Oxygen-free copper rod production line

An oxygen-free copper rod and a production line technology, which is applied to the field of copper rod production equipment by the upward continuous casting method, can solve the problems of uneven density of oxygen-free copper rods and the occurrence of pores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

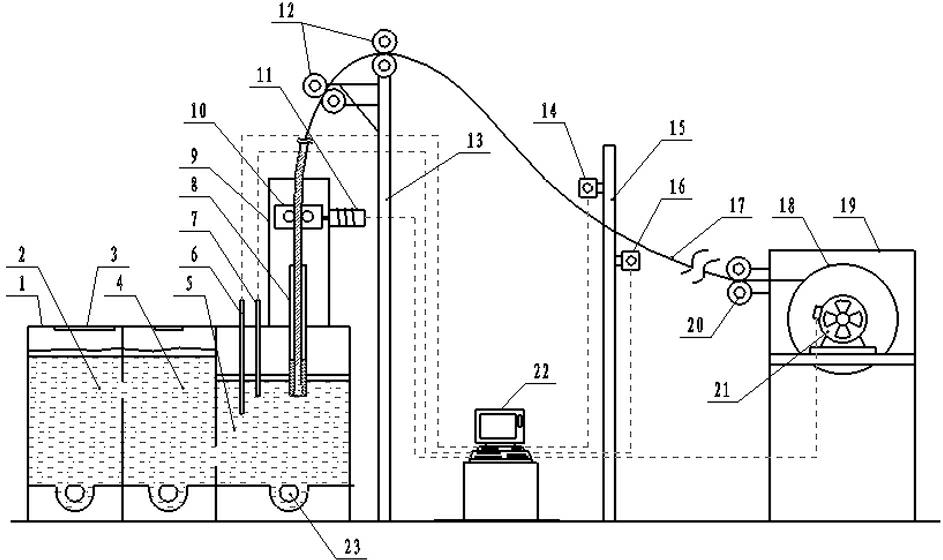

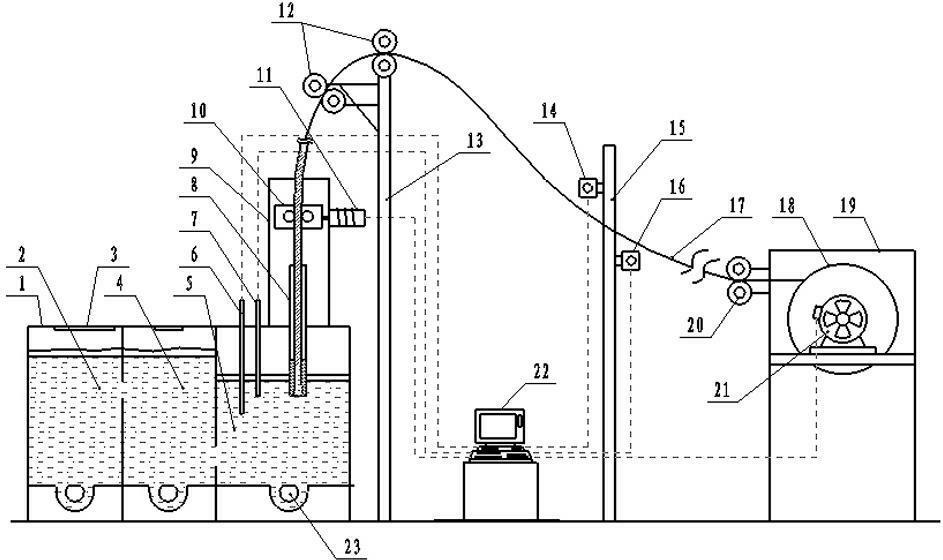

[0011] Example: such as figure 1 As shown, an oxygen-free copper rod production line is composed of a melting furnace 1, an upper lead mechanism 9 and a wire take-up mechanism 19. A production speed control system is installed on the production line; the production speed control system includes a computer 22 and a computer connected to the computer 22. Temperature sensor 6, pressure sensor 7, lead up motor 11, wire take-up motor 21, infrared sensors 14 and 16, and production speed control system control copper rod's upper lead and wire take-up speed.

[0012] The melting furnace 1 has a cuboid structure, including a melting zone 2, a static zone 4 and an upper lead zone 5. A constant temperature heating device 23 is installed at the bottom of the three zones; the top of the melting zone 2 is provided with a copper feeding port 3, and the upper right There is a liquid copper flow port, through which molten copper enters the static area 4; the lower right part of the static area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com