Netted weather strip for motor vehicle roof

A technology for motor vehicles and windshields, applied to mechanical equipment, vehicle parts, engine components, etc., can solve problems such as inconvenient disassembly, too tight or too loose nets, affecting the use of windshields, etc., to achieve disassembly and assembly and Easy to clean, good tension and elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

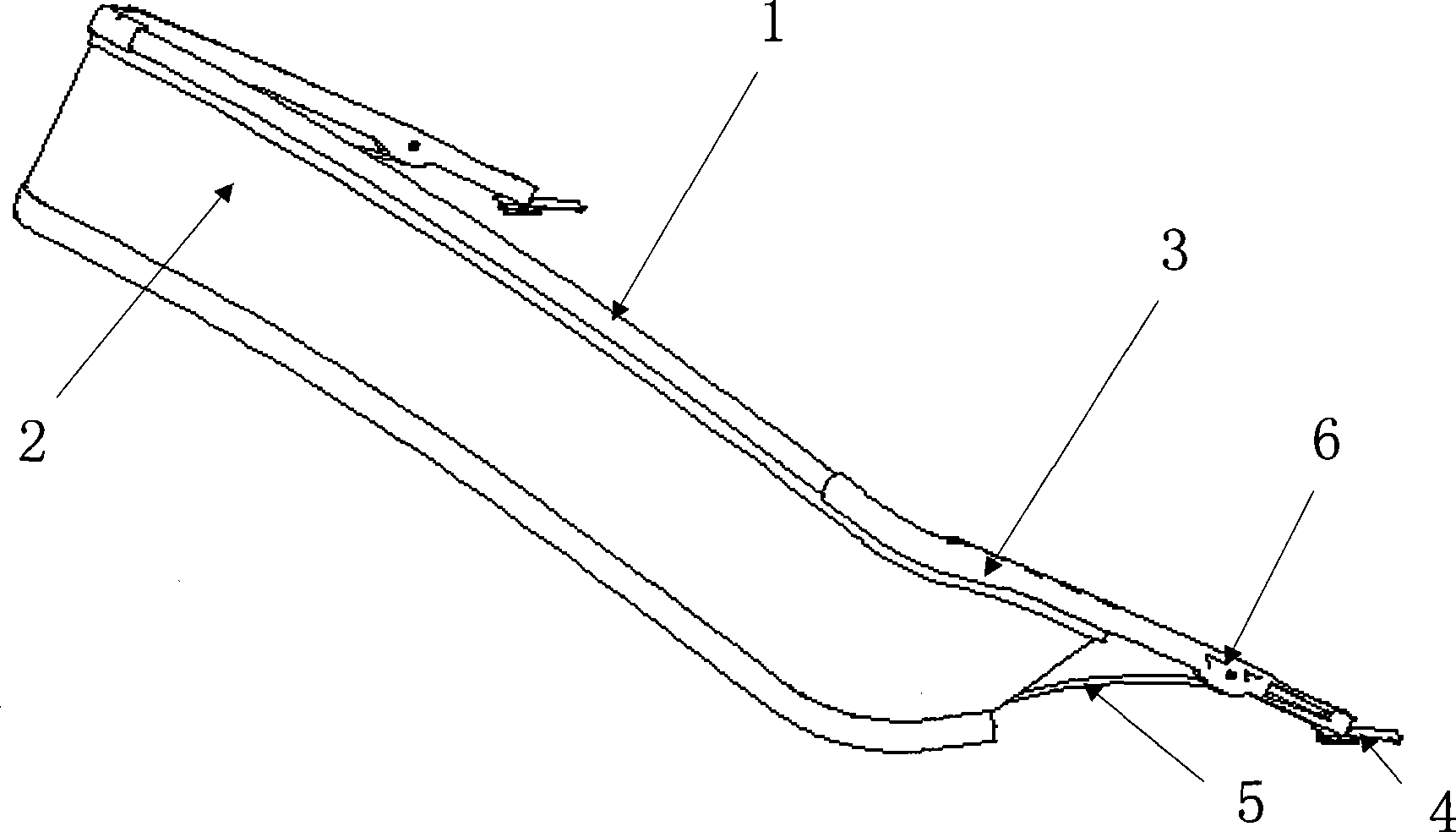

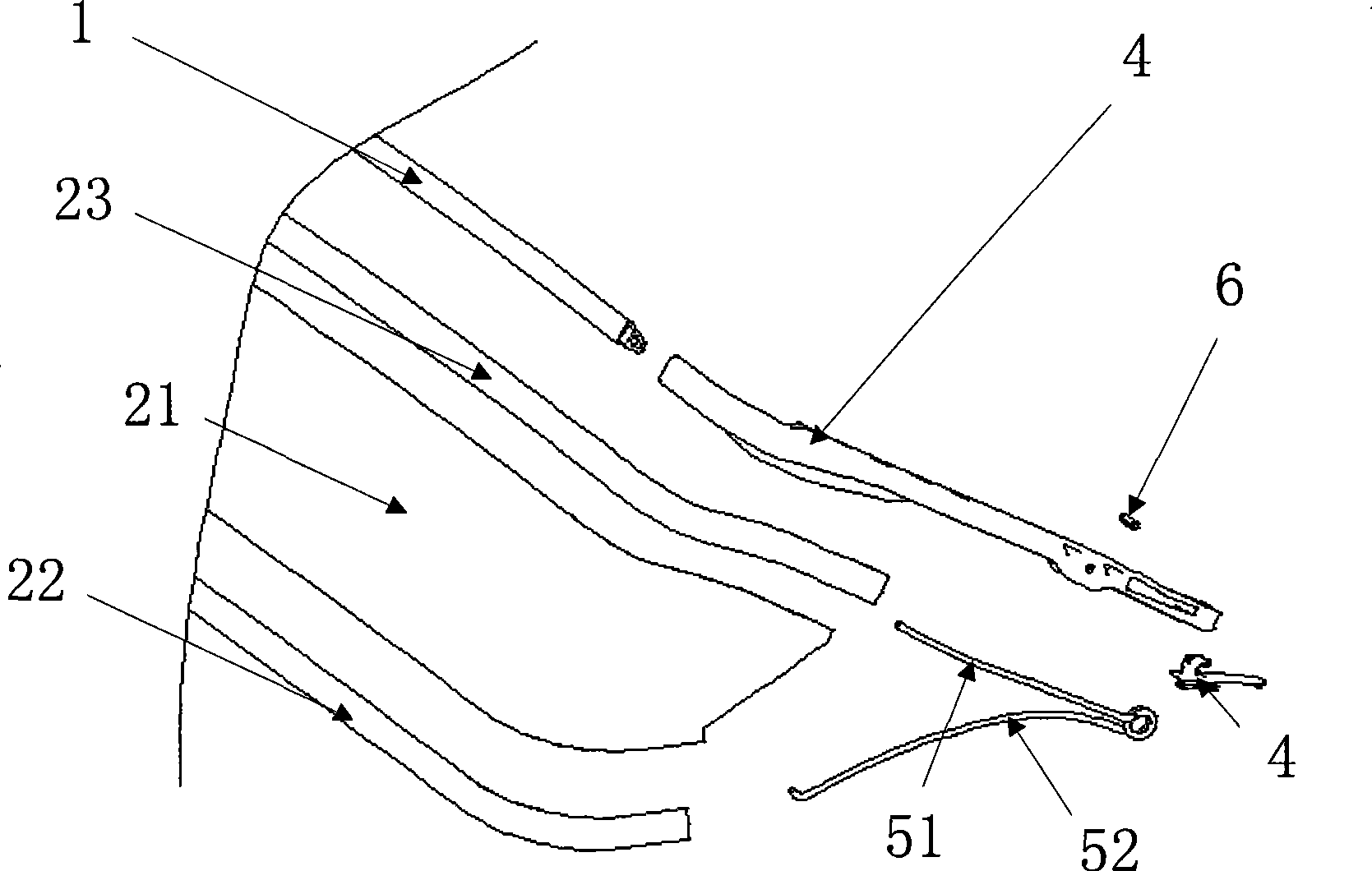

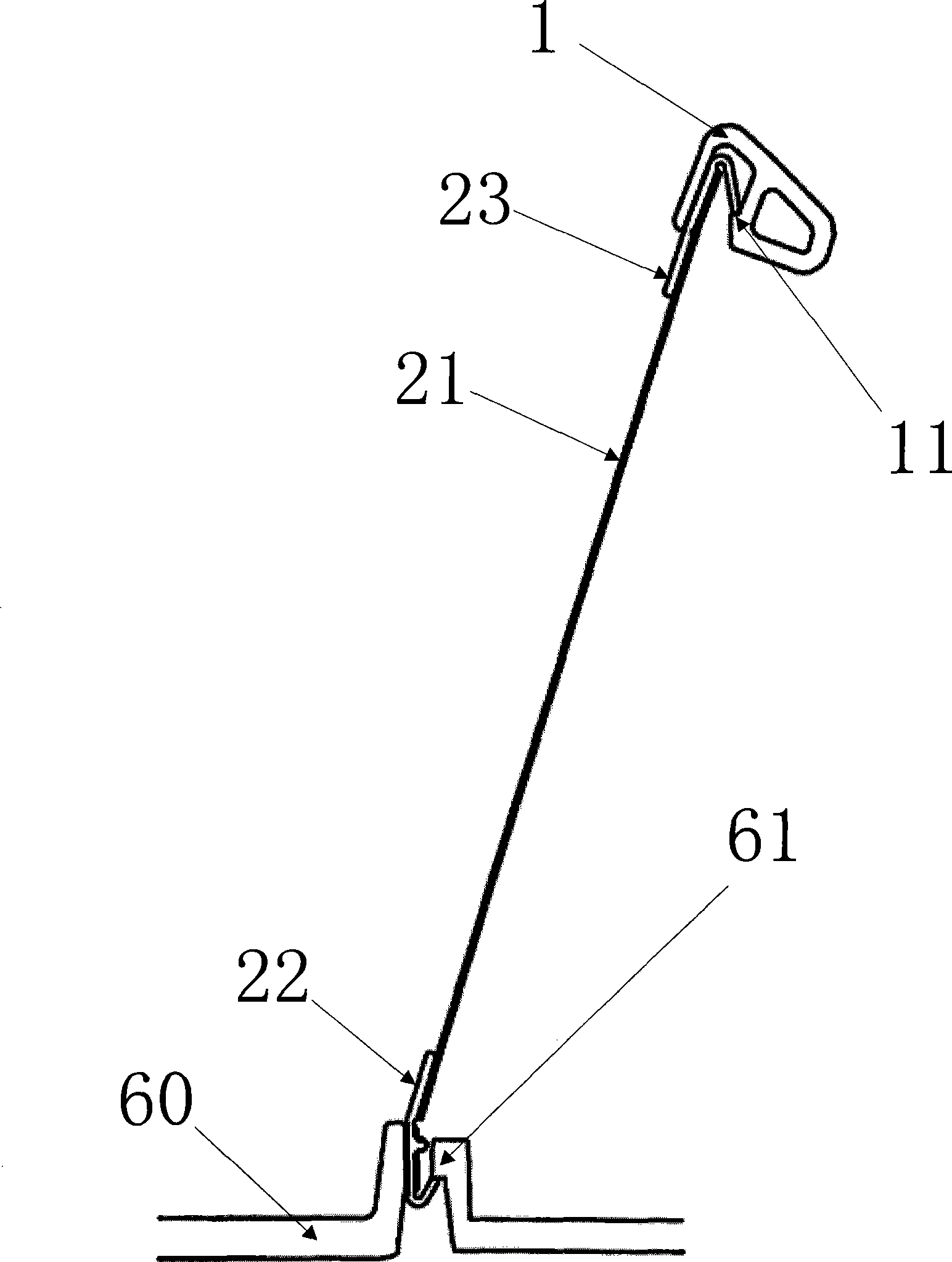

[0020] like figure 1 , figure 2 As shown, a mesh windshield strip for the roof of a motor vehicle includes a warping rod 1 and a net 2, and the upper side of the net 2 is fixedly connected with the warping rod 1, and is characterized in that it also includes the At least one end of the lifting rod 1 is provided with a bending connecting rod 3, a clip 4, and a spring 5, and one end of the bending connecting rod 3 is connected with one end of the lifting rod 1, and the bending connecting rod The other end of 3 is rotatably connected with the clip 4, one leg 51 of the spring 5 is fixed in the bending link 3, and the other leg 52 of the spring 5 is fixed in the front frame 30 of the sunroof On the above, the clamping foot 4 is clamped on the guide rail 70, such as Figure 4 , Figure 5 shown. The mesh windshield strip for the motor vehicle roof of this structural design has the advantages of convenient assembly and disassembly, small and exquisite structure, and light weight....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com