Full automatic reel-to-reel screen process press

A printing machine, fully automatic technology, applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems affecting product quality, unbalanced tension, etc., and achieve the effect of simple structure, balanced tension, and accurate printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

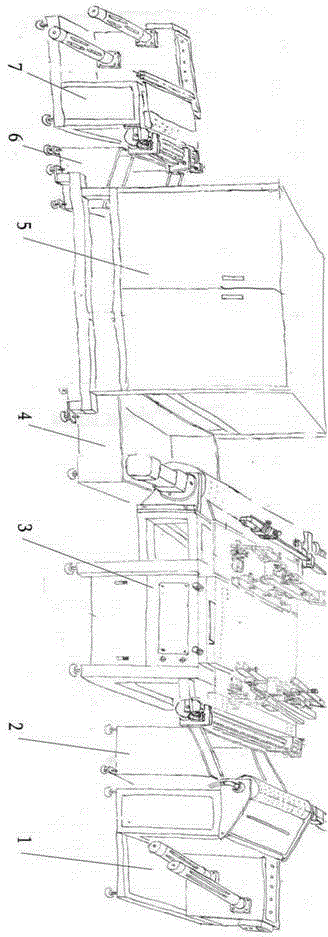

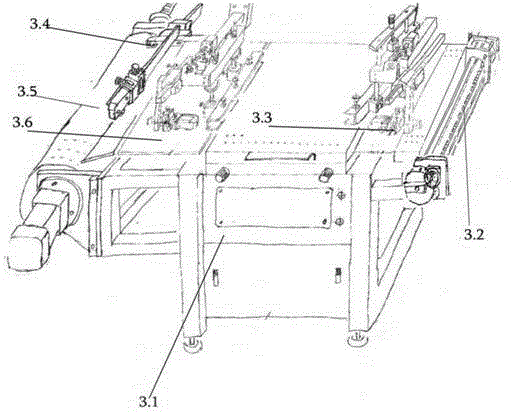

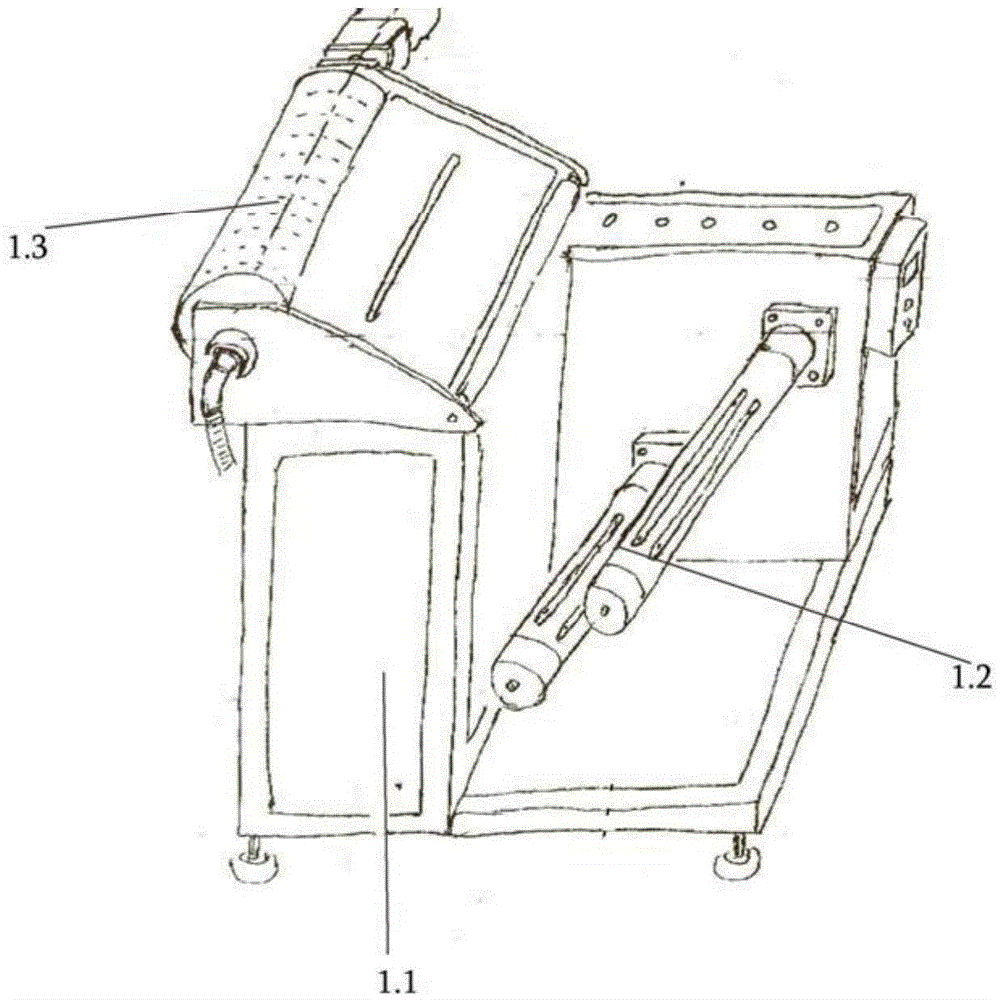

[0022] Please refer to the figure, in the embodiment of the present invention, the fully automatic roll-to-roll screen printing machine includes an unwinding device 1, a first suction receiving box 2, a printing device 3, and a second suction receiving box placed in sequence 4. Drying device 5, third suction receiving box 6, rewinding material device 7, unwinding material device 1 includes unwinding frame 1.1, biaxial device 1.2 arranged in the middle of unwinding frame 1.1 and Unwinding frame 1.1 Negative pressure roller 1.3 at the upper part of the film release end; printing device 3 includes printing frame 3.1, a drum semi-negative pressure concave-convex guide set at the upper part of the printing frame 3.1 film release end and left and right adjustment card positions The device is fixed with the damping suction cup 3.2 and the electric eye 3.3 on the working table of the printing frame 3.3 to track the position, the manual and automatic integrated static fine-tuning screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com