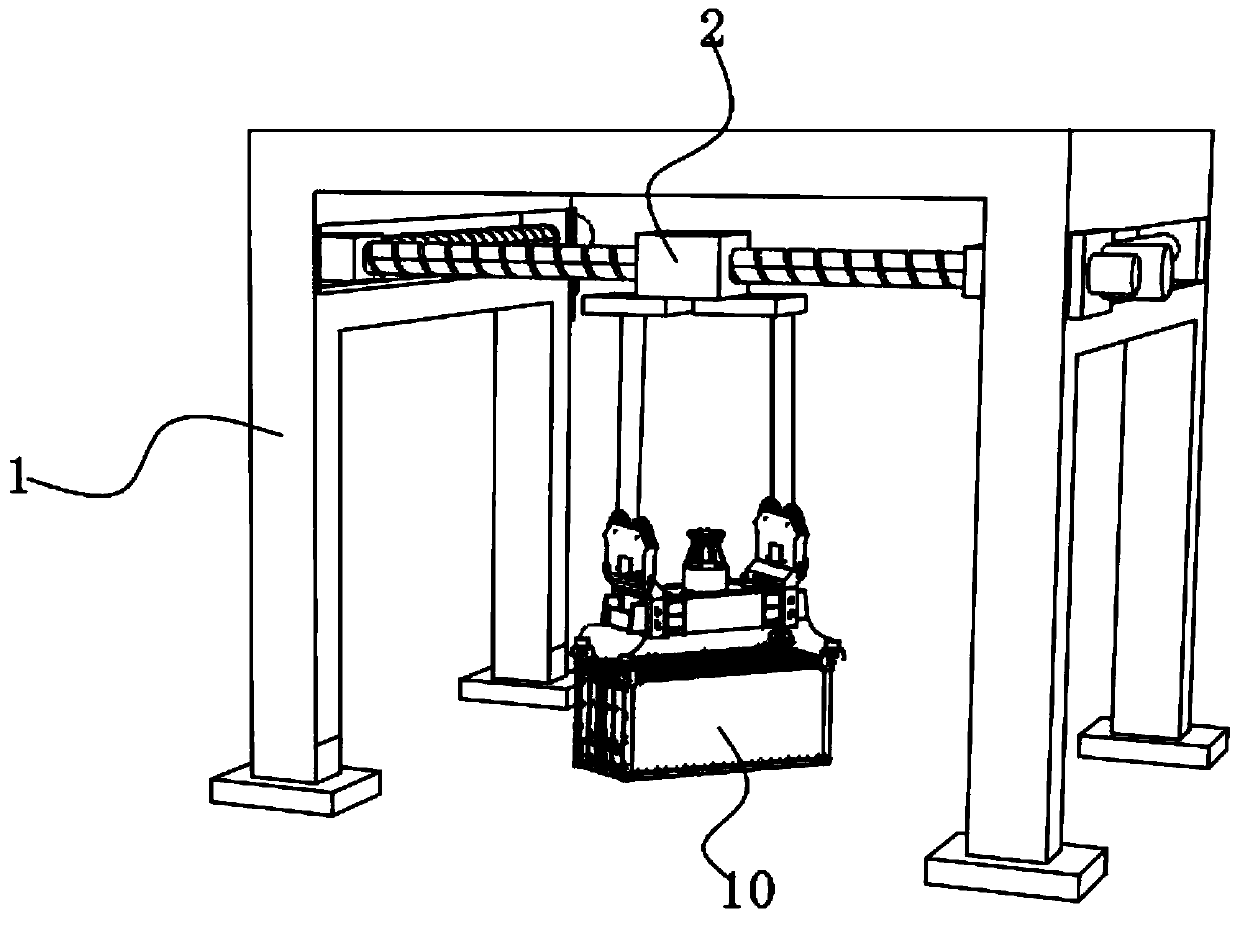

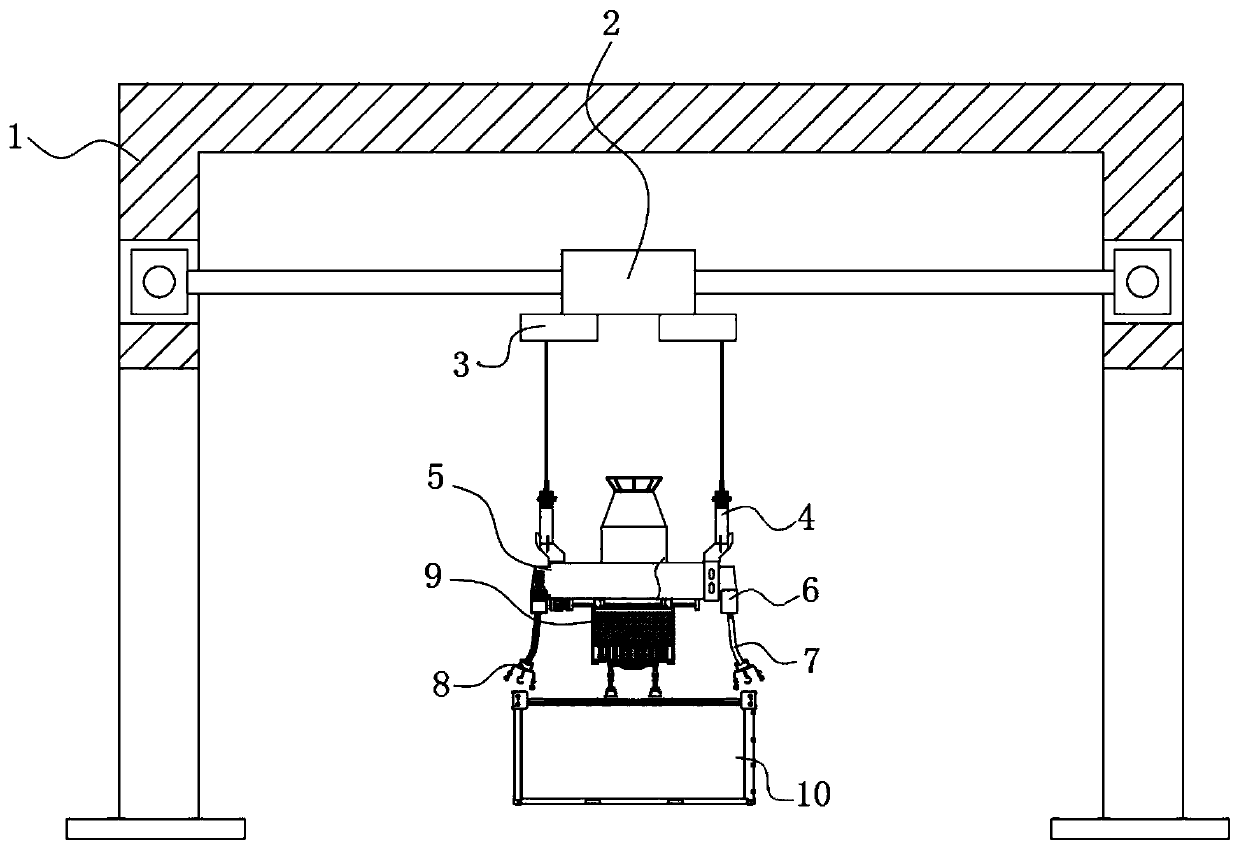

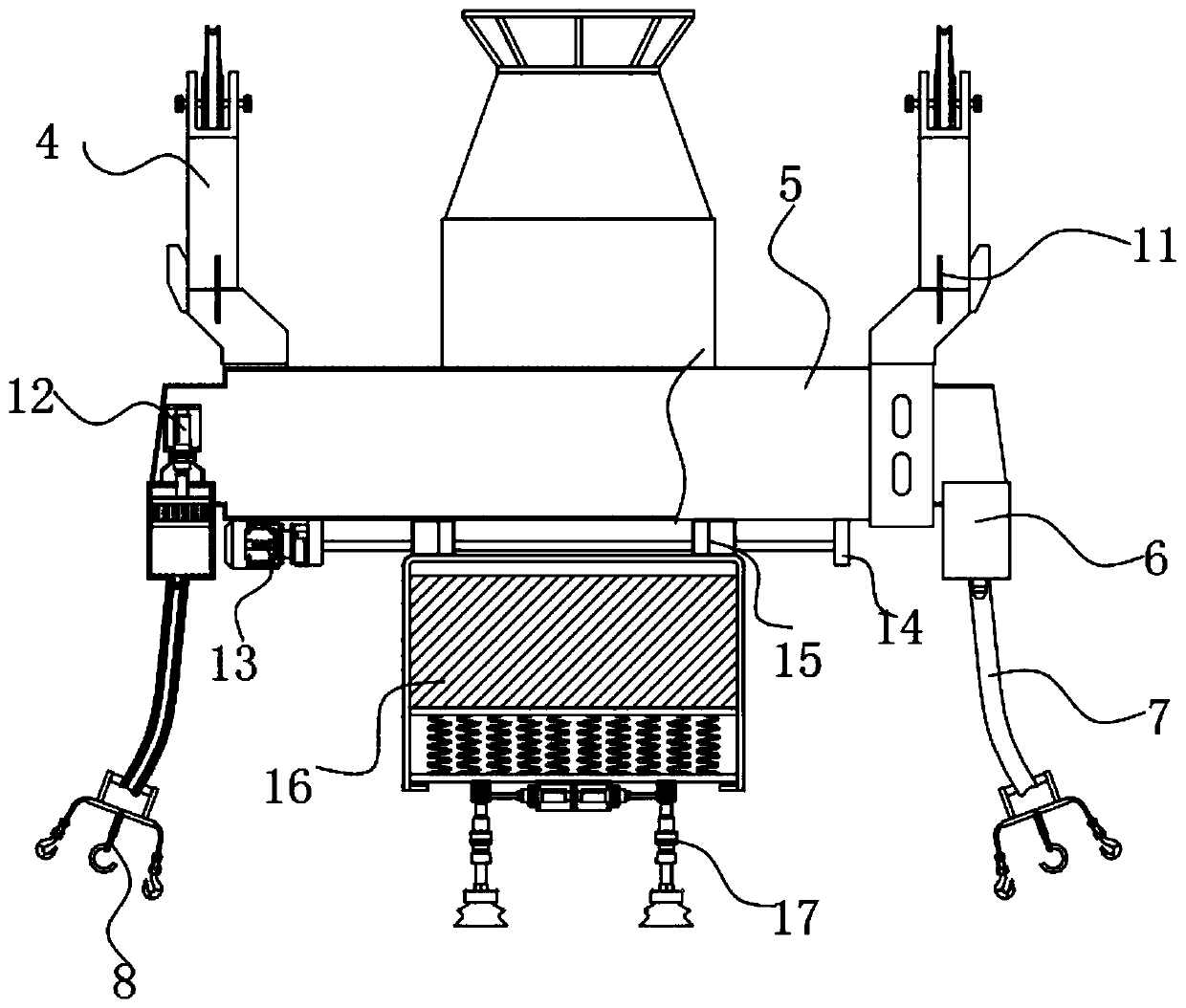

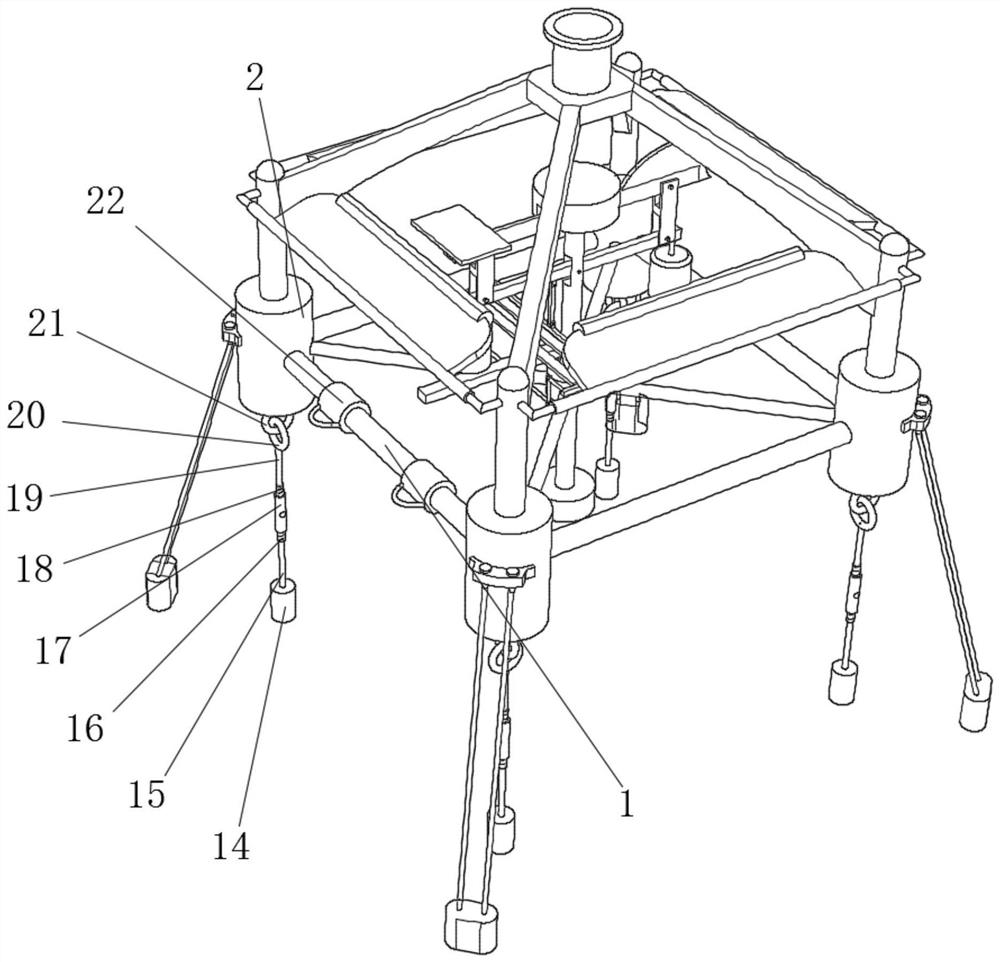

Fast hoisting mechanism of logistics box for terminal logistics

ActiveCN111302197AShorten the protruding lengthReduce shakingBase supporting structuresBraking devices for hoisting equipmentsLogistics managementAgricultural engineering

The invention discloses a fast hoisting mechanism of a logistics box for terminal logistics. The fast hoisting mechanism includes a moving seat, a winch and a hoisting mechanism body. The moving seatis arranged on a gantry crane, and the lower part of the moving seat is connected with the hoisting mechanism body through the winch. The hoisting mechanism body includes a connecting platform, a lifting rope and an oscillation adjusting assembly. A lifting arm is fixed above the connecting platform, the other end of the lifting arm is fixedly connected with the retractable end of the winch, adjusting cylinders are arranged at the four corners below the connecting platform, the lower parts of the adjusting cylinders fixedly communicate with the lifting rope, and a lifting claw is arranged at the other end of the lifting rope; the adjusting cylinders and the lifting rope are filled with slurry, and the adjusting cylinders can adjust the pressure of the slurry, so that the ability of the deformation of the lifting rope is changed; and the oscillation adjusting assembly is arranged below the connecting platform by a lead screw nut mechanism, and the oscillation adjusting assembly can adjust the position of the lifting claw in an oscillating mode when the lifting claw lifts the logistics box.

Owner:HANDAN COLLEGE

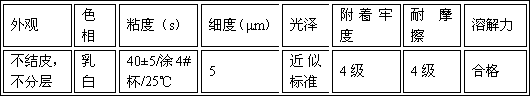

Environment-friendly high-abrasion-resistance high-gloss water-based varnishing oil

InactiveCN108587363ASolve the problem of VOCs exceeding the standardSmall smellCoatingsWaxWater based

The invention relates to the technical field of printing, and discloses environment-friendly high-abrasion-resistance high-gloss water-based varnishing oil. The varnishing oil comprises the followingcomponents in percentage by weight: 35-45% of environment-friendly water-based acrylic resin, 35-45% of self-drying water-based acrylic emulsion, 1-5% of a high-abrasion-resistance modified wax emulsion, 0.5-1% of a BYK defoaming agent, 1-5% of a BYK leveling agent, 0.5-2% of an anti-curl auxiliary agent, 1-5% of an anti-scratch agent, and 5-8% of deionized water. Compared with the prior art, thevarnishing oil provided by the invention can effectively avoid the shrinkage and curling of paper, has high abrasion resistance and high smooth degree, can be dried thoroughly, and has low residue ofvolatile organic compounds (VOCs).

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

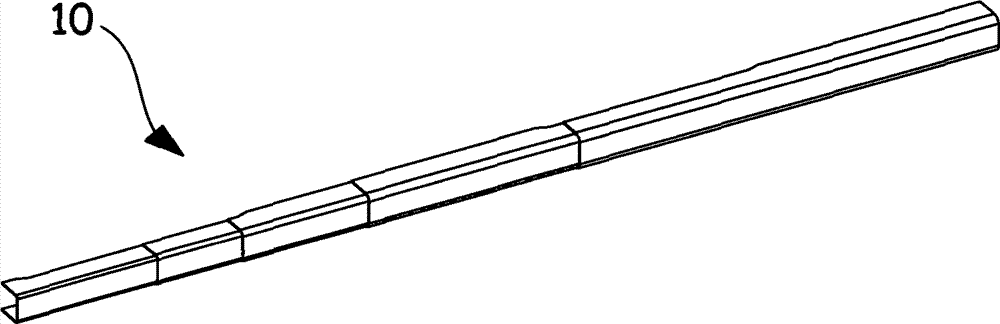

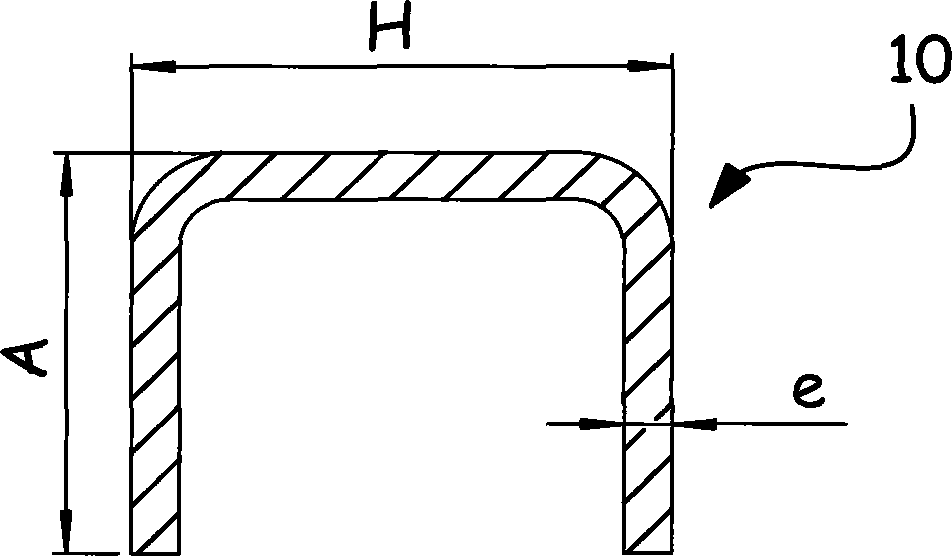

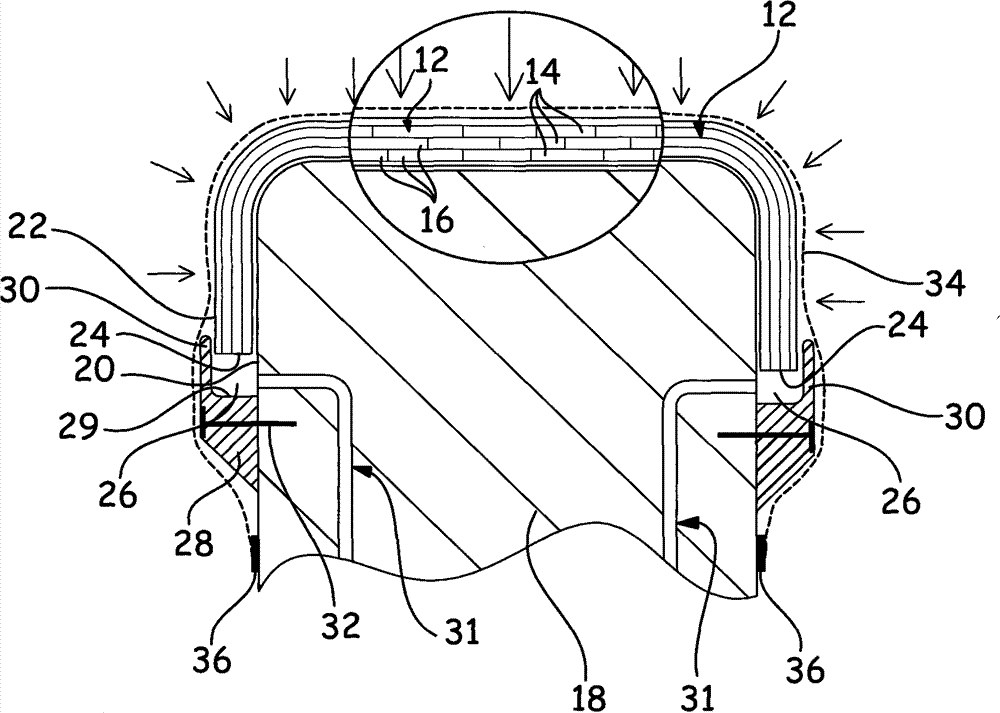

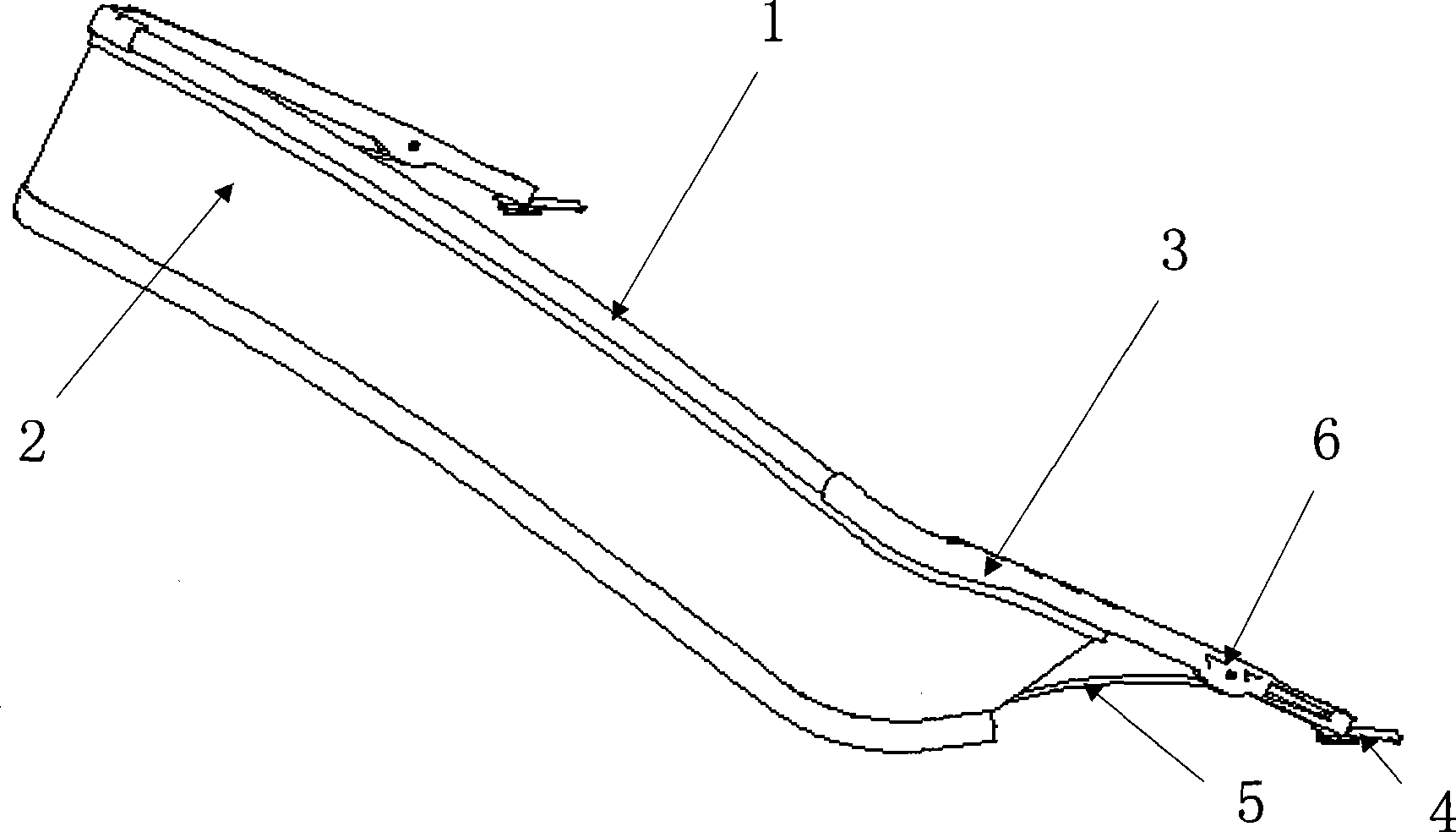

Method for obtaining a part made of a composite material including a phase of tensioning filaments, and tools for implementing same

ActiveCN103302868ATension balanceReduce volatility riskLaminationLamination apparatusMechanical engineeringFibrous layer

A method for obtaining a composite material part from a preform (12) of layers of fibers pre-impregnated with resin stacked on top of one another on a tool (18), the preform (12) being delimited by a lower surface, an upper surface(22), and a peripheral flank (24). The method includes attaching to the tool, after the last layer has been laid, a peripheral part (28) comprising a wing adapted to cover the peripheral edge of the upper surface (22), so as to create, in the periphery of the preform, a peripheral cavity (26) adjacent to the flank of the preform and, before the polymerization phase, to withdraw the gas present in the peripheral cavity (26) so as to tension filaments of the preform by exerting a traction force at the ends of the filaments.

Owner:AIRBUS OPERATIONS (SAS)

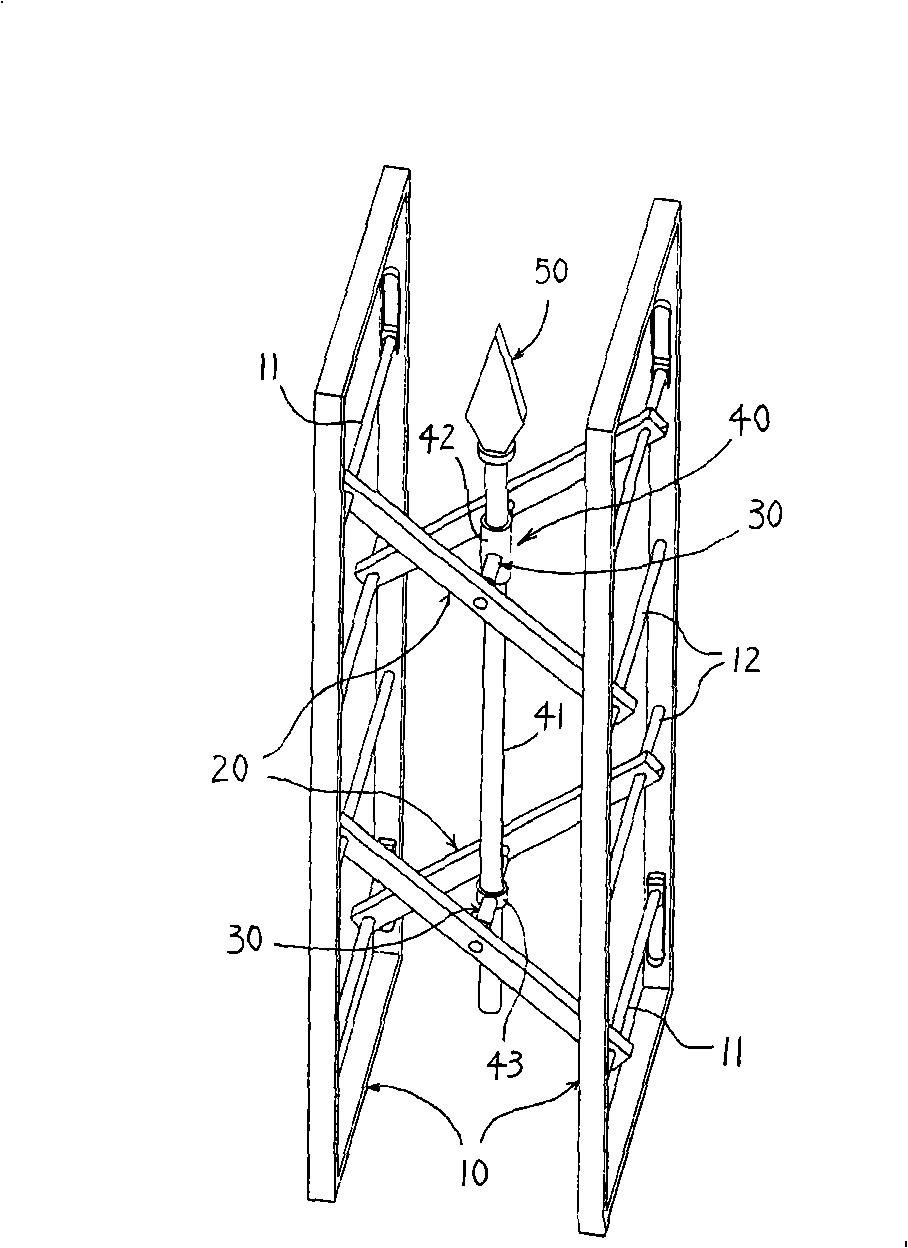

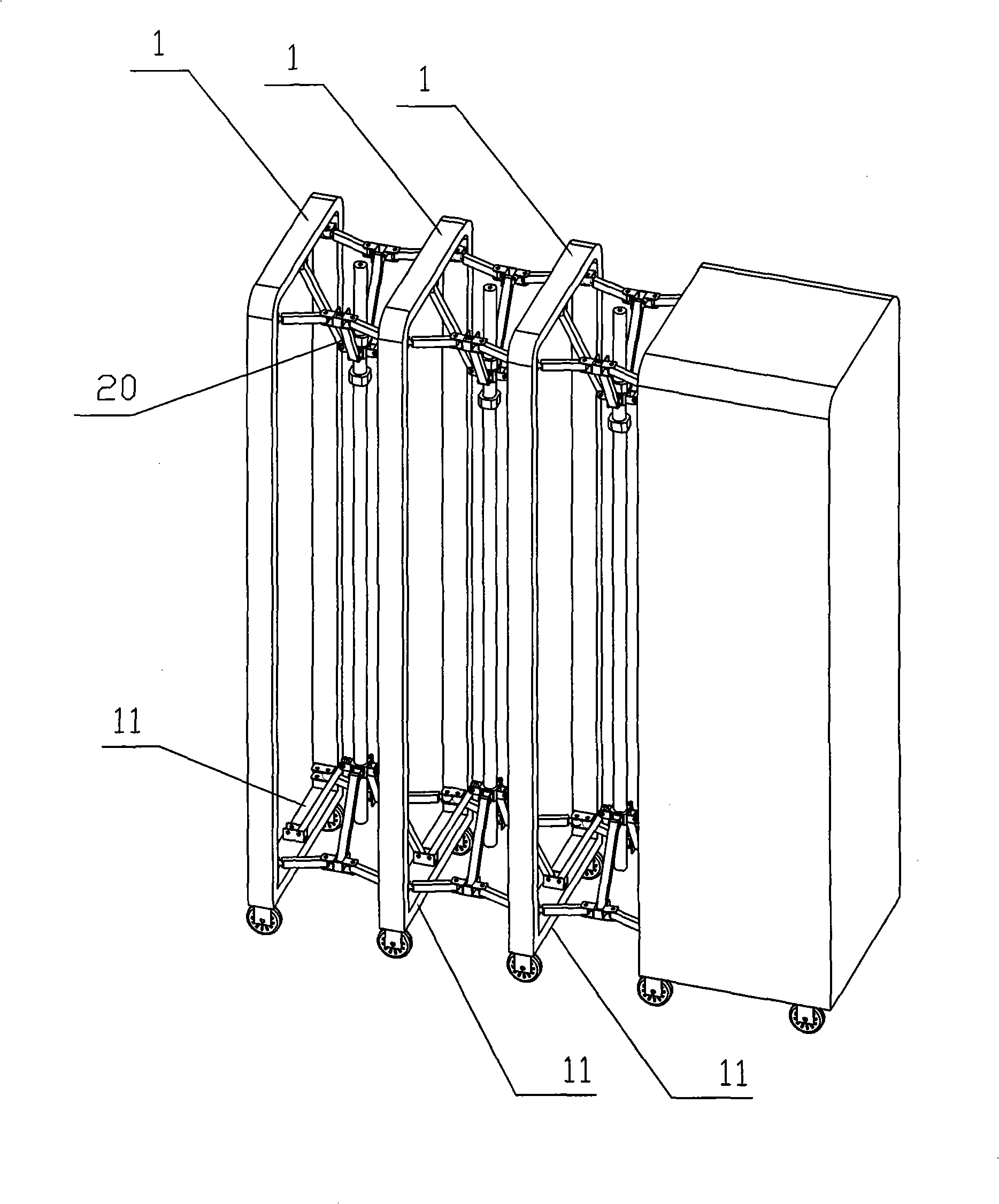

Extension door

The invention relates to an extension door, in particular to an extension door with good stability, small running resistance, environmental protection and energy saving. The extension door comprises a door body, a principal axis among door body and a lantern ring arranged on the principal axis and capable of up and down slipping, wherein, the principal axis is nested equipped with a six points balance device used for balancing the stress effect among neighboring door bodies, both front and rear ends symmetry axis of the lantern ring are equipped with a balance supporting bar used for connecting neighboring door bodies, the balance supporting bar is axially connected with the beam midpoint of the door body, the balance supporting bar is capable of rotating along up and down directions around the beam of the door body, balance link devices are symmetrically arranged on the left and right sides along the extension door moving direction of the lantern ring, the balance link devices are respectively connected with the two neighboring door bodies and the balance link devices can rotate around the fixed point of the door body along left and right direction and up and down direction. The beneficial effects of the extension door are of strong intensity, firm, small resistance, small required power, environmental protection and energy saving, no friction transmission, more reasonable structure, electric motor required small power and lowering cost.

Owner:深圳市威捷机电技术有限公司

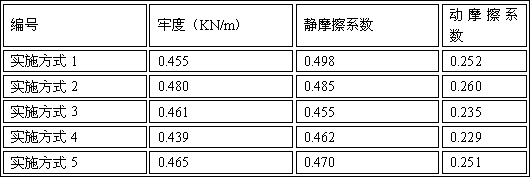

Anti-rib-forming and anti-wrinkling printing film and preparation method thereof

ActiveCN109397916AGood flexibilityReduce coefficient of frictionDuplicating/marking methodsSynthetic resin layered productsEngineeringTotal thickness

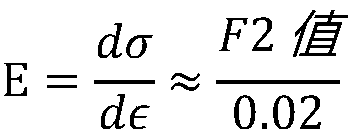

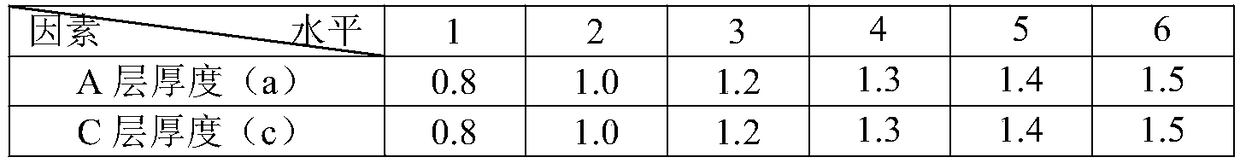

The invention discloses an anti-rib-forming and anti-wrinkling printing film and a preparation method thereof, wherein by means of specific components and technologies, the total thickness, as well thickness of every layer and thickness ratio, of the printing film in an A / B / C layered lamination structure are defined, so that stiffness and thickness uniformity of the printing film are improved, thereby improving the anti-rib-forming and anti-wrinkling properties thereof.

Owner:HONGTA PLASTIC CHENGDU CO LTD

Construction method for underneath passing of road section with heavy traffic pressure

The invention discloses a construction method for an underneath pass road in a road section with heavy traffic pressure, which comprises the following steps of: arranging a pile type ground anchor asa pile foundation; fixedly installing prestressed concrete tunnel gates at the two ends of the roadbed, holes are drilled in the roadbed side by side in the direction of the tunnel gates at equal intervals to generate reserved mud jacking holes, the roadbed and the tunnel gates are arranged on pile type ground anchors, and the bottoms of the tunnel gates are connected with the pile type ground anchors; steel pipes are arranged in the roadbed and comprise a top steel pipe and two side steel pipes, and reinforcing steel bars are arranged in the steel pipes; and grouting construction is conductedbetween the top steel pipes, between the top steel pipes and the soil body and in the top steel pipes. The method has the advantages of simple and advanced technology, reliable and stable safety, small influence degree on original road traffic, convenience in main body structure construction and the like.

Owner:CHINA FIRST METALLURGICAL GROUP

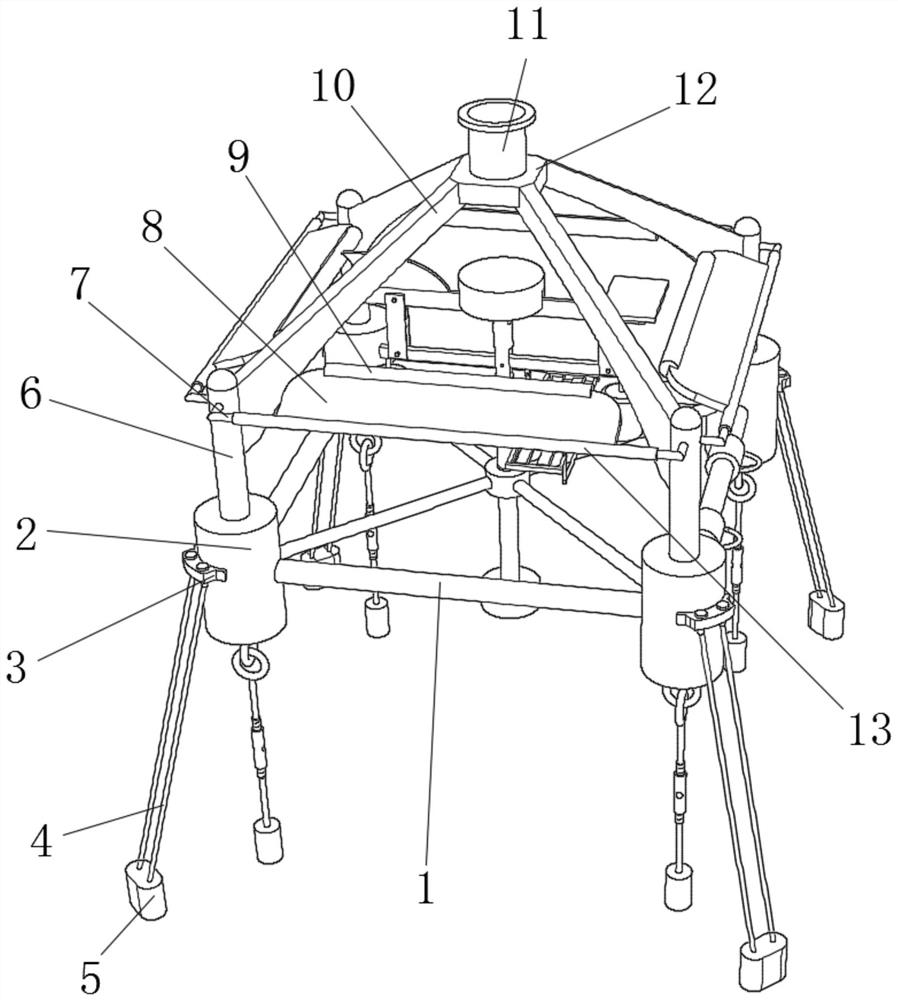

Self-floating towing marine wind power floating foundation and construction method thereof

ActiveCN113650741AAvoid the problem of increased forceExtended service lifeWaterborne vesselsWind energy generationBalancing machineStructural engineering

The invention provides a self-floating towing marine wind power floating foundation, fixing blocks are fixed to one sides of main buoys through bolts, side ropes are fixed to the bottoms of the fixing blocks through bolts, first fixing bases are fixed to the bottoms of the side ropes through bolts, the device is reinforced through the side ropes, and the installation stability of the device is improved; connecting rods are fixed between the main buoys through bolts, the main buoys provide main buoyancy for the whole device, installation of other equipment is facilitated, connecting rods are fixed to one sides of the main buoys through bolts, guide rings are fixed between the connecting rods through bolts, and balance mechanisms are arranged in the guide rings. The problem that in an existing offshore wind turbine floating foundation, a rope on one side of an anchoring system can bear large pulling force when the floating foundation is impacted, and consequently the service life of the rope is shortened is solved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Netted weather strip for motor vehicle roof

InactiveCN101428551ATension balanceBalance elasticityEngine sealsVehicle sealing arrangementsEngineeringSkylight

A reticular draught strip used at the top of the motor vehicle comprises a warped rod and a net, and the upper side edge of the net is in fixed connection with the warped rod. The draught strip is characterized in that a bending connection rod, a clamp foot and a spring are arranged at at least one end of the warped rod; one end of the bending connection rod is connected with one end of the warped rod and the other end thereof is rotationally connected with the a clamp foot; one support leg of the spring is fixed in the bending connection rod and the other support leg thereof is fixed on the front frame at the skylight on the top of the vehicle; and the clamp foot is clamped in a guiding rail. Furthermore, the net comprises an upper connection strip, a lower fixation strip and mesh fabric. The mesh fabric is fixed in a position between the upper connection strip and the lower fixation strip; the upper connection strip is fixed in the warped rod and the bending connection rod; and the lower fixation strip is fixed on the front frame at the skylight on the top of the vehicle. The invention can better balance the tension and elasticity of the net, and has the advantages of convenient disassembly and cleaning.

Owner:WEBASTO SHANGHAI

Mining elevator traction cable connecting apparatus and measuring method therefor

InactiveUS9156655B2Simple structureBalanced hoisting rope tensionAlarmsElevatorsHydraulic cylinderRelative displacement

A mining elevator traction cable connecting apparatus and a measuring method therefor, for use in a mining elevator serving a deep-mine. The apparatus includes an industrial personal computer (IPC), a signal collector connected to the IPC, multiple symmetrically arranged cable rings for use in connecting to one end of a traction cable, and a traction cable tension adjusting apparatus connected to the multiple of cable rings. Arranged within the traction cable tension adjusting apparatus are a plurality of hydraulic cylinders, and a plurality of draw wire displacement sensors for use in monitoring the relative displacement between each hydraulic cylinder plunger and a corresponding hydraulic cylinder body. The draw wire displacement sensors and an oil pressure sensor connected to a hydraulic pipeline are connected to the IPC via the signal collector, forming a traction cable tension and degree of adjustment measuring system.

Owner:CHINA UNIV OF MINING & TECH +1

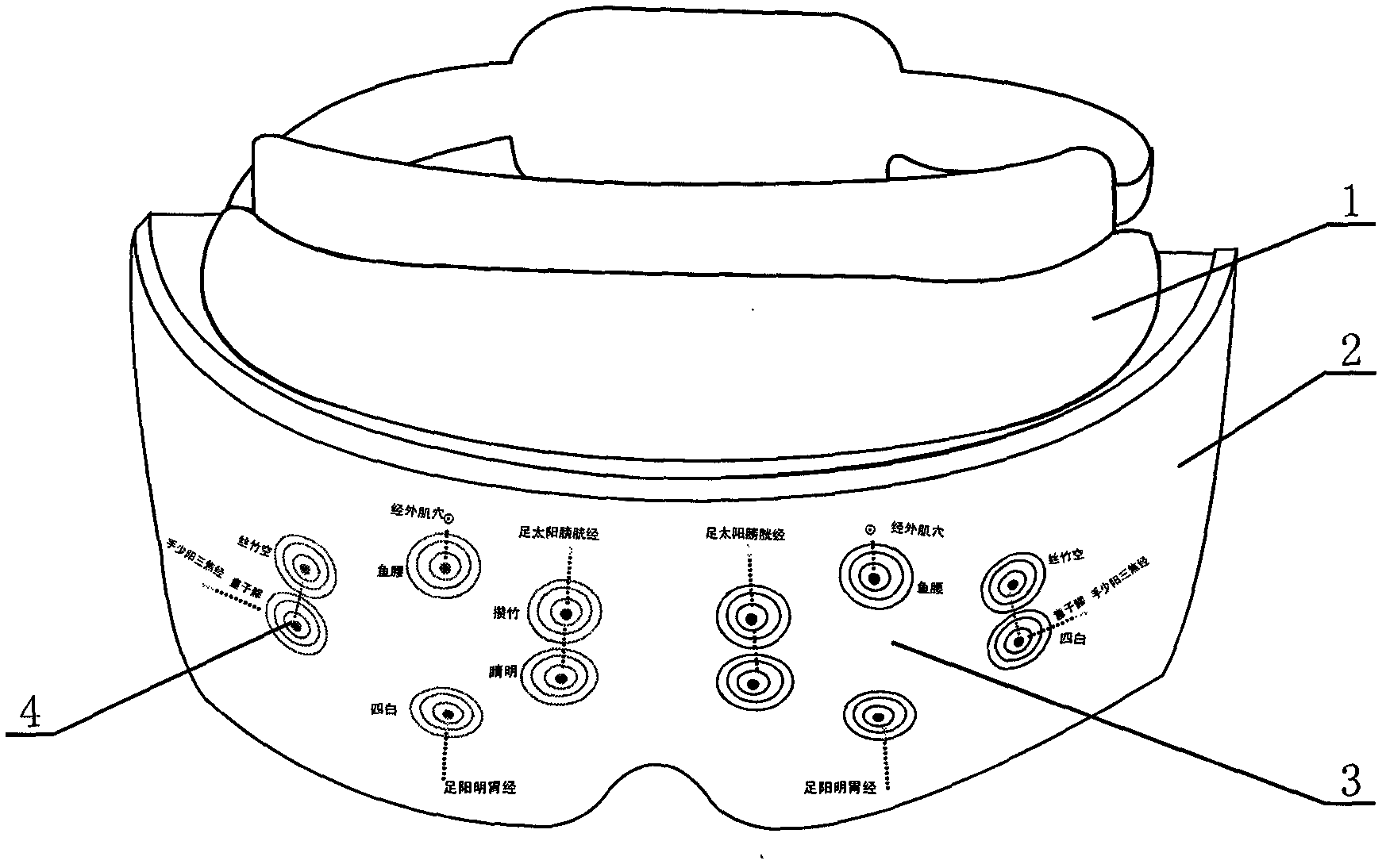

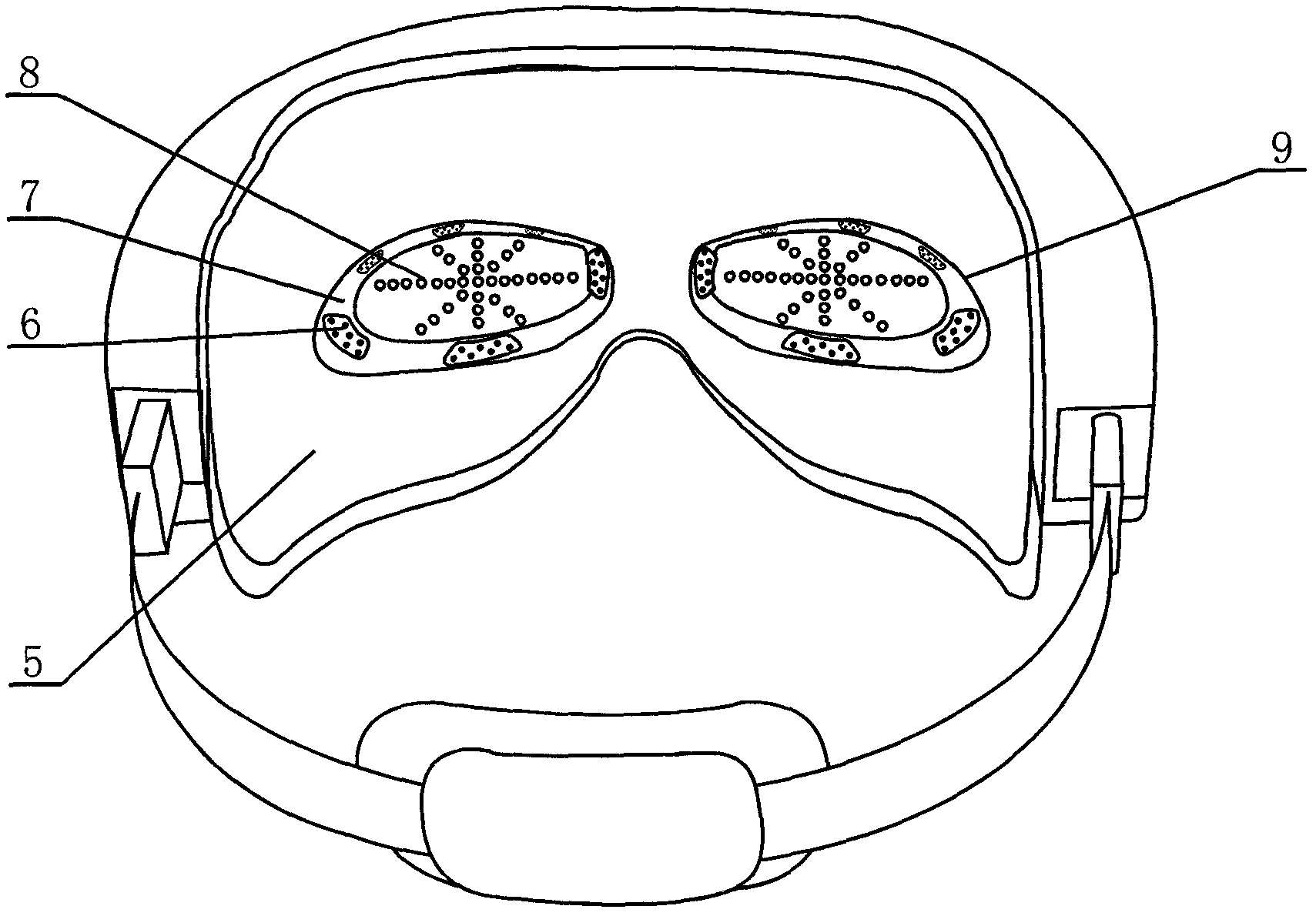

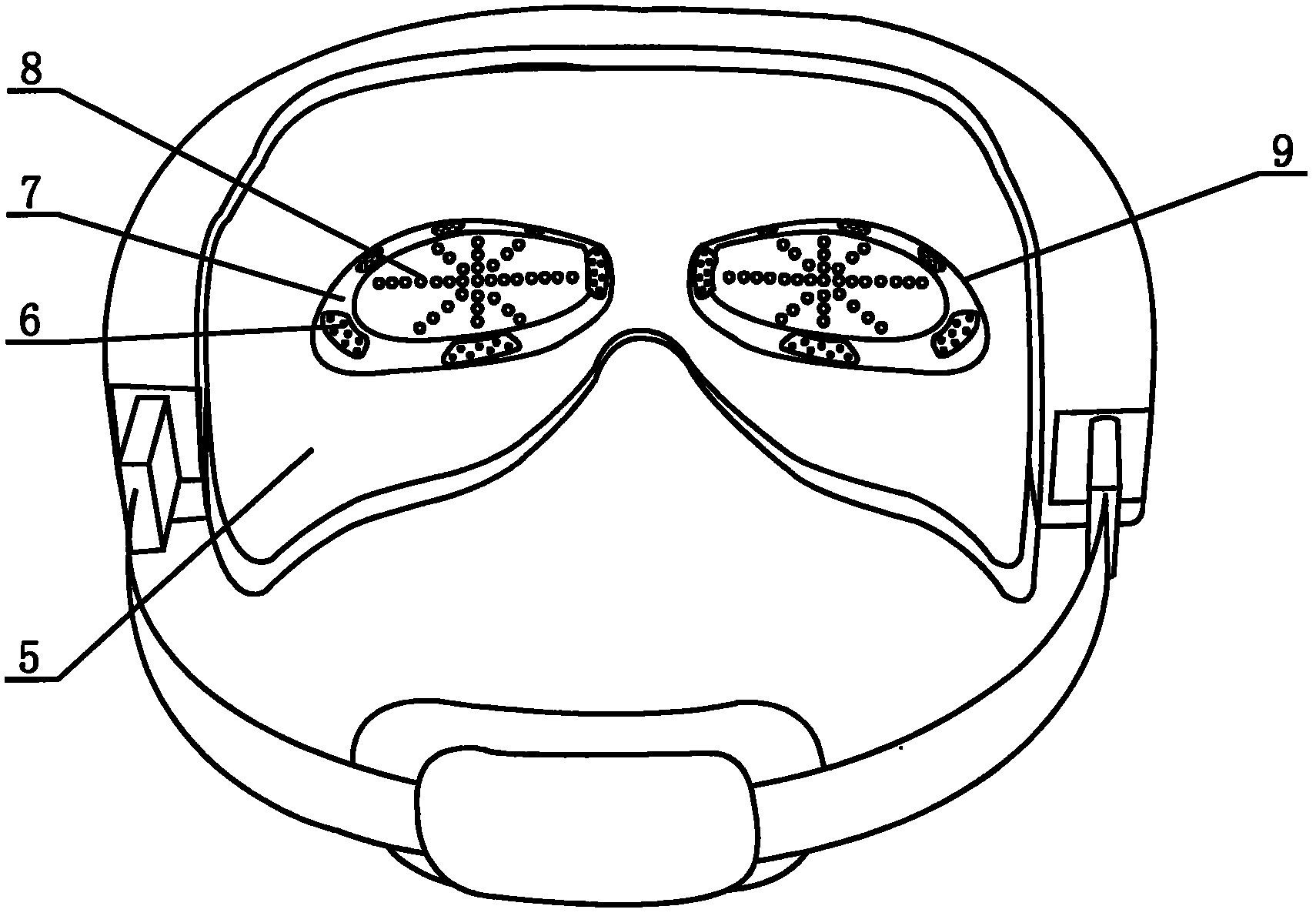

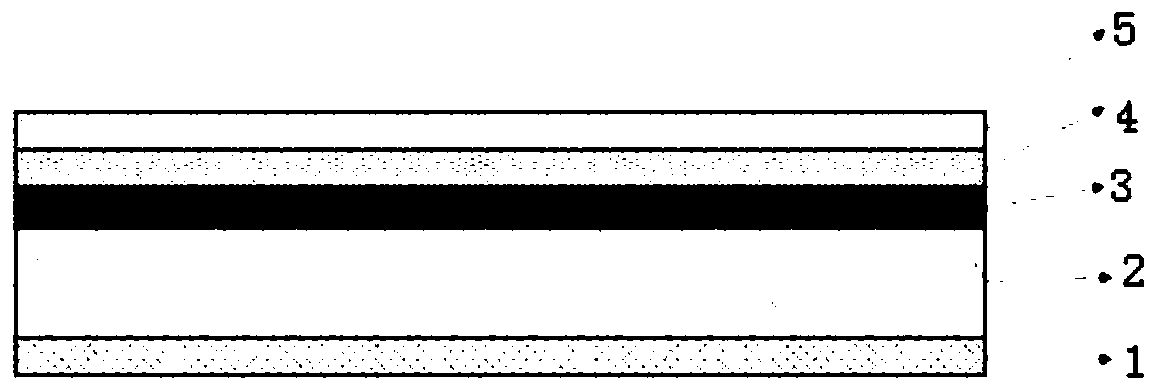

Strengthened automatic photothermal exercise instrument for eye muscle

ActiveCN102204853APromote aerobic metabolismSignificant improvementEye exercisersEye treatmentEngineeringExtraocular muscles

The invention relates to a strengthened automatic photothermal exercise instrument for eye muscle. The exercise instrument comprises a closed cavity provided with a front face plate (3) and a rear face plate (5); the rear face plate (5) is an arc vertical plate in fit with the shape of a human face; a controller and a motion photothermal generation device connected with the controller are arranged in the closed cavity; six groups of motion photothermal output holes (6) respectively formed in a left side and a right side are formed in the rear face plate (5) of the closed cavity; the positionsof the six groups of the motion photothermal output holes (6) respectively correspond to the positions of six acupoints around a human eye; the central part position of a motion photothermal output area (7) is provided with a plurality of automatic tracking motion guide lights (8) arranged according to a rule; and the automatic tracking motion guide lights (8) are respectively connected with the controller. By adopting the exercise instrument, the eyeball stretching and fixed unbalance of the external eye muscle caused by long-time fixing can be prevented better, the eye muscle tension of an eye can be effectively balanced, and normal refraction is kept.

Owner:蒋泉涛

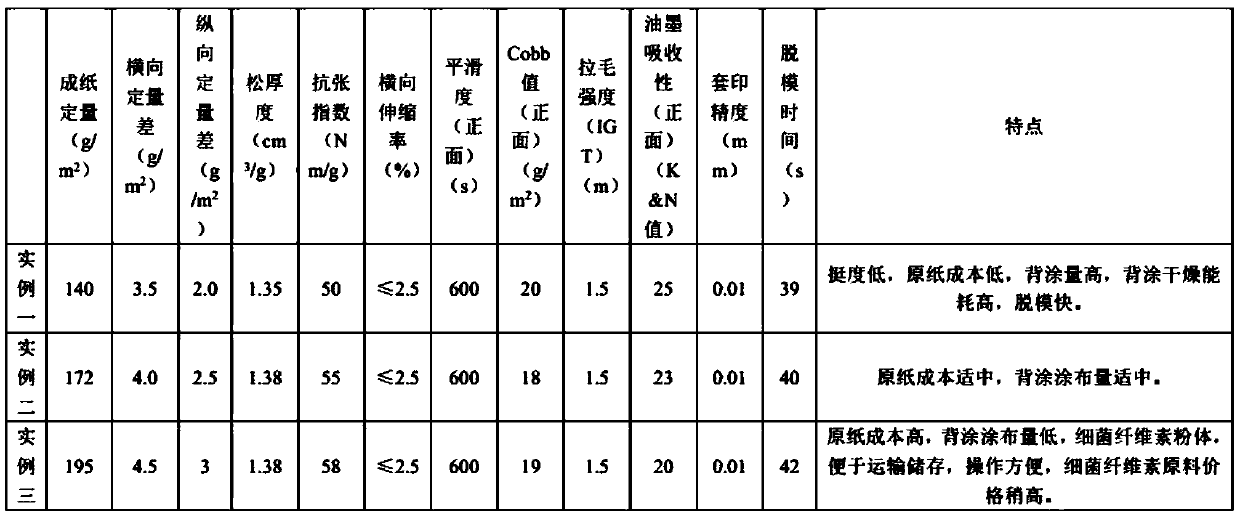

Water transfer paper and preparation method thereof

ActiveCN111472205AAccurate overprintGood printabilitySpecial paperPaper/cardboardSolid contentMaterials science

The invention discloses water transfer paper and a preparation method thereof. The water transfer paper comprises a back coating layer, base paper, a prime coating layer, a water-soluble coating layerand a waterproof coating layer which are distributed layer by layer. Coating of the back coating layer comprises 8-15 parts by weight of a bacterial cellulose wet film; 0.08-0.15 part by weight of hydrogen peroxide, 0.1-0.2 part by weight of sodium hydroxide and 30-40 parts by weight of water, and is prepared by shearing and dispersing at 70-90 DEG C in a high-speed dispersion machine for 30-45 min, adding 40-60 parts by weight of water for dilution, and then sieving the mixture to obtain the back coating, with the solid content of the coating being 2-5%. According to the prepared water transfer paper, on the premise that the water permeation speed of the paper is guaranteed, the back face is coated with the bacterial cellulose glue solution, and the water transfer paper which is stable in size, high in demolding speed and excellent in printing and transferring effect is prepared.

Owner:山东金蔡伦纸业有限公司

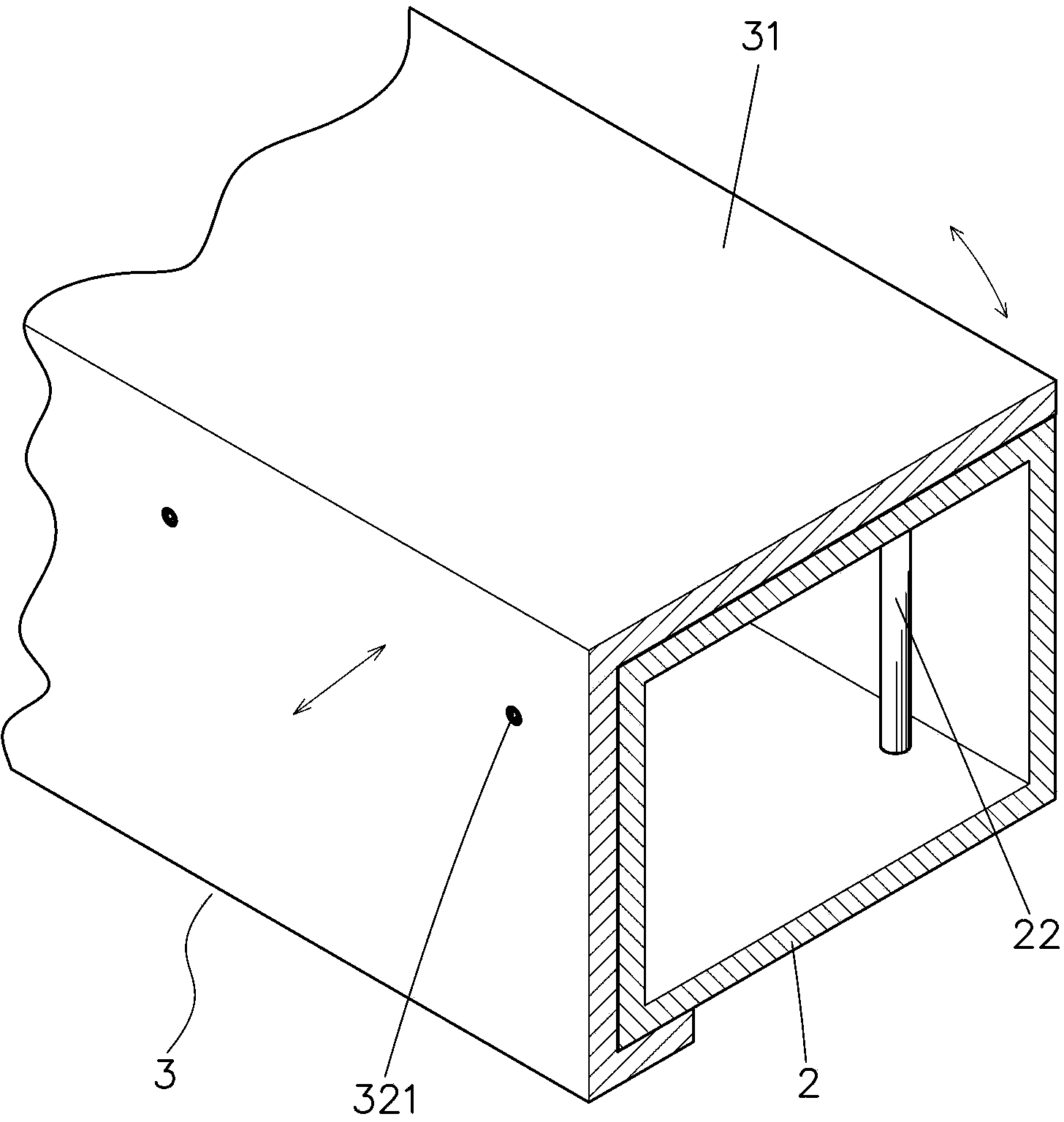

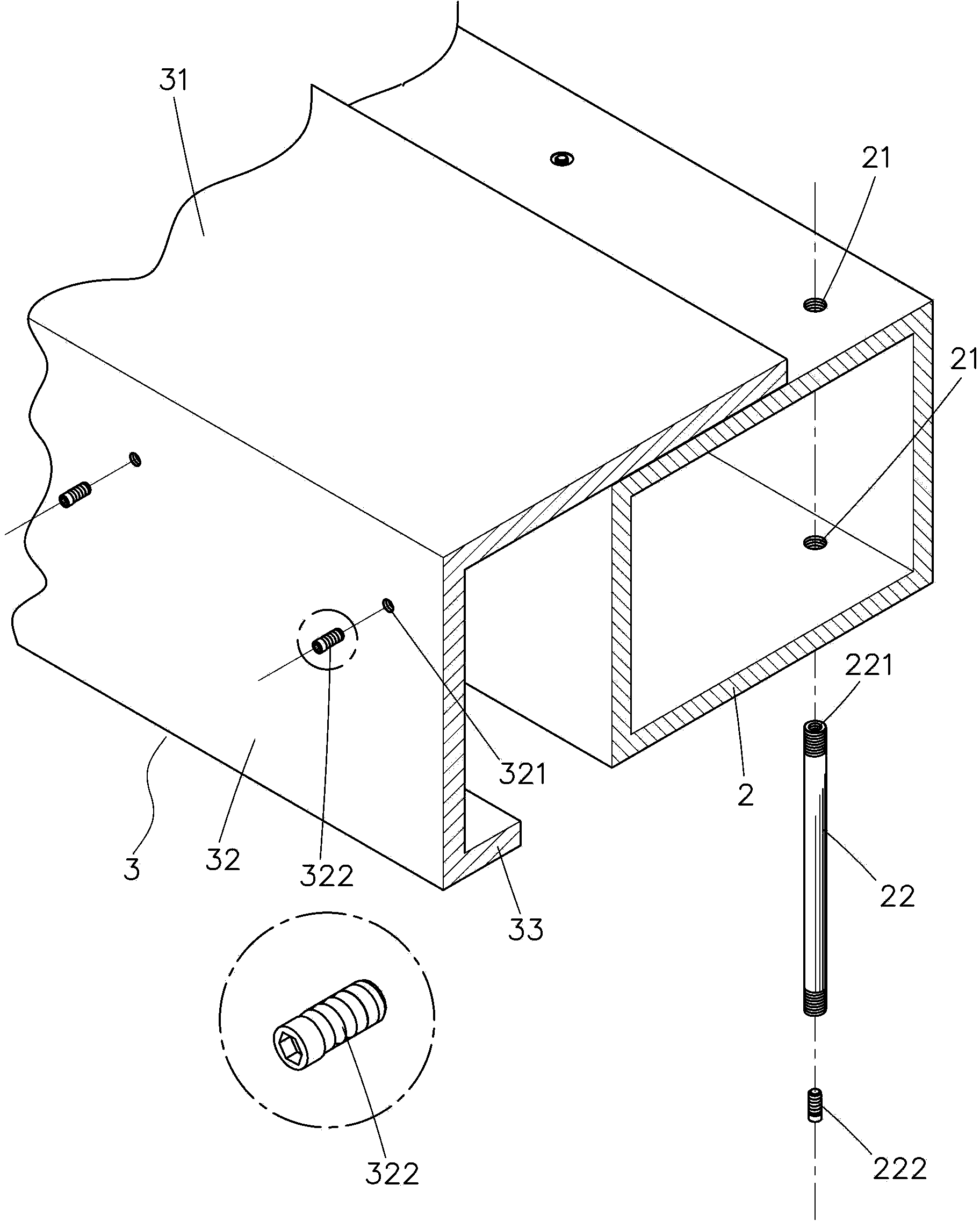

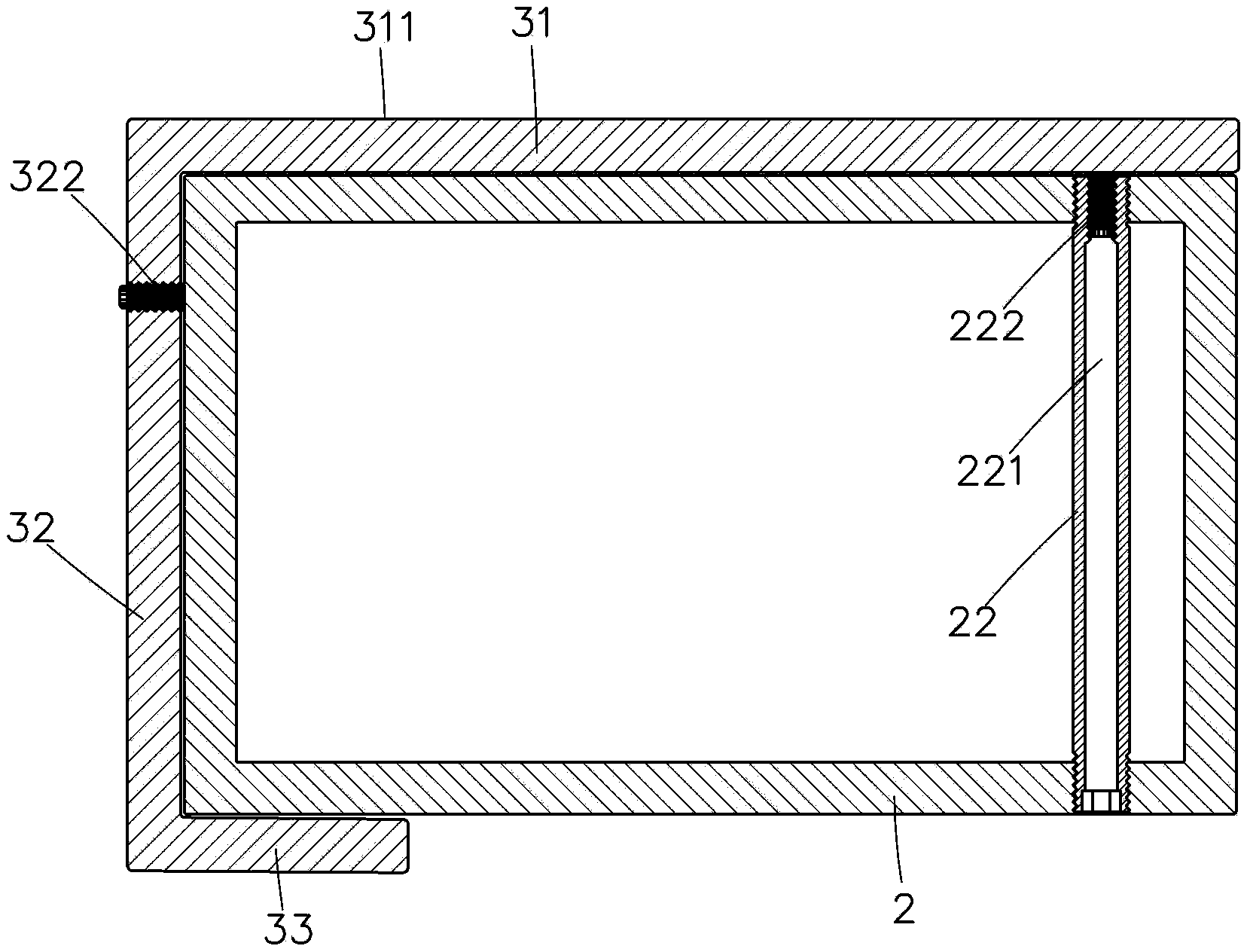

Screen plate aluminum frame capable of adjusting and enhancing fixing effect

InactiveCN103722870AComply with high-precision screen printing requirementsTension balanceScreen printersScreen printingEngineering

The invention provides a screen plate aluminum frame capable of adjusting and enhancing the fixing effect and particularly relates to a specific device which is capable of adjusting the transverse tension and the longitudinal and horizontal orientation of printing screen plates on the screen plate aluminum frame and enhancing the effect that the printing screen plates are fixed to the screen plate aluminum frame. The screen plate aluminum frame is characterized in that an L-shaped tension screen plate adjusting strap is arranged on a rectangular screen frame tube on each side of the screen plate aluminum frame in a sleeved mode and is capable of moving left and right and up and down to adjust the transverse tension and the longitudinal and horizontal orientation of the printing screen plates, screen plate viscose faces where the printing screen plates are adhered to the screen plate aluminum frame are provided with longitudinal barbed grooves or right-angle grooves or rectangular grooves respectively, so that the fixing effect that the printing screen plates are attached to the screen plate aluminum frame is enhanced, and requirements for electronic high-precision screen printing are met.

Owner:吴德木

Wind turbine blade structure, machining method and applications thereof

InactiveCN101666290BEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the root segment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

Garment processing winding device preventing cloth from drawing

The invention discloses a garment processing winding device preventing cloth from drawing. The garment processing winding device comprises a fixed base, the upper surface of the fixed base is fixedlyconnected with first supporting plates, the inner surfaces of the first supporting plates are fixedly connected with first bearings, the inner surfaces of the first bearings are fixedly connected witha first rotating shaft, the outer surface of the rotating shaft is fixedly connected with spring tubes, the inner surfaces of the spring tubes are movably connected with springs, and the tops of thesprings are movably connected with position-limiting plates. According to the garment processing winding device preventing the cloth from drawing, by means of the manner that one end of a soft non-slip rubber plate and a winding tube are movably connected with the outer surfaces of fourth rotating shafts, the soft non-slip rubber plate is made to be capable of moving on the inner surface and the outer surface of the winding tube optionally, the cloth can be fixed with even strength to prevent drawing damage, the cloth can also be loosened easily, so that the effect of removing the cloth from winding rollers conveniently is achieved.

Owner:嘉兴市名汇服饰有限公司

Novel belt measuring ruler

InactiveCN102235848ATension balanceConvenience to workMechanical counters/curvatures measurementsTension measurementEngineeringTortuous retinal vessels

The invention provides a novel belt measuring ruler. In the ruler, the tail end of the ruler is inserted into the lower side of a spring of a sleeve through a through hole in the middle of a leveling ruler, and the central line of the ruler is vertical to the plane of the leveling ruler. When being used, the top of the ruler is supported against a vee belt, the leveling ruler is placed on a moving wheel and a moved wheel, the ruler handle is pressed to be parallel to the scale on the leveling ruler to indicate the tortuosity of a belt, and the scale parallel to the mouth of the sleeve indicates the tightening degree of the vee belt. By utilizing the belt measuring ruler, particular conditions of respective tortuosity and tightening degree among a plurality vee belts can be accurately measured, so that people can adjust or change the vee belt in time to balance the tightening degree to facilitate work.

Owner:尚受刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com