After-treatment production line having automatic roll changing and winding function

A production line and functional technology, applied in the direction of thin material processing, coiling strips, transportation and packaging, etc., can solve the problems of personnel input, unfavorable continuous and stable production of copper foil, shutdown and scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

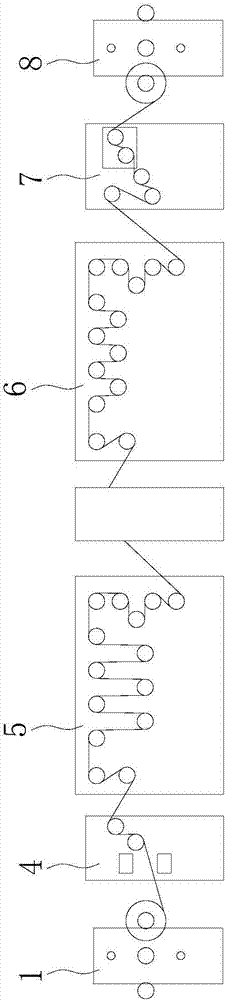

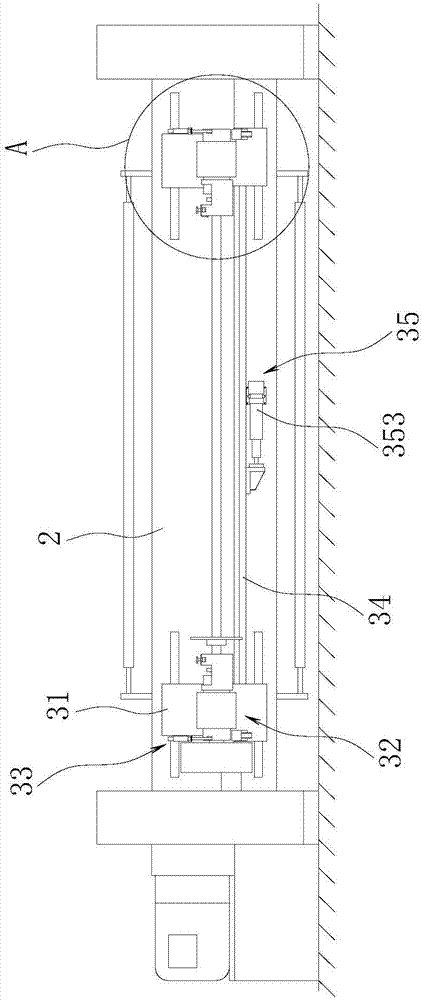

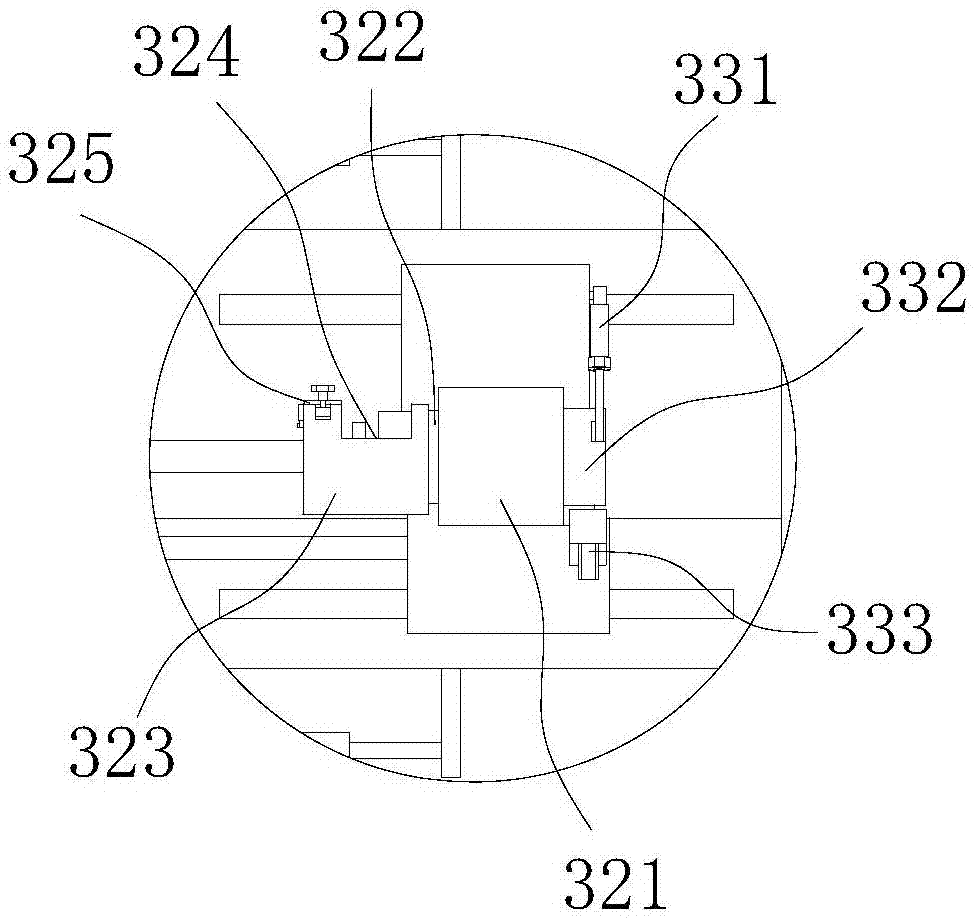

[0049] refer to Figure 1 to Figure 4 As shown, a post-processing production line with automatic roll changing and winding function of the present invention includes a first frame 1, wherein a first rotating seat 2 is movable along the horizontal direction on the first frame 1. Unwinding units 3 are respectively provided on both sides of a rotating base 2; the first rotating base 2 is connected with a first rotary drive motor, and one of the unwinding units 3 rotates 180° with the first rotating base 2 as a rotating shaft and is connected with the other The unwinding unit 3 overlaps; the first frame 1 is sequentially provided with an unwinding connection device 4, an unwinding foil storage device 5, a copper foil post-processing device, a winding foil storage device 6, and a winding foil storage device 6 along the copper foil advancing direction. Roll connection device 7 and roll changing device 8 . The first rotating seat 2 is driven by the first rotation drive motor, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com